Metal Stamping Die Sets: Match Specs To Your Application Fast

Understanding Metal Stamping Die Sets and Their Critical Role

Ever wondered what keeps those upper and lower die components perfectly aligned during high-speed stamping operations? The answer lies in metal stamping die sets—the foundational framework that makes precision manufacturing possible. Whether you're new to die tooling or a seasoned buyer evaluating your next investment, understanding these critical assemblies is your first step toward better part quality and longer tool life.

So, what are dies in the context of metal stamping? At their core, die sets are precision-engineered platforms that hold cutting and forming components in exact alignment while a press applies tremendous force. Think of them as the structural backbone of your entire stamping operation—without proper alignment, even the best punches and buttons won't deliver consistent results.

The Anatomy of a Die Set

A complete die set consists of several integrated components working in harmony. The foundation starts with die shoes—also called die plates—which serve as the upper and lower mounting surfaces where all other die components attach. According to industry standards, these die plates are typically made from steel or aluminum and must be ground or machined to maintain parallelism and flatness.

The upper die shoe mounts to the press ram, while the lower die shoe attaches to the press bed. Between them, guide posts and guide bushings create the precision alignment system that ensures repeatable positioning with every press stroke. When you're setting die components for a new job, this alignment system determines whether your first part matches your ten-thousandth part.

Core Components That Drive Precision

Understanding each component's role helps you evaluate die sets more effectively:

- Die Shoes (Upper and Lower): Steel or aluminum plates that provide mounting surfaces for punches, buttons, and other tooling. The expected cutting and forming pressure determines the required shoe thickness.

- Guide Posts: Hardened steel pins that maintain alignment between upper and lower shoes. Available in friction and ball-bearing styles—ball-bearing pins have become the industry standard due to their ease of separation and smooth operation.

- Guide Bushings: Precision-machined sleeves, often made from aluminum-bronze, that receive the guide posts. These components are manufactured to tolerances within .0001" to ensure accurate positioning.

- Heel Blocks and Wear Plates: Steel components attached to both shoes that absorb side pressure during operations, preventing guide pin bending and misalignment.

Why Die Set Quality Determines Part Accuracy

Here's where the difference between adequate and exceptional die sets becomes clear. Every time a die stamp contacts your material, the alignment system must position components within thousandths of an inch. Poor-quality die sets introduce variables that compound with every stroke—slight misalignments lead to burrs, dimensional drift, and premature punch wear.

The relationship between die set precision and finished part quality is direct and measurable. High-volume production environments demand die sets that maintain alignment through millions of cycles. When tolerances slip, you'll see it first in your stamped parts: inconsistent hole positions, uneven edges, and increasing reject rates.

Proper die set selection isn't just about buying quality—it's about matching specifications to your specific application. The tonnage your press delivers, the complexity of your operations, and your production volume requirements all influence which die set configuration will deliver optimal results. In the sections ahead, you'll learn exactly how to match these specifications to your stamping needs.

Die Set Types and Configuration Selection Guide

You've seen them listed in catalogs—two-post, four-post, diagonal, back-post—but what do these configurations actually mean for your stamping operation? Choosing the right die press configuration isn't just about fitting your available space. It directly impacts how operators interact with the die, how precisely your parts come out, and how long your tooling lasts under production conditions.

Let's break down each configuration so you can match your requirements to the right design the first time.

Two-Post vs Four-Post Configurations Explained

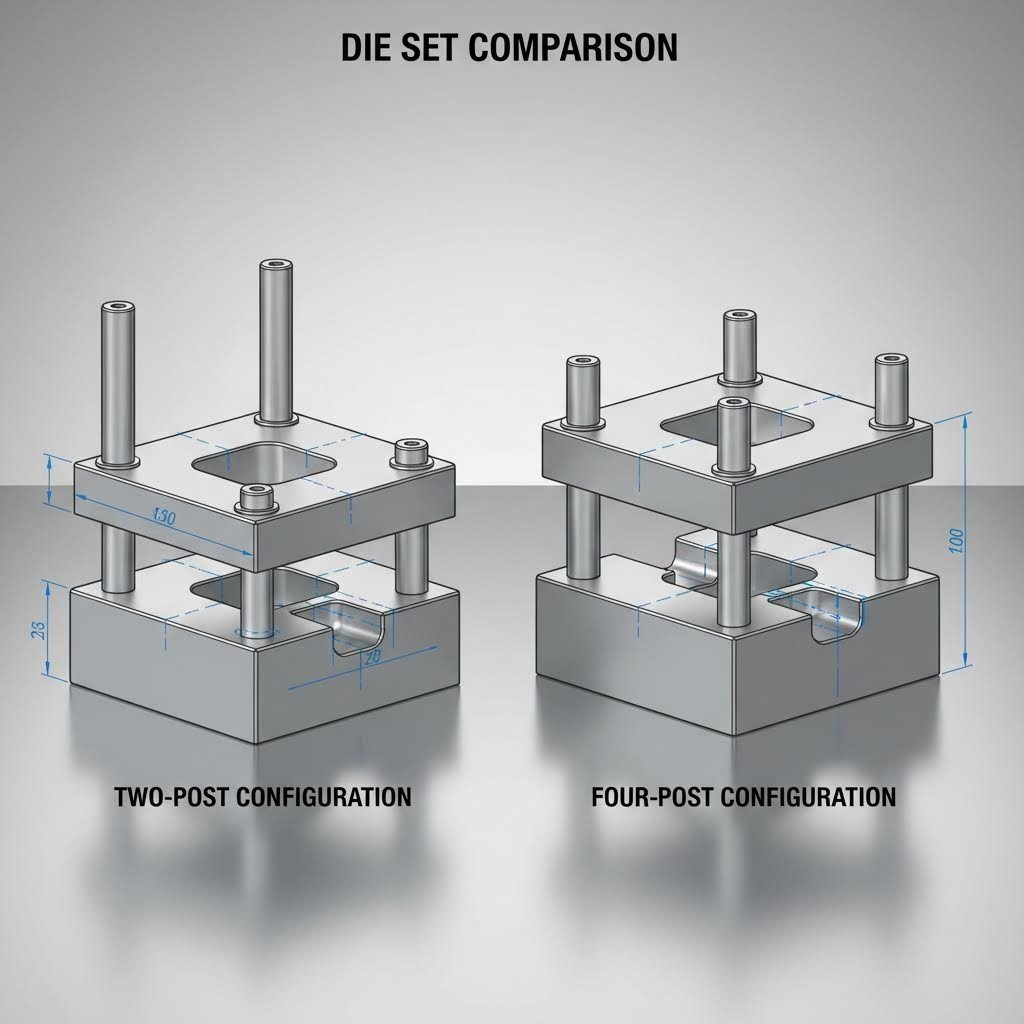

The fundamental difference comes down to how many guide posts support alignment between upper and lower die shoes—and where those posts are positioned.

Two-post die sets use a pair of guide posts, typically positioned at the back of the die tool assembly. This arrangement leaves the front and sides completely open, making it ideal for operations where operators need clear access for feeding material, removing parts, or monitoring the stamping process. Back-post configurations are the most common two-post style, with both posts mounted along the rear edge of the die shoes.

Diagonal post arrangements place the two posts at opposite corners—typically front-left and back-right, or front-right and back-left. This configuration accommodates angular feeding requirements where material enters the die at an angle rather than straight on. You'll find diagonal setups in specialized punch press dies designed for strip feeding at non-standard orientations.

Four-post die sets position a guide post at each corner of the die shoes. This design delivers maximum rigidity and alignment stability because the upper shoe is supported at four points rather than two. When precision is non-negotiable—think progressive dies running tight tolerances at high speeds—four-post configurations are the standard choice.

Within four-post designs, you'll encounter two primary variations:

- Center configurations: Posts are positioned inward from the corners, leaving more clearance around the die perimeter for clamping and material handling.

- Back configurations: All four posts are shifted toward the rear of the die set, providing better front access while maintaining four-point support.

Matching Die Set Design to Your Stamping Operation

So how do you decide which configuration fits your needs? Consider three critical factors: the type of operation you're running, your precision requirements, and how operators will interact with the die during production.

For blanking and piercing operations requiring frequent operator access, two-post back-post configurations often make sense. Operators can load material and clear parts without reaching around guide posts. However, if you're running a hydraulic press die set for heavy-tonnage blanking where rigidity matters more than accessibility, four-post designs prevent the deflection that causes burrs and uneven cuts.

Progressive dies almost always demand four-post press die sets. These complex die tools run multiple stations in sequence, and any misalignment compounds as the strip advances through each station. The additional rigidity of four-post designs keeps every station aligned to the master, maintaining part consistency from first hit to last.

For forming and drawing operations, consider how material behaves under pressure. Drawing operations create significant side loads that can stress two-post arrangements. Four-post configurations distribute these loads more evenly, reducing wear on guide bushings and extending die life.

Configuration Selection Decision Framework

When evaluating die tools for your specific application, use this comparison to guide your decision:

| Configuration | Rigidity Level | Accessibility | Typical Applications | Precision Level |

|---|---|---|---|---|

| Two-Post Back | Moderate | Excellent (front and sides open) | Simple blanking, piercing, manual feed operations | Standard to moderate |

| Two-Post Diagonal | Moderate | Good (two corners open) | Angular strip feeding, specialized forming | Standard to moderate |

| Four-Post Center | High | Moderate (perimeter access) | Progressive dies, precision blanking, high-speed operations | High precision |

| Four-Post Back | High | Good (front access retained) | Heavy-tonnage forming, drawing operations | High precision |

Beyond these standard configurations, specialty press dies exist for unique applications. Some manufacturers offer three-post designs for specific space constraints, while others provide adjustable post positions for maximum flexibility. When standard catalog options don't match your requirements, custom configurations become necessary.

Remember that configuration choice also affects die protection. Four-post designs better resist the twisting forces that occur when punches hit off-center or when material thickness varies. If you're stamping materials with inconsistent gauge, the additional support points reduce stress on individual guide posts and bushings.

With your configuration selected, the next critical decision involves material selection for die set components—a choice that determines weight, thermal behavior, wear resistance, and ultimately, how long your die set delivers accurate results under production conditions.

Material Selection and Precision Requirements

You've chosen your configuration—now comes the decision that determines how your die set performs over millions of cycles. The base materials used in your die shoes, guide posts, and bushings directly impact everything from thermal stability during high-speed runs to wear resistance under heavy tonnage. Yet most product catalogs skip this critical detail entirely.

Understanding why manufacturers choose specific materials for metal die components helps you evaluate quality differences that aren't visible at first glance. Let's examine how material selection shapes production outcomes.

Steel vs Cast Iron Die Shoes

The die shoe material debate often comes down to steel versus cast iron—and the right choice depends entirely on your application requirements.

Steel die shoes offer superior strength-to-weight ratios and excellent machinability. According to the ASM Handbook on Sheet Forming, tool steels remain the preferred choice for stamping dies requiring high wear resistance and the ability to withstand tremendous forming forces. Steel dies can be heat-treated to achieve specific hardness levels, making them adaptable to various production demands.

Cast iron die shoes excel in applications where vibration damping matters. The graphite structure within cast iron absorbs shock better than steel, reducing noise and extending component life in high-cycle environments. However, cast iron is more brittle and heavier than steel alternatives.

Here's where material choice gets interesting for metal forming dies: aluminum die shoes have gained significant traction in specific applications. They weigh roughly one-third of equivalent steel shoes, reducing press wear and making die handling safer for operators. The tradeoff? Aluminum wears faster and requires more frequent replacement in high-volume production.

How Material Selection Impacts Production Quality

Every stamping dies component interacts with your material, press, and environment. Material selection affects these critical performance factors:

- Tool Steel (D2, A2, S7): Highest wear resistance and hardness after heat treatment. Ideal for precision dies running millions of cycles. Best suited for blanking hardened materials and emboss stamping operations requiring sharp detail retention.

- Cast Iron (Meehanite, Ductile Iron): Excellent vibration damping and dimensional stability. Cost-effective for larger die shoes. Works well in heavy forming applications where shock absorption matters more than extreme precision.

- Aluminum Alloys (6061-T6, 7075): Lightweight with good thermal conductivity. Reduces handling injuries and press wear. Best for prototype runs, low-volume production, and applications where die weight is a limiting factor.

- Steel Alloys (4140, 4340): Balanced combination of toughness and machinability. Can be heat-treated to various hardness levels. Suitable for general-purpose steel dies serving moderate production volumes.

Thermal stability deserves special attention. During extended production runs, friction generates heat that causes materials to expand at different rates. Steel dies maintain tighter tolerances under thermal stress compared to aluminum, which expands roughly twice as much per degree of temperature increase. For high-speed operations where precision dies must hold position through thousands of strokes per hour, thermal behavior often determines material choice.

Tolerance Requirements for Precision Stamping

Now imagine you've selected the perfect material—but how precisely must your die shoe surfaces be machined? The answer lies in understanding how tolerances cascade through your finished parts.

Die set accuracy is measured in thousandths of an inch, and standard dimensional tolerances for precision stamping can be held to ±0.002" in demanding applications. However, achieving these results requires die set components manufactured to even tighter specifications. Guide post and bushing fits typically require tolerances within 0.0001" to ensure repeatable alignment.

Surface finish requirements vary by component function:

- Die shoe mounting surfaces: Ground flat to within 0.0005" across the full surface to ensure proper mating with press beds and rams.

- Guide post running surfaces: Polished to minimize friction and prevent galling against bushings.

- Bushing bores: Honed to precise diameters with surface finishes below 16 microinches for smooth operation.

Heat treatment considerations tie directly back to production volume expectations. For runs exceeding one million cycles, precision dies should use hardened tool steel components with Rockwell hardness ratings between 58-62 HRC. Lower-volume applications can use softer materials that cost less but wear faster.

The relationship between material hardness and expected production life isn't linear. Harder materials resist wear but become more brittle and expensive to machine. Finding the optimal balance requires understanding your specific part requirements, press tonnage, and target production quantities—factors that also determine how you'll match die set specifications to your stamping operations.

Application-Based Die Set Specification Matching

You know your configuration. You've selected your materials. Now comes the question that actually determines success or failure: does your die set match what you're trying to accomplish? Whether you're running a blanking die for high-volume production or a forming die for complex geometries, the specifications must align with your specific operation—not just fit your press.

Let's walk through how to match die set specifications to the four most common stamping operations, then tackle the calculations that ensure everything works together.

Die Sets for Blanking and Piercing Operations

Blanking and piercing represent the most straightforward stamping operations—cutting shapes from sheet metal using shear force. But "straightforward" doesn't mean "simple to specify." These operations demand maximum rigidity from your stamping die because cutting forces concentrate at the moment of material fracture.

When selecting a sheet metal punch and die set for blanking operations, prioritize these specifications:

- Shoe thickness: Must resist deflection under full tonnage. As a baseline, die shoes should be thick enough to limit deflection to 0.001" per foot of unsupported span under maximum load.

- Post diameter: Larger posts resist bending forces better. For heavy blanking operations, posts should be sized to handle side thrust without measurable deflection.

- Four-post configurations: Preferred for metal stamping dies running tight tolerances. The additional support points distribute cutting forces evenly across the die set.

Piercing operations share similar requirements but add alignment precision as a critical factor. When a punch press die creates holes, any misalignment between punch and button creates burrs, accelerates wear, and compromises hole quality. Guide post and bushing fits become even more critical—look for die sets with ball-bearing guide systems that maintain alignment within 0.0002" throughout the stroke.

According to industry design guidelines, cutting force calculations determine tonnage requirements using the formula: Cutting Force (lbs) = Perimeter Length × Material Thickness × Shear Strength. This calculation directly informs die set selection—your shoes and posts must handle this force without deflection.

Forming and Drawing Application Requirements

Forming dies and drawing operations introduce challenges that blanking doesn't: controlled material flow, springback compensation, and side loads that stress die alignment differently than straight cutting forces.

For bending and forming applications, your sheet metal punch and die must accommodate:

- Controlled deflection: Unlike blanking where rigidity is paramount, some forming operations actually benefit from slight die deflection that allows material to flow. However, this deflection must be predictable and consistent.

- Side load resistance: Bending operations create lateral forces as material pivots around the bend radius. Die sets need heel blocks and wear plates sized to absorb these loads without shifting alignment.

- Springback compensation: Metals partially return toward their original shape after bending. Your die set must position punches precisely enough to achieve over-bend angles that relax into correct final dimensions.

Drawing operations—where flat blanks are formed into cups, shells, or complex shapes—require specialized die set considerations. The blank holder pressure, draw depth, and material flow characteristics all influence specifications. Four-post configurations with larger post diameters help maintain alignment through the extended strokes typical of deep drawing.

For forming dies running multiple operations in sequence, the center of pressure calculation becomes essential. According to progressive stamping guidelines, you must determine where all applied forces converge and ensure this point aligns with your press centerline. Any offset causes uneven wear and alignment drift.

Calculating Die Set Specifications for Your Press

Now for the practical framework that ties everything together. Matching die set specifications to press capabilities requires understanding three interconnected dimensions: shut height, stroke length, and overall die dimensions.

Shut height—also called die height—is the vertical distance from the press slide at bottom dead center to the press bed. As technical references explain, this dimension determines the maximum total die height your press can accommodate. Your combined upper and lower die shoe thicknesses, plus all mounted tooling, must fit within this space.

Here's the critical calculation framework:

- Determine total required die height: Add upper shoe thickness + lower shoe thickness + punch length + die button height + any additional tooling height.

- Compare to press shut height: Your total die height must be less than press shut height. Most designers leave 5-10mm margin to prevent collisions.

- Account for adjustment range: Presses typically offer 40-80mm of slide adjustment. Your die should fit within the adjustment range, not just at one extreme.

- Verify stroke clearance: The press stroke must exceed material thickness plus sufficient clearance for part ejection and strip advancement.

| Application Type | Recommended Shoe Thickness | Post Diameter Guidance | Configuration | Special Considerations |

|---|---|---|---|---|

| Light Blanking (<50 tons) | 1.5" - 2" | 1" - 1.25" | Two-post or Four-post | Standard rigidity sufficient |

| Heavy Blanking (>100 tons) | 2.5" - 4" | 1.5" - 2" | Four-post | Maximize rigidity, consider heel blocks |

| Precision Piercing | 2" - 3" | 1.25" - 1.5" | Four-post | Ball-bearing guides essential |

| Forming/Bending | 2" - 3" | 1.25" - 1.75" | Four-post back | Account for side loads |

| Deep Drawing | 3" - 4" | 1.5" - 2" | Four-post center | Extended stroke clearance required |

When calculating tonnage requirements for progressive dies, remember to sum all loads across every station: piercing forces, forming forces, spring stripper pressures, nitrogen pad forces, and scrap cutting. The total determines minimum press capacity, which in turn influences die set specifications. A die set rated for 50 tons won't survive in a 200-ton application—even if it physically fits the press.

The relationship between these specifications isn't just about fitting parts together. Proper matching extends die life, improves part consistency, and prevents the catastrophic failures that occur when punch press die sets operate beyond their design limits. With specifications properly matched to your application, the next consideration is how to maintain that precision throughout the die set's production life.

Maintenance Requirements and Lifespan Optimization

You've invested in quality tooling dies, matched specifications to your application, and achieved first-article approval. Now comes the factor that separates operations running millions of trouble-free cycles from those constantly chasing quality problems: maintenance. The complete die set lifecycle—from initial selection through eventual replacement—determines your true cost per part, yet most die manufacturing documentation barely mentions upkeep requirements.

Let's change that. Here's everything you need to keep your die assembly running at peak performance and recognize when components need attention before quality suffers.

Preventive Maintenance Schedules That Extend Die Life

Proper die machining and precision manufacturing mean nothing if components aren't maintained correctly during production. According to die set guiding optimization research, guide components that aren't properly maintained force technicians into a cycle of constant replacement and excessive downtime—something few operations can afford.

The foundation of any preventive program starts with understanding what each component needs:

- Clean all die surfaces thoroughly after each production run. Remove metal shavings, lubricants, and debris that collect on die shoes and in cavities. Skipping this step accelerates wear and creates cosmetic or dimensional flaws in stamped parts. Regular cleaning also makes early damage detection possible.

- Lubricate guide posts and bushings according to manufacturer specifications. For ball bearing guide components, avoid grease entirely. Because these assemblies operate with negative working clearances, grease tends to hold contaminants that work into the rolling press fit. Instead, use refined mineral oil (viscosity of 290/340 SSU at 100°F) containing extreme-pressure additives and rust inhibitors.

- Inspect all critical surfaces on a documented schedule. Evaluate cut edges, punches, dies blank surfaces, and guide pins for early signs of wear, cracking, or misalignment. Detailed scheduled inspections catch problems before they cause costly downtime.

- Verify alignment using precision measurement tools. Check that guide post and bushing fits remain within specification. Any measurable clearance increase indicates wear progression that will eventually affect part quality.

- Store dies properly between production runs. After maintenance, store pressing die assemblies in clean, dry, controlled environments. Proper storage prevents corrosion and protects precision surfaces from damage.

For operations using lube pins—guideposts with internal cross-drilled lubrication holes—connect these to automatic lubrication systems that deliver oil at specified intervals. This eliminates reliance on operator memory and ensures consistent lubrication regardless of production schedule demands.

Recognizing Wear Patterns Before Quality Suffers

Even with perfect maintenance, tooling dies eventually wear. The key is recognizing wear indicators before they manifest as defective parts. Here's what experienced technicians watch for:

Excessive clearance in guide systems appears gradually. When ball bearing cages no longer maintain proper preload against guideposts and bushings, alignment precision degrades. You might notice this first as slightly inconsistent hole positions or edge quality variations across a production run.

Visible galling on post surfaces signals serious problems. According to industry experts, tracking lines that indent working surfaces require immediate attention. If tracking appears only on one side of a guidepost or bushing, investigate the bored-hole location, bore straightness, and guidepost parallelism—these indicate alignment issues rather than normal wear.

Dimensional drift in stamped parts often provides the first measurable evidence of die wear. When parts that previously held tolerance begin trending toward specification limits, the die assembly is telling you something. Don't wait for out-of-spec parts to trigger investigation.

Unusual noise during operation deserves immediate attention. Changes in sound—particularly metallic scraping or intermittent contact noises—indicate component contact that shouldn't be occurring. This could signal cage creep, misalignment, or imminent component failure.

Blue discoloration on bearing cages indicates a specific problem: cage creep causing bearings to skid rather than roll during the preloaded condition. The blue color comes from excessive heat generated by this skidding action. If you observe this, the die requires immediate corrective action.

Troubleshooting Common Die Set Problems

When problems emerge, systematic troubleshooting saves time and prevents misdiagnosis. Here are the most common issues and their root causes:

| Problem | Likely Causes | Corrective Actions |

|---|---|---|

| Cage creep (bearing cage moves out of position) | Component sizing, die design factors, insufficient preload relief | Install positive stop/bumper; consider moving to preload-relieved or fully disengaged operating condition |

| Excessive tracking on one side | Bore location error, bore straightness issues, side loading from workpiece | Verify bore specifications; consider demountable bushings; evaluate workpiece loading patterns |

| Premature bushing wear | Interference fit too tight (exceeding 0.0005") | Use demountable-style bushings with wring fit instead of straight-sleeve |

| Damaged set screw dog points | Cage creep causing screw to hit guidepost slot end | Address underlying cage creep issue; install positive stops |

| Upward cage movement | Inadequate bushing venting causing air pressure buildup | Verify proper bushing venting at bottom; add positive stop on guidepost if needed |

For machining dies that run on servo presses, be aware that rapid acceleration and direction changes can cause cage creep even in partially relieved or fully disengaged configurations. Inertia may move bearing cages out of position faster than they can reset. Solutions include adjusting stroke speed or inducing controlled drag on the bearing cage.

When punch chipping or cracking occurs—a common issue affecting the entire die assembly—systematic analysis should examine coupling nut tightness, punch-to-die alignment, clearance settings based on material thickness, and stripper pressure uniformity. Collecting broken components and material samples for supplier analysis often reveals process improvements that prevent recurrence.

The bottom line? Proactive maintenance costs far less than reactive repairs. Industry experience confirms that routine die repair and maintenance programs reduce downtime, extend tooling lifespan, and maintain the precision dies quality that keeps stamped parts within specification. Without regular care, even the best die manufacturing produces components that gradually degrade—and by the time defects appear in finished parts, significant damage has already occurred.

With maintenance protocols established, the next consideration is ensuring your die set supplier can support these ongoing requirements—a factor that extends well beyond initial purchase price when evaluating total cost of ownership.

Sourcing Strategies and Supplier Evaluation

You've specified the perfect die set—configuration matched to your operation, materials selected for longevity, maintenance protocols ready to go. Now comes a decision that many buyers overlook until problems surface: where does your stamping tool and die actually come from? The supplier you choose affects far more than the number on your purchase order. It shapes lead times, communication quality, support availability, and ultimately, your total cost of ownership.

Let's examine what separates adequate suppliers from exceptional partners in tool and die manufacturing—and why the lowest quote rarely delivers the lowest cost.

Evaluating Die Set Suppliers Beyond Price

When sourcing metal stamping die sets, the initial price tempts many buyers to focus on per-unit cost alone. But total cost of ownership analysis reveals hidden expenses that often exceed any upfront savings from offshore suppliers.

Consider these factors that directly impact your bottom line:

- Die quality and longevity: Domestically manufactured dies using premium tool steel typically guarantee 1,000,000+ strikes before maintenance is required. Lower-quality offshore dies wear faster, introducing defects sooner and causing production downtime that erases initial savings.

- Communication efficiency: Working with a supplier 13 time zones away means your morning questions get answered the next day—at best. Language barriers add another layer of potential misunderstanding. When production issues arise, these delays compound rapidly.

- Shipping logistics: Ocean transit times, customs clearance, port congestion, and tariff fluctuations all add cost and unpredictability. Shipping container prices quadrupled in 2020, and lead time variability continues affecting manufacturers today.

- Intellectual property protection: Any drawings, CAD models, or proprietary processes shared with offshore vendors risk being copied. Your custom tool fabrication investment could end up competing against you in the marketplace.

Punch and die manufacturers offering domestic production simplify these challenges considerably. Same-timezone communication means faster problem resolution. Shorter shipping distances reduce lead time variability. And stronger IP protection laws keep your proprietary designs secure.

Quality Certifications That Matter for Precision Applications

How do you verify that a stamping die manufacturer can actually deliver the quality they promise? Certifications provide objective evidence—but not all certifications carry equal weight.

For automotive and precision applications, IATF 16949 certification represents the gold standard. Established by the International Automotive Task Force, this global quality management standard ensures consistent quality throughout the automotive supply chain. Suppliers maintaining this certification have demonstrated their ability to meet the strictest industry requirements.

Beyond IATF 16949, look for these quality indicators when evaluating die making partners:

- ISO 9001 certification: Confirms the supplier operates a documented quality management system with regular audits and continuous improvement processes.

- First-pass approval rates: Suppliers tracking this metric demonstrate commitment to getting parts right the first time. Rates above 90% indicate mature processes and defect prevention systems.

- In-house heat treating capabilities: Suppliers controlling heat treatment internally maintain tighter quality control and faster turnaround compared to those outsourcing this critical process.

- State-of-the-art equipment: Wire EDM machines, CNC lathes, and precision surface grinders enable the tight tolerances that precision stamping demands. Ask about equipment age and calibration schedules.

According to ASQ supplier quality guidelines, effective supplier evaluation goes beyond checking certifications. It includes assessing technical capability, production capacity, financial stability, and track record with similar projects. The goal? Finding partners whose quality systems prevent defects rather than simply detecting them after the fact.

Engineering Support as a Supplier Differentiator

Here's where advanced stamping die manufacturers truly separate themselves from commodity suppliers: engineering capabilities that add value before production begins.

Imagine partnering with a supplier offering CAE (Computer-Aided Engineering) simulation capabilities. Before cutting any steel, they can model material flow, predict springback, and identify potential forming problems. This defect prevention approach catches issues during design—when corrections cost pennies—rather than during production, when they cost thousands.

Rapid prototyping services provide another significant advantage. Suppliers capable of delivering prototype tooling in days rather than weeks enable faster design iteration and shorter time-to-market. When you need to validate a new part design quickly, this capability becomes invaluable.

What should you look for when evaluating engineering support?

- Design consultation: Can they review your part designs and suggest improvements for manufacturability? Experienced die making engineers often identify cost-saving opportunities that part designers miss.

- Simulation capabilities: Do they use CAE software to validate designs before cutting tooling? This investment in defect prevention technologies directly reduces your total cost of ownership.

- Prototyping speed: How quickly can they deliver sample parts? Some advanced suppliers offer rapid prototyping in as little as 5 days.

- OEM-standard quality: For automotive applications, can they demonstrate experience meeting major OEM quality requirements?

The relationship between engineering support and total cost extends beyond initial tooling. Suppliers like Shaoyi, with IATF 16949 certification and advanced CAE simulation, achieve 93% first-pass approval rates—meaning fewer iterations, less scrap, and faster production ramp-up. Their comprehensive mold design and fabrication capabilities, combined with rapid prototyping and high-volume manufacturing expertise, exemplify how engineering-focused suppliers deliver value beyond competitive pricing.

When you've evaluated suppliers across all these dimensions—quality certifications, engineering capabilities, communication efficiency, and total cost factors—you're ready to make an informed decision that balances immediate needs with long-term partnership value.

Making the Right Die Set Investment Decision

You've absorbed a lot of information—configurations, materials, applications, maintenance protocols, and supplier evaluation criteria. Now it's time to pull everything together into a decision-making framework you can actually use. How do you specify metal stamping die sets that balance your application requirements, production volumes, precision needs, and budget constraints without over-engineering or under-investing?

Let's build a systematic approach that transforms all this knowledge into actionable purchasing decisions.

Building Your Die Set Specification Checklist

Before contacting any supplier or browsing any catalog, answer these fundamental questions. Your responses form the foundation of every specification decision that follows:

- What operation are you performing? Blanking, piercing, forming, drawing, or progressive multi-station? Each operation has distinct rigidity and alignment requirements that influence configuration choice.

- What material are you stamping? Material type, thickness, and hardness directly affect tonnage requirements, which determine die shoe thickness and post diameter specifications.

- What's your target production volume? A set of die components designed for 50,000 parts differs significantly from one intended for 5 million cycles. Volume expectations drive material selection and quality tier decisions.

- What precision level do your parts require? Tolerances measured in thousandths versus hundredths of an inch require different guide system specifications and post configurations.

- What press will run this die set? Shut height, stroke length, tonnage capacity, and bed dimensions all constrain your die set options.

With these answers documented, you've established the parameters that guide every subsequent specification decision. Skip this step, and you risk purchasing die sets for press applications that don't match your actual requirements.

Standard vs Custom Die Set Decision Criteria

Here's a question many buyers struggle with: when does a standard die from a catalog make sense, and when should you invest in custom-engineered solutions?

Standard catalog die sets work well when your requirements align with common configurations and sizes. They offer faster delivery, lower upfront cost, and proven designs. For prototype runs, lower-volume production, or straightforward blanking and piercing operations, standard options often provide excellent value.

However, standard die sets impose limitations. Fixed post positions may not optimize accessibility for your specific operation. Standard shoe thicknesses might under-deliver or over-deliver for your tonnage requirements. And catalog dimensions may not maximize your press capacity efficiently.

Custom die solutions become the smarter investment when:

- Your press die requirements don't align with standard catalog sizes

- Production volumes justify higher upfront investment for optimized performance

- Part precision demands tighter alignment than standard configurations provide

- Your operation requires specialized features—non-standard post positions, integrated sensors, or unique die plate configurations

- Total cost of ownership analysis favors premium quality over initial savings

The decision often comes down to production volume thresholds. As a general guideline, when annual production exceeds 100,000 parts or total lifetime volume exceeds 1 million cycles, custom-engineered die sets typically deliver positive ROI through reduced maintenance, longer service life, and improved part consistency.

Die Set Specification Decision Matrix

Use this framework to match your application characteristics to recommended specifications:

| Application Characteristic | Low Volume (<50,000/year) | Medium Volume (50,000-500,000/year) | High Volume (>500,000/year) |

|---|---|---|---|

| Configuration | Two-post standard die acceptable | Four-post recommended for precision | Four-post with ball-bearing guides required |

| Die Shoe Material | Aluminum or mild steel | Pre-hardened steel alloy | Hardened tool steel (D2, A2) |

| Guide System | Friction pins acceptable | Ball-bearing preferred | Ball-bearing with automatic lubrication |

| Tolerance Class | Standard commercial | Precision grade | Ultra-precision with documented certification |

| Supplier Tier | Standard catalog suppliers | Engineering-capable suppliers | IATF 16949 certified with CAE simulation |

| Investment Priority | Minimize upfront cost | Balance cost with longevity | Maximize total cost of ownership value |

This matrix provides starting-point guidance—your specific situation may warrant adjustments. A low-volume application producing safety-critical components might justify high-volume specifications. Conversely, high-volume production of non-critical parts might accept medium-volume quality tiers.

When Premium Quality Delivers ROI

Investing more upfront in metal stamping die sets pays dividends when the math works in your favor. Consider these scenarios where premium die set quality delivers measurable returns:

Extended maintenance intervals: A hydraulic press die built with hardened tool steel and precision ball-bearing guides might cost 40% more than a standard alternative. But if it runs 500,000 additional cycles before requiring maintenance, and each maintenance event costs $2,000 in labor and downtime, the premium investment pays for itself quickly.

Reduced scrap rates: Better alignment precision means fewer out-of-spec parts. If upgrading from standard to precision-grade die sets reduces scrap by just 0.5% on a million-part run, the material savings alone often exceed the cost difference.

Faster changeover: Die sets designed with precision alignment systems reduce setup time because operators spend less time adjusting and tweaking. When changeover occurs weekly and each minute of downtime costs $50, those saved minutes accumulate rapidly.

Consistent part quality: Premium die sets maintain dimensional accuracy longer into production runs. This consistency reduces quality escapes, customer complaints, and the hidden costs of managing non-conforming material.

Partnering with Engineering-Focused Suppliers

The final piece of your decision framework involves choosing suppliers who offer more than commodity products. When you partner with engineering-focused manufacturers, you gain access to capabilities that prevent problems before they occur.

Look for suppliers offering:

- Comprehensive mold design and fabrication capabilities: Single-source suppliers who handle design through production eliminate communication gaps between multiple vendors.

- Rapid prototyping services: The ability to validate designs quickly—some advanced suppliers deliver prototypes in as little as 5 days—accelerates your time-to-market and reduces iteration costs.

- CAE simulation: Defect prevention through computer-aided engineering catches problems during design, when corrections cost pennies rather than thousands.

- High-volume manufacturing expertise: Suppliers experienced in scaling from prototype to production quantities understand the quality systems needed for consistent high-volume output.

- OEM-standard quality: IATF 16949 certification and demonstrated first-pass approval rates above 90% indicate mature quality systems.

Shaoyi's precision stamping die solutions exemplify this engineering-driven approach. With IATF 16949 certification, advanced CAE simulation for defect-free results, rapid prototyping capabilities, and a 93% first-pass approval rate, they deliver cost-effective tooling tailored to OEM standards. For operations requiring die sets for press applications where quality and engineering support matter as much as price, suppliers with these capabilities provide measurable value beyond competitive quotes.

The right die set investment decision balances immediate budget constraints against long-term operational costs. By systematically evaluating your requirements—using the frameworks, specifications, and supplier criteria covered throughout this guide—you'll select metal stamping die sets that deliver reliable performance, consistent part quality, and optimal total cost of ownership for your specific application.

Frequently Asked Questions About Metal Stamping Die Sets

1. How much does a metal stamping die cost?

Metal stamping die costs range from $500 to $15,000+ depending on complexity, size, material requirements, and production volume expectations. Simple blanking dies for low-volume runs fall at the lower end, while progressive dies with multiple stations for high-volume automotive applications command premium pricing. Beyond initial cost, consider total cost of ownership including maintenance intervals, expected lifespan, and part consistency—premium die sets with hardened tool steel often deliver better ROI through extended service life and reduced scrap rates.

2. What is the difference between die cut and stamping?

Die cutting and stamping are distinct metal forming processes with different material states and applications. Die casting uses molten metal heated past its melting point, poured into molds to create complex 3D shapes from ingots or billets. Metal stamping is almost always a cold working process that uses sheet metal blanks or coils, applying mechanical force through dies to cut, bend, or form flat material into desired shapes. Stamping is faster for high-volume flat parts, while die casting excels at complex three-dimensional components.

3. What are the four types of metal stamping?

The four primary metal stamping types are progressive die stamping, transfer die stamping, deep draw stamping, and micro/miniature stamping. Progressive die stamping moves strip material through multiple stations in a single die for efficient high-volume production. Transfer die stamping uses mechanical transfer systems to move individual blanks between separate die stations for larger or more complex parts. Deep draw stamping forms flat blanks into cup-shaped or shell components. Micro stamping produces extremely small precision parts for electronics and medical devices.

4. What is the best material for die shoes in metal stamping?

The optimal die shoe material depends on your specific application. Tool steel (D2, A2, S7) offers highest wear resistance and hardness after heat treatment, ideal for precision dies running millions of cycles. Cast iron provides excellent vibration damping and dimensional stability at lower cost for heavy forming applications. Aluminum alloys reduce weight by two-thirds compared to steel, improving operator safety and reducing press wear—best for prototypes and low-volume production. Steel alloys like 4140 offer balanced toughness and machinability for general-purpose applications.

5. When should I choose a four-post die set over a two-post configuration?

Choose four-post die sets when precision, rigidity, and alignment stability are critical—particularly for progressive dies, high-speed operations, heavy blanking over 100 tons, and deep drawing applications. Four-post configurations support the upper shoe at four points, distributing forces evenly and preventing the deflection that causes burrs and dimensional drift. Two-post back-post configurations work well for simpler operations requiring operator access for feeding material or removing parts, such as manual-feed blanking and piercing with moderate precision requirements.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —