Manufacturers of motor vehicle components must respond very quickly to changes in the market. They need to quickly respond to the introduction of new environmental norms and standards, the emergence of new technologies and changing requirements of automakers. At Shaoyi Precision Machining, we are constantly striving to improve our processes to keep up with these changes.

IATF TS16949:2016/Critical to Quality

Factory Area

R&D Engineer

Steel & Aluminum

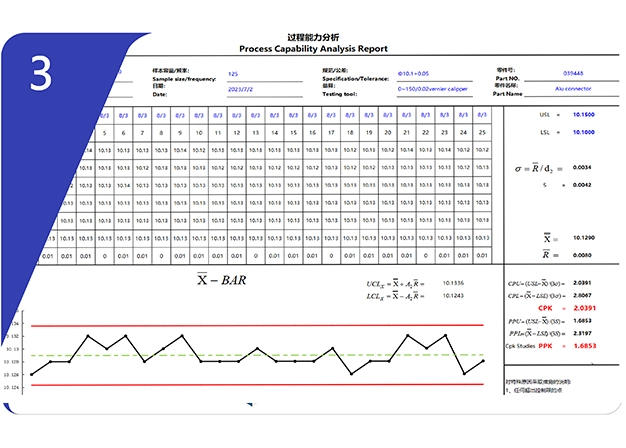

We use a variety of quality control methods to ensure that the products we deliver to our customers are of the right size and performance for their needs.

Our unwavering commitment to quality is bolstered by our IATF 16949 certification, ensuring a stringent quality control system throughout every phase of production. This certification is a testament to our meticulous approach, from the initial design to the final product delivery. -IATF16949 Certification

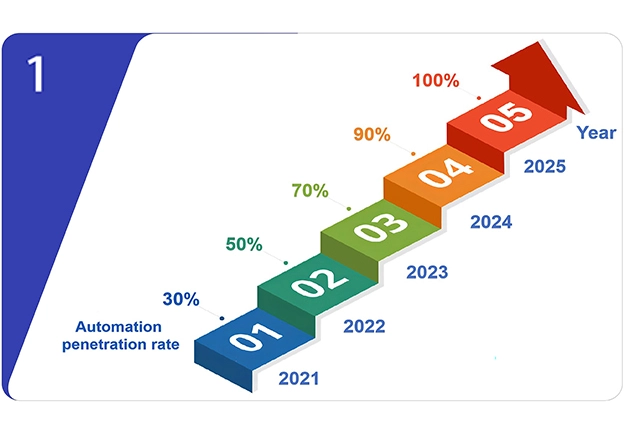

Leveraging top-tier production and inspection equipment, our state-of-the-art, fully automated machinery guarantees product quality with every manufacturing process, ensuring consistency and excellence in every output.

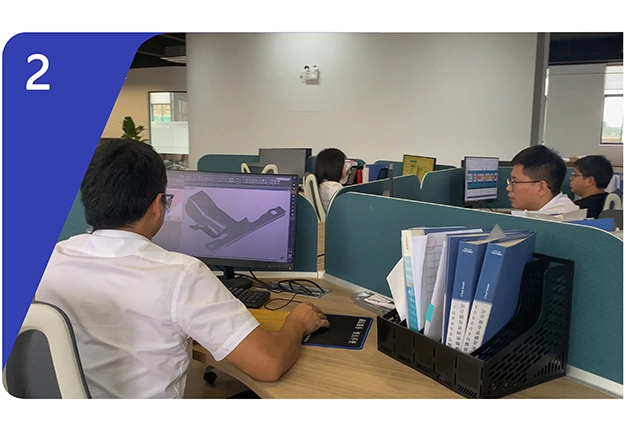

Our team of technical experts, each with over a decade of experience in metal fabrication, forms the backbone of our operations. These elite engineers bring a wealth of knowledge and expertise to every project, ensuring that our products not only meet but exceed industry standards for quality and innovation.

We possess an automatic material feeding pipe cutting machine and a 100% bushing inspection equipment,enabling automated production that effectively reduces costs and increases efficiency.

The R&D technical team consists of over 20 people.The average age is 33 years old. We prioritize stringent standards, meeting high-quality demands, and fostering innovation for diverse automotive needs. Our focus is on pushing product development boundaries.

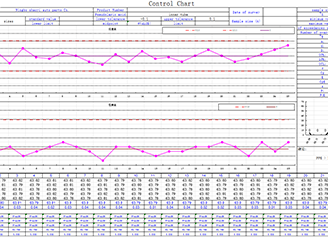

SPC, which stands for Statistical Process Control, is a method of using statistical techniques to monitor and manage production processes. It involves collecting and analyzing data to ensure consistent product quality.

We have ultrasonic cleaning equipment, if the customer has high requirements for the product, we can carry out ultrasonic cleaning to ensure that the product surface is free of impurities.

We deliver more than just parts — we deliver peace of mind. Trusted by 30+ automotive brands worldwide. Partner with a manufacturer who understands your quality, lead time, and budget needs.

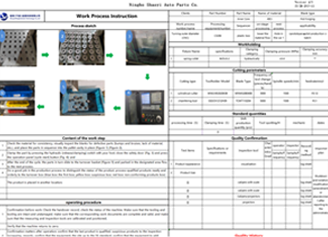

Standardized,process-oriented refined production standards efforts to provide you with up to 99.8%qualified string of precision parts

Pre-manufacturing feasibility assessment and optimization

Benchmarking,assembly,and inspection criteriadevelopment foridentification of key dimensions

For DFM and work instructions standard full-sizeinspection proofing process problems

Summarize the proofing problems, close the problerpointsand continuously optimize the productlon process

Determine the correctness of the manufacturing process and that the product meets the customer's specifications and process requirements.

Control of special requirements and processesimplementation of CPK>l.33 for key dimensions

Perform according to AQC standards and requirements

Through precise data monitoring and process optimization, we ensure timely delivery of products.

| Processing Capabilities | Processing Capabilities | ||

| Maximum Part Size | 300mm*200mm*200mm | Perpendicularity | 0.05mm |

| Minimum Part Size | 8mm*6mm*4mm | Oxidize | Film thickness 8-15um |

| Tolerances | 0.02mm | Heat treatment | Hardness 28°-65° |

| Concentricity | 0.05mm | Electrophoresis | Film thickness 15-35um, salt spray test 720h without red rust |

| Manufacturing Processes and Materials | Manufacturing Processes and Materials | ||

|---|---|---|---|

|

CNC Machining Materials |

Metals |

Pipe Processing

|

steel tube |

|

Cold Extrusion |

steel |

|

Our flexible production system supports both prototypes and mass production, tailored to the fast-paced needs of the automotive industry.

As automotive product development cycles continue to accelerate, rapid prototyping has become a critical step in metal parts manufacturing. At Shaoyi, we offer end-to-end rapid prototyping services—from design review to sample delivery—to help our customers quickly validate and refine their designs

In automotive development, low-volume CNC production enables engineers to verify design feasibility, validate manufacturing processes, and test functional performance before committing to mass production.

After completing prototype validation, trial production, and PPAP approval, automotive projects enter the mass production stage. At Shaoyi, our industry-specific production processes and rigorous quality management system ensure the delivery of high-precision metal components with exceptional consistency. Our automated equipment and optimized workflows further guarantee fast turnaround and strict tolerance control.

Focus on chassis welded assemblies, shock-absorbing welded assemblies, chassis stamping, and machining parts.

After years of development, the company's welding technology mainly includes gas shielded welding, arc welding, laser welding and kinds of welding technologies, combined with automatic assemble lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT) Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick quotation to provide customers with better service for chassis stamping parts and machining parts.