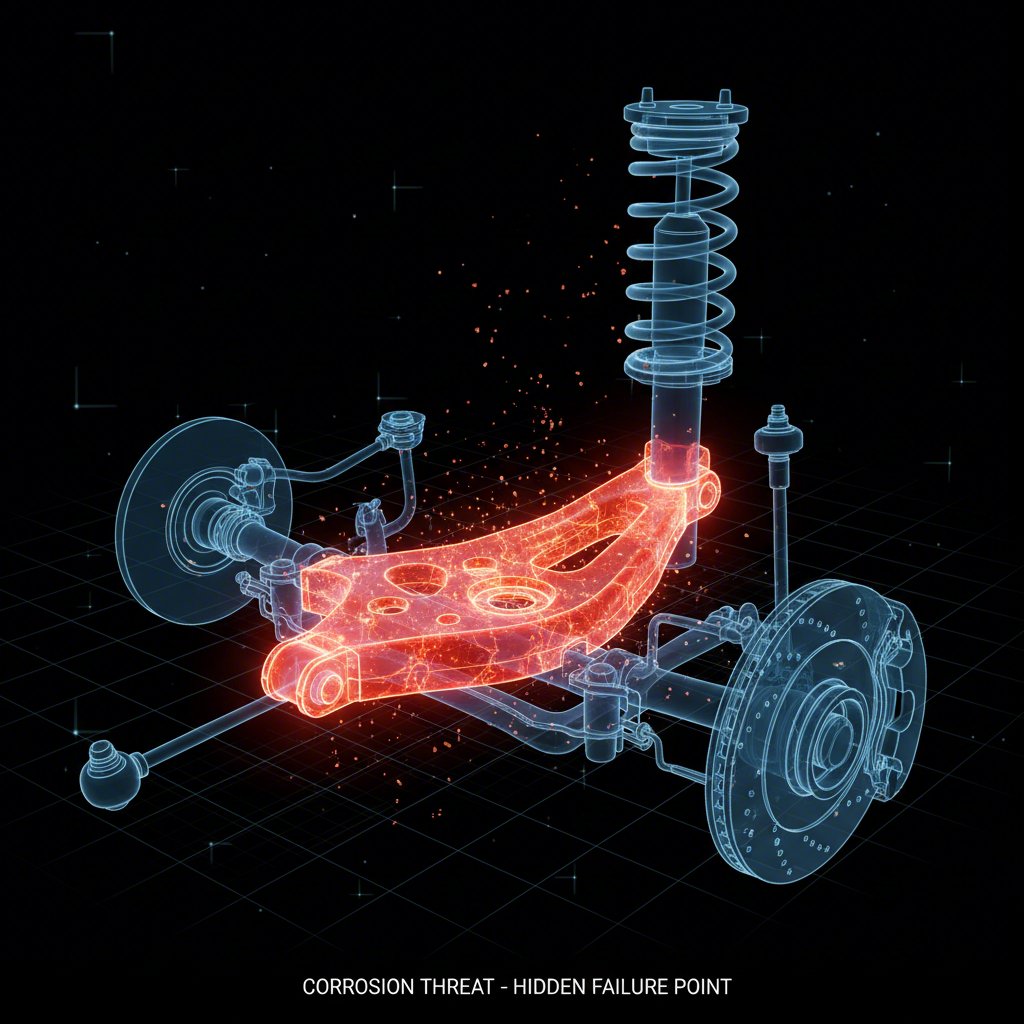

Стамперани челични контролни оружји: скривена опасност од корозије

ТЛ;ДР

Контролне руке од челика са штампом су веома подложне рђе и корозији, посебно када су изложене соли и влаги. Ова детерминација структурно ослабљује компоненту, скраћујући њен животни век и потенцијално доводећи до отказа. Кључни знаци упозорења укључују бучну гласовност у ударима, нестабилан или лабав волан, прекомерне вибрације и неравномерно знојење гума. Од пресудне је важности да их редовно прегледате на било шта осим на лакшу рђаву површину.

Усаглашена слабост: Зашто се челична контрола рупа кородира

Контролне руке су кључна веза у систему суспензије вашег возила, које повезују оквир са скупом точкова и омогућавају глатко кретање горе-доле које апсорбује удараце на путу. Међу различитим врстама, штампани челични контролни рамени се широко користе због ниских трошкова производње и једноставног процеса производње. Међутим, ова економска предност долази са значајним недостатком: дубоком рањивошћу на корозију.

Главна слабост штампаног челика је његов састав и начин производње. Ове руке се формирају штампањем челичних плоча у жељени облик. Иако је ефикасан, овај процес не ствара део са истом густином или инхерентном отпорношћу на корозију као алтернатива од ливеног гвожђа или алуминијума. Као што је наведено у детаљној анализи из експерата за аутомобилске компоненте , када се класирани челични регулациони кракови користе у влажним срединама, готово је сигурно да ће се распадати због рђе. Управо је ова ефикасност производње разлог зашто су они чести. За аутомобилске компаније, сарадња са стручним фирмама за класирање метала је кључна за масовну производњу ових компонената. На пример, Shaoyi (Ningbo) Metal Technology Co., Ltd. специјализована је за високотонасажне прецизне делове за аутомобилско класирање , што показује напредне процесе укључене у израду компонената попут регулационих кракова.

Многи возачи се питају да ли је нормално да се контролне полуге рђају. Иако мрежа површинске рђи на незаштићеним металним деловима може бити уобичајена и често без последица, корозија штампаних челичних полуга може бити много агресивнија. Излагање путном сољи током зиме и висока влажност убрзавају овај процес, услед чега се метал лупи, растурa и губи структурну интегритет. За разлику од благе рђи коју можете видети на другим деловима испод тела возила, ова дубока корозија може компромитовати саму полугу, стварајући озбиљну сигурносну опасност.

Утврђивање квара контролне полуге: кључни симптоми и дијагностички прегледи

Контролна полуга која престаје да ради не само што се распада; она активно сигнализира своје проблеме низом приметних симптома. Занемаривање ових знакова може довести до озбиљнијег оштећења система за вешање и угрозити вашу контролу над возилом. Према дијагностичком водичу од Аутозона , способност препознавања ових упозорења је кључна за спречавање опасног квара на путу.

Туцкање или ударање

Један од најчешћих индикатора је изразито клопоћући или ударајући звук, посебно при вожњи преко неравних површина, дупљи или при оштрим скретањима. Овај шум често настаје због истрошених облога — гумених тачака оправа који повезују управљачку полугу са оквиром. Кад корозија ослаби полугу, то може довести до већег оптерећења ових облога, услед чега се оне могу расцепити или разградити. То омогућава директан метално-метални контакт, због чега настаје чујно клопоћање.

Нестабилан одзив управљача

Ако вам се управљач чини блажим, блата или повлачи у једну страну, оштећена управљачка полуга може бити узрок. Задатак управљачке полуге је да задржи стуб точка у правилном положају. Кад буде ослабљена услед рђе или савијена услед удара, више не може одржавати исправно поравнавање точкова. То резултира осећајем нестабилности и захтева стална исправљања управљача како би возило наставило да се креће праволинијски.

Претеране вибрације

Вибрације које се осећају кроз волан или под возила, посебно на већим брзинама, такође могу указивати на проблем. Изношени бушинзи не могу ефикасно апсорбовати вибрације са пута, те их преносе у простор за возача. Штавише, изоловани или неисправни тракторски крак може изазвати неравномерно хабање гума, што на крају доводи до вибрација док се точак окреће.

Неравномерно или превремено хабање гума

Визуелна провера ваших гума може откријати много о стању вашег ословања. Лош управљачки крак нарушује поравнање возила, услед чега се гуме неравномерно хабе. Потражите знаке као што су хабање на унутрашњим или спољашњим ивицама гуме (хабање рамена) или перјасте шаре преко глече. Ово је јасан индикатор да точак не долази у сталан, равномеран контакт са путем.

Да бисте потврдили своје сумње, можете извршити неколико једноставних провера:

- Визуелна инспекција: Безбедно подигните возило и употребите батеријску лампу да испрате траке управљача и њихове облоге. Потражите дубоку рђу, одламање метала, пукотине или поресане гумене облоге.

- Тест трзања: Док је возило подигнуто, покушајте да померате точак хоризонтално и вертикално. Превелики люфт или кретање може указивати на изношене шарке или облоге прикачено за траку управљача.

- Тест отпуштања: Чврсто притисните сваки предњи угао возила и пустите. Ако се возило више од једном или двапут отпушта, то може указивати на опште проблеме са овисима који могу бити повезани са тракама управљача.

Судар материјала: Штампан челик против ливеног гвожђа против ливеног алуминијума

Kada je u pitanju zamena rukavca upravljača oštećenog korozijom ili razumevanje sistema za voštanje vašeg vozila, poznavanje razlika između materijala je od suštinskog značaja. Izbor između čeličnih limova, livanog gvožđa i livanog aluminijuma podrazumeva kompromis između cene, trajnosti i težine. Svaki materijal ima svojstvene karakteristike prilagođene različitim tipovima vozila i uslovima vožnje.

Sledeća tabela prikazuje ključne karakteristike svakog materijala:

| Материјал | Прос | Конти | Обично се налази на |

|---|---|---|---|

| Стакленог | Ekonomično u proizvodnji. | Sklon rđi i koroziji, manje izdržljiv pod opterećenjem. | Ekonomska i masovna putnička vozila. |

| Ливеног гвожђа | Izuzetno jak, visoko izdržljiv, podnosi teške uslove. | Веома тешка, што може утицати на управљање и ефикасност горива. | Тркари, SUV возила и тешка возила. |

| Ливено алуминијумско | Одличан однос снаге и тежине, супериорна отпорност на корозију. | Коштају више, могу се пукати или савијати на јаком удару. | Перформансне, луксузне и модерне возила у којима је смањење тежине приоритет. |

Као што је детаљно описано у преглед материјала контролне руке, главна предност штампаног челика увек је била његова ниска цена и лакоћа производње. Међутим, због тога што је подложна рђавању, она је опасна у подручјима са суровим зимама или високом влажношћу. Ливено гвожђе пружа огромно побољшање чврстоће и је погодно за возила која морају издржавати тешка оптерећења и грубе услове. Његова тежина је главни недостатак. Лијечени алуминијум представља модерно инжењерско решење, пружајући добру чврстоћу при значајно мањој тежини и са природном отпорношћу на ржу. То га чини идеалним за побољшање одговора суспензије и ефикасности, иако долази по већој цени и може бити мање опростив на ударе од гвожђа.

Често постављана питања

1. Постављање Која је разлика између контролних руку од ливеног гвожђа и челика?

Главна разлика је у њиховој производњи, чврстоћи и отпорности на корозију. Сталне руке се праве притиском челичних листова, што их чини лаким и јефтинним, али веома склоним рђавању. Руке од ливеног гвожђа направљене су од топљеног гвожђа који се сипа у калупу, што резултира много тежим, јачим компонентом који се издрже на тешке окружења много боље од штампаног челика.

2. Уколико је потребно. Да ли је нормално да контролишу руке?

Нормално је да многи делови који се налазе испод возила добију благу површинску рђу, што уопште није разлог за забринутост. Међутим, кутијасти челични кракови полуге склони су дубокој, структурној корозији која одлама метал и ослабљује део. Овакав степен оштећења није нормалан нити безбедан и захтева одмах пажњу.

3. Који је најбољи материјал за регулажне кракове?

Не постоји јединствени „најбољи“ материјал; све зависи од намене возила. За теретна возила и СУВ-ове, челични лив се често преферира због своје сирове чврстоће. За перформансна и луксузна аутомобиле, лити алуминијум је идеалан због мале тежине и отпорности на корозију. Калибран челик је приступачна опција за економична возила, али захтева пажљиву проверу корозије у одређеним климама.

Мале партије, високи стандарди. Наша услуга брзе прототипирања чини валидацију бржем и лакшим

Мале партије, високи стандарди. Наша услуга брзе прототипирања чини валидацију бржем и лакшим