Shaoyi Conducts Comprehensive Fire Drill and Safety Training on June 27

Shaoyi Conducts Comprehensive Fire Drill and Safety Training on June 27

At Shaoyi Metal Technology, we firmly believe that a safe workplace is the foundation of sustainable manufacturing excellence. On Friday, June 27, our company conducted a comprehensive fire drill and fire safety training program, reinforcing our deep commitment to workplace fire prevention, emergency preparedness, and employee safety awareness.

Why Fire Safety Training Matters in Industrial Environments

Fire safety is not merely a compliance requirement — it is a critical life-saving knowledge base for every employee, especially in automotive metal manufacturing environments where flammable materials, electrical equipment, and heat sources are prevalent.

Equipping staff with the right knowledge to prevent, identify, and respond to fires effectively can mean the difference between a controlled incident and a devastating catastrophe. That’s why Shaoyi conducts regular fire safety training and emergency drills, in line with local regulations and international safety standards.

We have also established a micro fire station on-site and installed fire extinguishers at multiple key locations across all production workshops, including stamping, CNC machining, and die casting zones. These measures form a critical part of our layered defense approach to fire safety.

Shaoyi's Micro Fire Station

Real Case Study: The “9.29 Incident” – A Tragic Lesson from Our Local Industry

During the training, employees watched a detailed case study of the "9.29 Incident", a devastating industrial fire that took place at a daily necessities factory in our local area. This tragic event served as a wake-up call for the importance of fire safety awareness and proper first response techniques.

Fire safety training in Shaoyi

The fire began when static electricity ignited flammable vapor, quickly escalating due to improper extinguishing attempts. Initially, employees used cardboard and plastic barrels to suppress the flames — a dangerous and ineffective method. For over 4 minutes, the fire continued to spread, eventually melting plastic containers and igniting surrounding combustibles.

By 13:16, thick toxic smoke and carbon monoxide filled the premises, spreading rapidly through stairwells and igniting multiple floors of packaging materials. Within less than 30 minutes, the factory was engulfed in full three-dimensional combustion, with multiple explosions. This catastrophic event was a result of inadequate employee fire awareness and improper emergency handling.

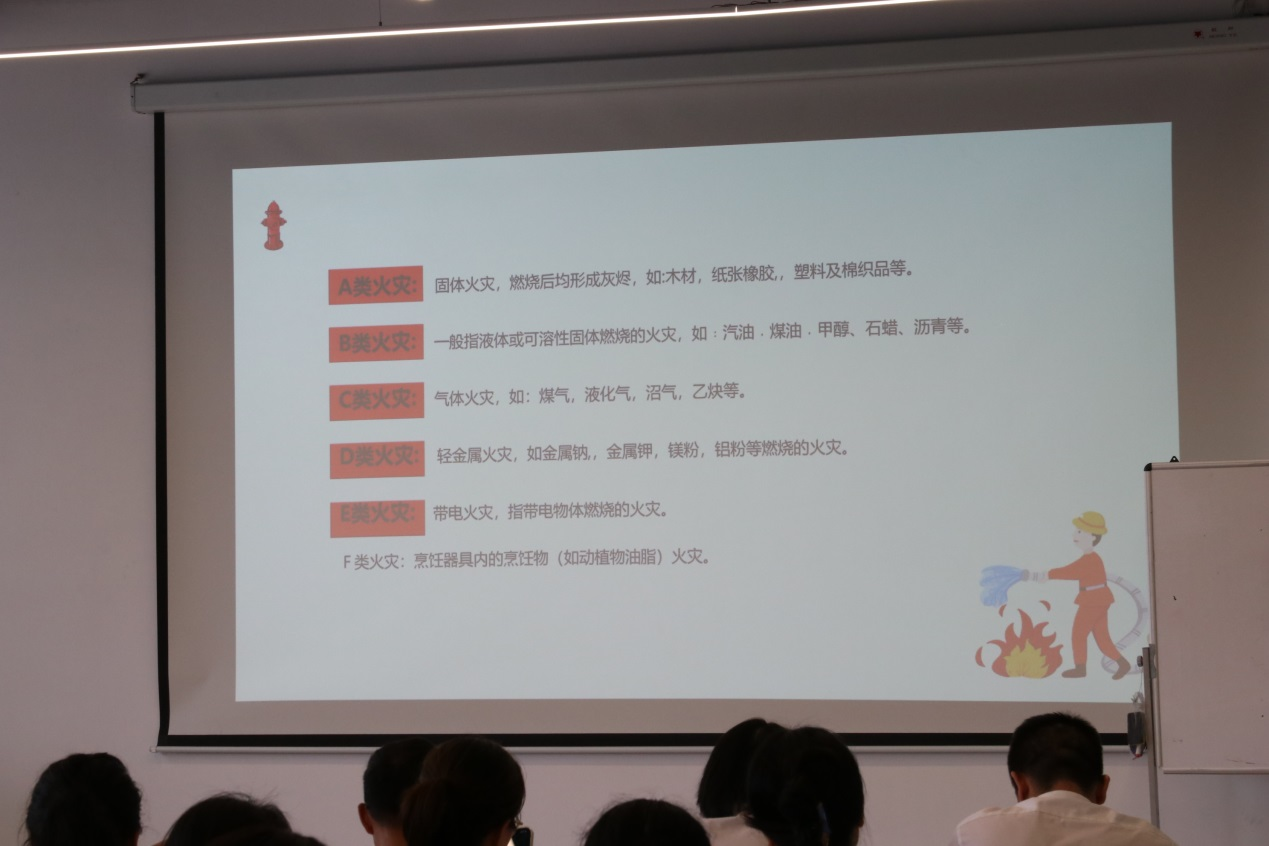

Fire Extinguisher Training: Knowing the Right Tool for the Right Fire

Following the case study, our safety instructors provided a comprehensive guide to fire classification and extinguisher usage. Employees were trained to recognize:

Class A fires (solids like paper, wood, textiles): Use water or foam extinguishers.

Class B fires (flammable liquids such as oil, paint, solvents): Use foam or dry chemical extinguishers.

Class C fires (gas): Shut off the gas supply, use dry powder extinguishers.

Class E (electrical fires): Use carbon dioxide (CO₂) or dry chemical extinguishers — never use water.

Class F fires (cooking oils/fats): Use wet chemical extinguishers, particularly in kitchen areas.

Real-world examples helped staff understand the dangers of using the wrong extinguishing method — such as using water on oil fires, which can cause splashing and worsen the blaze.

Classification of fire types

Hands-On Fire Extinguisher Practice: Turning Knowledge into Action

Understanding theory is one thing — but practical experience is essential. Employees were guided outdoors to conduct hands-on fire extinguisher drills, allowing them to simulate real-life firefighting scenarios using CO₂ and dry chemical extinguishers.

Trainers demonstrated the PASS method:

Pull the pin.

Aim the nozzle at the base of the fire.

Squeeze the handle.

Sweep from side to side.

This part of the training empowered staff to feel confident and capable in the event of a real emergency.

Fire safety training in Shaoyi

Emergency Evacuation Simulation: Practicing Safe Escape

The final stage of our fire safety program was a full-scale evacuation drill, where employees simulated escaping from a smoke-filled environment. This immersive exercise helped teams internalize escape routes, practice coordination, and understand the urgency required during real emergencies.

Shaoyi's fire escape drill

The drill also tested the response time of our in-house safety team and evaluated the functionality of alarm systems, emergency lights, and exits.

Our Ongoing Commitment to Workplace Safety

At Shaoyi Metal Technology, we recognize that fire safety is not a one-time event — it is an ongoing commitment that requires regular training, facility upgrades, and organizational focus.

By conducting structured fire drills and safety education, we aim to:

Strengthen employee emergency response capability

Reduce property and life risks

Create a culture of safety-first in every department

We will continue to invest in training programs, improve emergency infrastructure, and stay aligned with the latest fire safety practices in the automotive manufacturing industry.

Final Thoughts: Safety Starts with Awareness

Fire safety starts with awareness, education, and empowerment. Through this June 27th fire drill and training, Shaoyi once again demonstrated our proactive approach to risk prevention and employee care.

As a trusted automotive metal parts manufacturer, our clients can rest assured knowing that Shaoyi’s workshops and warehouses are operated with maximum safety consciousness and professional standards.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —