aluminijum serije 7000: otključavanje izuzetnog odnosa čvrstoće i težine

KRATKO

алуминијум серије 7000, посебно легура 7075-T6, има један од највиших односа чврстоће према тежини међу свим алуминијумским легурама. Ова изузетна карактеристика дефинише се типичном крајњом чврстоћом на затег од око 572 MPa (83.000 psi) у комбинацији са ниском густином од приближно 2,81 g/cm³. Ова јединствена комбинација чини га незаобилазним материјалом за примену у условима високог напона и где је критична тежина, првенствено у аерокосмичкој, одбрамбеној и индустрији спортске опреме високих перформанси.

Разумевање односа чврстоће према тежини

У науци о материјалима и инжењерству, однос чврстоће према тежини је кључни параметар за процену ефикасности материјала. Познат и као специфична чврстоћа, овај параметар мери колико оптерећења материјал може да издржи у односу на своју масу. Виши однос указује на материјал који је истовремено јачи и лакши, што је веома пожељна карактеристика у бројним применама где су перформансе и ефикасност од пресудног значаја.

Израчунавање овог односа је једноставно: чврстоћа материјала (обично његова крајња чврстоћа на затег) дели се са његовом густином. Добијена вредност омогућава инжењерима да упореде различите материјале на исти начин. На пример, иако неке легуре челика имају већу апсолутну чврстоћу од алуминијума, њихова густина је скоро три пута већа, због чега често имају нижи однос чврстоће према тежини. Због тога су материјали као што је серија 7000 алуминијума од суштинског значаја за изградњу бржих авиона, возила са бољом потрошњом горива и лакше опреме за високе перформансе.

Техничка својства алуминијума серије 7000

Алуминијумске легуре серије 7000 добијају своју изузетну чврстоћу првенствено због цинка као главног легирног елемента, често у комбинацији са магнезијумом и бакром. Легура 7075 је најзначајнији члан ове серије, нарочито у стању Т6 (решење топлотне обраде и вештачко старење), што значајно побољшава њене механичке карактеристике. Овај процес топлотне обраде од суштинског је значаја за постизање високих нивоа чврстоће због којих је серија позната.

Кључне механичке карактеристике дефинишу перформансе ових легура под напоном. Увршња чврстоћа на истезање (УТС) је максимални напон који материјал може да издржи док се истеже или повуче пре него што се прекине. Чврстоћа при затезању је тачка у којој материјал започиње трајно деформисање. За високоперформанску легуру као што је 7075-Т6, ове вредности су изузетно високе за лаки метал. Подаци испод, преузети из водећих база података о материјалима и индустријских добављача, истичу могућности кључних легура серије 7000.

| Легура и стање | Увршња чврстоћа на истезање (УТС) | Чврстоћа при затезању | Плотност |

|---|---|---|---|

| 7075-T6 | 572 MPa (83,000 psi) | 503 MPa (73,000 psi) | 2,81 g/cm³ |

| 7085 | Није наведено; принос је примарни параметар | 503 – 510 MPa (72.950 – 73.970 psi) | ~2,82 g/cm³ |

| 7050 | Није наведено; принос је примарни параметар | 390 – 500 MPa (57.000 – 72.500 psi) | ~2,83 g/cm³ |

Подаци синтетизовани из MatWeb и CEX Casting .

Импресивни подаци за легуру 7075-Т6 посебно показују због чега се често пореди са неким врстама челика по питању чврстоће, али само са трећином тежине. Због тога је овај материјал први избор када не може доћи до компромиса у погледу перформанси. Међутим, важно је напоменути да ова висока чврстоћа може имати своје мане, као што су нижа отпорност на корозију у односу на легуре серије 6000 и смањена заварљивост.

Кључне примене засноване на високом односу чврстоће и тежине

Изузетна специфична чврстоћа алуминијума серије 7000 директно омогућава његову употребу у неким од најзахтевнијих инжењерских области. Његова својства нису само предност; често су основни услов за постизање модерних стандарда перформанси.

У аеропростор и одбрамбена индустрија , легуре серије 7000 су незамењиве. Легуре као што су 7075 и 7050 се интензивно користе за кључне структуралне делове као што су оквир фуселажа авиона, крилна репла и делови стајног трапа. У овим применама, сваки килограм уштеде масе директно се преводи у већу носивост, дужи домет и бољу ефикасност потрошње горива. Способност материјала да издржи велики напон и замор услед цикличног оптерећења осигурава безбедност и поузданост авиона током целокупног века трајања.

У аутомобилски сектор , посебно у возилима високих перформанси и електричним возилима, такође користе ове легуре како би смањиле укупну масу. Олакшана возила брже убрзавају, имају бољу управљивост, а у случају ЕВ-ова, постижу већи домет по пуњењу. За аутомобилске пројекте који захтевају прецизно конструисане делове, размотрите произвољне алуминијумске екструзије од провереног партнера. Shaoyi Metal Technology нуди комплексну једнокорачну услугу, од брзог израдјивања прототипова до потпуне производње у оквиру строгог система квалитета сертификованог према IATF 16949, специјализован за јаке, лагане делове прилагођене тачним спецификацијама.

Поред транспортних средстава, алуминијум серије 7000 користи се и у висококвалитетним спортским производима . Рамови за високоперформанске бицикле, опрема за пењање на стене и ланчаници за теренска возила често су направљени од алуминијума 7075 како би обезбедили максималну чврстоћу са минималном тежином, давши такмичарима предност. У свим овим применама, висок однос чврстоће према тежини је одлучујућа карактеристика која подстиче иновације и перформансе.

Упоредна анализа: серија 7000 против других материјала

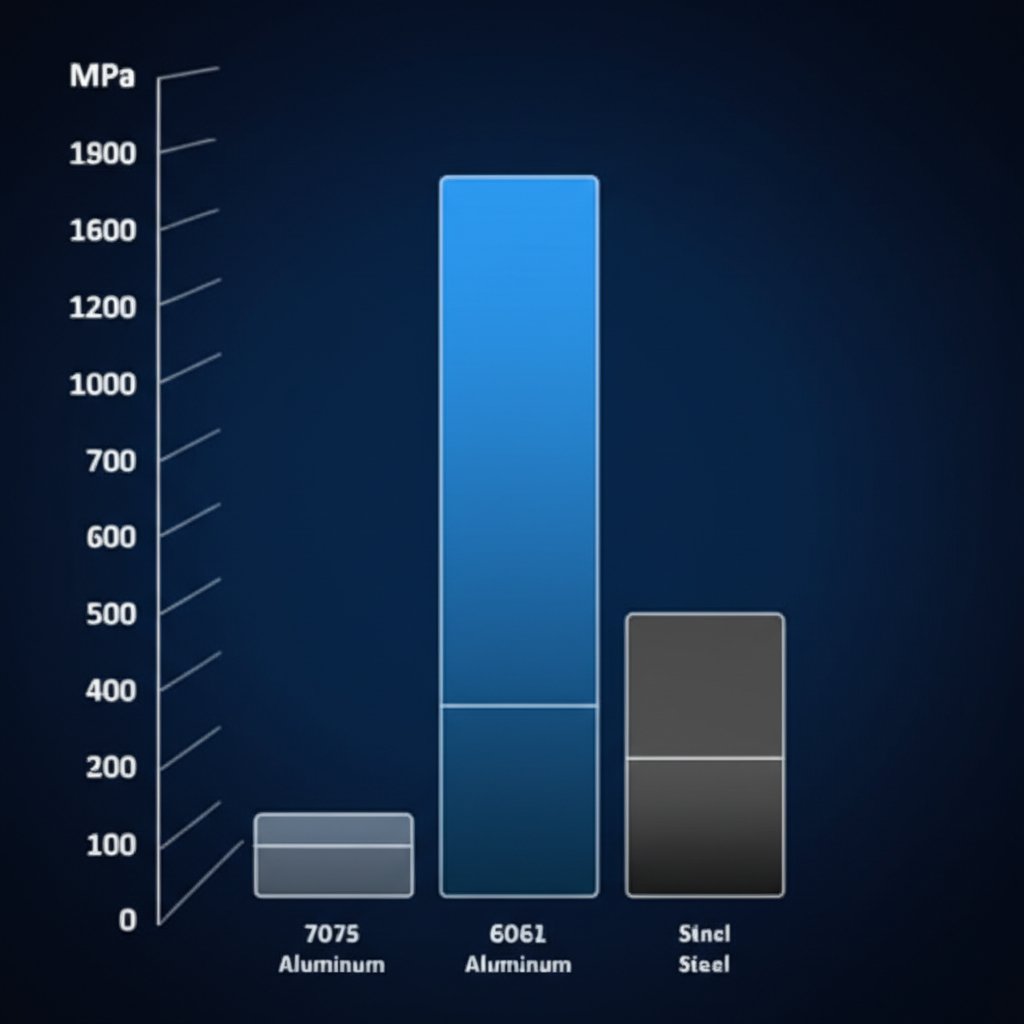

Да би се у потпуности оценила вредност алуминијума серије 7000, корисно је упоредити однос чврстоће и тежине са другим уобичајеним инжењерским материјалима. Иако је апсолутна чврстоћа важна, специфична чврстоћа често пружа релевантнију слику за примене где је тежина први критеријум. Следећа табела пружа јасну упоредбу.

| Материјал | Типична затегнута чврстоћа (MPa) | Густина (г/см3) | Однос чврстоће и тежине (kNm/kg) |

|---|---|---|---|

| Алуминијум 7075-T6 | 572 | 2.81 | ~203 |

| Aluminijum 6061-T6 | 310 | 2.70 | ~115 |

| Мека челик | 370 | 7.85 | ~47 |

| Титанијум (Ti-6Al-4V) | 900+ | 4.43 | ~203+ |

Подаци синтетизовани из Yaji Aluminum и други извори из индустрије.

Kao što tabela pokazuje, aluminijum legura 7075-T6 nudi specifičnu čvrstoću koja je skoro dvostruko veća od često korišćene legure 6061-T6 i više od četiri puta veća od mehkog čelika. Ovo objašnjava zašto jednostavna zamena jačim, ali težim materijalom poput čelika često nije izvodljivo rešenje za izazove u konstrukciji lakih struktura. Iako neke legure titanijuma mogu da nadmaše ili bar dosegnu odnos čvrstoće i težine legure 7075-T6, one su znatno skuplje po pitanju materijala i procesne obrade, što ograničava njihovu upotrebu na najzahtevnije primene u pogledu performansi. Za veliki broj konstrukcija sa visokim naponima, aluminijum legure serije 7000 nudi optimalnu ravnotežu između performansi, obradivosti i cene.

Често постављана питања

1. Kolika je čvrstoća aluminijuma serije 7000?

Čvrstoća aluminijuma serije 7000 varira u zavisnosti od legure i termičke obrade, ali poznata je kao jedna od najjačih dostupnih legura aluminijuma. Najčešća legura visokih performansi, 7075-T6, ima tipičnu zateznu čvrstoću na kidenje od 572 MPa (83 000 psi) i granicu elastičnosti pri zatezanju od 503 MPa (73 000 psi). Druge legure u seriji, kao što je 7085, imaju minimalne vrednosti granice elastičnosti u opsegu od 503–510 MPa.

Mali serijski izlozi, visoki standardi. Naša usluga brzog prototipiranja omogućava bržu i jednostavniju validaciju —

Mali serijski izlozi, visoki standardi. Naša usluga brzog prototipiranja omogućava bržu i jednostavniju validaciju —