Laser Cutting Service Metal Pricing Exposed: What Actually Drives Your Quote

Understanding Metal Laser Cutting Technology

Ever wondered how manufacturers create those impossibly precise metal components you see in everything from smartphones to spacecraft? The answer often lies in one of modern manufacturing's most transformative technologies. Before you request a quote or compare prices, understanding exactly how laser cutting service metal works gives you the knowledge to make smarter decisions about your projects.

What Exactly Is Metal Laser Cutting

At its core, a metal laser cutter uses concentrated light energy to slice through steel, aluminum, and other metals with remarkable accuracy. Unlike traditional cutting methods that rely on physical contact, this process harnesses a high-power laser beam directed through computer numerical control (CNC) systems to follow precise programmed paths.

Laser cutting is a thermal process where a focused laser beam melts, burns, or vaporizes material along a programmed path, leaving behind a high-quality surface finished edge with minimal post-processing required.

This technology has revolutionized how industries approach metal fabrication. Whether you're searching for laser etching services near me or need complex structural components, understanding this foundation helps you communicate more effectively with service providers.

The Science Behind Precision Metal Cuts

How does light cut through solid metal? The physics is fascinating yet straightforward. According to TWI Global, the laser beam is created by stimulating lasing materials through electrical discharges inside a closed container. This energy is amplified by internal reflection until it escapes as a stream of coherent monochromatic light.

Here's what happens during cutting laser metal operations:

- The focused beam reaches the metal surface at temperatures exceeding the material's melting point

- The intense heat instantly liquefies or vaporizes the metal along the cut path

- Assist gases (typically oxygen or nitrogen) blow away molten material

- A clean, precise kerf remains with minimal heat-affected zones

At its narrowest point, a laser beam typically measures under 0.0125 inches (0.32 mm) in diameter. However, kerf widths as small as 0.004 inches (0.10mm) are achievable depending on material thickness. This precision is why laser cutting metal has become the gold standard for intricate designs.

From Light Beam to Finished Part

Understanding the journey from digital design to finished component demystifies what you're actually paying for when you order parts. The process begins when your CAD file translates into CNC instructions that guide the laser cutter for metal along exact coordinates.

When cuts need to start away from the material's edge, a piercing process initiates the work. A high-power pulsed laser creates an entry point—this can take 5-15 seconds to burn through a half-inch-thick stainless steel sheet, according to industry specifications from TWI.

The entire laser cutting cutting sequence happens rapidly once piercing completes. Modern systems can achieve cutting speeds ranging from 100 to over 1,000 inches per minute on thin sheet metals, though thicker materials require slower, more controlled passes. This speed-versus-precision balance directly impacts both quality and cost—a relationship we'll explore throughout this guide.

Now that you understand what this technology actually does, you're better equipped to evaluate quotes, ask informed questions, and recognize when a provider truly understands their craft versus simply operating equipment.

CO2 vs Fiber vs Nd YAG Laser Systems Explained

Here's something most laser cutting service providers won't tell you: the type of laser technology they use directly impacts your quote, part quality, and production timeline. Yet competitors rarely explain these differences. Understanding whether your project calls for a CO2, fiber, or Nd:YAG laser cutting machine for metal gives you negotiating power and helps you choose the right provider for your specific needs.

CO2 Lasers and Their Strengths

CO2 lasers have been the workhorses of metal cutting for decades. These systems use a gas mixture primarily composed of carbon dioxide, nitrogen, and helium to generate their cutting beam. When an electric current excites the nitrogen molecules, they transfer energy to the CO2 molecules, which then emit light in the infrared spectrum at a wavelength of 10,600 nm.

What makes a co2 laser cut metal machine particularly valuable? Consider these characteristics:

- Excellent performance on thicker materials, especially mild steel and stainless steel

- Superior edge quality on materials over 0.25 inches thick

- Versatility across both metals and non-metals when needed

- Cutting speeds up to 1,200 mm/s on compatible materials

- Power outputs ranging from 30W for light work up to 400W for industrial applications

However, CO2 systems require regular maintenance, including replacement of gas tubes and mirror alignment. Their energy efficiency sits around 10-20%, meaning higher operational costs compared to newer technologies. For projects involving highly reflective metals like copper or aluminum, CO2 lasers struggle without specialized coatings or treatments.

Why Fiber Lasers Dominate Modern Shops

Walk into any cutting-edge fabrication facility today, and you'll likely find fiber laser systems running the show. These metal cutting laser machines use glass fiber doped with rare earth elements (typically ytterbium) as their gain medium, producing a wavelength of 1064 nm that metals absorb more efficiently.

The advantages explain their rapid adoption across industries:

- Superior performance on reflective metals including aluminum, copper, and brass

- Cutting speeds 2-3 times faster than CO2 on thin sheet metals

- Energy efficiency exceeding 30%, dramatically reducing operating costs

- Minimal maintenance with lifespans reaching 100,000 hours

- Compact footprint ideal for space-constrained facilities

- Extremely high precision for intricate designs

When evaluating a sheet metal laser cutting machine for production work, fiber technology often delivers the best value proposition. The laser beam is generated and guided through an integrated flexible medium, allowing better delivery to the target location without the complex mirror systems CO2 lasers require.

That said, fiber lasers have limitations. They're primarily designed for metal fabrication and won't perform well on non-metal materials. The initial equipment investment runs higher than CO2 systems, though lower operating costs often offset this over time. For hobbyists considering a metal laser cutting machine for home use, entry-level fiber markers are becoming more affordable, though industrial-grade cutters remain a significant investment.

Nd:YAG Lasers for Specialized Applications

Nd:YAG (neodymium-doped yttrium aluminum garnet) lasers occupy a specialized niche in the cnc laser cutting landscape. These solid-state systems generate pulsed laser beams at 1.06 μm wavelength, making them particularly suited for applications requiring extreme precision and controlled energy delivery.

According to STYLECNC's technical comparison, Nd:YAG systems excel where other technologies fall short:

- Micro-cutting with exceptional detail on thin materials

- Medical device manufacturing requiring surgical precision

- Aerospace components with strict tolerance requirements

- Processing ceramics, plastics, and other non-metals alongside metals

- Applications requiring pulsed operation for minimal heat-affected zones

The trade-offs? Nd:YAG lasers have lower photoelectric conversion efficiency, making them more costly to operate. The crystal rod creates internal temperature gradients during operation, limiting average power output. These systems also demand more complex maintenance, including flash lamp replacements, and require dedicated optical paths to function properly.

Choosing the Right Laser Technology

Your project requirements should drive technology selection, not just what equipment a provider happens to own. Here's a comprehensive comparison to guide your decisions:

| Factor | CO2 Laser | Fiber Laser | Nd:YAG Laser |

|---|---|---|---|

| Material Compatibility | Steel, stainless, wood, acrylic, glass | Steel, aluminum, copper, brass, titanium | Metals, ceramics, plastics, specialty alloys |

| Thickness Range | Up to 1" steel; excels on thick materials | Best under 0.5"; struggles with very thick stock | Thin materials; precision work under 0.25" |

| Cutting Speed | Moderate (up to 1,200 mm/s) | Fastest (2-3x faster than CO2 on thin metals) | Slower; optimized for precision over speed |

| Operating Costs | Higher (10-20% efficiency, regular maintenance) | Lowest (30%+ efficiency, minimal maintenance) | Highest (complex maintenance, flash lamp replacement) |

| Best Applications | Thick steel cutting, mixed-material shops | High-volume metal production, reflective metals | Medical devices, aerospace, micro-cutting |

| Lifespan | ~20,000 hours (tube replacement needed) | ~100,000 hours | Variable (depends on flash lamp cycles) |

When requesting quotes for laser cutting machine metal services, ask providers which technology they'll use for your project. A shop using fiber lasers for aluminum work will deliver faster turnaround and cleaner edges than one forcing CO2 equipment to handle reflective materials. Understanding these distinctions transforms you from a passive customer into an informed partner in the manufacturing process.

With laser technology fundamentals covered, the next critical factor affecting your quote involves the specific metals you're cutting and their thickness limitations—variables that determine which laser type is even viable for your project.

Compatible Metals and Thickness Specifications

You've selected your laser technology—but here's what really determines whether your project succeeds or fails: the specific metal you're cutting and how thick it is. Sounds straightforward? The reality is more nuanced. Each metal behaves differently under that intense laser beam, and thickness limitations vary dramatically based on material properties and laser power. Understanding these variables before you request a quote saves you from costly surprises and helps you optimize designs for both quality and budget.

Steel and Stainless Steel Cutting Capabilities

Steel remains the most commonly processed material in metal laser cutting operations, and for good reason. Carbon steel absorbs laser energy efficiently, producing clean cuts with minimal complications. Laser cutting steel delivers predictable results across a wide range of thicknesses, making it the baseline against which other materials are measured.

According to HGTECH's cutting thickness guide, here's what different power levels can achieve with carbon steel:

- 500W laser: Maximum 6mm thickness

- 1000W laser: Maximum 10mm thickness

- 2000W laser: Maximum 16mm thickness

- 3000W laser: Maximum 20mm thickness

- 10,000W+ lasers: Carbon steel up to 40mm with bright surface cutting at 18-20mm/s

Stainless steel laser cutting requires more power for equivalent thicknesses due to the material's reflective properties and chromium content. A 3000W laser maxes out at 10mm for stainless, compared to 20mm for carbon steel. However, when you laser cut stainless steel properly, the results are exceptional—clean edges, minimal oxidation, and superior corrosion resistance in the finished part.

Material grades matter significantly here. Austenitic stainless steels like 304 and 316 are popular choices because they balance cuttability with corrosion resistance. According to Accurl's stainless steel guide, typical cutting tolerances range from ±0.1mm to ±0.2mm for thin materials, widening to ±0.3mm to ±0.5mm for thicker sections. These specifications directly impact achievable precision in your final parts.

Working with Reflective Metals

Here's where things get interesting—and where many providers struggle. Reflective metals like aluminum, copper, and brass present unique challenges because they bounce laser energy away from the cutting zone. This isn't just an efficiency problem; reflected beams can damage equipment if not properly managed.

Aluminium laser cutting has become increasingly viable with fiber laser technology. The 1064nm wavelength of fiber lasers is absorbed more readily by aluminum than the 10,600nm wavelength of CO2 systems. Still, aluminum laser cutting demands higher power levels:

- 500W laser: Maximum 2mm aluminum

- 1000W laser: Maximum 3mm aluminum

- 2000W laser: Maximum 5mm aluminum

- 3000W laser: Maximum 8mm aluminum

- 10,000W laser: Aluminum alloy up to 40mm

Copper and brass push these challenges even further. Both metals have excellent thermal conductivity—they dissipate heat faster than the laser can concentrate it. According to MetalsCut4U, advanced laser metal cutting equipment handles copper effectively, but expect thickness maximums around 2-8mm depending on power levels.

Titanium occupies a unique position. Despite being one of the strongest metals, its relatively lower thermal conductivity makes it surprisingly cooperative with laser cutting of metal sheets. Aerospace and medical industries rely heavily on titanium laser cutting for components requiring exceptional strength-to-weight ratios.

Material Thickness Guidelines by Metal Type

When planning your project, use these guidelines to match material choices with realistic thickness expectations:

| Metal Type | 500W Max | 1000W Max | 2000W Max | 3000W Max | Best Laser Type |

|---|---|---|---|---|---|

| Carbon Steel | 6mm | 10mm | 16mm | 20mm | CO2 or Fiber |

| Stainless Steel | 3mm | 5mm | 8mm | 10mm | Fiber preferred |

| Aluminum | 2mm | 3mm | 5mm | 8mm | Fiber required |

| Copper | 2mm | 3mm | 5mm | 8mm | Fiber required |

| Brass | 2mm | 3mm | 5mm | 8mm | Fiber required |

| Titanium | 3mm | 5mm | 8mm | 10mm | Fiber preferred |

One critical distinction often overlooked: maximum cutting thickness isn't the same as quality cutting thickness. HGTECH notes that if you need a bright, smooth surface finish, reduce these maximums by approximately 60%. A 3000W laser might cut 12mm stainless steel, but achieving a quality bright-surface finish requires staying under that threshold.

When selecting materials for your project, consider these key factors:

- Tolerance requirements: Thinner materials yield tighter tolerances (±0.1mm versus ±0.5mm for thick sections)

- Edge quality needs: Reflective metals may require nitrogen assist gas for oxide-free edges

- Post-processing plans: Some material-thickness combinations produce edges needing minimal finishing

- Budget constraints: Thicker cuts require more machine time and higher power, increasing costs

- Provider capabilities: Not all shops have high-power lasers for maximum thicknesses

Understanding these material-specific behaviors transforms how you approach project planning. Rather than simply specifying "stainless steel," you can now ask informed questions about grades, thickness limitations, and expected tolerances—details that directly influence both quote accuracy and final part quality.

With material selection covered, how does laser cutting compare against alternative methods like waterjet, plasma, or CNC routing? The answer depends entirely on your specific project requirements.

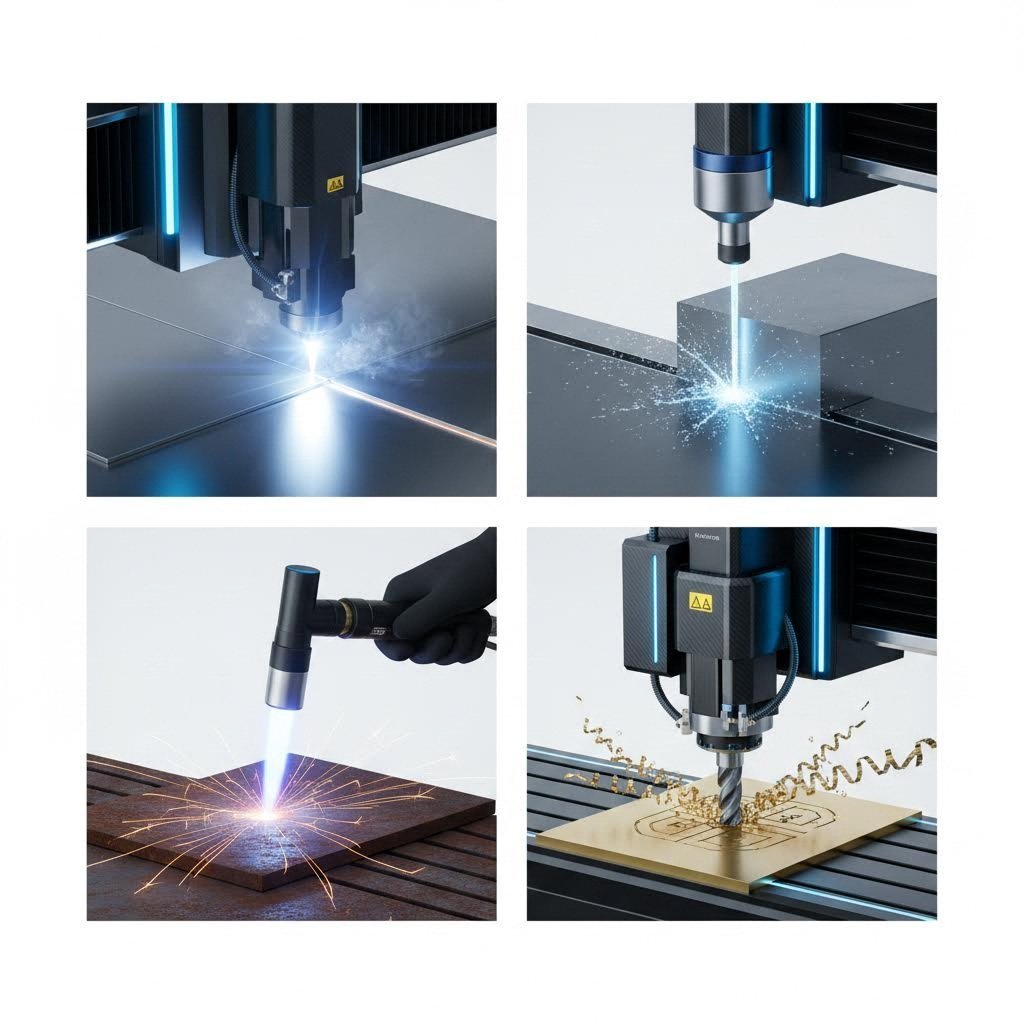

Laser Cutting vs Waterjet Plasma and CNC Methods

So you know you need metal parts cut—but is laser actually the right choice? Here's where most provider websites fail you. They'll mention "laser vs plasma" in a headline, then immediately pivot to a quote button without explaining anything useful. The truth is, each cutting technology genuinely excels in specific scenarios, and choosing wrong can cost you thousands in rework, wasted material, or subpar results.

Let's break down what actually matters when comparing precision laser cutting against waterjet, plasma, and CNC routing—covering the real-world factors that impact your project outcomes and bottom line.

Laser vs Waterjet for Precision Work

When precision tops your priority list, the laser cutting and waterjet comparison gets interesting. Both technologies deliver exceptional accuracy, but they achieve it through fundamentally different approaches—and those differences matter for your specific application.

A metal cutting laser uses concentrated light energy, reaching temperatures that instantly vaporize material along programmed paths. According to Wurth Machinery's testing, laser cutting produces the tightest tolerances of any thermal cutting method:

- Precision tolerances as tight as ±0.001" on thin materials

- Exceptionally clean edges requiring minimal post-processing

- Superior performance for intricate designs and small holes

- Best results on materials under 0.25" thick

Waterjet cutting takes a completely different approach. High-pressure water (up to 90,000 PSI) mixed with abrasive particles erodes material along the cut path. This cold-cutting process eliminates heat-affected zones entirely—a critical advantage for certain applications:

- No thermal distortion or material hardening

- Cuts virtually any material including stone, glass, and composites

- Maintains material integrity for heat-sensitive alloys

- Tolerances typically around ±0.005" to ±0.01"

Here's the honest trade-off: waterjet systems operate at 5-20 inches per minute, while cutting laser technology achieves speeds exceeding 100 inches per minute on comparable materials. For high-volume production runs, this speed difference translates directly into cost per part. However, when you absolutely cannot introduce heat into the workpiece—think aerospace components or pre-hardened tool steels—waterjet becomes the only viable option.

When Plasma Cutting Makes More Sense

Searching for "plasma cutting near me" instead of laser services? You might be onto something. Plasma cutting uses an accelerated jet of ionized gas reaching temperatures up to 45,000°F to blast through conductive metals. While it lacks the surgical precision of laser, plasma dominates specific applications where speed and cost efficiency matter most.

According to StarLab CNC's 2025 guide, plasma cutting offers compelling advantages for the right projects:

- Cutting speeds exceeding 100 inches per minute on 0.5" steel

- Excellent performance on materials from 0.018" to 2" thick

- Operating costs roughly 40-60% lower than laser per foot of cut

- Complete plasma systems starting around $90,000 versus $195,000+ for comparable waterjet

- Superior bevel cutting capabilities for weld preparation

The thickness comparison is particularly revealing. While laser cutting slows dramatically on materials over 0.25" thick, plasma maintains consistent speeds through 1" steel and beyond. For structural steel fabrication, heavy equipment manufacturing, or shipbuilding applications, plasma delivers unmatched value.

What about edge quality? Modern high-definition plasma systems have closed the gap significantly. According to industry testing, HD plasma achieves edge quality rivaling laser on materials over 0.25" thick while cutting substantially faster. Tolerances of ±0.010" to ±0.015" satisfy most structural and industrial applications, though they won't match the ±0.001" precision that laser cutting delivers on thin sheet work.

CNC Routing vs Laser for Your Project

CNC routing occupies a different space entirely in the metal cutting landscape. Rather than thermal or erosive cutting, routing uses rotating cutting tools to physically remove material—a subtractive machining process that offers unique capabilities alongside real limitations.

A cnc laser cutter for metal excels at 2D profile cutting with exceptional speed and edge quality. CNC routing, however, opens doors to operations that lasers simply cannot perform:

- Three-dimensional contouring and complex surface machining

- Threading, tapping, and precision hole-making

- Variable-depth pocketing and cavity creation

- Simultaneous processing of multiple part features

According to James Manufacturing's technique comparison, CNC machining offers unmatched versatility—from simple cuts to complex 3D shapes—making it highly adaptable for both prototyping and production. However, speed and cost work against routing for pure 2D cutting applications where laser or plasma would suffice.

The decision often comes down to project requirements. Need intricate 2D patterns in sheet metal? Laser wins on speed and precision. Require 3D contours, threaded holes, or complex geometries in a single setup? CNC routing becomes essential. Many sophisticated parts actually require both technologies in sequence.

Complete Cutting Method Comparison

With all four methods examined, here's the comprehensive comparison that helps you match technology to project requirements:

| Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting | CNC Routing |

|---|---|---|---|---|

| Precision Tolerance | ±0.001" to ±0.005" | ±0.005" to ±0.01" | ±0.010" to ±0.015" | ±0.001" to ±0.005" |

| Thickness Range | Best under 0.5"; max ~1" | Up to 12"+ any material | 0.018" to 2"; excels 0.5-1.5" | Varies; typically under 4" |

| Edge Finish Quality | Excellent; minimal finishing | Good; smooth but may need finishing | Good with HD; may need grinding | Excellent with proper tooling |

| Heat Distortion | Minimal heat-affected zone | None (cold cutting) | Moderate; wider HAZ | None (mechanical process) |

| Cost Per Part (Thin) | Low to moderate | Moderate to high | Low | Moderate to high |

| Cost Per Part (Thick) | High (slow cutting) | Moderate | Low | Moderate |

| Cutting Speed | Fast on thin; slow on thick | Slow (5-20 IPM) | Fast (100+ IPM on 0.5" steel) | Moderate; depends on operation |

| Ideal Applications | Electronics, medical, precision parts, thin intricate work | Aerospace, heat-sensitive materials, stone, glass | Structural steel, heavy equipment, HVAC, shipbuilding | 3D parts, complex geometries, threaded features |

Making Your Technology Decision

After examining all four methods, the "best" cutting technology depends entirely on your specific project variables. Consider these decision factors:

Choose precision laser cutting when:

- Working with thin sheet metals under 0.25" thick

- Intricate designs require tight tolerances

- Clean edges without secondary finishing matter

- Production volumes justify the operating costs

Choose waterjet when:

- Heat-affected zones are unacceptable

- Cutting non-metals or heat-sensitive alloys

- Material integrity must be preserved completely

- Cutting thick materials where laser struggles

Choose plasma when:

- Processing thick conductive metals (0.5"+ steel)

- Speed and cost efficiency outweigh precision needs

- Structural or industrial applications don't require tight tolerances

- Budget constraints favor lower operating costs

Choose CNC routing when:

- Three-dimensional features are required

- Parts need threading, tapping, or precision holes

- Complex geometries exceed 2D cutting capabilities

- Single-setup completion reduces handling costs

Many fabrication shops maintain multiple technologies precisely because no single method handles everything optimally. When evaluating providers, those offering multiple cutting capabilities can often recommend the best approach for your specific project—rather than forcing your requirements into their only available technology.

Understanding these technology trade-offs positions you to ask better questions and recognize when a quote reflects the right method for your project. Beyond cutting technology, however, another distinction significantly impacts both capability and cost: the difference between sheet metal and tube cutting services.

Sheet Metal Cutting vs Tube Cutting Services

Ever noticed how some laser cutting providers list "sheet cutting" and "tube cutting" as completely separate services? There's a reason for that division—and understanding it helps you request accurate quotes and choose the right provider for your project. These aren't interchangeable processes with minor differences. They require fundamentally different equipment, programming approaches, and expertise.

Flat Sheet Cutting Fundamentals

When you think of traditional sheet metal laser cutting, you're picturing flat sheet processing. The material lies stationary on a cutting bed while the laser head moves across programmed paths. This simplicity is actually a significant advantage—parts remain retained within the sheet from which they've been cut, regardless of thickness, material type, or the complexity of geometries obtained.

A laser cutter sheet metal system focuses on two-dimensional profile cutting with remarkable efficiency. The process follows a straightforward workflow:

- Flat sheet stock loads onto the cutting table (manually or via automated loaders)

- The laser head traverses X and Y axes following CNC-programmed paths

- Cut parts remain nested within the parent sheet until processing completes

- Finished parts are separated from the skeleton (remaining sheet material)

- Secondary operations like bending or finishing follow as needed

Material optimization in sheet work relies heavily on nesting algorithms—software that positions and rotates all parts to maximize material usage. These algorithms pack parts as close together as possible, leaving minimal waste and fitting more components per sheet. For high-volume production, sophisticated nesting can reduce material costs by 15-25% compared to inefficient layouts.

The laser sheet metal cutter approach works exceptionally well for brackets, panels, enclosures, gaskets, and virtually any flat component. If your project involves parts that start as flat profiles—even if they'll later be bent into three-dimensional shapes—sheet cutting is your starting point.

Tube and Pipe Laser Cutting Explained

Here's where things get considerably more complex. According to BLM Group's technical analysis, the first thing that distinguishes tube laser cutting services is that the material moves throughout the entire process. This fundamental difference has major consequences for both reliability and productivity.

A laser cutting machine sheet metal setup keeps workpieces stationary. Tube systems, by contrast, must continuously rotate and advance cylindrical or profiled stock through the cutting zone. This creates unique engineering challenges:

- Thin, flexible tubes tend to bend and jam without proper guidance, increasing interruption risks

- Heavy tubes apply stress through shocks and vibrations requiring mechanical robustness

- Variable profiles demand automatic adjustment of laser power for consistent cut quality

- Weld seams require power compensation where thickness isn't constant

The variety of tube profiles adds another layer of complexity. Tube laser cutting services handle far more than simple round pipes. Modern systems process:

- Round tubes: The original profile for tube cutting—consistent radius simplifies programming

- Square tubes: Require corner compensation and careful power management at flat-to-corner transitions

- Rectangular tubes: Similar to square but with varying wall distances affecting cut parameters

- Open profiles: C-channels, angles, and structural shapes with complex geometries

- Variable-thickness sections: Profiles where wall thickness changes require dynamic power adjustment

BLM Group notes that each section and shape poses challenges for correct management—from loading and handling to correctly adjusting laser power for consistently high-quality cuts. The three-dimensionality of tubes makes part compaction more complicated than sheet nesting, especially when parts differ from each other. Many meters of material can be saved when optimizing from a mediocre solution to an optimal one.

One capability unique to tube cutting: 3D bevel cutting. This involves tilting the laser beam relative to the tube surface during cutting to create chamfered holes, inclined edges, and precise joints between tubes. These features simplify welding operations downstream but require sophisticated programming and machine control.

Typical Applications by Service Type

Understanding which service applies to your project starts with recognizing common applications for each:

Sheet Metal Laser Cutting Applications:

- Electronic enclosures and chassis components

- Automotive body panels and structural brackets

- Architectural panels and decorative metalwork

- HVAC ductwork components and fittings

- Medical device housings and surgical instrument blanks

- Signage and display components

- Industrial machinery guards and covers

Tube Laser Cutting Applications:

- Furniture frames and structural supports

- Automotive exhaust systems and roll cages

- Architectural railings and structural frameworks

- Fitness equipment frames

- Agricultural machinery components

- Bicycle and motorcycle frames

- Industrial conveyor systems and material handling equipment

Combining Sheet and Tube Services

Many real-world projects don't fit neatly into one category. Imagine designing a steel equipment frame—you might need laser-cut tube sections for the structural skeleton plus sheet metal panels for enclosure sides, mounting plates, and access doors. This is where understanding both services becomes valuable.

Complete fabrication workflows often integrate multiple operations beyond just cutting:

- Bending and forming: Flat sheet parts frequently require brake pressing into three-dimensional shapes

- Welding and assembly: Cut tube sections and sheet components join together into finished structures

- Surface finishing: Powder coating, painting, or plating protect and beautify completed assemblies

- Hardware insertion: PEM nuts, studs, and standoffs install into laser-cut holes

- Quality inspection: Dimensional verification ensures parts meet specifications

Providers offering both sheet and tube capabilities under one roof can coordinate these operations more efficiently than splitting work across multiple vendors. They understand how tube joints align with sheet mounting points, how cutting tolerances compound through assembly, and how to optimize the entire workflow rather than just individual operations.

When requesting quotes for projects requiring both service types, ask potential providers about their integrated capabilities. A shop that cuts sheets but outsources tube work—or vice versa—introduces handoff delays, communication gaps, and potential tolerance stack-up issues that impact both timeline and quality.

With service types clarified, the next factor affecting your quote involves something entirely within your control: how well you prepare your design files and follow best practices for laser-ready drawings.

Design Guidelines and File Preparation

Here's a frustrating reality: your design could be technically brilliant yet completely wrong for laser cutting. Most service providers mention "design guidelines" somewhere on their websites—then leave you guessing about what actually matters. The truth? Proper file preparation and design optimization can slash your quote by 20-30% while dramatically improving part quality. Let's fill that knowledge gap with specifics that actually help.

File Formats and Preparation Requirements

Before any laser touches metal, your design must translate into machine-readable instructions. Not all file formats are created equal, and submitting the wrong type creates delays, revision cycles, and potentially higher costs.

According to Xometry's sheet cutting design guide, understanding the difference between raster and vector files is fundamental. Laser cutters require vector graphics—mathematical descriptions of lines and curves—rather than pixel-based raster images. A photograph of your part won't work; you need actual CAD geometry.

Accepted file formats for laser cut metal sheets typically include:

- DXF (Drawing Exchange Format): The industry standard for 2D cutting paths—universally compatible across CAD systems

- DWG (AutoCAD Drawing): Native AutoCAD format with full layer and entity support

- STEP/STP: 3D model format useful when parts require bending or secondary operations

- AI (Adobe Illustrator): Vector format popular for decorative or artistic laser cut parts

- PDF: Acceptable when exported as vector graphics from CAD software

File optimization matters more than format selection. Xometry emphasizes removing excess information—construction lines, dimensions, duplicate geometry, and annotation layers—before submission. Text must be converted to outlines or paths since fonts don't transfer between systems. These seemingly minor issues create quoting delays and programming errors that inflate costs.

One common mistake? Scale errors. A part drawn in inches but interpreted as millimeters arrives 25 times smaller than expected. Always verify units and include a reference dimension your provider can check against.

Design Rules for Optimal Cut Quality

Understanding kerf width transforms how you approach laser fabrication design. The kerf—the material removed by the cutting process—typically ranges from 0.1mm to 1.0mm depending on material thickness and laser parameters, according to MakerVerse's best practices guide.

Why does this matter? If you need a 10mm hole, you don't draw a 10mm circle. The laser removes material along that path, so the actual hole ends up slightly larger. Precision laser cut sheet metal work requires kerf compensation—either applied by you or your provider.

Critical design specifications to follow:

- Minimum feature size: Generally 1-2x material thickness for reliable cutting

- Hole-to-edge distance: Maintain at least 1.5x material thickness to prevent tearing or deformation

- Spacing between cuts: Space cutting geometry at least 2x sheet thickness to avoid distortion

- Minimum hole diameter: Typically equal to or greater than material thickness

- Tab width for retained parts: At least 2x material thickness for parts that remain attached during cutting

Dimensional tolerances represent the allowable deviation in your finished part. For laser cut aluminum and other metals, typical tolerances range from ±0.1mm to ±0.2mm on thin materials, widening to ±0.3mm to ±0.5mm for thicker sections. These specifications should drive your design decisions—don't specify ±0.05mm tolerances on features that laser cutting simply cannot achieve.

Avoiding Common Design Mistakes

Even experienced engineers submit designs with issues that increase costs or compromise quality. Here are the mistakes providers see repeatedly:

Holes too close to edges: MakerVerse notes that if holes are placed too close to the edge, the possibility of the hole tearing or deforming is higher—especially if the part later undergoes forming operations. Allow adequate margin.

Inconsistent bend radii: For sheet metal laser cutter projects that include bending, using varying bend radii and orientations means the part will need to be reoriented more often during forming. This requires more operator time and increases costs.

Ignoring bending tool access: When using a bending tool, leave enough room so it can access the corners. The tool needs to come 90° from the bending corner—cramped geometries become impossible to form.

Design Best Practices Checklist:

- Submit vector files (DXF, DWG, or AI) with clean, single-line geometry

- Remove duplicate lines, construction geometry, and dimension annotations

- Convert all text to outlines or paths

- Verify scale and include a reference dimension

- Maintain minimum hole-to-edge distances (1.5x material thickness)

- Space features at least 2x material thickness apart

- Use consistent bend radii and orientations where possible

- Specify realistic tolerances achievable with laser cutting (±0.1mm to ±0.5mm)

- Consider kerf width in precision fits and assemblies

- Avoid ultra-fine details smaller than material thickness

Following these guidelines doesn't just improve part quality—it signals to providers that you understand laser fabrication constraints. Shops quote laser-ready files faster and more accurately than designs requiring extensive revision discussions. Your preparation directly impacts both your timeline and final price.

With design fundamentals covered, the next major factor influencing your quote involves the cost drivers that most providers keep deliberately opaque—until now.

Cost Factors and Pricing Transparency

Ready to request a laser cutting quote? Here's what most providers won't tell you: that instant quote button hides a complex calculation involving dozens of variables. Understanding what actually drives laser cutting charges transforms you from a passive price-taker into an informed buyer who can optimize designs, negotiate intelligently, and predict costs before submitting files. Let's pull back the curtain on pricing that competitors keep deliberately opaque.

What Drives Laser Cutting Costs

Every laser cut services quote reflects a combination of fixed and variable expenses. According to Komacut's pricing analysis, the primary factors affecting laser cutting costs include material type, thickness, design complexity, cutting time, labor costs, and finishing processes. Each element contributes to the overall expense by impacting the efficiency and resources required.

Primary cost factors ranked by impact:

- Material costs: Raw material represents 30-50% of most quotes—steel grades, aluminum alloys, and specialty metals vary dramatically in price per pound

- Machine time: Laser operating time directly correlates to cost—thicker materials cut slower, intricate designs require more pierce points, and complex paths extend cutting duration

- Design complexity: More cutouts mean more pierce points where the laser initiates each cut—each pierce adds time and energy consumption

- Material thickness: Thicker materials require more energy and slower cutting speeds, increasing both time and power consumption

- Secondary operations: Processes like deburring, bending, threading, and surface finishing add labor, equipment time, and material costs

- Setup and programming: Fixed costs for file preparation, machine setup, and quality verification spread across your order quantity

Here's a pricing reality most providers avoid mentioning: cutting stainless steel generally costs more than cutting carbon steel at equivalent thicknesses. Why? Stainless requires more energy, cuts slower, and creates greater equipment wear. Similarly, reflective metals like aluminum and copper demand specialized parameters that extend processing time.

The number of cutouts significantly affects pricing because each cutout requires a pierce point. More pierce points and longer cutting paths increase time and energy requirements. Intricate designs with numerous cutouts also demand greater precision, adding to labor and equipment expenses.

Volume Pricing and Quantity Breaks

Wondering why per-unit costs drop dramatically at higher quantities? The economics favor batch processing for several compelling reasons.

According to Vytek's cost optimization guide, laser cutting is typically more efficient when done in batches. Setting up a laser cutter takes time, so running larger quantities in one session reduces the need for frequent machine adjustments, saves setup time, and lowers costs per part.

How quantity affects your metal laser cutting services quote:

- Setup cost distribution: A $150 setup fee adds $15 per part at 10 units but only $0.30 per part at 500 units

- Material efficiency: Larger orders enable better nesting—fitting more parts per sheet reduces waste and material cost per piece

- Continuous operation: Batch runs minimize machine downtime between parts, improving overall efficiency

- Supplier discounts: Bulk orders often qualify for material discounts from suppliers, further lowering costs

- Reduced handling: Processing 100 identical parts requires less operator intervention than processing 10 different designs

For companies with predictable demand, batching orders or scheduling recurring production runs can significantly reduce per-unit costs. If you need 50 parts monthly, ordering 150 quarterly often delivers better pricing than three separate orders.

Design Optimizations That Reduce Costs

Your design decisions directly impact your quote—sometimes more than material selection or quantity. Strategic optimization can reduce laser cutting charges by 20-30% without sacrificing functionality.

Simplify geometries where possible: Complex designs with intricate details require more precise laser control and longer cutting times. According to Vytek's analysis, avoiding sharp interior corners, minimizing small intricate cuts, and using fewer curves can result in substantial savings. Rounded corners or straight lines are generally faster to cut than intricate shapes or tight radii.

Optimize nesting efficiency: Efficient nesting maximizes material usage by arranging parts closely together on the sheet, minimizing waste. According to Komacut, this reduces raw material requirements and decreases cutting time, leading to significant cost savings. Strategic nesting can reduce material scrap by 10-20%.

Match edge quality to application: Achieving high-quality edges often requires slowing down the laser or using more power—both increase costs. Not every application demands the same precision. For parts that will be welded, assembled into larger components, or undergo further finishing, specifying standard edge quality rather than premium finishes reduces processing time.

Cost-reducing design strategies:

- Reduce the number of individual cutouts and pierce points

- Use standard material thicknesses that providers stock rather than custom gauges

- Design parts that nest efficiently together on standard sheet sizes

- Eliminate ultra-fine features that slow cutting speed

- Specify realistic tolerances—tighter specs cost more to verify and achieve

- Choose cost-effective materials that meet requirements without over-engineering

- Combine similar parts in single orders to maximize setup efficiency

Lead Times and Turnaround Factors

Beyond per-part pricing, delivery timeline significantly impacts total project cost. Rush orders typically carry premiums of 25-50%, while flexible scheduling can sometimes unlock discounts.

Factors affecting production speed:

- Material availability: Common materials like mild steel ship from stock; exotic alloys may require procurement delays

- Machine scheduling: Provider capacity and existing commitments determine when your job enters the queue

- Design revision cycles: Laser-ready files process faster than designs requiring back-and-forth optimization discussions

- Secondary operations: Bending, finishing, and assembly steps extend total lead time beyond cutting alone

- Quality requirements: Inspection and documentation for certified applications add processing days

When searching for a laser cutting service near me or evaluating laser cutting services near me, ask providers about standard versus expedited timelines. Understanding the cost-to-speed trade-off helps you plan projects realistically and avoid premium rush charges when advance planning would have delivered the same parts at lower cost.

Transparent pricing builds trust—and now you understand the mechanics behind every laser cutting quote. With cost factors demystified, the next consideration involves recognizing the specific advantages that make laser cutting the right choice for your application in the first place.

Key Advantages of Professional Laser Cutting

You've seen the lists before—precision, speed, quality. But those bullet points tell you nothing about why laser cutting actually delivers these benefits or when they matter most for your project. Understanding the physics and mechanics behind each advantage transforms generic marketing claims into actionable decision criteria. Let's dig into what makes a laser metal cutter genuinely superior for specific applications—and equally important, when these advantages actually impact your bottom line.

Precision That Traditional Methods Cannot Match

When manufacturers claim "precision," what does that actually mean in measurable terms? According to Wikipedia's technical documentation, laser cutters achieve positioning accuracy of 10 micrometers with repeatability of 5 micrometers. For context, a human hair measures roughly 70 micrometers—meaning laser metal cutting positions cuts with accuracy seven times finer than a single strand of hair.

The physics behind this precision starts with the focused beam itself. The parallel rays of coherent light from the laser source typically measure 1.5-2.0mm in diameter before focusing. Mirrors and lenses then concentrate this energy to a spot as small as 0.025mm (0.001 inches)—creating an incredibly intense cutting point that removes material with surgical accuracy.

Why does this matter for your project? Consider these real-world implications:

- Assembly fit: Parts machined to ±0.001" tolerances assemble without grinding, filing, or force-fitting

- Interchangeability: Every part from a production run measures identically—swap any unit without custom fitting

- Complex geometries: Intricate patterns, tight radii, and detailed features cut cleanly where mechanical tools cannot reach

- Reduced scrap: Consistent accuracy means fewer rejected parts and lower waste costs

Repeatability deserves special attention. Unlike mechanical cutting where tool wear gradually degrades accuracy, a laser that cuts metal maintains consistent precision because there's no physical contact causing degradation. The hundredth part measures identical to the first—critical for precision laser cutting services supporting aerospace, medical, and automotive applications where dimensional consistency is non-negotiable.

Edge Quality and Post-Processing Savings

Here's where laser cutting's advantages translate directly into cost savings. According to industry specifications, typical surface finish from laser beam cutting ranges from 125 to 250 micro-inches (0.003mm to 0.006mm). This exceptionally smooth finish often eliminates secondary grinding, deburring, or polishing operations.

Advantages of laser cutting over mechanical cutting include easier work holding, reduced contamination of workpiece, and a reduced chance of warping since laser systems have a small heat-affected zone.

The machine cutter metal comparison becomes particularly striking when examining heat-affected zones. Traditional plasma cutting creates wide HAZ areas requiring post-cut treatment. Laser cutting's concentrated energy delivery minimizes thermal spread into surrounding material—preserving metallurgical properties right up to the cut edge.

Steel laser cutting demonstrates this advantage clearly. When cutting low carbon steel with 800W laser power, standard roughness measures just 10μm for 1mm sheets, 20μm for 3mm sheets, and 25μm for 6mm sheets. These finishes satisfy most application requirements directly off the machine, eliminating finishing labor that adds 15-30% to traditional cutting costs.

The contamination advantage matters for sensitive applications. Mechanical cutting tools contact the workpiece, potentially transferring lubricants, wear particles, or foreign materials. Laser cutting is non-contact—nothing touches your part except focused light and assist gas. Medical device manufacturers and food processing equipment fabricators specifically choose laser for this reason.

From Prototype to Production Scale

Perhaps laser cutting's most underappreciated advantage lies in its scalability. The same technology that produces a single prototype processes thousands of production parts with zero tooling changes. According to Amber Steel's industry analysis, industrial laser cutting can be automated, meaning machines can be programmed to do the cutting—speeding up the process and reducing manual labor requirements.

Speed comparisons reinforce this advantage. For many purposes, a laser can be up to thirty times faster than standard sawing. Common industrial systems (≥1kW) cut carbon steel from 0.51mm to 13mm thickness efficiently. Maximum cutting rates depend on laser power, material thickness, process type, and material properties—but even conservative estimates show dramatic time savings.

Design flexibility compounds the speed advantage. CNC programming changes between different parts take minutes, not hours. Need to modify a design mid-production? Update the program file and resume cutting. This agility supports:

- Automotive: Rapid iteration on chassis components, body panels, and structural brackets during development cycles

- Aerospace: Precision components for aircraft parts meeting strict industry tolerances

- Electronics: Delicate components like circuit boards and microchips requiring exceptional accuracy

- Architecture: Custom decorative panels, structural elements, and artistic metalwork with unique geometries

Material versatility extends these advantages across virtually any metal. Unlike specialized equipment limited to specific materials, a single fiber laser system handles steel, aluminum, copper, brass, and titanium—switching between them with parameter changes rather than equipment swaps. According to GCC World's technical guide, this versatility makes laser technology useful across many different industries, from sheet metal fabrication to jewelry making to rapid prototyping.

The economics favor laser cutting increasingly as complexity increases. Simple straight cuts might be cheaper with shearing or plasma. But as designs incorporate curves, cutouts, tight tolerances, or intricate patterns, laser's advantages compound while alternative methods' limitations multiply. Evaluating total cost—including post-processing, scrap rates, and rework—often reveals laser cutting as the economical choice even when initial cutting costs appear higher.

Understanding these advantages helps you recognize when laser cutting delivers genuine value versus when simpler methods suffice. But advantages mean nothing without access to a capable provider—which brings us to the critical question of how to evaluate and select the right service partner for your specific requirements.

Selecting the Right Laser Cutting Service Provider

You've mastered the technology, compared cutting methods, and optimized your design—but none of that matters if you choose the wrong provider. Here's what separates a trusted manufacturing partner from one that delivers headaches: the ability to translate your requirements into quality parts, on time, without endless back-and-forth. When searching for laser cutting near me or evaluating cnc laser cutting services, knowing exactly what to look for transforms a gamble into an informed decision.

Certifications and Quality Standards That Matter

Certifications aren't just wall decorations—they represent verified systems for maintaining consistent quality. But which ones actually matter for your project? According to AIAG's official documentation, IATF 16949:2016 defines quality management system requirements for organizations across the global automotive industry. This certification was developed with unprecedented industry engagement from OEMs and suppliers worldwide.

If your metal parts feed into automotive supply chains, IATF 16949 certification should top your evaluation checklist. This standard goes beyond basic ISO 9001 requirements to address automotive-specific concerns:

- Production Part Approval Process (PPAP): Ensures suppliers can consistently manufacture parts meeting all customer requirements

- Advanced Product Quality Planning (APQP): Structured approach to product design and development

- Failure Mode and Effects Analysis (FMEA): Systematic identification and mitigation of potential failures

- Measurement Systems Analysis (MSA): Verification that measurement processes provide reliable data

- Statistical Process Control (SPC): Ongoing monitoring to maintain quality consistency

For non-automotive applications, ISO 9001:2015 certification demonstrates fundamental quality management commitment. According to Laser Cutting Shapes' provider guide, look for a company with experienced professionals who understand the nuances of different materials and laser cutting techniques—review their portfolio, read customer reviews, and inquire about certifications.

Specialty certifications matter for specific industries:

- AS9100: Aerospace and defense applications

- ISO 13485: Medical device manufacturing

- NADCAP: Special processes including welding and heat treatment

- ISO 14001: Environmental management systems

Evaluating Equipment and Capabilities

A provider's equipment directly determines what they can deliver. According to LS Precision Manufacturing's evaluation guide, the simplest verification method is visiting their factory—whether in person or via real-time video—to observe brand equipment, facility appearance, workshop management, and operation standards.

When evaluating laser metal cutting near me options, investigate these equipment factors:

- Laser power levels: Higher wattage handles thicker materials and cuts faster—ask about their maximum capacity

- Bed sizes: Larger cutting beds accommodate bigger parts and enable efficient nesting for production runs

- Laser technology types: Fiber lasers excel on reflective metals; CO2 systems offer versatility—match equipment to your materials

- Automation level: Automated loading/unloading systems improve consistency and reduce labor costs on high-volume orders

- Secondary equipment: Brake presses, welders, and finishing equipment enable one-stop fabrication

LS Precision notes that aging laser machines have poor dynamic performance—the cutting head oscillates at high cutting speeds, leading to large errors in cut shapes and design patterns. If you require accurate custom metal laser cutting, such inaccuracy causes parts to be scrapped entirely. Request samples of previous work on materials similar to yours to verify actual capability.

Beyond cutting equipment, evaluate integrated capabilities. Providers offering complete sheet metal processing—cutting, bending, welding, and finishing under one roof—eliminate handoff delays and tolerance stack-up issues that occur when splitting work across multiple vendors. For automotive applications requiring chassis, suspension, or structural components, manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate how IATF 16949-certified quality combined with comprehensive fabrication capabilities streamlines supply chains from prototype through mass production.

Assessing DFM Support and Turnaround Times

Design for Manufacturability (DFM) support separates order-takers from true manufacturing partners. According to LS Precision's analysis, experienced providers proactively analyze your blueprints for potential processing issues—offering professional cost-saving and feasibility recommendations before production begins. This early intervention effectively prevents design flaws, improves production efficiency, and keeps costs controlled from the outset.

When evaluating DFM capabilities, ask providers:

- Do you provide free DFM review before quoting?

- How quickly do you identify potential manufacturability issues?

- What optimization suggestions have you provided for similar projects?

- Can you recommend material substitutions that reduce cost without sacrificing performance?

Turnaround time commitments reveal operational capability. Laser Cutting Shapes emphasizes that turnaround time varies significantly depending on project complexity, volume, and provider workload—clear communication about deadlines is essential. Some services offer rush options at premium cost, while others maintain consistent lead times through disciplined capacity management.

For time-sensitive projects, look for providers offering rapid prototyping capabilities. The ability to deliver sample parts within 5 days—rather than weeks—accelerates development cycles and enables design validation before committing to production tooling. Combined with fast quote turnaround (12 hours or less signals operational efficiency), rapid prototyping demonstrates the responsiveness your projects demand.

Questions to Ask Before Ordering

Before committing to any laser cut near me provider, gather answers to these critical questions:

Technical capability questions:

- What laser types and power levels do you operate?

- What's your maximum material thickness for my specific metal type?

- What tolerances can you guarantee for my part geometry?

- Do you have experience with my specific material grade?

- What secondary operations do you offer in-house versus outsource?

Quality and process questions:

- What quality certifications do you hold?

- How do you verify dimensional accuracy on finished parts?

- What documentation do you provide with shipments?

- How do you handle non-conforming parts?

- Can you provide samples before full production runs?

Commercial questions:

- What's your standard lead time for orders of my quantity?

- Do you offer expedited processing, and at what cost premium?

- How do you handle design changes mid-order?

- What are your minimum order quantities?

- Do you offer volume pricing or blanket order arrangements?

Red Flags to Avoid

Experience teaches which warning signs predict problems. According to LS Precision's analysis, suppliers often rashly shorten production cycles to secure orders, then struggle with serial delays due to capacity overload, machine breakdown, or poor management. Here's what should trigger caution:

Communication red flags:

- Slow or vague responses to technical questions

- Inability to explain their process or equipment capabilities

- Customer service representatives lacking technical knowledge

- Reluctance to provide references or sample work

Operational red flags:

- Unrealistically low quotes compared to competitors (often hiding quality compromises)

- Promises of delivery timelines that seem too aggressive for your order complexity

- Unwillingness to allow facility visits or provide video tours

- Outdated or poorly maintained equipment visible in photos or videos

Business practice red flags:

- No clear quality certifications or reluctance to share documentation

- Excessive payment demands upfront before any work begins

- Lack of formal quotes with detailed line items

- History of disputes visible in online reviews

Provider Evaluation Checklist

Use this comprehensive checklist when comparing custom laser etching or precision cutting providers:

| Evaluation Category | Key Criteria | Verification Method |

|---|---|---|

| Certifications | ISO 9001, IATF 16949 (automotive), AS9100 (aerospace) | Request copies; verify with certifying bodies |

| Equipment | Modern fiber/CO2 lasers; adequate power and bed size | Facility tour; equipment list with specifications |

| Material Expertise | Documented experience with your specific metals and thicknesses | Sample parts; reference projects |

| DFM Support | Proactive design review; optimization recommendations | Submit test file; evaluate feedback quality |

| Turnaround | Quote speed; standard lead times; rush capabilities | Test quote request; documented lead times |

| Communication | Technical competence; responsiveness; project management | Interaction quality during evaluation |

| Secondary Operations | Bending, welding, finishing available in-house | Capability list; integrated workflow examples |

| Quality Control | Inspection equipment; documentation; traceability | QC process overview; sample reports |

Finding the right laser cutter service near me requires balancing capability, quality, cost, and responsiveness. Providers who transparently demonstrate their qualifications—through certifications, equipment investments, and customer references—earn the trust that long-term manufacturing partnerships require. The time invested in thorough evaluation pays dividends through consistent quality, reliable delivery, and collaborative problem-solving when challenges arise.

Frequently Asked Questions About Metal Laser Cutting Services

1. What materials can be cut with laser cutting services?

Professional laser cutting services handle a wide range of metals including carbon steel, stainless steel, aluminum, copper, brass, and titanium. Fiber lasers excel with reflective metals like aluminum and copper, while CO2 lasers perform well on thicker steel materials. Maximum thickness varies by material and laser power—for example, a 3000W fiber laser cuts up to 20mm carbon steel but only 8mm aluminum. Specialty alloys and mixed-material projects may require specific laser technologies for optimal results.

2. How much does laser cutting service metal cost?

Laser cutting costs depend on multiple factors: material type (stainless costs more than carbon steel), thickness (thicker materials cut slower), design complexity (more pierce points increase time), and quantity (setup costs spread across larger orders reduce per-part pricing). Material typically represents 30-50% of quotes, with machine time as the second largest factor. Design optimization—simplifying geometries, efficient nesting, and specifying realistic tolerances—can reduce costs by 20-30% without sacrificing quality.

3. What is the difference between CO2 and fiber laser cutting?

CO2 lasers use a gas mixture to generate a 10,600nm wavelength beam, excelling on thicker materials and offering versatility across metals and non-metals. Fiber lasers use rare earth-doped glass fiber producing 1064nm wavelength light that metals absorb more efficiently. Fiber lasers cut 2-3x faster on thin sheet metals, achieve 30%+ energy efficiency versus CO2's 10-20%, and handle reflective metals like aluminum and copper without issues. However, fiber lasers primarily serve metal fabrication and cost more upfront, though lower operating costs offset this over time.

4. How do I prepare files for laser cutting?

Submit vector files (DXF, DWG, or AI format) with clean, single-line geometry. Remove duplicate lines, construction geometry, and dimension annotations before submission. Convert all text to outlines since fonts don't transfer between systems. Verify scale and include a reference dimension to prevent sizing errors. Follow design rules including minimum hole-to-edge distances of 1.5x material thickness, feature spacing of at least 2x thickness, and realistic tolerances (±0.1mm to ±0.5mm depending on material thickness).

5. How do I choose the best laser cutting service provider?

Evaluate providers based on certifications (IATF 16949 for automotive, ISO 9001 for general quality), equipment capabilities (laser types, power levels, bed sizes), and DFM support availability. Request samples on your specific materials, verify turnaround commitments, and assess communication responsiveness. For automotive applications, IATF 16949-certified manufacturers like Shaoyi Metal Technology offer integrated capabilities from rapid prototyping to mass production with comprehensive quality documentation. Avoid providers with vague technical answers, unrealistically low quotes, or reluctance to share facility information.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —