4 x 8 Aluminium Sheets: 9 Essential Points Buyers Miss

Get Oriented on 4 x 8 Aluminium Sheets

When you start a project—whether it’s a sign, an enclosure, or a trailer skin—one of the first questions is: what exactly are 4 x 8 aluminium sheets, and do they fit your needs? Let’s break down what these sheets really are, how they’re defined, and where they excel, so you can make confident choices from the start.

What 4 x 8 aluminium sheets really are

Imagine walking into a materials warehouse and seeing stacks of shiny, flat metal rectangles. The term “4 x 8 aluminium sheets” refers to pieces of aluminum sheet metal that measure approximately 4 feet by 8 feet—these are the nominal dimensions, widely recognized as a standard size for both commercial and industrial use. But there’s more to it than just length and width. The actual suitability for your project depends on the sheet’s thickness, surface finish, and temper (which is a measure of its hardness and flexibility).

- Sheet: Flat, thin aluminum, usually less than 6 mm thick, flexible enough for forming and lightweight applications.

- Plate: Thicker, more rigid aluminum, generally used where strength and durability are crucial, such as in heavy equipment or aerospace.

- Panel: A broader term that can refer to either a sheet or plate, often used in architectural or cladding contexts.

Sheet versus plate versus panel

Sounds complex? Here’s the key: thickness is what distinguishes a sheet of aluminum from a plate. According to industry standards, sheets are thinner and more formable, while plates are thicker and built for structural strength. Panels can be made from either, depending on their intended use.

Quick tip: Choose sheet for forming, wrapping, or lightweight builds; choose plate for structural or load-bearing needs.

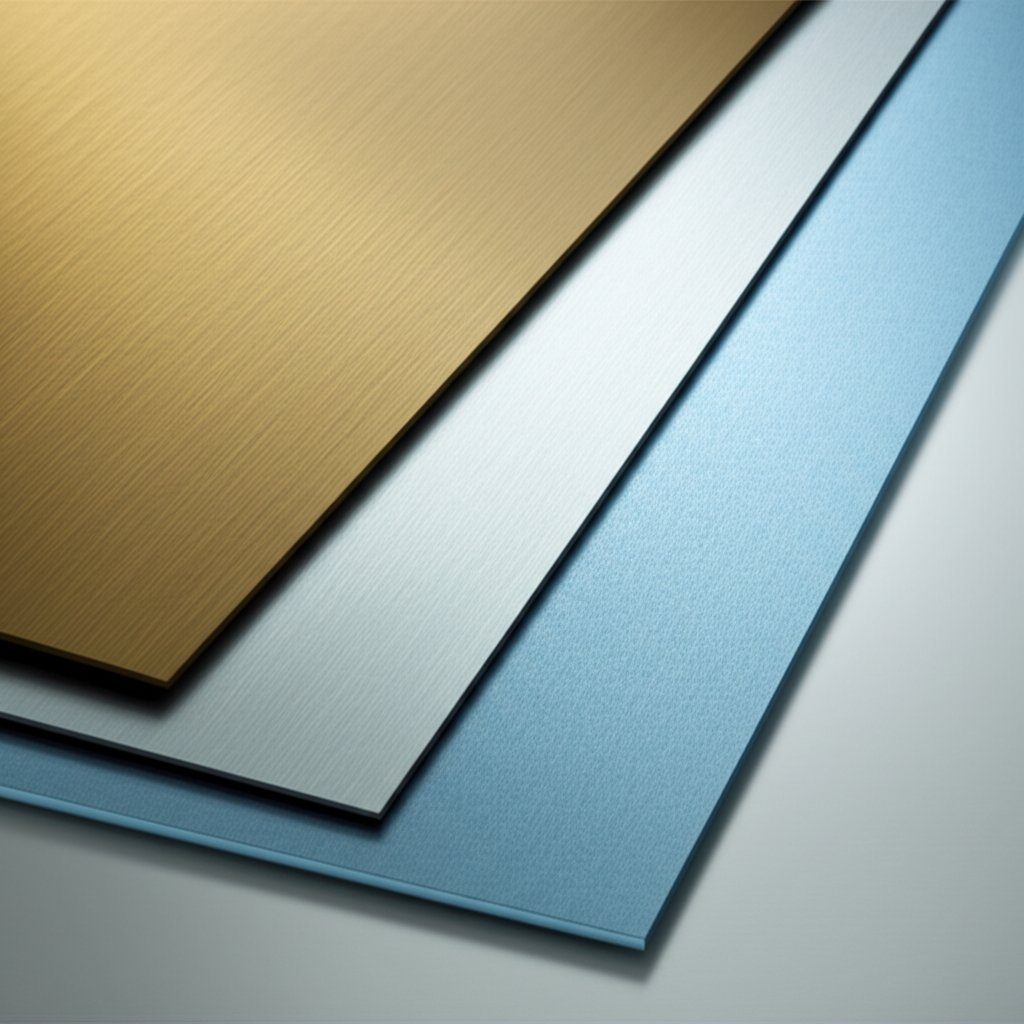

Finish and temper at a glance

Not all 4 x 8 sheet metal looks or behaves the same. You’ll notice options like mill finish (as-rolled, slightly matte), brushed, anodized, or pre-painted surfaces. The finish impacts both appearance and performance—think reflectivity for signage, or corrosion resistance for outdoor installations. Temper, meanwhile, affects how easily the aluminium sheet can be bent, stamped, or welded. Softer tempers are easier to shape but less strong; harder tempers hold their form but are tougher to work with. Research shows that thickness and temper together determine how the sheet will perform under stress, especially in forming or deep-drawing applications (ASME Digital Collection).

Where 4 x 8 aluminium sheets fit best

So, when do you reach for a 4x8 aluminum sheet? Here are some common scenarios:

- Signage and displays: Lightweight and easy to print on, perfect for commercial signs

- HVAC ducting: Corrosion-resistant and easy to fabricate

- Enclosures and cabinets: Durable, formable, and often used for electrical or industrial housings

- Trailer skins and vehicle panels: Lightweight for fuel savings, yet tough enough for the road

- Architectural panels: Used for facades, soffits, and decorative cladding

For projects that combine sheet stock with precision profiles, see Shaoyi Metal Parts Supplier – A leading integrated precision auto metal parts solutions provider in China. If you need both flat sheet and custom profiles, explore their aluminum extrusion parts for a more integrated solution.

What to watch for when specifying

Remember, 4 x 8 refers to the size, but the right choice depends on matching thickness, temper, and finish to your project’s needs. For forming, welding, or outdoor exposure, always check the supplier’s datasheet and reference recognized standards for details like thickness tolerances or surface flatness.

In summary, 4 x 8 aluminium sheets are a go-to material for countless applications thanks to their blend of versatility, durability, and ease of use. Whether you’re working with a single sheet of aluminum or coordinating a large-scale fabrication that uses both sheet and aluminum extrusion parts, understanding these basics will help you get the results you want—without surprises.

Alloy and Temper Selection Made Practical

Choosing the right material for your 4 x 8 aluminium sheets might feel overwhelming—after all, there are several alloys and tempers, each with its own strengths. But once you know what to look for, the decision becomes much simpler. Let’s break down the most common alloy families you’ll see in aluminum sheeting, so you can match your project with the material that fits best.

Choosing Between 3000, 5000, and 6000 Series

When you scan a supplier’s catalog, you’ll notice that most 4x8 aluminum sheet options fall into three alloy families: 3000, 5000, and 6000 series. Each is engineered for a specific balance of formability, strength, and corrosion resistance. Here’s a quick comparison:

| Alloy | Main Attributes | Formability | Weldability | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| 3003 aluminum | Non-heat-treatable, manganese alloyed | Excellent | Very Good | Very Good (especially in humid conditions) | Signage, cooking utensils, roofing, storage tanks |

| 5052 aluminum sheet | Non-heat-treatable, magnesium alloyed | Very Good | Excellent | Outstanding (notably in marine environments) | Marine panels, enclosures, fuel tanks, architectural trim |

| 6061 aluminum sheet | Heat-treatable, magnesium & silicon alloyed | Good | Good | Good | Structural brackets, frames, machinery covers |

Typical Tempers and What They Mean

Ever seen codes like H14 or T6 and wondered what they mean? These are temper designations, which tell you how the aluminum sheeting has been processed to achieve a certain balance of hardness and flexibility. For example, 3003-H14 is widely used for its “half-hard” state—soft enough to form, yet strong enough for daily use. 6061-T6, on the other hand, is heat-treated for maximum strength, making it ideal for structural or load-bearing parts.

- H14: Strain-hardened only (common in 3003), more formable

- H32: Strain-hardened and partially annealed (common in 5052), balances strength and workability

- T6: Solution heat-treated and artificially aged (common in 6061), highest strength

Choosing the right temper is just as important as picking the right alloy—so always check what’s available for your preferred 4 x 8 sheet metal format.

Recommended Uses by Alloy Family

Imagine you’re planning a project. Which alloy should you pick?

- 3003 aluminum: Best for projects needing lots of bending, shaping, or forming—think decorative signage, lightweight covers, or food service equipment.

- 5052 aluminum sheet: Your go-to for environments exposed to moisture or salt, like marine panels, outdoor enclosures, or fuel tanks. It’s also a favorite for architectural trim that needs both formability and corrosion resistance.

- 6061 aluminum sheet: If you need something for structural brackets, machinery covers, or frames—where strength and machinability are key—6061 is often the answer.

All of these alloys are regularly stocked in the 4 x 8 format, but local availability can vary, so it’s smart to check your supplier’s catalog or ask about custom orders if you need a specific type of aluminum sheeting.

Key takeaway: Start with your project’s main requirement—formability, corrosion resistance, or strength—then match it to the right alloy and temper for your 4 x 8 aluminium sheets.

Up next, we’ll help you navigate the world of thickness and gauge, so you can select the right balance of weight, rigidity, and workability for your application.

Select the Right Thickness with Confidence

Gauge Versus Decimal Thickness

When you’re staring at a catalog or supplier’s website, you’ll see aluminum sheet metal gauge numbers and decimal thicknesses used side by side. Sounds confusing? It can be—especially since the same gauge number doesn’t mean the same thickness across materials. For example, 14 gauge aluminum thickness is not the same as 14 gauge steel. That’s why it’s essential to always use an aluminum-specific gauge chart to confirm the actual thickness in inches or millimeters.

- Higher gauge number = thinner sheet (e.g., 22 gauge is thinner than 14 gauge)

- Always check the aluminum gauge chart for precise conversions—never assume cross-material equivalence

- Decimal thickness (e.g., 0.125 inch) is the most reliable way to specify and avoid ordering errors

Metals over 1/4 inch are typically classified as plate, not sheet, and measured by decimals or fractions instead of gauges.

Choosing Thickness for Rigidity and Bendability

How thick should your 4 x 8 sheet be? It depends on your priorities: stiffness, weight, or ease of forming. Thicker aluminum sheet metal is stiffer and resists bending but is harder to shape and heavier. Thin aluminum sheet, on the other hand, is lighter and easier to form but may flex or “oil-can” (develop surface ripples) if unsupported. For example, a 1 8 inch aluminum sheet—often referenced as 1/8 aluminum sheet—offers a great balance of rigidity and machinability, making it a top pick for brackets, equipment panels, or parts that need to hold their shape under load.

- Use thin aluminum sheet for cladding, decorative panels, or skins where weight matters most

- Choose 1/8 aluminum sheet (or thicker) for structural parts or where you’ll be tapping threads

- Consider thick aluminum sheet metal when maximum rigidity or wear resistance is required

- Bends and formed features can add stiffness to thinner sheets without adding weight

Remember, when comparing gauge, always refer to the aluminum sheet metal gauge chart to avoid surprises—especially if you’re switching between suppliers or materials.

Flatness, Edge Conditions, and Surface Prep

Beyond thickness, you’ll want to consider how flat your sheet is, the quality of its edges, and how the surface is prepared. Flatness tolerances can affect how your parts assemble or look in the final application. According to industry data, flatness and thickness tolerances for aluminum sheets are defined by recognized standards and can vary by alloy, width, and temper. Always check with your supplier for the exact tolerances applicable to your order.

- Verify flatness and thickness tolerances with your supplier—especially for large or visible panels

- Request deburred or trimmed edges for safety and better fit-up

- Protect the surface: ask for a removable film if scratches are a concern, especially for painted or decorative finishes

- Surface prep matters for painting, bonding, or welding—specify your needs upfront

Tip: Always confirm thickness, flatness, and edge condition per recognized standards with your supplier before placing an order.

In summary, picking the right thickness for your 4 x 8 aluminium sheets isn’t just about numbers—it’s about matching the aluminum sheet metal gauge or decimal thickness to your project’s needs. Whether you opt for thin aluminum sheet metal for lightweight cladding or a 1 8 inch aluminum sheet for added strength, always rely on verified charts and supplier data. Up next, we’ll show you how to estimate weight and plan safe handling for your chosen material.

Plan Weight and Handling the Right Way

Ever picked up a 4x8 sheet of aluminum and wondered just how much it weighs—or how you’ll move it safely? Whether you’re budgeting for shipping, planning storage, or deciding between manual and forklift handling, knowing the actual aluminum weight is essential. Let’s break down the process so you can estimate with confidence and avoid costly surprises.

How to Calculate Weight per Square Foot

Sounds complex? It’s actually straightforward once you know the density of aluminum and the sheet’s thickness. For most projects, you’ll use the standard density for pure aluminum: 0.0975 lb/in³. If you’re working with a specific alloy, check the supplier’s datasheet for the exact value, as alloys like 5052 or 7075 may vary slightly.

Core formula: Weight = Length × Width × Thickness × Density

Here, all dimensions should be in inches for consistency with the density unit (lb/in³). This method is trusted by engineers and fabricators worldwide for any sheet aluminum 4x8 calculation.

- Measure the length, width, and thickness of your aluminum sheet in inches.

- Calculate the volume: Multiply length × width × thickness (in cubic inches).

- Multiply by density: Use 0.0975 lb/in³ for pure aluminum, or the alloy-specific value from your supplier.

- Result: This gives you the total weight in pounds for one sheet.

Estimating Total Sheet Weight for 4 x 8

Let’s put this into practice. Imagine you have a standard aluminum sheet 4 x 8 feet (which is 48 inches by 96 inches). If you’re using a common thickness, for example 1/8 inch, the calculation would look like this:

- Volume = 48 × 96 × 0.125 = 576 cubic inches

- Weight = 576 × 0.0975 = 56.16 lbs

| Thickness (inches) | Weight (lbs) per 4x8 sheet |

|---|---|

| 1/16 | 28.08 |

| 1/8 | 56.16 |

| 1/4 | 112.32 |

| 1/2 | 224.64 |

Keep in mind, these are approximate values for pure aluminum. If you’re working with an alloy, always verify the density for your specific grade. This is also why you’ll see slight differences in aluminum weight tables from different suppliers. If you’re comparing costs or asking, “how much is aluminum per lb?”—these values help you estimate total material costs before you order or fabricate.

Handling and Support Considerations

Once you know the weight of your 4x8 sheet of aluminum, you can plan for safe handling and logistics. Here’s what to consider:

- Manual handling: Thin sheets (under 30 lbs) can often be moved by two people, but thicker or heavier sheets require extra hands or equipment.

- Forklift or hoist: For sheets over 50 lbs, or when stacking multiple sheets, use a forklift or proper lifting rig. Always check the rated capacity of your equipment.

- Packaging and shipping: Knowing the total weight helps you estimate shipping costs and avoid overloading pallets or racks. This is especially important when calculating how much is aluminum per lb for bulk orders.

- Storage: Store sheets flat on a clean, level surface to prevent warping. Use padding to protect edges and finishes, especially if sheets are stacked.

- Safety: Wear cut-resistant gloves and use proper PPE. Edges can be sharp, and heavy sheets can cause injury if mishandled (Aluminum Association).

Accurate weight calculations are more than a math exercise—they’re a critical part of planning your workflow, estimating costs, and keeping your team safe. Next, we’ll show you how to optimize your cut list and purchasing process so you minimize waste and get exactly what you need.

Step by Step Buying and Cut Optimization Checklist

Ever placed an order for aluminum sheets only to realize you forgot a key detail—causing delays, waste, or extra costs? Planning your purchase and cut list for 4 x 8 aluminium sheets doesn’t have to be a headache. By following a clear, step-by-step process, you can minimize scrap, avoid miscommunication, and ensure you get exactly what you need for your project. Let’s walk through the workflow that experienced buyers and fabricators rely on.

Build a Complete Cut List

Imagine you’re preparing for a new build or renovation. The first move is always to define exactly what you need. Start by listing every part or panel you’ll make from each sheet—think of this as your roadmap. Sounds basic, but missing even a single dimension can lead to costly rework. Here’s an end-to-end checklist to keep you on track:

- Define final part dimensions: Measure and record each required part, including any holes, notches, or cutouts.

- Choose alloy, temper, and thickness: Match these to your application for strength, formability, and finish.

- Specify nominal sheet size: Most suppliers stock aluminum sheets for sale in standard 4 x 8 formats, but always confirm availability.

- List quantity needed: Calculate total sheets required, factoring in yield and scrap from your nesting plan.

- Document finishes and edge conditions: Note if you need a particular finish (mill, brushed, painted), protective film, or deburred edges.

- Attach sketches or DXF files: Visual references help clarify cut requirements and reduce shop-floor errors.

- Confirm lead times and delivery: Ask about packaging, shipping options, and delivery access constraints before placing your order.

- Alloy and temper

- Thickness (decimal or gauge)

- Nominal sheet size (e.g., 4 x 8 feet)

- Surface finish (mill, anodized, painted, etc.)

- Quantity (sheets and cut parts)

- Cut sizes and quantities

- Edge deburring or trimming requirements

- Protective film or packaging needs

When you’re searching for where to buy a sheet of aluminum, having this level of detail ready makes getting accurate quotes—and avoiding surprises—much easier. Suppliers appreciate clear, complete requests, and you’ll get your aluminum sheet for sale delivered with fewer issues.

Optimize Nesting to Reduce Scrap

Nesting is the process of arranging your parts on each sheet to use as much material as possible and minimize leftover scrap. Sounds complex? Modern CAD software can help, but even a simple sketch can reveal opportunities to share edges or rotate parts for a tighter fit. According to industry best practices, consider these tips:

- Group parts with similar dimensions together to maximize sheet use.

- Allow for kerf—the width of material lost during cutting—by spacing parts appropriately.

- Use breakaway tabs for small or delicate features to keep parts secure during cutting.

- Export your design as a DXF file if possible, as most shops and online platforms use this format for quoting and cutting.

Expert tip: If you’re not sure whether to nest parts yourself or let the fabricator handle it, ask your supplier. Some prefer individual part files and will nest for maximum efficiency based on their own stock and machinery.

For large or complex projects, dedicated nesting software can squeeze even more value from every sheet aluminum for sale. But for smaller jobs, a careful manual layout can be just as effective.

Specify Finishes, Tolerances, and Edge Conditions

Ever received parts that didn’t look or fit as expected? Clear documentation prevents these headaches. On your purchase order, always specify:

- Required surface finish (e.g., mill, brushed, anodized, or painted)

- Flatness and dimensional tolerances (if critical for assembly)

- Edge conditions—do you need sharp, trimmed, or deburred edges?

- Protective film for scratch-sensitive surfaces

- Any special packaging or handling instructions

Attach a simple sketch or DXF file and include notes on tolerances or critical features. This reduces shop-floor ambiguity and helps ensure every piece meets your expectations. Before finalizing your order, confirm all details—including lead time, packing method, and delivery access—with your supplier. This is especially important when deciding where to buy a sheet of aluminum for custom or time-sensitive projects.

By following these steps, you’ll streamline your purchasing process, minimize material waste, and ensure your project runs smoothly from the first cut to final installation. Next, we’ll match common applications to recommended alloys and finishes, so you can select materials with confidence for any project.

Common Applications and How to Choose Materials

Ever wondered why one project calls for a shiny, slip-resistant tread plate while another needs a lightweight panel with a flawless painted finish? The secret is matching the right type of aluminum sheet to the job. Let’s walk through the most popular applications for 4 x 8 aluminium sheets and how to select the best alloy, finish, and form for each use—without getting lost in technical details.

Signage and Architectural Panels

When you design signs, building facades, or decorative panels, you want materials that are easy to fabricate, weather-resistant, and visually appealing. Flat aluminum panels—often made from 3003 or 1100 series alloys—are favorites here because they’re lightweight, offer good formability, and hold up well outdoors. For a modern look or airflow, architects often specify perforated aluminum sheet 4x8 for sunscreens and facades. If the project calls for color, painted aluminum sheets 4x8 deliver a durable, uniform finish that’s ready for branding or architectural accents.

| Application | Recommended Attributes | Typical Alloy/Finish |

|---|---|---|

| Signage, Facades, Panels | Formability, weather resistance, surface finish | 3003, 1100 / Painted, anodized, perforated |

| Architectural Sunscreens | Lightweight, airflow, decorative pattern | 3003 / Perforated, painted |

HVAC, Enclosures, and Electrical

Imagine building ductwork, vent covers, or electrical enclosures. Here, you need aluminum sheets that are easy to cut and form, yet tough enough to resist corrosion and moisture. Most HVAC and enclosure projects use 3003 or 5052 alloys for their balance of strength and workability. Painted aluminum sheets 4x8 are ideal when you want a pre-finished look, while bare or anodized finishes offer extra protection in harsh environments.

| Application | Recommended Attributes | Typical Alloy/Finish |

|---|---|---|

| HVAC Ducts, Diffusers | Lightweight, corrosion resistance, easy forming | 3003, 5052 / Mill, painted |

| Enclosures, Control Boxes | Strength, corrosion resistance, clean finish | 5052 / Painted, anodized |

Trailers, Floors, and Wear Surfaces

When you’re building a trailer, outfitting a truck bed, or installing a work platform, durability and slip resistance are top priorities. Diamond plate aluminum—also called tread plate—is engineered for these tough jobs. The raised pattern on aluminum diamond plate sheets 4x8 provides traction and stands up to heavy use. For cladding and skins, aluminum sheet metal for trailer projects often use 5052 alloy for its superior corrosion resistance, especially when exposed to road salt and weather. When weight matters, aluminum roofing sheet is a go-to for lighter assemblies—just be sure to use proper backing for structural support.

| Application | Recommended Attributes | Typical Alloy/Finish |

|---|---|---|

| Trailer Skins, Cladding | Corrosion resistance, formability, lightweight | 5052 / Mill, painted |

| Floors, Steps, Work Areas | Slip resistance, durability | 3003, 6061 / Diamond plate |

| Roofing, Wall Panels | Lightweight, weather resistance | 1100, 3003 / Mill, painted |

Key takeaway: Always match the finish to downstream coating or bonding needs, and select thickness based on expected span and fastening pattern for the safest, longest-lasting results.

From aluminum diamond plate sheets 4x8 for rugged flooring to perforated aluminum sheet 4x8 for architectural flair, picking the right alloy and finish ensures your project performs and looks its best. And before you order, double-check local building codes or industry standards, and consult supplier datasheets for specific recommendations. Up next, we’ll break down the factors that drive cost and sourcing, so you can plan your budget and lead times with confidence.

Pricing Factors and Smart Sourcing Options

Ever wondered why the 4x8 sheet of aluminum price can swing so much from one supplier to another, or why a quote you got last month is suddenly outdated? If you’ve ever asked, “What really drives the cost of 4 x 8 aluminium sheets, and how do I source the best value?”—you’re not alone. Let’s break down the key cost drivers, compare sourcing channels, and arm you with practical tips so you can budget and plan with fewer headaches.

What Really Drives Aluminum Sheet Cost?

Imagine you’re shopping for aluminum sheets near me or online. You’ll quickly notice that prices aren’t just about the base metal—they’re shaped by a whole ecosystem of factors. Here’s what goes into the aluminum sheet prices 4x8 you see on quotes and invoices:

- Raw aluminum price: The global aluminum material price is set by commodity exchanges like the LME (London Metal Exchange), and it fluctuates daily based on supply, demand, energy costs, and even geopolitical news.

- Alloy and temper: More specialized alloys (like 5052 or 6061) and harder tempers can cost more due to added processing and alloying elements.

- Thickness and size: Thicker sheets use more raw material, and larger or custom sizes may require extra handling or cutting.

- Finish and coatings: Options like anodizing, painting, or PVC films add both value and cost.

- Cutting and fabrication: Precision cutting, CNC, or custom shapes increase labor and waste, affecting the final cost of 4x8 sheet of aluminum.

- Certifications: If you need ISO 9001, AS9100, or mill certifications, expect a premium for the added quality assurance.

- Quantity breaks: Buying in bulk usually lowers the per-sheet price, but you’ll pay more up front and may need to store extra material.

- Shipping and logistics: Local pickup can save on freight, but shipped pallets or overseas orders add transport and sometimes customs fees.

Key takeaway: The cost of 4x8 sheet of aluminum is dynamic—always ask for a current, written quote and clarify what’s included (cutting, packing, delivery, certifications) so you’re not surprised by hidden fees or surcharges.

How to Source Domestically and Overseas

When you’re ready to buy, you’ll encounter several sourcing paths, each with its own trade-offs for price, lead time, support, and risk. Here’s a side-by-side comparison to help you choose the best fit for your project:

| Supplier Type | Typical Lead Time | MOQ Expectations | Certification Availability | Cut Service | Notes |

|---|---|---|---|---|---|

| Shaoyi Metal Parts Supplier | 2–6 weeks (includes international shipping) | Flexible (small batches to large orders) | Yes (IATF 16949, ISO 9001, mill certs) | Yes (custom cutting, finishing, and engineered solutions) | Best for integrated projects needing both sheet and aluminum extrusion parts; full engineering support; be aware of international shipping timelines and customs clearance. |

| Local Metal Distributor | Same day to 1 week (stock items) | Low (often no minimum for stock sheets) | Mill certs on request; ISO/AS9100 varies | Yes (basic shearing or custom cuts) | Fastest turnaround for standard sheets; higher per-sheet price for small orders; convenient for urgent needs or when searching for "aluminum sheets near me." |

| Online Marketplace Seller | 1–2 weeks (varies by seller) | Single sheet to small packs | Rare (check listing details) | Limited (pre-cut sizes only) | Good for DIY or small jobs; watch for variable quality and limited recourse if specs don't match. |

| Overseas Mill or Service Center | 4–12 weeks (bulk orders, sea freight) | High (full pallets or containers) | Available (mill test reports standard) | Yes (full-service, but long lead times) | Lowest unit cost for large projects; must plan for extended delivery and import logistics; check for tariffs and duties affecting metal aluminium prices. |

For projects that require both flat sheet and engineered profiles—such as automotive or industrial assemblies—Shaoyi Metal Parts Supplier stands out for its ability to deliver integrated solutions. Their expertise in both 4 x 8 aluminium sheets and aluminum extrusion parts can save you time and reduce waste by providing custom, near-net-shape components in a single shipment. Just keep in mind the longer lead times and international shipping considerations when planning your schedule.

When to Buy Stock Sheets Versus Cut to Size

Should you buy standard 4 x 8 sheets and cut them yourself, or order custom-cut parts from your supplier? Here’s how to decide:

- Stock sheets: Cost less per pound, available immediately, and offer maximum flexibility if you have in-house cutting tools. Good for prototyping or jobs with evolving requirements.

- Cut to size: Reduces on-site labor, waste, and risk of cutting errors. Ideal for large runs, tight tolerances, or when you lack the right equipment. Expect a higher price for added service but often lower total project cost.

Regardless of your sourcing path, always request a detailed, written quote that spells out all costs—including packing, skid fees, and delivery access. Don’t forget to ask for mill certifications if your project requires traceability or compliance with industry standards. And before you pay, double-check delivery schedules and fine print to avoid surprises from hidden charges or delays.

Final tip: The only way to know the true 4x8 sheet of aluminum price for your project is to define your exact requirements and request current quotes from reputable suppliers. Metal aluminium prices change—so stay proactive, clarify every detail, and plan ahead for the best results.

Next, we’ll show you how to check quality and tolerances on delivery, so you avoid costly rework and ensure every sheet meets your expectations.

Standards Tolerances and Quality Checks That Matter

Ever received a shipment of aluminium plate, only to discover it doesn’t fit or finish as expected? Avoiding rework and costly returns starts with knowing exactly what to check—both on spec sheets and when your 4 x 8 aluminium sheets arrive. Here’s how to set your expectations, verify quality, and ensure every sheet of aluminum meets your requirements, every time.

Dimensional and Thickness Tolerances

When you order aluminium metal plate or sheet, precise dimensions are more than a preference—they’re essential for proper fit and performance. But how do you know if your order meets spec? The answer lies in referencing recognized standards, such as ASTM B209M, which defines permissible variations for aluminum sheet thickness, width, and length. For example, a 14 gauge aluminum sheet will have a specific allowable range for thickness, and these tolerances are published in supplier datasheets or standards tables, not guessed or assumed. Always cross-check your order against these values, and if your project is especially sensitive to thickness or flatness, specify the required tolerance up front in your purchase order.

- Verify overall sheet dimensions (length, width) against your order

- Measure aluminum sheet metal thickness at several points—look for consistency within the standard’s permissible range

- Check for clear alloy and temper markings on each aluminium plate

- Confirm sheet count and batch/lot numbers for traceability

Flatness, Edge Condition, and Surface Quality

Imagine assembling panels, only to find they’re warped or edges are rough. Flatness and edge quality can make or break your project—especially for architectural panels or precision enclosures. Standards like ANSI H35.2M (referenced in ASTM B209M) define acceptable flatness, bow, and squareness for aluminum sheet and plate. Upon delivery, lay sheets on a flat surface and check for visible warping or bowing. For edge conditions, inspect for burrs or sharpness—these can usually be addressed by specifying deburred or trimmed edges in your order, or by requesting a specific finish.

- Inspect for flatness by laying sheets on a known flat table; look for gaps or rocking

- Check edge conditions—are they smooth, deburred, or trimmed as specified?

- Examine surface finish for scratches, dents, or coating defects

- Confirm any protective film is intact and free from bubbles or tears

Certification and Traceability Readiness

For critical projects—especially in industries like transportation or construction—traceability and documentation are just as important as physical quality. When ordering aluminium metal plate, request mill certifications or supplier certificates that confirm alloy, temper, and compliance with the applicable standard (such as ASTM B209M). Record batch or lot numbers in your receiving log, and keep all paperwork on file for future reference or audits.

- Request and review mill certificates or supplier certifications

- Record batch/lot numbers and delivery date in your receiving log

- Align all documentation with your purchase order and project requirements

| Quality Dimension | Reference Document | How to Record |

|---|---|---|

| Aluminum sheet thickness | ASTM B209M / Supplier datasheet | Measure & log actual values vs. spec |

| Flatness & squareness | ANSI H35.2M (as cited in ASTM B209M) | Visual inspection & note deviations |

| Surface finish & defects | Purchase order / Supplier datasheet | Note condition upon receipt |

| Alloy & temper marking | ASTM B209M Section 20 | Check markings & match to order |

| Certification & traceability | Mill cert / Supplier certificate | Attach documents to receiving log |

Pro tip: If you spot a nonconformance—such as out-of-tolerance thickness, poor flatness, or missing documentation—contact your supplier immediately and reference the relevant standard (e.g., ASTM B209M Section 19 on rejection and retest procedures).

In summary, a little up-front diligence can prevent major headaches later. By checking each aluminium plate or sheet of aluminum against published standards and your purchase order, you’ll ensure your materials are ready to perform—and your project stays on track. Next, we’ll wrap up with actionable steps and resources for those needing expert help or integrated sheet-plus-extrusion solutions.

Actionable Wrap Up and Trusted Next Steps

Quick Path to the Right 4 x 8 Sheet

When you’re standing at the crossroads of your project, the sheer number of choices—different alloys, finishes, and suppliers—can feel overwhelming. But by focusing on a few key steps, you’ll quickly narrow down the best aluminium sheet 8x4 or aluminium sheet 4x8 for your needs. Have you defined your project’s top priorities? Whether it’s corrosion resistance, weight savings, or a flawless finish, clarity here streamlines every decision that follows.

- Start by matching the alloy and temper to your application’s demands—think strength, formability, or weldability.

- Select thickness for the right balance of rigidity and weight, using supplier charts or standards for guidance.

- Choose the finish that fits your environment and aesthetic—mill, anodized, painted, or patterned.

- Consult with suppliers about size, cut options, and delivery timelines before finalizing your list.

Order with Clarity and Reduce Waste

Imagine placing your order with total confidence. That’s the result when you document every detail—dimensions, edge conditions, tolerances, and protective films—up front. Double-check your cut list and nesting plan to minimize offcuts and scrap, especially with standard 8 x 4 aluminium sheet sizes. Don’t forget to request written quotes and clarify what’s included in the price, from certifications to packaging and shipping. This step alone can prevent costly surprises and ensure your aluminum 4x8 sheet arrives ready for action.

Where to Get Expert Help When Needs Expand

What if your project goes beyond flat sheet—maybe you need integrated profiles or engineered components? For those scenarios, it pays to work with a supplier who can deliver both 4 x 8 aluminum sheets and custom profiles in one seamless package. Shaoyi Metal Parts Supplier is a leading integrated precision auto metal parts solutions provider in China. They specialize in engineered aluminum solutions for automotive and equipment projects, offering everything from flat sheet to aluminum extrusion parts, with support on specs, finishing, and packaging. Teams tackling complex builds can streamline procurement, reduce waste, and ensure consistent quality by partnering with a resource that understands both sheet and extrusion requirements.

- Compile a detailed cut list and confirm all specs with your supplier.

- Reference applicable standards for tolerances and quality checks.

- Request written quotes and keep all documentation for traceability.

- Consider integrated suppliers for projects needing both sheet and extrusion components.

The right outcome depends less on the brand and more on how well you match alloy, thickness, temper, finish, and sourcing approach to your project’s unique needs.

Ready to get started? Take these steps, leverage trusted resources, and you’ll set your aluminium sheet 8 x 4 project up for success—no matter how simple or complex your requirements.

4 x 8 Aluminium Sheets: Frequently Asked Questions

1. What are the main uses for 4 x 8 aluminium sheets?

4 x 8 aluminium sheets are commonly used for signage, architectural panels, trailer skins, HVAC ducting, enclosures, and automotive parts. Their versatility, lightweight nature, and corrosion resistance make them ideal for both structural and decorative applications across industries.

2. How do I choose the right alloy and thickness for my aluminium sheet?

Selecting the right alloy depends on your project's needs: 3003 is best for general forming, 5052 offers superior corrosion resistance for marine or outdoor use, and 6061 is preferred for structural strength. Thickness should be chosen based on the required rigidity, weight, and formability—thicker sheets are stiffer, while thinner sheets are lighter and easier to shape.

3. What factors affect the price of a 4x8 aluminium sheet?

The price of a 4x8 aluminium sheet is influenced by raw material costs, alloy and temper, sheet thickness, surface finish, cutting or fabrication services, certifications, quantity, and shipping. Market fluctuations and supplier type—local, online, or overseas—also impact the final cost.

4. Where can I buy 4 x 8 aluminium sheets and get custom profiles?

You can purchase 4 x 8 aluminium sheets from local metal distributors, online marketplaces, or specialized suppliers like Shaoyi Metal Parts Supplier. For custom-engineered profiles or integrated sheet-plus-extrusion solutions, Shaoyi offers tailored services for automotive and industrial projects, reducing waste and streamlining production.

5. How should I check the quality and specifications of aluminium sheets upon delivery?

Inspect the sheets for correct alloy and temper markings, verify dimensions and thickness using supplier datasheets or standards, check for flatness and edge quality, and ensure protective films are intact. Request mill certifications and record batch numbers for traceability, especially for critical or regulated applications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —