Metal Stamping Processes Decoded: From Raw Sheet To Finished Part

What Is Metal Stamping and Why It Dominates Manufacturing

Ever wondered how manufacturers produce millions of identical metal components with remarkable precision? The answer lies in metal stamping - a powerhouse technique that shapes everything from tiny electronic connectors to large automotive body panels.

Metal stamping is a cold-forming manufacturing process that transforms flat sheet metal into specific shapes using specialized dies and stamping presses, applying high pressure without heating the material.

So, what is stamping at its core? Picture this: a flat metal sheet placed between two precision-engineered tools - a punch and a die. When the stamping press activates, immense force drives the punch downward, pressing the metal into the die cavity below. In that split second, the metal takes on a new form - bent, cut, embossed, or shaped according to the die's design.

How Metal Stamping Transforms Raw Sheets Into Precision Parts

The mechanics behind this process are elegantly simple yet remarkably powerful. A stamping press generates anywhere from a few tons to thousands of tons of force, depending on the application. This force flows through the punch, which acts like a precisely shaped hammer, pushing the metal blank into the die below. The die functions as a mold, defining exactly what shape the finished part will take.

What sets metal stamping apart from other manufacturing methods? Speed and consistency. A single stamping press can produce thousands of identical metal pressings per hour, each one matching the previous with tolerances measured in thousandths of an inch. This repeatability makes it indispensable for industries demanding high-volume production.

The Cold-Forming Advantage in Modern Manufacturing

Unlike processes that require heating metal to extreme temperatures, metal stamping works at room temperature. This cold-forming approach preserves the material's structural integrity while allowing manufacturers to achieve tight tolerances and excellent surface finishes. The result? Stronger parts, faster production cycles, and reduced energy costs.

Throughout this comprehensive guide, you'll discover everything from fundamental stamping techniques to advanced die selection strategies. We'll walk through the complete manufacturing workflow, compare different stamping methods, explore material selection, and address quality control challenges. Consider this your definitive single-source reference - eliminating the need to piece together information from multiple sources. Whether you're an engineer evaluating production options or a procurement specialist sourcing stamped components, you'll find the answers you need in the sections ahead.

The Complete Metal Stamping Manufacturing Process Explained

Now that you understand what metal stamping is, let's explore how manufacturers actually transform raw sheet metal into finished components. The metal stamping process follows a carefully orchestrated sequence - skip a step or execute one poorly, and the entire production run suffers. Think of it like baking a cake: ingredients, order, and technique all matter equally.

From Blueprint to Finished Part in Seven Critical Stages

The stamping manufacturing process unfolds across seven interconnected stages. Each phase builds upon the previous one, creating a chain where every link must hold strong. Here's how the complete metal stamping manufacturing process works:

-

Design and Engineering

Everything begins on the drawing board. Engineers and product designers collaborate to define part functionality, dimensional tolerances, and quality requirements. During this phase, teams select appropriate materials, gather cross-functional input, create detailed specifications, and develop prototypes for testing. Comprehensive documentation ensures everyone - from toolmakers to quality inspectors - shares the same vision. A flawed design creates problems that cascade through every subsequent stage. -

Tooling and Die Creation

With approved designs in hand, toolmakers craft the dies that will shape every part. This involves selecting appropriate die types (progressive, transfer, or compound), engineering the punch and die geometry, and machining components to precise tolerances. Quality tooling requires collaboration between design engineers and die makers to prove out the intended stamping process before full production begins. The die essentially becomes the DNA of your part - its precision determines everything that follows. -

Material Selection and Preparation

Choosing the right metal isn't guesswork. Engineers evaluate material properties like hardness, thickness consistency, and ductility against part requirements. Raw materials arrive as coils or flat sheets, then undergo inspection to verify specifications. Material characteristics directly impact stampability - too hard, and cracking occurs; too soft, and parts won't hold their shape. Preparation may include cleaning, lubrication application, or leveling to ensure optimal feeding. -

Blank Feeding

The manufacturing stamping process truly begins when metal enters the press. Coil-fed systems use feeders that advance precise lengths of material between each press stroke, while sheet-fed operations position individual blanks. Pilot holes punched in the first station keep the strip aligned as it moves through subsequent operations. Without accurate feeding, parts shift out of position, creating scrap and potential die damage. -

The Stamping Operation

This is where transformation happens. The press cycles, driving the punch into the die with tremendous force. Depending on part complexity, the metal may pass through multiple stations - piercing pilot holes, trimming profiles, forming bends, adding secondary features, and finally separating from the carrier strip. Here's something many overlook: friction between the die and metal generates heat during rapid production runs. This heat can alter material properties, affecting springback behavior and dimensional stability. Experienced manufacturers monitor temperature and adjust lubrication or cycle timing accordingly. -

Secondary Operations

Stamping rarely produces a completely finished part. Secondary operations refine the product through deburring (removing sharp edges), heat treatment (adjusting material properties), plating or coating (adding corrosion resistance), welding or assembly (joining multiple components), and dimensional finishing. These value-added processes bridge the gap between a stamped component and a ready-to-install part. -

Quality Inspection

The final gate ensures only conforming parts reach customers. Inspection protocols include first-piece verification, in-process monitoring using statistical process control, dimensional measurement with gauges or CMMs, surface finish evaluation, and final lot sampling. Quality control in stamping manufacturing heavily depends on raw material consistency - variations in hardness or thickness ripple through the entire process. Robust inspection catches problems before they become costly returns.

Why Each Step Determines Final Part Quality

Imagine skipping material preparation and feeding inconsistent stock into your die. The first station punches pilot holes slightly off-center. By the time the strip reaches forming stations, every bend lands in the wrong location. When parts finally separate at cut-off, dimensional checks reveal nothing is in tolerance. One upstream shortcut created an entire production run of scrap.

The metal stamping manufacturing process demands respect for sequence. Design errors multiply through tooling. Poor material selection causes forming failures. Inadequate feeding creates alignment problems. Improper stamping parameters generate defects. Skipped secondary operations leave unsafe edges. And without thorough inspection, defective parts escape into the supply chain.

Understanding this interconnected workflow helps you ask the right questions when evaluating stamping partners or planning your own production. With the complete process mapped out, you're ready to explore the specific techniques manufacturers use at each stamping station - and that's exactly where we're headed next.

Essential Metal Stamping Techniques and Their Applications

You've seen how the stamping workflow unfolds from design to final inspection. But what actually happens during that critical stamping operation stage? The answer depends entirely on which technique - or combination of techniques - the die employs. Understanding the stamping meaning behind each operation helps you specify the right approach for your parts and communicate effectively with manufacturing partners.

Think of these techniques as a toolbox. Some projects require just one tool; complex parts might demand six or seven working in sequence. Let's break down the nine essential operations that power modern stamping and pressing production.

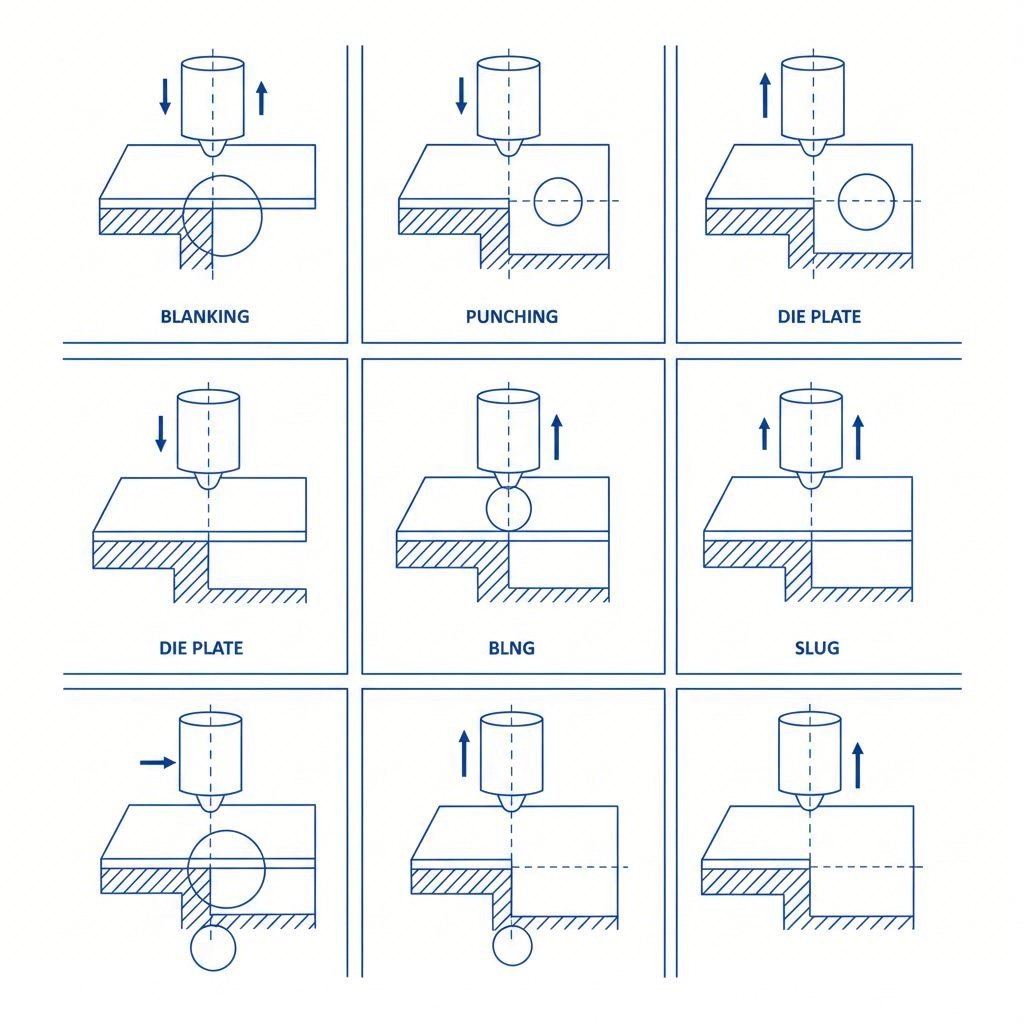

Nine Essential Stamping Operations Every Engineer Should Know

Blanking serves as the starting point for countless stamped parts. During this operation, a punch forces through sheet metal to cut a flat shape - the "blank" - that becomes the workpiece for subsequent operations. Blank stamping metal creates the foundational profile from which everything else develops. The cut piece is the desired product, while the remaining sheet becomes scrap. Blanking works best with materials that shear cleanly, including low-carbon steel, aluminum, and brass.

Punching looks similar to blanking but serves the opposite purpose. Here, the goal is creating holes or cutouts in the workpiece - the punched-out material is scrap, and the remaining sheet is the product. Die stamping operations frequently combine punching with other techniques to add mounting holes, ventilation slots, or weight-reduction features. This cold-forming process handles materials from thin aluminum to thick steel plate, though hole size relative to material thickness affects edge quality.

Bending transforms flat blanks into three-dimensional parts by plastically deforming metal along a straight axis. When force is applied, the metal stretches on the outer surface and compresses on the inner surface of the bend. The critical consideration? Every metal has a minimum bend radius - go tighter, and cracking occurs. Material grain direction matters too; bending perpendicular to grain lines risks splitting the workpiece. Successful bending operations account for springback, the elastic recovery that causes parts to partially unbend after forming.

Coining applies extreme pressure - often exceeding material flow stress - to create precise surface details and accurate dimensions. Unlike other forming operations, coining steel and other metals eliminates springback entirely because the material yields completely under pressure. This technique produces the sharp details you see on currency, medallions, and precision hardware. The trade-off? High tooling wear and significant press tonnage requirements make coining expensive for large parts.

Embossing creates raised or recessed patterns on metal surfaces without cutting through the material. Male and female dies press the workpiece between them, stretching metal into decorative or functional relief patterns. You'll find embossed features on appliance panels, automotive trim, and identification plates. Stamps and embossers work best with ductile materials that can stretch without tearing - aluminum and low-carbon steel excel here, while high-strength alloys may crack during embossing operations.

Flanging bends metal edges at specific angles - typically 90 degrees - to create reinforcing lips, mounting surfaces, or assembly features. Unlike full bending operations, flanging applies only to edge portions of the workpiece. Two types exist: stretch flanging curves the flange convexly (outer edge stretches), while shrink flanging creates concave curves (inner edge compresses). Material ductility determines how aggressive your flange geometry can be before wrinkling or cracking occurs.

Stretching expands metal surface area by pulling the material over a form die. This technique creates smooth, curved surfaces like automotive body panels and aircraft skins. During stretching, the metal thins as it expands - designers must account for this thinning to maintain structural integrity. Highly ductile materials like aluminum alloys and deep-drawing steel grades perform best, as brittle metals fracture before achieving the desired shape.

Curling rolls sheet metal edges into circular profiles, creating safe edges, decorative features, or structural reinforcement. Think of the rolled rim on a metal can or the curled edge of a hinge barrel. The curling operation progressively bends the material through successively tighter radii until the desired curl diameter is achieved. Thinner gauges curl more easily, while thicker materials require multiple forming stages or specialized tooling.

Drawing transforms flat blanks into hollow, three-dimensional shapes - cups, cylinders, boxes, and complex enclosures. The punch forces metal into a die cavity while blank holder pressure controls material flow. Deep drawing describes operations where the depth exceeds the diameter, requiring precise control of material movement to prevent wrinkling or tearing. Brass, copper, aluminum, and specialized deep-drawing steels work best because their ductility allows significant plastic deformation.

Matching Techniques to Part Requirements

Selecting the right stamping operation starts with understanding your part's functional requirements. Need a flat profile cut from sheet stock? Blanking delivers. Mounting holes for fasteners? Punching handles it. Structural rigidity from bent geometry? Bending and flanging combine to create strong, lightweight shapes.

The following table consolidates all nine techniques, helping you match operations to your specific application needs:

| Technique Name | Primary Function | Typical Applications | Material Considerations |

|---|---|---|---|

| Blanking | Cutting flat shapes from sheet metal | Metal sheet cutting, gaskets, washers, base components | Clean-shearing metals preferred; avoid extremely hard or brittle alloys |

| Punching | Creating holes or cutouts in workpieces | Mounting holes, ventilation slots, weight reduction features | Hole-to-thickness ratio affects edge quality; pilot holes common |

| Bending | Angular deformation along a straight axis | Brackets, enclosures, frames, chassis components | Minimum bend radius varies by material; grain direction critical |

| Coining | High-pressure surface detail and precision forming | Coins, medallions, jewelry, precision hardware with logos | High tonnage required; excellent for eliminating springback |

| Embossing | Creating raised or recessed surface patterns | Decorative panels, nameplates, appliance surfaces | Ductile materials essential; stretching limits pattern depth |

| Flanging | Forming bent edges at specific angles | Containers, pipes, automotive body reinforcement | Stretch vs. shrink flanging requires different ductility levels |

| Stretching | Expanding surface area over form dies | Automotive doors, roofs, aircraft skins | Material thins during forming; high ductility required |

| Curling | Rolling edges into circular profiles | Can rims, hinge barrels, decorative edges, safety edges | Thinner gauges curl easier; thicker stock needs progressive stages |

| Drawing | Forming deep hollow cavities from flat blanks | Cups, cylinders, enclosures, kitchen sinks | Deep-drawing grades essential; blank holder pressure critical |

In practice, most stamped parts combine multiple techniques in a single die. A progressive die might punch pilot holes, blank the perimeter, bend mounting tabs, and emboss a part number - all in one continuous operation. Understanding each technique's capabilities and limitations empowers you to design parts that manufacture efficiently while meeting functional requirements.

With these foundational operations clear, you're ready to explore how different stamping methods - progressive die, transfer die, fourslide, and fine blanking - organize these techniques into complete production systems.

Progressive Die vs Transfer Die vs Fourslide Stamping Methods

You've mastered the individual techniques - blanking, bending, drawing, and the rest. But here's where things get interesting: how do manufacturers organize these operations into efficient production systems? The answer lies in choosing the right stamping method for your specific project. Get this decision wrong, and you'll either overspend on unnecessary capabilities or struggle with a process that can't deliver what you need.

Four distinct approaches dominate modern stamping machines and production floors. Each brings unique advantages, limitations, and cost profiles. Let's break them down so you can match your project requirements to the optimal method.

Progressive Die vs Transfer Die - Choosing Your Production Method

Progressive Die Stamping represents the workhorse of high-volume production. Imagine a continuous strip of metal feeding through a series of stations - each station performs a different operation as the strip advances. Pilot holes punched in the first station keep everything aligned as the material moves through piercing, forming, bending, and final cutoff stages. The finished part drops from the end while the next part continues forming upstream.

What makes progressive die and stamping so powerful? Speed and efficiency. A single stroke of metal stamping presses produces work at every station simultaneously. While station five cuts off a finished part, station four completes the final bend, station three adds holes, and stations one and two prepare the next pieces. Production rates can exceed 1,500 parts per minute on high-speed stamping presses, making this method ideal for small to medium-sized components needed in massive quantities.

The trade-off? Progressive dies require significant upfront investment in complex tooling. They also limit part geometry - components must remain attached to the carrier strip throughout processing, constraining three-dimensional complexity. Parts with deep draws or features requiring repositioning mid-process push beyond progressive die capabilities.

Transfer Die Stamping solves the geometry limitations by physically moving individual parts between stations. Instead of remaining connected to a carrier strip, blanks are picked up by mechanical fingers or transfer mechanisms and repositioned for each operation. This freedom allows operations from multiple angles and enables complex three-dimensional forming impossible in progressive systems.

When does transfer stamping shine? Large parts that won't fit efficiently on a strip, components requiring operations from different directions, and geometries demanding significant repositioning between stations all favor transfer methods. Automotive structural components and appliance housings frequently use transfer die production. Each stamping machine station can access the part from optimal angles, enabling deeper draws and more intricate forming sequences.

The downside? Slower cycle times compared to progressive stamping, since mechanical transfer takes time between strokes. Tooling costs remain high, and the transfer mechanisms add complexity requiring skilled setup and maintenance.

Fourslide and Multislide Stamping takes a completely different approach. Instead of vertical press motion, four (or more) tool-carrying slides approach the workpiece horizontally from multiple directions. Wire or strip stock feeds into the machine, and forming tools simultaneously shape the material from all sides.

This method excels at producing complex bends, clips, springs, and intricate wire forms that would require multiple operations in conventional stamping machines. Electronic connectors, spring clips, and small brackets with bends in multiple planes are fourslide specialties. Because tools approach from several directions simultaneously, parts with returns, hooks, and complex bend sequences form efficiently.

Fourslide tooling costs significantly less than progressive or transfer dies - often 50-70% lower for comparable parts. Setup flexibility allows quick changeovers between part numbers. However, fourslide works best with smaller parts and lighter-gauge materials. Heavy forming operations requiring substantial tonnage exceed its capabilities.

When Fine Blanking Justifies the Premium Investment

Fine Blanking addresses a fundamental limitation of conventional stamping: edge quality. Standard blanking produces edges with shear zones, breakout, and burrs requiring secondary finishing. Fine blanking eliminates these issues by applying triple-action force - a V-ring impinges the material around the cut perimeter while counter-pressure from below supports the blank during shearing. The result? Fully sheared, smooth edges with dimensional tolerances measured in hundredths of a millimeter.

Precision stamping through fine blanking produces parts ready for assembly without deburring, grinding, or machining. Gear teeth, cam profiles, and safety-critical components benefit from the clean edges and tight tolerances. Automotive seat mechanisms, lock components, and power tool gears frequently specify fine blanking when precision and edge quality matter.

The premium investment reflects the specialized equipment and tooling required. Fine blanking presses operate more slowly than conventional stamping machines, and the triple-action mechanism demands precise setup. Per-part costs run higher than standard blanking. But when you factor in eliminated secondary operations and improved functional performance, fine blanking often delivers lower total cost for precision applications.

Still unsure which method fits your project? The following comparison breaks down the key decision factors:

| Stamping Method | Best For | Volume Range | Tolerance Level | Part Complexity | Relative Cost |

|---|---|---|---|---|---|

| Progressive Die | Small-to-medium parts in high volumes | 100,000 to millions annually | ±0.05 to ±0.1 mm typical | Moderate - limited by carrier strip attachment | High tooling; low per-part at volume |

| Transfer Die | Large or geometrically complex parts | 10,000 to 500,000 annually | ±0.05 to ±0.15 mm typical | High - repositioning enables complex geometry | High tooling; moderate per-part cost |

| Fourslide/Multislide | Complex bends, clips, springs, wire forms | 5,000 to millions annually | ±0.1 to ±0.25 mm typical | High for bends; limited for heavy forming | Low-to-moderate tooling; competitive per-part |

| Fine Blanking | Precision parts requiring clean edges | 10,000 to 500,000 annually | ±0.01 to ±0.05 mm achievable | Moderate - edge-focused applications | Premium tooling and per-part; offsets secondary ops |

Your selection depends on balancing several factors: annual volume requirements, geometric complexity, dimensional precision needs, and total cost including secondary operations. High-volume production of moderately complex small parts? Progressive die delivers the lowest per-piece cost. Large structural components with complex three-dimensional geometry? Transfer die handles what progressive cannot. Intricate bent forms at competitive tooling costs? Fourslide offers flexibility. Precision edges without finishing operations? Fine blanking justifies its premium.

With your stamping method selected, the next critical decision awaits: which metal will deliver the performance your application demands? Material selection directly impacts everything from formability to final part durability - and that's exactly what we'll explore next.

Metal Selection Guide for Stamping Success

You've chosen your stamping method - progressive, transfer, fourslide, or fine blanking. But here's the question that can make or break your project: which metal should you run through that die? Select the wrong material, and you'll battle cracking, excessive springback, or premature tooling wear. Choose wisely, and parts form cleanly, production runs smoothly, and finished components perform exactly as designed.

Material selection isn't guesswork. It's a calculated decision based on your part's functional requirements, forming complexity, and production economics. Let's explore the metal for stamping options that dominate modern manufacturing - and the properties that determine their stampability.

Steel, Aluminum, or Copper - Selecting the Right Metal for Your Stamping Project

Carbon Steel remains the workhorse of metal stamping materials. Affordable, widely available, and easy to form, carbon steel suits everything from automotive brackets to appliance housings. Different carbon levels create distinct grades:

- Low-carbon steel (0.05-0.25% carbon): Excellent formability and ductility make this the go-to choice for deep drawing and complex bends. Stamped steel parts from low-carbon grades form without cracking and hold tight tolerances.

- Medium-carbon steel (0.25-0.60% carbon): Balances strength with reasonable formability. Suitable for structural components requiring higher load capacity than low-carbon alternatives.

- High-strength low-alloy (HSLA) steel: Delivers superior strength-to-weight ratios for automotive and structural applications where reducing material thickness saves weight without sacrificing performance.

Coated and Galvanized Steel addresses corrosion concerns built into the raw material. Hot-dip galvanizing, electrogalvanizing, and proprietary coatings provide protection without post-stamping finishing operations. Consider coating thickness when calculating die clearances - the zinc layer affects material behavior during forming.

Stainless Steel combines corrosion resistance with impressive strength, making it essential for medical devices, food processing equipment, and marine applications. However, stainless steel stamping demands respect for its unique properties:

- 300 series (austenitic): Types 301, 302, and 305 offer excellent corrosion resistance and good formability. Work hardening occurs rapidly - material becomes harder and more brittle as you form it, requiring careful process planning.

- 400 series (ferritic and martensitic): Grades 410, 420, and 440A provide magnetic properties and higher strength but reduced ductility compared to austenitic grades.

- Precipitation-hardening grades: 17-4PH and 17-7PH achieve exceptional strength after heat treatment, though they present greater forming challenges.

A critical consideration with austenitic stainless: the meta-stable structure transforms during deformation, inducing a martensitic phase. According to Ulbrich's precision stamping guide, this martensite is brittle and easy to crack. As deformation increases, martensitic content rises along with residual stress - making careful process control essential for successful stainless steel stamping.

Aluminum Alloys deliver lightweight performance where weight reduction matters. Stamped aluminum weighs roughly one-third of comparable steel parts, making it invaluable for automotive, aerospace, and consumer electronics applications. Common aluminum stamping grades include:

- 1100 series: Commercially pure aluminum with exceptional formability and corrosion resistance - ideal for deep drawing and complex shapes.

- 3003 and 3004: Moderate strength with good workability; popular for cookware, signage, and general stamping applications.

- 5052 and 5083: Higher strength marine-grade alloys with excellent corrosion resistance for demanding environments.

- 6061: Heat-treatable alloy offering good strength and formability; commonly used for structural applications.

Aluminum's softness reduces tooling wear compared to steel, extending die life. However, its tendency to gall - stick to tooling surfaces - requires proper lubrication and sometimes specialized die coatings.

Copper and Copper Alloys excel in applications demanding electrical conductivity, thermal transfer, or antimicrobial properties. Copper stamping produces connectors, terminals, heat exchangers, and decorative hardware:

- Pure copper (C110): Maximum conductivity for electrical applications; excellent ductility allows complex forming.

- Brass (copper-zinc alloys): Combines good formability with attractive appearance and moderate conductivity; popular for decorative and electrical components.

- Phosphor bronze: Adds strength and spring properties while maintaining conductivity; ideal for contact springs and connectors.

- Beryllium copper: Premium alloy with exceptional strength and conductivity; used for springs and electrical contacts in demanding applications.

Specialty Materials serve niche applications with unique requirements. Titanium delivers extraordinary strength-to-weight ratios for aerospace and medical implants - though its springback behavior and galling tendency challenge stamping operations. Nickel alloys handle extreme temperatures and corrosive environments. Precious metals like silver and gold appear in electronics and jewelry manufacturing.

Material Thickness Guidelines for Optimal Results

Material thickness directly impacts what operations are possible and how parts perform. Too thin, and structural integrity suffers. Too thick, and forming forces exceed equipment capacity or material cracking limits. General guidelines by operation type:

- Blanking and punching: Hole diameter should generally equal or exceed material thickness to prevent punch breakage and ensure clean cuts. Thicker materials require larger clearances between punch and die.

- Bending: Minimum bend radius typically ranges from 0.5 to 2 times material thickness, depending on material ductility and grain direction. Sharper bends risk cracking on the outer surface.

- Drawing: Drawing ratio (blank diameter to punch diameter) limits how deep you can draw in a single operation. Thinner gauges generally allow deeper draws without intermediate annealing.

- Embossing: Pattern depth depends on material thickness and ductility - deeper features require thicker, more formable materials to prevent tearing.

Cold-rolled materials offer tighter thickness tolerances than hot-rolled alternatives. According to manufacturing experts, cold-rolled steel provides smooth finished surfaces, precise edges, dimensional uniformity, and greater strength - characteristics that make it ideal for precision stamping operations requiring consistent results.

How does material choice impact your bottom line? Harder materials accelerate tooling wear, increasing maintenance frequency and die replacement costs. Highly work-hardening materials like stainless steel may require intermediate annealing operations between forming stages. Production speed drops when material properties demand slower press cycles or additional lubrication. And final part performance - strength, corrosion resistance, conductivity, weight - all trace directly back to that initial material selection decision.

Choosing the right metal is just half the equation. The equipment that forms your selected material matters equally - and that brings us to stamping press selection, where mechanical, hydraulic, and servo technologies each bring distinct advantages to the production floor.

Stamping Press Types and Equipment Selection

You've selected your metal - now you need the right machine to shape it. The metal stamping press you choose directly impacts production speed, part quality, energy costs, and long-term maintenance expenses. Pick a press that matches your application, and production hums along efficiently. Mismatch the equipment to your requirements, and you'll fight limitations at every turn.

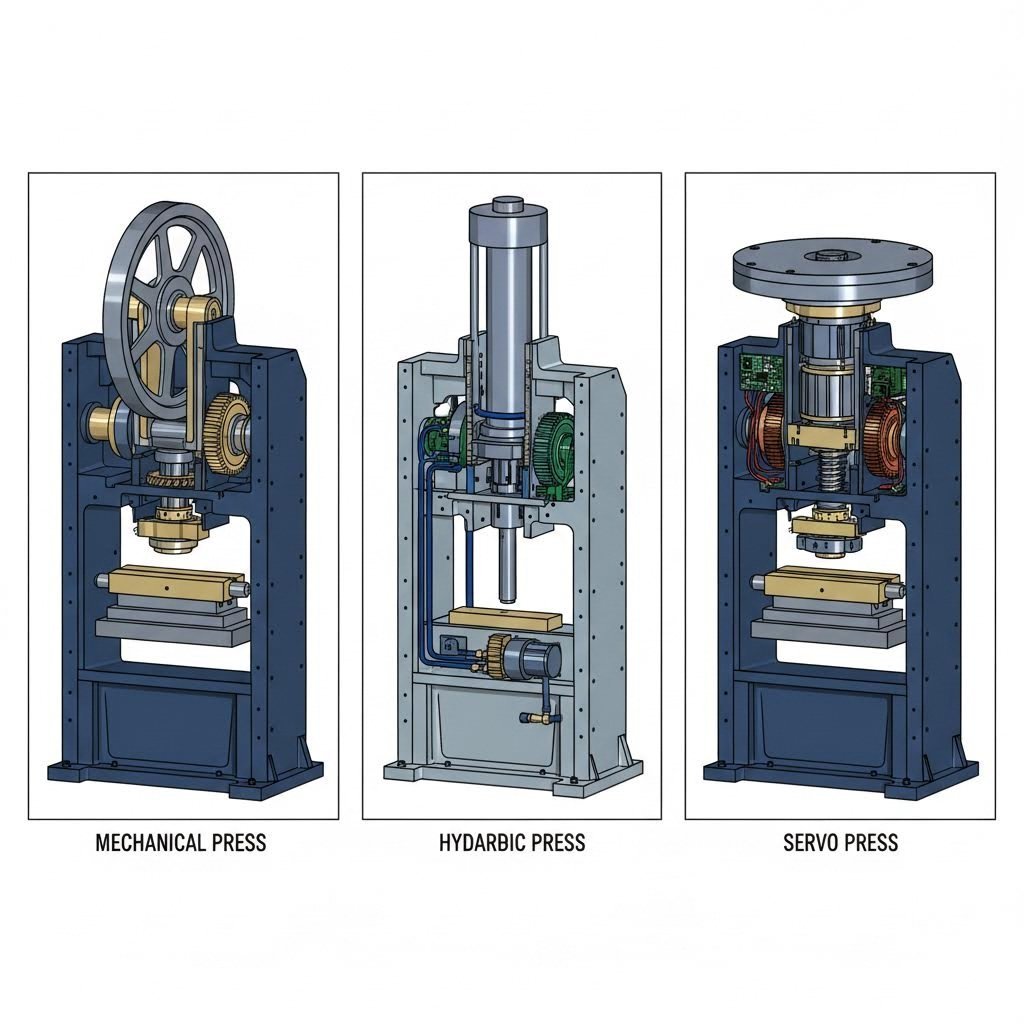

Three primary press technologies dominate modern metal stamping machines: mechanical, hydraulic, and servo-driven systems. Each brings distinct strengths to specific applications - understanding these differences helps you match press capabilities to your production requirements.

Mechanical vs Hydraulic vs Servo Presses - A Technical Comparison

Mechanical Presses deliver unmatched speed for high-volume production. An electric motor drives a flywheel that stores rotational energy. When the clutch engages, this energy transfers through a crankshaft to power the ram's downward stroke. The result? Consistent, repeatable motion at impressive speeds.

What makes mechanical metal stamping press machines so fast? The flywheel continuously spins, storing energy between strokes. Standard mechanical presses achieve 10 to 18 strokes per minute, while high-speed variants exceed 1,400 strokes per minute for small-part production. This speed advantage makes mechanical presses ideal for blanking, piercing, and shallow forming operations where volume matters most.

The limitation? Force availability depends on stroke position. A steel stamping press delivers maximum tonnage only at a specific point near the bottom of the stroke. Operations requiring full force throughout the entire stroke - like deep drawing - push beyond mechanical capabilities. Additionally, the fixed stroke length limits flexibility when part heights vary significantly.

Hydraulic Presses trade speed for control. Hydraulic fluid pressurized by pumps drives the ram, providing full tonnage at any point in the stroke - not just at the bottom. This characteristic makes hydraulic systems the preferred choice for deep drawing, where material needs consistent pressure throughout the forming operation.

Beyond force control, hydraulic presses offer adjustable stroke lengths and dwell times at full pressure. Need the ram to hold position while material flows into a complex die cavity? Hydraulic systems accommodate easily. Working with different die heights or material thicknesses? Adjust the stroke without mechanical modifications.

The trade-off appears in cycle time. Hydraulic presses typically run slower than mechanical alternatives - often significantly slower for simple operations. However, when forming large or irregularly shaped parts that demand precise force control, the quality improvements justify the speed sacrifice.

Servo Presses represent the newest evolution in stamping machinery. Instead of flywheels or hydraulic pumps, servo motors directly drive the ram through programmable motion profiles. This technology combines mechanical-like speed with hydraulic-like control - and adds capabilities neither traditional type can match.

The programmability advantage transforms production flexibility. According to industry analysis, servo presses enable advanced control including varied stroke speeds within a single cycle, precise positioning at any point, and quick setup adjustments between part numbers. Need to slow down during the forming portion of a stroke while maintaining high speed during approach and return? Servo technology delivers.

Energy efficiency adds another servo press benefit. The motor draws power only when actively working - unlike mechanical presses that continuously spin flywheels or hydraulic systems that run pumps constantly. For operations with significant idle time between strokes, energy savings accumulate substantially.

Matching Press Capabilities to Production Requirements

Selecting the right metal stamping machine starts with understanding your specific application demands. Consider these critical factors:

- Tonnage requirements: Calculate the force needed for your forming operation. Undersized presses risk overload damage; oversized equipment wastes capital investment.

- Stroke rate needs: High-volume production of simple parts favors mechanical speed. Complex forming operations benefit from hydraulic or servo control regardless of volume.

- Part geometry: Deep draws and complex shapes requiring sustained force point toward hydraulic or servo systems. Shallow blanking and piercing operations suit mechanical presses.

- Material characteristics: Difficult-to-form materials like stainless steel or high-strength alloys often benefit from servo programmability to optimize forming speed and force profiles.

- Production flexibility: Job shops running varied parts appreciate servo quick-change capabilities. Dedicated production lines running millions of identical parts may not need that flexibility.

The following comparison summarizes key differences across press types:

| Press Type | Speed Range | Force Control | Energy Efficiency | Best Applications | Maintenance Considerations |

|---|---|---|---|---|---|

| Mechanical | 10-1,400+ strokes/min | Full force only near bottom of stroke | Moderate - flywheel runs continuously | Blanking, piercing, shallow forming, high-volume production | Clutch and brake wear; flywheel bearing maintenance; consistent lubrication required |

| Hydraulic | 10-50 strokes/min typical | Full tonnage available throughout entire stroke | Lower - pumps run during operation | Deep drawing, forming large parts, operations requiring dwell time | Hydraulic fluid monitoring and replacement; seal integrity; pump maintenance |

| Servo | Variable - programmable per application | Fully programmable force and position profiles | Highest - power on demand only | Complex forming, varied production, precision applications | Servo motor and drive electronics; fewer mechanical wear components |

Still uncertain which direction to go? Consider your decision through the lens of your most demanding application. A metal stamping press machine that handles your toughest job will easily manage simpler work. But a press selected for easy parts may struggle when complexity increases.

With press type understood, another critical aspect awaits your attention: what happens when parts don't come out right? Defects occur even in well-designed stamping operations - and knowing how to diagnose and eliminate them separates struggling production lines from world-class manufacturing. Let's explore the troubleshooting strategies that keep quality on target.

Troubleshooting Defects and Quality Control Standards

Even the most carefully designed metal stamping processes encounter problems. Parts emerge with rough edges, unexpected curves, or dimensions that miss their targets. When defects appear, knowing exactly what went wrong - and how to fix it - separates productive operations from costly scrap piles.

The reality? Most stamping defects trace back to predictable causes. Understanding these root issues transforms reactive firefighting into proactive prevention. Let's examine the six most common defects plaguing stamped metal parts and the proven solutions that eliminate them.

Diagnosing and Eliminating Common Stamping Defects

Burrs appear as raised metal edges or sharp protrusions along cut surfaces. These unwanted formations create safety hazards, interfere with assembly, and signal underlying process problems.

- Primary causes: Excessive clearance between punch and die allows material to flow rather than shear cleanly. Worn or chipped cutting edges produce the same effect. According to industry research, burr height exceeding 0.1mm typically indicates clearance or wear issues requiring immediate attention.

- Solutions: Adjust die clearance to 8-12% of material thickness - using smaller values for mild steel and larger for harder materials. Implement regular die inspection schedules, checking cutting edges every 50,000 strokes. For persistent problems, consider fine blanking technology with V-shaped blank holders that produce burr-free edges.

Wrinkles form when excess material buckles during forming operations, creating wavy surfaces or gathered edges that compromise part functionality and appearance.

- Primary causes: Insufficient blank holder pressure allows material to flow uncontrolled into die cavities. Improper lubrication creates uneven friction zones. Drawing ratios exceeding material capabilities force excess metal into confined spaces.

- Solutions: Increase blank holder force using servo-controlled hydraulic pads for precise adjustment. Optimize drawing rib layout to balance material flow. For deep drawing operations, implement step-by-step forming with an initial 60% draw followed by secondary shaping operations.

Springback occurs when stamped parts partially return toward their original flat shape after forming. This elastic recovery throws bend angles off target and causes dimensional deviations in precision metal stamping parts.

- Primary causes: All metals exhibit elastic recovery after plastic deformation - the material "springs back" when forming pressure releases. High-strength steels and aluminum alloys display particularly aggressive springback behavior. Insufficient overbending during the forming stroke fails to compensate for this natural tendency.

- Solutions: Design dies with springback compensation based on CAE simulation of material behavior. Coining operations eliminate springback entirely by exceeding material flow stress. For stamped steel parts requiring tight angular tolerances, add shaping processes with 0.05-0.1mm of strong pressure correction.

Cracking represents material failure - splits or fractures that render parts unusable. Cracks typically appear at bend radii, draw corners, or areas of high material stress.

- Primary causes: Exceeding material ductility limits during forming creates cracks. Die radii too small for the material thickness concentrate stress beyond what the metal can withstand. Cold working from previous operations reduces remaining formability.

- Solutions: Increase die corner radii to at least four times material thickness (R≥4t). For high-strength steel, implement hot forming at 200-400°C to improve ductility. Add intermediate annealing between forming stages to restore material workability. Consider switching to materials with better elongation properties.

Surface scratches damage part appearance and may compromise corrosion resistance when protective coatings are penetrated.

- Primary causes: Rough die surfaces transfer imperfections to parts during forming. Foreign particles trapped between material and tooling create drag marks. Inadequate or contaminated lubrication fails to prevent metal-to-metal contact.

- Solutions: Polish die surfaces to Ra 0.2μm or finer. Apply chrome plating or TD treatment for enhanced surface durability. Use volatile stamping oils such as ester-based lubricants that clean away easily. Pre-clean incoming materials to remove scale, dust, and surface contamination before stamping.

Dimensional variations - when parts drift outside tolerance specifications - undermine assembly fit and functional performance.

- Primary causes: Die wear gradually enlarges cavity dimensions. Material thickness variations from incoming stock propagate through forming operations. Insufficient press rigidity or poor slide parallelism allows deflection under load. Temperature changes during production affect both tooling dimensions and material behavior.

- Solutions: Add guide posts or precision positioning pins to dies. Regularly verify press parallelism and tonnage delivery. Implement incoming material inspection with thickness tolerance verification to ±0.02mm. According to quality control experts, dimensional tolerances for precision stamping parts often hover around ±0.05mm - equivalent to the thickness of two sheets of paper.

Quality Control Measures That Ensure First-Pass Approval

Catching defects after production wastes material, time, and money. Effective quality systems detect problems as they develop - or better yet, prevent them entirely. Three interconnected approaches build a complete quality framework:

In-Process Inspection (IPQC) monitors production in real-time. First article inspection verifies dimensions, appearance, and functionality before mass production begins. Patrol inspections sample parts at regular intervals - checking five pieces every 30 minutes catches drifting processes before thousands of defects accumulate. For stamped parts used in automotive safety or medical devices, 100% inspection may be required to ensure zero defects reach customers.

Statistical Process Control (SPC) transforms inspection data into actionable intelligence. Control charts tracking dimensional measurements reveal trends before tolerances are violated. A gradual increase in hole diameter might indicate guide post wear - catching this pattern early prevents an entire batch from going out of specification. Process capability indices (CPK) quantify whether your operation can consistently meet requirements. CPK values below 1.33 signal unstable processes requiring adjustment.

Final Verification serves as the last gate before shipment. Sampling inspection following AQL standards - for example, measuring 200 pieces from a batch of 5,000 - confirms overall batch quality. Critical dimensions identified by customers receive tightened inspection, often with documented measurement data accompanying shipments. For stress-sensitive materials like stainless steel, secondary inspection after 12-24 hours of settling catches dimensional changes from residual stress release.

Tolerance capabilities vary significantly across stamping methods. Progressive and transfer die operations typically achieve ±0.05 to ±0.15mm dimensional accuracy. Fine blanking delivers ±0.01 to ±0.05mm for applications demanding extreme precision. Understanding these capabilities helps you specify appropriate tolerances during design - avoiding the cost of demanding precision your selected process cannot reliably deliver.

Quality problems rarely exist in isolation. Burrs might indicate wear that will eventually cause dimensional drift. Cracks signal stress conditions that could worsen. Effective troubleshooting looks beyond individual defects to identify systemic issues. When problems persist despite individual fixes, examine the complete chain: incoming material quality, die condition, press parameters, and operator procedures all influence final part quality.

With defects understood and quality systems in place, you're equipped to produce stamped parts that meet specifications consistently. But where do these parts actually go? The answer spans nearly every industry - and each brings unique requirements that shape how stamping operations must perform. Let's explore these applications next.

Industry Applications From Automotive to Medical Devices

Stamped metal components surround you every day - you just don't notice them. The bracket holding your car's engine in place, the connector linking your smartphone's circuit boards, the housing protecting your pacemaker's electronics. Each application demands something different from the stamping process. Understanding these industry-specific requirements helps you specify the right process, material, and quality standards for your particular project.

Automotive Stamping - From Body Panels to Safety Components

A typical vehicle contains 300 to 500 stamped metal components. Under the hood, you'll find battery terminals, sensor mounting brackets, and heat shields. In the cabin, seat mechanisms and door latch components. Throughout the structure, body panels and crash absorption parts. Every one started as flat metal sheet.

Automotive metal stamping divides into distinct categories based on function and criticality:

- Body panels and closures: Doors, hoods, fenders, and roof panels require large-scale transfer die operations with precise surface quality for paint adhesion. These high volume metal stamping applications demand exceptional consistency across millions of parts.

- Structural components: Floor pans, cross members, and crash rails use high-strength steel to meet safety regulations. Tolerances tighten considerably for components that interface with suspension and drivetrain systems.

- Brackets and mounting hardware: Engine mounts, transmission brackets, and exhaust hangers experience constant vibration and thermal cycling. Material selection balances strength, corrosion resistance, and cost.

- Safety-critical parts: Seat belt anchors, airbag housings, and brake components require tolerances of ±0.002 inches or tighter - with zero defect tolerance.

The certification landscape shapes everything in automotive stamping. IATF 16949 certification is non-negotiable for supplying major automakers. This quality management standard builds on ISO 9001 with specific requirements for defect prevention, variation reduction, and supply chain management. PPAP (Production Part Approval Process) documentation proves your parts meet all engineering requirements before production begins.

Volume requirements in automotive applications often reach hundreds of thousands or millions of pieces annually. Progressive die stamping dominates for smaller components, producing 20 to 200 parts per minute depending on complexity. For manufacturers seeking precision stamping die solutions that meet these demanding OEM standards, partners with IATF 16949 certification and advanced CAE simulation capabilities - like those offered at Shaoyi's automotive stamping dies division - can accelerate production timelines with rapid prototyping in as little as 5 days and achieve 93% first-pass approval rates.

The shift toward electric vehicles creates new requirements for lightweight materials, electromagnetic shielding, and thermal management components. Stamped aluminum battery enclosures and copper bus bars are becoming increasingly critical as EV production scales.

Aerospace Applications - Where Precision Meets Extreme Conditions

Aerospace stamping demands the highest levels of precision, reliability, and documentation. Components must perform flawlessly in extreme environments while meeting rigorous FAA, NASA, and DOD regulatory standards.

Critical aerospace stamped components include:

- Structural brackets: Support aircraft systems while minimizing weight - every gram matters at 35,000 feet

- Avionics frames: Precision housings for navigation and communication equipment

- Landing gear supports: Components withstanding massive impact forces during touchdown

- Oxygen system valves: Absolutely reliability required - failure is not an option

- Lighting housings: Designed for extreme temperature variations from -65°F to +160°F

Material selection for aerospace metal parts stamping often involves specialized alloys. Titanium delivers extraordinary strength-to-weight ratios. Aluminum alloys reduce mass for weight-critical applications. Stainless steel metal stamping provides corrosion resistance for components exposed to harsh environments. Full traceability from raw material through final inspection is mandatory.

ITAR compliance adds another layer for defense-related aerospace work. Security procedures, personnel clearances, and controlled technical data handling become as important as dimensional accuracy.

Medical Devices - Life-Critical Precision

Medical device manufacturing combines precision requirements with biocompatibility considerations and strict FDA regulatory compliance. When parts go inside the human body, the stakes couldn't be higher.

Medical stamping applications encompass:

- Implantable device housings: Pacemaker and neurostimulator cases requiring biocompatible materials and hermetic sealing

- Surgical instrument components: Precise dimensions and smooth finishes for sterilization compatibility

- Diagnostic equipment covers: Protective housings for sensitive electronic systems

- Defibrillator cases: Combining protection with biocompatibility for life-saving devices

- Electrical connectors: Reliable connections for patient monitoring equipment

Biocompatibility requirements drive material selection toward grades like 316L stainless steel and titanium alloys proven safe for medical applications. Surface finish specifications often exceed those in other industries - smooth surfaces are crucial for both functionality and sterilization compatibility.

Many medical components must withstand gamma radiation, electron beam sterilization, or chemical sterilization processes without degradation. Stamped metal components must maintain their properties and performance throughout their entire lifecycle - often decades inside a patient's body.

Electronics - Miniaturization Meets High Volume

The electronics industry demands miniaturization, precision, and cost-effectiveness that makes metal stamping components ideal for countless applications.

Electronic stamping applications include:

- Terminals and connectors: Circuit board connections requiring tolerances measured in thousandths of an inch

- EMI/RFI shields: Electromagnetic interference protection for sensitive electronics - custom shields come in various sizes including ovals, rounds, and specialized geometries

- Heat sinks: Thermal management components dissipating heat from processors and power electronics

- Contact springs: Switches and relays requiring precise spring properties over millions of cycles

- Chassis components: Enclosures combining structural support with electromagnetic protection

Precision requirements in electronics often exceed those in other industries. Surface finish specifications affect electrical performance - rough surfaces increase contact resistance. Stamping components for consumer electronics can require annual volumes reaching millions of pieces, making progressive die stamping the dominant production method.

EMI/RFI shielding applications require both precise dimensional control and appropriate material properties. Conductive materials must maintain their electromagnetic properties through the stamping process - something that requires careful attention to work hardening and surface conditions.

HVAC and Industrial Equipment

Heating, ventilation, and air conditioning systems rely heavily on stamped metal components for functionality and durability.

Common HVAC stamping applications include:

- Ductwork components: Flanges, collars, and transitions forming air distribution systems

- Mounting brackets: Supporting blowers, compressors, and heat exchangers

- Fan housings: Combining structural support with airflow management

- Heat exchanger fins: Maximizing surface area for thermal transfer

- Control panel enclosures: Protecting electronic controls from environmental conditions

HVAC components often prioritize durability and cost-effectiveness over extreme precision. Galvanized steel dominates for corrosion resistance in humid environments. Production volumes range widely - custom commercial installations may need hundreds of pieces while residential equipment components run into hundreds of thousands annually.

Industry-Specific Requirements That Shape Stamping Specifications

Each industry brings certification requirements that directly influence process selection and supplier qualification:

| Industry | Key Certifications | Typical Tolerances | Common Materials | Volume Characteristics |

|---|---|---|---|---|

| Automotive | IATF 16949, PPAP | ±0.002" to ±0.010" | HSLA steel, aluminum, stainless | 100,000 to millions annually |

| Aerospace | AS9100, ITAR, NADCAP | ±0.001" to ±0.005" | Titanium, aluminum alloys, Inconel | 1,000 to 100,000 annually |

| Medical | ISO 13485, FDA 21 CFR | ±0.001" to ±0.003" | 316L stainless, titanium, biocompatible alloys | 1,000 to 500,000 annually |

| Electronics | ISO 9001, IPC standards | ±0.002" to ±0.005" | Copper alloys, brass, phosphor bronze | 100,000 to millions annually |

| HVAC/Industrial | ISO 9001, UL listings | ±0.010" to ±0.030" | Galvanized steel, aluminum, stainless | 5,000 to 500,000 annually |

Volume considerations directly influence stamping method selection. Aerospace parts numbering in the low thousands may justify transfer die operations with their flexibility, while automotive stamped metal components running into millions demand progressive die efficiency. Medical devices often fall in between - requiring precision that approaches aerospace standards with volumes closer to automotive production.

Understanding these industry-specific requirements helps you communicate effectively with stamping partners and specify appropriate quality standards. But when does metal stamping make sense compared to alternative manufacturing methods? That decision framework comes next.

When to Choose Metal Stamping Over Alternative Methods

You've explored what metal stamping can do - but here's the critical question: should you use it for your project? The answer depends on your specific requirements for volume, precision, geometry, and budget. Choosing the wrong manufacturing method wastes money, time, and engineering resources. Choosing correctly positions your project for success from day one.

Let's break down how sheet metal stamping compares against four major alternatives - and build a decision framework you can apply to any project.

Metal Stamping vs CNC Machining - Making the Right Choice

This comparison comes up constantly, and for good reason. Both processes produce precise metal components - but they excel in fundamentally different scenarios.

CNC machining starts with solid blocks or bars of material and removes everything that isn't the finished part. This subtractive approach delivers exceptional precision - tolerances of ±0.001 inches are routine, and skilled shops achieve even tighter specifications. Complex three-dimensional geometries, deep pockets, and intricate internal features present no problem.

The trade-off? Speed and material waste. According to manufacturing analysis, CNC machining works well with a broad range of materials including metals, plastics, and composites - but because machining involves cutting away material from a solid block, there can be significant material waste, especially with metals. Each part requires individual machining time, making per-piece costs relatively constant regardless of volume.

Custom metal stamping takes the opposite approach. Once tooling is complete, each press stroke produces a finished or near-finished part in seconds. Material utilization improves dramatically - the sheet metal process uses flat stock efficiently, with scrap limited to peripheral trim and punched holes. High-volume production spreads tooling costs across millions of pieces.

When does each method win?

- Choose CNC machining when you need fewer than 1,000 parts, require complex 3D geometries with deep features, demand the tightest possible tolerances, or expect frequent design changes that would require expensive die modifications.

- Choose metal stamping when annual volumes exceed 10,000 pieces, part geometry suits sheet metal forming, and production will continue long enough to amortize tooling investment.

Stamped metal vs die casting presents different considerations. Die casting injects molten metal into molds, producing complex three-dimensional shapes with excellent surface finish. It excels at parts requiring thick walls, internal ribs, and cast-in features impossible to achieve through stamping.

However, die casting limits your material options to metals with suitable melting and flow characteristics - primarily aluminum, zinc, and magnesium alloys. Steel and stainless steel aren't viable. Stamping accommodates nearly any sheet metal alloy, from mild steel through titanium and specialty nickel alloys.

Surface finish tells another story. Die casting produces as-cast surfaces requiring minimal finishing for many applications. Stamping creates clean, smooth surfaces on flat areas but may show tool marks at formed features. For decorative parts, either process might require secondary finishing.

Laser cutting vs stamping represents flexibility versus speed. Laser cutting requires no tooling - just upload your design file and start cutting. According to cost analysis research, laser cutting delivers 40% cost reduction compared to stamping for batches under 3,000 units by eliminating $15,000+ tooling costs. Precision reaches ±0.1mm compared to stamping's ±0.3mm for standard blanking operations.

The math shifts dramatically at higher volumes. That same research indicates laser cutting averages $8.50 per unit versus stamping's $14.20 for small batches - but the equation reverses for high-volume production exceeding 10,000 units, where stamping's per-unit processing cost advantage begins offsetting tooling expenses.

Timeline matters too. Laser cutting delivers parts within 24-48 hours, while stamping requires 4-8 weeks for tooling fabrication before production begins. When project urgency drives decisions, laser cutting often wins regardless of volume calculations.

Fabrication and welding assemble parts from multiple pieces rather than forming them from single blanks. This approach handles geometries impossible to stamp - large enclosures, structural frames, and assemblies combining different materials or thicknesses. However, labor intensity increases costs significantly at volume, and weld quality requires skilled operators and careful inspection.

Metal pressing operations shine when designs consolidate multiple fabricated pieces into single stamped components. A bracket that previously required cutting, bending, and welding three pieces might stamp complete in one progressive die operation - eliminating labor, reducing weight, and improving consistency.

Cost Factors That Determine Stamping Project Viability

Understanding the true economics of metal stamping services requires looking beyond per-piece prices to total project costs over time.

Tooling investment represents the largest upfront expense. Progressive dies for complex parts range from $15,000 to $100,000 or more depending on size, complexity, and material requirements. Transfer dies often exceed progressive die costs due to additional mechanisms. Fine blanking tooling commands premium prices but eliminates secondary finishing operations.

This investment creates a break-even calculation. Divide tooling cost by the difference between alternative per-piece costs and stamped per-piece costs. That number tells you how many pieces you need before stamping becomes economical. For a $30,000 die saving $0.50 per part versus machining, break-even occurs at 60,000 pieces.

Per-part costs at volume favor stamping dramatically once tooling is amortized. According to manufacturing experts, once the tooling is built, a stamping press can produce dozens to hundreds of identical parts per minute, maintaining tight dimensional consistency over millions of cycles. While the upfront cost to create a die can be significant, that one-time expense is spread across large production runs, lowering the cost per part.

The following table summarizes how manufacturing methods compare across key decision factors:

| Manufacturing Method | Setup Cost | Per-Part Cost at Volume | Tolerance Capability | Material Options | Ideal Volume Range |

|---|---|---|---|---|---|

| Sheet Metal Stamping | $10,000-$100,000+ (tooling) | Very low ($0.10-$2.00 typical) | ±0.005" standard; ±0.001" with fine blanking | All sheet metals: steel, aluminum, copper, stainless, titanium | 10,000 to millions annually |

| CNC Machining | $500-$5,000 (programming/fixturing) | Moderate to high ($5-$100+ depending on complexity) | ±0.001" routine; ±0.0005" achievable | Nearly unlimited: metals, plastics, composites | 1 to 10,000 annually |

| Die Casting | $5,000-$75,000 (mold tooling) | Low ($0.50-$5.00 typical) | ±0.002" to ±0.005" typical | Aluminum, zinc, magnesium alloys only | 5,000 to millions annually |

| Laser Cutting | $0-$500 (programming only) | Moderate ($5-$20 for small batches) | ±0.004" (±0.1mm) typical | Most sheet metals up to 25mm thickness | 1 to 3,000 annually |

| Fabrication/Welding | $500-$5,000 (fixtures/jigs) | High (labor-intensive) | ±0.010" to ±0.030" typical | Nearly unlimited combinations | 1 to 5,000 annually |

Part geometry shapes method selection fundamentally. Sheet metal press operations work best with parts featuring relatively uniform thickness, moderate draw depths, and features achievable through cutting, bending, and forming operations. Deep three-dimensional shapes with varying wall thicknesses favor casting or machining.

Material requirements eliminate some options immediately. Need stainless steel? Die casting won't work. Require a specific aluminum alloy for aerospace certification? Verify it's available in sheet form for stamping. Working with exotic materials like Inconel or titanium? Both machining and stamping are viable, but tooling wear and processing costs increase substantially.

Volume projections drive the fundamental economic decision. Low volumes favor flexible processes with minimal setup costs. High volumes justify tooling investment through dramatic per-piece savings. When volumes are uncertain, consider hybrid approaches - laser cutting for initial production while stamping tooling is developed, then transitioning to stamping as demand confirms projections.

Tolerance needs must match process capabilities realistically. Specifying ±0.001" tolerances on features that could function at ±0.010" increases costs without adding value. Conversely, selecting stamping for parts genuinely requiring machining-level precision leads to expensive secondary operations or rejected parts.

The decision framework ultimately balances these factors against your specific priorities. A startup prototyping new products values flexibility and low setup costs - laser cutting or machining makes sense. An established manufacturer with proven designs and predictable demand optimizes for per-piece cost - stamping delivers. Medical device companies may accept higher costs for the precision and traceability that machining provides.

With your manufacturing method selected, one critical element remains: the tooling that makes stamping possible. Die design and project planning determine whether your stamping program succeeds or struggles - and that's exactly where we'll focus next.

Tooling Design and Stamping Project Planning Essentials

Your manufacturing method is selected, your material specified, and your stamping partner identified. But here's the reality that catches many project managers off guard: the die itself determines whether your production stamping program thrives or struggles. A brilliantly designed part means nothing if the tooling can't produce it reliably, economically, and at the speed your schedule demands.

Think of stamping design as the bridge between engineering intent and manufacturing reality. Every decision made during die development - from component materials to simulation protocols - ripples through years of production. Let's explore what separates tooling that delivers from tooling that disappoints.

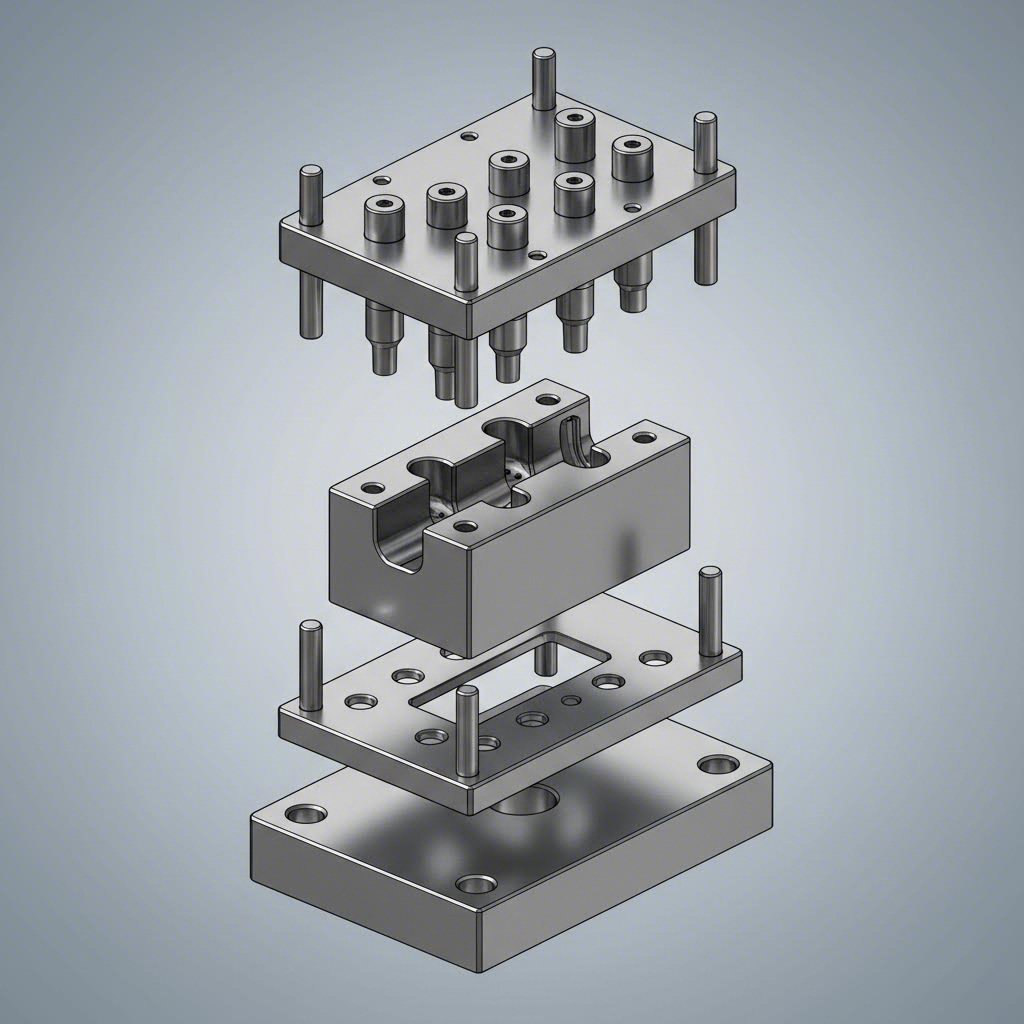

Die Design Fundamentals That Determine Production Success

A stamping die appears deceptively simple from the outside - two halves that come together under pressure. Inside, precision components work in concert to transform flat metal into finished parts. Understanding these elements helps you evaluate tooling proposals and communicate effectively with die makers.

The punch serves as the male forming element - the component that actively shapes material by pressing into or through it. Punch geometry defines the shape being created, whether that's a hole during piercing, a profile during blanking, or a contour during forming. According to die design experts, punch design directly determines part quality and production efficiency - a poorly designed punch leads to premature wear, inconsistent dimensions, and frequent production stoppages.

The die block functions as the female counterpart, providing the cavity or cutting edge against which the punch works. The clearance between punch and die block - typically 8-12% of material thickness - controls edge quality, burr formation, and tool wear. Too tight, and excessive friction accelerates wear. Too loose, and burrs become unacceptable.

Stripper plates hold material flat during operations and strip finished parts from punches after forming. Spring-loaded strippers apply controlled pressure, preventing material distortion during piercing and ensuring clean part separation. Stripper design significantly impacts cycle speed - efficient stripping allows faster press operation.

Guide pins and bushings maintain precise alignment between upper and lower die halves throughout millions of cycles. Even slight misalignment causes dimensional variation, accelerated wear, and potential die damage. Premium tooling uses hardened guide components with ground finishes to maintain accuracy over extended production runs.

The interaction between these components creates what experienced die makers call a "mechanical ballet" - each element timed to fractions of a second within the press cycle. This precision explains why custom metal stamping die development requires collaboration between part designers and tooling engineers from the earliest project stages.

Material selection for die components follows different rules than part material selection:

- Tool steel grades (D2, A2, S7): Balance hardness with toughness for punches and forming sections

- High-speed steel (M2, M4): Handles high-speed operations and abrasive materials

- Carbide inserts: Extend life dramatically for high-wear areas - especially when stamping stainless steel or high-strength alloys

- Surface treatments: TiN coating, TD treatment, and chrome plating reduce friction and extend component life

According to industry experience, choosing the wrong die material creates a painful cycle of "saving a little money upfront and spending a lot later." A startup client who insisted on lower-cost YK30 steel for an entire die discovered this after fewer than 5,000 parts when punches began wearing, causing severe burrs and daily production line shutdowns.

The Simulation Advantage in Modern Die Development

Building a stamping die used to require significant faith - you designed based on experience, built the tool, and hoped the first tryout would reveal manageable problems rather than fundamental flaws. Stamping technology has transformed this gamble into a calculated process through computer simulation.

CAE (Computer-Aided Engineering) and FEA (Finite Element Analysis) software now simulate the entire stamping process digitally before cutting steel. These platforms model material behavior under forming pressure, predicting where problems will occur and guiding design refinements.

Simulation capabilities include:

- Stress distribution analysis: Identifies areas of excessive material stress that could cause cracking

- Material flow prediction: Shows how metal will move during forming, revealing potential wrinkles or thinning

- Springback compensation: Calculates elastic recovery so dies can be designed to produce accurate final dimensions

- Blank optimization: Determines ideal blank size and shape to minimize material waste while ensuring adequate forming material

This virtual validation dramatically reduces physical tryout cycles. It's far cheaper and faster to adjust a digital model than to re-machine hardened tool steel. For manufacturers seeking to accelerate automotive production timelines, partners offering advanced CAE simulation for defect-free results - such as Shaoyi's precision stamping die solutions - can prevent costly revisions before steel is ever cut.

Beyond simulation, prototyping validates designs with physical evidence. Soft tooling using aluminum or pre-hardened steel produces sample parts for fit checks and functional testing before committing to production-grade dies. This approach catches problems that even sophisticated simulation might miss - the "perception gap" between digital models and tangible parts that customers can actually hold and evaluate.

Planning Your Stamping Project From Prototype to Production

Successful stamping projects follow predictable timelines - understanding these phases helps you plan effectively and set realistic expectations with stakeholders.

Phase 1: Design and feasibility (2-4 weeks)

Part print analysis determines whether stamping is the right approach and identifies potential forming challenges. This gatekeeping process evaluates material formability, tolerance achievability, and process economics before committing resources.

Phase 2: Tooling design and simulation (3-6 weeks)

Strip layout development determines the sequence of operations and optimizes material utilization. Detailed 3D modeling defines every punch, die section, and guide component. Simulation runs validate the design and drive refinements.

Phase 3: Die fabrication (6-12 weeks)

The actual machining of die components represents the longest phase for complex progressive dies. CNC machining, wire EDM, grinding, and heat treatment transform designs into hardened steel components. Assembly and initial alignment prepare the tool for tryout.

Phase 4: Tryout and refinement (1-4 weeks)

First pieces reveal how well simulation predicted reality. Adjustments address dimensional variations, surface issues, and process optimization. Multiple tryout iterations are normal for precision parts.

Phase 5: Production approval (1-2 weeks)

PPAP or equivalent documentation proves the process meets all requirements. Capability studies confirm consistent production. First article inspection validates dimensions against specifications.

Total timeline from project start to approved production typically runs 13-28 weeks depending on complexity. However, manufacturers with rapid prototyping capabilities can compress early phases significantly - some partners deliver prototype parts in as little as 5 days, allowing design validation to proceed while production tooling develops.

Die maintenance requirements extend beyond initial development. A metal stamp die isn't a "set and forget" asset - it requires systematic care to maintain quality over millions of cycles:

- Level 1 maintenance (daily): Surface cleaning, debris removal, lubrication application

- Level 2 maintenance (weekly/monthly): Spring replacement, wear measurement, sharpening as needed

- Level 3 maintenance (annually/as-needed): Complete disassembly, component replacement, re-grinding of worn surfaces

According to tooling specialists, shops with strong maintenance routines keep everything running smoothly behind the scenes - if maintenance is skipped, you'll feel it in part consistency and delivery timeline. Regular inspection catches wear before it affects part quality or causes tool failure during production.

Die lifespan varies enormously based on design decisions, material choices, and maintenance practices. Steel stamping dies running mild steel parts may produce millions of pieces before major refurbishment. The same die running stainless steel might need attention after 100,000 cycles. High-volume automotive applications often specify die life requirements in their contracts - 1 million cycles minimum is common for production stamping programs.

When evaluating stamping partners, look for these indicators of tooling competence:

- In-house die design and build capabilities - reducing communication gaps and accelerating revisions

- Advanced simulation software and demonstrated expertise using it

- Regular tool maintenance protocols with documented procedures

- Ability to modify dies quickly when design changes occur

- Experience with your specific industry's certification requirements

The tooling investment you make today shapes production economics for years to come. A well-designed, properly maintained die delivers consistent parts at low per-piece costs throughout its lifetime. A poorly conceived tool creates an ongoing burden of quality issues, maintenance costs, and production interruptions. When moving from learning to implementation, partnering with suppliers who combine state-of-the-art equipment with deep, experience-based knowledge of the complete process - from sheet metal stamping design through final inspection - positions your project for long-term success.

Frequently Asked Questions About Metal Stamping Processes

1. What is the process of metal stamping?

Metal stamping is a cold-forming manufacturing process that transforms flat sheet metal into specific shapes using dies and stamping presses. The process involves placing metal between a punch and die, then applying high pressure to cut, bend, or form the material. A complete stamping workflow includes seven stages: design and engineering, tooling/die creation, material selection and preparation, blank feeding, the stamping operation itself, secondary operations like deburring or plating, and quality inspection. This method produces thousands of identical parts per hour with tolerances measured in thousandths of an inch.

2. What are the 7 steps in the stamping method?

The seven steps in metal stamping are: 1) Design and Engineering - defining part specifications and creating prototypes; 2) Tooling and Die Creation - crafting precision dies that shape every part; 3) Material Selection and Preparation - choosing appropriate metals and preparing stock; 4) Blank Feeding - advancing material into the press with precise positioning; 5) The Stamping Operation - where the punch drives into the die to form parts; 6) Secondary Operations - including deburring, heat treatment, and coating; 7) Quality Inspection - verifying dimensions and surface finish through statistical process control and final verification.

3. What are the four types of metal stamping?

The four primary types of metal stamping are: Progressive Die Stamping - where a continuous strip feeds through multiple stations at speeds up to 1,500 parts per minute, ideal for small-to-medium parts in high volumes; Transfer Die Stamping - individual parts move between stations for complex three-dimensional geometries; Fourslide/Multislide Stamping - horizontal tool slides approach from multiple directions for intricate bends and wire forms with 50-70% lower tooling costs; and Fine Blanking - produces smooth, burr-free edges with tolerances of ±0.01mm, eliminating secondary finishing operations for precision applications.