Wichtige Anzeichen eines defekten Stanzstahl-Längslenkers

Zusammenfassung

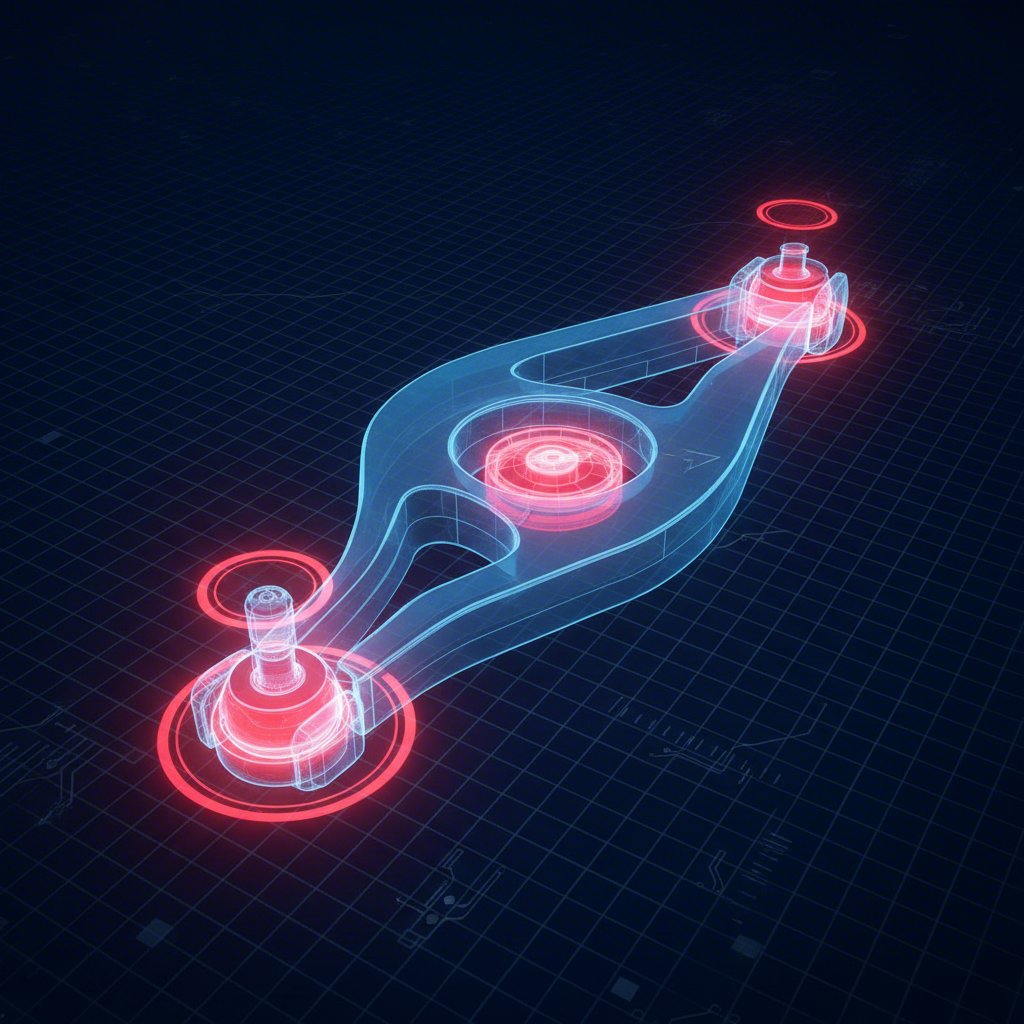

Ein versagender Stahlblech-Querlenker macht sich typischerweise durch deutliche Warnhinweise bemerkbar. Zu den häufigsten Symptomen eines defekten Stahlblech-Querlenkers gehören poltern oder Klopfgeräusche bei Fahrten über Unebenheiten unsichere oder wandernde Lenkung , die ständige Korrektur erfordern, übermäßige vibrationen, die am Lenkrad spürbar sind , und ungleichmäßiger oder vorzeitiger Reifenverschleiß . Diese Symptome deuten darauf hin, dass kritische Komponenten wie Lagerbuchsen oder Kugelgelenke verschlissen oder der Querlenker selbst beschädigt ist, wodurch die Sicherheit und das Fahrverhalten Ihres Fahrzeugs beeinträchtigt werden.

Die charakteristischen Anzeichen: Häufige Symptome eines defekten Querlenkers

Der Querlenker ist eine entscheidende Verbindung im Fahrwerksystem Ihres Fahrzeugs und verbindet die Radschalen und die Lenkkopplung mit dem Fahrzeugrahmen. Er bewegt sich auf flexiblen Buchsen und ermöglicht so, dass sich das Rad bei Unebenheiten der Fahrbahn auf und ab bewegen kann, während gleichzeitig die Stabilität erhalten bleibt. Wenn ein Querlenker oder seine Komponenten ausfallen, sind die Symptome oft nicht zu übersehen. Die Beachtung dieser Anzeichen ist entscheidend für Ihre Sicherheit und kann verhindern, dass an Ihrem Fahrzeug weitergehender Schaden entsteht.

Eines der am häufigsten gemeldeten Symptome ist ein deutliches klapper- oder Knackgeräusch . Dieses Geräusch macht sich besonders bemerkbar, wenn über Unebenheiten, Schlaglöcher gefahren wird oder sogar beim Beschleunigen und Bremsen. Wie von Experten bei NAPA Auto Parts beschrieben, entsteht dieses Geräusch, wenn abgenutzte Buchsen übermäßige Bewegung zulassen, wodurch der metallene Querlenker gegen den Rahmen oder andere Bauteile schlägt. Es ist ein deutliches Zeichen dafür, dass das Teil nicht mehr sicher gehalten wird.

Ein weiterer wichtiger Hinweis ist eine Veränderung des Lenkverhaltens Ihres Fahrzeugs. Sie könnten das sogenannte spurwandern bemerken, bei dem das Fahrzeug zur Seite zieht und Sie ständig kleine Korrekturen vornehmen müssen, um geradeaus zu fahren. Dies geschieht, weil ein lockerer Querlenker die Radspur nicht mehr stabil halten kann. Die Lenkung kann sich außerdem träge oder weniger präzise anfühlen, da das Spiel in den abgenutzten Teilen einen Teil der Lenkbewegung absorbiert, bevor sie die Reifen erreicht.

Vibrationen sind ebenfalls ein häufiges Problem. Ein defekter Querlenker kann ein Vibrieren oder Zittern verursachen, das Sie am Lenkrad spüren können. Laut MOOG Parts , kann sich diese Vibration je nach Geschwindigkeit in der Intensität verändern und ist oft ein Zeichen für verschlissene Buchsen oder ein ausfallendes Kugelgelenk. Abschließend sollten Sie Ihre Reifen genau prüfen. Ein defekter Querlenker stört die Radausrichtung, was zu ungleichmäßigem und schnellem Reifenverschleiß führt, typischerweise an den inneren oder äußeren Kanten. Wenn Sie dieses Muster erkennen, ist dies ein deutlicher Hinweis darauf, dass eine Aufhängungskomponente beschädigt ist.

Es ist hilfreich, zwischen den beiden Hauptausfallstellen eines Querlenkers zu unterscheiden:

- Defekte Buchsen: Abgenutzte Gummibuchsen sind das häufigste Problem. Sie verursachen typischerweise Klappergeräusche, insbesondere beim Bremsen oder Beschleunigen, da sich der Lenker in seiner Halterung vor und zurück bewegt.

- Defekte Kugelgelenke: Das Kugelgelenk verbindet den Arm mit dem Lenkknöchel. Ein versagendes Kugelgewinnungsgerät erzeugt beim Drehen oft ein Klick- oder Knallgeräusch und trägt wesentlich zum Steuerwandern und einem lockeren Gefühl bei.

Der Unterschied zwischen "gestempeltem Stahl" und "stempeltem Stahl": Einzigartige Ausfallmodi und Risiken

Nicht alle Steuerungen sind gleich. Viele moderne Fahrzeuge verwenden gestempelte Stahlsteuerungsarme, die durch Stempeln und Schweißen von Stahlblechen hergestellt werden. Diese Methode ist kostengünstig und leicht, schafft aber auch spezifische Schwachstellen im Vergleich zu schwereren, massivem Gusseisen oder geschmiedeten Aluminiumarmen. Diese Unterschiede zu verstehen, ist der Schlüssel zur genauen Diagnose möglicher Probleme.

Die Hauptschwäche eines aus Stahlblech gestanzten Designs liegt in seiner hohlen, geschweißten Konstruktion. Obwohl diese Arme unter normalen vertikalen Belastungen stabil sind, können sie anfällig für Verbiegungen, Beulen oder Risse durch seitliche Aufpralle sein, wie beispielsweise beim Anstoßen an einen Bordstein oder beim Überfahren einer tiefen Schlaglochstelle in einem Winkel. Auch die Schweißnähte können zu Schwachstellen werden, insbesondere wenn Korrosion einsetzt. Langfristig kann Streusalz und Feuchtigkeit zu Durchrostungen entlang dieser Nähte führen, wodurch die strukturelle Integrität des Bauteils erheblich beeinträchtigt wird.

Die Qualität des Stanzens und Schweißens ist entscheidend für die Haltbarkeit und Sicherheit des Bauteils. Für Automobilhersteller ist es daher von größter Bedeutung, mit Spezialisten im Bereich Metallstanzen zusammenzuarbeiten, um sicherzustellen, dass die Teile jahrelangen Belastungen standhalten. Zum Beispiel spezialisieren sich Unternehmen wie Shaoyi (Ningbo) Metal Technology Co., Ltd. auf die Herstellung hochpräziser, langlebiger Komponenten – von Prototypen bis zur Serienproduktion – und erfüllen dabei strenge Industriestandards wie IATF 16949. Diese Fertigungsexpertise trägt dazu bei, die inhärenten Risiken von gestanzten Designs zu verringern.

Hier ist ein Vergleich gängiger Querlenkertypen:

| Funktion | Gestanzter Stahl | Gusseisen / Geschmiedetes Aluminium |

|---|---|---|

| Vorteile | Leichtgewichtig, geringere Herstellungskosten. | Extrem stabil, hochgradig langlebig, widerstandsfähig gegen Verbiegung. |

| Nachteile | Anfällig für Verbiegung durch Seitenaufprall, kann an den Nähten rosten. | Schwerer, teurer in der Herstellung. |

| Häufige Fehlerursache | Verbiegung, Schweißnahtrisse, Lagerverschleiß. | Vorwiegend Verschleiß der Buchsen und des Kugelgelenks; der Lenker selbst versagt selten. |

Bei der Inspektion eines gestanzten Stahl-Querlenkers achten Sie sorgfältig auf Anzeichen von Verbiegung oder Verformung. Prüfen Sie die Schweißnähte auf Risse oder starke Rostbildung. Selbst wenn die Buchsen und das Kugelgelenk intakt erscheinen, führt ein verbogener Lenker zu einer dauerhaften Fehlausrichtung der Fahrzeugachse und muss ersetzt werden.

Ursachen und langfristige Risiken des Ignorierens von Ausfällen

Ein Ausfall des Querlenkers geschieht nicht ohne Grund. In der Regel ist er das Ergebnis von aufgelaufenen Belastungen und Umwelteinflüssen. Die häufigste Ursache ist einfach Verschleiß; die Gummilager reißen und verschleißen nach Zehntausenden von Kilometern, und die Kugelgelenke verlieren ihre Schmierung und weisen zunehmend Spiel auf. Andere Faktoren können diesen Prozess jedoch erheblich beschleunigen.

Die Hauptursachen für vorzeitigen Ausfall sind:

- Schlagbeschädigung: Das Überfahren von Schlaglöchern, Bordsteinen oder Straßenschutt ist eine der häufigsten Schadensursachen. Ein starker Aufprall kann einen gestanzten Stahlquerverbinder verbiegen oder ein Lager zerreißen und so sofortige Probleme verursachen.

- Korrosion: In Regionen, in denen im Winter Streusalz verwendet wird, ist Rost ein großer Feind. Er kann den Stahlkörper des Querlenkers, insbesondere an den Schweißnähten, angreifen und ihn bis zum Bruchpunkt schwächen.

- Verschleiß von Komponenten: Der Ausfall erfolgt oft als Kettenreaktion. Wenn ein Lager verschleißt, erhöht dies die Belastung für das Kugelgelenk und den Querlenker selbst und beschleunigt so den Verschleiß aller verbundenen Teile.

Die Symptome eines defekten Querlenkers zu ignorieren, ist äußerst gefährlich. Eine verschlissene Komponente, die heute nur Geräusche verursacht, könnte morgen zu einem katastrophalen Ausfall führen. Die langfristigen Risiken sind gravierend und können einen vollständigen Verlust der Lenkkontrolle beinhalten, falls ein Kugelgelenk abreißt oder der Querlenker sich vom Rahmen löst. Dies kann zum Einklappen des Rades führen und einen schweren Unfall verursachen. Selbst vor einem solchen Ausfall führt ein defekter Querlenker zu schnellem und kostspieligem Reifenverschleiß und belastet andere Fahrwerkteile wie Federbeine, Stoßdämpfer und die Lenkracke. Aus Sicherheitsgründen ist es entscheidend, Ihr Fahrzeug bei ersten Anzeichen von Problemen von einer qualifizierten Fachwerkstatt überprüfen zu lassen.

Häufig gestellte Fragen

1. Welche Symptome weisen defekte Buchsen des Schwingarms auf?

Während der Begriff „Schwinge“ bei Motorrädern am gebräuchlichsten ist, sind bei Autos Querlenker die Hauptverbindungselemente der Aufhängung, die die Räder mit dem Fahrzeugrahmen verbinden. Die Symptome defekter Buchsen sind nahezu identisch: ein Poltern oder Klopfen über Unebenheiten, ein Gefühl von Spiel oder Instabilität im hinteren Bereich des Fahrzeugs sowie ungleichmäßiger Reifenverschleiß. Die Geräusche entstehen, wenn die Metallhülse innerhalb der Buchse mit der Aufhängungsbefestigung in Kontakt kommt, während der Gummi abbaut.

2. Welche häufigen Probleme treten beim Austausch von Querlenkerbuchsen auf?

Das Austauschen nur der Buchsen kann schwierig sein. Ein häufiges Problem ist die Herausforderung, die alte Buchse aus dem Querlenker zu entfernen, was oft eine spezielle hydraulische Presse oder ein Buchsenentfernungswerkzeug erfordert. Wird die neue Buchse nicht korrekt eingepresst, kann sie beschädigt werden oder vorzeitig ausfallen. Ein weiteres Problem besteht darin, dass bei längerem Verschleiß der alten Buchse die Aufnahmelochung des Querlenkers übermäßig verschlissen sein kann, wodurch ein fester Sitz der neuen Buchse erschwert wird. Aus diesen Gründen entscheiden sich viele Mechaniker und Heimwerker dafür, die gesamte Querlenkereinheit auszutauschen, die bereits mit neuen Buchsen und einem neuen Kugelgelenk vormontiert ist.

Kleine Chargen, hohe Standards. Unser Rapid-Prototyping-Dienst macht die Validierung schneller und einfacher —

Kleine Chargen, hohe Standards. Unser Rapid-Prototyping-Dienst macht die Validierung schneller und einfacher —