見積もりから納品まで:レーザー切断サービスの実際の仕組み

レーザー切断とは何か、そしてその仕組み

製造業者がどのようにして、きれいで滑らかなエッジを持つ非常に正確な金属部品を製作しているのかと思ったことはありますか? その答えは、現代の製造業で最も多用途な技術の1つであるレーザー切断にあります。プロトタイプの制作を検討している場合でも、量産の計画を立てている場合でも、レーザー切断がどのようなものであるかを理解することで、どのレーザー切断サービスを利用する場合でも、より賢明な判断を行うための基礎が得られます。

基本的には、レーザー切断は集中的な光エネルギーのビームを使用して材料を非常に高い精度で切断する熱加工プロセスです。 according to TWI Global この集中されたビームは、コンピュータ制御された経路に沿って材料を燃焼、溶融、または気化させることで、高品質な表面仕上げのエッジを残します。その結果、寸法精度は±0.0005インチまで、また切断幅(ケルフ幅)は最小0.004インチまで可能になります。

集光がどのように精密なツールになるか

拡大鏡を通して太陽光を集める様子を想像してみてください。しかし、そのエネルギーは数千倍も増幅されています。これがまさにレーザー切断機内部で起こっていることです。レーザー光線は、密閉されたチャンバー内で放電によって活性化された発振物質から生成されます。このエネルギーは鏡の間で反射を繰り返し、やがて一方向に揃った単一波長の強力な光線として放出されます。

一度放出された光線は、複数の光学レンズを通って直径0.32mm以下の非常に微細な一点にまで集中します。この高密度のエネルギーが材料に当たると、奇跡が起こります。 intense heat instantly transforms solid material into gas or molten metal, which is then blown away by a jet of assist gas to create your desired shape.

すべてのレーザー切断機が同じ性能を持っているわけではありません。産業界では、それぞれ特徴を持つ3つの主要なタイプがあります:

- 炭素レーザー: 10.6マイクロメートルの波長で動作するこれらの主力機は、アクリル、木材、布地などの非金属をレーザーで切断するのに優れており、軟鋼やアルミニウムの切断も効果的に行えます。複数の素材を扱う用途において最も汎用性の高い選択肢です。

- ファイバーレーザー: これらの高出力レーザーは固体素子技術を用いて光ファイバーを通じてビームを生成します。稼働寿命は25,000時間以上とされ、特に5mm以下の金属切断で広く使われています。銅や真鍮など反射性の高い金属を加工する際には、CO2レーザーシステムよりも優れた性能を発揮します。

- Nd:YAG レーザー: 1064 nmの波長で動作するこれらの固体レーザーは、熱影響を最小限に抑えつつ極めて高精度な切断を実現します。医療機器製造など、敏感な素材に対してきれいな切断が求められる産業では、その正確さからNd:YAGレーザー技術が信頼されています。

ビームと材料の相互作用に関する科学

当該の レーザーが材料に接触して切断する仕組み 同時にいくつかの現象が起こります。集中されたエネルギーにより、材料は数ミリ秒以内に融点または気化点を超えて加熱されます。酸素や窒素などの補助ガスが切断ノズルを通って流れ込み、2つの目的を果たします。溶融した材料を切断部から吹き飛ばし、化学反応によって切断プロセスをさらに効率化します。

材料の端からではなく他の場所で開始するプロジェクトの場合、最初に穿孔(ピアシング)処理が必要です。TWI Globalによると、高出力パルスレーザーを使用すれば、この初期のピアシング工程で0.5インチ厚のステンレス鋼をわずか5〜15秒で貫通できます。

すべてのレーザー切断システムは、以下の5つの主要な構成要素が連携して動作することに依存しています:

- レーザー源: 電気的または光学的な励起によって切断用ビームを生成する、システムの中心となる部分です。

- 切断ヘッド: ビームを集中させ、補助ガスを被加工物に導くためのフォーカスレンズおよびノズルを内蔵しています。

- モーションシステム: 精密サーボモーターと線形ガイドで,切断頭または材料プラットフォームをマイクロンの精度で動かす.

- ガス配送支援: 切断を強化し,割れ目から残骸を除去するために酸素,窒素,または圧縮空気を供給します.

- 制御装置: 設計ファイルを正確な動きの指示に変換する 脳です 波の強度 切断速度 ガス圧力を調整して 最適な結果が得られます

レーザーカットメーカーと効果的にコミュニケーションをとり,質の高いサービスを他のサービスと区別するものを認識するのに役立ちます. この知識があれば 次のプロジェクトに最適な材料を探り出すことができます

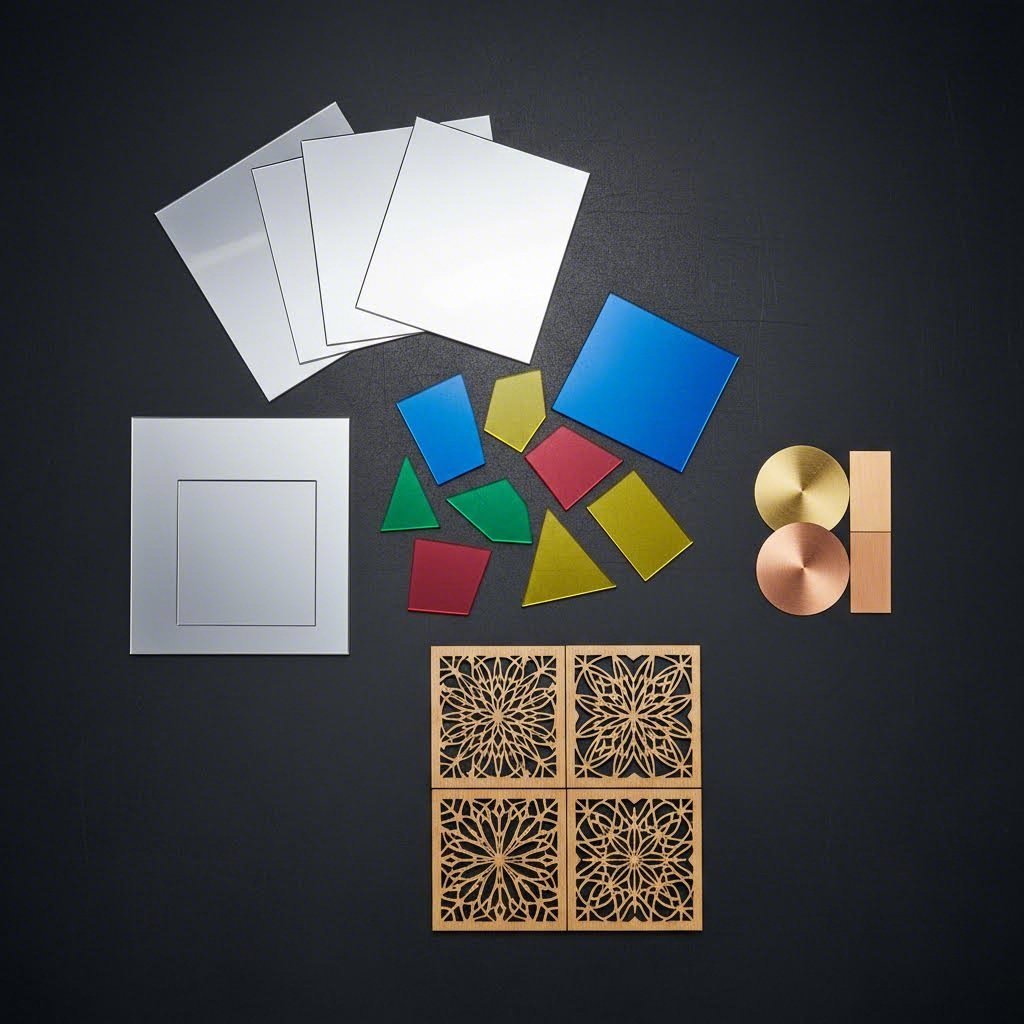

レーザー で 切れる 材料

適切な素材を選ぶことは レーザーカットプロジェクトを壊す 完璧な設計を持っていても、レーザー技術と相性の悪い素材を選択すれば、切断エッジの品質が低下したり、廃材が増えたり、最悪の場合、安全上の危険を招くことになります。では、どのレーザー加工可能な素材を検討すべきで、また全く避けるべき素材はどれでしょうか。

プロのレーザー加工サービスが日常的に扱う主な3つのカテゴリ—金属、プラスチック、特殊素材—について見ていきましょう。

レーザー精度に優れた金属

金属をレーザー切断する必要がある場合、ファイバーレーザーが最も適しています。その短い波長は金属表面により効率的に吸収され、熱変形を最小限に抑えながらきれいな切断が可能です。以下は、最も一般的な金属素材の加工結果の概要です。

- 炭素鋼: 金属のレーザー切断における主力素材です。酸素をアシストガスとして使用することで、最大25mm厚の板材を切断でき、優れた切断面品質を得られます。

- ステンレス鋼: 食品サービス、医療機器、建築用部品におけるステンレス鋼のレーザー切断に最適です。窒素をアシストガスとして使用することで、酸化物のない清潔な切断面が得られ、二次仕上げ工程が不要になります。最新のファイバーレーザーは最大20mmまでの板厚を効果的に処理できます。

- アルミニウム: 高反射性と高い熱伝導性を持つため加工が難しいですが、高出力ファイバーレーザーの普及により、アルミニウムのレーザー切断は標準的な手法となっています。適切な窒素アシストを使用すれば、最大15mm厚まできれいに切断できます。

- 銅: これらの高反射金属を加工するには、特別な高出力ファイバーレーザーシステムが必要です。 according to IVY CNC によると、銅の最大切断厚さは通常10mmに達し、真ちゅうは適切な装置を使用することで最大12mmまで対応可能です。

金属レーザー切断機はこれらの材料を効率的に処理できますが、覚えておいてください:反射性の表面はより多くの出力と注意深いパラメータ調整を必要とします。常に、ご自身の特定の金属および板厚要件について実績のある業者であることを確認してください。

レーザー加工向けプラスチックおよび代替材料

プラスチックをレーザー切断する必要がある場合、素材選定はさらに重要になります。一部のプラスチックは美しく切断できますが、他のものでは有毒な煙を発生させ、人体に害を与えたり装置を損傷させることがあります。

レーザー切断に適した安全なプラスチック:

- アクリル(PMMA): レーザー切断用途におけるゴールドスタンダードです。きれいに気化し、炎で磨かれたような美しいエッジが得られます。看板、ディスプレイ、ジュエリーに最適です。

- デルリン(POM/アセタール): ギアやブッシュ、機械部品などの機能部品に理想的なエンジニアリングプラスチックです。溶けひずみなくきれいに切断できます。

- ポリエステル(マイラー): 寸法精度の高い薄膜や柔軟なステンシルに最適です。

レーザー加工サービスで一般的に扱われる特殊材料:

- 天然木: マツなどのソフトウッドは低出力で簡単に切断できますが、クルミなどのハードウッドは速度を落としてより高いエネルギーが必要です。切断前にマスキングテープを貼ることで、スモーク汚れを防げます。

- 合板およびMDF: コストパフォーマンスに優れていますが注意が必要です。接着剤やバインダーからホルムアルデヒドやその他の有毒な煙が出ることがあります。十分な換気が不可欠です。

- 生地: 綿やデニムなどの天然繊維はきれいに切断されますが、ポリエステルなどの合成繊維はレーザーで素材が溶けるため、ほつれのない密封されたエッジになります。

- 植物から焼いた皮革: ファッションやアクセサリー用の美しく彫刻・切断された作品を作成できます。

| 素材カテゴリ | 共通用途 | 厚さ範囲 | エッジ品質 | 推奨されるレーザーの種類 |

|---|---|---|---|---|

| 炭素鋼 | ブラケット、パネル、構造部品 | 0.5mm - 25mm | 酸化皮膜に対して非常に良好 | ファイバーレーザー |

| ステンレス鋼 | 医療機器、食品機器、看板 | 0.5mm - 20mm | 窒素による清浄で酸化物のない状態 | ファイバーレーザー |

| アルミニウム | 筐体、ヒートシンク、航空宇宙部品 | 0.5mm - 15mm | 適切なパラメータで良好 | ファイバーレーザー |

| 真鍮/銅 | 電気部品、装飾品 | 0.5mm - 10mm | 専門的な設定を必要とする | 高出力ファイバーレーザー |

| アクリル | 看板、ディスプレイ、ジュエリー、プロトタイプ | 1mm - 25mm | フレームポリッシュ済み、非常に良好 | CO2レーザー |

| デルリン (POM) | ギア、ベアリング、機械部品 | 1mm - 12mm | 清潔で正確 | CO2レーザー |

| 木材(天然) | 芸術品、家具部品、包装材 | 1mm - 15mm | わずかに焦げた端 | CO2レーザー |

| 生地 | ファッション、 upholstery(張り地)、産業用フィルター | 0.1mm - 5mm | 合成素材の端部はシール加工済み | CO2レーザー |

絶対にレーザー切断してはいけない材料

これはこのガイド全体で最も重要な情報である可能性があります。 according to Fortune Laser 誤った素材を切断すると、有毒ガスが発生したり、火災が発生したり、レーザー加工機の部品が永久的に腐食する可能性があります。

以下の素材は完全に避けてください:

- PVC(ポリ塩化ビニル): 最もひどい素材の例です。加熱するとPVCは塩素ガスを放出し、これが水分と結合して塩酸を生成します。これにより光学部品が損傷し、金属部品が腐食するだけでなく、健康にも重大なリスクを及ぼします。

- ABSプラスチック: シアン化水素ガスを発生させます。これは極めて毒性の強い物質です。また、きれいに切断されるのではなく、溶けてベタベタした状態になります。

- 厚手のポリカーボネート(レキサン): レーザーエネルギーをほとんど吸収しないため、変色や溶融が起こりやすく、火災の危険性も高くなります。Xometryが指摘しているように、1mm未満の薄いポリカーボネートでさえ、結果は非常に悪くなります。

- クロム鞣しレザー: クロム6価など、有毒な重金属を放出します。レーザー切断には植物タンニン鞣しレザーのみを使用してください。

- ガラス繊維およびコーティング済みカーボンファイバー: これらの素材を構成するエポキシ樹脂は燃焼時に極めて有害な煙を発生させます。

使用する素材について疑問がある場合は、絶対に切断しないでください。レーザー加工サービス提供業者に相談するか、その素材の安全データシート(SDS)を請求して、レーザー加工との適合性を確認してください。

金属のレーザー切断やその他のレーザー加工に適した素材について理解できたので、次に必要なのは、完璧な結果を得るために設計ファイルを正しく準備することです。

完璧な結果のための設計ファイルの準備

最適な素材を選択し、優れたデザインを思いついたところでしょう。しかし、ここで多くのプロジェクトが失敗するポイントがあります:それはファイルの準備です。ご希望のデザイン通りの高精度なレーザー切断ができるか、あるいは不要な廃材の山となるかは、設計ファイルの準備の仕方にかかっているのです。レーザー切断・彫刻のプロジェクトであれ、アクリルのカスタムカットであれ、この工程を正しく行うことで時間と費用、そして手間を節約できます。

設計ファイルは、レーザー切断CNC機械にとってのレシピのようなものです。指示が不明確であったり誤りを含んでいれば、出力結果は期待したものになりません。ここでは、知っておくべきことを正確にご説明します。

レーザー切断サービスが受け付けるファイル形式

すべてのファイル形式がレーザー加工サービスと互換性を持っているわけではありません。以下は、ほとんどのサービスプロバイダーが受け入れている形式と、それぞれの特定の要件です。

- DXF(Drawing Exchange Format): レーザー切断の業界標準です。DXFファイルは塗りつぶしやエフェクトを含まない純粋なベクターデータを保持しており、切断ソフトウェアへの直接インポートに最適です。ファイルでは実際の単位(インチまたはミリメートル)を使用し、処理ソフトウェアで混乱を引き起こす可能性のあるネストされたブロックは避けてください。

- AI (Adobe Illustrator): 広く受け入れられており、汎用性が高いです。According to Cut By Beam によると、ドキュメントのカラーモードをRGBに設定し、切断線には赤(RGB)、線幅0.1を使用し、スコア線には青を使用してください。ラスターエンボス加工部分は黒で塗りつぶす必要があります。

- SVG(Scalable Vector Graphics): Webベースのアップロードポータルに最適です。SVGはサイズに関係なく数学的な精度を維持しますが、インポートの問題を引き起こす可能性のある非表示のメタデータを含むことがあります。エクスポート前にファイルを簡略化してください。

- EPS(カプセル化PostScript): 古い形式ですが依然使用可能ですが、変換が必要な場合が多いです。EPSを使用する場合は、最大限の互換性を得るためにバージョン8以前に限定してください。

- PDF(Portable Document Format): 一部のサービスでは、ベクターアートが埋め込まれたPDFを受け付けています。ただし、保存前にすべてのフォントをアウトライン化し、効果をフラット化しておくことを確認してください。

カスタムレーザー彫刻プロジェクトの場合、JPEGファイルは画像からのラスタ彫刻に直接使用できます。しかし、JPEGでは切断パスを作成できないことに注意してください。切断操作を行う場合は、常にベクター線が必要になります。

切断品質を損なう設計上のエラー

経験豊富なデザイナーでさえも、結果の質を低下させたりファイルが拒否されたりするようなミスを犯すことがあります。以下は避けたい最も一般的な問題です。

閉じられていないパス: 切断機は追跡するための連続したラインを必要としています。閉じられていないパスでは、ソフトウェアがどこを切断すべきか混乱し、不完全な切断や予期しない動作につながることがあります。Cut By Beamが指摘しているように、図形が複数のパスから構成されている場合は、それらを結合して閉じた形状にしてください。これは特にソリッド彫刻において極めて重要です。

重複または重なったライン: この厄介な問題により、切断時間とコストが2倍になります。さらに悪いことに、レーザーが同じパスを2回切断するため、素材を貫通してしまうか、見た目が悪く、過剰に切断されたエッジができてしまう可能性があります。 According to John Duthieのレーザー切断ガイド によると、常に互いに重なった状態で隠れた重複ストロークがないか確認してください。

輪郭化されていないテキスト: これは非常に重要なので特に強調する価値があります:

デザインファイルを提出する前に、必ずフォントをパスに変換してください。この手順を省くと、特定のフォントがインストールされていない別のシステムで開いたときに、テキストが正しく表示されない、または完全に消えてしまうことがあります。

不適切なスケール設定: 実際のサイズではなくピクセル単位で設計すると、部品のサイズがまったく異なってしまいます。常にミリメートルまたはインチで作業し、エクスポート前に寸法を確認してください。

アンカーポイントが多すぎる: ノードが多すぎる複雑なカーブは処理速度を遅くし、機械の動きがカクつく原因になることがあります。デザインの形状を保ちつつ、不要なアンカーポイントを減らしてパスを簡素化してください。

段階的なファイル準備ワークフロー

次のチェックリストに従ってください。 精密レーザー切断にファイルを送信する前には 提供元:

- ドキュメントを実際の単位に設定してください。 デザインソフトウェアをミリメートルまたはインチを使用するように設定し、アートボードのサイズが目的の部品サイズと一致していることを確認してください。

- すべての切断パスをベクターとして作成してください。 ペンツール、シェイプツールを使用するか、ラスタ画像をトレースして、数学的に正確なパスを作成します。

- すべてのテキストをアウトラインに変換: Illustratorでは、テキストを選択し、「タイプ」>「アウトラインを作成」を選んでください。編集しやすくするために、生成されたシェイプのグループ化を解除します。

- 開いたパスを閉じたシェイプに結合してください。 端点を選択し、ソフトウェアの結合機能を使用します。アウトライン表示モードに切り替えて確認してください。

- 重複する線を削除: すべてのオブジェクトを選択し、「結合」または「パスファインダーユナイテッド」機能を使用するか、重なったパスを手動で削除してください。

- アンカー点を減らす: デザインを歪めることなくノード数を最小限に抑えるために、パスの簡略化機能を使用してください。

- カーフ補正を適用: レーザー光は材料を除去します(通常幅0.1〜0.3mm)。精密なフィットが必要な部品については、切断ラインをカーフ幅の半分だけ内側にオフセットしてください。

- 最小特徴サイズを確認: ほとんどのサービスでは、ポジティブな形状には少なくとも1mm、切断幅には0.5mm以上が必要です。これより細い部分は焼けてしまったり、きれいに切断できなかったりする可能性があります。

- 切断間隔の確認: 切断中に反りや破損を防ぐため、平行な切断線の間には少なくとも材料の厚さ分のスペースを確保してください。

- アウトライン表示でプレビュー: Cut By Beam社が推奨しているように、[表示] > [輪郭] を使用して、レーザー加工ソフトウェアがあなたのファイルをどのように解釈するかを正確に確認してください。アートボードの外側に意図せず存在しているオブジェクトがないか確認しましょう。

ステンシルデザインに関するもう一つのヒント:「O」「A」「B」などの文字の内側の島状部分は、周囲の素材とつなぐブリッジ(橋渡し)がなければ脱落してしまいます。フォントを修正するか、専用のステンシル用書体を選んでください。

適切に準備されたファイルがあれば、次に、あなたのプロジェクトが他の切断方法と比べてどう異なるかを理解し、どのような場合にレーザー切断が本当に最適な選択肢となるのかを把握する準備が整います。

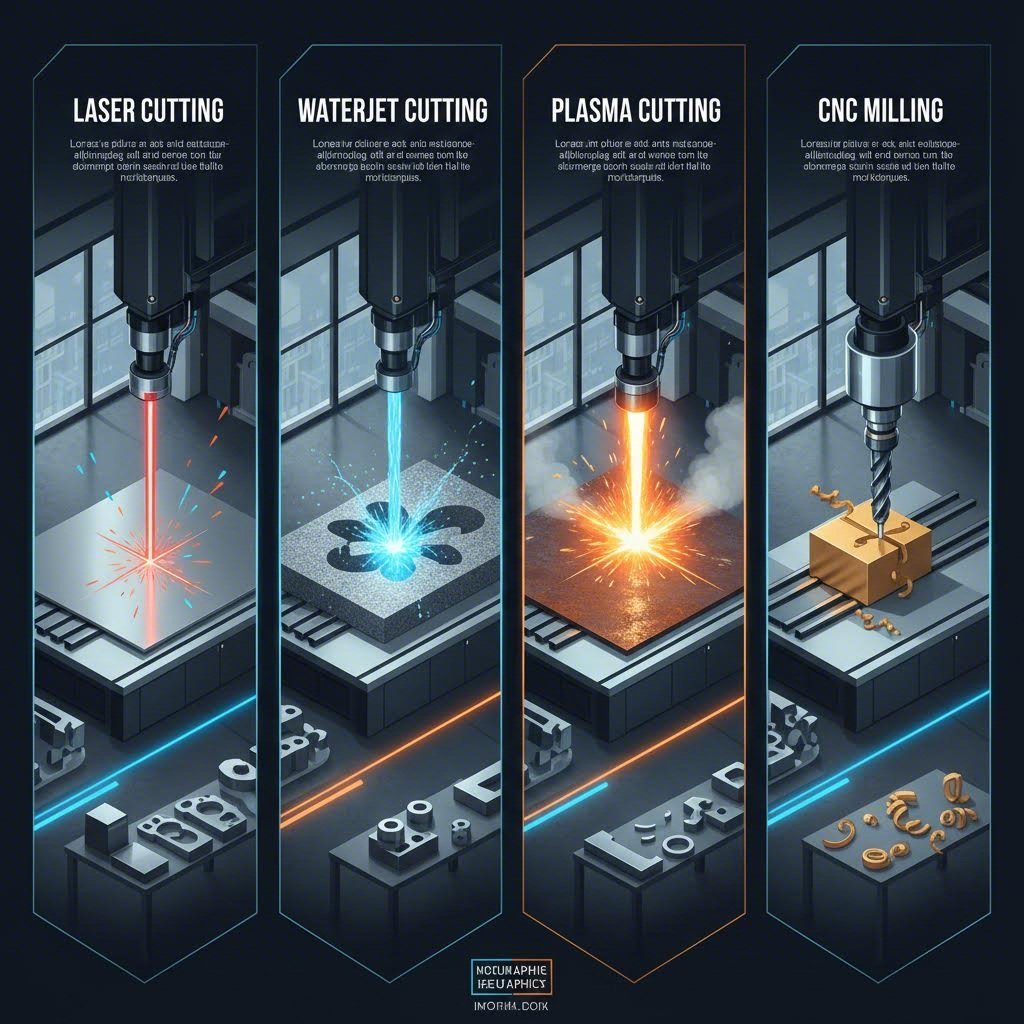

レーザー切断とウォータージェット、プラズマ、CNC方式の比較

設計ファイルの準備ができて、材料も選んだところでしょう。しかし、ここで一つの重要な質問があります。これにより時間と費用を大幅に節約できるかもしれません:本当にレーザー切断がこのプロジェクトに最適な方法なのでしょうか?正直に言えば、それはケースによるのです。CNCレーザー切断がウォータージェットやプラズマその他の金属切断技術と比べてどのような違いがあるのかを理解すれば、すべてを一律に一つの技術で処理するのではなく、より賢明な判断ができるようになります。

これらの異なる技術間の現実的な利点と欠点を比較してみましょう。そうすれば、それぞれのニーズに最も適した加工方法を選べるようになります。

レーザー切断が他の方法を上回る場合

金属用レーザー切断は、特定の状況下で真価を発揮します。鋭いコーナーや細かいディテールを含む複雑なデザインが必要な場合、他の方法では到底かなわない精度でレーザー技術は対応できます。 according to StarLab CNC レーザー切断は熱切断法の中で最も高い切断面品質を実現し、滑らかで直角に近い切断面を形成し、バリの発生も最小限に抑えられます。

以下のような場面で、金属レーザー切断が最も適しています:

- 薄板から中厚板の材料の場合: ファイバーレーザーは1/4インチ以下の薄板において優位を占めており、他の技術を大きく引き離す卓越した速度を実現します。

- 複雑な形状: 複雑なパターン、小さな穴、狭い公差を持つ加工はレーザーの得意分野です。集光されたビームは、プラズマやウォータージェットでは困難な鋭いコーナーも正確にナビゲートできます。

- 大量生産: 一度セットアップすれば、レーザーシステムは部品間のばらつきが極めて少なく、高速で運転できるため、一貫性があり繰り返しの作業に最適です。

- 二次仕上げを必要としないきれいな切断面: 外観が重要な用途や直後の溶接工程がある場合、レーザー切断の切断面は多くの場合、後処理をまったく必要としません。

レーザーとCNCの組み合わせは、非常に高い柔軟性も提供します。物理的な工具交換ではなく、パラメータの変更だけで、軟鋼からステンレス、アルミニウムの切断へと簡単に切り替えられます。

他の方法が優位となる状況

ほとんどのレーザー切断サービス提供者が明かさない真実があります。彼らの技術が常に最良の選択とは限らないということです。場合によっては、「近くのプラズマ切断」を探すか、代わりにウォータージェット加工を検討する方が賢明なこともあります。

ウォータージェット切断が適しているのは次のような場合です:

- 熱に敏感な材料を扱っており、熱による歪みに耐えられない場合

- 1インチを超える厚板をヒートエフェクトゾーンなしで切断する必要がある場合

- 素材の多様性が重要—ウォータージェットはチタン、花こう岩、ガラスまであらゆるものを処理可能

- 重要な用途において金属組織が完全に変化しないように保つ必要がある場合

最大90,000 PSIの圧力で動作するウォータージェットシステムは、熱を発生させることなく事実上すべての素材を切断できます。その代償は速度です。ウォータージェットは通常毎分5~20インチの速度で切断しますが、薄板ではレーザーの方がはるかに高速です。

プラズマ切断が適しているのは以下のような場合です。

- 1/2インチから2インチの厚鋼板を迅速かつ経済的に切断する必要がある場合

- 予算上の制約があり、装置コストおよび運転コストが低い方法を優先する場合

- 溶接準備用のビベル切断が必要な場合

- 完璧な精度ではなく、レーザーに近い品質で十分な場合

最新のCNCプラズマテーブルは、1/2インチの軟鋼を毎分100インチ以上の速度で切断できます。これは厚板においてレーザーよりも大幅に高速であり、装置の導入費用は同等のレーザーシステムのごく一部で済みます。

次の場合はCNCフライス加工が適しています:

- 部品に2D切断では作成できない3D形状、ポケット、または面取りが必要な場合

- ±0.001インチという非常に厳しい公差が必須の場合

- 表面仕上げの要件が熱間切断で得られるものを上回る場合

パンチプレスが適しているのは次の場合です:

- 大量生産のため、金型投資が正当化される場合

- 標準的な穴パターンを持つシンプルな形状の部品が中心である場合

- 大量生産において部品単価を最小限に抑える必要がある場合

主要技術の概要比較

| テクノロジー | 最高の材料 | 板厚能力 | 精度レベル | エッジ品質 | 速度 | 費用因子 |

|---|---|---|---|---|---|---|

| レーザー切断 | 鋼材、ステンレス、アルミニウム、薄板金属 | 最大1"(0.25"以下が最適) | ±0.005インチ以上 | 素晴らしい,滑らかな仕上げ | 薄い素材では非常に高速 | 中程度の装置費、低い運転コスト |

| ウォータージェット | ガラス、石材、複合材料など、あらゆる素材 | 材質により6"以上可能 | ±0.005" から ±0.010" | 良好。熱影響なし | 遅い(5〜20 ipm) | 運転コストが高い(研磨材費用) |

| 血球 | 導電性金属のみ | 0.018" から 2"(最適は1/2" から 1") | ±0.015" から ±0.030" | 高密度プラズマで良好 | 厚手の材料では高速 | 装置費が低く、運転コストも低い |

| CNCミリング | 金属、プラスチック、複合材料 | 工作機械の加工範囲に制限される | ±0.001インチが達成可能 | 優れた切削仕上げ | 適度 | 金型コストは高いが、運転コストは中程度 |

| パンチプレス | 板金部品に限る | 通常1/4インチ未満 | 高品質な金型で±0.005インチ | 良好だが、バリ取りが必要な場合あり | 非常に高速(1ショットあたり) | 金型コストが高いが、量産時には部品単価が低くなる |

レーザー切断の限界に関する正直な考察

レーザー切断サービスを利用する前に、以下の制約を理解しておきましょう。

反射性材料は扱いが難しい: 銅や真鍮など高反射金属はレーザーエネルギーを光学系に反射させてしまい、装置に損傷を与える可能性がある。最新のファイバーレーザーは従来技術よりこれらに対応できるが、コストが高くなり、加工速度も遅くなると考えてよい。

板厚の制約は現実的な問題である: 材料の厚さが増すにつれて切断速度は著しく低下する。業界データによると、1インチを超える材料ではレーザーの性能が大きく下がり、プラズマまたはウォータージェット加工の方が実用的になる。

熱影響領域(HAZ)が存在する: プラズマより精密ではあるが、レーザー切断も熱エネルギーを加えることになる。熱影響領域(HAZ)により切断端部近くの材料特性が変化し、金属組織の純度が求められる用途では懸念事項となる。

初期設備投資費用は高額になる: ファイバーレーザー装置は大きな資本投資を伴います。このコストは、特に多数の部品に割り当てられない小ロット生産において、顧客に転嫁される傾向があります。

結論として、賢いバイヤーはあらゆる問題に無理やり一つの解決策を適用するのではなく、用途に応じて適切な技術を選択します。こうしたトレードオフを理解していれば、選定したサプライヤーと価格について話し合う際に、より良い見積もりと結果を得られるようになります。

レーザー切断のコスト構造を理解し、適正な見積もりを入手する方法

『近くでレーザー切断サービスを探しているのですが、料金体系がまるでブラックボックスのようで、とても不満です。設計データをアップロードしてレーザー切断の見積もりを依頼しても、その金額がどのように算出されたのかほとんど説明されません。なぜある業者は他の業者の3倍もの料金を請求するのでしょうか? また、見た目がシンプルな部品なのに、隣人の複雑な部品よりも高くなるのはなぜでしょう?』

実際、レーザー切断の費用には論理的な計算式があります。コストに影響を与える要素を理解すれば、より賢明な設計の意思決定ができ、見積もりを自信を持って評価できます。 according to Fortune Laser あなたのコストを最も左右する重要な要素は、使用する材料の面積ではなく、設計を切断するために必要な機械稼働時間です。同じシートから作られる2つの部品でも、その複雑さによって価格が大きく異なることがあります。

レーザー切断の見積もりを高くも低くもする要因とは

受け取るすべてのレーザー切断の即時見積もりは、次の基本的な計算式に基づいています。

最終価格 = (材料費 + 変動費 + 固定費) × (1 + 利益率)

それぞれの項目が実際にあなたの出費にどのように関わっているのかを見ていきましょう。

材料の種類と厚さ: これは2つの点で価格に影響します。第一に、素材の原価は大きく異なります。例えばMDFは安価ですが、ステンレス鋼ははるかに高価です。第二に、板厚が切断時間に大きな影響を与えます。Komacutが説明しているように、材料の厚さが2倍になると、レーザーがきれいに切断するためにはるかに遅い速度で動く必要があるため、切断時間とコストが2倍以上になることがあります。

切断総長(外周) 機械稼働時間は、あなたが主に支払っているサービスです。レーザーが移動する総直線距離によって、作業に要する時間が決まります。同じ面積の場合でも、12インチの正方形を切断するよりも、周長が長い12インチの円を切断する方が高価になります。

穿孔回数: レーザーが新しい切断を開始するたびに、まず材料を「穿孔(ピアス)」しなければなりません。これは、貫通して入り口を作成するために焼尽する工程です。100個の小さな穴を持つデザインは、大きな切り抜き一つよりも累積的な穿孔時間があるため、コストが高くなります。業界データによると、高出力パルスレーザーでは、0.5インチのステンレス鋼を穿孔するだけでも5〜15秒かかる場合があります。

設計の複雑さ: 複雑なカーブや鋭い角を持つ精巧なパターンでは、機械が大幅に速度を落とさざるを得なくなります。機能上必要以上の厳しい公差を指定するとコストが上がります。精度を確保するには、より遅く、より制御された速度で運転しなければならないためです。

注文数量: 固定されたセットアップ費用は、注文内のすべての部品に按分されます。その結果、数量が増えるにつれて部品単価が大幅に低下します。大量注文の場合、最大70%の割引が適用されるため、一括購入ははるかに経済的になります。

仕上げの要件: バリ取り、曲げ加工、ねじ切り、または粉体塗装などの二次工程は、それぞれ労力、専門設備、および生産時間の延長を必要とします。これらは別途料金が発生し、合計コストを著しく増加させる可能性があります。

納期: 急ぎの注文にはプレミアムなレーザー切断料金が適用されます。標準納期には正当な理由があります。業者は効率的な生産スケジュールを最適化しているため、順番を飛び越えることは追加費用がかかります。

注意すべき隠れたコスト

明らかないくつかの要因以外にも、初めて購入する人を意外に驚かせる費用があります。

セットアップ料金および最低料金: 近くのほとんどのレーザー切断サービスでは、セットアップ料金または最低注文額を設定しています。これは、オペレーターが材料を装着し、機械をキャリブレーションし、お客様のファイルを準備するための作業時間をカバーするものです。小規模な注文の場合、セットアップ費用が実際の切断費用を超えることもあります。

ファイル準備料金: デザインファイルにエラー(重複する線、開いた輪郭、または欠落した要素など)が含まれている場合、技術者が修正を行う必要があります。多くのサービスでは、この作業に対して追加料金を請求します。なお Smart Cut Quoteの注意点 少量生産やワンオフの仕事の場合、セットアップや準備にかかるコストは特に大きな要因となります。

材料のマージン: サービス提供会社は原材料を卸売価格で購入しますが、小売価格にハンドリング料を加えてあなたに販売します。在庫にある材料を選ぶことで、特別発注手数料を回避でき、リードタイムを短縮できることがよくあります。

出荷および包装: 大型または重量のある部品は特別な取り扱いが必要です。繊細な部品には保護包装が必要です。こうした物流コストは、遠隔地への注文で急速に増加します。

「送って切断して返す」サービスの価格を現地のプロバイダーと比較する際は、往復の送料を考慮に入れてください。一見「安い」オンライン見積もりでも、配送費を含めると高くなる可能性があります。

実際に効果のあるコスト削減戦略

最終的な価格について、あなたが思っている以上にコントロールできる余地があります。以下の戦略は、機能性を損なうことなく一貫してコストを削減できます:

- 部品を効率的にネスト配置: 材料シート上に部品を密接に並べることで、廃材を最小限に抑えられます。より良いネスト配置は、直接的に材料費と切断時間を削減します。

- 設計を簡素化してください: 複雑なカーブを減らし、複数の小さな穴を大きなスロットに統合して、不要な形状を排除してください。これにより、切断距離と穴開け工程による時間の増加を最小限に抑えることができます。

- 可能な限り薄い材料を使用してください: これはコスト削減において最も効果的な方法です。厚い材料は機械加工時間を指数関数的に増加させます。構造要件を満たすか確認した上で、常に薄めの規格を使用できないか検討してください。

- 標準的な材料を選択: 特殊合金や特殊プラスチックは高価であり、特別注文が必要になる場合があります。工場で在庫している一般的な材料を使用すれば、費用と時間を節約できます。

- 大量発注を行う: ニーズを少数の大きな発注にまとめてください。セットアップコストがより多くの部品に分散されるため、単価が大幅に低下します。

- 設計データを整理してください: アップロード前に重複する線分、非表示のオブジェクト、および施工に関するメモを削除してください。自動見積もりシステムではすべてを切断しようとするため、二重の線分はその機能のコストを実際に2倍にします。

- 可能な限り公差を緩和してください: 機能上必要な箇所にのみ厳しい公差を指定してください。±0.010"で十分な場合に±0.001"を要求するよりも、標準精度のほうがコストが低くなります。

準備費用と部品単価の違いを理解する

この区別は予算面で非常に重要です。準備費用は数量に関係なく固定されます。材料の装着、機器のキャリブレーション、テストカットの実施などにかかる費用は、1個でも100個でも同じです。一方、部品単価は数量に応じて変化し、実際の切断時間、消費される材料、ハンドリングなどが含まれます。

単一のプロトタイプの場合、初期設定費用として50ドルに加え、個々の部品あたり5ドルのコストがかかり、合計55ドルになります。同じ部品を100個注文すれば、50ドルの初期設定費は1個あたりわずか0.50ドルにまで分散されます。これに1個あたり5ドルの切断費用を加えると、部品単価は55ドルではなく5.50ドルに低下します。これが、プロトタイプの価格が量産時と比べて非常に高額に感じられる理由です。

機械の時間当たりの料金は、レーザー出力や性能に応じて通常60〜120ドルの範囲で変動します。これを理解することで、提示された価格が妥当な範囲内にあるかどうかを判断できます。

複数の業者からの見積もりの評価

「近くのレーザー切断サービス」を比較する際には、最終的な金額だけでなくそれ以外の点にも注目してください。

オンラインの即時見積もりプラットフォーム は、比類ないスピードと利便性を提供します。CADファイルをアップロードすれば、数秒で価格が表示されます。予算の即時フィードバックが必要な迅速なプロトタイピングには最適です。ただし、自動化されたシステムでは高コストとなる設計ミスを検出できず、利便性に対してプレミアム料金を課すことが多いです。

従来の製造工房 技術者に依存してファイルを手動で確認してもらいます。これには時間がかかり—数時間から数日かかる場合もありますが—製造性設計(DFM)に関する無料のフィードバックを受けられ、コストを大幅に削減できる可能性があります。彼らはエラーを発見し、より効率的な設計を提案し、顧客提供材料に関して柔軟な対応を行うことがよくあります。

見積もりを依頼する際は、何が含まれているかを必ず確認してください:価格に材料費は含まれますか?配送費はどうですか?ファイル準備や仕上げ加工に追加料金がかかりますか?すべてが含まれたやや高めの見積もりは、さまざまな追加料金が発生する低価格ベースの見積もりよりも優れていることが多いです。

レーザー切断の価格設定の背後にある経済構造を理解した今、ファイルのアップロードから完成品の自宅受け取りまで、実際の発注プロセスを円滑に進められる準備が整いました。

見積もりから納品まで、レーザー切断サービスを利用する

部品の設計が完了し、ファイルの準備ができ、適正な見積もりを取得しました。次に何をすればよいでしょうか?初めて購入する方にとって、「注文を確定」をクリックしてから完成品を受け取るまでの間は、まるで謎のように感じられるかもしれません。オンラインレーザー切断サービスでは、その裏で一体何が行われているのでしょうか?実際にどのくらい待つべきなのでしょうか?また、何か問題が起きた場合はどうなるのでしょうか?

全体の工程を理解することで不確実性がなくなり、プロジェクトのスケジュールを現実的に計画できるようになります。試作用でも量産用でもレーザー切断サービスを利用する場合、プロセスには追跡可能で影響を与えることのできる予測可能なステップがあります。

アップロードから納品まで、5つのステップ

オンラインのレーザー切断サービスはすべて同様の手順を踏みますが、期間や連絡方法については業者によって異なります。以下が、お客様のプロジェクトが通る標準的な流れです。

- 設計データの送信とファイル確認: CADファイルをプロバイダーのポータルを通じてアップロードします。システムが未閉じパス、サポートされていないファイル形式、寸法の欠落などの基本的なエラーをチェックします。多くのオンラインレーザー切断サービスプラットフォームは、明らかな問題について即時フィードバックを提供します。より詳細な確認は、注文を進めた後に手動で行われます。

- 見積もりの確認と注文確定: 材料、複雑さ、数量に基づいた価格が提示されます。見積もりを注意深く確認し、材料の仕様、板厚、含まれる仕上げ工程などを確認してください。承認後、支払いを送信すると、注文は生産キューに入ります。

- 材料の確認と生産スケジューリング: 工場は材料の在庫状況を確認します。標準的な材料は在庫から直ちに出荷可能です。特殊材料の場合は調達が必要となり、納期に数日追加される場合があります。 according to California Steel Services 、生産能力および現在のキューの状況が、あなたの作業がスケジュールされるタイミングに直接影響します。

- 切断、仕上げ、品質検査: 部品は切断後、寸法精度とエッジ品質を検査され、その後、バリ取り、曲げ加工、粉体塗装、または組立など、ご依頼いただいた二次加工工程へと進みます。各工程には処理時間が必要ですが、最終製品が仕様を満たすことを保証します。

- 梱包と輸送 完成した部品は、素材および数量に応じた適切な保護包装が施されます。追跡情報はお客様のメールアドレスへ送信され、部品は目的地へ出荷されます。

この一連の流れは、カスタムサイン、機能プロトタイプ、装飾用プロジェクト向けのレーザー切断木材サービスのいずれを注文する場合にも適用されます。基本的な手順は、素材や用途に関わらず一貫しています。

設計内容を送信した後の流れ

ファイルがシステムに入力されると、訓練を受けた技術者が対応を担当します。即時見積もりを行う自動化されたプラットフォームが明らかなエラーしか検出できないのに対し、人によるレビューでは結果を損なう可能性のある繊細な問題点を発見できます。

優れたサービス提供者は、以下の点を確認します。

- 機械作業時間を2倍にしてしまう重複またはオーバーラップした切断ライン

- 切断工程を耐えきれないほど小さすぎる、または薄すぎる形状

- 材料の安定性にとってきつい間隔での切断

- 反りや歪みを引き起こす可能性のある設計要素

問題がある場合は、質問や提案を含むメールが届きます。「 NerdBotのワークフローガイド 」にもあるように、この段階での小さな変更は最終製品の品質を大幅に向上させる可能性があります。リビジョンの要請を障害と見なすのではなく、より良い結果を得るためのチャンスとして捉えてください。

コミュニケーションの期待値はプロバイダーによって異なります。オンラインプラットフォームでは通常、メールチケットを通じて24〜48時間以内に返信があります。地域のショップでは、直接電話で連絡でき、質問に対する対応がより迅速な場合があります。遅延を避けるために、最初にプロバイダーの推奨する連絡手段を明確にしてください。

納期の期待値

実際にどのくらい待つべきでしょうか?現実的な期待を持つことで、イライラを防ぎ、下流の組立や設置スケジュールを計画しやすくなります。

リードタイムを延ばす要因:

- 設計の複雑さ: 多数の穴あけ加工やきついカーブを伴う複雑なパターンは、機械速度を遅くする必要があり、切断サイクルが長くなります。

- 材料の入手性: 特殊合金、非標準的な厚さ、または特殊プラスチックは特別発注が必要な場合があります。炭素鋼やアクリルなどの標準素材は通常、在庫から出荷されます。

- 現在の生産待ち行列: 繁忙期の工場ではバックログが長くなる傾向があります。業界ガイドラインによると、納期が重要な場合は常に現在の生産能力について確認することが推奨されます。

- 仕上げ工程: 粉体塗装、溶接、組立その他の二次加工は、それぞれ処理日数を要します。単純な切断のみの注文は、複数の仕上げ工程を要するものより早く出荷できます。

- 品質要件: 厳しい公差を要する部品は追加の検査時間が必要で、複数回の検証測定を要する場合があります。

一般的なリードタイムは、切断のみの簡単な作業で3〜5営業日、仕上げ加工を伴う複雑な部品で2〜3週間です。急ぎサービスも存在しますが、プレミアム料金が発生し、標準料金より50%以上高くなることがあります。

期待すべき品質保証の取り組み

信頼できるレーザー切断サービスは、ただ切断して出荷するだけではありません。部品が工場から出荷される前に、結果を検証します。

寸法検証: 重要な寸法は、キャリパー、マイクロメーター、または三次元測定機を使って、お客様の仕様と照合して測定されます。これにより、部品が意図した通りに適合し、正常に機能することが確認されます。

切断面品質の検査: オペレーターは、切断エッジに過剰なドロス、バリ、あるいは熱による変色がないかを点検します。清潔なエッジは、適切な機械設定と材料取り扱いが行われていることを示しています。

視覚検査 表面の傷、材料の欠陥、取り扱いによる損傷は、出荷前に発見されます。基準を満たさない部品は再切断されるか、拒否されます。

初めてオンラインのレーザー切断サービスを利用する際は、大量注文を行う前に少量のテスト生産を注文することを検討してください。これにより、大きな材料投資のリスクを冒すことなく、業者の品質基準がご期待に沿っているか確認できます。

受注から納品までのプロセスを明確に理解することで、さまざまな業界がレーザー切断技術をどのように活用しているかを探り、次のプロジェクトのアイデアを見つける準備が整います。

レーザー切断に依存する業界とその応用分野

発注プロセスの仕組みを理解した今、実際に何が可能であるかを探ってみましょう。異なる業界が産業用レーザー切断をどのように活用しているかを知ることで、自身のプロジェクトのためのアイデアが湧き上がってくるかもしれません。また、この技術が最適な選択となる場面を認識するのにも役立ちます。自動車用ブラケットから建築用外装まで、精密さが求められるほぼすべての分野で、レーザー加工は活用されています。

レーザーによる金属切断の汎用性は、単純な平面部品以上の広がりを持っています。据え Accurlの業界分析 によると、レーザー技術は数十もの業界の製造工程を変革し、かつて不可能だったか、非常に時間がかかるとされていた精度を実現しています。レーザー切断部品が最も大きな影響を与えている分野を見てみましょう。

自動車および産業用アプリケーション<br>

現代の自動車製造工場を訪れると、生産のほぼすべての工程でシートメタルのレーザー切断を見ることができます。自動車業界では、狭い公差と大量生産における再現性を兼ね備えた部品が求められており、まさにレーザー技術がその要件を満たしています。

自動車用の典型的なレーザー切断部品には以下のようなものがあります:

- シャーシ用ブラケットおよび取付プレート: サスペンションシステム、エンジンマウント、ボディパネルを接続する構造部品は、数千個のユニットにおいても正確な穴位置と寸法の均一性が要求されます。

- ボディパネルおよびトリム部品: ライトや通気口、アクセスポイント用の複雑なカーブや切り抜きは、仕上げ加工を最小限に抑えるきれいな切断エッジで加工されます。

- ヒートシールドおよび排気系部品: これらは高温材料にも対応しつつ、複雑な形状周りへの精密なフィッティングが求められます。

- 内装トリムおよびダッシュボード部品: 複雑な模様やロゴを施した装飾パネルは、工具交換なしで詳細なデザインを切断できるレーザーの特性からメリットを得ています。

- 電気ブラケットおよびバッテリー外装: 電気自動車の製造は特に、バッテリー用ハウジングや電気部品取り付け用の金属板の精密レーザー切断に依存しています。

自動車用途において特に興味深いのは、レーザー切断が他の製造工程とどのように統合されるかです。精密にレーザー切断された部品は、シャシーおよびサスペンションシステムにおいてスタンピング部品と頻繁に組み合わされます。単一のアセンブリには、スタンピングされた鋼材補強材に溶接されたレーザー切断ブラケットが含まれ、その後最終形状に曲げ加工され、粉体塗装が施されることがあります。

IATF 16949認証品質および統合金属加工能力を必要とする製造業者にとって、相補的なサービスを提供するパートナーを見つけることが不可欠になります。例えば シャオイ (寧波) メタルテクノロジー のような企業は、完全な自動車部品ソリューション向けに、レーザー切断サービスが金属スタンピングとどのように補完し合うかを示しています。同社の5日間での迅速な試作および自動化された量産体制は、自動車サプライチェーンを効率化する統合型製造のあり方を体現しています。

自動車以外にも,産業用アプリケーションは,非常に幅広い範囲をカバーしています.

- 農業機器: 荒野 の 厳しい 状況 に 耐え られる プレート,固定 支架,機械 の 保護 装置 を 履く

- 重機械: 製造機器のための構造部品,保護具,およびカスタム固定装置

- 管のレーザー切断サービス 枠,ロールケージ,構造組成物 の 丸型,四角型,長方形 の 管 を 切る 専用 システム

電子機器およびエンクロージャー製造

電子機器産業は,レーザー切削サービスのもう1つの主要消費者を代表しています. 小型化傾向は,ますます厳しい耐性を要求し,熱管理の必要性は複雑な囲い設計を推進します.

電子機器の一般的な用途には,以下のものがある.

- 装置のキャビネットとシャシー: 精密に配置された換気パターンと設置穴を持つサーバーラック,制御箱,計器具のホース

- 熱吸収器具と熱管理部品: 放熱を最大化するために表面積を広げる複雑なフィンパターン

- EMIシールド: 電磁干渉を防止するための精密カット金属バリア

- PCBステンシル: 基板製造におけるはんだペースト塗布に使用される超薄型のステンレス鋼製テンプレート

- コネクターブラケットおよび取付用ハードウェア: デバイス内部でコネクターおよびケーブルの位置を決める小型で高精度な部品

業界専門家によると、電子機器業界はミリ単位のわずかな誤差が部品の適合性や機能に大きな影響を与えるため、精密切断技術に大きく依存している。

クリエイティブおよび建築用途

産業用製造の枠を超えて、レーザー切断は芸術的表現や建築デザインの革新を実現するツールとなっている。この技術により、看板、インテリアデザイン、建物の外装において可能なことが再定義された。

看板およびブランド関連用途:

- 立体文字: 鋼材、アルミニウム、アクリルを切断して作られ、平面のグラフィックでは実現できない奥行きと影の効果を生み出します

- 照光看板: バックライトはレーザー切断されたスチールパネルを、印象的なブランド表示に変えることができます

- 装飾パネル: 金属にカスタムパターンを切断することで、光を透過させ空間を区画するスクリーン、間仕切り、特徴的な壁面を作成できます

- フロントデスクの構成要素: ブランドのパターンやロゴを家具構造体に直接組み込むことができます

建築およびインテリアデザイン用途:

- 建物外観の構成要素: 光、換気、視覚的プライバシーを調整しながら独自の美観を創出する穿孔金属パネル

- 手すりおよび欄干: 安全性と芸術的なデザインを組み合わせた装飾用金属製品

- 空間仕切り: 自立式または天井取り付けのスクリーンで、光を遮ることなくオープンフロアを整理します

- オーダーメイド家具部品: テーブルベース、棚受け金具、装飾用ハードウェア

建築用途における金属板のレーザー切断では、RAL規格のカスタムカラーによる粉体塗装がよく行われ、デザイナーが任意のカラーパレットに合わせることが可能になります。そのため Icon Modernの備考 、ほぼすべてのデザインファイルをアップロードして、ブランド表現から複雑な装飾パターンまで、カスタムスチール部品に変換できます。

プロトタイピングと製品開発

おそらくどの応用分野よりも、プロトタイピングがレーザー切断の価値を明確に示しています。この技術は、デジタル設計と現実の物体との間のギャップを、他のほぼすべての方法よりも迅速に埋めることができます。

なぜプロトタイピングがレーザー切断に依存するのか:

- 速度: 金型が不要なため、CADファイルから物理的なプロトタイプまでの作成が数週間ではなく数時間で可能になります

- 柔軟性: 設計の反復も初期製作と同コスト—新しいファイルをアップロードするだけです

- 材料の種類: 3Dプリントによる近似モデルではなく、量産品と同等の素材で形状と適合性をテストできます

- 精度: プロトタイプの寸法は量産仕様に一致するため、信頼性の高い適合テストが可能です

一般的なプロトタイピングの用途には以下が含まれます:

- 機能モデル: 量産用金型の製作前に、機械的コンセプトを検証する動作するプロトタイプ

- 適合および組立テスト: 実際のアセンブリにおいて部品がどのように相互作用するかを確認すること

- クライアントへのプレゼンテーション: レンダリングよりもデザインの意図を伝える物理サンプル

- 小ロット生産: 生産ツールが開発される間,橋の製造

アクルルの研究によると,レーザー切断が迅速かつ正確に部品を生産する能力は,リサーチ&開発の繰り返しのプロセスにおいて重要な役割を果たし,新しい技術と製品の開発を推進しています.

レーザー 切断 が 他 の プロセス と 統合 さ れる 方法

レーザー切断部品は 追加操作なしで 直接船を運ぶことは滅多にありません レーザー切削が 幅広い製造作業流に どう組み込まれているか 理解することで 完全なプロジェクトを 計画できます

共通副業は以下の通りである.

- 曲げおよび成形: プレスブレーキやロール形成機器を使用して,レーザーで切断された平らな空白は三次元形に曲がります

- 溶接と組み立て レーザー 切断 部品 を 数つ 組み合わせ て MIG,TIG,または 点 溶接 を 通し て 複雑な 組成 物 に する

- 糸とハードウェアの挿入: レーザーで切った穴には,スレッドや押された固定装置が付いている

- 表面加工: 粉体塗装、塗装、陽極酸化処理、またはめっきにより、完成品部品を保護し、美観を向上させます

- バリ取りおよびエッジ仕上げ: 安全上または外観上の理由から、小さなバリを取り除いたりエッジを丸く仕上げたりします

この統合機能により、レーザー切断は現代のものづくりにおいて中核的な工程となっています。レーザー切断に加えて曲げ加工、溶接、仕上げを提供する単一のプロバイダーは、単なる切断素材ではなく完成したアセンブリを納入できるため、サプライチェーンを効率化し、調整の手間を軽減できます。

レーザー切断が各業界でどのように優れた成果を上げているかを理解すれば、自社のプロジェクトがこれらの実績ある用途に適しているかどうかを評価でき、設計を現実のものとするために最適なプロバイダーを選択する準備も整います。

プロジェクトに最適なレーザー切断プロバイダーの選定

アプリケーションを検討し、価格体系を理解し、発注プロセスで何を期待すべきかを把握しました。しかし、最終的に成功を決めるのは次の問いです:優れた金属レーザー切断サービスと平凡なサービスをどう見分けるかです。地元の加工店から全国展開するオンラインプラットフォームまで、数百もの事業者がビジネスを獲得しようとしている中で、正しい選択をするには、単に価格の比較だけでは不十分です。

選択した業者は、プロジェクトの成功または失敗においてパートナーとなります。LS Precision Manufacturingによると、間違ったサプライヤーを選ぶことで、納期の遅延、品質のばらつき、契約後に明らかになる隠れたコストといったリスクが生じ、プロジェクトが危険にさらされます。投資を守り、成果を確実に得られるよう、精密レーザー切断サービスを評価するための実用的なフレームワークを構築しましょう。

発注前に必ず確認すべき重要な質問

ファイルをアップロードしたり見積もりを依頼する前に、サプライヤーの真の能力を明らかにする重要な情報を収集してください。これらの質問により、プロジェクトの途中で対応に追われるような企業ではなく、本格的な候補者とそうでない企業を区別できます。

設備および能力:

- 使用しているレーザーの種類はどれですか?(ファイバーレーザーは金属加工に優れています。CO2 レーザーはプラスチックや有機物の加工に適しています)

- 最大加工面積および取り扱い可能な材料の厚さはどのくらいですか?

- 設備の使用年数はどれくらいですか?また、メンテナンススケジュールはどのようなものですか?

- 私の指定する材質および厚さに対応できますか?

品質および認証:

- 保有している品質認証はありますか?(ISO 9001が基本ですが、自動車業界ではIATF 16949、航空宇宙業界ではAS9100が重要です)

- 保証できる寸法公差はどのくらいですか?

- 出荷前の完成品の検査はどのように行っていますか?

- 材質の認証書や試験成績書を提供していただけますか?

に従って Rache Corporation 、認証は単なる書類ではなく、品質、正確さ、および業界標準への遵守に対する取り組みを示しており、それが直接的に信頼性の高い結果につながります。自動車用途においては、IATF 16949 認証が、業界の厳しい要件を満たす製品を一貫して提供する能力を示しています。

サービスとサポート:

- 通常の見積もり対応時間はどのくらいですか?

- 製造性を考慮した設計(DFM)に関するフィードバックを提供していますか?

- 技術的な質問には、営業担当者とエンジニアのどちらが対応しますか?

- 設計変更が必要になった場合の修正ポリシーはどのようなものですか?

これらの回答により、製造の複雑さを理解するカスタム金属レーザー切断のパートナーと取引しているのか、それとも単にソフトウェアでファイルを処理する機械オペレーターと取引しているのかが明らかになります。

必須機能とできれば良い機能

すべての機能が同等に重要というわけではありません。プロジェクトの成果に直接影響を与える機能に評価の重点を置くべきです。

必須機能:

- 素材に適したレーザー技術: 金属にはファイバーレーザー、非金属にはCO2レーザー——不適切な技術では品質の低い結果になります

- 十分なベッドサイズおよび厚さ対応能力: 部品は機械の物理的な制限内に収まる必要があります

- 文書化された品質プロセス: 部品に対する検査手順、寸法検証およびトレーサビリティ

- 明確なコミュニケーション手段: 技術的な質問に適切な時間内に回答できる連絡担当者

- 透明性のある価格設定: 材料費、切断費、仕上げ費用を個別に明記した詳細な見積もり

- 現実的な納期: 現在の生産待ち行列を考慮した、現実的な納入予定日

あると便利な機能:

- 即時オンライン見積もり: 便利だが必須ではない—手動での見積もりは、自動システムが見逃すエラーを検出できることが多い

- 社内での二次加工: 曲げ加工、溶接、仕上げを一括で行えることで、サプライチェーンが効率化される

- 材料の備蓄: 在庫材料は、都度発注と比べて納期を短縮できる

- 急ぎ対応オプション: 緊急時には有効だが、通常の運用モードとしては避けるべき

- 現地引き取りの可否: 近隣のお客様の場合、輸送費と時間を節約できる

信頼できない業者を示す赤信号

場合によっては、プロバイダーが言わないことの方が、彼らのマーケティング上の約束よりも重要であることがあります。将来の問題を示す警告サインに注意してください。

価格に関する懸念:

- 市場相場を著しく下回る見積もり: 業界専門家によると、低価格帯または旧式の装置は動的性能が低く、形状誤差が生じてロット単位での廃棄が必要になることがあります。その安価な見積もりは、結果として高額な手直しにつながることが多いのです。

- あいまいな、または包括された価格体系: 各内訳項目の内容を明確に説明できないのであれば、後で予期せぬ追加費用が発生すると考えてください。

- セットアップ料金についての言及がない: セットアップ費用はどこにでも発生するものです。もし開示されていないなら、他の部分に隠されていると考えてください。

コミュニケーションの問題:

- 見積もりに対する返答が遅い: 価格の提示に1週間かかるのであれば、生産中に問題が発生した際に回答を待つ時間を考えると想像がつくでしょう

- 技術的知識のない営業担当者が仕様を扱っている: あなたと製造現場との間で誤解が生じると、高額なエラーにつながります

- サンプルや実績の提示に消極的である: 品質を重視するサプライヤーは、自社の能力を検証することを歓迎します

能力の不足:

- 設備の詳細について話すことをためらう: 評判の良い工場は、自社の機械や能力を誇って説明します

- 品質認証がない: すべての作業にISO認証が必要というわけではありませんが、品質に関する文書が全く存在しないことは懸念材料です

- 非現実的な納期の約束: 不可能なほど短い納期を保証する業者は、現実が明らかになったときに納期を守れないことがよくあります

LS Precisionが指摘しているように、最も簡単な検証方法は工場を訪問するか、リアルタイムで作業風景の動画を確認することです。設備の状態、ワークショップの管理レベル、作業基準を直接観察することで、その業者の真の能力が明確になります。

地域のサービス vs オンラインプラットフォーム

「近くのレーザー切断」や「私の近くのレーザーカッター」と検索すると、伝統的な地域の加工業者と全国市場にサービスを提供するオンライン中心のプラットフォームという、2つの異なるカテゴリーの結果が得られます。それぞれのアプローチには考慮する価値のある正当な利点があります。

地域業者のメリット

- 対面でのコミュニケーション: 複雑なプロジェクトでは、対面での技術的な打ち合わせが有益です

- 迅速な出荷: 現地での引取により、輸送時間と送料が完全に不要になります

- 関係構築: 長期的なパートナーシップにより信頼が築かれ、優先対応されることがよくあります

- 問題解決が容易: 工場まで直接行くことができれば、問題はより迅速に解決されます

- 地域での責任の所在: 地域社会における評判が、高品質なサービスを提供する動機になります

オンラインプラットフォームの利点

- より広範な能力: 全国規模のプラットフォームは、地域の工場では採算が取れない特殊な設備に投資していることが多いです

- 競争力のある価格設定 大量の取引によって規模の経済が実現され、部品単価を削減できます

- 即時見積もり: ファイルをアップロードすれば、すぐに価格が提示されます。迅速なプロトタイピングの意思決定に最適です。

- 24/7での利用可能: 営業時間に関係なく、いつでも注文を提出できます。

- 一貫したプロセス: 標準化されたワークフローにより、予測可能で再現性のある結果が得られます。

に従って FM Sheet Metal オンラインサービスは、需要に応じて生産量を柔軟に調整できるオンデマンド型サービスを提供するため、多くの場合、地元の企業よりも迅速かつ費用対効果が高いです。ただし、設計から納品まで一貫してサポートしてくれるフルサービス企業を選ぶことが重要です。

最適な選択は、お客様の優先事項によって異なります。明日中に自宅近くでレーザー刻印サービスを利用して急ぎの仕事を持ち帰りたい場合——その場合は地元の業者が有利です。一方、標準仕様の同じブラケットを500個発注する場合——オンラインプラットフォームの方が、価格も納期も優れている可能性が高いです。

プロトタイプと量産の検討事項

評価基準は、プロトタイプ開発を行うか、量産を行うかによって変えるべきです。

プロトタイプ作成の際は、以下の点を重視してください:

- スピードと柔軟性: 少量での迅速な納期と容易な設計の反復

- DFMフィードバック: 生産用金型への投資前に、製造上の問題点を特定できるエンジニア

- 最小発注数量の低さ: セットアップ費用が高額にならない単品注文

- 材料の種類: 異なるアプローチをテストするための複数の選択肢へのアクセス

量産の際は、以下の点を重視してください:

- 一貫した品質: 統計的工程管理および文書化された検査手順

- 生産能力とスケーラビリティ: 遅延なく貴社の生産量に対応可能な設備と人員

- コスト効率: 貴社の数量レベルに応じた競争力のある単価

- サプライチェーンの統合: 二次加工、キッティング、ジャストインタイム納品への対応能力

統合型製造パートナーの評価

認定品質と補完的な金属加工能力を必要とするメーカーにとって、評価は単なる切断工程を超えて広がります。最適なパートナーとは、生産の全工程にわたり必要なサービスを提供できる存在です。

以下のサービスを提供するサプライヤーを探しましょう。

- 複数の加工プロセス: レーザー切断に加え、スタンピング、曲げ、溶接、組立を一括して対応可能

- 包括的なDFMサポート: 生産開始前に、設計を生産性向上に向けて最適化するためのエンジニアリング支援

- 量産と並行した迅速な試作対応: コンセプト検証から本格的な量産まで、あらゆる段階でサポート可能な能力

- 業界固有の認証: 自動車用IATF 16949、航空宇宙用AS9100、医療機器用ISO 13485

統合製造パートナーを評価する際には、能力と同様に迅速な対応が重要です。12時間以内の見積もり返信や5日間での迅速なプロトタイピングといったベンチマークは、サプライチェーンの緊急性を理解しているサービス志向の運営を示しています。こうした基準は、「 シャオイ (寧波) メタルテクノロジー 」のような企業が維持しており、包括的なDFMサポートとIATF 16949認証は、自動車製造ワークフローを最適化する統合的アプローチを持っていることを示しています。

目的は、最も安価なサプライヤーや派手なウェブサイトを持つサプライヤーを見つけることではありません。むしろ、自社のプロジェクト要件に合致する能力、品質基準、およびサービス哲学を持つパートナーを特定することです。主張内容を検証し、サンプルを請求し、詳細な質問を行う時間を確保してください。サプライヤー評価への初期投資は、成功したプロジェクトと長期的な製造関係を通じてリターンとして還元されます。

レーザー切断サービスに関するよくある質問

1. レーザー切断の一般的な費用はいくらですか?

レーザー切断サービスは通常、機械稼働時間あたり50〜150ドルを請求します。最終的なコストは、素材の種類や厚さ、切断長さの合計、デザインの複雑さ、穴開け(ピアス)回数、および注文数量によって異なります。セットアップ費用は通常、1件あたり25〜75ドルです。シンプルな部品の場合、1個あたり5〜50ドル程度を見込むことができますが、仕上げ加工を必要とする複雑なデザインでは、さらに高額になることがあります。大量注文を行うことで、固定のセットアップ費用がより多くの部品に分散されるため、単価が大幅に低下します。

2. レーザー切断の費用はどのように計算されますか?

レーザー切断のコストは次の式に従います:最終価格 = 材料費 + 変動費 + 固定費、全体に利益率を乗算。主な変動費は機械稼働時間であり、これは総切断距離と穿孔数によって決定されます。材料の厚さは切断速度およびコストに指数関数的に影響します。設計の複雑さにより機械速度が遅くなり、時間が増加します。ほとんどのサービス提供業者は切断長さをインチまたはメートル単位で計算し、その後材料ごとの単価を乗算します。緊急注文、仕上げ工程、厳密な公差はいずれも基本切断コストに追加料金を加えます。

3. レーザー切断サービスの料金はいくらですか?

レーザー切断サービスの価格は、プロジェクトの詳細によって大きく異なります。シンプルなアクリル部品は1個あたり10〜30ドル程度ですが、高精度のステンレス鋼部品は1個あたり50〜200ドル以上になる場合があります。SendCutSendなどのオンラインプラットフォームでは即時見積もりが可能で、通常は切断長さに応じた料金に材料費を加算して課金されます。従来の加工業者は手動で見積もりを出し、量産向けには1個あたりの単価が安くなる場合があります。一部の見積もりには材料費が含まれているのに対し、他の業者は素材費用を別途請求するため、常に注意深く比較することが重要です。

4. レーザー切断サービスでは、どのようなファイル形式を受け付けていますか?

ほとんどのレーザー切断サービスでは、効果を含まない純粋なベクターデータを持つDXFファイルが業界標準として受け入れられています。特定の色分けで切断線とスコア線を指定できるため、Adobe IllustratorのAIファイルも良好に動作します。SVGファイルはウェブベースのアップロードポータルに適しています。EPSファイルも互換性がありますが、使用頻度はそれほど高くありません。一部のサービスでは、ベクトルデータを埋め込んだPDFファイルも受け付けています。彫刻(エンボス)加工の場合は、JPEGファイルを使用できますが、切断パスを作成することはできません。提出前に、必ずテキストをアウトライン化し、重複する線分を削除して、寸法を確認してください。

5. レーザー切断できる素材にはどのようなものがありますか?

レーザー切断は主に3つの材料カテゴリを扱います。金属には、炭素鋼(最大25mm)、ステンレス鋼(最大20mm)、アルミニウム(最大15mm)、およびファイバーレーザーを使用した真鍮や銅(最大10mm)が含まれます。CO2レーザーでクリーンに切断できるプラスチックにはアクリル、デルリン、ポリエステルがあります。特殊材料には天然木、合板、布地、植物なめし革が含まれます。安全上の危険性があるため、塩素ガスを発生させるPVC、シアン化物を発生させるABS、厚手のポリカーボネート、クロムなめし革、ガラス繊維(fiberglass)は避けてください。

少量のバッチ、高い基準。私たちの迅速なプロトタイピングサービスにより、検証がより速く簡単になります——

少量のバッチ、高い基準。私たちの迅速なプロトタイピングサービスにより、検証がより速く簡単になります——