Шампирана стомана срещу ковано стоманени рамени: Реален анализ на разходите

Накратко

Кованите лостове са значително по-скъпи от своите аналогове от шампирена стомана поради по-сложен и енергоемки производствен процес. Шампираната стомана е икономически ефективен OEM стандарт, напълно подходящ за повечето случаи на ежедневно каране. Въпреки това, кованата стомана предлага по-голяма якост и издръжливост, което прави по-високата цена разумна инвестиция за вдигнати джипове, внедорожници или всеки случай, при който се изисква максимална надеждност на окачването.

Разбиране на разликата в производството: шампирано срещу ковано

Основните разлики в цена, якост и производителност между лостовете от шампирана стомана и кованите лостове идват от различните им производствени методи. Разбирането на тези процеси е от съществено значение, за да се оцени защо единият е бюджетен стандарт, а другият — премиум надстройка за производителност.

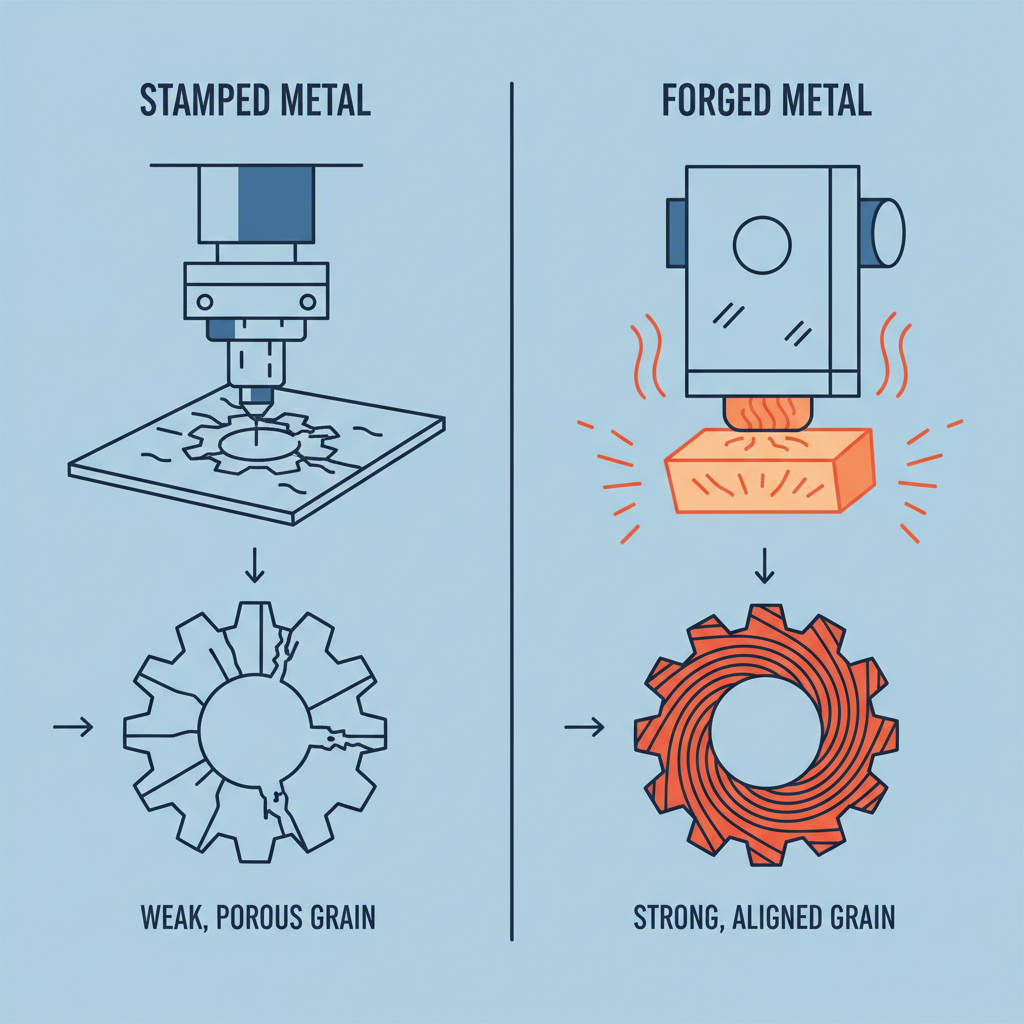

Контролерите от штампана стомана са най-често срещаният тип, срещан при серийни превозни средства. Процесът включва използване на големи листове стомана и оформяне чрез високотлачен прес, подобно на формичка за бисквити. Често двете штампани половини се заваряват заедно, за да се получи крайният кух компонент. Този метод е изключително ефективен и икономически изгоден за масово производство, което обяснява защо автомобилните производители го предпочитат за стандартни леки коли и камиони. За автомобилните производители точността при този процес е от първостепенно значение. Компании, специализирани в тази област, като Shaoyi (Ningbo) Metal Technology Co., Ltd. , осигуряват необходимата инженерна експертиза и автоматизирани съоръжения за производството на тези сложни компоненти в големи мащаби.

Кованите управляеми лостове, напротив, се изработват от единичен цял къс метал, обикновено било от стомана или алуминиев сплав. Този къс се нагрява до изключително висока температура и след това се чука или пресва под голямо налягане в окончателната форма. Този процес на коване компресира метала и подрежда вътрешната му зърнеста структура, елиминира порите и създава значително по-плътен и по-силен компонент. Тъй като няма заваръчни съединения, които да служат като потенциални слаби точки, кованите лостове предлагат изключителна устойчивост към огъване, пукане и разрушаване при екстремни натоварвания.

Основните различия между тези два метода могат да бъдат обобщени по следния начин:

- Произход на материала: Управляемите лостове от плочи започват като стоманени листове; кованите лостове започват като цял блок (било) от метал.

- Строителство: Лостовете от плочи често са кухи и заварени; кованите лостове са единичен цял къс.

- Сила: Коването създава по-плътна, насочена зърнеста структура, която осигурява по-голяма якост в сравнение с ненасочената зърнеста структура на шамаруваната стомана.

- Слаби страни: Рамената от шамарувана стомана имат заварки, които могат да бъдат потенциални точки на повреда, докато кованите рамена нямат такива.

Основно сравнение на разходите: Анализ на ценовата разлика

Най-прякият въпрос за повечето собственици на превозни средства е прост: колко по-скъпи са кованите контролни рамени? Ценовата разлика е значителна и директно отразява производствените сложности и качеството на материала, обсъдени по-рано. Кованите контролни рамени постоянно са по-скъпият вариант, често с голяма маржа.

По-високата цена на кованите рамени се дължи на няколко фактора. Процесът на коване изисква повече ръчен труд, специализирано тежко оборудване и консумира голямо количество енергия за загряване на металните пръти. Освен това суровините често са сплави с по-високо качество, предназначени за по-голяма якост. В сравнение с това процесът на штамповане е високо автоматизиран и оптимизиран за скорост и обем, което значително намалява цената на единица продукт.

За да поставим това в контекст, стандартно штампано стоманено рамо за замяна от тип OEM може да струва между 50 и 150 щатски долара на бройка. В дискусия на форум потребител споменава, че двойка стоманени рамена с шарнири струват 150 долара, докато алуминиевите рамена с шарнир са по 250 долара за двойката. Комплектите с ковани рамена от вторичен пазар, проектирани като усъвършенствания за по-добра производителност, започват от много по-висока начална цена. Например комплект ковани горни рамена Rough Country за вдигнат камион може да струва около 340 долара, докато високопроизводителни варианти от прецизно обработен алуминиев прът могат да надвишат 1300 долара.

| Тип лост за управление | Типична цена (за лост) | Типична цена (пълен комплект) |

|---|---|---|

| Части от штампуван стоман (OEM заместителни) | $50 - $150 | $100 - $300 |

| Кован стоман/алуминий (надстройка) | $175 - $700+ | $350 - $1,400+ |

Тези цени могат да варират и в зависимост от марката и модела на автомобила, репутацията на производителя, както и от това дали са включени компоненти като сферични куплунги с голям ъгъл или нови бушинги. За прост ремонт на автомобил, използван всекидневно, штампуваната стомана е ясният икономически избор. Въпреки това, при модифициран автомобил по-високата първоначална цена на кованите лостове трябва да се разглежда като важна част от общия бюджет за надстройка.

Производителност и издръжливост: Стоманата ли си заслужава допълнителната цена?

Освен ценовия етикет, истинският въпрос е дали по-добрата производителност на кованите носачи оправдава допълнителните разходи. За много приложения отговорът е категорично положителен. Решението напълно зависи от това как използвате превозното си средство. Повишена якост и издръжливост на кованата стомана директно се превръщат в по-голяма безопасност и надеждност при тежки условия.

За стандартно превозно средство, използвано за пътуване до работа и ежедневно шофиране, серийните носачи от тегава стомана са напълно достатъчни. Те са проектирани да издържат нормалните пътни условия през целия живот на автомобила. Предимствата в производителността на кован носач вероятно няма да бъдат забелязани в този контекст. В момента обаче, в който модифицирате окачването на превозното си средство, като добавите комплект за повдигане или по-големи гуми, натоварванията върху носачите нарастват експоненциално. Точно тук носачите от тегава стомана могат да станат рисков фактор. Те са по-склонни да огъват под натоварване и могат да бъдат повредени или напълно да се повредят от силните удари, чести при внедрене.

Кованите лостове за управление са проектирани специално за тези високонапрежени сценарии. Тяхната плътна и масивна конструкция осигурява необходимата огъваща жесткост, за да се запази правилната геометрия и подреждане на окачването при рязко завиване, буксиране на тежки натоварвания или движение по труден терен. Затова те са задължителна модернизация за всеки пикап или джип, който е повдигнат, оборудван с гуми с по-големи размери или използван за сериозни внедростни приключения. Както отбелязва един всеобхватен наръчник за ръчно изработени лостове за управление, специализираните ковани стоманени лостове са проектирани да бъдат почти неунищожими.

Предимства и недостатъци – сравнение

За да ви помогнем да вземете решение, ето ясно разграничение на предимствата и недостатъците на всеки тип:

Контролни лостове от тегава стомана

- Плюсове: Много ниска цена, широко разпространени като оригинални резервни части, леки.

- Минуси: По-ниска якост в сравнение с кованите, заваръчните шевове могат да бъдат слаби точки, склонни към огъване или повреди при високо напрежение.

Ковани стоманени лостове за управление

- Плюсове: Надминаваща якост и издръжливост, висока устойчивост към огъване и разрушаване, задължителни за повдигнати или внедростни превозни средства.

- Минуси: Значително по-висока цена, може да е по-тежък от стоманените аналогови продукти от штампованата стомана.

Как да идентифицирате управляемите рамена на вашия автомобил

Преди да поръчате резервни части или да планирате модернизация, е важно да знаете какъв тип управляеми лостове има в автомобила ви в момента. Несъвпадащи части може да не се поберат правилно, което води до загуба на време и пари. За щастие, обикновено можете да ги идентифицирате чрез проста визуална проверка.

Следвайте тези стъпки, за да определите дали имате штампани или кованите управляеми лостове:

- Безопасност Първо: Паркирайте автомобила си на равна повърхност и включете спирачката за стоене. Ако трябва да работите под него, използвайте домкрат, за да вдигнете предната част на автомобила и го закрепете с домкратни стойки. Никога не работете под автомобил, поддържан само от домкрат.

- Намерете управляемите лостове: Погледнете зад предното си колело. Ще видите два А-образни лоста — горен и долен — които свързват сборката на стъпалната кутия (наконечника) с рамата на автомобила.

- Очистване на областта: Управляемите лостове често са покрити с мръсотия и мазнини. Използвайте кърпа или четка с метални жици, за да почистите един участък, така че ясно да виждате метала.

- Проверете за шевове: Това е ключов идентификатор. A щампосани стоманени рамото обикновено се състои от две метални части, заварени заедно. Вгледете се внимателно в краищата на рамото. Ще видите ясно изразен шев или ръб, който минава по периметъра, където са съединени двете половини.

- Търсете цялостна форма: A ковано или леяно рамо ще изглежда като единична, масивна метална част. Няма да има видими заваръчни шевове. Кованите рамена често изглеждат по-масивни и по-здрави в сравнение с тези от табла.

Ако все още не сте сигурни след визуална проверка, най-добрият вариант е да се консултирате със служебното ръководство за вашия автомобил, да потърсите в онлайн форуми за вашия конкретен марка и модел или да попитате доверен механик за потвърждение. Знанието какво притежавате е първата стъпка към правилното решение за ремонт или модернизация.

Често задавани въпроси

1. Кой материал е най-добър за лостовете на окачване?

„Най-добрият“ материал зависи от приложението. За стандартно ежедневно шофиране щампосаната стомана е идеална поради ниската си цена и достатъчна якост. За високи постижения, луксозни или превозни средства за условия с дъжд, кован алуминий често се предпочита поради комбинацията си от якост, лекота и устойчивост на корозия. За тежкотоварни камиони, внедорожници или ситуации, изискващи максимална якост, кована стомана обикновено е най-добрият избор поради издръжливостта си и устойчивостта на повреди при екстремни натоварвания.

2. Каква е разликата между лостове от сиво желязо и шампирана стомана?

Основната разлика е в якостта и приложението. Рамената от щампосана стомана са сравнително евтини и често се срещат при съвременните леки автомобили. Те се изработват от преснати стоманени листове, заварени заедно. Рамената от леен чугун са много по-силни и по-тежки, произведени чрез наливане на разтопен чугун в форма. Поради здравината и способността им да издържат на сурови условия, рамената от леен чугун обикновено се използват при тежкотоварни превозни средства като големи камиони и SUV-ове.

Малки порции, високи стандарти. Нашата услуга за бързо проектиране на прототипи прави валидацията по-бърза и лесна —

Малки порции, високи стандарти. Нашата услуга за бързо проектиране на прототипи прави валидацията по-бърза и лесна —