Metal Laser Cutting Service Secrets: From Design File To Delivered Parts

What Metal Laser Cutting Actually Does to Your Material

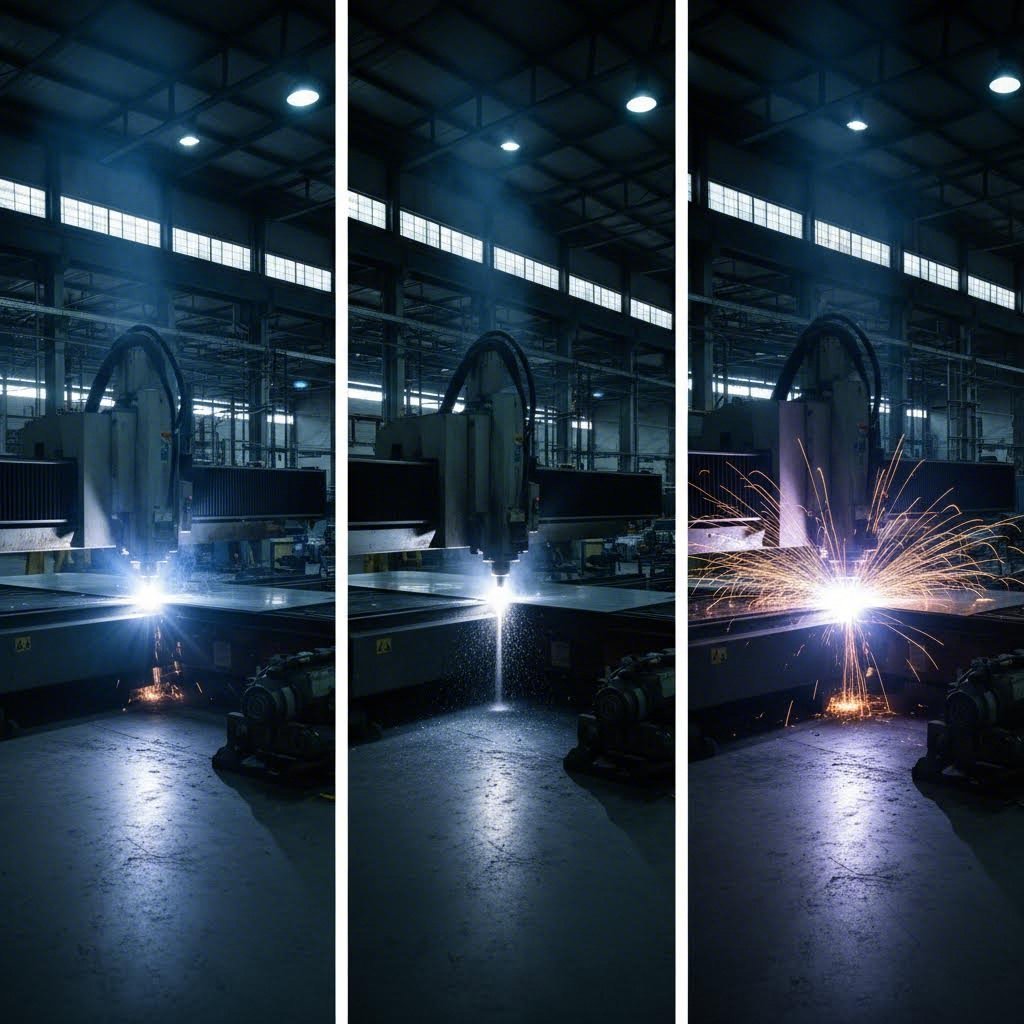

Ever wondered how a beam of light can slice through solid steel like butter? A metal laser cutting service uses highly concentrated light energy to melt, vaporize, or burn through metal along computer-controlled paths. Imagine focusing sunlight through a magnifying glass, but amplified millions of times and guided with pinpoint accuracy. That's essentially what happens when a laser that cuts metal goes to work on your raw material.

The process begins when a laser beam, often less than 0.32 mm in diameter, focuses on the metal surface. This creates temperatures intense enough to either melt or completely vaporize the material. According to Wikipedia's documentation on laser cutting, the focused beam can achieve kerf widths as small as 0.10 mm, enabling incredibly precise cuts that traditional machine cutter metal tools simply cannot match.

How Laser Beams Transform Raw Metal into Precision Parts

When the laser beam hits metal, something remarkable happens. The concentrated energy heats the surface to its flashpoint, creating what engineers call a "keyhole." This keyhole rapidly deepens as the material boils, and the vapor pressure blows molten metal away from the cutting zone. High-pressure gas jets assist this process, clearing debris and leaving behind clean, precise edges.

What makes metal laser cutting so effective? The heat-affected zone remains incredibly small. Unlike plasma or traditional cutting methods, this precision means minimal warping and distortion of your workpiece. You'll notice that parts come out ready for assembly or finishing with little to no secondary processing required.

Modern cutting laser metal systems operate with positioning accuracy of approximately 10 micrometers and repeatability of 5 micrometers. This level of precision makes laser metal cutting ideal for applications ranging from intricate electronics components to heavy-duty automotive parts.

The Science Behind Thermal Cutting Technology

Not all lasers work the same way. Understanding the three main laser cutting methods helps you communicate effectively with your service provider:

- Fiber Lasers: These solid-state systems generate beams through specially designed glass fibers. With wavelengths of 1.064 micrometers, they produce focal spots up to 100 times smaller than CO2 lasers. According to Trotec Laser, fiber lasers are maintenance-free with service lives exceeding 25,000 hours, making them the go-to choice for high-volume metal cutting operations.

- CO2 Lasers: Gas-based systems using carbon dioxide mixtures stimulated electrically. Operating at 10.6-micrometer wavelengths, they excel with non-metallic materials but can cut metals including titanium, stainless steel, and aluminum when equipped with sufficient power.

- Crystal Lasers (Nd:YAG/Nd:YVO): Solid-state lasers using neodymium-doped crystals. These share the same wavelength as fiber lasers but require more maintenance, with pump diodes needing replacement every 8,000 to 15,000 hours.

Today's leading metal laser cutting services increasingly rely on fiber optic technology. Systems running at 6kW and higher are now approaching the cutting capabilities of plasma machines while maintaining superior precision. This advancement means thicker materials can be processed with excellent edge quality, something that was impossible with earlier 1,500-watt systems.

The bottom line? When you submit a design to a professional service, sophisticated physics and engineering work together to transform your digital file into precision metal parts with tolerances often within 0.025 mm.

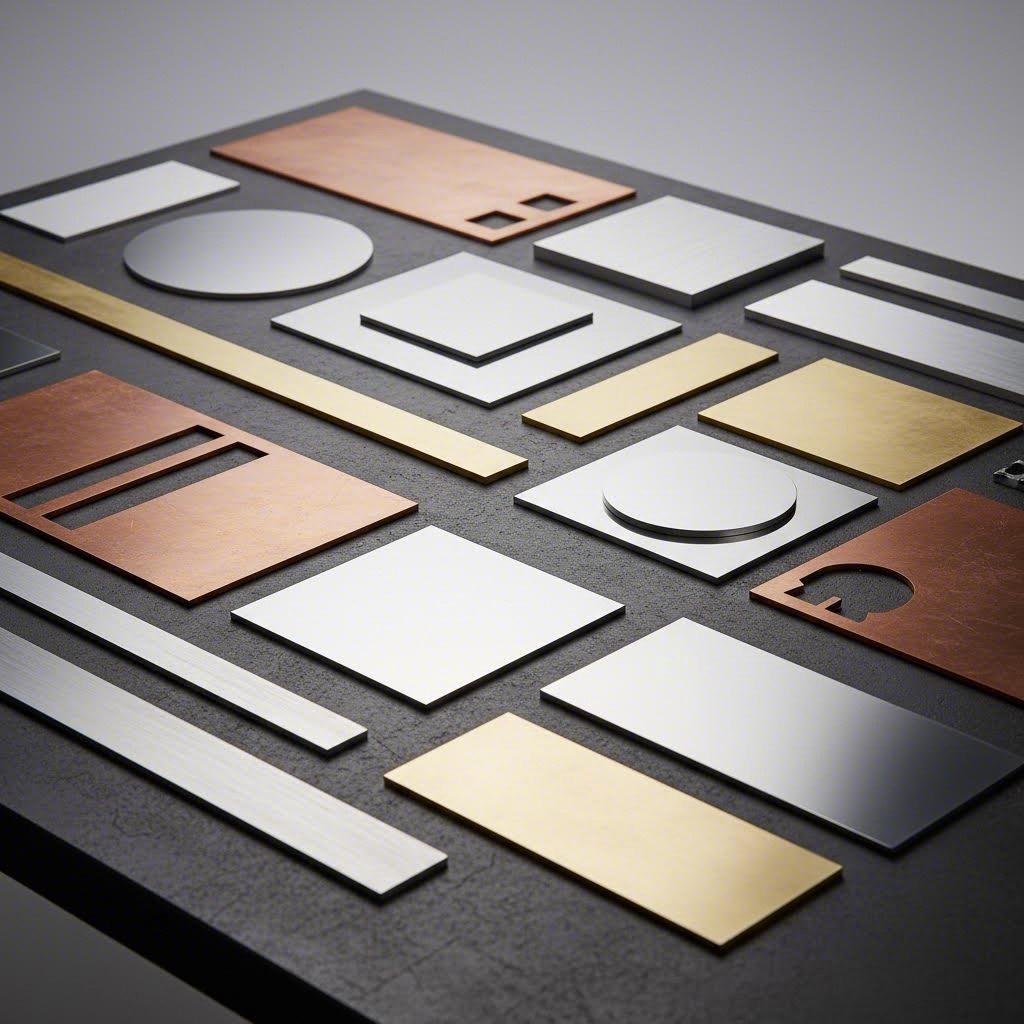

Materials You Can Process Through Laser Cutting Services

Sounds complex when someone says they can laser cut metal across dozens of different alloys? The reality is that not all metals behave the same under that concentrated beam of light. Some absorb energy efficiently and cut like a dream. Others fight back, reflecting the beam and conducting heat away from the cut zone. Understanding these material-specific behaviors helps you choose the right metal for your project and communicate effectively with your service provider.

Quality metal laser cutting services maintain extensive material inventories covering everything from common carbon steel to exotic specialty alloys. Each material presents unique characteristics that affect cutting speed, edge quality, and overall project cost. Let's break down what happens when different metals meet the laser beam.

Steel and Stainless Steel Cutting Characteristics

Steel remains the workhorse of laser cutting metal operations. Carbon steel absorbs laser energy efficiently, making it one of the easiest materials to process. You'll notice clean edges, minimal dross buildup, and fast cutting speeds across most thickness ranges.

When it comes to stainless steel laser cutting, the process requires slightly more power due to the material's thermal properties. Stainless steel doesn't conduct heat as readily as aluminum or copper, which actually works in your favor. The heat stays concentrated in the cut zone, enabling precise kerf lines and excellent edge quality. Common grades like 304 and 316 stainless laser cutting are routine operations for experienced fabricators.

Steel laser cutting typically uses oxygen as an assist gas for carbon steel, creating an exothermic reaction that adds cutting energy. For laser cut stainless steel applications where oxidation-free edges matter, nitrogen gas produces bright, clean cuts ready for welding or visible installations.

Working with Reflective Metals Like Aluminum and Brass

Here's where things get interesting. Laser cut aluminum presents challenges that catch many newcomers off guard. Aluminum's high reflectivity means a significant portion of laser energy bounces off the surface instead of penetrating the material. According to 1CutFab's technical analysis, this reflection causes three major issues: incomplete cuts, energy loss requiring multiple passes, and potential damage to laser optics from back-reflected beams.

Modern fiber lasers have largely solved the aluminium laser cutting challenge. Their 1.07-micrometer wavelength couples much better with reflective surfaces than older CO2 technology. Still, cutting aluminum requires higher power settings and careful parameter tuning. Nitrogen assist gas prevents oxidation and produces the bright edges that aluminum applications typically demand.

Brass and copper belong to what fabricators call the "Red Metals" category. These materials push laser cutting to its limits. YIHAI Laser's technical documentation explains that copper has thermal conductivity approximately eight times higher than steel. Heat literally races away from the cut zone, making it difficult to maintain the stable melt pool needed for clean cuts.

Pure copper requires aggressive parameters: maximum power, fast pierce times, and high-pressure nitrogen (18-22 Bar). Even experienced operators approach copper with respect. Brass behaves differently despite looking similar. Its zinc content (30-40%) creates vapor pressure during cutting that actually helps eject molten material. However, this zinc also produces toxic fumes requiring robust extraction systems.

| Material Type | Typical Thickness Range | Cutting Quality | Special Considerations |

|---|---|---|---|

| Carbon Steel | 0.5mm - 25mm | Excellent; clean edges with minimal dross | Oxygen assist gas adds cutting energy; most cost-effective option |

| Stainless Steel | 0.5mm - 20mm | Very good; bright edges with nitrogen | Requires more power than carbon steel; nitrogen prevents oxidation |

| Aluminum | 0.5mm - 15mm | Good with proper settings | High reflectivity requires fiber lasers; higher power settings needed |

| Brass | 0.5mm - 10mm | Good; may require edge finishing | Zinc vapor creates fumes; robust extraction required; volatile cutting behavior |

| Copper | 0.5mm - 8mm | Challenging; dross common | Highest difficulty; extreme thermal conductivity; requires maximum power and fast processing |

| Specialty Alloys | Varies by alloy | Application-dependent | Titanium, Inconel, and tool steels each require specialized parameters |

Specialty alloys like titanium, Inconel, and tool steels each demand custom parameter development. Titanium cuts relatively well with nitrogen assist but requires careful attention to prevent oxygen contamination that affects material properties. These materials typically cost more to process due to slower cutting speeds and specialized setup requirements.

When requesting quotes, always specify your exact material grade. A 6061-T6 aluminum behaves differently than 5052. Similarly, 316L stainless steel processes differently than 17-4 PH. The more precise your material specification, the more accurate your quote and the better your final parts will turn out.

Thickness Capabilities and Precision Standards Explained

When you submit a design file to a metal laser cutting service, thickness matters more than you might expect. It affects everything from cutting speed to edge quality, and ultimately, whether your parts will meet dimensional requirements. Yet this critical information often gets buried behind instant quote buttons without explanation. Let's change that.

Understanding thickness capabilities and precision tolerances helps you design smarter, set realistic expectations, and communicate effectively with your fabricator. Whether you're working with thin gauge sheet metal laser cutting or pushing into thicker plate territory, these specifications directly impact your project success.

Understanding Thickness Limits for Different Metals

Every metal has a practical maximum thickness that a laser can cut cleanly. Push beyond these limits, and you'll encounter incomplete penetration, excessive dross buildup, and compromised edge quality. According to Accurl's technical specifications, the most powerful fiber laser cutting machines can achieve maximum thicknesses up to 50mm for certain metals, though practical limits for quality cuts typically fall below these maximums.

Laser power directly determines what thickness you can cut. A sheet metal laser cutting machine running at 6kW offers dramatically different capabilities than a 1kW system. Here's what you can expect from a 6kW fiber laser cutter:

- Carbon Steel: Up to 25mm maximum cutting thickness

- Stainless Steel: Up to 20mm maximum cutting thickness

- Aluminum: Up to 15mm maximum cutting thickness

- Copper: Up to 8mm maximum cutting thickness

Why does material type create such variation? Thermal conductivity plays the starring role. When laser cutting steel sheet, heat concentrates efficiently at the cut zone. Copper, by contrast, wicks heat away rapidly, requiring more energy to maintain the cutting temperature. Reflective metals like aluminum also bounce laser energy away from the surface, further complicating thick section processing.

According to Senfeng Laser's technical documentation, 6kW fiber laser systems occupy a strategic sweet spot for metal fabrication. They process materials 50% faster than 4kW machines on medium-thin sheets while handling thicker metals that lower-powered systems simply cannot cut. This balance makes them increasingly popular among professional sheet metal laser cutter operations.

What Precision Tolerances Mean for Your Project

Precision isn't a marketing buzzword. It's a measurable specification that determines whether your parts fit together properly. When fabricators talk about tolerance, they're describing the allowable deviation from your specified dimensions. According to ADH Machine Tool's comprehensive analysis, high-end industrial laser cutting machines can maintain tolerances as tight as ±0.1mm, with fiber lasers achieving even tighter precision of ±0.05mm or ±0.025mm in precision laser cutting applications.

Here's what affects the tolerances you can actually achieve:

- Material Type: Metals with stable thermal properties like stainless steel produce more consistent tolerances than thermally conductive materials like copper or aluminum.

- Material Thickness: Thicker materials present exponentially greater challenges. Thin sheets under 3mm routinely achieve ±0.1mm tolerances, while cuts exceeding 15mm may widen to ±0.3mm or more due to beam divergence and heat accumulation.

- Machine Calibration: Motion system accuracy, optical alignment, and regular maintenance directly impact achievable precision. Linear motor drives achieve positioning precision of ±0.001mm, while ball screw systems typically reach ±0.005mm.

- Operator Expertise: Parameter optimization for specific material-thickness combinations requires experience. Skilled operators adjust power, speed, focus position, and assist gas pressure to extract maximum precision from the equipment.

Thickness creates the biggest tolerance challenge. As material gets thicker, several physical phenomena work against precision. The laser beam's Gaussian profile means it's inherently conical rather than perfectly parallel. In thick plate laser cutting of metal sheets, this creates measurable differences between top and bottom kerf widths, producing taper. Additionally, deeper kerfs make molten material ejection more difficult, potentially affecting edge quality.

Fiber optic technology at 6kW and above addresses many of these challenges. Higher power enables faster cutting speeds, which reduces overall heat input into the workpiece. Shorter wavelengths couple more efficiently with metals, creating narrower kerf widths and smaller heat-affected zones. Modern 6kW systems deliver edge quality on thicker materials that simply wasn't achievable with previous generation equipment.

What does this mean practically? For precision laser cutting of thin gauge materials, expect tolerances between ±0.05mm and ±0.1mm. Medium thickness work typically falls within ±0.1mm to ±0.2mm. Heavy plate applications may require ±0.25mm to ±0.5mm tolerance allowances. When designing laser cut metal sheets, factor these realistic capabilities into your fit and function requirements from the start.

Preparing Your Design Files for Laser Cutting Success

You've selected your material and understand thickness capabilities. Now comes the step that separates smooth projects from frustrating delays: file preparation. According to Quote Cut Ship's analysis, they review hundreds of files each week and consistently encounter the same preventable design mistakes. The good news? A few minutes of preparation saves hours of back-and-forth revisions.

Whether you're submitting your first custom laser cutting project or your hundredth, proper file setup directly impacts quote accuracy, production speed, and part quality. Think of your design file as the recipe. Even the best laser cutter sheet metal equipment can't produce excellent results from poorly prepared instructions.

File Formats and Technical Requirements for Submission

Here's something many first-time customers don't realize: laser cutters don't understand photos or pixel-based images. According to Xometry's design guidelines, laser cutting requires vector-based file formats with mathematically precise edges. Unlike bitmap files made up of pixels, vector images define edges through mathematical expressions that maintain their precision regardless of scale.

For CNC laser cutting operations, services typically accept these formats:

- DXF (Drawing Exchange Format): The industry standard for 2D laser cutting. Compatible with virtually every CAD program and laser cutting machine for metal systems.

- DWG (AutoCAD Drawing): Native AutoCAD format that preserves layer information and complex geometry. Works well for intricate designs.

- AI (Adobe Illustrator): Popular among designers for its intuitive interface. Excellent for artistic and custom laser work.

- SVG (Scalable Vector Graphics): Open standard that works across platforms. Good for web-based design tools.

- STEP/STP (3D Files): Required for parts designed in 3D CAD programs. According to SendCutSend's guidelines, these are preferred when your design originates from software like Autodesk Fusion.

What happens if you upload a JPEG or PNG? These raster formats must be converted to vectors before processing, which adds time and often introduces inaccuracies. Some services offer tracing capabilities, but the results rarely match purpose-built vector files. Free tools like Inkscape can trace bitmap images and convert them to vector format, though designing in vector format from the start always produces superior results.

Scale matters enormously. Always build your file at 1:1 scale, preferably in inch or millimeter units. A laser sheet metal cutter interprets your dimensions literally. If your design shows 50mm but you intended 500mm, that's exactly what you'll receive.

Avoiding Common Design Mistakes That Delay Production

Even experienced designers stumble into these traps. Understanding what causes production issues helps you deliver files that quote quickly and cut cleanly.

Open or Unjoined Paths: This is the most frequent issue services encounter. When paths don't form closed shapes, the laser doesn't know where to cut. According to SendCutSend's technical documentation, your part preview typically won't fill in gray if open cut paths are present. Use your CAD software's path cleanup and "join" features to ensure every line connects properly.

Lines Too Close Together: When design lines sit too tightly or overlap, the laser overburns those areas. Quote Cut Ship recommends maintaining at least 0.010 inches (0.254mm) of spacing between critical paths. For thick materials with low melting points, closely spaced cuts may cause localized melting or warping between the paths.

Features Smaller Than Material Thickness: Here's a practical guideline from Xometry: avoid design features smaller than the thickness of your material. Cutting an 8mm hole in 10mm thick steel produces poor edge quality and dimensional inaccuracy. While technically possible, the results rarely meet expectations.

Ignoring Kerf Compensation: The laser beam removes material as it cuts, creating what fabricators call "kerf." According to Xometry's technical specifications, kerf width typically ranges from 0.1mm to 1.0mm depending on material, laser power, and cutting speed. If your parts need precise fitment, offset your cut path so the kerf falls outside your intended dimensions. Many laser cutting software packages handle this automatically, but specifying your requirements upfront prevents surprises.

Text Left as Fonts: Forgetting to convert text to outlines or curves causes frequent problems. If the fabricator's system lacks your specific font, it may substitute something entirely different or disappear completely. Always convert text to paths before exporting.

Your Pre-Submission Checklist

Before uploading your file to any custom laser cutting service, run through this verification process:

- Confirm file format: Verify you're submitting .dxf, .dwg, .ai, .eps, or .step/.stp files only. Avoid mesh files and image formats.

- Check scale: Ensure your design is built at 1:1 scale in inch or millimeter units.

- Close all paths: Verify every cut path forms a closed shape with no open contours.

- Remove stray geometry: Delete all stray points, duplicate lines, empty objects, and overlapping paths.

- Convert text: Transform all text to outlines or paths before exporting.

- Verify minimum feature sizes: Confirm holes and cutouts meet minimum requirements (typically at least 50% of material thickness for laser cut parts).

- Check line spacing: Ensure at least 0.010" spacing between cut paths to prevent overburning.

- Unite shapes: Combine, merge, or unite all objects that should cut as single entities.

- Consolidate layers: Place all cutting geometry on the same layer.

- Review nested parts: If submitting multiple parts in one file, ensure they don't share cut paths or overlap.

For nested files containing multiple parts, SendCutSend emphasizes that parts should never share cut paths, have overlapping geometry, or include parts within parts. Each piece needs its own complete perimeter. Tab placement for nested parts requires planning; tabs hold parts in place during cutting but must be removed afterward. Position them in non-critical areas where minor cleanup won't affect function.

Taking fifteen minutes to verify these elements before submission typically saves days of revision cycles. Your fabricator's design review team will appreciate receiving clean files, and you'll receive quotes faster with fewer questions.

The Complete Journey From Design to Delivered Parts

You've prepared your design files and selected materials. Now what? Many laser cut services hide behind instant quote buttons without explaining what happens after you click "submit." Understanding the complete project lifecycle helps you set realistic timelines, anticipate questions, and avoid costly surprises. Let's pull back the curtain on the quote-to-delivery process.

Whether you're searching for a laser cutting service near me or working with a specialized fabricator across the country, the fundamental workflow remains consistent. According to SendCutSend's documentation, modern services can deliver prototypes in as few as 2-4 business days, with some offering rapid prototyping capabilities as fast as 5 days for complex projects. Understanding each step helps you navigate the process efficiently.

From Quote Request to Finished Parts

Every successful metal laser cutting project follows a predictable path. Some steps happen automatically, while others require your input. Here's the typical journey your project takes:

- File Submission and Initial Quote: You upload your vector files through the service's online platform. Automated systems analyze geometry, calculate cutting paths, and generate preliminary pricing. Leading providers like those offering laser cutter service near me options often return quotes within 12 hours or less.

- Design Review and DFM Analysis: Engineers examine your file for manufacturability issues. They check for minimum feature sizes, appropriate tolerances, and potential production challenges. This critical step catches problems before cutting begins.

- Material Selection and Confirmation: You specify exact material grade, thickness, and finish requirements. The fabricator confirms material availability and adjusts pricing if needed. Some tube laser cutting services maintain extensive inventories, while others source specialty materials per project.

- Quote Approval and Order Placement: Once you approve the final quote, your order enters the production queue. Payment typically triggers scheduling, though some services offer net terms for established accounts.

- Production Scheduling and Cutting: Your job gets assigned to appropriate equipment based on material type, thickness, and complexity. According to Xometry's process documentation, the laser cutting machine follows programmed instructions, with gas assist blowing vapor and droplets clear while creating narrow kerfs along the cutting path.

- Quality Inspection: Finished parts undergo dimensional verification and visual inspection. Critical features get measured against specifications. Parts that don't meet standards get recut before shipping.

- Packaging and Shipping: Parts receive appropriate protection based on material and finish requirements. Many services offer detailed order tracking so you know exactly when to expect delivery.

The entire process can move remarkably fast. For simple parts in stock materials, some laser cutting services near me deliver finished components within a week of initial file submission.

What Happens During Design Review

Design for Manufacturability review separates professional laser cut services from basic job shops. During DFM analysis, engineers evaluate whether your design can be produced as submitted, or whether modifications would improve quality, reduce cost, or prevent failures.

What do reviewers look for? First, they verify that all geometry translates properly from your file format. According to Xometry's technical guidelines, the laser cutting machine will follow its programmed instructions exactly. If your file contains issues, the machine cuts those issues into expensive material.

DFM engineers also assess practical considerations that automated quoting systems miss:

- Heat accumulation zones: Closely spaced cuts in certain patterns can cause localized overheating and warping.

- Part stability during cutting: Large parts with many interior cutouts may shift as material falls away, affecting final cuts.

- Edge quality requirements: Some features may require parameter adjustments or post-processing to meet your specifications.

- Nesting efficiency: Engineers may suggest rearranging parts on the sheet to reduce material waste and lower your costs.

Good DFM support transforms a transactional service into a manufacturing partnership. When engineers catch a potential issue and suggest alternatives before cutting begins, they save you time, money, and frustration.

How long does this all take? Rapid quote turnaround has become an industry standard, with some providers responding within 12 hours. According to SendCutSend's process overview, standard orders ship in 2-4 business days, meaning you can go from design file to delivered parts in under a week for straightforward projects.

For those exploring laser cut near me options, understanding this workflow helps you evaluate providers effectively. Ask about their DFM process, typical turnaround times, and quality inspection procedures. The answers reveal whether you're working with a genuine precision manufacturing partner or a basic cutting service.

When Laser Cutting Beats Alternative Cutting Methods

Here's a question that trips up even experienced fabricators: should you use laser cutting, or would plasma or waterjet serve your project better? The honest answer is that no single metal cutting laser technology wins every scenario. Each method excels in specific situations and falls short in others. Understanding these trade-offs helps you select the right approach before requesting quotes from metal cutting services.

According to Wurth Machinery's comparative analysis, many successful fabrication shops eventually incorporate multiple technologies because each addresses different project requirements. Let's examine where each method shines and where it struggles.

Laser Cutting vs Waterjet and Plasma Methods

Think of these three technologies as specialized tools rather than direct competitors. A metal cutting laser machine delivers surgical precision on thin to medium materials. Plasma cutting dominates thick conductive metals at lower costs. Waterjet handles virtually anything without heat effects.

Laser Cutting Strengths: When precision matters most, a laser cutter for metal typically wins. According to Universal Tool & Engineering's technical documentation, fiber lasers achieve tolerances of ±0.001" or better due to precise beam control and minimal kerf width. The focused beam creates exceptionally clean edges with minimal post-processing needed. For thin sheets requiring intricate details, small holes, or complex geometries, laser cutting delivers results that alternative methods simply cannot match.

Laser Cutting Limitations: Every technology has constraints. Laser cutting works best up to certain thickness limits, beyond which speed and quality drop significantly. For heavy plate work exceeding 25mm, plasma or waterjet often proves more economical. Additionally, while fiber lasers handle reflective metals far better than older CO2 systems, materials like pure copper still present challenges.

Plasma Cutting Advantages: If you're working with thick conductive metals and prioritize speed over precision, plasma deserves serious consideration. Wurth Machinery's testing showed that plasma cutting 1-inch steel runs 3-4 times faster than waterjet, with operating costs roughly half as much per foot. For structural steel fabrication, heavy equipment manufacturing, and shipbuilding applications, plasma offers unmatched value. A complete plasma system costs around $90,000 compared to approximately $195,000 for similar-sized waterjet equipment.

Waterjet Advantages: When heat damage must be avoided or you're cutting non-metals, waterjet stands alone. The cold-cutting process produces no heat-affected zone, meaning no warping, no hardening, and no altered material properties near the cut edge. Waterjet handles materials that both lasers and plasma cannot touch: stone, glass, carbon fiber composites, and layered materials. The waterjet market continues growing rapidly, projected to reach over $2.39 billion by 2034.

Matching Your Project Requirements to the Right Technology

Choosing the right custom metal cutting method comes down to six key decision factors. Walk through each one before committing to a technology:

- Material Type: Laser excels with steel, stainless, and aluminum. Plasma works only on electrically conductive metals. Waterjet cuts almost anything including stone, composites, and glass.

- Thickness Requirements: For thin to medium sheets under 15mm, laser typically offers the best combination of speed and precision. Thick conductive metals favor plasma. Waterjet handles any thickness but runs slower.

- Precision Needs: Tight tolerances under ±0.005" point toward laser cutting. Plasma produces rougher edges requiring secondary finishing. Waterjet achieves good precision but leaves small entry/exit notches.

- Edge Quality: Laser produces ready-to-use edges on appropriate materials. Plasma almost always requires post-processing. Waterjet creates clean edges but with slightly more radius on inner corners.

- Production Volume: High-volume thin sheet work favors laser's speed and automation. Lower-volume thick plate jobs may favor plasma's lower operating costs.

- Budget Constraints: Laser has higher capital cost but lower per-part finishing requirements. Waterjet consumes expensive abrasives. Plasma costs less per cut but adds finishing labor.

| Method | Best For | Thickness Range | Edge Quality | Cost Factors |

|---|---|---|---|---|

| Fiber Laser | Thin to medium sheets; intricate designs; high precision requirements | 0.5mm - 25mm (material dependent) | Excellent; often ready for assembly | Higher equipment cost; lowest finishing costs; high throughput |

| Plasma | Thick conductive metals; structural steel; cost-sensitive projects | 3mm - 75mm+ | Rougher; usually requires finishing | Lowest equipment cost; moderate consumables; adds finishing labor |

| Waterjet | Heat-sensitive materials; non-metals; avoiding material property changes | 0.5mm - 200mm+ | Good; no heat-affected zone | Moderate equipment cost; high consumables (abrasive, pump wear) |

| CNC Routing | Softer materials; plastics; wood; foam; large format work | Material dependent | Good for appropriate materials | Lower cost for non-metal applications |

When should you specifically avoid laser cutting? According to Universal Tool's analysis, very thick plates beyond your laser's capacity will cut slowly with degraded quality. Materials requiring zero heat-affected zone, such as certain aerospace components with strict metallurgical requirements, may need waterjet processing. And if you're searching for plasma cutting near me because you need fast, economical cuts on thick steel plate, that instinct is probably correct.

The bottom line? Match the technology to your specific requirements rather than defaulting to any single method. For many projects, laser cutting delivers the optimal combination of precision, speed, and cost. But honest evaluation sometimes points toward alternatives. Understanding when each method excels makes you a more informed customer and leads to better project outcomes.

Industries and Applications That Rely on Laser Cut Parts

Now that you understand how to select the right cutting technology, let's explore where metal laser cutting services actually make a difference. The versatility of laser fabrication spans far beyond what most people imagine. From the car you drive to the smartphone in your pocket, laser cut parts appear in nearly every manufactured product you encounter daily.

What makes this technology so widely adopted? According to Accurl's comprehensive industry analysis, laser cutting has transformed various industries with its precision and versatility. Different sectors have vastly different requirements for tolerances, certifications, and material specifications. Understanding these variations helps you communicate your specific needs effectively when working with custom metal laser cutting providers.

Automotive and Industrial Component Manufacturing

In the automotive industry, laser cutting stands as a pivotal tool for crafting intricate components and customizations. Think about what's actually inside your vehicle: chassis brackets, suspension components, exhaust system parts, body panels, and countless structural elements. Each requires precise dimensional accuracy and consistent quality across thousands of production units.

According to Xometry's certification documentation, automotive applications often require IATF 16949 certification for quality assurance. This framework, built on ISO 9001 standards, ensures consistency, safety, and quality across automotive products. When you're sourcing laser cut parts for automotive applications, working with certified providers isn't optional. It's a requirement that OEMs and tier-one suppliers mandate throughout the supply chain.

Common automotive applications include:

- Chassis and frame components: Structural brackets, mounting plates, and reinforcement panels that demand tight tolerances and consistent material properties

- Suspension system parts: Control arm brackets, spring perches, and mounting hardware requiring precise fitment

- Body and trim elements: Interior trim components, decorative panels, and exterior accents

- Electrical system components: Battery trays, wiring brackets, and sensor mounts

- Engine bay components: Heat shields, mounting brackets, and accessory supports

A laser cutting machine metal system significantly outperforms traditional die cutting or plasma processes for automotive work. The high-power fiber laser provides precision that's essential where every millimeter counts.

Aerospace and Electronics Applications

The aerospace industry demands something most other sectors don't: zero compromise on precision. When components fly at 35,000 feet carrying passengers, tolerance specifications become non-negotiable. Laser fabrication meets these stringent requirements by producing components that maintain strict dimensional accuracy while preserving material integrity.

According to Accurl's technical documentation, aerospace benefits from laser cutting's ability to handle lightweight, high-strength materials while meeting strict tolerance levels. Whether processing titanium alloys, aluminum aerospace grades, or specialized stainless steels, the process maintains the structural integrity that aerospace applications demand.

In electronics manufacturing, miniaturization drives everything. Devices keep getting smaller while functionality expands. Metal laser cutting services enable this evolution by producing precision components for:

- EMI shielding enclosures: Protective housings that block electromagnetic interference

- Heat sinks and thermal management: Precisely cut fins and channels for heat dissipation

- Connector housings: Miniature enclosures with exacting dimensional requirements

- PCB mounting hardware: Standoffs, brackets, and support structures

- Consumer device housings: Smartphone frames, laptop enclosures, and wearable device components

The electronics industry relies heavily on precision cutting capabilities where a fraction of a millimeter makes a significant difference. Modern fiber lasers achieve the tight tolerances that these applications require.

Architectural and Custom Design Applications

Walk through any contemporary building and you'll encounter custom cut metal elements everywhere. According to Stealth Industry's architectural documentation, custom metal fabrication enables architects and designers to surpass conventional choices, providing full authority over dimensions, forms, surface treatment, and material selection.

Architectural applications showcase laser cutting's creative potential:

- Facades and cladding systems: Decorative exterior panels, perforated screens, and weathering steel installations

- Interior decorative elements: Staircase railings, room dividers, and geometric wall panels

- Custom signage: Dimensional letters, branded logos, and wayfinding systems

- Landscape features: Planters, trellises, and outdoor sculptures

- Furniture components: Table bases, chair frames, and decorative hardware

The technology's ability to cut through thick steel plates while producing precise, intricate patterns makes it invaluable in modern architecture. Whether creating Corten steel facades with natural rusted patina or brushed stainless steel railings with detailed geometric patterns, laser cutting transforms design concepts into reality.

For custom fabrication projects, metal laser cutting services offer something traditional methods cannot: the ability to economically produce one-off designs or limited runs without expensive tooling. This flexibility makes laser cutting the preferred method for prototypes, architectural samples, and bespoke installations where each piece is unique.

How to Evaluate and Choose the Right Service Provider

You've explored materials, understood precision capabilities, and learned about the project lifecycle. Now comes the decision that determines whether your project succeeds or stumbles: selecting the right metal laser cutting service provider. With dozens of fabricators competing for your business, how do you separate genuinely capable partners from those who simply talk a good game?

According to Thin Metal Parts' evaluation guide, finding the right partner requires checking all factors from capabilities and quality to customer service experience. The cheapest quote rarely delivers the best value. Let's walk through the criteria that actually matter when evaluating CNC laser cutting services.

Essential Questions to Ask Before Choosing a Provider

Before committing to any precision laser cutting services provider, gather answers to these fundamental questions. The responses reveal far more about capability than marketing claims ever could.

What equipment do they operate? Modern metal laser cutters directly impact your project outcomes. According to AccuPath's selection guide, the tools a company uses affect your project's success. Advanced machines work faster and cut more precisely, handling tricky designs and tough materials easily. Ask specifically about laser power levels, whether they run fiber or CO2 systems, and the age of their equipment. A shop running 6kW fiber lasers delivers dramatically different results than one operating older 2kW systems.

Can they handle your specific materials? Not all metal laser cutter operations process every material. Some specialize in steel and stainless, while others excel with aluminum or exotic alloys. Before requesting quotes, confirm the provider has experience with your exact material grade. According to Thin Metal Parts, most fabricators assist with steel, aluminum, and copper, but specialized requests require upfront confirmation.

What's their production capacity? Ask about production runs and whether they can scale from prototype quantities to full production. A provider perfect for your initial 50-piece order may struggle when you need 5,000 units monthly. Understanding their capacity prevents painful transitions later.

How fast can they turn quotes around? Quoting speed often indicates overall operational efficiency. When researching laser metal cutting near me options, look for providers who respond within 24 hours or less. Some leading fabricators, including manufacturers like Shaoyi (Ningbo) Metal Technology, offer 12-hour quote turnaround. This responsiveness signals a well-organized operation that values your time.

Do they offer DFM support? Design for Manufacturability assistance separates transactional cutting services from genuine manufacturing partners. Quality providers review your files, identify potential issues, and suggest improvements before cutting begins. Comprehensive DFM support prevents costly mistakes and often reduces per-part costs through optimization.

Certifications and Quality Standards That Matter

Certifications aren't just badges on a website. They represent verified commitments to consistent quality, documented processes, and continuous improvement. According to Hartford Technologies' certification overview, quality certifications demonstrate commitment to the customer and to their profession, producing premium components while providing an added layer of assurance for buyers.

Here's what each major certification tells you about a provider:

- ISO 9001: The foundational quality management certification. It confirms the organization maintains documented procedures, tracks quality metrics, and implements continuous improvement processes. Any serious CNC laser cutter for metal operation should hold this baseline certification.

- IATF 16949: Critical for automotive applications. This certification builds upon ISO 9001 with additional requirements specific to automotive manufacturing, including product design controls, production process verification, and customer-specific standards. When sourcing laser tube cutting services for automotive components, IATF certification isn't optional. Manufacturers like Shaoyi demonstrate these quality standards through their IATF 16949-certified operations serving chassis, suspension, and structural component applications.

- AS9100: The aerospace industry standard ensuring parts meet strict safety and quality requirements. If your laser cut parts fly, work only with AS9100-certified providers.

- ISO 13485: Essential for medical device applications, ensuring components meet rigorous safety and traceability requirements.

- ISO 14001: Environmental management certification indicating responsible manufacturing practices.

Beyond certifications, evaluate their quality inspection processes. Ask what measurement equipment they use, how often they calibrate machines, and what percentage of parts get inspected. According to AccuPath's guidance, companies with strict quality rules give clean cuts and smooth edges, reducing extra work after cutting.

Your Provider Evaluation Checklist

Use this comprehensive checklist when comparing potential metal laser cutting service providers:

- Equipment Capabilities: Laser type (fiber vs CO2), power levels, maximum sheet size, and equipment age

- Material Options: Range of metals stocked, specialty alloy experience, and material sourcing capabilities

- Certifications: ISO 9001 at minimum; IATF 16949 for automotive; AS9100 for aerospace; ISO 13485 for medical

- Turnaround Times: Quote response speed, standard lead times, and rush order capabilities

- DFM Support Quality: Engineering review processes, design optimization suggestions, and communication during review

- Communication Responsiveness: Single point of contact, response times to questions, and proactive project updates

- Quality Inspection: Inspection equipment, calibration schedules, and inspection sampling rates

- Prototyping Capabilities: Rapid prototyping availability, minimum order quantities, and prototype-to-production transition support

- Pricing Transparency: Complete quotes without hidden fees, clear explanations of cost factors, and willingness to discuss optimization

- Customer References: Portfolio examples, industry experience, and testimonials from similar applications

According to Thin Metal Parts, effective communication keeps the production chain smooth. When requesting quotes or assessing providers, identify your point of contact. This streamlines communication and optimizes the entire production process. Test responsiveness by asking questions and observing how quickly and thoroughly they respond.

For automotive and precision manufacturing applications, look for providers demonstrating the complete package: IATF 16949 certification, rapid prototyping capabilities moving from concept to parts in as few as 5 days, and comprehensive DFM support that optimizes your designs before production begins. These capabilities, exemplified by manufacturers like Shaoyi, indicate a provider prepared to function as a genuine manufacturing partner rather than simply a cutting service.

Remember, the lowest quote often costs more in the long run. According to AccuPath's analysis, low-cost services might lack good tools or skilled workers, causing mistakes or damage to materials. Spending more now prevents costly errors later. Evaluate providers holistically, balancing cost against capability, certification, and communication quality to find the partner who delivers consistent results project after project.

Taking the Next Step Toward Your Laser Cutting Project

You've now explored the complete landscape of metal laser cutting service capabilities, from the physics of how lasers transform raw material into precision parts, through material selection, file preparation, and provider evaluation. The question is no longer whether laser cutting fits your project. It's how to move forward confidently with your first order or your hundredth.

Getting started doesn't require perfection. It requires action guided by the decision framework you've just learned. Let's crystallize that framework into practical next steps that turn knowledge into results.

Your Action Plan for Getting Started

Moving from research to results follows a logical sequence. Whether you're exploring online laser cutting platforms or working directly with specialized fabricators, this action plan guides your next moves:

- Define your project requirements clearly: Document material type, thickness, quantity, tolerance needs, and any certification requirements before contacting providers. The more specific your requirements, the more accurate your quotes.

- Prepare your design files properly: Export clean vector files in DXF, DWG, or STEP format at 1:1 scale. Close all paths, convert text to outlines, and verify minimum feature sizes meet material thickness guidelines.

- Evaluate providers against quality criteria: Check equipment capabilities, relevant certifications, DFM support quality, and communication responsiveness. Don't let price alone drive your decision.

- Request quotes from multiple sources: Compare at least three providers for significant projects. Look beyond per-part pricing to evaluate total value including lead times, quality assurance, and support quality.

- Start with a prototype run: Before committing to production quantities, validate your design with a small batch. This confirms both your specifications and the provider's capabilities.

Understanding laser cutting charges upfront prevents budget surprises. According to Komacut's pricing analysis, primary cost factors include material type, thickness, design complexity, cutting time, and finishing processes. Optimizing your design for efficient nesting and simplified geometries reduces costs without sacrificing functionality.

Key Takeaways for Successful Laser Cutting Projects

After exploring every aspect of the metal laser cutting process, these insights deserve special emphasis:

File preparation quality determines project success more than any other single factor. Fifteen minutes spent verifying closed paths, proper scaling, and minimum feature sizes prevents days of revision cycles and costly remake charges.

The cheapest laser cutting quote rarely delivers the best value. Evaluate providers holistically, balancing per-part cost against equipment capabilities, certification status, DFM support quality, and communication responsiveness.

Match the cutting technology to your specific requirements rather than defaulting to any single method. For thin to medium sheets requiring precision and clean edges, laser cutting typically delivers optimal results. For very thick plates or heat-sensitive materials, plasma or waterjet may serve better.

For readers in automotive or precision manufacturing, the evaluation criteria become even more critical. IATF 16949 certification isn't optional for automotive supply chain work. Rapid prototyping capabilities that move from concept to parts in as few as 5 days accelerate development cycles. And comprehensive DFM support catches issues before they become expensive production problems.

Manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate what to look for in a quality provider: IATF 16949-certified operations, 12-hour quote turnaround, 5-day rapid prototyping, and comprehensive DFM support for chassis, suspension, and structural components. These capabilities represent the standard you should expect from any serious precision manufacturing partner.

Your laser metal cutter project starts with a single step: preparing that first design file and requesting your first laser cutting quote. The knowledge you've gained positions you to navigate the process confidently, communicate effectively with providers, and achieve results that meet your exact specifications. The technology is proven, the providers are capable, and the path forward is clear.

Frequently Asked Questions About Metal Laser Cutting Services

1. What materials can be processed through metal laser cutting services?

Metal laser cutting services process a wide range of materials including carbon steel, stainless steel, aluminum, brass, copper, and specialty alloys like titanium and Inconel. Carbon steel cuts most efficiently due to excellent laser energy absorption, while reflective metals like aluminum and copper require higher power settings and fiber laser technology. Quality providers like Shaoyi maintain extensive material inventories and can advise on optimal material selection for your specific application requirements.

2. How thick of metal can a laser cutter cut?

Thickness capabilities depend on laser power and material type. A 6kW fiber laser typically cuts carbon steel up to 25mm, stainless steel up to 20mm, aluminum up to 15mm, and copper up to 8mm. Higher-powered systems exceeding 12kW can process even thicker materials. However, cutting quality and precision decrease as you approach maximum thickness limits, so consider your tolerance requirements when selecting material thickness.

3. What file formats are required for laser cutting services?

Laser cutting requires vector-based file formats including DXF, DWG, AI, SVG, and STEP/STP for 3D designs. These formats use mathematical expressions to define edges precisely, unlike pixel-based images like JPEG or PNG. Always submit files at 1:1 scale with closed paths, converted text, and minimum feature sizes appropriate for your material thickness to ensure accurate quoting and production.

4. How long does it take to get laser cut parts?

Turnaround times vary by provider and project complexity. Leading services offer quotes within 12-24 hours and deliver standard orders in 2-4 business days. Rapid prototyping can produce parts in as few as 5 days, while complex or high-volume production runs may require longer lead times. Providers like Shaoyi offer 12-hour quote turnaround and 5-day rapid prototyping for automotive applications.

5. What certifications should I look for in a metal laser cutting service provider?

Essential certifications include ISO 9001 for baseline quality management and IATF 16949 for automotive applications. Aerospace projects require AS9100 certification, while medical device components need ISO 13485. These certifications verify documented procedures, quality tracking, and continuous improvement processes. For automotive supply chain work, IATF 16949 certification is mandatory and demonstrates commitment to the stringent quality standards required for chassis, suspension, and structural components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —