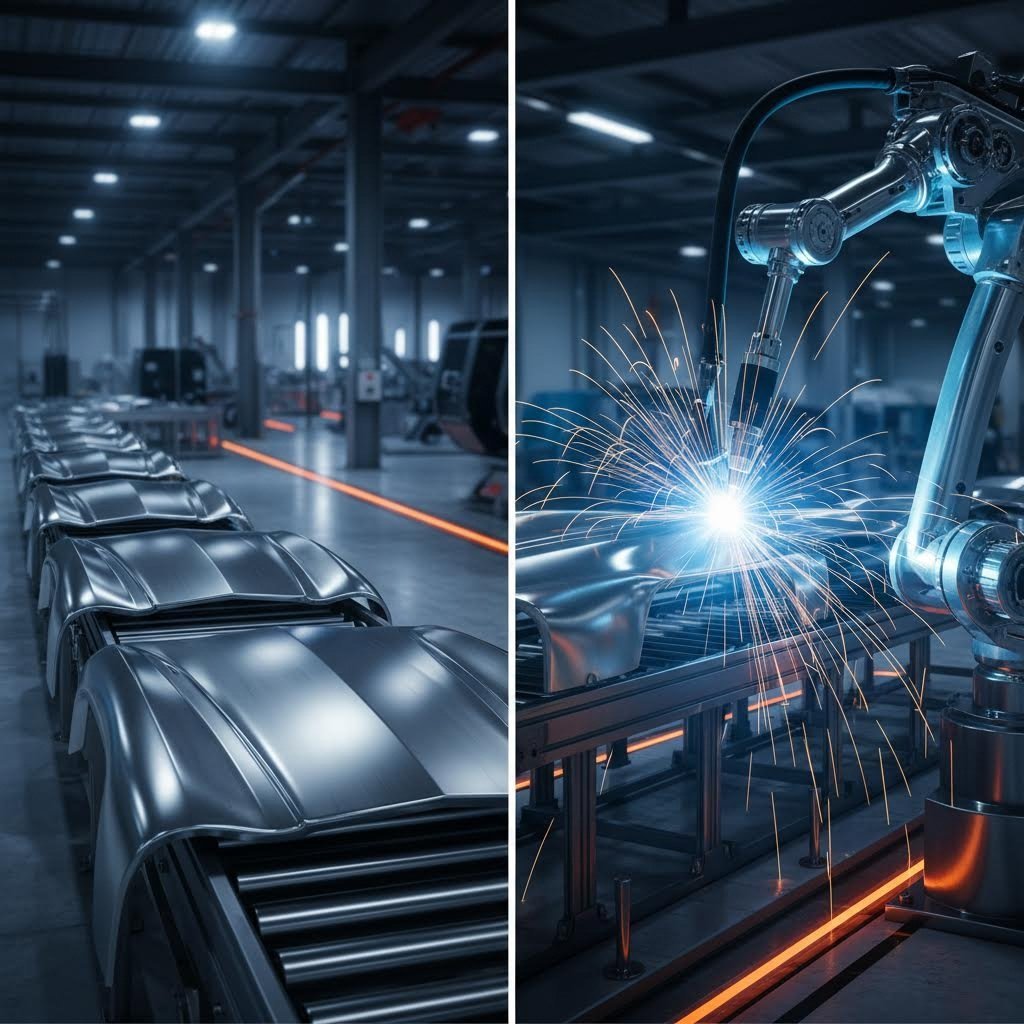

Lubricants For Automotive Stamping: Match The Right Formula To Your Metal precision lubricant application enables flawless automotive stamping operations

The Critical Role of Lubricants in Modern Automotive Stamping

Imagine pressing thousands of tons of force onto a sheet of metal, transforming it into a perfectly shaped automotive component in mere seconds. Now consider what stands between flawless production and catastrophic tool failure. The answer? A thin film of lubricant, often just microns thick, yet absolutely essential to every successful stamping operation.

Lubricants for automotive stamping are specialized metal forming fluids designed to reduce friction between tooling surfaces and workpiece materials during high-pressure forming operations. These formulations create a protective barrier that prevents direct metal-to-metal contact, enabling smooth material flow while protecting both the die and the stamped part from damage.

Why Lubricant Selection Determines Stamping Success

Proper lubrication directly influences three critical production outcomes: part quality, tool life, and overall efficiency. When you select the right metal lubricant for your application, material flows uniformly into die cavities, surfaces remain scratch-free, and dimensional tolerances stay consistent across production runs. The tooling experiences reduced wear, extending service intervals and lowering replacement costs significantly.

However, the complexity of lubricant selection has grown dramatically as automotive materials have evolved. Traditional mild steel stamping operations could often succeed with basic metal lubricants and minimal optimization. Today's manufacturing landscape looks entirely different. AHSS steel (Advanced High-Strength Steel) and ultra high strength steel now comprise significant portions of modern vehicle structures, demanding lubricants with exceptional film strength and extreme-pressure additives.

The Hidden Cost of Poor Lubrication in Automotive Manufacturing

Poor lubricant choices create cascading problems throughout production. Insufficient lubrication leads to galling, scoring, and premature die wear. Excessive application wastes material and complicates downstream processes like welding and painting. The wrong formulation for your specific material can cause coating damage on zinc-plated surfaces or adhesion issues with aluminum alloys.

Consider these real production impacts:

- Tool replacement costs can multiply when improper lubrication accelerates wear

- Scrap rates increase when surface defects or dimensional issues occur

- Production downtime accumulates from frequent die maintenance requirements

- Quality complaints arise when lubrication residues interfere with welding or paint adhesion

Throughout this comprehensive guide, you'll discover how to match lubricant types to specific materials, understand the chemistry behind different formulations, master concentration monitoring techniques, and troubleshoot common lubrication-related defects. Whether you're stamping ultra high strength steel for structural components or forming aluminum panels for exterior applications, the right metal forming fluids strategy will transform your production outcomes.

Understanding the Four Main Lubricant Categories

Selecting the right lubricant starts with understanding what options are available. Automotive stamping operations rely on four primary lubricant categories, each with distinct chemical compositions and performance characteristics. Knowing how these metal forming lubricants differ helps you match the right formulation to your specific production requirements.

Water-Soluble Lubricants for High-Volume Production

Water-soluble lubricants dominate high-volume automotive stamping operations for good reason. These formulations combine water with specialized additives including emulsifiers, corrosion inhibitors, and boundary lubrication agents. When mixed with water at concentrations typically ranging from 3% to 15%, they create stable emulsions that deliver excellent cooling properties during forming operations.

The chemistry behind water-soluble forming oil is straightforward yet effective. Water serves as the primary carrier, absorbing and dissipating heat generated during stamping. Meanwhile, the oil-based additives form thin protective films on metal surfaces, reducing friction and preventing direct tool-to-workpiece contact. This dual functionality makes water-soluble lubricants particularly valuable when heat management is critical.

Key advantages include:

- Superior cooling capacity compared to oil-based alternatives

- Easy removal through standard washing processes

- Lower material costs due to water dilution

- Reduced fire hazards in production environments

When Neat Oils Outperform Synthetic Alternatives

Neat oils, also called straight oils, contain no water and consist entirely of petroleum-based or mineral oil formulations with extreme-pressure additives. These lubricants excel in demanding applications where maximum film strength takes priority over cooling performance.

When you're forming complex geometries or working with materials that generate extreme pressures, neat oils create thicker, more resilient protective barriers. The undiluted oil film maintains its integrity under conditions that would break down water-soluble emulsions. This makes neat forming oil particularly effective for deep drawing operations and severe forming applications.

However, neat oils present trade-offs. They require more aggressive cleaning processes before welding or painting. Environmental considerations also come into play, as disposal and recycling require specialized handling compared to water-based products.

Synthetic Metal Forming Lubricants: Engineered Performance

Synthetic metal forming lubricants represent the cutting edge of lubricant technology. Unlike petroleum-derived products, these formulations use chemically engineered base stocks designed for specific performance characteristics. They offer consistent viscosity across temperature ranges, enhanced oxidation resistance, and precisely tailored friction coefficients.

Manufacturers often choose synthetic formulations when stamping specialty materials like aluminum alloys. Aluminum oil specifically designed for these applications prevents the adhesion and galling issues common with conventional lubricants. Some formulations incorporate aluminium complex grease technology for enhanced boundary lubrication in the most demanding aluminum forming operations.

Vanishing Oil: Clean Parts Without Washing

Vanishing oil represents a unique category designed to evaporate after forming, leaving minimal residue on stamped parts. These volatile lubricants contain carrier solvents that dissipate at room temperature or with minimal heat application, eliminating the need for post-stamping cleaning operations.

This characteristic proves invaluable for parts proceeding directly to welding or painting. By removing the cleaning step, manufacturers reduce processing time, eliminate wastewater treatment concerns, and streamline production flow. However, vanishing oil formulations typically provide less lubrication than conventional alternatives, limiting their use to lighter-duty forming operations.

Comprehensive Lubricant Comparison

Understanding how these four categories compare across critical performance factors helps you narrow your selection quickly:

| Lubricant Type | Cooling Properties | Film Strength | Ease of Removal | Environmental Considerations | Typical Applications |

|---|---|---|---|---|---|

| Water-Soluble | Excellent | Moderate | Easy (water wash) | Lower disposal concerns; biodegradable options available | High-volume production; general stamping; moderate forming severity |

| Neat Oils | Poor to Moderate | Excellent | Requires solvent or alkaline cleaning | Recycling required; higher disposal costs | Deep drawing; severe forming; heavy-gauge materials |

| Synthetic Lubricants | Good to Excellent | Good to Excellent | Varies by formulation | Often more environmentally friendly; longer service life | Aluminum forming; specialty materials; precision applications |

| Vanishing Oil | Poor | Low to Moderate | Self-evaporating | VOC emissions may require monitoring | Light forming; parts requiring no post-cleaning; welding-ready components |

Balancing Trade-Offs in Lubricant Selection

Every lubricant choice involves balancing competing priorities. High-performance metal forming lubricants with exceptional film strength often resist removal, complicating downstream operations. Formulations that clean easily may not provide adequate protection for severe forming applications.

Consider your complete manufacturing sequence when evaluating options. A lubricant that performs perfectly during stamping but creates welding defects or paint adhesion failures ultimately costs more than a slightly less effective alternative that integrates smoothly with subsequent processes. Understanding material-specific requirements further refines your selection, which brings us to the specialized demands of different automotive steels and aluminum alloys.

Material-Specific Lubricant Requirements for Steel and Aluminum

Not all metals behave the same way under stamping pressure. The lubricant that works perfectly for mild steel might destroy a zinc coating or cause severe galling on aluminum. As automotive manufacturers increasingly rely on lightweight materials and advanced steels for safety and fuel efficiency, understanding material-specific lubrication requirements becomes essential for production success.

AHSS and UHSS Lubricant Challenges

What happens when you try to form steel that's three times stronger than conventional grades? The pressures skyrocket, and lubricant demands change dramatically.

AHSS meaning (Advanced High-Strength Steel) encompasses a family of steel grades engineered for exceptional strength-to-weight ratios. These materials, along with UHSS steel (Ultra High-Strength Steel), now form the backbone of modern vehicle safety structures. However, their superior strength creates unique lubrication challenges that conventional formulations simply cannot address.

When forming UHSS, die pressures can exceed those of conventional steel stamping by 50% or more. This extreme loading crushes ordinary lubricant films, allowing metal-to-metal contact that accelerates die wear and creates surface defects on stamped parts. The spring-back characteristics of these materials also increase friction as the workpiece resists deformation.

Effective lubricants for AHSS and UHSS applications must provide:

- Enhanced extreme-pressure additives - Chemical compounds that react under high pressure to form protective boundary films

- Superior film strength - Formulations that maintain integrity under crushing loads without breaking down

- Consistent viscosity - Stable performance despite the heat generated during severe forming operations

- Compatibility with coated surfaces - Many AHSS grades feature zinc or other protective coatings that require careful lubricant selection

Manufacturers working with uhss steel often find that neat oils or high-performance synthetic formulations outperform water-soluble alternatives. The undiluted lubricant provides the film strength necessary to survive the extreme pressures these materials generate.

Zinc Coated and Galvanized Steel Considerations

Zinc coating on steel serves a critical purpose: preventing corrosion throughout the vehicle's lifespan. However, this protective layer introduces specific lubrication challenges that, if ignored, can compromise both part quality and downstream manufacturing processes.

Zinc coated steel and zinc plated steel surfaces are softer than the underlying base metal. During stamping, aggressive lubricant formulations or insufficient lubrication can damage or remove this coating, creating bare spots vulnerable to corrosion. Equally problematic, zinc has a tendency to transfer onto die surfaces under pressure, a phenomenon called galling that progressively worsens tool condition.

Key considerations for zinc-coated materials include:

- Neutral pH formulations - Acidic or highly alkaline lubricants can chemically attack zinc coatings

- Anti-galling additives - Specialized compounds that prevent zinc transfer to tooling surfaces

- Appropriate film thickness - Sufficient lubricant to prevent coating abrasion during material flow

- Residue compatibility - Lubricants that won't trap zinc particles or create surface contamination

Galvanized steel presents similar challenges, with the hot-dip galvanizing process creating a thicker, more reactive zinc layer. Lubricants must protect this coating while still providing adequate friction reduction for forming operations.

Aluminum Stamping Demands Different Lubrication Strategies

Aluminum forming represents an entirely different challenge from steel stamping. The material's natural tendency to adhere to die surfaces, combined with its lower melting point and different thermal properties, requires a fundamentally different lubrication approach.

When aluminum contacts tool steel under pressure, microscopic welding can occur between the surfaces. This adhesion transfers aluminum particles onto the die, creating buildup that progressively degrades part quality. Once started, this cycle accelerates rapidly, with transferred aluminum attracting more material until the die requires cleaning or reconditioning.

Successful aluminum forming lubricants must address:

- Anti-adhesion chemistry - Barrier-forming compounds that prevent aluminum-to-steel bonding

- Heat management - Aluminum's thermal conductivity requires lubricants that dissipate heat effectively

- Surface finish protection - Exterior automotive panels demand flawless surfaces, requiring lubricants that prevent scratching and marking

- Compatibility with alloy variations - Different aluminum alloys (5000 series, 6000 series) may require tailored formulations

- Cleaning requirements - Aluminum parts often proceed to painting or anodizing, demanding easily removable lubricant residues

Specialized aluminum forming lubricants typically feature polar additives that preferentially coat die surfaces, creating a chemical barrier against adhesion. Some manufacturers use synthetic formulations engineered specifically for aluminum's unique behavior, while others rely on water-soluble emulsions with specialized anti-weld additives.

The stakes for getting aluminum lubrication right are particularly high. Exterior closure panels and hoods represent some of the most visible components on finished vehicles. Any surface defect from inadequate lubrication translates directly into quality complaints and potential warranty claims. Understanding how lubricant selection affects not just forming success but also subsequent welding and painting operations becomes critical for complete manufacturing optimization.

Lubricant Compatibility with Welding and Painting Processes

Your stamping operation might produce flawless parts, but what happens next? If lubricant residue interferes with welding or prevents paint from adhering properly, all that upstream success becomes meaningless. The connection between lubricant selection and downstream manufacturing processes often determines whether stamped components meet final quality standards.

How Lubricant Residue Affects Welding Quality

What is welding spatter, and why should stamping engineers care about it? Weld spatter refers to the molten metal droplets that scatter during welding operations, adhering to surrounding surfaces and creating quality defects. While some welding spatter occurs naturally, lubricant contamination dramatically worsens this problem.

When stamped parts carrying lubricant residue enter welding cells, the heat instantly vaporizes organic compounds in the lubricant. This creates gas pockets within the weld pool and surrounding areas, leading to porosity, inconsistent penetration, and excessive spatter welding defects. The resulting welding splatter not only compromises joint integrity but also creates cleanup requirements that slow production.

Chloride sulfate compounds present in some lubricant formulations create additional concerns. These chemicals can become trapped in weld zones, promoting corrosion that may not appear until months or years after vehicle assembly. Testing lubricant residues for chloride content has become standard practice for manufacturers producing safety-critical structural components.

Preparing Stamped Parts for Paint and Adhesive Bonding

Modern vehicle assembly relies heavily on adhesive bonding alongside traditional welding. Structural adhesives join dissimilar materials, reduce weight, and improve crash performance. However, these bonds depend entirely on clean, properly prepared surfaces.

Lubricant residues create barriers between adhesives and metal surfaces, preventing the molecular-level contact necessary for strong bonds. Even thin residual films can reduce bond strength by 50% or more, turning what should be structural connections into potential failure points.

Consider these compatibility requirements for common downstream processes:

- Resistance welding - Requires minimal surface contamination; lubricant residue increases electrical resistance, causing inconsistent weld nugget formation and elevated spatter welding rates

- MIG/MAG welding - Organic lubricant compounds vaporize in the arc zone, creating porosity and excessive weld spatter that requires post-weld grinding

- Adhesive bonding - Surface energy must remain high for proper adhesive wetting; many lubricants lower surface energy and prevent adequate bond formation

- E-coating (electrocoating) - Residual oils and greases repel the water-based coating, creating bare spots and uneven coverage that compromise corrosion protection

- Paint adhesion - Lubricant contamination causes fish-eyes, cratering, and delamination in topcoat finishes, resulting in visible defects on exterior panels

Choosing Lubricants That Support Downstream Success

Given these challenges, why do vanishing oils and easily cleanable formulations dominate applications requiring subsequent welding or painting? The answer lies in residue management.

Vanishing oils evaporate after stamping, leaving surfaces essentially ready for downstream processes without washing. This eliminates cleaning steps, reduces water treatment requirements, and ensures consistent surface preparation. For lighter forming operations where these lubricants provide adequate protection, they represent an elegant solution to residue concerns.

When forming severity demands more robust lubrication, easily cleanable water-soluble formulations offer the next best option. These products remove readily with standard alkaline wash systems, leaving surfaces prepared for welding, bonding, or coating operations.

Lubricant residue testing should become part of your quality control routine. Simple tests can verify that cleaning processes adequately remove lubricant contamination before parts proceed to welding or painting. Monitoring chloride levels in lubricant formulations and residues helps prevent long-term corrosion issues in finished assemblies, particularly for structural components exposed to road salt and moisture throughout their service life.

Selecting lubricants that balance forming performance with downstream compatibility requires understanding both stamping requirements and subsequent process demands. This integration becomes even more critical when you consider the precision needed for concentration monitoring and quality control throughout production.

Concentration Monitoring and Quality Control Methods

You've selected the right lubricant for your materials and downstream processes. Now comes a question many manufacturers overlook: how do you ensure that lubricant maintains its effectiveness day after day? The answer lies in systematic concentration monitoring and quality control protocols that catch problems before they affect production.

Water-soluble lubricants for automotive stamping require precise dilution ratios to perform correctly. Too concentrated, and you waste material while risking residue problems. Too diluted, and protection disappears, leading to galling, tool wear, and surface defects. Maintaining the sweet spot demands regular measurement and adjustment.

Using Refractometers for Concentration Control

How do you quickly determine whether your lubricant mixture contains the right concentration? A brix scale refractometer provides the answer in seconds.

Refractometers measure how light bends when passing through a liquid sample. The degree brix reading indicates the refractive index of the solution, which correlates directly to dissolved solids content. For water-soluble stamping lubricants, this measurement translates into concentration percentage when you apply the correct conversion factor.

Here's how measuring brix works in practice:

- Place a few drops of your lubricant mixture on the refractometer prism

- Close the cover plate and point the device toward a light source

- Read the brix reading where the shadow line intersects the scale

- Multiply the reading by your lubricant's specific refractometer factor to determine actual concentration

Every lubricant formulation has a unique refractometer factor provided by the manufacturer. For example, if your lubricant has a factor of 1.5 and your brix reading shows 6.0, your actual concentration is 9% (6.0 × 1.5 = 9.0%). Without applying this correction, you'll consistently misjudge your mixture strength.

The brix percentage alone doesn't tell the complete story. Contamination from tramp oils, metal fines, and process debris affects readings over time. Clean samples and calibrated instruments ensure accurate results that you can trust for production decisions.

Typical Brix Readings for Lubricant Types

Different lubricant categories operate within specific concentration ranges. Understanding these targets helps you establish monitoring benchmarks for your operations:

| Lubricant Type | Typical Brix Reading Range | Actual Concentration Range | Refractometer Factor (Typical) | Monitoring Frequency |

|---|---|---|---|---|

| Light-duty water-soluble | 2.0 - 4.0 | 3% - 6% | 1.3 - 1.5 | Daily |

| General-purpose emulsions | 4.0 - 8.0 | 5% - 10% | 1.2 - 1.4 | Daily |

| Heavy-duty forming compounds | 6.0 - 12.0 | 8% - 15% | 1.1 - 1.3 | Per shift |

| Synthetic water-soluble | 3.0 - 7.0 | 4% - 8% | 1.0 - 1.2 | Daily |

| Aluminum-specific emulsions | 5.0 - 10.0 | 6% - 12% | 1.2 - 1.4 | Per shift |

Note that these ranges represent general guidelines. Your specific lubricant supplier provides exact specifications for their formulations. Always consult product technical data sheets for accurate refractometer factors and target concentration ranges.

Establishing Effective Lubricant Monitoring Programs

Consistent monitoring prevents problems that sporadic checking misses. When concentration drifts gradually over days or weeks, occasional spot checks may happen to catch acceptable readings while missing the overall trend toward failure.

An effective monitoring program includes these elements:

- Scheduled testing intervals - Daily minimum for most operations; per-shift for demanding applications or high-volume production

- Standardized sampling procedures - Collect samples from the same location, at the same point in the process, to ensure comparable readings

- Documentation and trending - Record all readings to identify patterns before they cause quality issues

- Defined action limits - Establish when to add concentrate, when to add water, and when concentrations indicate systemic problems requiring investigation

- Calibration schedules - Verify refractometer accuracy weekly using distilled water (should read zero) and standard solutions

Beyond concentration, monitor for signs of lubricant degradation. Unusual odors, color changes, or separation indicate bacterial contamination or chemical breakdown that concentration readings alone won't reveal.

Copper Sulfate Testing for Film Protection

Refractometers tell you concentration, but not whether your lubricant actually protects metal surfaces. The copper sulfate test provides a direct measure of lubricant film integrity and corrosion protection capability.

This test works by challenging the lubricant film with a corrosive copper sulfate solution. When you apply the solution to a lubricated steel surface, properly protected areas resist attack while inadequate film coverage allows copper plating to occur. The resulting pattern reveals exactly where protection fails.

Conducting a copper sulfate test involves:

- Applying lubricant to a clean steel test panel at your working concentration

- Allowing the film to develop according to your normal application method

- Immersing the panel in copper sulfate solution for a specified duration

- Rinsing and examining for copper deposits indicating film breakdown

This test proves particularly valuable when evaluating new lubricant formulations, verifying performance after concentration adjustments, or troubleshooting corrosion issues on stamped parts. A lubricant that shows adequate concentration by brix reading but fails copper sulfate testing likely suffers from contamination or additive depletion.

Regular quality control through refractometer monitoring and periodic film integrity testing creates a complete picture of lubricant health. These methods catch degradation before it affects production, reducing scrap rates and extending tool life. With concentration under control, your attention can shift to optimizing how lubricant reaches the workpiece through proper application methods and equipment selection.

Lubricant Application Methods and Equipment Selection

Having the right lubricant means nothing if it doesn't reach the workpiece properly. How you apply lube for metal surfaces during stamping operations directly affects forming success, material consumption, and part quality. The best lubricant for metal on metal contact fails when application methods create uneven coverage or excessive waste.

Different automotive stamping operations demand different application approaches. A complex drawing stamping operation forming deep body panels requires different coverage than a simple blanking operation. Understanding your options helps you match equipment to production requirements.

Roller Coating vs Spray Systems for Different Part Geometries

Roller coating systems apply lubricant through direct contact between rotating rollers and sheet material. As coil stock or blanks pass between applicator rollers, they receive a controlled film of lubricant on one or both surfaces. This method delivers exceptional consistency for flat or gently contoured materials entering progressive dies.

When should you consider roller coating?

- High-volume coil-fed operations where consistent coverage matters

- Flat blanks requiring uniform lubrication before forming

- Applications where precise film thickness control reduces waste

- Production lines where you need to machine aluminum or steel with predictable results

Spray systems atomize lubricant into fine droplets directed at workpiece surfaces. This approach reaches areas that rollers cannot contact, making it ideal for pre-formed blanks, complex geometries, and applications requiring targeted lubrication in specific zones.

Spray application excels when:

- Part geometry includes raised features or irregular surfaces

- Different areas require different lubricant coverage levels

- Quick changeovers between part types demand flexibility

- Transfer press operations need lubrication between stations

Comparing Application Methods Across Key Factors

Each application method presents distinct trade-offs. This comparison helps you evaluate options against your specific production requirements:

| Application Method | Coverage Uniformity | Lubricant Consumption | Part Complexity Suitability | Maintenance Requirements |

|---|---|---|---|---|

| Roller Coating | Excellent for flat surfaces | Low - precise film control | Limited to flat/simple shapes | Moderate - roller cleaning and replacement |

| Spray Systems | Good - adjustable patterns | Moderate - some overspray | Excellent for complex geometries | Higher - nozzle cleaning and calibration |

| Drip Application | Fair - gravity dependent | Low - minimal waste | Limited - best for localized areas | Low - simple systems |

| Flood Application | Complete coverage assured | High - recirculation required | Good for all geometries | High - filtration and cooling systems |

Optimizing Lubricant Coverage for Complex Stampings

Excess lubricant creates as many problems as insufficient coverage. Drips, pooling, and inconsistent film thickness lead to quality variations and downstream processing issues. This is where airknife systems prove invaluable.

An airknife directs a high-velocity curtain of air across lubricated surfaces, removing excess material while leaving a uniform thin film behind. When positioned after roller or spray application stations, airknife systems accomplish several important functions:

- Remove pooled lubricant from recessed areas and edges

- Equalize film thickness across the entire workpiece surface

- Reduce lubricant consumption by recycling removed excess

- Improve consistency for demanding downstream processes

The combination of spray application followed by airknife treatment often delivers optimal results for complex automotive stampings. You get complete coverage of irregular surfaces while maintaining the thin, uniform films that support quality forming and clean post-processing.

Matching Application Methods to Lubricant Types

Not every application method works with every lubricant formulation. Viscosity, volatility, and chemical composition influence which delivery systems perform effectively.

Water-soluble lubricants adapt well to spray systems, where atomization creates fine mist patterns that coat surfaces evenly. Roller systems also handle these formulations effectively, though roller material compatibility requires verification.

Neat oils with higher viscosity may resist atomization in standard spray equipment, requiring heated delivery systems or specialized nozzles. Roller coating often proves more practical for these heavier formulations.

Vanishing oils demand careful application control since their volatile nature means excess material evaporates rather than recycling. Precise spray systems with minimal overspray maximize efficiency with these premium formulations.

Production Volume Considerations

High-volume automotive stamping lines justify sophisticated application equipment investments. Automated roller coaters with closed-loop thickness control, multi-zone spray systems, and integrated airknife units deliver the consistency these operations demand while minimizing per-part lubricant costs.

Lower-volume operations or job shops face different economics. Simpler spray systems with manual adjustment, drip applicators for localized lubrication, or even brush application may prove more cost-effective. The key lies in matching equipment sophistication to production requirements without over-investing in capability you won't fully utilize.

Whether you're running millions of parts annually or producing specialty components in smaller batches, proper application equipment ensures your carefully selected lubricant delivers its full performance potential. When problems do occur despite proper formulation and application, systematic troubleshooting identifies root causes and guides corrective action.

Troubleshooting Common Lubrication-Related Stamping Defects

Even with the right lubricant properly applied and monitored, stamping forming issues still occur. When defects appear on your parts, how do you determine whether lubrication is the culprit? Understanding the connection between specific defects and their lubrication-related causes helps you diagnose problems quickly and implement effective solutions.

The relationship between lubrication and defect formation follows predictable patterns. Learn to recognize these patterns, and you'll transform reactive firefighting into proactive quality control.

Diagnosing Galling and Scoring Problems

Galling represents one of the most damaging lubrication failures in automotive stamping. This defect occurs when metal transfers from the workpiece to the die surface under extreme pressure. Once started, galling creates a rough texture on tooling that scratches every subsequent part, accelerating the damage cycle.

What causes galling? When lubricant film breaks down under pressure, direct metal to metal lubricant failure allows microscopic welding between surfaces. The softer workpiece material tears away and adheres to harder die steel. With each press stroke, this transferred material accumulates and roughens, creating progressively worse surface damage.

Scoring produces similar visual results but through a different mechanism. Rather than material transfer, scoring involves hard particles (metal fines, debris, or contaminants) dragging across surfaces and cutting grooves into both tooling and parts.

Common causes and solutions for galling and scoring include:

- Insufficient film strength - Switch to a lubricant for metal applications with enhanced extreme-pressure additives; neat oils often outperform water-soluble alternatives for severe galling conditions

- Inadequate lubricant coverage - Verify application equipment delivers complete coverage; check for plugged spray nozzles or worn roller applicators

- Contaminated lubricant - Metal fines accumulating in recirculating systems create abrasive particles; improve filtration or increase fluid change frequency

- Incompatible lubricant chemistry - Some materials (particularly aluminum and zinc-coated steels) require specialized anti-galling formulations

- Excessive die temperature - Heat degrades lubricant films; consider formulations with better thermal stability or add cooling systems

Solving Wrinkling and Splitting Through Lubrication Adjustments

Wrinkling and splitting represent opposite ends of the material flow spectrum, yet both connect directly to metalwork lubrication effectiveness.

Wrinkling occurs when material flows too freely, creating excess metal that buckles and folds rather than stretching smoothly. While die design and blank holder pressure primarily control wrinkling, excessive lubrication reduces friction below necessary levels, allowing uncontrolled material movement.

Splitting happens when material cannot flow enough to accommodate forming demands. The sheet stretches beyond its limits and tears. Insufficient lubrication increases friction, restricting material draw-in and concentrating strain in localized areas until failure occurs.

Finding the balance requires understanding your specific forming operation:

- Wrinkling from over-lubrication - Reduce concentration or switch to formulations with higher friction coefficients; consider selective lubrication only where needed

- Splitting from under-lubrication - Increase concentration or upgrade to higher-performance metal to metal lubricant formulations; verify complete coverage on critical draw areas

- Mixed defects on same part - Different zones may require different lubrication approaches; spray systems allowing zone-specific application offer flexibility

- Inconsistent defects across production - Check concentration monitoring frequency; drifting lubricant strength causes intermittent problems

Surface Scratches and Their Root Causes

Surface scratches on stamped parts often trace back to lubrication problems, though the connection isn't always obvious. These defects particularly concern manufacturers producing exterior automotive panels where any surface imperfection becomes visible in painted finishes.

Lubrication-related causes of surface scratching include:

- Film breakdown during forming - Lubricant thickness insufficient to separate surfaces throughout the complete stroke; increase concentration or upgrade film strength

- Lubricant contamination - Abrasive particles suspended in lubricant drag across surfaces during forming; improve filtration and increase maintenance frequency

- Dried lubricant residue - Evaporated lubricant leaves behind solid deposits that scratch subsequent parts; address application timing or switch to more stable formulations

- Incompatible viscosity - Lubricant too thin for the forming severity fails to maintain protective films; match viscosity to application demands

The Viscosity-Film Strength Relationship

Understanding how lubricant properties connect to defect prevention helps you select formulations that match your specific forming challenges. Viscosity determines how lubricant flows and distributes across surfaces. Film strength determines whether that lubricant survives the pressures of forming without breaking down.

For light forming operations with modest pressures, lower viscosity lubricants spread easily and provide adequate protection. As forming severity increases through deeper draws, tighter radii, or stronger materials, both viscosity and film strength requirements escalate.

When troubleshooting, consider whether your current lubricant matches your actual forming demands. A formulation that worked perfectly for mild steel may fail completely when you transition to advanced high-strength materials. Similarly, adding complexity to part geometry increases lubrication requirements even with the same material.

While this guide focuses on metal stamping, manufacturers working with mixed-material assemblies sometimes ask about the best lubricant for plastic on metal interfaces. These specialized applications require formulations compatible with both materials and fall outside typical metalwork lubrication recommendations. Consult lubricant suppliers for specific guidance on these unique requirements.

Systematic troubleshooting transforms lubrication problems from frustrating mysteries into solvable challenges. Document your findings, track defect patterns against process variables, and build institutional knowledge that prevents repeat issues. With defects under control, you can focus on optimizing lubricant selection for specific automotive component categories.

Lubricant Selection Guide for Automotive Component Categories

How do you translate everything you've learned about lubricant types, material requirements, and application methods into practical decisions for specific automotive components? The answer lies in understanding that different parts within the same vehicle demand fundamentally different lubrication strategies.

A structural B-pillar reinforcement faces entirely different forming challenges than an exterior door skin. The stamping oil that excels for one application may fail completely for the other. This section guides you through systematic selection criteria that match lubricant characteristics to component requirements.

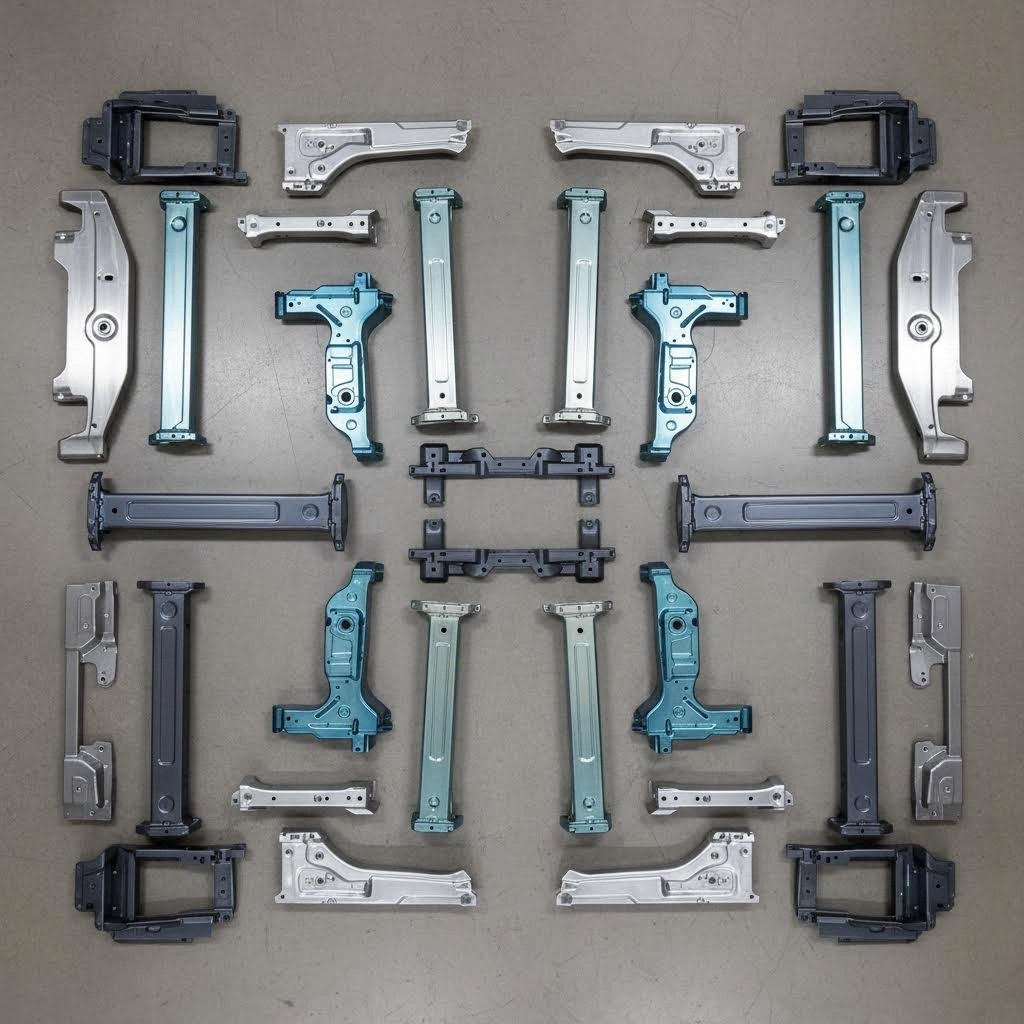

Matching Lubricants to Body-in-White Components

Body-in-white (BIW) structural components form the safety cage protecting vehicle occupants. These parts increasingly use AHSS and UHSS materials, creating extreme lubrication demands during forming operations.

When stamping structural members like floor pans, cross members, and pillar reinforcements, consider these factors:

- Extreme-pressure performance - High-strength materials generate crushing forces that demand robust film strength; neat oils or high-performance synthetics typically outperform water-soluble alternatives

- Welding compatibility - Most BIW components proceed directly to resistance welding; select easily cleanable formulations or vanishing oils where forming severity permits

- Zinc coating protection - Many structural components use zinc coated materials for corrosion resistance; lubricants must protect this coating during forming

- Deep draw requirements - Complex structural geometries often involve significant draw depths requiring enhanced deep draw lubricant formulations

Galvanized steel stamping operations for BIW components present particular challenges. The combination of high material strength and protective coatings requires lubricants that deliver extreme-pressure protection without chemically attacking the zinc surface.

Selection Criteria for Structural vs Exterior Panel Stamping

Exterior panels represent the opposite end of the stamping spectrum from structural components. While B-pillars hide beneath interior trim, door skins and fenders define the vehicle's visual identity. Every surface imperfection becomes visible under paint.

Exterior panel stamping priorities differ significantly:

- Surface finish preservation - Lubricants must prevent any scratching, galling, or marking that would show through painted finishes

- Clean removal - Residue-free surfaces are essential for proper e-coating and paint adhesion; water-soluble formulations or vanishing oils dominate these applications

- Aluminum compatibility - Lightweight closures increasingly use aluminum alloys requiring specialized draw oil formulations that prevent adhesion

- Moderate forming severity - Gentler forming operations allow use of lighter lubricant formulations compared to deep-draw structural parts

The growing use of aluminum for hoods, deck lids, and doors has transformed exterior panel lubrication requirements. Aluminum forming demands anti-adhesion chemistry that steel-focused formulations simply don't provide.

Comprehensive Lubricant-Component Matching Guide

This table synthesizes material considerations, forming requirements, and downstream process compatibility into practical lubricant recommendations for major automotive component categories:

| Component Category | Typical Materials | Forming Severity | Recommended Lubricant Types | Key Selection Considerations |

|---|---|---|---|---|

| BIW Structural (pillars, rails, reinforcements) | AHSS, UHSS, zinc coated steel | High to Extreme | Neat oils, high-EP synthetics, heavy-duty water-soluble | Maximum film strength; welding compatibility; coating protection for zinc coated materials |

| Closure Panels (doors, hoods, deck lids) | Aluminum alloys, mild steel, galvanized steel | Moderate to High | Aluminum-specific synthetics, water-soluble emulsions, vanishing oils | Surface finish quality; easy cleaning; aluminum anti-adhesion for lightweight closures |

| Chassis Components (control arms, brackets, crossmembers) | High-strength steel, galvanized steel | Moderate to High | Water-soluble with EP additives, neat oils for severe draws | Welding residue control; corrosion protection; deep draw lubricant for complex geometries |

| Exterior Panels (fenders, quarter panels, roof) | Mild steel, aluminum, galvanized steel | Low to Moderate | Water-soluble emulsions, vanishing oils, light synthetics | Class A surface requirements; residue-free removal; paint adhesion compatibility |

| Interior Structural (seat frames, cross car beams) | AHSS, conventional high-strength steel | Moderate to High | Water-soluble with EP additives, moderate-duty neat oils | Welding process compatibility; balanced cost-performance ratio |

How Part Geometry Influences Lubricant Requirements

Beyond material type, three geometric factors dramatically influence lubricant selection: complexity, draw depth, and material thickness.

Geometry complexity determines how material must flow during forming. Simple shallow draws with generous radii require less lubrication than parts featuring sharp corners, deep pockets, and compound curves. As complexity increases, lubricant must maintain its protective film through increasingly severe conditions.

Draw depth directly correlates with friction distance and pressure duration. Shallow stampings contact die surfaces briefly, while deep draws maintain tool-workpiece contact through extended forming strokes. Deep draw lubricant formulations incorporate enhanced boundary additives that sustain protection throughout these longer contact periods.

Material thickness affects both forming forces and heat generation. Thicker materials require greater forming energy, generating higher temperatures that can degrade lubricant films. Heavier gauges also concentrate stress at die radii, demanding superior extreme-pressure performance.

Consider a practical example: stamping a simple bracket from 1.0mm mild steel might succeed with a basic water-soluble lubricant at 5% concentration. That same lubricant would likely fail catastrophically when forming a deep-drawn structural reinforcement from 1.8mm AHSS, where draw oil with maximum film strength becomes essential.

Collaborating with Die Designers and Tooling Engineers

Lubricant selection doesn't happen in isolation. The most effective approach involves collaboration between stamping engineers, lubricant specialists, and die designers from the earliest project stages.

Why does early collaboration matter? Die geometry and lubricant performance are interdependent. Draw radii, binder surfaces, and material flow paths all influence lubrication requirements. Similarly, knowing which stamping oil the production operation will use allows die designers to optimize tooling for that specific lubrication condition.

This integration becomes particularly valuable when working with challenging materials or complex geometries. Advanced CAE simulation can predict lubrication requirements before cutting any steel, identifying potential problem areas where enhanced lubrication or tooling modifications might be necessary.

Manufacturers seeking this integrated approach benefit from working with tooling suppliers who understand both die design and lubrication optimization. Companies like Shaoyi, with IATF 16949 certified engineering capabilities, offer precision stamping die solutions that incorporate advanced CAE simulation to predict forming behavior and optimize tooling design for specific lubricant types. This approach catches potential lubrication issues during development rather than production.

Validating Lubricant Selection Through Prototyping

Even the most sophisticated analysis benefits from physical validation. Prototype stamping trials using production-intent lubricants reveal real-world performance that simulation alone cannot fully predict.

Effective validation includes:

- Running trials with the specific stamping oil grade intended for production

- Testing across the expected concentration range to identify sensitivity

- Evaluating parts through subsequent welding and painting to verify downstream compatibility

- Documenting optimal settings as the baseline for production launch

Rapid prototyping capabilities accelerate this validation process. When tooling suppliers can deliver prototype dies quickly, manufacturers gain additional cycles to optimize lubricant selection before committing to production tooling. High first-pass approval rates during this phase indicate that lubricant-die interactions have been properly addressed.

With systematic selection criteria and proper validation, lubricant choices transform from educated guesses into confident engineering decisions. The final step involves implementing these strategies effectively across your production operations.

Implementing Effective Lubricant Strategies for Production Excellence

You've explored lubricant types, material-specific requirements, application methods, and troubleshooting techniques. Now comes the critical question: how do you translate this knowledge into measurable improvements across your stamping operations? Success requires a structured approach that addresses both immediate optimization opportunities and long-term strategic development.

The difference between manufacturers who struggle with lubrication issues and those who achieve consistent production excellence often comes down to systematic implementation. Random adjustments rarely solve persistent problems. Deliberate, data-driven optimization does.

Building Your Lubricant Optimization Roadmap

Think of lubricant optimization as a journey rather than a destination. Materials evolve, production requirements change, and new formulations enter the market. The manufacturers who stay ahead build systems that continuously adapt rather than settling for "good enough" solutions.

Your roadmap should address three horizons:

- Immediate actions - Audit current lubricant practices, establish baseline measurements, and identify obvious improvement opportunities

- Short-term improvements - Implement monitoring programs, optimize concentrations, and validate lubricant-process compatibility

- Long-term strategy - Develop supplier partnerships, integrate lubrication planning into die design, and build institutional knowledge

When you define brix scale parameters for your operations, you create objective benchmarks that remove guesswork from concentration management. Understanding brix def (the measurement of dissolved solids concentration) transforms subjective assessments into quantifiable targets your team can consistently achieve.

Match your lubricant selection to the complete manufacturing chain—from material type and forming severity through welding requirements and paint adhesion—not just the stamping operation in isolation.

Key Factors for Long-Term Stamping Success

Sustainable improvement requires addressing root causes rather than symptoms. When weld spatter increases, the immediate reaction might focus on welding parameters. But understanding what is weld spatter and its connection to lubricant residue reveals that the solution often lies upstream in the stamping operation.

Similarly, when forming UHS steel or A.H.S.S. materials, lubricant selection becomes inseparable from tooling design. The extreme pressures these materials generate demand integrated solutions where lubricant formulation, die geometry, and process parameters work together.

Consider these priorities when evaluating your current practices:

- Audit your material portfolio - Document every material grade you stamp, from mild steel through UHSS steel, and verify that lubricant selections match each material's specific requirements

- Map downstream processes - Identify which stamped parts proceed to welding, adhesive bonding, or painting, then confirm lubricant compatibility with each subsequent operation

- Establish monitoring protocols - Implement daily concentration checks using calibrated refractometers with documented target ranges for each lubricant type (this is where degree brix definition knowledge becomes practical)

- Create defect-cause databases - Track lubrication-related quality issues and their root causes to build troubleshooting knowledge that prevents repeat problems

- Evaluate application equipment - Assess whether your current application methods deliver consistent coverage appropriate for part complexity

- Review supplier relationships - Partner with lubricant suppliers who provide technical support, not just product delivery

- Integrate with die development - Include lubrication requirements in die design specifications from project inception

The Value of Integrated Tooling Partnerships

Lubricant performance and die design exist in a feedback loop. Tooling geometry influences lubrication requirements, while lubricant behavior affects how dies perform and wear over time. Manufacturers who treat these as separate concerns miss optimization opportunities that integrated approaches capture.

Experienced tooling suppliers understand this relationship. They design draw radii, binder surfaces, and material flow paths with specific lubricant types in mind. When challenges arise during tryout, they can distinguish between lubrication issues and tooling design problems, addressing root causes rather than applying band-aid solutions.

Rapid prototyping capabilities prove particularly valuable for lubricant validation. When you can test production-intent formulations on prototype tooling quickly, you identify potential issues before committing to production dies. This approach reduces risk and accelerates launch timelines.

Manufacturers seeking this integrated expertise benefit from partnerships with suppliers like Shaoyi, whose rapid prototyping capabilities and 93% first-pass approval rates demonstrate effective lubricant-die optimization during development. Their IATF 16949 certified engineering team brings the material knowledge and process understanding necessary to validate lubricant performance before production launch.

Moving Forward with Confidence

Effective lubricant strategies don't require revolutionary changes. They require consistent attention to fundamentals: selecting formulations matched to your materials, maintaining proper concentrations, applying lubricants uniformly, and monitoring for problems before they affect production.

Start with your most challenging applications—the parts where forming issues occur most frequently or where material costs make scrap particularly expensive. Optimize these first, document your improvements, then systematically extend successful practices across your operation.

The knowledge you've gained throughout this guide provides the foundation. Your specific materials, part geometries, and production requirements define the application. By combining sound fundamentals with systematic implementation, you'll transform lubricant management from a reactive necessity into a competitive advantage that delivers consistent quality, extended tool life, and efficient production.

Frequently Asked Questions About Lubricants for Automotive Stamping

1. What types of lubricants are used for metal stamping?

Four main lubricant categories dominate automotive stamping: water-soluble lubricants offering excellent cooling for high-volume production, neat oils providing maximum film strength for severe forming operations, synthetic metal forming lubricants engineered for specialty materials like aluminum, and vanishing oils that evaporate post-stamping for parts proceeding directly to welding or painting. Selection depends on material type, forming severity, and downstream process requirements.

2. How do you choose the best lubricant for stamping aluminum?

Aluminum stamping requires specialized lubricants with anti-adhesion chemistry to prevent microscopic welding between the workpiece and die surfaces. Look for formulations containing polar additives that create chemical barriers against aluminum transfer. Synthetic lubricants engineered specifically for aluminum forming typically outperform conventional options, while water-soluble emulsions with anti-weld additives offer cost-effective alternatives for moderate forming severity.

3. What causes galling in metal stamping and how can lubricants prevent it?

Galling occurs when lubricant film breaks down under extreme pressure, allowing direct metal-to-metal contact and material transfer from workpiece to die. Prevention requires selecting lubricants with enhanced extreme-pressure additives, ensuring complete coverage through proper application equipment, maintaining correct concentrations through regular refractometer monitoring, and choosing formulations specifically designed for your material type—particularly important for zinc-coated steels and aluminum alloys.

4. How do stamping lubricants affect welding quality?

Lubricant residue significantly impacts welding outcomes. When contaminated parts enter welding cells, heat vaporizes organic compounds creating gas pockets that cause porosity, inconsistent penetration, and excessive weld spatter. Chloride compounds in some lubricants promote long-term corrosion in weld zones. Manufacturers producing weld-ready parts should select vanishing oils or easily cleanable water-soluble formulations and implement residue testing protocols before welding operations.

5. How do you monitor lubricant concentration in stamping operations?

Refractometers provide quick, accurate concentration measurements for water-soluble lubricants. The brix scale reading multiplied by your lubricant's specific refractometer factor determines actual concentration percentage. Effective monitoring programs include daily testing at minimum, standardized sampling procedures, documentation for trend analysis, defined action limits for adjustments, and weekly calibration verification. Copper sulfate testing complements concentration monitoring by directly measuring lubricant film integrity and protection capability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —