ステンプドスチール対鋳鉄アーム:重要な選択

要点まとめ

プレス鋼板と鋳鉄製のコントロールアームを選択する際には、強度、重量、長期的なメンテナンス性の間でトレードオフがあります。鋳鉄製コントロールアームははるかに強く剛性も高いため、過酷な使用条件に最適です。ただし、重量が重く、ボールジョイントが一体化されていることが多いため、ジョイントが故障した場合はアーム全体を交換する必要があります。一方、プレス鋼板製のコントロールアームは軽量であり、乗り心地の向上につながります。また、通常は交換可能なボールジョイントを採用しているため、修理がより安価で簡単になります。

プレス鋼板製と鋳鉄製アームの見分け方

交換部品やサスペンションのアップグレードを注文する前に、車両のコントロールアームを正しく特定することが最も重要な第一歩です。機能は同じでも、その構造や素材特性は異なります。幸いなことに、視覚による点検と簡単な音響テストという、誰でも自信を持って違いを判別できる数少ない方法があります。

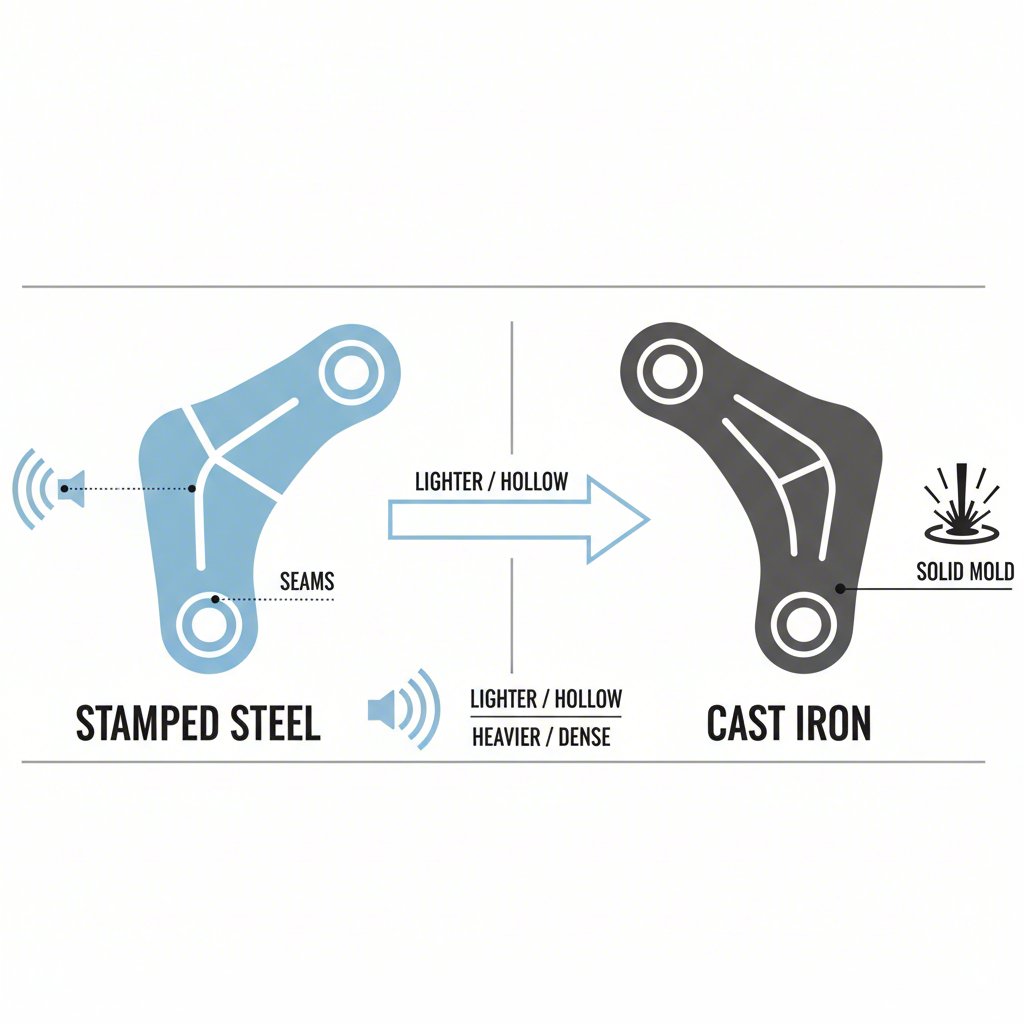

外観的には、製造工程の違いにより、2種類のアームは異なる見た目をしています。プレス加工されたスチール製コントロールアームは、厚手のシートメタルを成形し、溶接して作られたように見えます。金属を最終的な形状に曲げた部分の継ぎ目や折り目が見えることがよくあります。一方、鋳鉄製コントロールアームは、一塊の鋳造金属のように見え、単一の固体部品に見えます。表面はより粗く、テクスチャーが目立ち、スチール製のものに比べて明らかに頑丈で分厚く見えます。

外観による確認がはっきりしない場合は、いくつかの簡単な物理的テストで明確な判断ができます。ある技術資料で詳述されているように MOOG Parts 磁石とハンマーによるテストは非常に効果的です。まず、アームに磁石が付くかどうかを確認します。付く場合は、ステンピング鋼または鋳鉄製です。付かない場合は、おそらくアルミ製のアームです。2種類の鋼材を区別するには、アームを小さなハンマーで軽く叩いてみます。ステンピング鋼製のアームは中空で鳴るような音を出し、鋳鉄製のアームは密度が高く鈍い音を出します。

| 方法 | プレス成形鋼板 | 鋳鉄 |

|---|---|---|

| 視覚的外観 | 金属板から成形されており、目立つ継ぎ目や溶接部がある場合があります。軽く見える外観です。 | 一体成型で、ざらついた質感を持ち、ずっしりと重厚に見えます。 |

| 音響テスト(ハンマーでの軽打) | 中空で鳴るような音を発生します。 | 鈍く、重い音を発生します。 |

| 磁石テスト | 磁石が付きます。 | 磁石が付きます。 |

強度、耐久性、および性能の比較

コントロールアームを評価する際、最も顕著な性能差は、荷重下での強度と耐久性にあります。鋳鉄は、ステンレス鋼板よりも本質的に強く、剛性が高いです。そのため、鋳鉄製のコントロールアームは、サスペンションに極端なストレスや重負荷がかかる過酷な使用条件となる大型トラック、作業車両、オフロード愛好家にとって好ましい選択となります。鋳鉄の堅牢で一体構造は、旋回時や凹凸のある地形走行時の強いねじれやたわみを防ぎ、適切なサスペンションジオメトリを維持するのに役立ちます。

ステンレス鋼板製のアームは、鋳鉄ほど剛性はありませんが、ほとんどの乗用車やライトデューティトラックの要求に対して十分な性能を持っています。その構造により、荷重がかかった際にわずかなたわみが生じますが、これは高性能用途には理想的ではありませんが、日常の運転では全く問題ありません。ただし、アフターマーケットスペシャリストが指摘しているように ReadyLIFT 、新しい設計のスタンプ鋼製部品は、ボールジョイントの保持に必要な表面積が小さくなる場合があり、補助クリップが欠けることで特にリフトされた車両で故障の原因となる可能性があります。

故障の形態もこの二つの素材間で異なります。極端な衝撃や応力がかかった場合、もろい鋳鉄は亀裂が入ったり完全に破断しやすいのに対し、より延性のあるスタンプ鋼は曲がったり変形しやすいです。これは場合によって有利になることもあります。たとえば、曲がったアームはまだ機能して車両を帰宅させることが可能な一方で、破断したアームは重大なサスペンション故障につながる可能性があるためです。以下に、性能に関する長所と短所を示します。

各素材の利点と欠点

鋳鉄

- 利点は 優れた強度と剛性で、重荷およびオフロード走行に最適であり、応力下でもサスペンションジオメトリを維持します。

- 欠点: 突然の極端な衝撃により亀裂が入りやすい。大幅に重量が重い。

プレス成形鋼板

- 利点は 軽量で、壊れるよりも曲がりやすく、日常の運転には十分な強度があります。

- 欠点: 重い負荷がかかると変形し、アライメントが変わる可能性がある。一部の設計ではボールジョイントの保持力が弱い。

決定的な要因:ボールジョイントのメンテナンス性

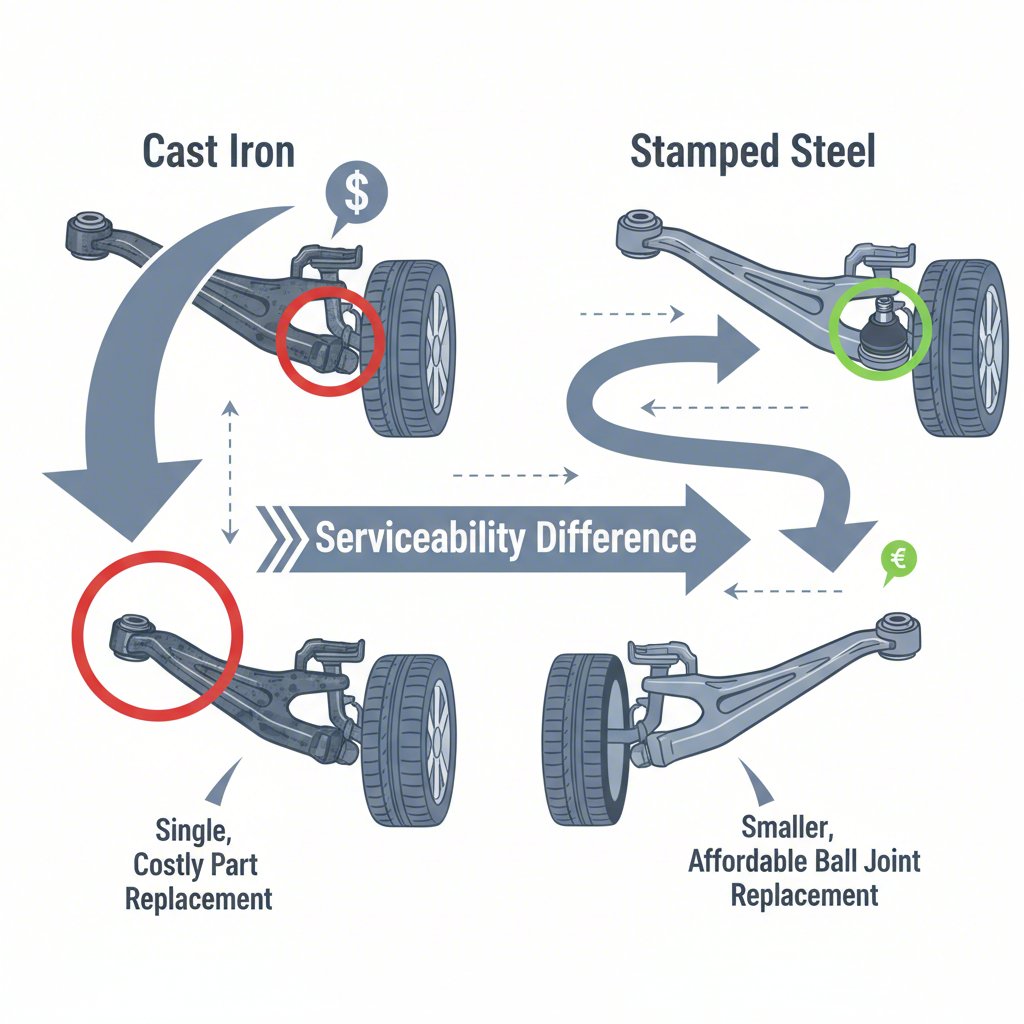

車両所有者にとって最も実用的な違いは、おそらくボールジョイントの交換方法である。この一点が、サスペンションの長期的なメンテナンス費用や複雑さに大きく影響する可能性がある。根本的な問題は、多くの鋳鉄製コントロールアームが、一体型で交換不可能なボールジョイントを採用している点にある。対照的に、ほとんどのプレス鋼板製コントロールアームは、独立して交換可能なボールジョイントを備えている。

典型的な鋳鉄製アームのボールジョイントが摩耗した場合、古いジョイントを押出して新しいものに交換することはできない。コントロールアーム全体を交換しなければならない。これにより、部品代だけでなく作業工数も含めて修理費用が大幅に高くなる。これはオーナーフォーラムでよく議論されるポイントであり、車両購入や修理を検討する上で重要な情報である。

一方、プレス鋼製のアームは通常、圧入式またはボルトオン式のボールジョイントを備えています。これらの部品のいずれかが摩耗した場合、整備士は古いジョイントを取り外して交換用部品を取り付けることができ、新品のアーム全体を購入するコストを節約できます。これにより、長期的なメンテナンス費用がはるかに安価になります。DIYで整備を行う人にとっても、コントロールアーム全体を交換するよりもボールジョイントのみを交換する方が、より簡単な作業となることが多いです。以下の表は、メンテナンスにおける現実の明確な違いを示しています。

| 要素 | プレス鋼製アーム | 鋳鉄製アーム(一体型ジョイント) |

|---|---|---|

| 修理作業 | 摩耗したボールジョイントのみを交換。 | コントロールアームアセンブリ全体を交換。 |

| 平均部品費用 | 低価格(ボールジョイント単体の費用)。 | 高価格(アーム全体の費用)。 |

| 修理時間 | 中程度(ジョイントの押し込み/引き抜きに時間がかかる場合がある)。 | アームに容易にアクセスできる場合は、より短時間で作業可能。 |

| 長期 的 な 価値 | 優れている。生涯メンテナンスコストが低い。 | 劣る。生涯メンテナンスコストが高い。 |

重量、コスト、および最終的な推奨事項

強度や保守性に加えて、最終的な検討項目として重量とコストがあり、これらは乗り心地から製造上の意思決定まであらゆる面に影響を与える。鋳鉄はプレス鋼板よりも明らかに重い。この余分な重量により、車両の非懸架質量(サスペンションスプリングで支えられていない部品の総重量)が増加する。非懸架質量が大きくなると、サスペンションが段差に反応する際に克服すべき慣性が大きくなるため、乗り心地が悪くなり、ハンドリングの応答性もわずかに低下する可能性がある。

プレス鋼板は軽量であるため、乗り心地において明確な利点があり、燃費のわずかな向上にも寄与する。ある分析によると Metrix Premium Parts 、鋼鉄はアルミニウムなどの材料と比較して一般的に低コストであるため、スタンプ加工された鋼製アームは大衆車向けの完成車メーカー(OEM)にとって費用対効果の高い選択となります。スタンピング工程は大量生産において非常に効率的です。高品質で高精度な部品を必要とする自動車メーカー向けには、紹益(寧波)金属科技有限公司のような企業が 自動車用プレス部品 これらの信頼性が高く軽量なコンポーネントの基盤を形成しています。

最終的に、プレス鋼と鋳鉄のどちらを選ぶかは、完全にあなたの車両およびその使用方法によって決まります。どちらが明確に優れているというわけではなく、単に異なる目的に応じて設計されているだけです。自分の状況に最適な判断をするために、以下の枠組みを使用してください。

鋳鉄製のコントロールアームを選ぶべきケース:

- 牽引または積載用の大型トラックを運行している場合。

- 最大の強度が求められる本格的なオフロード走行を頻繁に行う場合。

- 極端な負荷下でも剛性を保ち、正確なサスペンションジオメトリを維持することを重視する場合。

次のような場合は、プレス鋼製のコントロールアームを選んでください。

- 日常の通勤用に、普通乗用車、クロスオーバー、またはライトデューティトラックを運転している場合。

- 長期的なメンテナンス費用を抑えたい、またボールジョイントを個別に交換可能であることが重要な場合。

- よりスムーズな乗り心地と、非懸架重量の低減による利点を重視する場合。

よく 聞かれる 質問

1. 鋳鋼製とプレス鋼製のコントロールアームの見分け方は?

最も簡単な方法は、外観と音による確認を組み合わせることです。プレス鋼製のアームは、折り曲げたり溶接したりした薄板金属のように見え、ハンマーでたたいたときに中空な音がします。鋳鉄製のアームは単一の一体成型のように見え、たたいたときに鈍い音がします。

3. コントロールアームに最適な素材は何ですか?

最良の素材は一概には言えず、用途によって異なります。強度と過酷な使用には鋳鉄が最適です。プレス鋼は、コストが低くメンテナンス性に優れているため、日常使用の車両に適したオールラウンドな選択です。アルミニウムは、軽量で腐食に強いことから、高性能車や高級車によく使用されます。

3. スタンプ鋼と鋳鉄の違いは何ですか?

主な違いは製造工程にあります。スタンプ鋼は金属板を切断して所望の形状にプレス加工して作られます。一方、鋳鉄は溶けた鉄を金型に流し込んで作られます。その結果、鋳鉄は密度が高く、重く、より剛性がありますが、スタンプ鋼は軽量である程度の柔軟性を持っています。

4. 鋳鉄製のコントロールアームは優れていますか?

はい、鋳鉄製のコントロールアームはその用途において優れています。高い強度と剛性により、トラックやSUVなど、作業用または過酷な使用を想定した車両のステアリングとハンドリングを重荷下でも維持するのに優れているため、こうした車両に広く採用されています。

少量のバッチ、高い基準。私たちの迅速なプロトタイピングサービスにより、検証がより速く簡単になります——

少量のバッチ、高い基準。私たちの迅速なプロトタイピングサービスにより、検証がより速く簡単になります——