অ্যালুমিনিয়াম প্রোফাইলের জন্য বেন্ড রেডিয়াস সীমাবদ্ধতা আয়ত্ত করা

সংক্ষেপে

এক্সট্রুডেড অ্যালুমিনিয়াম প্রোফাইলের জন্য সর্বনিম্ন বেন্ড রেডিয়াস একটি নির্দিষ্ট মান নয়; এটি কয়েকটি পরস্পর সম্পর্কযুক্ত ফ্যাক্টর দ্বারা নির্ধারিত একটি গুরুত্বপূর্ণ ইঞ্জিনিয়ারিং প্যারামিটার। অর্জনযোগ্য ব্যাসার্ধ অ্যালুমিনিয়াম খাদ এবং এর টেম্পার, প্রোফাইলের প্রাচীরের পুরুত্ব ও জ্যামিতি এবং ব্যবহৃত নির্দিষ্ট বাঁকানোর পদ্ধতির উপর নির্ভর করে। গণনা করা সীমার বাইরে একটি প্রোফাইল বাঁকানোর চেষ্টা করলে ফাটল, বাঁকা হয়ে যাওয়া বা অগ্রহণযোগ্য বিকৃতির মতো ত্রুটি হতে পারে, যা অংশটির কাঠামোগত অখণ্ডতা এবং সৌন্দর্যময় গুণাবলীকে ক্ষতিগ্রস্ত করে।

সর্বনিম্ন বেন্ড রেডিয়াস সম্পর্কে বোঝা

ধাতু নির্মাণে, সর্বনিম্ন বাঁকের ব্যাসার্ধ হল সেই ক্ষুদ্রতম ব্যাসার্ধ যাতে একটি প্রোফাইলকে বাঁকানো যেতে পারে যাতে উপাদানের ক্ষতি বা উল্লেখযোগ্য ত্রুটি না হয়। যখন একটি অ্যালুমিনিয়াম এক্সট্রুশনকে বক্রাকারে পরিণত করা হয়, তখন উপাদানটি অপরিমেয় চাপের সম্মুখীন হয়। বাইরের পৃষ্ঠটি টানা পড়ে এবং টানের মুখোমুখি হয়, যেখানে ভিতরের পৃষ্ঠটি চাপে থাকে। যদি বাইরের দেয়ালে টানের শক্তি উপাদানের স্থিতিস্থাপকতা অতিক্রম করে, তবে এটি পাতলা হওয়া শুরু করবে, দুর্বল হবে এবং অবশেষে ফাটবে। তদ্বিপরীতে, ভিতরের দেয়ালে চাপের শক্তি যদি সঠিকভাবে সমর্থিত না হয় তবে তা কুঁচকে যেতে পারে বা ভাঙতে পারে।

এই সীমার উপরে যাওয়া কেবল দৃশ্যগত বিষয় নয়; এটি একটি গাঠনিক বিষয়। সূক্ষ্ম ফাটল, যা খালি চোখে দৃশ্যমান নাও হতে পারে, উপাদানটিকে গুরুতরভাবে দুর্বল করে দিতে পারে, লোডের অধীনে ব্যর্থতার জন্য এটিকে সংবেদনশীল করে তোলে। তাই, নির্ভরযোগ্য, উচ্চ-গুণগত বাঁকানো অ্যালুমিনিয়াম অংশগুলি ডিজাইন এবং উৎপাদনের জন্য সর্বনিম্ন বাঁকের ব্যাসার্ধ বোঝা এবং সম্মান করা মৌলিক। এটি চূড়ান্ত পণ্যের কার্যকরী কর্মক্ষমতা এবং নির্দিষ্ট আয়ু উভয়কেই নিশ্চিত করে।

বাঁকানোর সীমাবদ্ধতা নির্ধারণকারী গুরুত্বপূর্ণ বিষয়গুলি

একটি নির্বহনকৃত অ্যালুমিনিয়াম প্রোফাইলের জন্য সঠিক বাঁকের ব্যাসার্ধ গণনা করতে হলে কয়েকটি প্রধান চলরাশির বিস্তারিত বিশ্লেষণ প্রয়োজন। উপকরণটি কীভাবে গঠনের চাপে প্রতিক্রিয়া জানাবে তার প্রতিটি বিষয় একটি গুরুত্বপূর্ণ ভূমিকা পালন করে, এবং তাদের মধ্যে যেকোনো একটিকে উপেক্ষা করা ব্যয়বহুল উৎপাদন ব্যর্থতার দিকে নিয়ে যেতে পারে।

অ্যালুমিনিয়াম খাদ এবং টেম্পার

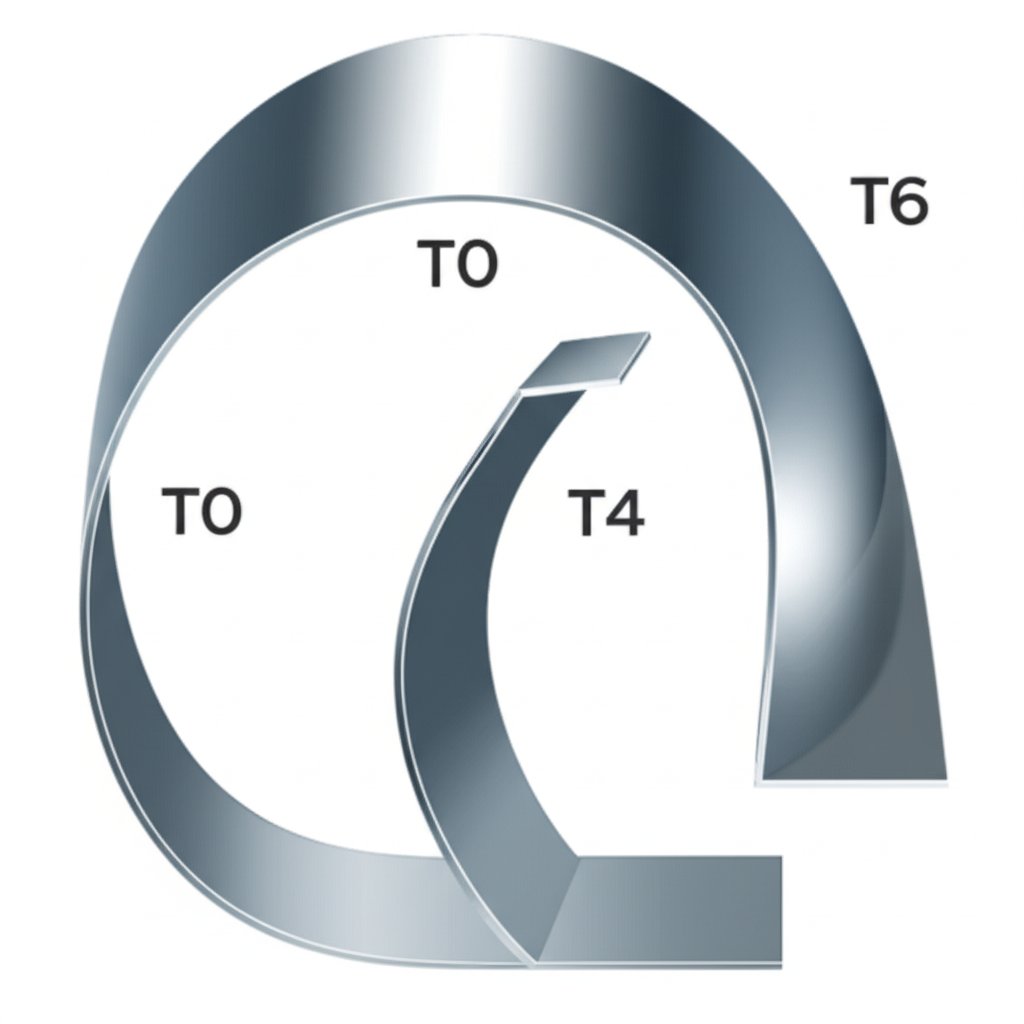

খাদ এবং এর টেম্পার অবস্থার পছন্দই সম্ভবত সবচেয়ে গুরুত্বপূর্ণ বিষয়। বিভিন্ন অ্যালুমিনিয়াম খাদের আলাদা আলাদা যান্ত্রিক বৈশিষ্ট্য থাকে, এবং তাপ চিকিৎসা (টেম্পার) এই বৈশিষ্ট্যগুলি আরও পরিবর্তন করে। উদাহরণস্বরূপ, 6XXX সিরিজের খাদগুলি শক্তি এবং আকৃতি দেওয়ার জন্য তাদের চমৎকার সমন্বয়ের জন্য জনপ্রিয়। তবে, তাদের টেম্পার বাঁকানোর ক্ষমতাকে উল্লেখযোগ্যভাবে প্রভাবিত করে। T4 টেম্পার-এ (সলিউশন হিট ট্রিটমেন্ট এবং স্বাভাবিকভাবে বার্ধক্যপ্রাপ্ত) একটি প্রোফাইল বেশি নমনীয় এবং T6 টেম্পার-এ (সলিউশন হিট ট্রিটমেন্ট এবং কৃত্রিমভাবে বার্ধক্যপ্রাপ্ত) একই প্রোফাইলের চেয়ে অনেক কম ব্যাসার্ধে বাঁকানো যায়, যা বেশি শক্তিশালী কিন্তু বেশি ভঙ্গুর। একটি নিবন্ধ অনুযায়ী ফ্যাব্রিকেটর , খুব ছোট ব্যাসার্ধের জন্য, প্রায়শই T4 টেম্পার সুপারিশ করা হয়, যেখানে T0 (অ্যানিলড) সেরা ফর্মেবিলিটি প্রদান করে কিন্তু সবচেয়ে কম শক্তি থাকে। কখনও কখনও অ্যালুমিনিয়ামকে নরম টেম্পারে বাঁকানো প্রয়োজন হয় এবং পরে চূড়ান্ত তাপ চিকিৎসা প্রয়োগ করে প্রয়োজনীয় শক্তি অর্জন করা হয়।

প্রাচীরের পুরুত্ব এবং প্রোফাইল জ্যামিতি

এক্সট্রুশনের ভৌতিক আকৃতি একটি অন্যতম গুরুত্বপূর্ণ বিষয়। সমান প্রাচীরের পুরুত্বযুক্ত প্রোফাইলগুলি বাঁকানো সহজ কারণ উপাদানটি ডাইয়ের মধ্য দিয়ে আরও সমানভাবে প্রবাহিত হয়। তদ্বিপরীতে, পুরুত্বের পরিবর্তনশীল প্রোফাইলগুলি অসম চাপ বন্টনের শিকার হতে পারে, যা মোড়ানো বা বিকৃতির দিকে নিয়ে যায়। আকৃতির সামগ্রিক জটিলতা এবং প্রতিসাম্যতাও একটি প্রধান ভূমিকা পালন করে। সি-চ্যানেলের মতো অপ্রতিসম প্রোফাইলগুলি বাঁকানোর সময় মোড়ানোর প্রবণতা রাখে কারণ বলগুলি সামঞ্জস্যপূর্ণ নয়। গাব্রিয়ান অনুসারে, প্রতিসাম্যযুক্ত, গোলাকার কোণযুক্ত এবং যথেষ্ট অভ্যন্তরীণ সমর্থনযুক্ত প্রোফাইল ডিজাইন করা বাঁকানোর প্রক্রিয়ার সময় স্থিতিশীলতা উল্লেখযোগ্যভাবে উন্নত করতে পারে।

বাঁকানোর দিক এবং যন্ত্রপাতি

প্রোফাইলের ক্রস-সেকশনের সাপেক্ষে বেঁকে যাওয়ার দিক—যা প্রায়শই "সহজ উপায়ে" (দুর্বলতর অক্ষের বিরুদ্ধে) বা "কঠিন উপায়ে" (শক্তিশালী অক্ষের বিরুদ্ধে) বাঁকানো হিসাবে পরিচিত—সরাসরি সর্বনিম্ন ব্যাসার্ধকে প্রভাবিত করে। "কঠিন উপায়ে" বাঁকানোর জন্য উল্লেখযোগ্যভাবে বেশি বলের প্রয়োজন হয় এবং সাধারণত বড় সর্বনিম্ন বাঁকের ব্যাসার্ধ হয়। এছাড়াও, ব্যবহৃত টুলিং এবং মেশিনারি অত্যন্ত গুরুত্বপূর্ণ। সঠিকভাবে ডিজাইন করা টুলগুলি প্রোফাইলকে সমর্থন করে, ভেঙে পড়া রোধ করে এবং বিকৃতি কমায়। বাঁকানোর পদ্ধতির পছন্দটি নিজেই, যা পরবর্তী অনুচ্ছেদে আলোচনা করা হয়েছে, অর্জনযোগ্য ব্যাসার্ধের সাথে অন্তর্নিহিতভাবে যুক্ত।

| গুণনীয়ক | বাঁকের ব্যাসার্ধের উপর প্রভাব | বিবেচনা |

|---|---|---|

| ধাতু ও তাপমাত্রা | নরম টেম্পার (যেমন T4) আরও কম ব্যাসার্ধের অনুমতি দেয়। শক্ত টেম্পার (যেমন T6) আরও শক্তিশালী হয় কিন্তু বড় ব্যাসার্ধের প্রয়োজন হয়। | চূড়ান্ত শক্তির প্রয়োজনীয়তা এবং কাঙ্ক্ষিত বক্রতার উপর ভিত্তি করে টেম্পার নির্বাচন করুন। বাঁকানোর পরে তাপ চিকিত্সার কথা বিবেচনা করুন। |

| প্রাচীরের পুরুত্ব | বেশি ঘন প্রাচীরের জন্য সাধারণত বড় বাঁকের ব্যাসার্ধ প্রয়োজন। বিকৃতি রোধ করার জন্য সমান ঘনত্ব আদর্শ। | প্রোফাইল ডিজাইনের মধ্যে প্রাচীরের ঘনত্বের উল্লেখযোগ্য পরিবর্তন এড়িয়ে চলুন। |

| প্রোফাইলের প্রতিসাম্যতা | সমমিত প্রোফাইলগুলি স্থিতিশীল এবং পূর্বানুমেয়ভাবে বাঁক নেয়। অসমমিত প্রোফাইলগুলি মোড়ানোর প্রবণতা রাখে। | টোর্সনাল বল কমাতে সর্বদা সম্ভব হলে বাঁকানো অক্ষ বরাবর সমমিত ডিজাইন করুন। |

সাধারণ বাঁকানো পদ্ধতি এবং তাদের ব্যাসার্ধের উপর প্রভাব

অ্যালুমিনিয়াম এক্সট্রুশন বাঁকানোর জন্য ব্যবহৃত কৌশলটি সরাসরি বক্ররেখার গুণমান এবং ন্যূনতম অর্জনযোগ্য ব্যাসার্ধকে প্রভাবিত করে। প্রতিটি পদ্ধতির আলাদা সুবিধা রয়েছে এবং বিভিন্ন অ্যাপ্লিকেশন, উৎপাদন পরিমাণ এবং প্রোফাইলের জটিলতার জন্য উপযুক্ত।

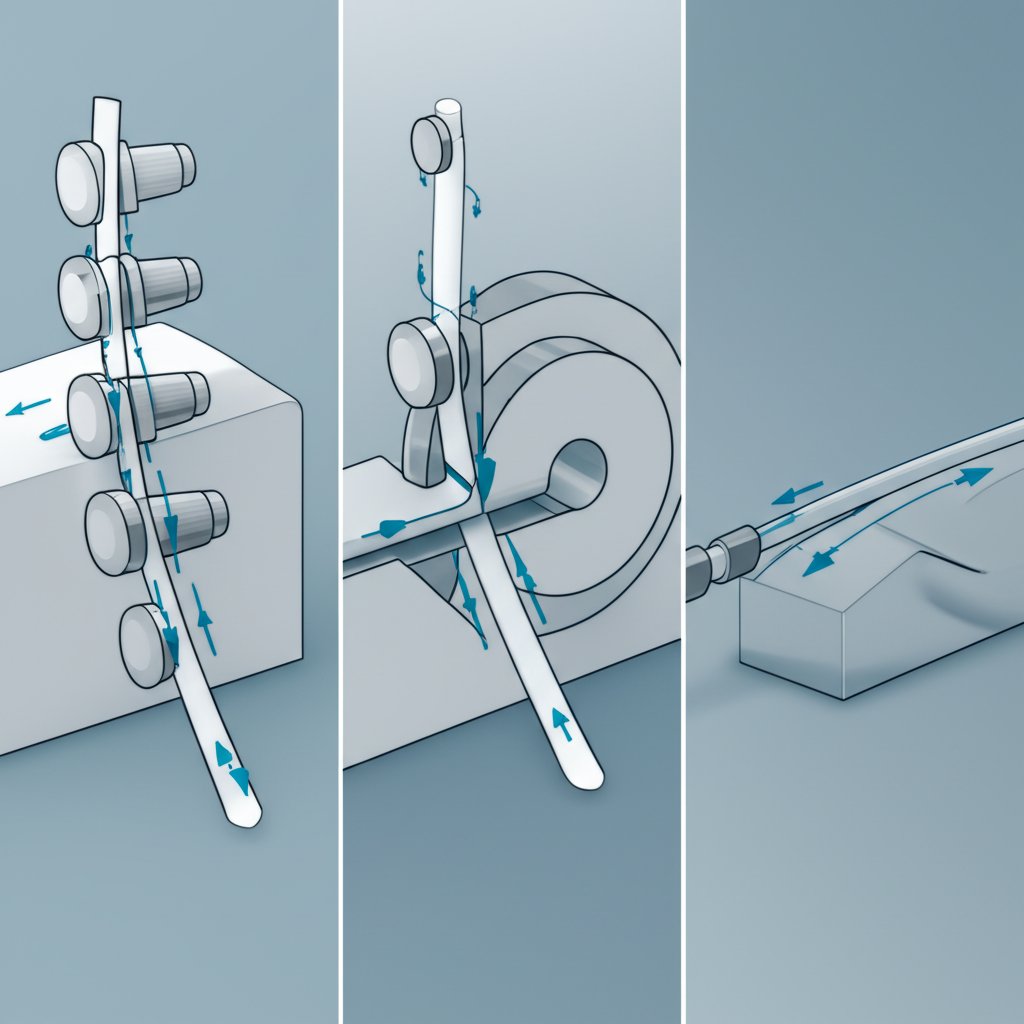

সবচেয়ে সাধারণ কৌশলগুলির মধ্যে একটি হল রোলার বাঁকানো যা প্রোফাইলের দৈর্ঘ্য জুড়ে ধীরে ধীরে একটি বক্ররেখা তৈরি করতে তিন বা ততোধিক রোলার ব্যবহার করে। এই পদ্ধতিটি বড় ব্যাসার্ধের বাঁক এবং পূর্ণ বৃত্ত তৈরির জন্য নমনীয় এবং খরচ-কার্যকর, তবে ছোট ব্যাসার্ধের জন্য এটি কম নির্ভুলতা দিতে পারে এবং চূড়ান্ত আকৃতি অর্জনের জন্য একাধিক পাসের প্রয়োজন হতে পারে। রোটারি ড্র বাঁকানো হল আরেকটি জনপ্রিয় পদ্ধতি যা এক্সট্রুশনকে আটকে রেখে এবং ঘূর্ণায়মান ডাইয়ের চারপাশে টেনে আনার মাধ্যমে উচ্চ নির্ভুলতা প্রদান করে। এটি কঠোর, নির্ভুল বাঁক অর্জনের জন্য চমৎকার এবং বিশেষ করে ভেতরের ম্যানড্রেল দ্বারা সমর্থিত হলে জটিল প্রোফাইলগুলি পরিচালনা করতে পারে।

স্ট্রেচ বেন্ডিং এর অর্থ হল উভয় প্রান্তে এক্সট্রুশনকে ধরে রাখা এবং ফর্মিং ডাইয়ের চারপাশে মোড়ানোর সময় এটিকে সামান্য প্রসারিত করা। এই প্রক্রিয়াটি উপাদানটিকে টানের মধ্যে রাখে, যা কুঁচকে যাওয়া এবং স্প্রিং-ব্যাক কমাতে সাহায্য করে, ফলস্বরূপ কম ক্রস-সেকশন বিকৃতির সাথে অত্যন্ত নির্ভুল বক্ররেখা পাওয়া যায়। তবে, এটি সাধারণত বৃহত্তর ব্যাসার্ধের জন্য সীমিত। সহজ প্রয়োগের জন্য, র্যাম বেন্ডিং (অথবা পুশ বেন্ডিং) একটি কম খরচের সমাধান প্রদান করে যেখানে একটি হাইড্রোলিক র্যাম সমর্থনের বিরুদ্ধে প্রোফাইলকে চাপ দেয়, কিন্তু এটি প্রোফাইল আকৃতির উপর কম নিয়ন্ত্রণ প্রদান করে এবং বিকৃতি ঘটানোর সম্ভাবনা বেশি থাকে।

সঠিক পদ্ধতি নির্বাচন করা অত্যন্ত গুরুত্বপূর্ণ এবং জটিল জ্যামিতি বা কঠোর স্পেসিফিকেশনের ক্ষেত্রে প্রায়ই গভীর দক্ষতা প্রয়োজন। নির্ভুল ইঞ্জিনিয়ারিঙের উপাদান চাহিয়া গাড়ি উৎপাদনের প্রকল্পগুলির জন্য, একজন বিশেষজ্ঞের সঙ্গে পরামর্শ করা প্রায়ই লাভজনক। উদাহরণস্বরূপ, শাওয়াই মেটাল টেকনোলজি একটি কঠোর গুণগত মান ব্যবস্থার অধীনে প্রোটোটাইপিং থেকে উৎপাদন পর্যন্ত ব্যাপক পরিষেবা প্রদান করে, যা অত্যন্ত কাস্টমাইজড অংশগুলির জন্য সঠিক বেন্ডিং প্রক্রিয়া এবং উপাদান নির্বাচনে সহায়তা করে।

বাঁকানো এক্সট্রুডেড প্রোফাইলের জন্য ডিজাইনের সেরা অনুশীলন

প্রকৌশলীরা ডিজাইনের প্রাথমিক পর্যায়ে সেরা অনুশীলনগুলি অন্তর্ভুক্ত করে অ্যালুমিনিয়াম প্রোফাইলের বাঁকানোর সুবিধা উল্লেখযোগ্যভাবে উন্নত করতে পারেন এবং উৎপাদনের সময় সমস্যা এড়াতে পারেন। ভালোভাবে ডিজাইন করা প্রোফাইল শুধুমাত্র সহজেই বাঁকানো যায় তাই নয়, বরং উচ্চ মানের, কম খরচের চূড়ান্ত পণ্যও তৈরি করে। এই নির্দেশাবলী মেনে চলা ফাটল, বিকৃতি এবং মোচড় এর মতো সাধারণ ত্রুটি প্রতিরোধ করতে পারে।

- প্রাচীরের বেধ সমান রাখুন: ধ্রুব প্রাচীরের পুরুত্ব সহ একটি প্রোফাইল এক্সট্রুশনের সময় অ্যালুমিনিয়ামের সমানভাবে প্রবাহিত হওয়ার অনুমতি দেয় এবং বাঁকানোর চাপের প্রতি ভবিষ্যদ্বাণীযোগ্যভাবে প্রতিক্রিয়া জানায়। যদি পুরুত্বের পরিবর্তন প্রয়োজন হয়, তবে চাপের কেন্দ্রীভবন এড়াতে সম্ভব হলে স্থানান্তরগুলি ধীরে ধীরে করুন। শিল্প বিশেষজ্ঞদের দ্বারা উল্লেখিত এটি একটি গুরুত্বপূর্ণ স্পেস যেমন সিলভার সিটি অ্যালুমিনিয়াম .

- প্রচুর কোণার ব্যাসার্ধ নির্দিষ্ট করুন: তীক্ষ্ণ অভ্যন্তরীণ এবং বাহ্যিক কোণগুলি হল গুরুত্বপূর্ণ চাপের বিন্দু যেখানে বাঁকানোর সময় ফাটল তৈরি হওয়ার সম্ভাবনা সবচেয়ে বেশি। গোলাকার কোণ সহ প্রোফাইল ডিজাইন করা, এমনকি ছোট ব্যাসার্ধ সহ, চাপকে আরও সমানভাবে ছড়িয়ে দেয় এবং আকৃতি দেওয়ার সামর্থ্যকে উল্লেখযোগ্যভাবে উন্নত করে।

- সামঞ্জস্য অনুযায়ী ডিজাইন করুন: যতটা সম্ভব, বাঁকানোর অক্ষ বরাবর প্রোফাইলটি সামঞ্জস্যপূর্ণ হতে ডিজাইন করুন। সামঞ্জস্যপূর্ণ আকৃতি স্বতঃস্ফূর্তভাবে আরও স্থিতিশীল এবং বাঁকানোর চাপের নিচে মোড়ানোর প্রাকৃতিক প্রবণতাকে প্রতিরোধ করে। যদি অসামঞ্জস্য এড়ানো না যায়, তবে বাঁকানোর পরে মেশিন করে সরানো যায় এমন অস্থায়ী বৈশিষ্ট্য যোগ করার বিষয়ে বিবেচনা করুন যাতে সমর্থন প্রদান করা যায়।

- অভ্যন্তরীণ সমর্থন রিব অন্তর্ভুক্ত করুন: নতুন করা প্রোফাইলগুলির জন্য, নতুনের সমতলে অভ্যন্তরীণ শক্তকারক বা খাঁজ যোগ করা গুরুত্বপূর্ণ সমর্থন প্রদান করতে পারে। এই বৈশিষ্ট্যগুলি প্রোফাইলের দেয়ালগুলি ভেঙে পড়া বা অবতল হওয়া থেকে রোধ করতে সাহায্য করে, যাতে প্রোফাইলটি তার নির্ধারিত আকৃতি বজায় রাখে।

- বৈশিষ্ট্যগুলি যত্নসহকারে স্থাপন করুন: স্ক্রু পোর্ট বা নাট ট্র্যাকের মতো বিশেষ বৈশিষ্ট্যগুলি সাবধানতার সাথে স্থাপন করা উচিত। নতুনের ব্যাসার্ধের সাথে সমান্তরাল একটি স্ক্রু পোর্ট একটি শক্তকারকের মতো কাজ করে, যা প্রক্রিয়াকে সহায়তা করে। তবে, যদি নতুনের সাথে লম্বভাবে স্থাপন করা হয়, তবে অভ্যন্তরীণভাবে সঠিকভাবে সমর্থন না করা হলে এটি বিকৃত বা ভেঙে পড়তে পারে।

প্রায়শই জিজ্ঞাসিত প্রশ্নাবলী

1. আপনি কি এক্সট্রুডেড অ্যালুমিনিয়াম নতুন করতে পারেন?

হ্যাঁ, ধাতুর প্রাকৃতিক নমনীয়তার কারণে এক্সট্রুডেড অ্যালুমিনিয়াম নতুন করার জন্য অত্যন্ত উপযুক্ত। নতুন করার সাফল্য সঠিক খাদ এবং টেম্পার নির্বাচন, উপযুক্ত নতুন করার পদ্ধতি ব্যবহার এবং নতুন করার উপযোগী ডিজাইনের উপর নির্ভর করে। স্থাপত্য, অটোমোটিভ এবং শিল্প সরঞ্জামসহ অনেক শিল্পে ব্যবহৃত হওয়া এটি একটি সাধারণ উৎপাদন প্রক্রিয়া।

2. ন্যূনতম অনুমোদিত বাঁকের ব্যাসার্ধ কত?

অ্যালুমিনিয়ামের জন্য কোনো সার্বজনীন ন্যূনতম অনুমোদিত বাঁকের ব্যাসার্ধ নেই। উপাদানের খাদ ও টেম্পার, প্রোফাইলের প্রাচীরের পুরুত্ব ও প্রস্থ, আকৃতির জটিলতা এবং ব্যবহৃত বাঁকানোর কৌশলের মতো কারণগুলির ভিত্তিতে প্রতিটি নির্দিষ্ট ক্ষেত্রে এটি গণনা করা আবশ্যিক। সাধারণ মান ব্যবহার করার চেষ্টা করলে উপাদানের ব্যর্থতা ঘটতে পারে।

3. 6061-T6 অ্যালুমিনিয়ামের ন্যূনতম বাঁকের ব্যাসার্ধ কত?

6061-T6 হল একটি শক্তিশালী কিন্তু কম নমনীয় খাদ, তাই এটি নরম টেম্পারের তুলনায় আরও বড় বাঁকের ব্যাসার্ধের প্রয়োজন হয়। প্রোফাইল জ্যামিতি না জানা পর্যন্ত কোনো নির্ভুল সূত্র নেই, তবে 6061-T6 শীট মেটালের জন্য একটি সাধারণ নিয়ম হল উপাদানের পুরুত্বের 1.5 থেকে 4 গুণ ভিতরের ব্যাসার্ধ। এক্সট্রুশনের ক্ষেত্রে আকৃতির জটিলতার উপর নির্ভর করে এটি আরও বেশি হতে পারে। নির্দিষ্ট গণনার জন্য সর্বদা একজন ফ্যাব্রিকেশন বিশেষজ্ঞের সাথে পরামর্শ করুন অথবা প্রকৌশল হ্যান্ডবুকগুলি দেখুন।

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —