El paper fonamental d'un SMS per a la certificació IATF 16949

TL;DR

L'estàndard IATF 16949 estableix els requisits obligatoris per a un Sistema de Gestió de la Qualitat (SGC) dins del sector automotriu global. La funció principal d'un SGC segons la IATF 16949 és servir de marc operatiu que una organització utilitza per garantir la consistència del producte, impulsar la millora contínua i complir els objectius fonamentals de l'estàndard: prevenir defectes i reduir la variació i el desperdici al llarg de la cadena d'aproviment.

Definint els Fonaments: Què són la IATF 16949 i un SGC?

En el sector automotriu, la precisió, la seguretat i la fiabilitat són imprescindibles. Per assolir-ho, el sector compta amb un marc rigorós en matèria de qualitat. Al centre d'aquest marc hi ha dos conceptes diferents però íntimament relacionats: la IATF 16949 i el Sistema de Gestió de la Qualitat (SGC). Comprendre la seva relació és el primer pas per assolir el compliment normatiu i l'excel·lència operativa.

L'IATF 16949 és l'especificació tècnica internacional i l'estàndard de gestió de la qualitat per a la indústria automotriu. Desenvolupat per l'International Automotive Task Force (IATF), no és un sistema de gestió de la qualitat (SGC) en si mateix, sinó el llibre de regles definitiu que detalla què ha d'assolir un SGC automotriu. Aquesta norma armonitza els diferents sistemes d'avaluació i certificació de la cadena global d'aprovisionament automotriu, creant un conjunt únic i clar de requisits per als proveïdors. És important destacar que l'IATF 16949 no és un document autònom; s'ha d'implementar com a complement i en conjunció amb l'ISO 9001:2015, que proporciona els requisits fonamentals per a qualsevol SGC.

Un sistema de gestió de la qualitat (SGQ), per altra banda, és el conjunt específic de polítiques, processos, procediments i registres que una organització implementa per complir amb els requisits dels clients i reglamentaris. És el marc operatiu pràctic que l'empresa construeix i utilitza diàriament. Un SGQ defineix com assegura l'organització que els seus productes i serveis siguin coherents, fiables i de gran qualitat. Encara que un SGQ pot existir en qualsevol sector, al sector automobilístic, un SGQ eficaç ha d'estar dissenyat i operat per complir amb els criteris rigorosos establerts per la IATF 16949.

La diferència fonamental rau en els seus rols: la IATF 16949 és el 'quin'—defineix els requisits i objectius. El SGQ és el 'com'—és el sistema viu que l'organització crea per executar aquests requisits. Una organització no pot ser certificada segons un SGQ, però pot obtenir la certificació segons l'estàndard IATF 16949 demostrant que el seu SGQ compleix totalment amb totes les clàusules especificades.

La funció principal: Com un sistema de gestió de la qualitat compleix els requisits de l'IATF 16949

Un sistema de gestió de la qualitat és el motor que impulsa una organització cap al compliment de l'IATF 16949. Tradueix els requisits abstractes de la norma en accions concretes i resultats mesurables. El sistema de gestió de la qualitat actua com a sistema central i integrat per gestionar tots els aspectes de la qualitat, des del disseny inicial del producte fins a l'entrega final i el servei. El seu paper és multifacètic, afectant totes les parts de l'organització per garantir un enfocament unificat de la qualitat.

Les funcions principals d'un sistema de gestió de la qualitat en el context de l'IATF 16949 inclouen:

- Assegurar la qualitat i la seguretat del producte de manera consistent: Un sistema de gestió de la qualitat estableix processos i instruccions de treball estandarditzats per garantir que cada producte es fabriqui segons les mateixes especificacions, complint de manera consistent els requisits del client i de seguretat.

- Impulsar el control del procés i l'eficiència: Proporciona les eines i metodologies per monitoritzar, mesurar i controlar els processos de fabricació, cosa que comporta una major eficiència i efectivitat en l'ús dels recursos.

- Gestió de la variació de la cadena d'aprovisionament: La norma fa especial èmfasi en tota la cadena d'aprovisionament. Un sistema de gestió de la qualitat conforme inclou processos sòlids per a la selecció, supervisió i desenvolupament de proveïdors, amb l'objectiu de reduir la variació i el desperdici provinents de proveïdors externs.

- Facilitació de la gestió de riscos i el compliment normatiu: Un sistema de gestió de la qualitat es basa en un enfocament de pensament centrat en el risc, ajudant les organitzacions a identificar, avaluar i mitigar els riscos relacionats amb la qualitat del producte, la seguretat i el compliment normatiu.

En implementar aquestes funcions, el sistema de gestió de la qualitat (SGQ) esdevé més que un conjunt de documents; es converteix en una eina dinàmica per a la gestió del rendiment. Proporciona l'estructura necessària per recollir dades, analitzar el rendiment i prendre decisions basades en evidències. Aquest enfocament sistemàtic assegura que l'organització no només compleixi els requisits mínims de la IATF 16949, sinó que també construeixi un model operatiu resistent capaç d'adaptar-se a les demandes canviants dels clients i a les condicions del mercat.

Pilars clau d'un SGQ conforme a la IATF: processos i objectius

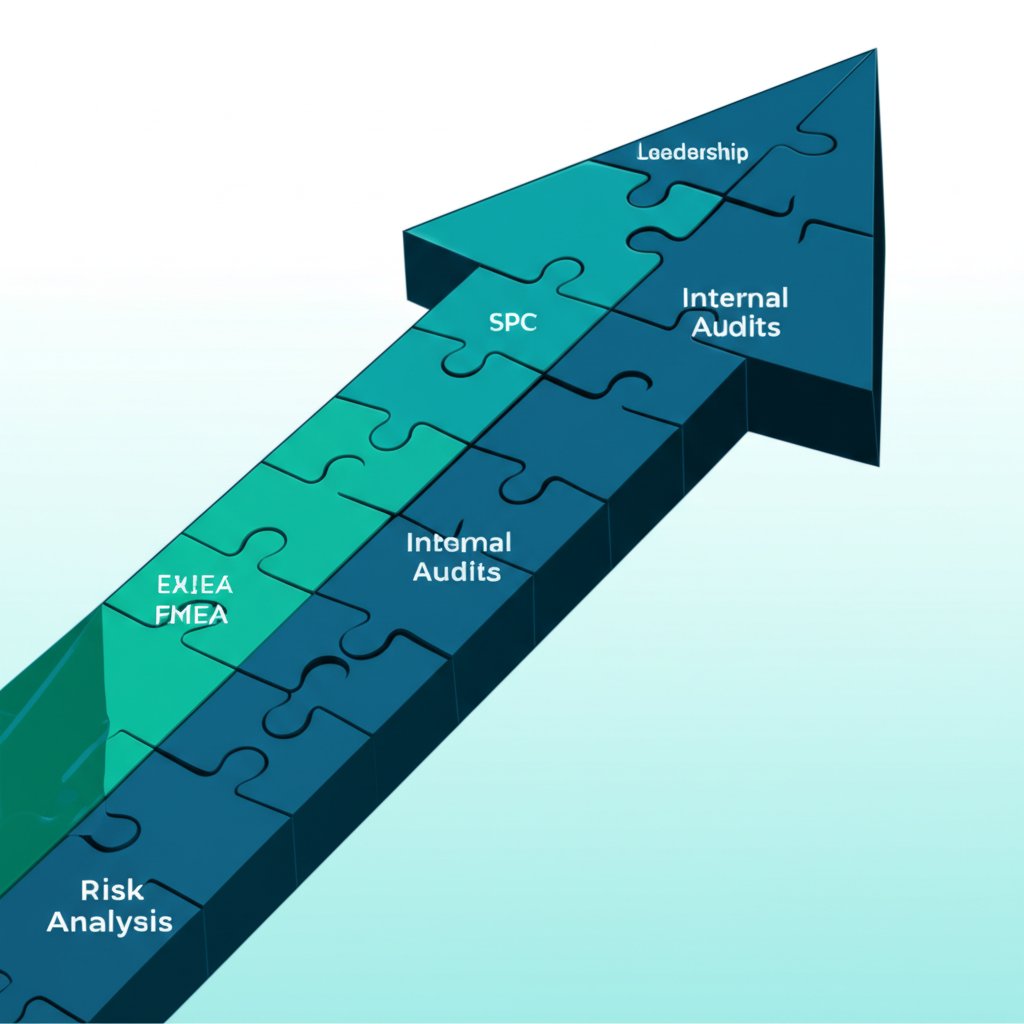

L'estàndard IATF 16949 es basa en diversos principis fonamentals que un sistema de gestió de la qualitat ha de posar en pràctica. Aquests pilars anaven més enllà del simple compliment i pretenen crear una cultura d'excel·lència. Els tres objectius més importants són la prevenció de defectes, la reducció de la variació i dels residus, i el compromís amb la millora contínua. Un sistema de gestió de la qualitat sòlid proporciona els processos i eines específics necessaris per assolir aquests objectius.

La prevenció de defectes és una pedra angular de l'IATF 16949, ja que canvia l'enfocament de la detecció a l'evitació proactiva de no conformitats. Un sistema de gestió de la qualitat eficaç integra aquesta filosofia mitjançant eines estructurades com el Planificació Avançada de la Qualitat del Producte (APQP) i l'Anàlisi de Modes i Efectes de Fallada (FMEA). L'APQP assegura que la qualitat es planifiqui dins del disseny del producte i del procés des del principi, mentre que el FMEA s'utilitza per identificar sistemàticament els possibles modes de fallada i implementar controls per evitar-los. Aquesta postura proactiva minimitza les revisions costoses, les matalasses i les reclamacions dels clients.

El segon pilars és la reducció implacable de la variació i el desperdici en la cadena d'aprovisionament. La variació en els processos o components provoca una qualitat del producte inconsistent, mentre que el desperdici consumeix recursos sense afegir valor. Un sistema de gestió de la qualitat (SGQ) aborda aquest aspecte mitjançant metodologies com el control estadístic de processos (SPC) i l'anàlisi dels sistemes de mesura (MSA). El SPC utilitza dades estadístiques per monitoritzar i controlar els processos, mentre que el MSA assegura que els sistemes de mesura emprats per recopilar aquestes dades siguin precisos i fiables. La gestió de la cadena d'aprovisionament també és fonamental en aquest context. Per a projectes automotrius que requereixen components dissenyats amb precisió, l'adquisició d'extrusions personalitzades d'alumini d'un proveïdor amb un sistema certificat IATF 16949, com Shaoyi Metal Technology , assegura que les peces compleixin exactament amb les especificacions, contribuint directament a la reducció de la variació en el muntatge final.

Finalment, la millora contínua no és només un objectiu sinó una activitat obligatòria i permanent. El sistema de gestió de la qualitat (SGQ) facilita això mitjançant processos estructurats d'auditories internes, revisions de la direcció i accions correctores. Les auditories internes verifiquen que el SGQ funcioni segons el previst, mentre que les revisions de la direcció asseguren que el lideratge superior estigui activament implicat en l'avaluació del rendiment i en la direcció dels esforços de millora. Quan sorgeixen problemes, un procés formal de resolució de problemes i anàlisi de causes arrel assegura que no només es corregeixin, sinó que també es realitzin canvis sistèmics per prevenir la seva reaparició.

Alineació estratègica: De la implementació del SGQ a la certificació IATF 16949

L'assoliment de la certificació IATF 16949 és un esforç estratègic que requereix alinear el GMA de qualitat d'una organització amb les exigències rigoroses de l'estàndard. Aquest procés va més enllà de simples procediments d'escriptura; implica incrustar una mentalitat centrada en la qualitat a tota l'organització, defensada per la direcció superior i abraçada per cada empleat. El camí de la implementació a la certificació és un camí estructurat que transforma la forma en què una empresa opera.

El primer element crític és el compromís de lideratge. La IATF 16949 exigeix explícitament que la direcció superior sigui responsable de l'eficàcia del SGQ. Això significa que els líders no només han de proporcionar recursos sinó també participar activament en el fixar objectius de qualitat, revisar el rendiment del sistema i fomentar una cultura en què la qualitat sigui responsabilitat de tots. Sense aquest suport visible i sostenit des de dalt, és probable que qualsevol implementació de l'SGC no sigui suficient.

A continuació, hi ha la documentació i el control de processos. Un SGQ conforme amb la IATF requereix informació clara i documentada per a tots els processos clau, des del disseny i el desenvolupament fins a les activitats de producció i post-entrega. Això inclou plans de control, instruccions de treball i registres que proporcionen proves de conformitat. Les modernes eines de gestió de requisits poden ser inestimables per mantenir un control estricte dels requisits, gestionar els canvis i garantir la traçabilitat, que són fonamentals per a un sistema de gestió de qualitat robust.

La pista d'auditoria és l'última etapa preparatòria abans de la certificació. Les organitzacions han de dur a terme audits interns exhaustius del seu SGC, processos de fabricació i productes per verificar el compliment i identificar àrees de millora. Aquestes avaluacions internes preparen l'organització per a la auditoria externa rigorosa realitzada per un organisme de certificació de tercers, com ara: NSF superar amb èxit aquesta auditoria de dues fases —que inclou una revisió de preparació i una auditoria de certificació in situ— comporta l'obtenció de la certificació IATF 16949, indicant a la indústria automotriu global que el SMS de l'organització compleix els estàndards més elevats de qualitat.

Més enllà del compliment: Una cultura de la qualitat

En definitiva, el paper d'un Sistema de Gestió de la Qualitat segons l'IATF 16949 va molt més enllà de l'obtenció d'un certificat per penjar a la paret. Es tracta de transformar fonamentalment l'enfocament de l'organització respecte a les seves operacions. Un SMS implementat correctament fomenta una cultura de millora contínua, de pensament basat en riscos i d'atenció al client inquebrantable, que esdevé essencial per a la identitat i l'èxit de l'empresa.

Implementar un SMQ per complir els requisits de l'IATF 16949 obliga una organització a examinar detingudament els seus processos, eliminar el despilfarro i incorporar eficiència en totes les activitats. Això comporta beneficis empresarials tangibles, incloent una millora de la satisfacció del client, un augment de la productivitat i una major credibilitat al mercat. Proporciona un llenguatge comú i un marc de qualitat que alinea els equips interns i tota la cadena d'aproviment cap a un objectiu compartit.

En el sector automobilístic, competitiu i crític des del punt de vista de la seguretat, un SMQ conforme no és només un requisit, sinó un actiu estratègic. Ofereix l'estructura necessària per entregar de manera consistent productes de gran qualitat, gestionar cadenes d'aproviment complexes i adaptar-se a les exigències en constant evolució del sector, assegurant la viabilitat i el creixement a llarg termini.

Preguntes freqüents

1. És l'IATF 16949 un sistema de gestió de la qualitat?

No, la IATF 16949 no és un sistema de gestió de la qualitat (SGQ) en si mateix. És una norma tècnica internacional que defineix els requisits específics per a un SGQ en el sector automobilístic. Les organitzacions desenvolupen i implementen els seus propis SGQ per complir amb els criteris establerts per la norma IATF 16949 conjuntament amb la ISO 9001.

2. Quina és la diferència entre SGQ i IATF 16949?

La diferència clau és que un SGQ és el conjunt de processos interns, polítiques i procediments que una organització utilitza per gestionar la qualitat, mentre que la IATF 16949 és la norma externa que especifica què han d'aconseguir aquests processos. Penseu en la IATF 16949 com al plànol i en el SGQ com al sistema real construït a partir d'aquest plànol. La IATF 16949 proporciona les regles; el SGQ és la manera com l'organització les segueix.

3. Quin és l'objectiu principal d'un sistema de gestió de la qualitat (SGQ)?

L'objectiu principal d'un SMQ és garantir que una organització pugui complir de manera consistent els requisits del client i millorar la satisfacció del client. Això s'aconsegueix establint un marc de processos empresarials centrats en la consistència, l'eficiència i la millora contínua. En el context de l'IATF 16949, aquest objectiu s'estableix més clarament per incloure objectius específics com la prevenció de defectes i la reducció de residus i variacions en la cadena d'aprovisionament automotriu.

4. Quina és la funció d'un SMQ per a un compliment normatiu eficaç?

Un SMQ té un paper fonamental en el compliment normatiu, ja que proporciona una aproximació estructurada i sistemàtica al compliment dels requisits legals i reglamentaris. Garanteix que les activitats relacionades amb el compliment siguin definides, controlades i documentades. Per al sector automotriu, això inclou requisits relacionats amb la seguretat del producte, les regulacions medioambientals i la declaració de materials, que són parts integrals de l'estàndard IATF 16949.

Petits lots, altes estàndards. El nostre servei d'prototipatge ràpid fa que la validació sigui més ràpida i fàcil —

Petits lots, altes estàndards. El nostre servei d'prototipatge ràpid fa que la validació sigui més ràpida i fàcil —