Полное руководство по ценообразованию на штампы для листовой штамповки в автомобилестроении

Введение: почему штампы важны в автомобилестроении

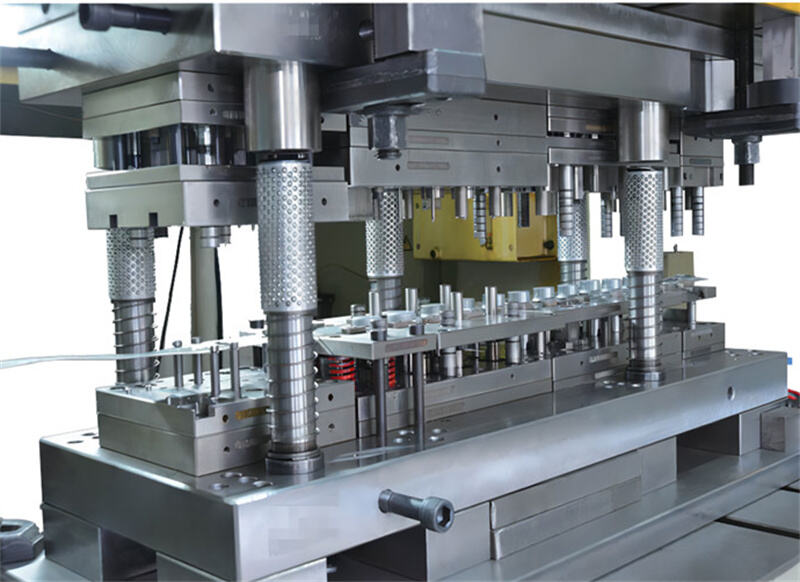

Штампы играют решающую роль при производстве автомобильных деталей. По сравнению с литьем и ковкой, штампованные детали обладают рядом преимуществ: они тоньше, более однородные, легче и прочнее. Эти характеристики делают штамповку одним из самых экономически эффективных и широко используемых процессов в современном автомобилестроении.

Для компаний, которые занимаются производством машины для штамповки , цена является ключевым фактором, на который обращают внимание покупатели автомобильных запчастей. В этом руководстве раскрывается структура ценообразования штампов и факторы, влияющие на нее.

Основные компоненты ценообразования штампов

1. Материальные затраты

Материалы являются основой каждого штампа и обычно включают высококачественную импортную сталь, используемую для изготовления пуансонов и матриц. Эти материалы также должны пройти термическая обработка чтобы обеспечить долговечность.

2. Стоимость термообработки

Термообработка необходима для повышения прочности и долговечности деталей штампов. Существует два основных типа:

Стандартная термическая обработка : Применяется для крупных деталей с низкой точностью; средняя стоимость составляет около $1,5/кг.

Вакуумная термообработка : Используется для небольших деталей высокой точности; дороже, но минимизирует деформацию.

3. Стоимость проволочной резки

Стоимость проволочно-вырезного станка (электроэрозионной обработки) рассчитывается по площади:

Быстрая проволочная резка : Примерно $0.0007 за мм²

Медленная проволочная резка : Примерно $0.003 за мм² Формула: Площадь = Периметр x Высота (на основе оценки CAD-модели)

4. Стандартные компоненты

Стандартные компоненты обычно включают:

Пружины : Цветовая маркировка по прочности (зеленый и коричневый = тяжелые, красный = средние, синий/желтый = легкие)

Направляющие колонны и втулки

Винты и крепежные элементы

5. Стоимость рабочей силы

Стоимость рабочей силы зависит от региона. Например, в Китае средняя дневная ставка для квалифицированных инструментальщиков составляет около $35/день.

6. Прочие расходы

К ним относятся:

-Испытательная оснастка и использование пресса

-Материал прототипа

-Сверление отверстий

-Стоимость проектных работ в CAD

-Стоимость управления проектом

7. Торговая наценка

После расчета всех вышеперечисленных затрат обычно добавляется наценка в размере 30–40% для покрытия прибыли.

Факторы, которые следует учитывать при составлении сметы Штамповочная матрица

Даже при четкой ценовой структуре каждое предложение должно разрабатываться с учетом следующих факторов:

- Тип материала и толщина

Разные материалы (например, алюминий и высокопрочная сталь) оказывают большое влияние как на конструкцию штампа, так и на его стоимость.

- Объем выпускаемых деталей и ожидаемый срок службы инструмента

Высокие объемы производства могут потребовать использования более качественных материалов для штампов или нескольких полостей, что влияет как на стоимость, так и на сложность процесса.

- Проектирование штампа и требования к изделию

Многоступенчатые последовательные штампы, штампы для переноса заготовок или комбинированные штампы требуют различного уровня затрат на проектирование и изготовление.

- Запасные части и послепродажное обслуживание

Включение резервных компонентов или предоставление плана сервисного обслуживания увеличит общую стоимость заказа.

- Ответственность за пробную партию

Уточните, кто предоставляет материалы для пробной штамповки и сколько образцов необходимо поставить.

- Давление спецификации

Понимание клиентом тоннажа пресса, размера стола и уровня автоматизации помогает оптимально спроектировать штамп.

Почему важна точная стоимость штампа

Точное ценообразование приносит пользу не только поставщику — оно также гарантирует клиенту прозрачность затрат и экономическую целесообразность. Четко структурированное штамп для металла предложение помогает:

- Избежать скрытых расходов

- Установить реалистичные сроки проекта

- Укрепить доверие между поставщиком и клиентом

Наша команда в Shaoyi Metal Technology понимает, насколько эти предложения важны для успеха проекта. Вот почему мы уделяем внимание тщательному расчету затрат и точному проектированию штампов, адаптированным под ваши производственные потребности.

Заключение: Прозрачное коммерческое предложение — выигрыш для обеих сторон

Когда речь идет об автомобильных штампах, цена — это не просто число. Это отражение конструкции, материалов, качества и обслуживания. Понимая, как каждый компонент влияет на общую стоимость, покупатели и поставщики могут совместно производить качественные детали эффективно и экономично.

Хотите получить индивидуальное предложение для вашего следующего проекта штампа? Свяжитесь с нашей командой по производству штампов, чтобы узнать, как мы можем помочь в решении ваших задач по штамповке.

Малые партии, высокие стандарты. Наша служба быстрого прототипирования делает проверку точнее и проще —

Малые партии, высокие стандарты. Наша служба быстрого прототипирования делает проверку точнее и проще —