Tajemnice układu linii matryc tandemowych: od planu zabudowy po bezawaryjną produkcję

Zrozumienie podstaw układu linii matryc tandemowych

Gdy zostaniesz powierzony produkcją dużych paneli karoserii samochodowej lub złożonych elementów konstrukcyjnych, sposób rozmieszczenia pras na hali produkcyjnej staje się kluczowym aspektem strategicznym. Właśnie w tym momencie pojawia się układ linii matryc tandemowych – a zrozumienie jego podstaw decyduje o powodzeniu realizacji, odróżniając je od kosztownych błędów.

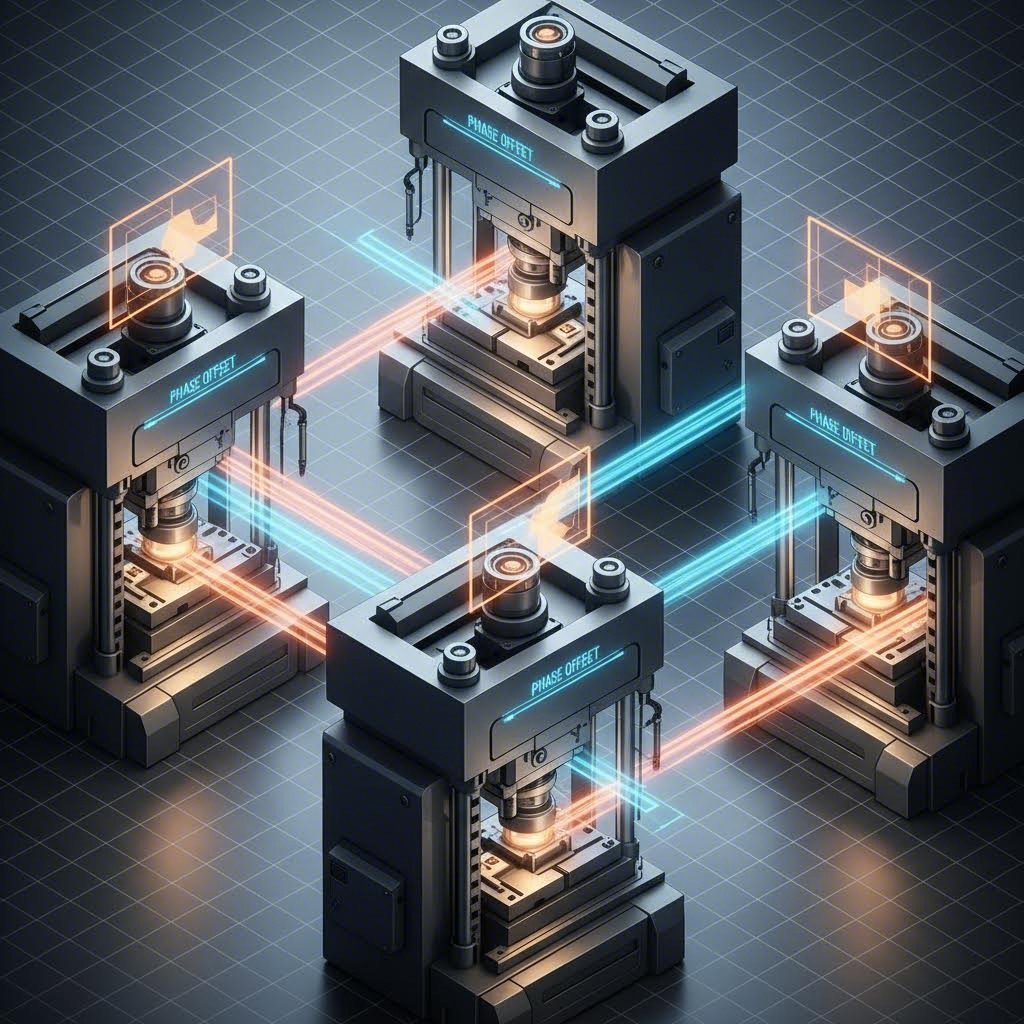

Układ linii matryc tandemowych odnosi się do strategicznego rozmieszczenia wielu jednooperacyjnych pras ustawionych kolejno, gdzie detale są przekazywane pomiędzy stanowiskami w celu kolejnych operacji kształtowania. Każda prasa w linii wykonuje wydzieloną operację, a prasy są zsynchronizowane – zazwyczaj ze stopniem rozstrojenia 60 stopni w cyklu suwu – aby umożliwić płynny przepływ części ze stanowiska na stanowisko.

Brzmi skomplikowanie? W rzeczywistości jest to eleganckie i proste pojęcie, gdy się je rozłoży na czynniki pierwsze. Wyobraź sobie sztafetę, w której każdy biegacz (prasa) pokonuje jeden konkretny odcinek trasy, przekazując pałeczkę (Twój przedmiot) następnemu zawodnikowi w idealnym momencie.

Co odróżnia linie matryc tandemowych od innych konfiguracji tłoczenia

Zrozumienie tego, co czyni tę konfigurację unikalną, wymaga porównania jej z dwiema głównymi alternatywami: matrycami progresywnymi i matrycami transferowymi.

Matryce progresywne utrzymują części połączone z ciągłą taśmą materiału, która przesuwa się przez jedną prasę, gdzie przy każdym uderzeniu wykonywane są kolejne operacje. Świetnie nadają się do szybkiej produkcji mniejszych elementów – czasem osiągając prędkość nawet 1 500 sztuk na minutę – jednak ich możliwości ograniczają wielkość i złożoność detali.

Matryce transferowe konsolidują wiele operacji w jednej ramie prasy, wykorzystując wewnętrzne szyny do przemieszczania części między stacjami w stałej odległości podawania. Są kompaktowe, ale wymagają, by wszystkie komponenty były już umieszczone w matrycy przed rozpoczęciem cyklu.

Linia pras tandemowych stosuje zasadniczo inne podejście. Każda prasa może wykonać cykl, gdy poszczególny element zostanie umieszczony w jej stemplu, a wydajność linii zależy od zsynchronizowanego działania, a nie od fizycznego sprzęgania. Ta niezależność daje unikalne zalety:

- Poszczególne stemple można regulować, naprawiać lub wymieniać bez konieczności wycofywania całego zintegrowanego systemu

- Różne nośności pras można dostosować do konkretnych wymagań operacji

- Układ może pomieścić części zbyt duże lub złożone dla rozwiązań opartych na pojedynczej prasie

- Możliwe jest etapowe inwestowanie kapitałowe – można rozbudowywać system stopniowo

Wyjaśnienie układu sekwencyjnego pras

W dobrze zaprojektowanej linii pras zauważysz, że prasy nie są po prostu ustawione obok siebie przypadkowo. Odległość między środkami pras powinna być jak najkrótsza, ale nadal zapewniać dostęp niezbędny do konserwacji i napraw – stanowi to podstawę całego układu oraz rozmieszczenia wszystkich kolejnych komponentów.

Zgodnie z praktykami branżowymi, nowoczesne linie tandemowe wykorzystują zsynchronizowane prasy z zmiennym przesunięciem fazy – zazwyczaj o 60 stopni względem siebie. Oznacza to, że prasa 1 osiąga dolny martwy punkt jako pierwsza, a następnie prasa 2 robi to 60 stopni później w cyklu, i tak dalej wzdłuż całej linii.

Dlaczego to ma znaczenie dla projektowania matryc i planowania układu? Relacja fazowa bezpośrednio określa okna transferowe – krótkie chwile, w których części mogą bezpiecznie przemieszczać się między stacjami. Jeśli to źle dobrać, grożą kolizje, błędy synchronizacji lub znacznie zmniejszona wydajność.

Producenci urządzeń często pomijają te zasady działania, przechodząc od razu do specyfikacji i funkcji. Jednak zanim ocenisz jakiekolwiek konkretne wyposażenie lub przydzialisz miejsce na hali, potrzebujesz tej podstawowej wiedzy. Pozostałe sekcje tego przewodnika będą oparte na tych podstawach, prowadząc Cię przez wymagania synchronizacji, planowanie wymiarów, mechanizmy transferowe oraz kompletny proces projektowy – od koncepcji po gotowy układ produkcyjny.

Kiedy warto wybrać układ linii matryc tandemowych zamiast alternatyw

Teraz, gdy znasz podstawy, pojawia się pytanie, przed którym staje każdy inżynier produkcji: kiedy układ linii matryc tandemowych rzeczywiście ma sens dla Twojej działalności? Odpowiedź nie zawsze jest prosta – a wybór błędnej opcji może skutkować latami niskiej efektywności lub niepotrzebnymi wydatkami kapitałowymi.

Przejdźmy od razu do sedna i przedstawmy praktyczną ramę decyzyjną opartą na czterech kluczowych czynnikach: cechach części, wielkości produkcji, potrzebach związanych z transportem materiału oraz ograniczeniach inwestycyjnych.

Cechy części sprzyjające wyborowi linii tandemowej

Wyobraź sobie, że tłoczysz panel drzwiowy samochodu lub element konstrukcyjny podwozia. Takie części mają wspólne cechy, które skłaniają do wyboru konfiguracji tandemowej:

- Duże wymiary fizyczne: Części przekraczające 500 mm w dowolnym kierunku często nie mieszczą się w stacjach matryc progresywnych ani w polu pras transferowych

- Wymagania dotyczące głębokiego tłoczenia: Elementy wymagające wielu etapów kształtowania ze znacznymi zmianami głębokości korzystają z dedykowanych pras zoptymalizowanych pod kątem każdej operacji

- Złożone geometrie: Gdy kształty wymagają różnych kierunków tłoczenia lub nietypowych sekwencji kształtowania, niezależne stacje prasowe zapewniają niezbędną elastyczność

- Materiały o dużej grubości: Grubsze materiały – szczególnie zaawansowana stal o wysokiej wytrzymałości (AHSS) stosowana w konstrukcjach nowoczesnych pojazdów – wymagają dedykowanej siły tłoku na każdym etapie kształtowania

Według analiza branży , linie tłoczące tandemowe są przede wszystkim przeznaczone do „dużych części i pokryw” oraz „złożonych procesów i części o wysokich wymaganiach jakościowych”. Nie jest to przypadkowe – niezależna natura każdej stacji prasy pozwala na precyzyjną kontrolę parametrów kształtowania, której nie da się osiągnąć przy skoncentrowanych operacjach.

Próg objętości produkcji dla konfiguracji tandemowej

Właśnie tutaj wielu inżynierów popełnia błędy. Można założyć, że wyższa objętość zawsze sprzyja szybszym rozwiązaniom matryc progresywnych – ale to nadmierne uproszczenie.

Linie pras tandemowych działają zazwyczaj z prędkością 10-15 uderzeń na minutę (SPM), w porównaniu do 30-60+ SPM dla matryc progresywnych oraz 20-30 SPM dla matryc transferowych. Czy oznacza to, że linie tandemowe nadają się wyłącznie do zadań o niskiej objętości? Niekoniecznie.

Weź pod uwagę następujące punkty decyzyjne związane z objętością:

- Części o niskim do umiarkowanym popycie: Gdy miesięczne objętości nie uzasadniają inwestycji w matryce progresywne, konfiguracje tandemowe oferują lepszy zwrot z inwestycji

- Wysokie wymagania jakościowe: Części, w których wykańczanie powierzchni i dokładność wymiarowa są ważniejsze niż surowa wydajność — np. powierzchnie klasy A w przemyśle motoryzacyjnym

- Produkcja wielomodelowa: Zakłady produkujące różne warianty części czerpią korzyści z łatwiejszej wymiany matryc, jaką oferują niezależne prasy

- Stopniowy wzrost mocy produkcyjnych: Gdy konieczny jest stopniowy rozwój produkcji, dodawanie pras do linii tandemowej jest znacznie prostsze niż przebudowa zintegrowanej matrycy progresywnej

Rzeczywisty wybór polega na znalezieniu równowagi między kosztem pojedynczej sztuki a elastycznością. Matryce progresywne zapewniają najniższy koszt jednostkowy przy dużych serii, ale linie tandemowe oferują znacznie większą adaptowalność, gdy linia tłocznia musi dostosować się do zmian projektowych lub operacji krytycznych dla jakości.

Porównanie projektowania matryc tłoczarskich: dokonywanie właściwego wyboru

Aby ułatwić wizualizację kompromisów, oto szczegółowe porównanie trzech głównych konfiguracji tłoczenia:

| Kryteria | Postępowa forma | Wyciskanie przenośne | Linia tandemowa |

|---|---|---|---|

| Możliwość rozmiaru detalu | Tylko części małe i średnie | Części średnie | Duże części i panele pokrywowe |

| Prędkość produkcji (SPM) | 30-60+ | 20-30 | 10-15 |

| Elastyczność narzędzi | Niska – zintegrowany projekt matrycy | Umiarkowana – ograniczenia wspólnego prasy | Wysoka – niezależne regulacje stanowisk |

| Czas zmiany | Najdłuższy – cała matryca musi zostać wymieniona | Umiarkowana – wiele matryc na jednej prasie | Najkrótsze możliwe indywidualne zmiany biegów |

| Wymagania dotyczące powierzchni podłogowej | Kompaktny - jednoosobowy odcisk prasy | Średnia - pojedyncza duża praska | Największa - wielokrotna linia prasowa |

| Wykorzystanie materiału | Ograniczenia w zakresie karmienia nisko-przewodnikowego | Wyżywienie z wysokiej ilości płyt | Opt. wolne od umiarkowanego do wysokiej elastyczności |

| Konserwacja matryc | Trudne - złożone zintegrowane narzędzia | Niewygodne - ograniczenia dotyczące współdzielenia biegów | Łatwy - niezależny dostęp do stacji |

| Początkowy koszt narzędzi | Umiarkowany | Wysoki | Niski poziom inwestycji (wyższa łączna inwestycja) |

| Najlepsze zastosowania | Małe części konstrukcyjne o dużej objętości | Części wiązki, wzmocnienia, regularne kształty | Pozostałe części, z wyłączeniem części do maszyny |

Zauważyłeś ten model? Linie tandemne poświęcają prędkość surową dla elastyczności i możliwości rozmiaru części. Jeśli w przypadku Twojej działalności wymagana jest możliwość produkcji dużych, złożonych komponentów przy jednoczesnym utrzymaniu łatwej konserwacji i niezależnej kontroli procesu, inwestycja w powierzchnię podłogową jest opłacalna.

Często pomijana zaleta: wymiana linii. Jak wskazano w badania produkcyjne w przypadku linii tandemnych istnieje "wysoka wymiana linii", co oznacza, że matryce mogą być wykorzystywane na różnych liniach produkcyjnych - co stanowi znaczącą zaletę dla zakładów z wieloma liniami prasowymi.

Mając w ręku ramy decyzyjne, jesteś gotowy do rozwiązania technicznych wymagań, które sprawiają, że linie tandemne działają. Następne ważne rozważenie? Jak zsynchronizować wiele prasy w skoordynowany, wydajny system produkcji.

Wymagania dotyczące synchronizacji i czasowania

Miejsce, w którym układ linii tłoczników staje się technicznie wymagający – i gdzie wiele wdrożeń napotyka trudności. Możesz mieć idealnie zaprojektowane tłoczniki i optymalnie rozmieszczone prasy, ale bez dokładnej synchronizacji cała linia staje się wąskim gardłem zamiast mnożnikiem wydajności.

Wyobraź to sobie w ten sposób: każda prasa w Twojej linii działa niezależnie, ale musi być idealnie zsynchronizowana z każdą inną prasą i mechanizmem transferowym. To jak kierowanie orkiestrą, w której każdy muzyk gra w nieco innym tempie – magia pojawia się, gdy ich indywidualne rytmy łączą się w płynną, harmonijną grę.

Koordynacja suwów pras na wielu stanowiskach

Podstawą synchronizacji linii tandemowej jest zrozumienie zależności fazowych pras. Projektując sekwencje tłoczników w całej linii, napotkasz kluczowe pojęcie: pracę w trybie różnicowym (differential-phase operation).

Według Technologie synchronizacji linii AIDA , linie tandemowe skracają czasy cyklu poprzez "synchronizację ruchów pras i transferów oraz umożliwienie pracy pras w linii z różnym przesunięciem fazowym". Co to oznacza w praktyce?

Każda prasa osiąga swój dolny martwy punkt (BDC) – punkt maksymalnego siłowania – z zaplanowanym przesunięciem względem sąsiednich pras. To przesunięcie fazowe tworzy okna transferowe niezbędne do przemieszczania elementów między stanowiskami. Gdyby go nie było, wszystkie prasy osiągałyby BDC jednocześnie, co pozostawiłoby zero czasu na transfer części i spowodowałoby niebezpieczne warunki kolizyjne.

Zależność fazowa pełni również kluczową rolę w przypadku wycięć obejściowych w matrycach tłoczarskich do blach. Te wycięcia – niewielkie nacięcia ułatwiające pracę powierzchni roboczych matrycy – pozwalają mechanizmowi transferowemu bezpiecznie chwycić i puścić elementy w trakcie krótkich okien czasowych. Zrozumienie funkcji wycięć obejściowych w matrycach tłoczarskich jest niezbędne przy koordynowaniu chodu prasy z ruchami transferowymi.

Nowoczesna technologia prasy serwo rewolucjonizowała tę koordynację. Jak wspomniano w zaawansowanych realizacjach linii tandemowych, prasy serwo umożliwiają „precyzyjne sterowanie położeniem suwaka każdej prasy z wysoką prędkością na całym przebiegu tłoczyska”. Oznacza to, że inżynierowie projektujący operacje matryc mogą optymalizować każdy parametr niezależnie, a nie przyjmować ustalonych ograniczeń mechanicznych.

Okna czasowe dla bezpiecznego przekazywania elementu

Wyobraź sobie mechanizm transferowy jako rękę sięgającą do wnętrza matrycy, by chwycić detal. Ta ręka potrzebuje czasu, aby wejść, zabezpieczyć detal, wycofać się, przemieścić do następnego stanowiska, ustawić detal, zwolnić go i opuścić strefę – wszystko to podczas ruchu suwaków prasy.

Twoje okno czasowe to czas, w którym transfer może bezpiecznie nastąpić. Zbyt wąskie – i ryzykujesz kolizję. Zbyt szerokie – tracisz na szybkości produkcji.

W przypadku linii tandemowych produkujących blachy karoseryjne, wiodący producenci osiągnęli prędkość 18 SPM poprzez optymalizację «maksymalnych właściwości formowania prasy, maksymalnej elastyczności wyposażenia transportowego oraz maksymalnej prędkości transferu». Kompaktowe wysokoprędkościowe linie tandemowe z serwosterowaniem, wykorzystujące przewidywalne unikanie interferencji, mogą osiągnąć 30 SPM – co jest imponujące dla konfiguracji tandemowej.

Podczas projektowania układu, należy zsynchronizować następujące kluczowe parametry czasowe:

- Przesunięcie fazy prasy: Zależność kątowa (w stopniach obrotu wału korbowego) między kolejnymi uderzeniami prasy – zazwyczaj 60 stopni dla zrównoważonej pracy

- Okno wejścia transferu: Zakres położenia kątowego, w którym mechanizmy transferowe mogą bezpiecznie wejść do przestrzeni matrycy

- Czas ustalenia przedmiotu: Minimalny okres niezbędny, aby chwytaki lub ssawki zapewniły niezawodne trzymanie przedmiotu

- Czas przejazdu transferu: Czas potrzebny na przesunięcie przedmiotów pomiędzy osiami pras przy określonym rozstawie

- Moment zwolnienia elementu: Dokładny moment, w którym mechanizmy transferowe muszą zwolnić elementy do kolejnej operacji kształtowania

- Luźne zamknięcie matrycy: Minimalna odległość między opadającym suwnicą a mechanizmem transferowym podczas przekazywania

- Tolerancja pozycjonowania blanka: Dopuszczalne odchylenie w rozmieszczeniu elementu względem punktów odniesienia matrycy

- Okna odzyskiwania błędów: Rezerwy czasowe umożliwiające czujnikom wykrycie nieprawidłowego zaopatrzenia i bezpieczne zatrzymanie linii

Co się dzieje, gdy synchronizacja zawiedzie? Skutki wahają się od drobnych zakłóceń produkcji po katastrofalne uszkodzenia. Mechanizm transferowy uwięziony w przestrzeni matrycy podczas zamknięcia prasy oznacza zniszczone narzędzia, uszkodzone wyposażenie automatyzacyjne i potencjalnie tygodnie przestojów. Nawet niewielkie dryftowanie czasowania powoduje problemy jakościowe – elementy umieszczone lekko poza środkiem gromadzą błędy kształtowania w każdej kolejnej stacji.

Nowoczesne systemy sterowania radzą sobie z tą złożonością poprzez zintegrowane sterowniki linii, które w czasie rzeczywistym monitorują każdą pozycję prasy i odpowiednio dostosowują ruchy transferowe. Określając wymagania dotyczące układu, konieczne będzie zdefiniowanie dopuszczalnych odchyleń czasowych oraz zweryfikowanie, czy architektura sterowania jest w stanie zapewnić synchronizację przy docelowych prędkościach produkcji.

Po zrozumieniu wymagań dotyczących synchronizacji kolejnym kluczowym pytaniem staje się kwestia fizyczna: ile rzeczywiście potrzeba powierzchni podłogowej pomiędzy prasami oraz jakie rozważania odnoszące się do wymiarów będą decydować o planowaniu zakładu?

Planowanie wymiarowe i wymagania dotyczące powierzchni podłogowej

Masz już ustaloną strategię synchronizacji i parametry czasowe – nadszedł więc moment pytania, które decyduje o planowaniu zakładu: ile rzeczywiście potrzeba powierzchni podłogowej? To właśnie tutaj układ linii matryc tandemowych przechodzi od koncepcji teoretycznej do konkretnej rzeczywistości, a niedostateczne planowanie prowadzi do problemów, które utrudniają pracę przez dziesięciolecia.

W przeciwieństwie do układów progresywnych lub matryc transferowych, które konsolidują operacje w obrębie jednej prasy, konfiguracje tandemowe wymagają starannego planowania wymiarów na wielu maszynach. Jeśli te wymagania dotyczące odstępów zostaną źle dobranie, może to prowadzić do ograniczonego dostępu serwisowego, zakłóceń w automatyzacji lub w najgorszym przypadku – konieczności całkowitego przebudowania obiektu.

Obliczanie odstępów między prasami dla Twojego układu

Odległość od środka do środka pomiędzy prasami stanowi podstawę całego układu. Zgodnie z specyfikacjami linii pras tandemowych , odstępy te różnią się znacznie w zależności od wybranego mechanizmu transferowego:

- Roboty sześciu lub siedmiu osi obrotowych: Odległość między środkami pras wynosi od 6 m do 10 m

- Proste konfiguracje siedmioosiowe: Odległość między środkami pras wynosi od 5,5 m do 7,5 m

Dlaczego tak duża różnorodność? Mechanizm transferowy potrzebuje przestrzeni do działania. Ramiona robota z ruchem obrotowym wymagają większej przestrzeni roboczej niż systemy transferowe liniowe. Projektując sekwencje matryc, te wymagania dotyczące odstępów mają bezpośredni wpływ na obliczenia czasu transferu – większe odległości oznaczają dłuższe czasy przejazdu, co wpływa na ogólną szybkość cyklu.

Oto praktyczne podejście do określenia konkretnych wymagań:

- Rozpocznij od wymiarów prasy: Uwzględnij całkowitą powierzchnię zajmowaną przez każdą prasę, w tym wydłużenia stołu oraz wszelkie wyposażenie pomocnicze

- Dodaj wymagania dotyczące przestrzeni transferowej: Oblicz maksymalny zasięg i promień obrotu wybranego mechanizmu transferowego

- Uwzględnij bezpieczne odstępy: Weź pod uwagę minimalne odległości potrzebne dla kotar świetlnych, barier fizycznych i dostępu awaryjnego

- Zadbaj o ścieżki wymiany matryc: Zapewnij wystarczającą przestrzeń, aby wózki z matrycami i sprzęt podnoszący mogły uzyskać dostęp do każdego stanowiska

- Sprawdź zgodność synchronizacji: Potwierdź, że czas przejazdu transferu przy wybranej odległości spełnia wymagania okna czasowego

Jednym z kluczowych aspektów, który często jest pomijany: decyzja dotycząca odległości jest zasadniczo trwała. W przeciwieństwie do matryc, które można modyfikować lub wymieniać, zmiana pozycji pras po instalacji wymaga ogromnej pracy fundamentowej i długotrwałego przestoju.

Przydział powierzchni podłogowej poza śladem prasy

Wyobraź sobie spacer przez ukończoną linię tandemową. Same prasy zajmują tylko część całkowitej przydzielonej powierzchni podłogowej. Oto co jeszcze wymaga miejsca:

- Strefy przestrzeni roboczej automatyzacji: Roboty transferowe, mechanizmy szynowe i taśmociągi wymagają przestrzeni roboczej oraz przestrzeni bezpieczeństwa

- Korytarze dostępowe do konserwacji: Technicy potrzebują miejsca, aby uzyskać dostęp do wszystkich elementów serwisowych bez demontażu sąsiedniego sprzętu

- Strefy magazynowania materiałów: Stosy pustych blach wchodzące do linii i gotowe elementy opuszczające linię wymagają dedykowanych stref obsługi

- Pozycje przechowywania matryc: Operacje szybkiej wymiany wymagają stref przygotowania dla narzędzi docierających i odprowadzanych

- Trasy usuwania odpadów: Trasy przenośników lub pozycje pojemników do usuwania skrawków z każdej stacji

- Lokalizacje szaf sterowniczych: Szafy elektryczne wymagają przestrzeni do frontowego dostępu – zazwyczaj pełny wymiar otwarcia drzwi plus strefa robocza

- Kanały trasowania mediów: Przewody hydrauliczne, zasilanie pneumatyczne oraz kable elektryczne wymagają określonych tras

Według wytyczne dotyczące wstępnej instalacji urządzeń przemysłowych , promień ramienia zawieszenia oraz otwarcia drzwi obudowy sterowania należy dokładnie odnieść do rysunków fundamentów, aby zapewnić odpowiednią przestrzeń wolną od przeszkód lub przejść. Ten poziom szczegółowości dotyczy w równym stopniu planowania linii tandemowej.

Specyfikacje fundamentów wspierające układ

To, co znajduje się pod prasami, jest równie ważne jak to, co znajduje się nad nimi. Fundamenty pras tandemowych wymagają starannego projektowania inżynierskiego, które wykracza poza proste betonowe płyty.

Jak wskazano w wytycznych branżowych dotyczących instalacji, niezależnie od tego, czy używasz prasy próbnej o niewielkiej liczbie cykli, czy prasy produkcyjnej o dużej szybkości, ma to znaczący wpływ na wymagania dotyczące projektu fundamentów. W przypadku linii tandemowych każda stacja prasy może mieć inne parametry tonażu i cyklu, co potencjalnie wymaga indywidualnych specyfikacji fundamentów.

Kluczowe aspekty związane z fundamentami obejmują:

- Nośność gruntu: Standardowo minimum 2000 funtów na stopę kwadratową, choć rzeczywiste warunki należy potwierdzić raportem geotechnicznym

- Specyfikacje betonu: jakość 4000 psi przy odpowiednim dojrzewaniu – zazwyczaj siedem pełnych dni przed montażem maszyny

- Wymagania dotyczące zbrojenia: Zbrojenie stalowe w ilości 1/5 jednego procenta powierzchni przekroju betonu, rozmieszczone równomiernie

- Ciągłość fundamentu: Płyta betonowa pod każdą maszyną musi być ciągła – bez spoin w obszarze zajmowanym przez prasę

- Wymagania dotyczące wykopów: Systemy usuwania ś scrapu mogą wymagać tuneli z pokrywami podłogowymi pod linią

- Specyfikacja kotew: Studzinki fundamentowe wykonane ze stali średniewęglowej o minimalnej granicy plastyczności 60 000 psi

Zanim ustalisz rozmieszczenie na powierzchni podłogowej, upewnij się, że Twoje zakład może pomieścić wymagane głębokości wykopów i że istniejące fundamenty słupów budynku nie będą przeszkadzać w rozmieszczeniu pras. Przesunięcie wielotonowej prasy po instalacji jest niezwykle kosztowne – warto więc od początku dokładnie zaplanować jej położenie pod kątem optymalnego przepływu procesu.

Przestrzeń nad głową i trasy instalacji

Planowanie obejmuje nie tylko wymiar poziomy, ale także pionowy. Linie tandemowe z przenoszeniem robotycznym wymagają znacznej przestrzeni nad głową dla ruchów automatyzacji oraz dodatkowej wysokości umożliwiającej dostęp suwnicy podczas wymiany matryc i konserwacji.

Podczas planowania tras instalacji masz do wyboru kilka opcji zgodnych z najlepszymi praktykami projektowania obiektów: prowadzenie nad podłogą, rowki w podłodze z nakładkami lub przewody podziemne. Każda metoda ma swoje wady i zalety:

- Prowadzenie nad podłogą: Łatwiejsza instalacja i dostępność podczas konserwacji, jednak może zakłócać ruchy automatyzacji i pracę suwnic

- Rowki w podłodze: Instalacje pozostają dostępne, a powierzchnia podłogi jest wolna, choć nakładki zwiększają stopień skomplikowania

- Przewody podziemne: Najbardziej estetyczny wygląd podłogi, lecz najtrudniejsze do modyfikacji po instalacji

Wibracje to kolejzy aspekt pionowy. Praca pras tandemowych generuje znaczne siły dynamiczne, które mogą wpływać na wrażliwe pobliskie urządzenia. Badanie wibracji przed ustaleniem układu pozwala określić, czy w planowaniu powierzchni podłogowej należy uwzględnić środki izolacyjne – takie jak pianka obwodowa, dodatkowa masa betonowa lub specjalistyczne systemy montażowe.

Gdy wymagania dotyczące wymiarów są już określone, a ograniczenia zakładu znane, możesz przystąpić do wyboru mechanizmów odpowiedzialnych za przemieszczanie elementów między starannie rozmieszczonymi stacjami pras. Wybrany system transferowy bezpośrednio wpłynie na podjęte przez Ciebie decyzje dotyczące odstępów – oraz na czasy cyklu, które ostatecznie uda się osiągnąć.

Mechanizmy Transferu Części i Integracja Automatyzacji

Zaplanowałeś rozmieszczenie pras, określiłeś okna czasowe oraz przydzielone miejsce na hali - ale oto element, który faktycznie sprawia, że układ linii matryc tandemowych działa: mechanizm transferowy. To kluczowe połączenie między niezależnymi stacjami prasowymi, a decyzja w tej kwestii bezpośrednio wpływa na wszystko – od czasu cyklu, przez jakość wyrobu, po długoterminową elastyczność operacyjną.

Pomyśl o tym w ten sposób: Twoje prasy to muzycy, ale system transferowy to dyrygent. Bez skutecznej koordynacji nawet idealnie dostrojone indywidualne stacje tworzą chaos zamiast produktywności.

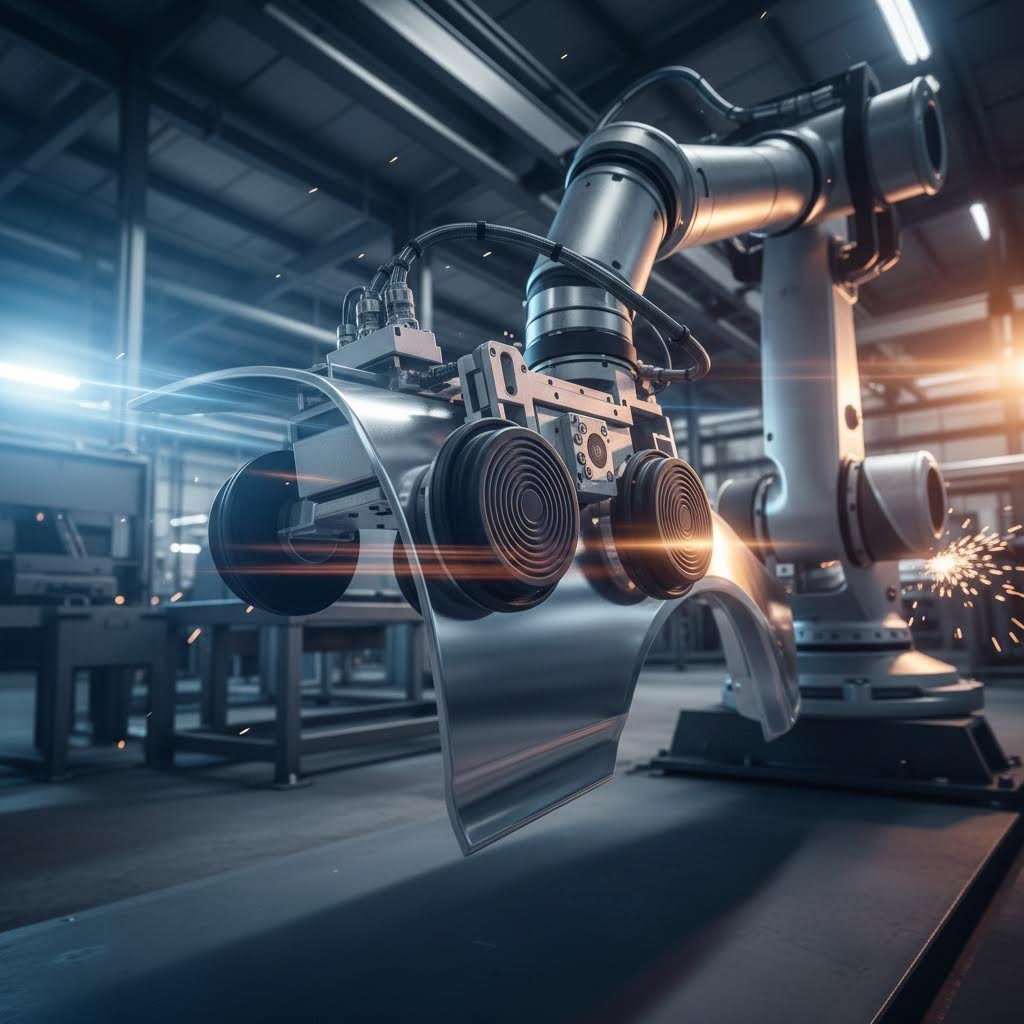

Opcje mechanizmów transferowych do integracji pras tandemowych

Oceniając systemy transferowe dla pras tandemowych, napotkasz trzy główne technologie. Każda z nich oferuje wyraźne zalety w zależności od charakterystyki wyrobu, wymagań dotyczących szybkości produkcji oraz ograniczeń zakładu.

Mechanizm transferowy typu shuttle

Mechanizm transferowy typu szyna działa na stosunkowo prostej zasadzie: liniowym przemieszczaniu się między ustalonymi pozycjami. Wyobraź sobie tackę przesuwającą się tam i z powrotem po szynach, pobierającą elementy na jednej stacji i umieszczającą je na następnej.

Systemy szynowe wyróżniają się w zastosowaniach wymagających:

- Stałej orientacji elementów podczas transferu

- Wysokiej powtarzalności dla precyzyjnego umieszczania

- Niższych początkowych nakładów inwestycyjnych w porównaniu z rozwiązaniami robotycznymi

- Prostego programowania i łatwej konserwacji

Wady? Ograniczona elastyczność. Mechanizmy szynowe zazwyczaj obsługują elementy przemieszczane w jednej płaszczyźnie bez obrotu, co ogranicza ich zastosowanie do geometrii nie wymagających zmiany orientacji między operacjami.

System transferowy typu walking beam

System transferowy typu walking beam wykorzystuje zsynchronizowany ruch podnoszenia i przenoszenia. Belka jednoczesne podnosi elementy ze wszystkich stanowisk, przesuwa je o jedno miejsce i opuszcza do następnej matrycy – podobnie jak moglibyśmy przesunąć jednocześnie kilka figurek szachowych.

To podejście oferuje kilka zalet w integracji pras tandemowych:

- Zsynchronizowany ruch na wielu stanowiskach zmniejsza złożoność czasowania

- Pozytywna kontrola detalu podczas całego cyklu transferowego

- Nadaje się szczególnie dla elementów wymagających stałej odległości i orientacji

- Prostota mechaniczna w porównaniu z całkowicie przegubowymi systemami

Systemy chodzącego belka bardzo dobrze sprawdzają się w przypadku elementów konstrukcyjnych o regularnych kształtach – np. belek i wzmocnień, gdzie trasa transferowa nie wymaga skomplikowanych manipulacji.

Robocze przenoszenie części w tłoczniarstwie

W celu osiągnięcia maksymalnej elastyczności jednostki transferowe zrobotyzowane oferują najbardziej uniwersalne rozwiązanie. Zgodnie z realizacjami OEM w branży motoryzacyjnej, systemy transferowe typu crossbar, takie jak Güdel roboBeam, umożliwiają „bezpośrednie przekazywanie części z prasy do prasy bez pośredniego stanowiska lub stacji orientacji”.

Nowoczesne systemy robotyczne oferują możliwości, których systemy mechaniczne nie są w stanie dorównać:

- Pełna programowalność: Wszystkie osie są regulowane, zapewniając maksymalną elastyczność podczas zmiany między programami części

- Złożone ścieżki ruchu: Części mogą być obracane, nachylane lub przestawiane podczas przenoszenia, aby odpowiadać wymaganiom matryc

- Adaptacyjne pozycjonowanie: Ruchy sterowane serwomechanizmami mogą dostosowywać się w czasie rzeczywistym na podstawie danych z czujników

- Duże przestrzenie robocze: Możliwość dłuższego zasięgu pozwala na większy odstęp pomiędzy prasami

W konstrukcjach transferowych belkowych, belka napędzana jest przez mechanizm zębatkowy i prowadzona za pomocą prowadnic liniowych, co umożliwia niezależny ruch belki i wózka. Ta architektura umożliwia tworzenie krzywych ruchu dopasowanych do konkretnych konturów matryc – szczególnie przydatne przy produkcji złożonych paneli karoserii samochodów.

Efektory końcowe automatyzacji – „ręce”, które faktycznie chwytają elementy – to niemal wyłącznie przyspawki próżniowe, choć w późniejszych generacjach dodano zaciski mechaniczne dla lepszej kontroli. Maksymalne wymiary pojedynczego elementu mogą wynosić 4160 mm od lewej do prawej i 2090 mm od przodu do tyłu, przy ograniczeniu masy blanku do około 60 kg dla pojedynczych części.

Porównanie technologii transferu dla Twojego zastosowania

Który system jest odpowiedni dla układu Twojej linii tłocznikowej tandemowej? Odpowiedź zależy od równowagi wielu czynników względem Twoich konkretnych wymagań:

| Cechy | Transfer szuflowy | Transfer strzałkowy | Transfer robotyczny |

|---|---|---|---|

| Możliwości prędkości (SPM) | 15-25 | 12-20 | 12–18 (do 30 przy optymalizacji serwomechanizmu) |

| Zakres rozmiarów części | Mała do średniej | Średnia do duża | Pełny zakres – od małych do nadwymiarowych |

| Ponowna orientacja części | Ograniczony - tylko jedna płaszczyzna | Umiarkowany - ruchy skoordynowane | Pełny - manipulacja na 6+ osiach |

| Elastyczność programowania | Niski - stałe ścieżki ruchu | Umiarkowany - regulowalne parametry | Wysoki - całkowicie programowalne trajektorie |

| Czas zmiany | Najdłuższy - regulacje mechaniczne | Umiarkowany - zmiana receptur | Najkrótszy - ładowanie receptur oprogramowania |

| Wymagana odległość pomiędzy prasami | Kompaktowa - typowo 4-6 m | Umiarkowana - typowo 5-7 m | Największa - 5,5-10 m w zależności od konfiguracji |

| Stosunkowy koszt kapitałowy | Najniższy | Umiarkowany | Najwyższą |

| Złożoność konserwacji | Prosta - mniej ruchomych części | Umiarkowana - zsynchronizowane mechanizmy | Złożona - systemy serwo i sterowania |

| Najlepsze zastosowania | Spójne części o dużej objętości | Elementy konstrukcyjne, belki | Płaszczyzny karoserii, złożone geometrie, produkcja mieszana |

Zauważ zależność między elastycznością a wymaganiami dotyczącymi odstępów? Systemy robotyczne wymagają większych odległości między prasami – wspomniane zakresy 6-10 metrów w planowaniu wymiarów – ponieważ ramiona sztuczne potrzebują przestrzeni do manewrowania. Jeśli ograniczenia Twojej instalacji sprzyjają ciasniejszemu rozmieszczeniu, rozwiązania typu szuflowe lub podajnikowe mogą być praktycznym wyborem.

Optymalizacja przepływu materiału pomiędzy stanowiskami

Wybór mechanizmu transferowego to tylko połowa zagadnienia. Nie mniejszą uwagę należy poświęcić temu, jak płaskowniki trafiają do linii i jak gotowe elementy ją opuszczają, aby osiągnąć rzeczywiście zoptymalizowany przepływ materiału.

Strategie obsługi płaskowników

Twoja stacja wstępna otrzymuje surowe płytki — a sposób, w jaki te płytki są prezentowane, ma bezpośredni wpływ na wydajność linii. Zgodnie z analizą linii tłocznia , konfiguracje tandemowe mogą wykorzystywać materiał z blachy zwijanej lub arkuszy, oferując dużą elastyczność w optymalizacji zużycia materiału.

W przypadku blach, systemy rozładunkowe z magnetycznym lub próżniowym oddzielaniem podnoszą pojedyncze blachy ze stosów i ustawiają je do pierwszej operacji. Istotne kwestie obejmują:

- Logistyka uzupełniania stosów – jak szybko można załadować nowe stosy blach?

- Wykrywanie podwójnych blach – czujniki muszą potwierdzić podawanie pojedynczych arkuszy przed uruchomieniem prasy

- Dokładność centrowania blach – niepoprawnie ustawione blachy prowadzą do problemów jakościowych na każdym kolejnym stanowisku

- Nanoszenie środka smarnego – kiedy i gdzie środek smarny jest nanoszony na powierzchnię blach

Obsługa wyjścia i zbieranie elementów

Po ostatniej operacji formowania gotowe elementy muszą opuścić linię bez tworzenia wąskich gardeł. Projekt taśmy wyjściowej wpływa zarówno na wydajność, jak i jakość elementów – paneli ślizgające się po sobie mogą ulec uszkodzeniu powierzchni, co psuje wykończenie klasy A.

Skuteczne strategie wyjściowe obejmują zazwyczaj:

- Taśmy wyjściowe z napędem grawitacyjnym lub elektrycznym dostosowane do prędkości linii

- Mechanizmy rozdzielania lub odstępowania elementów, aby zapobiec uszkodzeniom przez kontakt

- Zautomatyzowane systemy magazynowania do spójnego załadunku palet

- Stacje kontroli jakości zintegrowane z drogą wyjściową

Integracja usuwania odpadów

Nie pomijaj obsługi odpadów przy planowaniu przepływu materiału. Jak wspomniano w wytycznych projektowania systemów pras , „usuwanie odpadów często jest myślą wtórną” – ale nie powinno nią być. Odpady spływające przez płytę mocującą i stół oraz drzwi na odpady z przodu i tyłu każdej prasy to niezbędne cechy konstrukcyjne.

Twój układ musi uwzględniać trasy taśmociągów na odpady pod linią lub obok niej, pozycjonowanie pojemników na odpady oraz dostęp do okresowego czyszczenia. Pominięcie tych szczegółów prowadzi do problemów z porządkami i potencjalnych zakłóceń w działaniu transferu.

Wpływ doboru systemu transferowego na ogólną wydajność linii

Wybór systemu transferowego wpływa na cały układ linii matryc tandemowych:

- Limit czasu cyklu: Prędkość transferu często staje się czynnikiem ograniczającym – a nie możliwości prasy. Producenci OEM z branży motoryzacyjnej wykorzystujący zoptymalizowane systemy crossbar osiągają średnie cykle pracy na poziomie 12–15 SPM – co stanowi punkt odniesienia dla tłoczenia aluminium

- Rozstawienie układu: Wymagania dotyczące przestrzeni transferowej bezpośrednio określają odległości między osiami pras

- Elastyczność na potrzeby przyszłych zmian: Systemy programowalne obsługują nowe geometrie elementów; systemy mechaniczne mogą wymagać modyfikacji sprzętu

- Integracja systemu sterowania: Wszystkie ruchy serwomechanizmów podajników muszą być elektronicznie zsynchronizowane z kątami prasy w celu zapewnienia bezpieczeństwa

Najbardziej zaawansowane wdrożenia wykorzystują narzędzia symulacyjne do weryfikacji tras transferowych przed instalacją. Przyspieszenie, hamowanie, pozycjonowanie elementów oraz dane wejściowe sił G są przetwarzane przez programy symulacyjne linii pras, generując receptury elementów, które definiują trajektorie ruchu automatyzacji. Ta weryfikacja wirtualna zapobiega kosztownym kolizjom wykrywanym podczas rzeczywistej produkcji.

Po zakończeniu wyboru mechanizmu transferowego masz już wszystkie techniczne elementy składowe potrzebne do skonfigurowania linii tandemowej. Pozostaje jeszcze ułożenie tych elementów w spójny proces projektowania – prowadzący od początkowych wymagań produkcyjnych przez weryfikację techniczną aż po końcową implementację.

Proces projektowania układu krok po kroku

Poznałeś podstawy, zrozumiałeś kryteria decyzyjne, opanowałeś wymagania synchronizacji i wybrałeś odpowiedni mechanizm transferowy. Nadchodzi teraz pytanie, przed którym staje każdy inżynier: jak właściwie połączyć wszystkie te elementy w funkcjonalny układ matrycy liniowej tandemowej?

Właśnie w tym miejscu zawodzą większość dostępnych materiałów. Producenci urządzeń opisują swoje produkty. Prace akademickie omawiają teorie optymalizacji. Nikt jednak nie przeprowadza Cię krok po kroku przez cały proces projektowania linii tandemowej – od początkowego założenia po zweryfikowaną konfigurację. Aż do teraz.

Poniżej przedstawiono metodyczne podejście wypracowane w ramach rzeczywistych projektów weryfikacji inżynieryjnej linii tłocznikowej – nie chodzi o teoretyczne założenia, lecz o praktyczne kroki przekładające wymagania na gotowe do produkcji układy technologiczne.

Od wymagań produkcyjnych do koncepcji wstępnych układów

Każdy sukces w planowaniu układu linii pras zaczyna się w ten sam sposób: od jasnego określenia tego, co chce się osiągnąć. Brzmi oczywiste? Zaskoczyłoby Cię, ile projektów kończy się niepowodzeniem, ponieważ interesariusze opierali się na różnych założeniach dotyczących podstawowych wymagań.

Oto kroki konfiguracji linii matryc prowadzące od czystej kartki papieru do koncepcji wstępnej:

-

Zdefiniuj swoje portfolio części i cele produkcyjne

Rozpocznij od udokumentowania każdej części, którą zamierzasz produkować na tej linii. Dla każdej części zapisz wymiary, specyfikacje materiałowe, złożoność kształtowania oraz wymagane roczne wielkości produkcji. Zgodnie z badaniami nad optymalizacją linii pras , ostateczny kształt elementu blachy "wpływa na wybór typu prasy oraz liczbę potrzebnych etapów kształtowania." Twoja oferta części bezpośrednio określa liczbę stanowisk, wymagania dotyczące siły wykroju oraz złożoność projektowania matryc.

-

Określ wymagania dotyczące sekwencji procesu

Spójrz na operacje kształtujące, które wymaga każda część. Zidentyfikuj operacje, które mogą współdzielić stanowiska, oraz te, które wymagają dedykowanych pras. Weź pod uwagę takie czynniki jak:

- Postęp głębokości tłoczenia między etapami

- Umiejscowienie operacji cięcia i przebijania

- Wymagania dotyczące zaginania i przewijania brzegów

- Zmiany orientacji części wymagane pomiędzy operacjami

-

Określ specyfikację prasy dla każdego stanowiska

Na podstawie sekwencji procesu określ wymagania dotyczące siły wykroju, wielkości stołu, długości suwu oraz wysokości zamknięcia dla każdego stanowiska. Pamiętaj, że konfiguracje tandemowe pozwalają na różne pojemności pras w poszczególnych pozycjach – istotna zaleta, gdy siły kształtujące znacznie się różnią pomiędzy operacjami.

-

Wybierz technologię mechanizmu transferowego

Korzystając z ram porównawczych z poprzedniego rozdziału, wybierz system transferowy, który uwzględnia wymagania dotyczące szybkości, potrzeby związane z manipulacją elementów oraz ograniczenia budżetowe. Ta decyzja bezpośrednio wpływa na obliczenia odstępów między prasami w następnym kroku.

-

Oblicz wstępne odstępy między prasami

Po wybraniu mechanizmu transferowego ustal odległości osiowe pomiędzy prasami. W przypadku transferów robotycznych zaplanuj odstęp od 5,5 m do 10 m, w zależności od konfiguracji. Upewnij się, że czas przejazdu transferu przy tych odległościach mieści się w oknach czasowych synchronizacji.

-

Stwórz wstępne koncepcje planu zabudowy

Narysuj kilka wariantów układu pokazujących położenie pras, trasy transferowe, miejsca wprowadzania blanków, wyjścia gotowych elementów oraz trasy usuwania odpadów. Weź pod uwagę ograniczenia hali – lokalizację słupów, zasięg suwnic nadgłowicowych, punkty dostępu do mediów. Utwórz co najmniej trzy różne koncepcje do porównania.

-

Oceń koncepcje pod kątem spełnienia wymagań

Oceń każdy koncepcyjny układ pod kątem docelowej produkcji, potrzeb związanych z dostępem do konserwacji, efektywności zmiany produkcji oraz elastyczności rozbudowy. Wyznacz wiodącą koncepcję do szczegółowego opracowania technicznego.

Na tym etapie powinieneś mieć wstępny układ przedstawiający przybliżone położenia i wymiary. Celem nie jest doskonałość – chodzi o ustalenie punktu wyjściowego, który zostanie dopracowany podczas szczegółowego projektowania technicznego.

Uwagi dotyczące projektowania matryc wpływające na układ linii

Właśnie tutaj proces projektowania linii tandemowej staje się iteracyjny. Decyzje dotyczące projektu matryc i decyzje dotyczące układu linii wpływają na siebie nawzajem – zmiany w jednej dziedzinie przekładają się na drugą.

Zgodnie z badaniami symulacji tłoczenia: „podczas tworzenia matrycy projektant może wpływać na czas cyklu linii prasy tandemowej, wybierając różne rozwiązania matrycowe”. Chodzi tu nie tylko o poprawne formowanie elementu, ale także o projektowanie matryc działających harmonijnie w ramach ograniczeń narzuconych przez układ.

Kluczowe czynniki projektowania matryc wpływające na układ to:

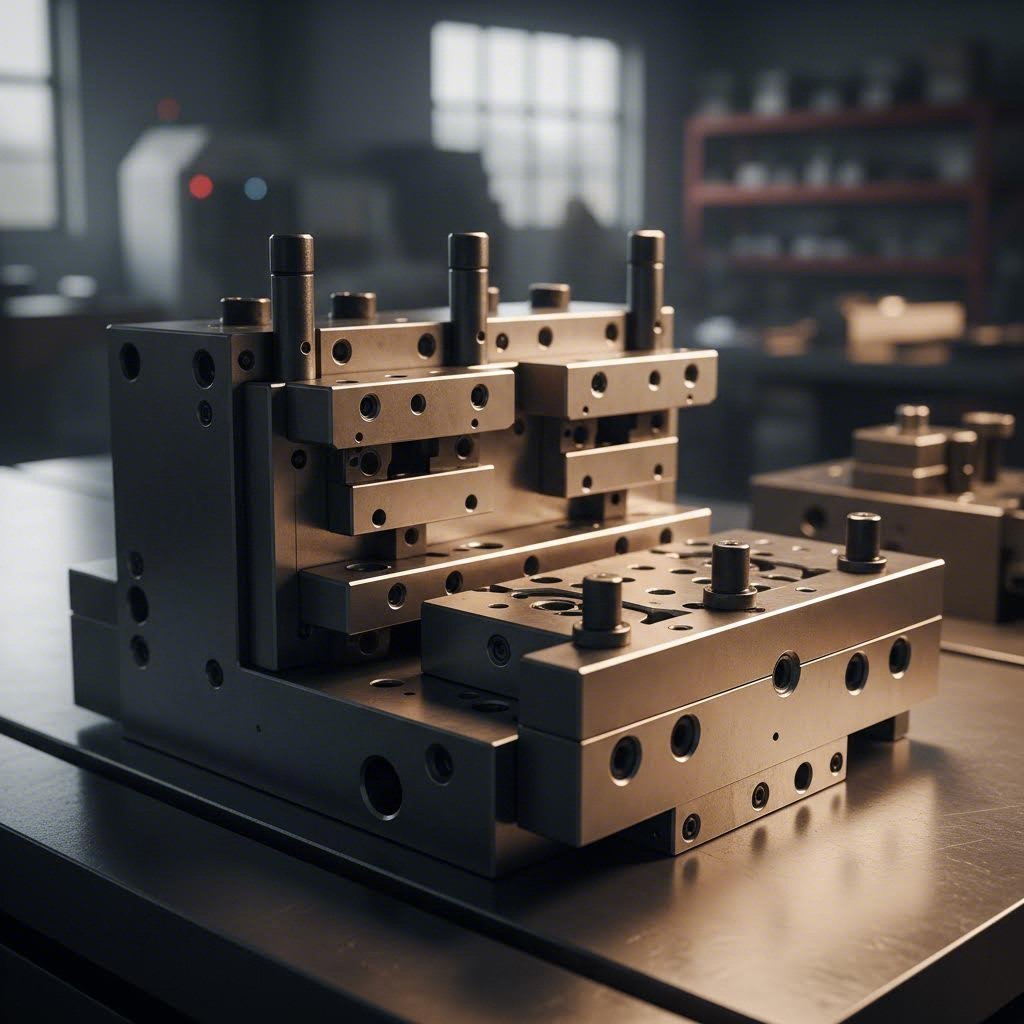

- Wymiary przestrzeni zajmowanej przez matrycę: Całkowity rozmiar twoich tłociszek musi mieścić się w granicach powierzchni roboczej prasy i zapewniać odstęp dla ruchów automatyzacji. Zbyt duże tłociszka wymuszają większy odstęp między prasami lub ograniczają opcje transferu.

- Wycięcia obejściowe w tłociszczach blacharskich: Te wycięcia kompensacyjne pełnią konkretną funkcję w obsłudze materiału – zapewniają luz umożliwiający szczypcom transferowym pewne chwytanie elementów w trakcie krótkich okien czasowych pomiędzy suwami prasy. Funkcja wycięć obejściowych w tłociszczach wykracza poza sam luz technologiczny; umożliwia szybsze ruchy transferowe i zmniejsza ryzyko kolizji.

- Ustawienie kanału odpływu śrucia: Projekty tłociszek muszą zapewniać odprowadzanie śrucia z torów transferowych. Słabe rozwiązanie obsługi śrucia powoduje zakłócenia, które wydłużają czas cyklu lub powodują zawieszenia.

- Orientacja prezentowania elementu: To, jak tłociszka ustawia elementy do podnoszenia, wpływa na złożoność programowania transferu. Spójna orientacja pomiędzy stanowiskami upraszcza automatyzację.

- Strefy dostępu szczypiec: Powierzchnie robocze muszą zapewniać wystarczającą powierzchnię dla przyssawek próżniowych lub chwytaków mechanicznych, aby mogły one zapewnić bezpieczne uchwycenie. Zgodnie z badaniami, instalacja i konserwacja chwytaków stanowią „większość problemów w projektowaniu produktu i procesu”.

Gdy nacięcia obejściowe w tłoczyskach do kształtowania blach są odpowiednio zaprojektowane, umożliwiają mechanizmowi transferowemu bezpieczne chwycenie i zwolnienie elementów w trakcie wcześniej omówionych wąskich okien czasowych. Niewłaściwie dobrana wielkość lub położenie nacięć wymusza dłuższe cykle transferowe lub grozi uszkodzeniem elementu podczas manipulacji.

Weryfikacja inżynieryjna przed ostateczną konfiguracją

Zanim zostaną przeznaczone znaczne środki na zakup sprzętu i modyfikacje obiektu, wstępny układ musi zostać poddany rygorystycznej weryfikacji inżynieryjnej linii tłocznikowej. Ten etap przekształca koncepcje w pewność działania.

-

Stwórz szczegółowe modele symulacyjne

Nowoczesne programy symulacyjne linii pras umożliwiają wirtualną weryfikację całego układu przed rozpoczęciem jakichkolwiek prac fizycznych. Badania Uniwersytetu Chalmers , symulacja służy jako "jedno z narzędzi do optymalnego wykorzystania linii prasowej" obejmujące "wysoką przepustowość, minimalne zużycie linii i wysoką jakość".

Twoja symulacja powinna modelować:

- Krzywy ruchu prasowego dla każdej stacji

- Mechanizm przeniesienia, kinematyka i ścieżki

- Geometria części przez każdy etap formowania

- Wykrywanie kolizji między wszystkimi ruchomymi elementami

- Relacje czasowe w całej linii

-

Weryfikacja parametrów synchronizacji

Wykonaj symulacje, aby sprawdzić, czy planowane relacje fazowe, okna przeniesienia i tolerancje czasowe osiągają docelowe prędkości cyklu bez kolizji. Badania wskazują, że "w stacji prasowej konieczne jest wykrywanie kolizji pomiędzy matrycami, prasą, częściami z blachu i uchwytami" - a zapobieganie kolizji "jest koniecznością, ponieważ kolizje między elementami w linii mogą prowadzić do zniszczenia sprzętu".

-

Optymalizuj ścieżki transferowe

Po zweryfikowaniu synchronizacji bazowej, dopracuj profile ruchu transferowego, aby zminimalizować czas cyklu, zachowując jednocześnie bezpieczne odstępy. Optymalizacja oparta na symulacji pozwala przeanalizować tysiące kombinacji parametrów, których nie dałoby się zbadać przy ręcznej kalibracji.

-

Zweryfikuj dostępność serwisową

Przeprowadź symulację procedur wymiany matryc, zapewniając, że wózki z matrycami mogą poruszać się między prasami, a narzędzia mogą być wyjmowane bez zakłóceń. Sprawdź, czy technicy mają dostęp do wszystkich elementów wymagających konserwacji.

-

Przeprowadź wirtualne uruchomienie

Przed fizyczną instalacją wirtualne uruchomienie testuje logikę sterowania i programowanie względem zasymulowanej linii. Zgodnie z badaniami, podejście to „zmniejsza zależność od wiedzy operatora” i umożliwia kalibrację parametrów w trybie offline, którą można bezpośrednio przenieść do zakładu produkcyjnego.

-

Dokumentuj końcowe specyfikacje

Zebranie zweryfikowanych wymiarów, parametrów czasowych i specyfikacji sprzętu w dokumentach zakupowych. Uwzględnić wymagania dotyczące fundamentów, zapotrzebowania na media oraz punkty integracji dla każdego systemu.

-

Zaplanuj etapy weryfikacji fizycznej

Nawet przy kompleksowej symulacji, próbne uruchomienie linii fizycznej pozostaje niezbędne. Zdefiniuj kolejność montażu sprzętu, weryfikacji poszczególnych stanowisk oraz stopniowej integracji linii, które doprowadzą układ do gotowości produkcyjnej.

Dlaczego to podejście oparte na procesie ma znaczenie

Zauważasz coś wyjątkowego w tej metodologii? Traktuje ona układ linii tłoczników tandemowych jako zintegrowany system, a nie jako zbiór specyfikacji sprzętu.

Zbyt wiele projektów przechodzi od razu od wyboru sprzętu do instalacji, odkrywając problemy z integracją dopiero wtedy, gdy prasy są już przykręcane do fundamentów. Etapy weryfikacji inżynieryjnej linii tłocznikowej opisane tutaj wykrywają te problemy wirtualnie – w momencie, gdy zmiany kosztują godziny symulacji zamiast tygodni przestojów produkcyjnych.

Badania symulacyjne potwierdzają tę wartość: "późne zmiany form i osprzętu są kosztowne. Dlatego symulacje pozwalają projektantom form i procesów przewidywać problemy, co prowadzi do większej efektywności, wyższej jakości i przychodów."

Niezależnie od tego, czy jesteś początkującym planującym swoją pierwszą konfigurację tandemową, czy doświadczonym inżynierem dążącym do ustandaryzowania swojego podejścia, ten proces sekwencyjny zapewnia strukturę, która przekształca wymagania w udane wdrożenia. Każdy krok bazuje na poprzednich decyzjach, jednocześnie przekazując dane do kolejnych etapów weryfikacji – tworząc zintegrowane zrozumienie, którego katalogi sprzętu po prostu nie mogą zapewnić.

Oczywiście, nawet najbardziej starannie zaplanowane układy napotykają wyzwania operacyjne, gdy rozpocznie się produkcja. W następnej sekcji omówione zostanie, co się dzieje, gdy rzeczy nie idą zgodnie z planem – oraz jak zdiagnozować, czy problemy wynikają z decyzji dotyczących układu, czy parametrów operacyjnych.

Rozwiązywanie najczęstszych problemów związanych z układem i działaniem operacyjnym

Układ Twojej linii tłoczników tandemowych wyglądał idealnie na papierze. Symulacje potwierdziły każdy parametr. Jednak produkcja opowiada inną historię – części nie przepływają płynnie, pojawiają się problemy z jakością lub wydajność nie osiąga założonych wartości. Brzmi znajomo?

Oto rzeczywistość: nawet dobrze zaprojektowane linie prasowe tandemowe napotykają wyzwania operacyjne, które wymagają systematycznego rozwiązywania problemów. Kluczem jest odróżnienie przyczyn związanych z układem od problemów z parametrami operacyjnymi – ponieważ rozwiązanie każdego z nich wygląda zupełnie inaczej.

Diagnozowanie problemów zsynchronizowania i transferu

Gdy linia niespodziewanie się zatrzymuje lub elementy docierają uszkodzone do kolejnych stanowisk, najczęstszą przyczyną są błędy synchronizacji. Zgodnie z Ekspertyzą pras transferowych AIDA , „zrozumienie, w jaki sposób prasa transferowa i jej wyposażenie pomocnicze ze sobą współdziałają, jest kluczowe przy doborze odpowiedniego systemu i osiąganiu celów produkcyjnych" – co znacząco zmniejsza konieczność rozwiązywania problemów po uruchomieniu systemu.

Ale co, jeśli problemy pojawią się mimo starannego doboru systemu? Rozpocznij od tych metod diagnostycznych:

Problemy z synchronizacją linii prasowej

Problemy z synchronizacją występują w przewidywalnych wzorcach. Zwracaj uwagę na te sygnały ostrzegawcze:

- Przypadkowe błędy transferu: Czasem elementy nie są poprawnie przekazywane, co powoduje aktywowanie zatrzymania awaryjnego. Często wskazuje to na dryft czasowania między fazami pracy prasy

- Stałe błędy pozycjonowania: Elementy systematycznie trafiają niecentrycznie do form w dalszych stacjach. Przesunięcie fazy mogło ulec zmianie, co skróciło okno transferu

- Zwiększony czas cyklu: Linia działa, ale wolniej niż przewidziano w specyfikacji. Systemy sterowania mogą dodawać opóźnienia bezpieczeństwa, aby zrekompensować niepewność synchronizacji

- Słyszalne odchylenia w synchronizacji: Nieprawidłowe dźwięki podczas przenoszenia – dźwięki tarcia, trzaski lub zmiany momentu uwalniania powietrza – wskazują na problemy z synchronizacją mechaniczną lub pneumatyczną

W przypadku diagnozowania błędów w prasach tandemowych sprawdź, czy każda prasa osiąga dolny martwy punkt z określonym przesunięciem fazowym względem sąsiednich. Nawet niewielkie odchylenia – kilka stopni kąta korbowodu – mogą spowodować, że ruchy transferowe wyjdą poza bezpieczne zakresy.

Diagnozowanie awarii transferu tłoczenia

Mechanizmy transferowe ulegają awariom z przyczyn innych niż brak synchronizacji prasy. Gdy części nie są przenoszone w sposób niezawodny między stanowiskami, przeanalizuj następujące potencjalne przyczyny:

- Zużycie się przyssawek próżniowych: Wynoszone lub zabrudzone przyssawki stopniowo tracą siłę chwytu. Części mogą uwalniać się przedwcześnie podczas ruchów o wysokim przyspieszeniu

- Niewłaściwe ustawienie chwytaków: Dryft mechaniczny w pozycjonowaniu chwytaka powoduje niestabilne pobieranie elementów. Zgodnie z badań dotyczących konserwacji matryc , niedokładne dopasowanie „może nie tylko naruszać dokładność wykrojów, ale także potencjalnie prowadzić do przedwczesnego zużycia matrycy”

- Błędy synchronizacji serwonapędów: Programowalne systemy transferowe opierają się na precyzyjnej synchronizacji serwosilników. Opóźnienia komunikacyjne lub dryft enkodera wpływają na dokładność ruchu

- Przenoszenie środka smarnego: Nadmiar środków smarnych formujących na powierzchniach elementów zmniejsza skuteczność uchwytu próżniowego. Przejrzyj ilości oraz miejsca aplikacji środka smarnego

Problemy jakościowe związane z układem linii i ich rozwiązania

Nie wszystkie problemy jakościowe wynikają z zużycia matrycy lub zmienności materiału. Czasem przyczyną leży w samym układzie linii matryc tandemowych – decyzje dotyczące odstępów, ścieżek transferowych lub konfiguracji stanowisk, które podczas planowania wydawały się optymalne, ale w trakcie produkcji powodują problemy.

Typowe objawy i związane z nimi przyczyny układu linii

Użyj tego ramowego podejścia diagnostycznego, aby powiązać objawy jakościowe z potencjalnymi przyczynami układu:

- Postępujące odchylenie wymiarowe pomiędzy stanowiskami: Części gromadzą błędy pozycjonowania przy każdym przeniesieniu. Sprawdź, czy odstępy między prasami powodują zbyt duży ruch podczas transferu, umożliwiając przesuwanie się części podczas manipulacji

- Ślady zadrapień lub znaki na powierzchni pojawiające się w środku linii: Punkty kontaktu mechanizmu transferowego mogą uszkadzać powierzchnie części. Oceń materiał podkładek chwytaków i ciśnienie kontaktowe – lub rozważ, czy wycięcia omijające w matrycach tłocznikowych blach stalowych nie powinny zostać przesunięte, aby umożliwić delikatniejsze manipulowanie

- Niestabilna głębokość wykroju na określonych stanowiskach: Wibracje z sąsiednich pras mogą wpływać na dokładność kształtowania. Przejrzyj izolację fundamentów pomiędzy stanowiskami i rozważ, czy odstępy między prasami nie prowadzą do sprzęgania wibracji

- Marszczenie się lub pęknięcia pojawiające się po transferze: Części mogą ulegać odkształceniom podczas manipulacji z powodu niewystarczającego podparcia. Celem nacięć obejściowych w tłoczyskach jest umożliwienie prawidłowego rozmieszczenia chwytaków – nieodpowiedni projekt nacięć zmusza chwytaki do opierania się na niepodpartych obszarach

- Interferencja śrutu z transferem: Odpady po operacjach cięcia mogą nie zostać usunięte z przestrzeni tłoczyska przed wejściem transferu. Oceń rozmieszczenie kanału odpływowego śrutu względem Twojej strefy transferowej

Gdy projekt nacięć obejściowych wymaga dostrojenia

Nacięcia obejściowe w tłoczyskach do kształtowania blach stalowych pełnią kluczową funkcję: zapewniają luz umożliwiający chwytakom transferowym bezpieczne chwycenie części w trakcie krótkich okien czasowych. Gdy nacięcia są za małe, źle rozmieszczone lub brakuje ich tam, gdzie są potrzebne, występują objawy takie jak:

- Chwytaki transferowe stykają się z czynnymi powierzchniami tłoczyska

- Niestabilne chwyty części, wymagające wielokrotnych prób

- Uszkodzenia części w strefach kontaktu z chwytakami

- Zmniejszenie prędkości transferu ze względu na niewygodne pozycje chwytu

Według praktyki diagnostyczne tłoczników , precyzja w inżynierii matryc tłocznych nie może być przeceniona; niedokładności dotyczące tolerancji mogą prowadzić do wad w produkcie końcowym lub nawet powodować awarie podczas procesu tłoczenia." To dotyczy w równym stopniu specyfikacji nacięć omijających.

Wąskie gardła przepływu na linii tandemowej

Gdy Twoja linia nie osiąga docelowych prędkości cyklu, wąskie gardło często kryje się w ograniczeniach związanych z układem, a nie w indywidualnych ograniczeniach sprzętu. Systematyczna diagnostyka wymaga sprawdzenia:

- Czas przejazdu transferu: Czy odstępy między prasami zmuszają do ruchów transferowych, które zajmują nadmierną część cyklu? Dłuższe odległości wymagają albo wolniejszego ruchu, albo wyższego przyspieszenia – oba mają swoje granice

- Opóźnienia podawania blanków: Czy stanowisko początkowe oczekuje na prezentację blanek? Transport materiału przed linią wpływa na całkowitą wydajność

- Ograniczenia przenośnika wyjściowego: Gromadzenie się części na wyjściu z linii może wymusić przerwanie produkcji. Zweryfikuj, czy zdolność obsługi wyjścia odpowiada prędkości linii

- Dostępność przy wymianie matryc: Częste przestawiania wydłużają ogólny czas działania sprzętu. Jeśli ograniczenia układu uniemożliwiają łatwy dostęp do matryc, czas przestawiania zwiększa się, prowadząc do znaczącej utraty wydajności

- Ograniczenia dostępu serwisowego: Małe odstępy, które wydawały się dopuszczalne podczas planowania, mogą utrudniać skuteczną diagnostykę i naprawy, przedłużając przestoje

Praktyczny protokół rozwiązywania problemów

Gdy wystąpią problemy, powstrzymaj się od chęci losowej zmiany parametrów. Zamiast tego postępuj według systematycznego podejścia:

- Dokładnie udokumentuj objaw: Kiedy występuje? Na którym stanowisku? W ilu procentach cykli?

- Przejrzyj ostatnie zmiany: Nowe programy części? Konserwacja matryc? Zmiany w partii materiału?

- Wyizoluj stanowisko: Czy można odtworzyć problem, uruchamiając tę stację niezależnie?

- Sprawdź parametry czasowe: Porównaj aktualne ustawienia synchronizacji z weryfikowanymi wartościami bazowymi

- Sprawdź komponenty transferowe: Sprawdź stan chwytaków, poziom podciśnienia oraz ustawienie mechaniczne

- Oceń czynniki układu: Rozważ, czy wzorzec objawów wskazuje na problemy związane z odstępami, dostępem lub konfiguracją

Jak podkreśla przemysłowa wytyczna dotycząca konserwacji: „Systematyczna dokumentacja na każdym etapie procesu diagnostycznego nie może być wystarczająco podkreślona. Ewidencja powinna obejmować wszystkie wyniki inspekcji, pomiarów i analiz”. Dokumentacja ta ma nieocenioną wartość przy identyfikowaniu powtarzających się problemów, które mogą wskazywać na ukryte błędy układu wymagające korekt projektowych, a nie kolejnych napraw operacyjnych.

Pomyślne rozwiązywanie tych wyzwań operacyjnych często wymaga współpracy z ekspertami inżynierskimi, którzy rozumieją zarówno projektowanie tłoczników, jak i integrację linii. Ostatnie pytanie? Wybór odpowiedniego partnera wspierającego wdrożenie – od początkowego układu po długoterminową optymalizację produkcji.

Skuteczne wdrażanie układu linii tłoczników tandemowych

Opanowałeś podstawy, przeanalizowałeś ramy decyzyjne, zrozumiałeś wymagania synchronizacji oraz rozwijasz umiejętności rozwiązywania problemów. Ale oto pytanie, które dzieli udane wdrożenie linii tłoczników tandemowych od kosztownych pomyłek: kto pomoże Ci je zrealizować?

Rzeczywistość jest prosta – nawet najdokładniejsze planowanie układu wymaga specjalistycznej wiedzy, której większość zakładów produkcyjnych nie posiada wewnętrznie. Złożoność projektowania tłoczników, weryfikacja narzędzi tłoczących za pomocą symulacji CAE oraz wyzwania związane z integracją wymagają partnerów, którzy wielokrotnie rozwiązywali te problemy w różnych zastosowaniach.

Wybór odpowiedniego partnera inżynieryjnego dla projektu układu

Wyobraź sobie zlecenie linii pras tandemowych bez wsparcia eksperta. Podejmowałbyś się projektowania matryc, które nie uwzględniają czasu transferu, parametrów synchronizacji opartych na teorii, a nie na doświadczeniu produkcyjnym, oraz decyzji dotyczących układu, które wyglądają dobrze na papierze, ale powodują operacyjne koszmary.

Alternatywa? Współpraca z partnerem inżynieryjnym matryc tłoczarskich, który wykazuje potwierdzoną kompetencję w całym cyklu życia projektu. Jednak nie wszyscy partnerzy są równoważni. Oceniając potencjalnych współpracowników dla projektu układu linii matryc tandemowych, kieruj się następującymi kryteriami:

- Zintegrowana zdolność od projektu do produkcji: Partnerzy, którzy obejmują całość – od projektowania oprzyrządowania w oparciu o CAD, przez produkcję, po walidację – zmniejszają ryzyko przekazywania prac i luki w komunikacji

- Zaawansowana wiedza w zakresie symulacji CAE: Wirtualna weryfikacja operacji kształtowania, tras przenoszenia i parametrów synchronizacji pozwala wykryć problemy zanim staną się kosztownymi fizycznymi odkryciami

- Możliwości szybkiego prototypowania: Możliwość szybkiego wytwarzania narzędzi prototypowych – czasem w ciągu zaledwie 5 dni – przyspiesza weryfikację koncepcji i skraca czas do produkcji

- Zaawansowane systemy zarządzania jakością: Certyfikaty mają znaczenie, ponieważ świadczą o systematycznym podejściu do zapewniania spójności i zapobiegania wadom

- Precyzyjne obróbki własne: Partnerzy posiadający centra frezarskie CNC, możliwości drutowego EDM oraz kompleksowe urządzenia warsztatowe oferują mniejsze dopuszczalne odchyłki i szybsze czasy realizacji

- Wsparcie projektowe: Zespoły biegłe w najnowszych narzędziach CAD, które potrafią zoptymalizować Twoje projekty pod kątem łatwości produkcji, dodają wartość wykraczającą poza podstawową realizację

- Doświadczenie w podobnych zastosowaniach: Doświadczenie w zakresie blach karoseryjnych, elementów konstrukcyjnych lub Twojej specyficznej branży przekłada się na praktyczną wiedzę, która skraca krzywą uczenia

Według wskazówki branżowe dotyczące wyboru partnerów oferujących precyzyjne tłoczenie , zintegrowane procesy inżynieryjne i produkcyjne pozwalają partnerom spełniać "najbardziej ambitne harmonogramy prototypowania", oferując jednocześnie "zoptymalizowane rozwiązania produkcji prototypów, które pomagają Twojej firmie płynnie przejść od niestandardowych produktów i prototypów do pełnoskalowej produkcji."

Standardy jakościowe gwarantujące sukces realizacji układu

Dlaczego certyfikaty jakości są ważne przy wdrażaniu linii matryc tandemowych? Ponieważ dobrze wykonana forma i matryca to podstawa skutecznych operacji tłoczenia – a certyfikaty potwierdzają rzeczywiste wprowadzenie systematycznych podejść do jakości.

Wykonanie form według IATF 16949: Standard motoryzacyjny

W zastosowaniach motoryzacyjnych – gdzie najczęściej występują linie prasowe tandemowe – certyfikat IATF 16949 stanowi standard złoty. Ten globalny standard zarządzania jakością, opracowany przez Międzynarodową Grupę ds. Motoryzacji (International Automotive Task Force), zapewnia stałą jakość w całym łańcuchu dostaw przemysłu motoryzacyjnego.

Jak zauważają eksperci od jakości w branży: „gdy forma lub matryca są wykonane z dużą precyzją, mogą produkować części spójne i powtarzalne. Jest to kluczowe dla spełnienia standardów IATF dotyczących jakości i spójności.” Dla Twojej linii tandemowej oznacza to:

- Matryce działające stabilnie przez miliony cykli

- Dokumentowane kontrole jakości na każdym etapie procesu produkcyjnego

- Śledzenie pochodzenia materiałów i procesów

- Systematyczne podejście do zapobiegania wadom, a nie ich wykrywania

Jak symulacja CAE zapewnia wyniki bez wad

Nowoczesna analiza matryc do symulacji tłoczenia metodą CAE przekształciła sposób, w jaki osiągane są poprawne wyniki od pierwszego podejścia. Zamiast odkrywać problemy z kształtowaniem podczas fizycznego uruchamiania – kiedy zmiany są kosztowne i czasochłonne – symulacja identyfikuje problemy wirtualnie.

Według badania symulacyjne kształtowania , kompleksowa analiza tłoczenia obejmuje cały proces: "od blachy lub półfabrykatu, takiego jak stopy stalowe i aluminium", aż po końcowe formowanie, przy czym symulacja potwierdza, że matryce "zostały zaprojektowane tak, aby pasować do prasy" i wyprodukują "pożądany kształt elementu."

W przypadku układów liniowych tandemowych symulacja weryfikuje:

- Możliwość formowania na każdej stacji

- Przepływ materiału i prognozy odbicia sprężystego

- Wykrywanie interferencji podczas przenoszenia

- Weryfikacja synchronizacji czasu

Szybkie prototypowanie: weryfikacja koncepcji przed ich zaakceptowaniem

Jedną z najcenniejszych możliwości w nowoczesnej produkcji matryc jest prototypowanie szybkie – zdolność do szybkiego wytwarzania funkcjonalnych narzędzi prototypowych w celu fizycznej weryfikacji przed przejściem na pełne narzędzia produkcyjne.

Ma to znaczenie przy wdrażaniu linii tandemowej, ponieważ koncepcje układu często opierają się na założeniach dotyczących zachowania części, sposobu przemieszczania ich między stanowiskami oraz interakcji stacji, które korzystają z potwierdzenia fizycznego. Możliwości szybkiego prototypowania pozwalają Ci:

- Testować rzeczywistą geometrię części w kolejnych etapach kształtowania

- Weryfikować pozycjonowanie chwytaków i projekt rowków omijania

- Potwierdzać, że zachowanie materiału odpowiada prognozom z symulacji

- Wykrywać potencjalne problemy jakościowe przed inwestycją w narzędzia produkcyjne

Partnerstwo dla sukcesu: Przykład praktyczny

Jak w praktyce wygląda skuteczne partnerstwo inżynieryjne? Rozważ producentów łączących certyfikat IATF 16949 z zaawansowanymi możliwościami symulacji CAE oraz kompleksową wiedzą z zakresu projektowania form

Shaoyi reprezentuje to zintegrowane podejście do partnerstwa w zakresie projektowania matryc tłocznych. Ich precyzyjne rozwiązania w zakresie matryc tłocznych pokazują, co jest możliwe, gdy systemy jakości, możliwości symulacji i doświadczenie produkcyjne się ze sobą łączą. Osiągając współczynnik akceptacji za pierwszym razem na poziomie 93%, potwierdzili, że ugruntowane procesy inżynieryjne gwarantują przewidywalne wyniki – dokładnie takie, jakich wymaga implementacja linii tandemowej.

Ich możliwości obejmują cały cykl życia produktu: od wstępnego konsultingu projektowego, przez szybkie prototypowanie (dostępne już w ciągu 5 dni), po produkcję seryjną. Dla producentów rozważających układ linii tandemowych, tego rodzaju kompleksowe wsparcie oznacza odpowiedzialność pojedynczego dostawcy zamiast koordynowania działań wielu podmiotów.

Możesz zapoznać się z ich możliwościami w zakresie produkcji matryc tłocznych dla przemysłu motoryzacyjnego na https://www.shao-yi.com/automotive-stamping-dies/– warto przejrzeć ten materiał podczas oceny potencjalnych partnerów technicznych dla Twojego projektu układu.

Twoja droga naprzód

Pomyślne rozmieszczenie linii tłoczników nie polega wyłącznie na zrozumieniu wymagań technicznych – choć ta podstawa jest niezbędna. Chodzi o przekształcenie tej wiedzy w rzeczywiste wyniki poprzez dyscyplinowaną inżynierię, zweryfikowane narzędzia oraz sprawdzone systemy jakości.

Niezależnie od tego, czy planujesz nową instalację, czy optymalizację istniejącej linii, zasady przedstawione w tym przewodniku stanowią dla Ciebie ramy: podstawy ustanawiające kontekst, kryteria decyzyjne gwarantujące odpowiednią konfigurację, wymagania synchronizacji i czasowania umożliwiające skoordynowaną pracę, planowanie wymiarowe wspierające wdrożenie, mechanizmy transferowe skutecznie łączące stanowiska, procesy projektowe weryfikujące koncepcje oraz metody rozwiązywania problemów pozwalające przezwyciężyć nieuniknione wyzwania.

Ostatni element? Odpowiedni partner inżynieryjny, który połączy wszystkie te elementy w gotową do produkcji rzeczywistość. Wybierz roztropnie, a układ linii tłoczysk tandemowych stanie się tym, czym powinien być: przewagą konkurencyjną zapewniającą wysokiej jakości części, elastyczność produkcji oraz wydajność operacyjną na lata naprzód.

Często zadawane pytania dotyczące układu linii tłoczysk tandemowych

1. Co to jest linia tandemowa w tłoczeniu metalu?

Linia tandemowa to strategiczne ustawienie wielu pras wykonujących pojedyncze operacje, ułożonych kolejno, gdzie detal przemieszcza się między stanowiskami do kolejnych operacji kształtowania. Każda prasa wykonuje oddzielną operację, przy czym prasy są zazwyczaj zsynchronizowane pod kątem 60 stopni różnicy w cyklach suwu. Linie tandemowe są głównie stosowane do produkcji dużych paneli karoserii samochodowych, takich jak drzwi, maski i błotniki, wymagających wielu etapów formowania oraz precyzyjnej kontroli jakości na każdym stanowisku.

2. Jaka jest różnica między linią transferową a linią pras tandemowych?

Matryce transferowe konsolidują wiele operacji w jednej ramie prasy, wykorzystując szyny wewnętrzne do przemieszczania elementów w stałych odstępach skoku, pracując z prędkością 20–30 uderzeń na minutę. Linie tandemowe używają oddzielnych pras do każdej operacji, a elementy są przekazywane między stacjami za pomocą mechanizmów szuflowych, belek chodzących lub robotów, zazwyczaj działając z prędkością 10–15 uderzeń na minutę. Konfiguracje tandemowe oferują lepszą elastyczność przy dużych elementach, łatwiejszą konserwację matryc oraz niezależną kontrolę procesu, podczas gdy matryce transferowe zapewniają bardziej kompaktową konstrukcję i szybsze cykle dla elementów średniej wielkości.

3. Jakie są składowe matrycy tłoczarskiej stosowanej w liniach tandemowych?

Wykrojniki w liniach tandemowych składają się z górnych wykrojników (zamocowanych na suwnicy prasy) i dolnych wykrojników (przymocowanych do stołu roboczego za pomocą płyt dociskowych i śrub). Do elementów krytycznych należą nacięcia obejściowe, które zapewniają luz dla chwytaków transferowych, kanały spustowe do usuwania odpadów oraz strefy dostępu chwytaków dla ssawk lub chwytaków mechanicznych. Każdy wykrojnik musi być zaprojektowany z wymiarami gabarytowymi pozwalającymi na ruchy automatyzacji oraz cechami pozycjonowania gwarantującymi stałą orientację części podczas transferu.

4. Jak obliczyć odległość między prasami przy układaniu linii tandemowej?

Odległości pomiędzy środkami pras zależą od wybranego mechanizmu transferowego. Transfery robotowe sześciu lub siedmiu osi wymagają rozstawu 6–10 metrów, podczas gdy proste konfiguracje siedmioosiowe potrzebują 5,5–7,5 metra. Aby obliczyć odległość, rozpocznij od wymiarów footprintu prasy, dodaj wymagania przestrzeni transferowej oraz bezpieczne odstępy, a następnie sprawdź, czy czas przejazdu transferu przy wybranych odległościach mieści się w oknach czasowych synchronizacji. W alokacji powierzchni podłogowej uwzględnij korytarze serwisowe, trasy wymiany stempli oraz drogi transportu odpadów.

5. Co powoduje problemy z synchronizacją w liniach pras tandemowych?

Problemy z synchronizacją wynikają zazwyczaj ze zmian czasowych w relacjach faz tłoków, błędów czasowych serwosterowania w programowalnych systemach transferowych, zużycia przysawek próżniowych powodującego zmniejszenie siły chwytu lub niewłaściwego ustawienia chwytaków prowadzącego do niestabilnego pobierania elementów. Objawy ostrzegawcze to okresowe błędy transferu, powtarzające się błędy pozycjonowania na stacjach dalszych, wydłużony czas cyklu oraz nietypowe dźwięki podczas transferu. Systematyczna diagnostyka obejmuje sprawdzenie, czy każdy tłok osiąga dolny martwy punkt z określonymi przesunięciami fazowymi oraz kontrolę komponentów mechanizmu transferowego pod kątem zużycia lub niewyważenia.

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —