A Practical Guide to Forged Auto Part Surface Finish Selection

TL;DR

Selecting the right surface finish for forged auto parts is a crucial engineering decision that balances performance, durability, and cost. It involves choosing a specific treatment—such as machining, grinding, or chemical processes—based on functional requirements, material properties, and the desired surface roughness. Achieving the correct finish, often measured in Ra (Roughness Average), is essential for ensuring optimal wear resistance, corrosion protection, and overall component longevity in demanding automotive applications.

Understanding Surface Finish: Key Metrics and Standards

Surface finish, or surface texture, describes the fine-scale irregularities on a part's exterior. In the context of forged automotive components, it is a critical attribute that influences everything from friction and wear to fatigue life and corrosion resistance. A proper finish ensures parts fit together correctly, form effective seals, and withstand the harsh operating conditions of a vehicle. Understanding the standardized metrics used to quantify surface finish is the first step in making an informed selection.

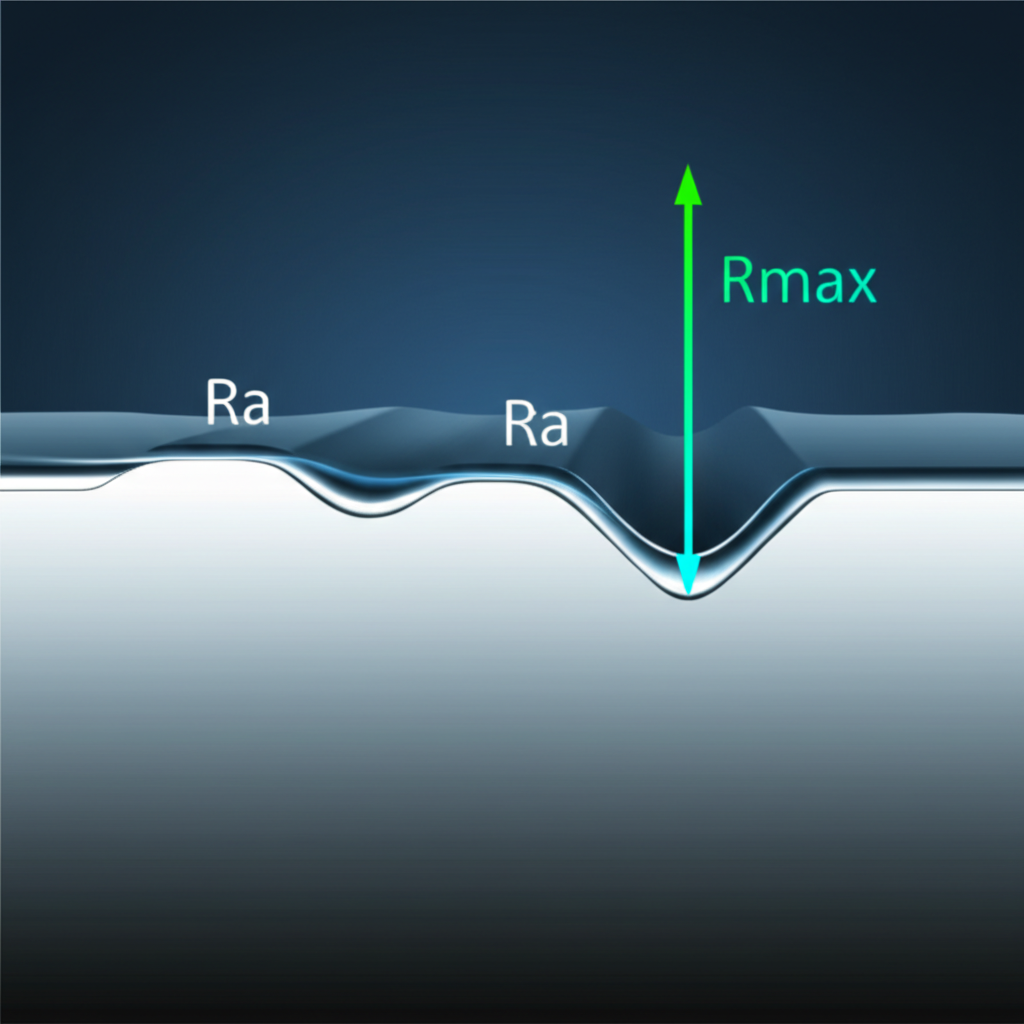

The most widely used parameter is the Roughness Average (Ra). As detailed in guides like the Surface Roughness Chart from RapidDirect, Ra represents the arithmetic average of the absolute values of the profile height deviations from the mean line. Because it averages all peaks and valleys, it provides a stable, general description of the surface texture and is less influenced by occasional scratches or blemishes. This makes it an excellent metric for quality control and specifying general machining requirements.

Other important metrics offer a more detailed view of the surface. Root Mean Square (RMS) is a similar statistical average to Ra but is calculated by squaring the deviations, averaging them, and taking the square root. It is slightly more sensitive to significant peaks and valleys than Ra. For applications where single, large imperfections can cause failure, metrics like Maximum Roughness Depth (Rmax) are used. Rmax measures the vertical distance between the highest peak and the lowest valley within the evaluation length, providing crucial information about the most extreme surface features. A comprehensive surface finishing chart is an invaluable tool for converting between these different standards and understanding their equivalents.

| Metric | Description | Primary Use Case |

|---|---|---|

| Ra (Roughness Average) | The arithmetic average height of roughness irregularities from a mean line. | General quality control and standard finish specifications. Most common industry metric. |

| RMS (Root Mean Square) | The square root of the mean of the squares of the profile height deviations. | Statistical analysis where peaks and valleys have a greater influence. |

| Rmax (Maximum Roughness Depth) | The largest peak-to-valley height within the evaluation length. | Identifying critical surface defects like scratches or burrs that could cause stress concentrations. |

Common Surface Finishing Methods for Forged Parts

Once the required surface metrics are defined, the next step is to choose a manufacturing process to achieve them. Forged parts, which typically have a rougher initial surface, can undergo various finishing treatments. These methods can be broadly categorized as mechanical or chemical, each offering distinct advantages for different automotive applications.

Mechanical Finishing

Mechanical processes physically alter the surface by removing or deforming material. These are often the primary methods for shaping and smoothing forged components.

- Machining: Processes like turning, milling, and drilling use cutting tools to remove material and achieve precise dimensions and a specified Ra value. This is fundamental for creating functional features like bearing surfaces or threaded holes.

- Grinding: This method uses an abrasive wheel to remove small amounts of material, producing a very fine and accurate finish. Grinding is essential for parts requiring tight tolerances and extremely smooth surfaces, such as shafts and gears.

- Polishing: Polishing uses fine abrasives to create a smooth, reflective surface. While often used for aesthetics, it also reduces microscopic flaws, which can improve fatigue resistance in highly stressed components.

- Shot Peening: In this process, the part's surface is bombarded with small, spherical media (shot). Shot peening doesn't primarily smooth the surface; instead, it creates a layer of compressive stress that significantly improves fatigue life and resistance to stress corrosion cracking. This is vital for components like connecting rods and suspension springs.

Chemical and Coating Treatments

Chemical treatments and coatings alter the surface at a molecular level or add a protective layer. These are primarily used to enhance corrosion resistance, improve appearance, or alter surface properties.

- Anodizing: Primarily used for aluminum forgings, anodizing electrochemically converts the surface into a durable, corrosion-resistant, and decorative aluminum oxide finish. It can be dyed in various colors, making it suitable for visible components.

- Passivation: This chemical treatment removes free iron from the surface of stainless steel forgings, enhancing their natural corrosion resistance by promoting the formation of a passive oxide layer.

- Powder Coating/E-Coating: These processes apply a protective layer of polymer or paint to the surface. They provide excellent corrosion protection and a durable, cosmetic finish, making them ideal for chassis and suspension parts exposed to the elements.

How to Select the Right Finish: A Step-by-Step Decision Framework

Choosing the optimal surface finish is a methodical process that requires balancing functional needs with manufacturing realities. Following a structured framework ensures all critical factors are considered, leading to a reliable and cost-effective component.

- Define Functional Requirements: The first and most important step is to identify the part's primary function. Will it slide against another surface? Does it need to resist corrosion from road salt? Is it subject to high cyclical loads? Answering these questions will point toward finishes that enhance wear resistance, corrosion protection, or fatigue life. For example, a gear tooth requires a hard, smooth finish from grinding, while a brake caliper bracket needs a robust coating for corrosion resistance.

- Consider Material Properties: The base material of the forging dictates which finishing processes are viable. For instance, anodizing is specific to aluminum, while passivation is used for stainless steel. The material's hardness will also affect the ease and cost of mechanical finishing processes like machining and grinding.

- Determine Aesthetic and Environmental Needs: Consider where the part will be used and if it will be visible. An engine component may only require a functional, corrosion-resistant finish, while a custom wheel or exterior trim piece needs a flawless, polished, or painted surface. The operating environment—temperature, humidity, and exposure to chemicals—will also narrow the choices to the most durable options.

- Balance Performance with Budget and Production Volume: More refined surface finishes almost always increase cost. Processes like lapping and superfinishing can produce exceptionally smooth surfaces but are expensive and typically reserved for critical applications. It's essential to specify a finish that is no finer than necessary for the part's function. For high-volume production, finding a reliable partner is key. Companies that specialize in custom forging services from Shaoyi Metal Technology offer integrated solutions from die manufacturing to mass production, ensuring consistency and efficiency.

Special Considerations for Forged Automotive Parts

The general principles of surface finishing must be applied with the specific demands of the automotive industry in mind. Different vehicle systems have unique requirements that dictate the ideal surface treatment.

For powertrain components like crankshafts, camshafts, and connecting rods, the primary concerns are fatigue life and wear resistance. These parts are subjected to millions of stress cycles and high contact pressures. Therefore, finishes like precision grinding to achieve a low Ra value on bearing journals are standard. Additionally, shot peening is frequently applied to connecting rods and crankshaft fillets to improve fatigue strength and prevent crack propagation.

In contrast, chassis and suspension components such as control arms, knuckles, and subframes prioritize corrosion resistance and durability. These parts are constantly exposed to water, road salt, and debris. As a result, robust protective coatings are essential. E-coating (electrophoretic deposition) followed by a powder coat top layer is a common combination that provides comprehensive protection against rust and physical damage, as described in guides on improving finishes for aluminum and other forgings.

Finally, for parts where safety and high-stress tolerance are paramount, such as steering components or brake system forgings, the focus is on defect-free surfaces. Any surface imperfection can act as a stress riser, potentially leading to catastrophic failure. For these critical parts, processes are tightly controlled to ensure a smooth, uniform finish, and non-destructive testing is often employed to verify surface integrity.

Frequently Asked Questions

1. How to choose the right surface finish?

To choose the right surface finish, you must systematically evaluate several factors. Start by defining the part's functional requirements, such as wear resistance, corrosion protection, or fatigue life. Next, consider the base material and its compatibility with different treatments. Finally, balance aesthetic needs and the operating environment with the overall budget and production volume. A detailed guide on types of metal surface finishes can help you compare options like polishing, anodizing, or powder coating.

2. How to decide surface finish value?

The surface finish value, typically specified as Ra, is determined by the engineering requirements of the component. For surfaces that mate or slide against each other, a lower Ra value (smoother finish) is needed to reduce friction and wear. For static parts or clearance surfaces, a higher Ra value (rougher finish) is often acceptable and more cost-effective. The value is calculated by taking the average of the absolute deviations from the surface's mean line over a specified length.

3. What is RA 6.3 surface finish equivalent to?

An Ra 6.3 micrometers (µm) surface finish is equivalent to approximately 250 microinches (µin). This is considered a medium-quality machined finish. It is often achieved through processes like coarse grinding, milling, or drilling. While not suitable for high-precision sliding or sealing applications, it is a common and economical specification for general-purpose parts and non-critical clearance surfaces where a highly refined finish is unnecessary.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —