Laser Cut Online: From Design File To Doorstep In 9 Smart Steps

What Is Laser Cutting and Why Order It Online

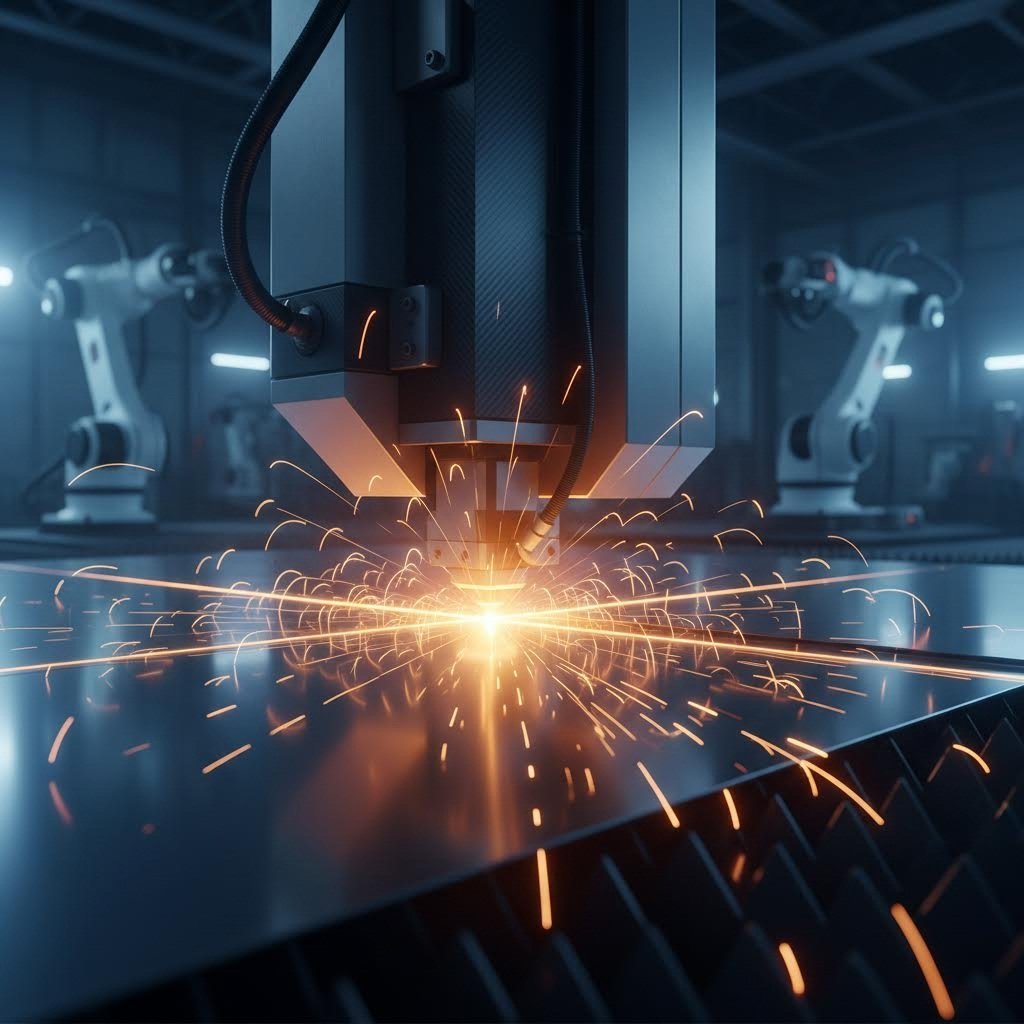

Imagine transforming a digital design into a perfectly cut physical part without ever stepping into a factory. That's the power of ordering laser cut online services. But what is laser cutting, exactly? At its core, this technology uses a highly focused beam of light to melt, burn, or vaporize materials with remarkable precision. The result? Clean edges, intricate details, and repeatable accuracy that traditional cutting methods simply cannot match.

Today, online laser cutting has revolutionized how hobbyists, small businesses, and professional engineers access industrial-grade manufacturing. You no longer need expensive equipment or specialized training to bring your designs to life. Simply upload your file, select your material, and wait for precision-cut parts to arrive at your doorstep.

How Focused Light Becomes a Precision Tool

The science behind a lazer cutter is fascinating yet straightforward. Inside the machine's resonator, electrons are excited to higher energy states through a process called stimulated emission. When these electrons return to their normal state, they release photons. These photons bounce between mirrors, creating a cascade that amplifies into a coherent, high-intensity beam of light.

This laser beam then travels through fiber optic cables or a series of mirrors until it reaches a focusing lens. The lens concentrates all that energy into an incredibly small point, sometimes less than a fraction of a millimeter in diameter. At this focal point, temperatures become intense enough to melt or vaporize virtually any material.

When the laser to cut metal makes contact, a high-pressure jet of gas, either inert nitrogen or reactive oxygen, blows the molten material away from the cut path. The result is a clean, precise edge with minimal heat-affected zones. For non-metallic materials like wood or acrylic, the laser essentially burns or vaporizes through the substrate.

From Industrial Floors to Your Desktop Browser

Laser cutting cutting technology once required massive capital investment and specialized operators. Today, laser online platforms have democratized this capability entirely. These digital services handle everything from G-code generation to quality control, allowing you to focus purely on design.

Here's how online laser cutting services have transformed accessibility:

- No equipment costs: Skip the $50,000+ investment in machinery

- No learning curve: Upload standard file formats like SVG, DXF, or AI

- Instant quoting: Know your costs before committing

- Material variety: Access metals, plastics, and specialty substrates

- Professional results: Industrial-grade precision without industrial overhead

Whether you're prototyping a single bracket or producing hundreds of custom signage pieces, these platforms scale to meet your needs.

Online laser cutting bridges the gap between imagination and manufacturing, turning anyone with a design file into a capable fabricator.

Throughout this guide, you'll discover everything needed to successfully order laser cut parts online. We'll explore the differences between CO2 and fiber laser technologies, helping you understand which works best for your materials. You'll learn which substrates from mild steel to exotic acrylics are compatible with these services. Most importantly, we'll walk through file preparation, the ordering process, pricing factors, and how to evaluate different providers.

By the end, you'll have the knowledge to confidently transform your next design from concept to reality, all from your desktop browser.

CO2 vs Fiber Laser Technology Explained

Ever wondered why some online services recommend different laser types for different materials? The answer lies in wavelength physics and how materials absorb light energy. Understanding the difference between CO2 and fiber lasers helps you make smarter decisions when ordering laser cut online services, ensuring optimal results for your specific project.

Think of it this way: choosing the wrong laser technology is like using a butter knife to cut steak. It might work eventually, but you won't get clean results. Let's break down what makes each technology shine.

CO2 Lasers for Organic Materials and Plastics

CO2 lasers operate at a wavelength of 10.6 micrometers, which organic materials absorb exceptionally well. This makes them the best laser for cutting wood, acrylic, leather, fabric, and paper. When that longer wavelength contacts these substrates, the material efficiently converts light energy into heat, creating clean vaporization with minimal charring.

Here's what CO2 technology handles beautifully:

- Wood and plywood: Smooth, slightly caramelized edges

- Acrylic (PMMA): Flame-polished, glass-like cut surfaces

- Leather and fabric: Sealed edges that resist fraying

- Paper and cardstock: Intricate details without tearing

- Rubber and cork: Clean profiles for gaskets and decorative items

While a CO2 laser cut metal machine exists, these systems struggle with reflective metals. The longer wavelength bounces off surfaces like aluminum and copper rather than being absorbed. For thicker steel plates exceeding 20mm, however, CO2 lasers still offer excellent edge quality that some applications require.

Efficiency represents CO2's main drawback. According to Xometry's technology analysis, these systems only convert 5-10% of electrical input into laser energy. The remaining power becomes heat, requiring substantial cooling infrastructure.

Fiber Lasers for Metal Precision Work

Fiber lasers emit at 1.064 micrometers, roughly ten times shorter than CO2 wavelength. This shorter wavelength penetrates metals efficiently, making fiber technology dominant for laser cutting metal and laser metal cutting applications. The physics favor metals because they absorb this wavelength readily rather than reflecting it away.

Modern fiber laser cutting services deliver remarkable advantages:

- Speed: 3-5 times faster than CO2 on comparable metal jobs

- Efficiency: Over 90% wall-plug efficiency versus 5-10% for CO2

- Precision: Narrower kerf widths and smaller heat-affected zones

- Lifespan: Approximately 25,000 working hours, ten times longer than CO2 devices

- Reflective metals: Cuts aluminum, brass, copper, and titanium confidently

The laser for cutting machine market has shifted dramatically toward fiber technology. Industry data from EVS Metal shows fiber lasers now capture 60% of the market, growing at 10.8-12.8% annually compared to just 3.1-5.4% for CO2 systems.

For laser cutting and engraving projects involving metals, fiber technology typically delivers superior results. The focused beam produces cleaner edges on stainless steel, carbon steel, and aluminum sheets up to 20mm thick.

Technology Comparison at a Glance

Choosing the best laser for cutting your specific project depends on material type, thickness, and quality requirements. This comparison helps you understand what to expect from each technology:

| Characteristic | CO2 Laser | Fiber Laser |

|---|---|---|

| Best Materials | Wood, acrylic, leather, fabric, paper, rubber, plastics | Steel, stainless steel, aluminum, copper, brass, titanium |

| Wavelength | 10.6 micrometers | 1.064 micrometers |

| Typical Thickness Range | Up to 25mm (organics); 10-25mm+ (thick steel plates) | 0.5mm to 20mm optimal; up to 100mm with high-power systems |

| Edge Quality | Excellent on organics; good on thick metals | Superior on thin-medium metals; flame-polished precision |

| Cutting Speed | Moderate; excels on non-metals | 3-5x faster on metals; up to 100 meters per minute on thin materials |

| Energy Efficiency | 5-10% | Over 90% |

| Operating Cost | Higher ($12-13/hour energy) | Lower ($3.50-4/hour energy) |

| Equipment Lifespan | ~2,500 working hours | ~25,000 working hours |

When to Choose Each Technology

Your project requirements determine the optimal technology choice. Here's a quick decision framework:

Choose CO2 laser services when:

- Working with wood, acrylic, leather, or fabric

- Cutting thick steel plates over 25mm where edge quality matters most

- Processing mixed organic materials in a single job

- Budget constraints favor lower equipment costs over operating efficiency

Choose fiber laser cutting services when:

- Cutting any metal under 20mm thickness

- Working with reflective metals like aluminum, brass, or copper

- Speed and production volume are priorities

- Tight tolerances and minimal heat-affected zones are critical

Most online services automatically select the appropriate technology based on your material choice. However, understanding these differences helps you communicate effectively with providers and set realistic expectations for edge quality, turnaround time, and pricing.

Now that you understand the technology behind the cut, let's explore the full range of materials these systems can process and what characteristics to expect from each substrate.

Materials You Can Laser Cut Through Online Services

Wondering what materials work with online laser cutting? The answer might surprise you. From aerospace-grade aluminum to decorative acrylic, modern metal laser cutting services process an impressive range of substrates. Understanding each material's characteristics helps you design smarter, anticipate results, and avoid costly mistakes.

Material selection directly impacts everything from edge quality to final cost. Let's explore what's possible when you laser cut metal, plastics, wood, and specialty substrates through professional services.

Metals from Mild Steel to Exotic Alloys

Metal laser cutting dominates the online fabrication landscape, and for good reason. Modern fiber lasers handle everything from thin decorative pieces to structural components with remarkable precision. According to 247TailorSteel's guidelines, professional services maintain tolerances following ISO9013 standards, with typical allowances of ±0.2mm for materials under 3mm thick.

Here's what you need to know about each metal category:

- Mild Steel (0.8-25mm): The workhorse of laser cutting of metal sheets. Cuts cleanly with either oxygen or nitrogen assist gas. Oxygen cutting offers faster speeds on thicker plates but creates an oxidized edge. Nitrogen produces cleaner, oxide-free surfaces ideal for painting or welding. Common applications include brackets, enclosures, and structural components.

- Stainless Steel (0.5-20mm): Stainless steel laser cutting requires nitrogen assist gas to prevent oxidation and maintain corrosion resistance. The material cuts slightly slower than mild steel but produces exceptional edge quality. Popular for food equipment, medical devices, and architectural elements.

- Aluminum (1-10mm): Reflective and thermally conductive, aluminum demands higher laser power and careful parameter control. When you laser cut aluminum, expect slightly wider kerf than steel and potential for burr formation on the underside. Applications range from electronic enclosures to automotive components.

- Copper and Brass: These reflective metals were historically challenging, but modern fiber lasers handle them effectively. Brass maximum dimensions typically reach 1,980mm x 980mm. Common uses include electrical components, decorative items, and heat sinks.

Two cutting methods apply to metals, according to Xometry's materials guide. Reactive laser cutting uses an oxygen jet to accelerate cutting through rapid oxidation, ideal for thick steel and titanium. Fusion cutting employs nitrogen and argon blends to blow molten metal away, producing cleaner edges on aluminum, stainless steel, copper, and nickel.

Understanding Metal Thickness Capabilities

Professional laser cutter for metal services handle varying thicknesses based on material type. Here's what to expect:

| Material | Minimum Thickness | Maximum Thickness | Minimum Hole Diameter (at max thickness) |

|---|---|---|---|

| Steel | 0.8mm | 25mm | 15mm |

| Stainless Steel | 0.5mm | 20mm | 5mm |

| Aluminum | 1mm | 10mm | 7mm |

| Brass | 1mm | 6mm | Varies by service |

Minimum feature sizes scale with material thickness. For steel and stainless, slot widths should measure at least 0.7 times the plate thickness between 2.5-15mm. At 20-25mm thickness, slots must equal or exceed the material thickness itself.

Plastics, Wood, and Specialty Substrates

Beyond metals, acrylic cutting service providers handle diverse organic and synthetic materials. CO2 lasers excel here, delivering clean cuts with minimal post-processing.

Plastics that cut beautifully:

- Acrylic (PMMA): The star performer. Laser-cut acrylic produces flame-polished, glass-like edges requiring no finishing. Available in countless colors and thicknesses up to 25mm. Perfect for signage, displays, and decorative applications.

- POM/Delrin (Acetal): This engineering thermoplastic offers strength, chemical resistance, and dimensional stability. According to Xometry's guidelines, POM cuts very cleanly with little heat-affected zone using CO2 lasers. An 80W system cuts 8mm Delrin at approximately 4mm/s. Essential for machine parts, gears, and precision components. Important note: cutting requires proper ventilation due to toxic fumes.

- Expanded Polystyrene and EVA Foam: Require very low power and high feed rates. Excellent for packaging prototypes, cosplay props, and modeling applications. Always ensure adequate ventilation.

Wood and fiber-based materials:

- Plywood: All plywood types can be laser cut, though bonding resins produce toxic gases requiring ventilation. High power and fast speeds work best for multiple cuts, which may increase kerf size. Higher blower pressure produces cleaner results.

- MDF (Medium Density Fiberboard): Challenging due to high density and adhesive content. Cuts slowly with significant heat-affected zones and wider kerf. Expect scorched, stained edges. An 80W laser cuts 10mm MDF at approximately 3.5mm/s.

- Cardboard: Low-cost and easy to cut. Use moderate power, fast feed speeds, and low blower pressure to prevent lifting. Excellent for packaging prototypes and architectural models.

How Material Choice Affects Your Results

Every material responds differently to laser energy. Understanding these behaviors helps you design appropriately and set realistic expectations:

Edge quality considerations:

- Acrylic delivers near-optical clarity on cut edges

- Steel cut with nitrogen shows bright, oxide-free surfaces

- MDF and plywood exhibit scorching and discoloration

- Aluminum may show slight roughness requiring secondary finishing

Heat-affected zones (HAZ): The area adjacent to cuts experiences thermal stress. Thin materials and high cutting speeds minimize HAZ. According to 247TailorSteel, small geometries and narrow webs experience more discoloration because heat cannot dissipate efficiently. For critical applications, you may need to account for material property changes near cut edges.

Post-processing requirements:

- Burr formation occurs on metal undersides and is technically unavoidable. Edge breaking or deburring services address this

- Laser splashes and soot may appear depending on material thickness and geometry

- Discoloration on metals typically requires grinding to remove

Professional services typically maintain dimensional tolerances of ±0.2mm for thin materials, expanding to ±0.45mm for 20-25mm thick plates across small features. These tolerances follow ISO9013 standards, giving you predictable results for engineering applications.

Now that you understand which materials work and what results to expect, let's tackle the often-overlooked skill of preparing your design files correctly for laser cutting success.

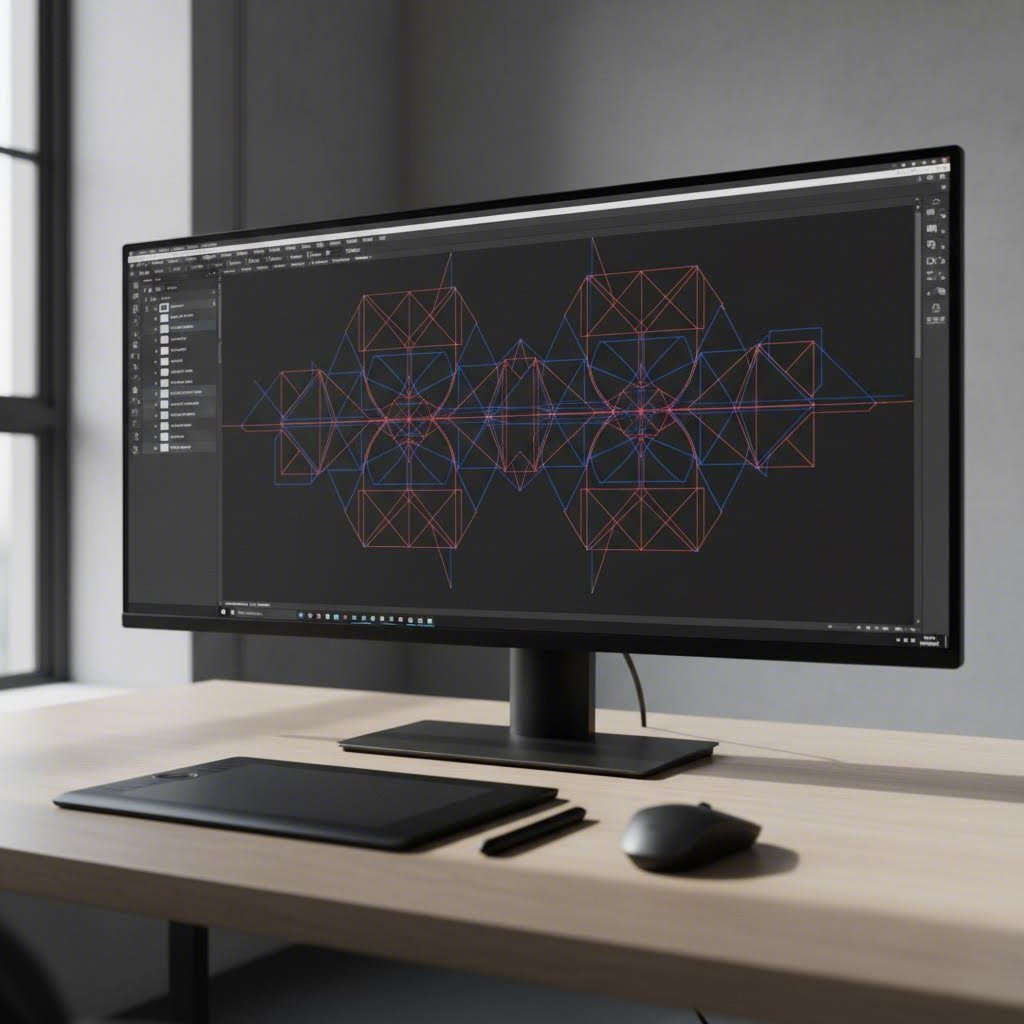

How to Prepare Your Design Files for Laser Cutting

Sounds complex? Getting your design files ready for precision laser cutting doesn't have to be intimidating. In fact, proper file preparation is where successful laser fabrication projects begin. The difference between a perfectly executed laser cut part and a failed job often comes down to how well you've prepared your digital files before uploading.

Most online services accept common vector formats, but simply having the right file type isn't enough. You'll need to understand line configurations, color coding systems, and critical design constraints that ensure your laser cnc machine interprets your intentions correctly. Let's walk through everything you need to know.

Preparing Vector Files That Cut Cleanly

Vector files form the foundation of successful laser cut parts. Unlike raster images that store pixel data, vectors contain mathematical paths the laser follows with precision. But not all vector files are created equal.

Accepted file formats and their best uses:

- SVG (Scalable Vector Graphics): Ideal for both cutting and engraving. Most universally compatible format across laser and cnc platforms. Exports cleanly from free software like Inkscape.

- DXF (Drawing Exchange Format): The industry standard for cutting paths. Favored by professional services because it contains pure geometry without embedded styles or fonts that cause interpretation errors.

- AI (Adobe Illustrator): Excellent for professional design work. Ensure you convert all text to outlines before saving, as fonts may not transfer correctly between systems.

- PDF (Portable Document Format): Acceptable when containing vector content. According to Craft Closet's file preparation guide, always verify your PDF contains actual vector paths rather than embedded raster images.

For custom laser etching and engraving work, raster images enter the equation. When using PNG or JPG files for engraved graphics, resolution matters significantly. Aim for 300+ DPI to achieve crisp, detailed results. Lower resolutions produce blurry, pixelated engravings that disappoint.

Critical file preparation requirements:

- All cut paths must be closed and continuous. Open lines confuse the machine and produce incomplete cuts

- Convert all text to paths or outlines. Font substitution causes sizing and spacing disasters

- Remove duplicate overlapping paths. Doubled lines mean the laser cuts twice, wasting time and potentially damaging material

- Eliminate stray points and zero-length segments that may not be visible but corrupt processing

Understanding Color Coding and Line Types

Here's where things get interesting. Most laser services use color conventions to distinguish between operations. While these can be customized, understanding the standard system prevents confusion:

| Color | Operation | Description |

|---|---|---|

| Red | Cut | Full-power cutting through material |

| Blue | Score | Light surface marking without penetrating |

| Black Fill | Engrave | Raster engraving of filled shapes |

According to Craft Closet's documentation, these color codes are standard in popular laser software like LightBurn, though services may specify their own conventions. Always check your provider's guidelines before finalizing files.

When organizing complex multi-part files, use separate layers for each operation type. This keeps your design manageable and helps services process your job efficiently. Name layers descriptively: "Cut_Outline," "Score_Folds," "Engrave_Logo."

Design Rules for Successful Laser Parts

Beyond file format, your design geometry determines whether parts cut successfully. These constraints ensure your laser cut cnc machine produces accurate results:

Minimum feature sizes:

- Spacing between cut lines should measure at least twice the material thickness. According to Eagle Metalcraft's design guidelines, closer spacing causes distortion, melting, or accidental bridges

- Minimum hole diameters depend on material thickness. For steel, holes should be at least 60% of plate thickness

- Avoid features smaller than your material thickness to prevent burning and distortion

Kerf compensation explained: The laser beam removes a small amount of material as it cuts, typically 0.1-0.3mm depending on laser type and material. This "kerf" means your cut parts will be slightly smaller than designed, while the surrounding material shows slightly larger openings. For precision laser cutting applications, adjust your design dimensions to account for this material loss.

Tab placement for nested parts: When cutting multiple small pieces from a single sheet, consider adding small holding tabs. These thin connections prevent parts from shifting during cutting, then snap off easily afterward. Place tabs on non-critical edges where small witness marks are acceptable.

Your File Preparation Checklist

Before uploading to any online service, run through this systematic verification process:

- Choose the correct format: Export as SVG or DXF for cutting operations. Use high-resolution PNG (300+ DPI) for engraved graphics

- Convert all text to paths: Select text objects and use "Create Outlines" or "Convert to Path" in your design software

- Verify closed paths: Zoom in on corners and endpoints to confirm all cutting lines form complete, closed shapes

- Check for overlapping lines: Select all objects and look for duplicates sitting on top of each other

- Apply correct colors: Assign cut, score, and engrave operations using your service's color convention

- Set canvas to actual size: Match your workspace dimensions to the final part size, not an arbitrary default

- Remove hidden objects: Delete anything outside the artboard or on hidden layers that could process unexpectedly

- Run a software preview: Use your design application's path preview to verify cut sequence and completeness

Common Mistakes to Avoid

Even experienced designers occasionally stumble. Watch for these frequent file preparation errors:

- Open lines for cutting: The machine cannot cut an incomplete path. Always close your shapes

- Wrong file format: Attempting to cut from a JPG produces unpredictable results. Vector files only for cut operations

- Low resolution engraving: Images below 300 DPI create blurry, disappointing engravings

- Forgetting to resize: Your file dimensions must match your intended physical part size

- Placing holes too close to bends: If your part will be bent after cutting, leave at least 1.5-2 times material thickness between holes and bend lines

Taking time to prepare files correctly saves frustration, material costs, and turnaround delays. Most precision laser cutting services offer DFM (Design for Manufacturability) feedback, but catching issues before upload demonstrates professionalism and speeds your project forward.

With your files properly prepared, you're ready to navigate the ordering process itself. Let's explore exactly what happens from the moment you upload your design until finished parts arrive at your door.

The Complete Online Ordering Process Explained

You've prepared your design files perfectly. Now what? The journey from digital file to physical part involves a streamlined workflow that modern laser cut services have refined to near-perfection. Whether you're searching for a laser cutting service near me or working with a nationwide provider, the process follows remarkably similar steps.

Understanding this workflow helps you set realistic expectations and avoid surprises. Let's walk through exactly what happens from the moment you upload your file until finished parts arrive at your doorstep.

From Upload to Instant Quote in Minutes

The ordering process begins the moment you drag your file onto a service's upload interface. Modern laser cut services have eliminated the back-and-forth email quoting that once delayed projects for days. Here's the typical sequence you'll experience:

- Upload your design file: Drop your SVG, DXF, or AI file into the upload zone. The system immediately analyzes geometry, calculates cutting paths, and identifies any potential issues.

- Select material and thickness: Choose from available substrates ranging from mild steel to specialty acrylics. Thickness options typically span 0.5mm to 25mm depending on material type.

- Specify quantity: Enter how many copies you need. Batch pricing often reduces per-piece costs significantly.

- Choose finishing options: Select deburring, powder coating, hardware insertion, or other secondary operations. According to Fabworks, adding bent parts or hardware will increase your lead time, so consider these impacts carefully.

- Receive laser cutting instant quote: Within seconds, you'll see itemized pricing including material costs, cutting time, finishing, and shipping. Many platforms display estimated ship dates that update dynamically as you adjust options.

- Review DFM feedback: The system flags potential manufacturability issues like features too small, spacing too tight, or geometry that may cause problems during cutting.

This entire process typically takes just minutes. As one customer described their experience with an online service: "I whipped up a few parts in SolidWorks for my sons go-cart project, uploaded them, picked my material and processing type. Bickety-Bam!" That simplicity defines modern laser cutting services near me and nationwide providers alike.

For projects requiring tube laser cutting services, the process works similarly but includes additional parameters. You'll specify tube diameter, wall thickness, and any secondary operations like notching or end preparation. Laser tube cutting services have become increasingly accessible through online platforms, though availability varies by provider.

What Happens After You Click Order

Once you approve the quote and complete payment, your order enters the production queue. Here's what unfolds behind the scenes:

- Order confirmation: You receive immediate email confirmation with order number and estimated delivery date.

- Production scheduling: Your job enters the queue based on material availability, machine scheduling, and your selected turnaround time.

- Material preparation: Technicians load appropriate sheet stock onto the cutting bed, verifying material type and thickness match your specifications.

- Cutting execution: The laser follows your design paths with precision. Quality technicians monitor the process for any anomalies.

- Secondary operations: If you selected deburring, bending, or hardware insertion, these steps follow cutting. According to Fabworks, "ordering bent parts outside of bending guidelines will potentially hold up the entire order."

- Quality inspection: Finished parts undergo dimensional verification against your original specifications.

- Packaging: Parts are wrapped, cushioned, and boxed appropriately. Delicate items receive extra protection to prevent damage during transit.

- Shipping and tracking: You receive tracking information once your order leaves the facility.

Realistic Timeline Expectations

Turnaround times vary dramatically based on several factors. Understanding these helps you plan projects accurately:

| Order Type | Typical Turnaround | Key Factors |

|---|---|---|

| Rush/Next-Day | 24-72 hours | Simple geometry, common materials, flat parts only |

| Standard Production | 3-5 business days | Most common option balancing speed and cost |

| Complex Orders | 5-10 business days | Includes bending, hardware, or specialty materials |

| Large Volume | 1-2+ weeks | Production runs requiring extended machine time |

Want faster delivery? Fabworks suggests several strategies: "Consider using hand bends on prototype parts and doing the bending yourself. This will potentially cut days off the part lead time." Similarly, selecting "No Deburring" for prototype parts speeds production when perfectly smooth edges aren't critical.

Customer testimonials consistently highlight speed as a key advantage. Reviews describe receiving parts "a few days later" with "fast shipping" and turnaround times that exceed expectations. One reviewer noted: "How are they so fast??" The answer lies in automated workflows, optimized nesting software, and streamlined production processes.

Quality Control and What Arrives at Your Door

Professional laser cut services implement multiple quality checkpoints throughout production. Here's what you can expect:

During production:

- Real-time monitoring detects cutting anomalies

- First-article inspection verifies dimensional accuracy

- Visual inspection catches surface defects or contamination

Packaging considerations:

- Small parts are bagged together or individually wrapped

- Large flat parts receive cardboard protection against scratching

- Fragile or polished surfaces get foam or paper interleaving

- Heavy parts use reinforced boxes to prevent crushing

Documentation included with delivery:

- Packing slip listing all items and quantities

- Material certifications for critical applications (when requested)

- Inspection reports for aerospace or medical-grade orders

The experience customers describe speaks to the reliability of modern services. Feedback like "Awesome experience, awesome customer service, excellent finished product" and "So impressed with the quality and price" reflects what well-executed online ordering delivers.

With the ordering process demystified, you're probably wondering about costs. Let's break down exactly what drives laser cutting pricing and how to optimize your budget without sacrificing quality.

Understanding Laser Cutting Pricing and Cost Factors

Ever received a laser cutting quote and wondered how those numbers were calculated? You're not alone. Pricing transparency remains one of the most frustrating aspects of ordering fabricated parts online. The good news? Once you understand the key cost drivers, you can make smarter design decisions that save money without sacrificing quality.

Whether you're hunting for cheap laser cutting options or evaluating premium services, the same fundamental factors determine what you'll pay. Let's pull back the curtain on laser cutting charges and show you exactly where your money goes.

What Drives Laser Cutting Costs

Five primary factors combine to determine your final price. Understanding each one helps you anticipate costs before uploading files and identify opportunities for savings.

1. Material type and thickness

Material costs represent the most visible expense. According to Komacut's pricing analysis, different materials have unique properties affecting cutting speed, energy consumption, and equipment wear. Cutting stainless steel generally requires more energy and time compared to carbon steel, making it more expensive. Soft or thin materials are typically faster and cheaper to cut.

Sheet metal laser cutting costs escalate with thickness because thicker materials require more energy, slower cutting speeds, and increased equipment maintenance due to wear and tear.

2. Total cutting length (perimeter)

The laser charges by the distance it travels. A simple square has four straight cuts, while an ornate decorative panel might have hundreds of meters of cut path. Every millimeter of perimeter adds to your total cutting time and cost.

3. Number of cutouts and pierce points

Each hole, slot, or internal feature requires a pierce point where the laser initiates cutting. More pierce points and longer cutting paths increase both time and energy consumption. Intricate designs with numerous cutouts demand greater laser cutting precision, adding to labor and equipment expenses.

4. Quantity ordered

Fixed setup costs get distributed across all units. Ordering one part means absorbing the entire setup fee yourself. Order fifty parts, and that same fee divides by fifty. Industry data confirms that bulk ordering significantly reduces per-unit costs by spreading fixed expenses and often qualifying for material discounts.

5. Turnaround time requirements

Rush orders command premiums. Services must reorganize production schedules, potentially bump other customers, and dedicate resources specifically to your urgent job. Standard timelines offer substantial savings.

Relative Cost Factors at a Glance

This breakdown shows how different elements contribute to your total laser cutting quote:

| Cost Factor | Impact Level | What Controls It | Optimization Potential |

|---|---|---|---|

| Material Cost | High | Material type, thickness, sheet size | Choose cost-effective materials; use standard sheet sizes |

| Cutting Time | High | Perimeter length, complexity, pierce count | Simplify geometry; reduce unnecessary features |

| Setup Fees | Medium | File preparation, machine configuration | Order larger quantities to spread costs |

| Secondary Operations | Variable | Deburring, bending, finishing | Specify only essential operations |

| Shipping | Low-Medium | Weight, dimensions, speed | Consolidate orders; choose standard shipping |

| Rush Premiums | High (when applicable) | Turnaround time selected | Plan ahead; use standard timelines |

Strategies to Optimize Your Budget

Smart designers reduce costs without compromising functionality. Here's how to get more value from every dollar spent on online laser cutting:

Maximize material utilization through nesting

Efficient nesting arranges parts closely together on material sheets, minimizing waste. According to Komacut, this reduces raw material needs and decreases cutting time, leading to significant savings. Advanced nesting software optimizes layouts automatically, but you can help by designing parts that tessellate efficiently.

Simplify your geometry

Every curve, angle, and detail adds cutting time. Quote Cut Ship's cost reduction guide recommends minimizing complexity where possible:

- Use straight lines instead of complex curves when functionally equivalent

- Reduce excessive detailing that increases processing time

- Apply common-line cutting by arranging parts to share cut edges

- Limit engraving and etching, which take longer than cutting

Choose materials strategically

Not every application requires premium materials. Mild steel costs less than stainless steel or aluminum. Using standard sheet sizes avoids custom cutting charges. Select the thinnest material that meets your strength requirements, since thicker stock cuts slower and costs more.

Batch your orders intelligently

If you anticipate needing additional parts, ordering larger quantities upfront saves money. Beyond spreading setup costs, larger batches improve production efficiency by reducing machine downtime and labor costs per unit.

Allow realistic lead times

Rush orders can double or triple your costs. Planning ahead and accepting standard turnaround times keeps pricing reasonable. Reserve expedited services for genuine emergencies.

Evaluating Quotes Objectively

When comparing prices from different services, look beyond the bottom line. Consider these factors:

- What's included: Does the quote cover deburring, or is that extra? Are material certifications provided?

- Tolerance specifications: Tighter tolerances may justify higher prices for precision applications

- Secondary processes: Finishing operations like chamfering, threading, and coating add cost but may be essential. According to Komacut, these steps increase complexity and production duration

- Minimum order requirements: Some services have minimums that affect small-quantity pricing

- Shipping costs: A lower part price means nothing if shipping doubles your total

Request itemized quotes whenever possible. Understanding exactly what drives costs helps you make informed trade-offs between budget and requirements.

Now that you understand pricing dynamics, you might wonder how laser cutting compares to alternative fabrication methods. Let's explore when this technology outperforms the competition and when other approaches make more sense.

Laser Cutting vs Waterjet CNC and Plasma Methods

Wondering if a metal cutting laser is actually the best choice for your project? It's a fair question. Laser cutting dominates many applications, but it's not universally superior. Waterjet, CNC routing, and plasma cutting each bring unique advantages that make them the smarter choice in specific situations.

Understanding these alternatives helps you match technology to project requirements rather than forcing every job through the same process. Let's compare these industrial laser cutting methods objectively so you can make informed decisions.

When Laser Cutting Outperforms Alternatives

Cutting with a laser excels in specific scenarios where precision, speed, and edge quality matter most. According to SendCutSend's fabrication analysis, laser cutting is often the quickest and most affordable option for a large variety of materials.

Where cnc laser cutting dominates:

- Thin sheet materials: On metals under 1/2 inch, lasers cut faster than any alternative

- Intricate geometries: Small holes, tight corners, and complex patterns benefit from the focused beam

- High production volumes: Cutting speeds reaching 2,500 inches per minute maximize throughput

- Clean edge requirements: Minimal post-processing needed for most applications

- Tight tolerances: Precision of +/- 0.005" achievable on appropriate materials

The cutting laser also handles mixed-operation jobs efficiently. You can cut, engrave, and score in a single setup, something waterjet and plasma simply cannot match.

However, every technology has limitations. Wurth Machinery's testing revealed that laser cutting struggles with materials over 1 inch thick, where plasma and waterjet take the lead. Heat-sensitive materials and certain reflective metals also present challenges.

Understanding Each Alternative Method

Plasma cutting near me: Speed on heavy plate

Plasma cutters use an electrical arc and compressed gas to melt and blast through conductive metals. If you're cutting 1/2 inch steel plate or thicker, plasma offers the best speed and cost efficiency. Key advantages include:

- Handles thick metal plates up to several inches

- Lower equipment and operating costs than laser or waterjet

- Fast cutting speeds on heavy materials

- Works with any conductive metal

The trade-off? Plasma produces rougher edges and wider kerf than laser laser cutting, requiring more post-processing for finished applications.

Waterjet cutting: Versatility without heat

Waterjets use high-pressure water mixed with abrasive to cut virtually anything without generating heat. According to industry projections, the waterjet market is projected to reach over $2.39 billion by 2034. This growth reflects unique capabilities:

- Cuts metals, glass, stone, composites, and ceramics

- Zero heat-affected zone preserves material properties

- No warping or hardening of cut edges

- Superior finish on difficult composites like carbon fiber and G10

Aerospace applications favor waterjet specifically because regulations often prohibit heat-affected zones on aircraft components.

CNC routing: Ideal for wood and plastics

CNC routers use rotating cutting tools rather than energy beams. This mechanical approach excels with:

- Wood and plywood without burning

- Plastics like ABS and HDPE

- Composite materials requiring clean edges

- Parts needing tapped holes or countersinks

According to SendCutSend, routing leaves superior surface finishes on many plastics and composites while maintaining tolerances of +/- 0.005". However, interior corners must have a radius of at least 0.063" to accommodate the cutter diameter.

Choosing the Right Cutting Method for Your Project

This comprehensive comparison helps you match technology to requirements:

| Characteristic | Laser Cutting | Waterjet Cutting | Plasma Cutting | CNC Routing |

|---|---|---|---|---|

| Precision Tolerance | +/- 0.005" | +/- 0.009" | +/- 0.020" | +/- 0.005" |

| Material Compatibility | Metals, plastics, wood, leather, acrylic | Nearly anything: metals, glass, stone, composites | Conductive metals only | Wood, plastics, composites, soft metals |

| Edge Quality | Excellent; minimal post-processing | Very good; no burrs or dross | Rougher; requires finishing | Good to excellent on appropriate materials |

| Heat Effects | Small heat-affected zone; can be minimized | None; cold cutting process | Significant; material property changes | None; mechanical cutting |

| Thickness Limits | Up to 1" optimal; struggles beyond | Up to 12"+ on some materials | Several inches; excels on thick plate | Material dependent; typically under 2" |

| Cutting Speed | Fastest on thin materials | Slowest of all methods | Fastest on thick metals | Moderate; varies by material |

| Relative Cost | Low-medium for appropriate applications | Higher; equipment costs ~$195,000 | Lower; system costs ~$90,000 | Medium; good value for suitable materials |

Decision Framework: Which Technology Fits Your Project?

Choose laser cutting when:

- Working with thin metals under 1/2 inch

- Intricate designs require tight tolerances

- Production speed and volume are priorities

- Mixed cutting and engraving operations needed

- Budget constraints favor economical processing

Choose waterjet cutting when:

- Heat damage must be completely avoided

- Cutting non-metals like glass, stone, or composites

- Material thickness exceeds laser capabilities

- Aerospace or medical regulations prohibit heat-affected zones

- Working with difficult composites like carbon fiber or G10

Choose plasma cutting when:

- Cutting thick conductive metals over 1 inch

- Speed matters more than edge finish

- Budget constraints favor lower equipment costs

- Post-processing is already planned

Choose CNC routing when:

- Working primarily with wood or plastics

- Parts require secondary operations like tapping or countersinking

- Burning or heat effects are unacceptable

- Interior corners cannot accommodate laser kerf

As Wurth Machinery concludes, many successful fabrication shops eventually incorporate multiple technologies, starting with the system that addresses their most common projects. Understanding these trade-offs positions you to select the optimal method for each unique application.

With cutting technology decisions clarified, the next critical step involves selecting a service provider who can deliver professional results. Let's explore how to evaluate online laser cutting services and identify the right partner for your projects.

How to Choose the Right Online Laser Cutting Service

Finding a laser cutter near me used to mean flipping through local directories and hoping for the best. Today, countless online platforms compete for your business, each promising exceptional quality and lightning-fast delivery. But how do you separate genuinely capable providers from those who overpromise and underdeliver?

Selecting the right laser cutting near me or nationwide service directly impacts your project's success, timeline, and budget. A poor choice means wasted materials, missed deadlines, and frustrating rework. The right partner becomes a seamless extension of your design workflow, transforming digital files into precision parts you can trust.

Let's break down the essential criteria that distinguish exceptional cnc laser cutting services from mediocre alternatives.

Essential Criteria for Service Evaluation

When comparing precision laser cutting services, look beyond flashy websites and marketing claims. According to Laser Cutting Shapes' evaluation guide, these fundamental factors determine whether a provider can actually deliver what you need:

Material capabilities and options

Does the service handle your specific materials? Common options include steel, aluminum, plastics, wood, and leather. If you have a unique substrate in mind, verify their equipment can process it. Pay close attention to thickness limitations, as some providers have restrictions based on their laser systems. Metal laser cutting services should clearly specify maximum thicknesses for each material type.

Precision and tolerance specifications

Professional services publish their achievable tolerances. Expect specifications like ±0.15mm for thin materials and ±0.45mm for thicker plates. If a provider won't commit to specific tolerances in writing, consider that a warning sign. Custom laser cutting service providers serving engineering applications should maintain ISO-documented quality standards.

Turnaround time transparency

Realistic lead times vary based on complexity, volume, and current workload. Rush options often come at premium costs. Clear communication about your deadlines is essential. Look for providers who display estimated ship dates during the quoting process rather than vague promises.

Pricing clarity

Get detailed quotes outlining all expenses involved. Avoid services that hide fees or surprise you with charges after production begins. Request quotes from multiple providers to compare value. Remember, the cheapest option isn't always the best, as quality, experience, and reliability factor into true project cost.

DFM support quality

Design for Manufacturability feedback separates basic services from professional partners. Quality providers flag potential issues before cutting begins, saving you material costs and production delays. Look for platforms offering automated DFM analysis during the quoting stage, plus human expertise for complex questions.

Customer service responsiveness

How quickly does the service answer questions? A responsive, communicative provider addresses concerns throughout the process. Check reviews highlighting their customer support quality. If possible, interact with their team directly before ordering to gauge their willingness to help.

Your Service Evaluation Checklist

Use this comprehensive checklist when comparing laser cutter service near me options or nationwide providers:

- Material compatibility: Confirm they process your specific materials and thicknesses

- Published tolerances: Verify precision specifications match your requirements

- File format support: Ensure they accept your design file types (SVG, DXF, AI, PDF)

- Quoting process: Check for instant online quotes with itemized pricing

- DFM feedback: Look for automated manufacturability analysis and human support

- Turnaround options: Confirm standard and rush timelines with clear pricing

- Secondary operations: Verify availability of deburring, bending, finishing as needed

- Quality certifications: Check for ISO, IATF 16949, or industry-specific credentials

- Sample availability: Request previous work samples to assess quality

- Customer reviews: Read testimonials focusing on quality, communication, and reliability

- Communication channels: Confirm phone, email, or chat support during business hours

- Shipping options: Check carriers used and tracking availability

Red Flags and Green Lights When Choosing a Provider

Experience teaches what warning signs to avoid and what positive indicators to seek. Here's what separates trustworthy laser metal cutting near me services from problematic alternatives:

Red Flags to Watch For

- No published tolerances: Reputable services commit to specific precision standards

- Hidden pricing: Vague quotes that require phone calls signal potential surprises

- No DFM feedback: Services that cut blindly without flagging issues cause expensive failures

- Poor communication: Slow email responses and unreturned calls predict production problems

- No portfolio or samples: Unwillingness to show previous work suggests quality concerns

- Unrealistic promises: Claims of overnight delivery on complex orders usually disappoint

- Missing certifications: For regulated industries, lack of credentials is disqualifying

Green Lights That Build Confidence

- Instant online quoting: Transparent pricing indicates established processes

- Detailed specifications: Published tolerances, material options, and capabilities show professionalism

- Comprehensive DFM support: Proactive manufacturability feedback prevents costly mistakes

- Verified customer reviews: Consistent positive feedback across multiple platforms

- Facility visits welcomed: Willingness to show operations demonstrates confidence

- Responsive communication: Quick, helpful answers to technical questions

- Industry certifications: ISO standards and sector-specific credentials validate quality systems

The Importance of Quality Certifications

For many applications, certifications aren't optional, they're essential. Understanding what these credentials mean helps you evaluate providers appropriately:

ISO 9001: The foundational quality management standard. Demonstrates documented processes, continuous improvement, and customer focus. Most professional services maintain this certification at minimum.

IATF 16949: Specifically for automotive supply chain applications. This rigorous certification ensures defect prevention, reduction of variation and waste, and continuous improvement. For chassis, suspension, and structural components, IATF 16949 certification is often a requirement, not a nice-to-have. For automotive and precision metal applications, manufacturers like Shaoyi offer IATF 16949-certified quality with rapid prototyping and comprehensive DFM support, exemplifying what to look for in a professional service.

AS9100: Aerospace quality management. Critical for aircraft components where safety is paramount.

ISO 13485: Medical device quality management. Required for parts entering healthcare applications.

When your application demands certified quality, verify credentials directly. Legitimate services display certification numbers and welcome verification requests.

Assessing Technical Capabilities

Beyond certifications, evaluate actual production capabilities through these approaches:

Review published specifications: Detailed machine specs indicate transparency. Look for laser power ratings, bed sizes, maximum material thicknesses, and achievable tolerances.

Request sample work: Ask for samples demonstrating precision and edge quality on materials similar to yours. This lets you physically assess their capabilities before committing.

Start with a test order: Before committing to large production runs, place a small prototype order. This reveals actual quality, communication, and turnaround time without major risk.

Ask technical questions: Inquire about kerf compensation, nesting optimization, and DFM considerations. Knowledgeable responses indicate experienced professionals; vague answers suggest inexperience.

Choosing a custom laser cutting service represents an investment in your project's success. Taking time to evaluate providers thoroughly pays dividends through reliable quality, predictable timelines, and professional support when questions arise.

With the right service partner identified, you're ready to launch your first project confidently. Let's wrap up with practical next steps and actionable recommendations tailored to your specific situation.

Getting Started with Your First Online Laser Cut Project

You've made it through the essential knowledge. From understanding how focused light becomes a precision cutting tool to evaluating service providers with confidence, you now possess everything needed to transform your designs into physical reality. The journey from concept to custom laser cutting success starts with taking that first deliberate step.

Let's crystallize the critical decisions and provide you with a clear roadmap for moving forward, whether you're crafting a weekend project or launching a production run.

Your Laser Cutting Project Roadmap

Every successful laser cutting online project follows the same fundamental sequence. Here's your decision framework distilled into actionable steps:

Technology selection: Choose CO2 lasers for wood, acrylic, leather, and organic materials. Select fiber laser services for metals including steel, aluminum, and brass. Most online laser cutting service platforms handle this automatically based on your material choice.

Material specification: Match substrate to application requirements. Consider thickness limitations, edge quality expectations, and post-processing needs. Remember that material choice directly impacts cost, so select the thinnest option meeting your strength requirements.

File preparation: Export clean vector files as SVG or DXF. Convert all text to paths. Verify closed geometries and eliminate duplicate lines. Apply correct color coding for cut, score, and engrave operations.

Service evaluation: Confirm material capabilities, published tolerances, turnaround options, and quality certifications before ordering. Start with a small test order to validate actual performance.

The difference between a successful laser cut online project and a frustrating failure almost always comes down to preparation. Master your file setup, understand your material, and choose a capable service partner, and precision parts arrive exactly as designed.

Taking the First Step with Confidence

Your specific situation determines the smartest approach. Here are tailored recommendations based on your project type:

For hobbyists starting small projects:

- Begin with forgiving materials like acrylic or plywood that cut cleanly and reveal mistakes clearly

- Start with simple geometries to learn the workflow before tackling complex designs

- Use free design software like Inkscape to create vector files without upfront investment

- Order small quantities initially to validate your designs before committing to larger batches

- Search for a laser cut near me option or reliable nationwide service offering reasonable minimums

For engineers prototyping parts:

- Factor kerf compensation into tolerance-critical dimensions from the start

- Request material certifications when metallurgical properties matter

- Leverage DFM feedback to catch manufacturability issues before cutting

- Consider secondary operations like deburring and hardware insertion during initial planning

- Establish relationships with certified providers who understand engineering documentation requirements

For businesses scaling production:

- Negotiate volume pricing and establish blanket orders for recurring parts

- Verify provider capacity can scale with your growth without quality degradation

- Prioritize services with quality certifications matching your industry requirements

- Build redundancy by qualifying multiple suppliers for critical components

- Track total cost of ownership including shipping, secondary operations, and quality failures

For readers with automotive or precision metal stamping needs, exploring manufacturers offering 5-day rapid prototyping combined with comprehensive DFM support accelerates product development significantly. Shaoyi's 12-hour quote turnaround and IATF 16949-certified quality represent the professional-grade manufacturing support that demanding applications require.

The laser cutting service online landscape continues evolving, with faster turnarounds, broader material options, and increasingly sophisticated DFM tools becoming standard. Your first project marks the beginning of a capability that scales from single prototypes to thousands of production parts.

Upload that first file. Select your material. Review the quote. Click order. Within days, precision-cut parts arrive at your door, exactly as designed, manufactured by industrial-grade equipment you never had to purchase, operated by specialists you never had to hire. That's the power of ordering laser cut online, democratized manufacturing at your fingertips.

Frequently Asked Questions About Laser Cut Online Services

1. What materials can be laser cut through online services?

Online laser cutting services process a wide range of materials including metals (steel, stainless steel, aluminum, copper, brass), plastics (acrylic, Delrin), wood, plywood, MDF, leather, fabric, and paper. Fiber lasers excel with metals up to 20mm thick, while CO2 lasers work best for organic materials and plastics. Each material offers different edge quality characteristics and thickness capabilities, with professional services maintaining tolerances of ±0.15mm to ±0.45mm depending on material and thickness.

2. How much does laser cutting service cost?

Laser cutting costs depend on five primary factors: material type and thickness, total cutting length (perimeter), number of pierce points and cutouts, quantity ordered, and turnaround time requirements. Thicker materials cut slower and cost more, while intricate designs with complex geometries increase cutting time. Batch ordering reduces per-unit costs by spreading setup fees. Rush orders command premiums, so planning ahead with standard timelines offers significant savings. Request itemized quotes from multiple providers to compare value objectively.

3. What file format is best for laser cutting?

DXF and SVG are the preferred vector formats for laser cutting operations. DXF is the industry standard containing pure geometry without embedded styles, while SVG offers universal compatibility across platforms. AI (Adobe Illustrator) files work well when text is converted to outlines. For engraving, use high-resolution PNG or JPG files at 300+ DPI. All cutting paths must be closed and continuous, with duplicate overlapping lines removed. Most services use color coding conventions where red indicates cuts, blue indicates scoring, and black fill indicates engraving.

4. How long does online laser cutting take?

Turnaround times vary based on order complexity and selected options. Rush or next-day orders for simple flat parts typically ship within 24-72 hours. Standard production takes 3-5 business days for most orders. Complex projects requiring bending, hardware insertion, or specialty materials may need 5-10 business days. Large volume production runs can extend to 1-2+ weeks. Adding secondary operations like deburring or bent parts increases lead time. Many services display estimated ship dates during the quoting process for accurate planning.

5. What is the difference between CO2 and fiber laser cutting?

CO2 lasers operate at 10.6 micrometers wavelength, making them ideal for organic materials like wood, acrylic, leather, and fabric with excellent edge quality. Fiber lasers emit at 1.064 micrometers, excelling at cutting metals including steel, aluminum, copper, and brass with 3-5x faster speeds than CO2 on comparable jobs. Fiber lasers offer over 90% energy efficiency versus 5-10% for CO2 systems and have approximately 25,000-hour lifespan compared to 2,500 hours for CO2. Most online services automatically select the appropriate technology based on your material choice.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —