Laser Cutting Design Secrets: From File Prep To Flawless Cuts

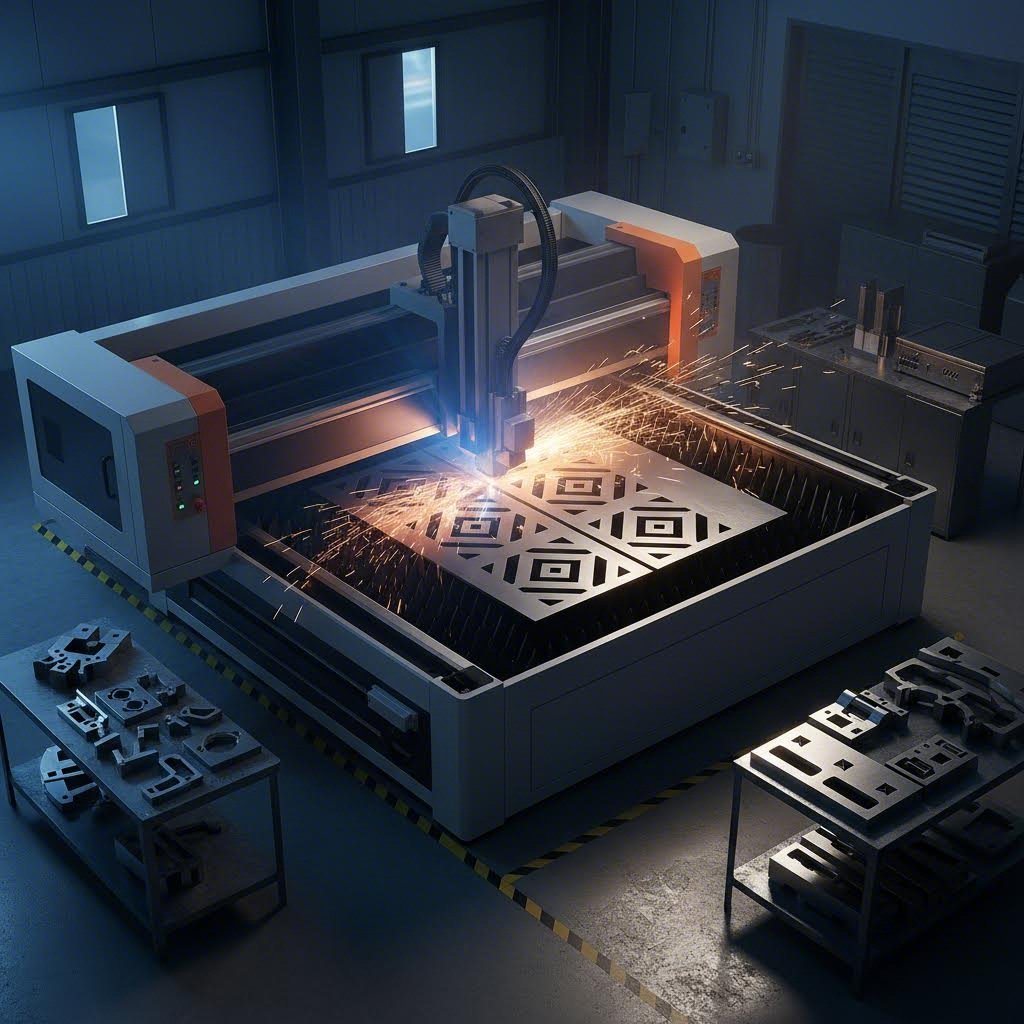

Why Your Laser Cutting Design Determines Manufacturing Success

Laser cutting design sits at the intersection where digital creativity meets precision manufacturing. It's more than just creating a nice-looking vector file—it's the engineering foundation that determines whether your parts come out perfectly or end up as expensive scrap. Before your laser cutter ever fires its first pulse, your design decisions have already sealed the fate of your project.

You likely understand the basics: vector paths become cut lines, raster images become engravings. But here's where many intermediate designers hit a wall. Knowing how to draw isn't the same as knowing what to draw for successful fabrication. That gap between good-looking laser cut designs and parts that actually function as intended? That's exactly what this guide addresses.

What Separates Good Designs from Great Cuts

Imagine sending two identical-looking files to a laser cutter. One produces clean, dimensionally accurate parts that snap together perfectly. The other results in warped edges, failed small features, and joints that don't fit. The difference isn't luck—it's design intelligence.

Great cuts start with understanding that your cutting designer role extends beyond aesthetics. According to SendCutSend's design guidelines, the better your file preparation, the better your parts will be. This means accounting for material behavior, machine limitations, and thermal dynamics before you finalize a single dimension.

The Design-to-Cut Connection Explained

Here's the critical insight that transforms your approach: every material demands a different design strategy. Steel conducts heat rapidly, affecting how closely you can space cuts. Acrylic melts and re-solidifies, creating polished edges but requiring specific feature sizing. Plywood's layered grain structure means kerf width can vary across a single sheet.

This material-first philosophy will guide everything ahead. Whether you're preparing files for laser etching intricate patterns or cutting structural components, you'll learn the specific measurements, tolerances, and design rules that apply to each substrate. As noted in MakerVerse's best practices, spacing cutting geometry at least two times the sheet thickness helps avoid distortion—just one example of the practical, measurement-focused guidance you'll find throughout this resource.

Ready to bridge the gap between design intent and manufacturing reality? The sections ahead deliver the technical depth you need—from file formats and minimum feature sizes to kerf compensation and joint design—all organized around the materials you're actually working with.

File Formats and Vector Preparation Essentials

Your design file is the blueprint your laser cutter follows—and just like a poorly drawn architectural plan leads to construction disasters, incorrectly formatted laser cutter files result in failed cuts, wasted material, and frustrating rework. Understanding which file format to use and how to prepare it correctly isn't optional knowledge; it's the foundation of every successful project.

The good news? Once you understand the core principles behind file preparation, you'll avoid the common mistakes that plague even experienced designers. Let's break down exactly what your laser cutter needs to produce flawless results.

Vector vs Raster Files for Cutting and Engraving

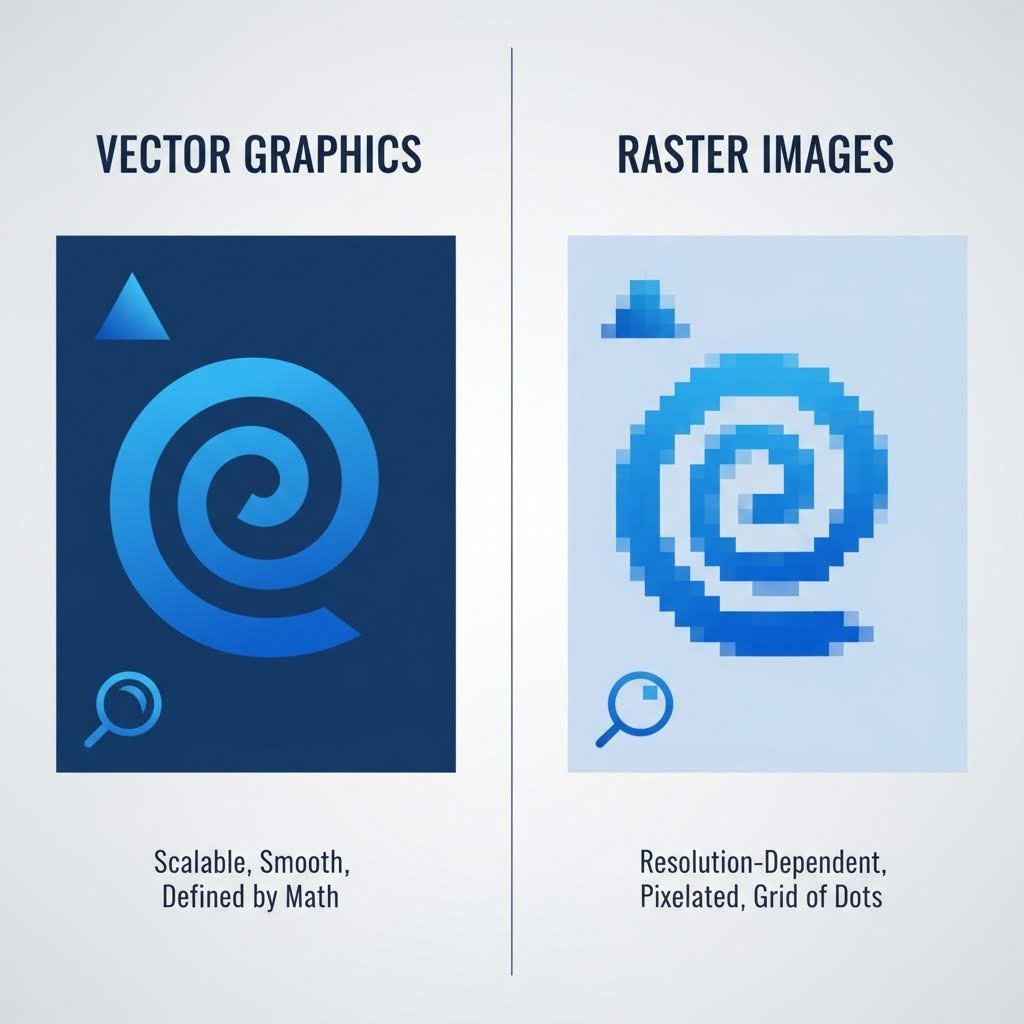

Here's the fundamental distinction you must understand: vector files and raster files serve entirely different purposes in laser cutting workflows.

Vector files consist of mathematically defined paths—lines, curves, and shapes that can scale infinitely without losing quality. According to HeatSign's file format guide, vector formats are essential for cutting operations because they provide the precision needed for clean, accurate paths. When your laser cutter reads a vector line, it follows that exact path to cut through your material.

Raster files are pixel-based images—think photographs or detailed artwork. These work beautifully for engraving because the laser moves back and forth like an inkjet printer, burning the image into the surface. However, raster images cannot be used for cutting operations since they lack the defined paths a laser needs to follow.

The critical difference in your design files:

- Cut lines must be vector paths with specific stroke properties—typically 0.1pt stroke weight in your designated cutting color

- Engraving areas can be either filled vector shapes or high-resolution raster images

- Vector etching uses low-power vector lines to create thin, precise surface marks without cutting through

Many designers make the mistake of importing a JPEG or PNG image into their vector software and assuming it's now "vector-ready." It's not. As Online Laser Cutting Australia explains, vector files need to be drawn in vector software rather than simply imported—zooming in on a true vector file shows clean lines, while raster images become blurry.

When to Use DXF Over SVG

Both DXF and SVG are excellent vector formats, but they excel in different scenarios. Choosing the right one can streamline your workflow and prevent conversion headaches.

DXF (Drawing Exchange Format) is the preferred choice for precision parts and technical designs. Originally developed for CAD applications, DXF files maintain exceptional dimensional accuracy and work seamlessly with engineering software. If you're designing mechanical parts, enclosures with tight tolerances, or anything requiring exact measurements, DXF should be your go-to format.

SVG (Scalable Vector Graphics) shines in web-based workflows and creative applications. It's an open-standard format supported by free software like Inkscape, making it accessible for hobbyists and designers who don't have expensive CAD licenses. SVG laser cut files are particularly popular for decorative projects, signage, and designs shared online—including many free laser cut files available in design communities.

Here's a quick reference for choosing your format:

- DXF files — Best for precision parts, CAD-originated designs, technical drawings, and when dimensional accuracy is critical

- SVG files — Ideal for web-based workflows, creative projects, cross-platform compatibility, and when using free design software

- AI (Adobe Illustrator) — Perfect for Adobe users, supports complex layering, and handles intricate designs with multiple operations

- EPS (Encapsulated PostScript) — Versatile format for professional design workflows, widely compatible across graphic software

Color Coding and Layer Organization

Your laser cutting files communicate instructions through color—and getting this wrong means your cutter won't know what to cut, engrave, or etch. Most laser software uses a standardized color system that you should adopt from the start.

According to Harvard's Fabrication Lab guidelines, you must use exact RGB color values (not CMYK) for your laser driver to correctly recognize geometry. Here's the typical color convention:

- Red (RGB: 255, 0, 0) — Cutting lines that pass completely through the material

- Black (RGB: 0, 0, 0) — Raster engraving areas

- Blue (RGB: 0, 0, 255) — Vector etching for thin, precise surface marks

Layer organization matters equally. Name your layers clearly—"Cut," "Engrave," "Etch"—and ensure all elements on each layer use the correct color. A common pitfall: an entity's color differs from its layer color, causing it to be processed incorrectly. Always verify that every path matches its intended operation.

Step-by-Step File Preparation Checklist

Before exporting your laser cutting files, run through this preparation process to catch errors that would otherwise ruin your cut:

- Convert all text to outlines — This prevents font substitution issues when your file opens on a different computer

- Set cut line strokes to 0.1pt — Thicker strokes may be interpreted as engraving areas rather than cut paths

- Eliminate overlapping paths — Stacked lines cause double-cutting, which burns material and increases cost

- Ensure all paths are closed — Open paths can cause incomplete cuts or unpredictable behavior

- Ungroup all objects — Grouped elements may not export correctly to DXF format

- Release clipping masks — Hidden geometry under masks will still be processed by the laser

- Use 1:1 scale — Design at actual size to avoid scaling errors during cutting

When exporting a DXF file specifically, choose the version compatible with your laser software (often R14 or 2007 format works broadly). Test your exported file by reopening it to verify all geometry transferred correctly—this simple step catches conversion errors before they waste material.

With your design files properly formatted and organized, you're ready to tackle the next critical challenge: understanding the minimum feature sizes and tolerances your materials can actually achieve.

Minimum Feature Sizes and Tolerance Specifications

Ever designed what looked like a perfect part, only to receive laser cut parts with missing holes, illegible text, or slots that vanished entirely? You're not alone. Understanding minimum feature sizes is where many intermediate designers struggle—and where proper knowledge separates functional parts from expensive failures.

The relationship between material thickness and achievable feature size isn't intuitive. Thicker materials require proportionally larger features, and each material type behaves differently under the laser beam. When you're working with laser cut metal sheets, the rules differ significantly from cutting plywood or acrylic. Let's establish the concrete specifications you need.

Minimum Hole Diameters by Material Thickness

Here's a principle that will save you countless failed cuts: hole diameters should never be smaller than the material thickness, and ideally should be 1.5x the thickness for reliable results. But that's just the starting point—specific materials have their own minimum thresholds regardless of this ratio.

According to SendCutSend's material specifications, thin metals like 0.030" mild steel can achieve minimum part sizes of 0.25" x 0.375", while thicker materials require proportionally larger minimums. For 0.500" thick 6061 aluminum, that minimum jumps to 1" x 1".

When using a sheet metal cutter on materials like stainless steel, the heat-affected zone around each cut influences what's achievable. Smaller holes in thicker stock can result in excessive heat concentration, causing distortion or incomplete cuts. The following table provides practical minimums based on real-world cutting capabilities:

| Material Type | Thickness Range | Min Hole Diameter | Min Slot Width | Min Text Height | Min Spacing |

|---|---|---|---|---|---|

| Mild Steel | 0.030" - 0.135" | 0.25" (6.35mm) | 0.25" | 0.20" | 50% of thickness |

| Mild Steel | 0.187" - 0.500" | 0.50" (12.7mm) | 0.50" | 0.30" | 1x thickness |

| 304 Stainless Steel | 0.030" - 0.125" | 0.25" (6.35mm) | 0.25" | 0.20" | 50% of thickness |

| 304 Stainless Steel | 0.187" - 0.500" | 0.50" (12.7mm) | 0.50" | 0.30" | 1x thickness |

| Aluminum (5052/6061) | 0.040" - 0.125" | 0.25" (6.35mm) | 0.25" | 0.18" | 50% of thickness |

| Aluminum (5052/6061) | 0.187" - 0.500" | 0.50" - 1.0" | 0.50" | 0.25" | 1x thickness |

| Acrylic | 1/16" - 1/8" | 1.5x thickness | 1.5x thickness | 0.15" | 1x thickness |

| Plywood | 1/8" - 1/4" | 1.5x thickness | 2x thickness | 0.20" | 1.5x thickness |

| MDF | 1/8" - 1/4" | 1.5x thickness | 1.5x thickness | 0.18" | 1x thickness |

Text Size Limits That Actually Cut Clean

Nothing frustrates designers more than beautiful typography that becomes an unreadable blob after cutting. Text is essentially a collection of very small features—thin strokes, tight curves, and narrow spacing—all of which push against minimum size limits.

When laser cutting metal sheet or any material, consider these text guidelines:

- Minimum text height — 0.20" (5mm) for most metals; 0.15" for thin acrylic

- Font selection matters — Sans-serif fonts with consistent stroke widths cut cleaner than serif fonts with thin/thick variations

- Stroke width minimum — Individual letter strokes should be at least 50% of material thickness

- Letter spacing — Maintain at least 0.02" between characters to prevent bridging from burning away

Sounds restrictive? It can be—but understanding these limits helps you design text that actually works. If your design requires smaller text, consider vector engraving instead of cutting through the material completely.

Understanding Laser Cutting Tolerance

The tolerance of laser cutting determines whether your parts fit together as designed or require frustrating post-processing. According to SendCutSend's tolerance guidelines, most laser cut materials have a cut tolerance of +/- 0.005" (0.127mm). This means any given feature could be up to 0.010" different from your design intent.

What does this mean practically? If you design a 1.000" hole, you might receive a hole measuring anywhere from 0.995" to 1.005". For decorative parts, this variation is invisible. For precision assemblies, it's the difference between parts that snap together and parts that don't fit at all.

Interference Fits vs Clearance Fits

When designing laser cut parts that must connect—whether a shaft through a hole or a tab into a slot—you'll choose between two fundamental fit types:

Clearance fits allow the mating parts to slide together freely without resistance. The hole or slot is intentionally larger than the inserted component. Use clearance fits when:

- You need easy assembly and disassembly

- Alignment isn't critical to function

- Fasteners or adhesives will secure the joint

Interference fits require force to assemble because the hole is slightly smaller than the inserted component. The friction between surfaces holds parts together. Use interference fits when:

- You want parts to stay connected without fasteners

- Precise alignment is essential

- The assembly won't be disassembled frequently

Here are practical adjustment values for each fit type, accounting for typical laser cutting tolerance:

- Close clearance fit — Add 0.005" to 0.010" to hole diameter beyond shaft size

- Free clearance fit — Add 0.015" to 0.020" for easy insertion with visible gap

- Light interference fit — Subtract 0.002" to 0.005" from hole diameter

- Press interference fit — Subtract 0.005" to 0.010" (requires tool for assembly)

Edge Distance and Feature Spacing Rules

How close can features get to edges or each other before problems occur? The SendCutSend design guidelines recommend keeping holes at least 1x their diameter from any edge, and slots at least 1.5x their width away from edges or other cut features.

These aren't arbitrary numbers. Features too close to edges create thin walls that can tear under stress or deform during cutting due to heat concentration. The bridging between adjacent cuts—whether between holes, slots, or decorative elements—needs sufficient width to survive both the cutting process and subsequent use.

For laser cut materials across the board, use this formula for safe feature placement:

Minimum edge distance = Feature diameter (or width) × 1.5 + material thickness × 0.5

When designing enclosures, brackets, or any structural components, conservative spacing ensures your parts arrive ready to use rather than requiring redesign. The small increase in overall part size is almost always worth the reliability.

With minimum feature sizes and tolerances now clearly defined, the next critical variable awaits: understanding how kerf—the material removed by the laser beam itself—affects your final dimensions and requires compensation in your design.

Kerf Compensation and Material Behavior in Design

You've designed your parts with perfect dimensions, accounted for minimum feature sizes, and specified tight tolerances. Yet when your laser cut wood or metal parts arrive, nothing fits quite right. Holes are slightly oversized. Tabs are too loose in their slots. What went wrong?

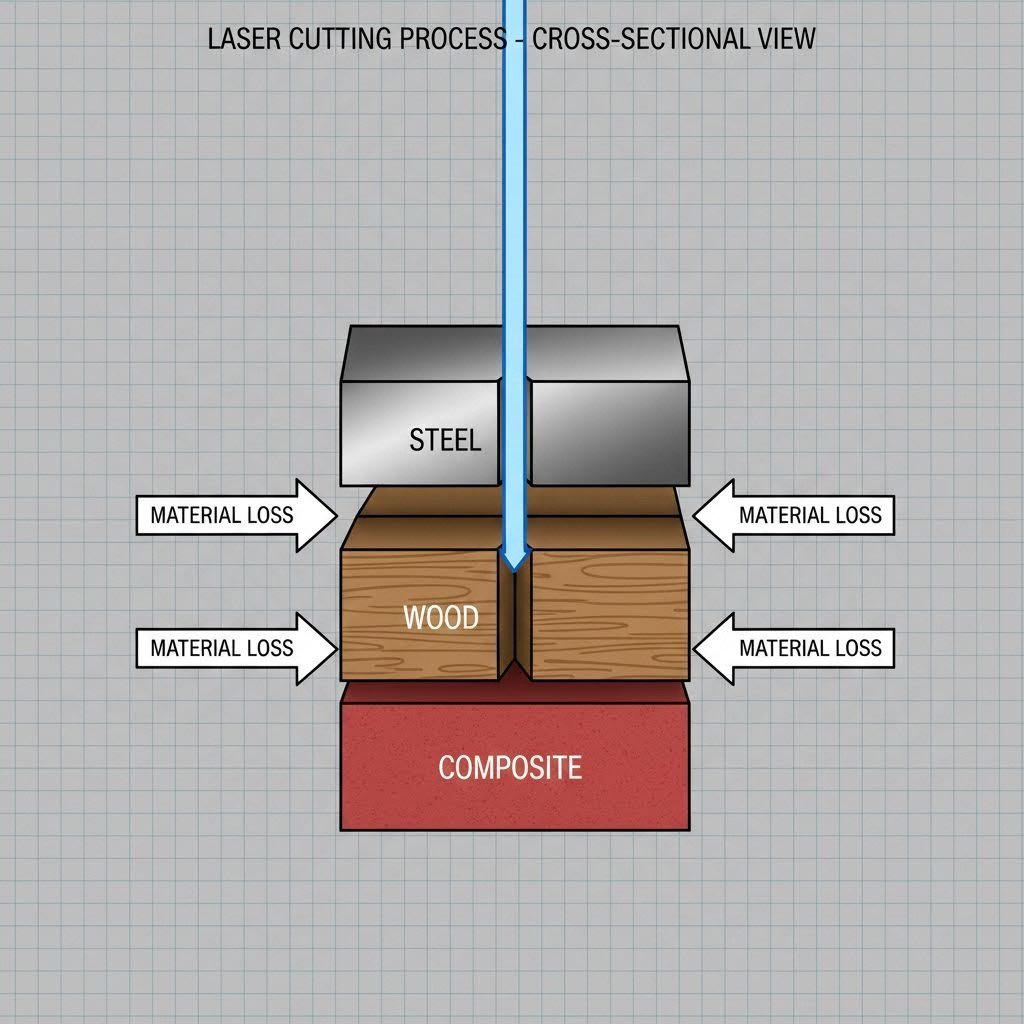

The answer lies in a factor many designers overlook: kerf. According to Craft Genesis, kerf is the amount of material removed by the laser beam as it cuts—typically around 0.005" but varying significantly based on your material and settings. If you don't compensate for this material loss in your design, every dimension will be slightly off.

Calculating Kerf Offset for Precision Fits

Here's the core concept: when a laser cuts along a line, it doesn't just separate material—it vaporizes a thin strip on either side of that path. The width of this removed material is the kerf. For a 1" square you've designed, the actual cut piece might measure 0.990" because the laser consumed approximately 0.005" from each edge.

Want to measure your specific kerf? Craft Genesis recommends this simple test:

- Cut a 1" x 1" square from your material

- Measure the resulting piece with digital calipers

- Subtract your measurement from 1" (this shows total material removed from both sides)

- Divide by 2 to find your kerf value per edge

This measurement becomes your compensation factor. When you need a hole that fits a 0.500" shaft perfectly, you'll adjust your design based on whether you want clearance or interference—and now you know exactly how much material the laser will remove.

When to Apply Kerf Compensation

Here's where many designers get confused: kerf compensation applies differently to inner contours (holes, slots) versus outer contours (part perimeters).

For outer contours — The laser removes material from the outside of your part, making it smaller than designed. To compensate, offset your cut path outward by half the kerf width.

For inner contours — The laser removes material from inside holes and slots, making them larger than designed. To compensate, offset your cut path inward by half the kerf width.

Using vector software like Inkscape or Illustrator, you can apply these offsets through the path offset function. As Craft Genesis explains, a negative offset value shrinks paths while a positive value expands them—choose accordingly based on whether you're adjusting inner or outer geometry.

Material-Specific Kerf Reference Values

Different materials respond to laser energy in dramatically different ways, producing varying kerf widths even with identical machine settings. According to xTool's kerf analysis, metals typically produce narrower kerfs (0.15mm to 0.38mm) compared to wood and plastics (0.25mm to 0.51mm) because metals resist laser heat without substantial material loss, while organic materials burn more readily.

| Material | Typical Kerf Width | Compensation Method |

|---|---|---|

| Mild Steel | 0.15mm - 0.25mm (0.006" - 0.010") | Offset paths by half kerf; consistent across sheet |

| Stainless Steel | 0.15mm - 0.30mm (0.006" - 0.012") | Offset paths by half kerf; test on scrap first |

| Aluminum | 0.20mm - 0.35mm (0.008" - 0.014") | Offset paths by half kerf; account for reflectivity |

| Acrylic | 0.25mm - 0.40mm (0.010" - 0.016") | Offset paths by half kerf; very consistent results |

| Plywood | 0.25mm - 0.50mm (0.010" - 0.020") | Test each batch; grain direction affects kerf |

| MDF | 0.30mm - 0.45mm (0.012" - 0.018") | Offset paths by half kerf; more consistent than plywood |

Why Materials Behave Differently Under the Laser

Understanding why kerf varies helps you predict and design for specific materials rather than guessing.

Steel and metals conduct heat rapidly away from the cut zone. This thermal conductivity means the laser energy stays concentrated in a narrow path, producing tighter kerfs. However, thicker metals exhibit a slightly conical kerf—as xTool notes, the beam widens as it penetrates deeper, so the kerf at the bottom of thick material exceeds the surface kerf.

Acrylic responds beautifully to laser cutting. An acrylic laser cutter melts and vaporizes the material cleanly, often leaving polished edges. Kerf remains remarkably consistent across sheets, making acrylic sheets for laser cutting ideal for precision projects. An acrylic cutter produces predictable results batch after batch.

Plywood and wood present the greatest challenge for consistent kerf. When laser cutting wood, grain direction, density variations, and moisture content all influence how much material burns away. A wood laser cutter may produce different kerf widths across the same sheet—one reason why Craft Genesis recommends always measuring material thickness with digital calipers before cutting, since organic materials vary between batches.

Formulas for Calculating Adjusted Dimensions

When tight fits are essential—like laser cut acrylic enclosures or interlocking wood assemblies—use these formulas to calculate your adjusted design dimensions:

For outer dimensions (making parts the correct final size):

Adjusted dimension = Desired dimension + Kerf width

For holes and internal cutouts (achieving correct opening size):

Adjusted dimension = Desired dimension - Kerf width

For mating parts that interlock:

Tab width = Slot width - Kerf width + Desired interference

Remember that cutting speed affects kerf as well. Higher speeds mean less time burning material at each point, resulting in narrower kerfs. If your machine allows speed adjustments, run your kerf test at your intended production settings to get accurate compensation values.

With kerf behavior now understood and compensated for in your designs, you're ready to tackle the next level of complexity: designing joints and interlocking connections that leverage these principles for strong, functional assemblies.

Joint Design and Interlocking Connection Methods

You've mastered file preparation, understand minimum feature sizes, and know how to compensate for kerf. Now comes the exciting part: designing joints that transform flat sheets into three-dimensional structures. Whether you're building enclosures, creating laser cut crafts, or engineering functional assemblies, the right joint design determines whether your project holds together beautifully—or falls apart under stress.

Joint design is where laser cutter projects truly come alive. A well-designed connection leverages the precision of laser cutting to create assemblies that snap together without fasteners, flex where needed, or lock permanently with simple mechanical interlocks. Let's explore the joint types that will expand your laser cutting ideas into professional-quality builds.

Understanding Your Joint Options

Before diving into specific parameters, here's an overview of the primary joint types available for laser-cut assemblies:

- Finger joints (box joints) — Interlocking rectangular tabs and slots creating strong corner connections; ideal for boxes and enclosures

- Tab-and-slot — Simple tab insertions into corresponding slots; perfect for quick assembly and alignment

- Living hinges — Patterns of thin cuts enabling flat material to bend; creates flexible sections without separate hardware

- Captive nut slots — Hexagonal or square pockets designed to hold fastener nuts in place; combines mechanical and hardware fastening

- Snap fits — Flexible tabs with catches that click into place; enables tool-free assembly and disassembly

Each joint type serves different purposes based on your material choice, load requirements, and whether the assembly needs to be permanent or removable. Cool laser cutter projects often combine multiple joint types within a single design.

Finger Joint Parameters for Strong Assemblies

Finger joints—sometimes called box joints—are the workhorses of laser-cut construction. According to xTool's box design guide, getting the proportions right determines whether your corners lock together tightly or wobble loosely.

Here are the critical parameters for successful finger joints:

- Tab depth — Should match your material thickness exactly (with kerf adjustments). As xTool explains, edges designed too deep relative to thickness will stick out at corners, while shallow edges result in loose assembly

- Tab width — Generally 2-4 times your material thickness works well. Narrower tabs create more interlocks for increased strength, but only up to a point—too narrow and tabs become fragile

- Kerf compensation — Apply half your kerf value to each mating surface. For a 0.010" kerf, reduce slot widths by 0.005" and increase tab widths by 0.005"

- Corner tabs — Always leave enough material at corners to support the interlocking tabs; typically at least 1.5x your tab width

For laser cut wood artwork and decorative panels, you can adjust tab width for visual appeal while maintaining structural integrity. Wider, fewer tabs create a bolder aesthetic; narrower, numerous tabs appear more refined.

Tab-and-Slot Design Rules

Tab-and-slot connections are simpler than finger joints but equally effective for many laser cutter ideas. They work particularly well for internal dividers, shelving, and parts requiring alignment without maximum strength.

Design parameters for reliable tab-and-slot joints:

- Tab length — Minimum 2x material thickness; 3x thickness provides more secure positioning

- Slot clearance — Add 0.005" to 0.010" beyond tab width for easy insertion; reduce for friction fit

- Tab thickness — Equals your material thickness (the tab is cut from the same sheet)

- Slot length — Match tab length plus 0.010" for clearance fit, or match exactly for tight fit

When creating laser cut artwork with internal supports, tab-and-slot connections allow disassembly for flat shipping while maintaining precise alignment during display.

Living Hinge Patterns That Actually Flex

Living hinges transform rigid flat materials into flexible sections—creating curves, bends, and articulation without separate hardware. According to Sculpteo's living hinge guide, this technique works by cutting long, thin strips that each rotate slightly; when you add up all these small rotations, the whole material bends significantly.

Several pattern types achieve flexibility with different characteristics:

- Straight parallel cuts — Simplest pattern; provides bending in one direction only

- Serpentine (wavy) patterns — Allows more dramatic bending; visually distinctive

- Lattice patterns — Cross-hatched cuts enabling multi-directional flex

- Spiral patterns — Creates twisting motion in addition to bending

Critical design parameters for living hinges:

- Cut length — Keep individual pattern units under 5mm (0.20") in length for proper rotation while maintaining strength

- Strip width — Thinner strips flex more but break easier; start with 2-3mm strips for testing

- Pattern repetition — More repetitions across the bend zone create smoother curves

- Material selection — Sculpteo warns that acrylics may melt and wood may burn due to heat concentration; test carefully before committing to production

Living hinges work best in plywood, MDF, and some flexible plastics. They're perfect for jewelry boxes, lamp shades, and any project requiring curves from flat stock.

Captive Nut Slots and Hardware Integration

When your design requires removable fasteners or handles higher loads than friction fits allow, captive nut slots integrate standard hardware into your laser-cut parts.

Design considerations for captive nut slots:

- Nut pocket dimensions — Design hexagonal or square pockets 0.010" to 0.015" larger than your nut's flat-to-flat measurement

- Pocket depth — Equals nut thickness; design multiple layers if material is thinner than the nut

- Alignment slot — Include a channel for the bolt to pass through, sized for clearance fit

- Material thickness — Use materials at least as thick as your nut for single-layer captive pockets

This technique is essential for enclosures requiring access panels, adjustable assemblies, and any project where laser cut crafts need to interface with mechanical components.

Snap Fits for Tool-Free Assembly

Snap fits use material flexibility to create connections that click together without tools or fasteners. They're ideal for enclosures opened frequently or projects requiring quick assembly.

Successful snap fit design requires:

- Cantilever length — Longer flexible tabs deflect more easily; start with 3-4x material thickness

- Catch depth — Typically 0.5-1x material thickness; deeper catches hold more securely but require more force

- Tab width — Wider tabs are stronger but stiffer; balance based on material flexibility

- Material choice — Works best in flexible plastics like acrylic; brittle materials may snap instead of flex

Applying Joints to Real Projects

Understanding when to use each joint type transforms your approach to laser cutter projects:

- Enclosures and boxes — Finger joints at corners for strength; tab-and-slot for internal dividers; captive nuts for removable lids

- Decorative panels — Tab-and-slot for layered dimensional effects; living hinges for curved display pieces

- Functional assemblies — Snap fits for access panels; captive nuts for load-bearing connections; finger joints for permanent structures

According to Komacut's design guide, selecting materials that align with your joint requirements—considering both functional needs and load conditions—ensures high-quality results while keeping costs manageable.

With joint design principles now in your toolkit, you're equipped to create sophisticated assemblies. But what happens when things don't go according to plan? The next section addresses the common design failures that derail projects—and how to prevent them before you ever send a file to cut.

Troubleshooting Common Design Failures

You've followed all the guidelines, compensated for kerf, and designed what should be perfect laser cutting patterns—yet your parts still come back warped, scorched, or missing features entirely. Frustrating? Absolutely. But here's the good news: most failures trace back to preventable design decisions, not machine problems.

Understanding why designs fail gives you the power to fix issues before they waste material and time. Let's diagnose the most common problems and apply design-side solutions that work across laser cutter patterns and materials.

Fixing Warping Before It Happens

Warping is perhaps the most frustrating failure mode because it often appears in parts that otherwise cut perfectly. According to Amber Steel's analysis, thermal cutting causes distortion when too much heat is applied too slowly—the more heat a process introduces and the longer it lingers, the more likely edges will lift or surfaces will shift.

The design-side fixes for warping focus on controlling how heat accumulates:

- Increase spacing between cuts — Cuts placed too close together create localized heat zones. Maintain at least 2x material thickness between adjacent cut lines

- Avoid long continuous cuts — Break extended straight cuts into segments with small bridges; this allows cooling between passes

- Redesign thin sections — Narrow peninsulas of material concentrate heat with nowhere to dissipate; widen critical sections or add cooling tabs

- Consider cut sequencing — Design files that encourage cutting from inside out reduce stress buildup. Interior features removed first allow outer contours to cut without trapped heat

Thin-gauge metals and unsupported cuts are especially prone to deformation. As Amber Steel notes, modern fiber lasers with 6,000W to 10,000W power create beams measuring just 100-150 microns in diameter—thinner than a human hair. This precision means heat affects only the immediate cut area, but only when designs allow proper thermal management.

Why Your Small Features Keep Failing

Designed a delicate laser etching pattern with intricate detail, only to receive parts with blobs where fine lines should be? Small features fail for predictable reasons—and recognizing these in your design file prevents disappointment at delivery.

Common causes of small feature failure:

- Features below minimum size thresholds — Review the minimum specifications for your material; holes smaller than material thickness and text under 0.15" height will likely fail

- Insufficient bridge width — The material connecting small islands to the main part must be wide enough to survive cutting. Use at least 0.020" bridges for metals, 0.030" for woods

- Heat accumulation in tight geometry — Multiple cuts converging in small areas create excessive heat that melts or burns away delicate features

- Undersized internal corners — Sharp 90-degree internal corners concentrate stress and often crack or burn; add corner reliefs

Identifying Problematic Geometry Before Cutting

Sounds complex? Here's a systematic approach to reviewing your laser patterns for potential failures before sending files to production:

- Zoom to 1:1 scale — View your design at actual print size; features that look reasonable zoomed in may reveal themselves as impossibly small at true scale

- Check minimum widths — Use your software's measurement tool to verify all bridges, tabs, and connecting elements meet minimum specifications

- Review spacing consistency — Scan for areas where cuts converge or cluster; these become heat concentration zones

- Test internal corners — Identify all sharp internal corners and verify corner relief cuts are present where needed

- Simulate nesting impact — If your parts will be nested closely, consider how adjacent parts' heat zones might overlap

Nesting Strategies That Prevent Heat Buildup

How you arrange parts on a sheet matters as much as the parts themselves. According to Amber Steel, smart nesting software plays a significant role in minimizing heat buildup—arranging parts to reduce torch movement and avoid heat stacking helps maintain material stability and overall flatness.

Design-side nesting considerations:

- Maintain minimum spacing — Keep parts at least 1x material thickness apart; 2x thickness for heat-sensitive materials like aluminum

- Avoid linear arrangements — Parts lined up in rows create continuous heat paths; staggered arrangements allow cooling between cuts

- Alternate cutting zones — Design layouts that encourage the laser to move across the sheet rather than concentrating in one area

- Consider shared edges carefully — While shared cuts save material, they can create stress concentrations; evaluate whether savings justify the risk

Corner Relief Techniques for Internal Corners

Sharp internal corners create stress risers that can crack, burn, or tear during and after cutting. According to SendCutSend's relief guide, removing a small area of material at stress points prevents unwanted tearing and warping.

Apply these corner relief approaches to your laser engraving patterns and cut designs:

- Dog-bone relief — Small circular cutouts at internal corners allow cutting tools to fully reach the corner while distributing stress

- T-bone relief — Extended cuts perpendicular to the corner achieve similar stress relief with a different aesthetic

- Radius corners — Replace sharp 90-degree internal corners with small radii (minimum 0.020" for most materials)

- Relief sizing — Relief width should be at least half the material thickness; depth should extend past the corner intersection

When material is bent or stressed, some material stretches while other material compresses. If you haven't provided a place for that stress to go, it'll find its own space—causing unwanted warping or tearing.

Common Design Failure Quick Reference

Use this checklist to identify and fix problems before they reach the laser:

- Incomplete cuts from insufficient spacing — Increase distance between cuts to at least 2x material thickness

- Burn marks from tight nesting — Add spacing between parts; stagger arrangements to distribute heat

- Warping from heat accumulation — Break long cuts into segments; design inside-out cut sequences

- Detail loss from undersized features — Verify all elements meet minimum size thresholds; enlarge or eliminate problem features

- Part dropout during cutting — Add holding tabs or bridges; verify bridge widths exceed minimums

- Cracked internal corners — Apply dog-bone, T-bone, or radius relief to all sharp internal corners

Following these cutting guidelines transforms your troubleshooting approach from reactive to preventive. By identifying problematic geometry in your design files before cutting, you eliminate the frustration—and cost—of failed parts.

With troubleshooting strategies now in your toolkit, the next step is selecting the right software to implement these design principles efficiently and accurately.

Design Software Comparison for Laser Cutting Workflows

You've mastered file formats, minimum features, kerf compensation, joint design, and troubleshooting—but all that knowledge means nothing without the right software to bring your designs to life. Choosing design software for laser cutting isn't just about personal preference; it directly impacts your workflow efficiency, design capabilities, and ultimately, the quality of your finished parts.

The landscape of laser engraving software and cutting tools ranges from free open-source options to professional subscriptions costing hundreds annually. Which one fits your needs? That depends on what you're building, how complex your projects get, and how much time you're willing to invest in learning. Let's break down your options with actionable recommendations.

Free vs Paid Software Trade-offs

Before diving into specific programs, understand the fundamental trade-offs you're making when choosing between free and paid solutions.

According to Thunder Laser USA's software guide, free tools like LaserGRBL and Inkscape provide enough capability for learning and basic projects, but most businesses eventually upgrade to paid solutions for advanced features and time savings.

Free software advantages:

- No financial barrier to entry—perfect for beginners exploring laser cutting

- Open-source options like Inkscape have large communities providing tutorials and plug-ins

- Sufficient for simple projects, decorative cuts, and learning fundamentals

Free software limitations:

- Fewer automation features mean more manual work per project

- Limited file format support may require conversion workarounds

- Less responsive support when problems arise

- May lack direct machine control integration

Paid software advantages:

- Advanced features like parametric design, simulation, and batch processing

- Direct machine control eliminates software switching

- Professional support and regular updates

- Better workflow efficiency saves time on complex projects

For businesses, paid software often pays for itself by reducing errors and saving hours of manual work. For hobbyists making occasional projects, free tools may serve indefinitely.

Software Comparison Table

Here's a comprehensive comparison of the most popular options for laser engraver software, organized by capabilities and use cases:

| Software Name | Price Point | Best For | Learning Curve | Export Formats |

|---|---|---|---|---|

| Inkscape | Free (open-source) | Budget-conscious designers; SVG-based workflows; beginners learning vector design | Moderate | SVG, DXF, PDF, EPS, PNG |

| Adobe Illustrator | $22.99/month (subscription) | Professional designers; complex artwork; integration with Adobe ecosystem | Moderate to Steep | AI, SVG, DXF, PDF, EPS |

| CorelDRAW | $249/year or $549 perpetual | Sign makers; professional graphics; users wanting perpetual license option | Moderate | CDR, SVG, DXF, AI, PDF |

| Fusion 360 | Free (personal) / $545/year (commercial) | Engineers; parametric designs; 3D models requiring flat patterns; precision parts | Steep | DXF, DWG, STEP, IGES |

| LightBurn | $60 one-time (G-code) / $120 (DSP) | All-in-one design and machine control; serious hobbyists; small businesses | Easy to Moderate | SVG, DXF, AI, native formats |

| LaserGRBL | Free (open-source) | GRBL-based diode lasers; beginners; simple engraving projects | Easy | G-code, SVG, images |

Understanding Workflow Differences

The software you choose shapes your entire design-to-cut process. Two distinct categories serve different needs:

2D Illustration Software (Inkscape, Illustrator, CorelDRAW)

These programs excel at creating and manipulating vector artwork. You draw shapes, curves, and text directly—perfect for decorative designs, signage, and artistic projects. According to Tuofa Machining, Adobe Illustrator offers extensive vector editing tools making it excellent for intricate designs requiring detailed artwork.

However, illustration software typically requires a separate program to control your laser. You'll export files (usually DXF or SVG) and import them into machine control software like LightBurn software or the controller that came with your laser.

CAD Programs (Fusion 360)

CAD software approaches design from an engineering perspective. You define parts using precise measurements, constraints, and mathematical relationships. Changes propagate automatically—adjust one dimension and related features update accordingly.

This parametric approach proves invaluable when designing mechanical parts, enclosures with specific hardware requirements, or any project where dimensions must relate to each other mathematically.

Integrated Control Software (LightBurn, LaserGRBL)

These programs combine design capabilities with direct machine control. You create or import designs, assign cutting parameters (speed, power, passes), and send jobs directly to your laser—all without switching applications.

As 1Laser notes, LightBurn software strikes a balance between user-friendly interfaces and advanced features, making it suitable for both beginners and professionals. If you're considering the lightburn download, know that it offers a 30-day free trial to explore features before purchasing.

Choosing Software by Project Complexity

Your project type should drive your software choice. Here's how to match tools to tasks:

Simple Decorative Projects

For basic signage, ornaments, and artistic cuts, start with Inkscape or laser grbl. These free options handle straightforward vector work without overwhelming you with features you won't use. LaserGRBL works particularly well for diode laser users running GRBL-based machines.

Professional Graphics and Signage

When clients expect polished deliverables and you're producing varied designs regularly, Adobe Illustrator or CorelDRAW justify their cost. The extensive tool libraries, typography controls, and professional output options streamline commercial work.

Precision Mechanical Parts

Enclosures, brackets, assemblies with specific tolerances—these demand Fusion 360's parametric capabilities. According to Tuofa Machining, Fusion 360 is a powerful option for those creating complex 3D models and generating toolpaths, suitable for both design and manufacturing workflows.

Why parametric design matters: imagine designing an enclosure for electronics. You specify that mounting holes sit 5mm from edges, and the overall size accommodates specific components. Later, you need a larger version for different electronics. In parametric software, you adjust the component dimensions and everything—hole positions, overall size, ventilation patterns—recalculates automatically. In illustration software, you'd manually redraw everything.

All-in-One Workflow

For users wanting design and machine control in one package, LightBurn software offers the best balance. It handles vector editing, image tracing, power/speed settings, and direct machine communication. As noted by Thunder Laser USA, LightBurn works on Windows, Mac, and Linux, supports hundreds of laser machine brands, and requires only a one-time purchase instead of ongoing subscription.

Some xTool machine owners may consider xtool software (xTool Creative Space), which offers a beginner-friendly experience specifically designed for xTool products. However, 1Laser cautions that its simplicity can be limiting for advanced users, lacking some customization found in more flexible solutions.

Recommendations by Experience Level

Beginners: Start with Inkscape for design fundamentals plus LaserGRBL if you're running a diode laser. This free combination teaches core concepts without financial risk. Upgrade to LightBurn when you're ready for integrated control and faster workflows.

Intermediate Users: LightBurn software covers most needs—design, edit, and cut from one interface. Add Fusion 360 (free for personal use) when projects require parametric precision or you're designing parts that interlock with specific tolerances.

Professionals: Combine Adobe Illustrator or CorelDRAW for client-facing design work with LightBurn for production. Consider Fusion 360 for engineering projects. The investment in multiple specialized tools pays dividends in efficiency and capability.

With your software selected and configured, you're ready to move from design to production—transforming carefully prepared files into physical parts through a manufacturing workflow designed for consistency and quality.

Design for Manufacturing and Production Workflow

You've created a flawless design file—proper formats, kerf compensation applied, joints sized perfectly. But there's still a critical gap between your finished design and a successful production run. Understanding the laser cutting process from file submission to finished part ensures your carefully prepared work translates into physical components that meet specifications every time.

This is where design knowledge meets manufacturing execution. Whether you're cutting a single prototype or scaling to thousands of laser cutting parts, the principles of design for manufacturability (DFM) determine efficiency, consistency, and cost. Let's bridge that final gap.

From Design File to Production-Ready Part

The journey from your laser cutter file to a physical part involves several stages where small oversights become expensive problems. Understanding this workflow helps you anticipate requirements and prepare files that sail through production without delays.

Stage 1: File Validation

When your file arrives at a cutting service or reaches your own machine, it undergoes validation. According to SendCutSend's design guidelines, common issues caught at this stage include unconverted text boxes, open contours, and dimension verification problems—especially in files converted from raster formats.

What happens during validation:

- Path continuity checks ensure all cut lines form closed shapes

- Color coding verification confirms operations are correctly assigned

- Dimension analysis catches scaling errors before material is wasted

- Feature size review identifies elements below minimum thresholds

Stage 2: Nesting and Material Optimization

Your individual part designs get arranged on sheet material to maximize yield and minimize waste. As Baillie Fab explains, the laser cutter requires a border of up to 0.5" around every part—meaning two 4'x4' parts won't actually fit on a 4'x8' sheet as you might expect. Designing parts with material sheet sizes in mind directly impacts your cost.

Stage 3: Parameter Assignment

Based on your material specification, the operator assigns cutting parameters—laser power, speed, assist gas type, and focus position. For metals, this choice between oxygen and nitrogen assist gas affects edge quality: oxygen helps achieve higher temperatures for thick carbon steel, while nitrogen provides smooth, oxide-free edges for stainless steel and aluminum.

Stage 4: Cutting and Quality Verification

The actual cutting happens quickly—often the shortest stage in the entire process. Post-cut inspection verifies dimensional accuracy, edge quality, and feature integrity. Parts that fail inspection trace back to design issues more often than machine problems.

DFM Principles Specific to Laser Cutting

Design for manufacturability isn't just about making parts that can be cut—it's about designing parts that cut efficiently, consistently, and economically. These principles separate amateur designs from production-ready files.

True Arcs vs. Segmented Curves

Does your CAD program draw curves with flat segments instead of solid arcs? According to Baillie Fab, longer segments can get interpreted as facets instead of continuous curves—imagine wanting a circle but receiving a hexagon. Before submitting files, verify that curved lines are drawn with true arcs.

Connected Geometry

Every contour must form a complete, closed path. Unconnected lines or open contours result in poorly cut parts or require additional drafting time that delays your project. Use your software's path analysis tools to identify and fix gaps before export.

Hole and Edge Distance Rules

Holes too close to material edges create fragile sections prone to tearing. As Baillie Fab notes, maintain a distance equal to at least the material's thickness between holes and edges—some materials like aluminum require 2x that distance or more.

Grain Direction Specification

For brushed metals or materials with directional properties, specify which side is "front" and indicate grain direction on your drawing. Most metal sheets are 4'x10' with lengthwise grain—orienting your parts along this grain maximizes yield and ensures consistent appearance.

Your Pre-Submission Checklist

Before sending any laser cut templates or production files, verify every item on this checklist:

- All paths are closed — No open contours or unconnected endpoints; run path validation in your software

- Correct layer colors assigned — Cut lines in designated cutting color (typically red RGB 255,0,0); engraving areas properly filled

- Appropriate file format exported — DXF for precision parts; SVG for web-based workflows; verify compatibility with your service

- Text converted to outlines — No active text boxes that could cause font substitution issues

- Overlapping paths eliminated — Use join or merge functions to remove duplicate lines that cause double-cutting

- Tolerance annotations included — Critical dimensions called out; fit requirements specified for mating parts

- Material and thickness specified — Clear documentation of intended material prevents costly assumptions

- Grain direction indicated — For directional materials, mark which side faces up and grain orientation

- Scale verified at 1:1 — Print your design at 100% scale to physically confirm dimensions before cutting

Working with Manufacturing Partners for Best Results

For complex projects—especially precision metal components for automotive, structural, or mechanical applications—working with manufacturers who offer comprehensive DFM support transforms your production experience. The right partner catches design issues before cutting begins and suggests optimizations you might not consider.

What to look for in a manufacturing partner:

- DFM review services — Engineers who analyze your designs and recommend improvements before production

- Rapid quote turnaround — Fast feedback allows quick iteration; delays here slow your entire project timeline

- Prototyping capabilities — Ability to produce small quantities quickly for validation before committing to volume

- Quality certifications — Standards like IATF 16949 indicate consistent, documented manufacturing processes

- Material expertise — Partners experienced with your specific materials can advise on design considerations you might miss

For automotive and structural metal applications requiring precision beyond typical laser cutting, manufacturers specializing in metal stamping and assemblies bring additional value. Companies like Shaoyi Metal Technology combine rapid prototyping capabilities—often 5-day turnaround—with automated mass production, offering the DFM support that catches design issues early. Their 12-hour quote turnaround enables the fast iteration essential for model laser cutting validation before committing to production volumes.

The key is finding partners who view your laser cut project as a collaboration rather than just a transaction. When manufacturers invest time reviewing your designs and suggesting improvements, they're helping you avoid costly mistakes while improving part quality.

Scaling from Prototype to Production

Your first successful cut validates the design—but scaling to production introduces new considerations:

Batch Consistency

Single prototypes allow manual verification, but production runs require designed-in consistency. Ensure your files specify exact parameters rather than relying on operator interpretation. Document material sources, cutting parameters, and quality criteria.

Cost Optimization

According to Baillie Fab, the real value in laser cutting is achieved in higher volume productions. If you only need a few parts, simpler processes might be more economical. Discuss volume breaks with your manufacturing partner to understand where laser cutting becomes the optimal choice.

Secondary Operations

Many laser cutting parts require additional processing—bending, welding, finishing, or assembly. Design with these downstream operations in mind. Add bend reliefs where folding will occur. Include alignment features for welded assemblies. Consider how parts will be handled and fixtured during secondary operations.

With your design-to-production workflow now complete, you've bridged the gap from digital creativity to manufactured reality. The final step? Consolidating everything you've learned into quick-reference resources that keep these principles accessible whenever you start your next project.

Essential Design Rules and Next Steps

You've journeyed through file formats, minimum features, kerf compensation, joint design, troubleshooting, and software selection. That's a lot of ground to cover—and a lot of details to remember when you're staring at a blank design canvas. This final section distills everything into actionable references you can return to before every project.

Think of what follows as your laser design safety net. When you're deep in a complex project and questioning whether that 0.15" hole will actually cut clean in 1/8" steel, you'll have answers at a glance. These consolidated principles transform the knowledge you've gained into practical tools for consistent success.

Your Pre-Cut Design Checklist

Before sending any file to production, run through this comprehensive verification process. According to Impact Fab's design guide, checklists are essential for ensuring your project turns out exactly as intended—none more important than consulting with your fabricator, but this list sets you up for success.

The golden rule of laser cutting designs: measure twice, verify thrice, cut once. Every minute spent checking your design file saves hours of rework and material waste.

File Preparation Verification:

- Design is in vector format and scaled to correct size (1:1 scale)

- All text converted to outlines—no active text boxes remaining

- Cut lines set to 0.1pt stroke width with correct RGB color coding

- All paths are closed with no open endpoints or gaps

- Overlapping paths eliminated through join or merge functions

- Clipping masks released and grouped objects ungrouped

- File exported in appropriate format (DXF for precision, SVG for web workflows)

Geometry and Feature Checks:

- Hole diameters meet or exceed material thickness minimum

- Text height above 0.15" for engraving, 0.20" for cutting through

- Bridge widths between features at least 2x material thickness

- Internal corners include relief cuts (dog-bone, T-bone, or radius)

- Edge distances from holes equal at least 1.5x hole diameter

Material and Production Specifications:

- Material type and thickness clearly documented

- Kerf compensation applied appropriately to inner and outer contours

- Grain direction indicated for directional materials

- Tolerance requirements annotated for critical dimensions

- Backup file created before final export

Quick Reference for Material-Specific Design

Designing for laser cutting requires adapting your approach to each material's unique behavior. The material-first philosophy running throughout this guide comes down to understanding that steel, acrylic, and plywood each demand different design decisions—before you draw a single line.

Use this quick-reference table when starting any project. It consolidates the critical rules that prevent the most common failures:

| Design Element | Rule | Why It Matters |

|---|---|---|

| Minimum Spacing | Maintain at least 2x material thickness between adjacent cuts | Prevents heat accumulation that causes warping and burn marks |

| Minimum Hole Size | Hole diameter should equal or exceed material thickness (1.5x for wood/acrylic) | Undersized holes concentrate heat and may not cut cleanly or at all |

| Minimum Text Height | 0.20" for metals; 0.15" for thin acrylic; use sans-serif fonts | Small text features merge or burn away during cutting |

| Kerf Compensation | Offset outer paths outward, inner paths inward by half kerf width | Uncompensated designs produce parts that don't match intended dimensions |

| Internal Corners | Add relief cuts or minimum 0.020" radius to all sharp internal corners | Sharp corners create stress concentrations that crack or tear |

| Edge Distance | Keep features at least 1.5x their diameter from part edges | Thin walls between features and edges are fragile and may tear |

| Bridge Width | Minimum 0.020" for metals, 0.030" for woods between connected elements | Narrow bridges burn away during cutting, causing part dropout |

| File Format | DXF for precision parts; SVG for web workflows; verify export settings | Wrong format or version causes conversion errors and lost geometry |

| Path Closure | All cut contours must form complete, closed paths with no gaps | Open paths cause incomplete cuts or unpredictable laser behavior |

| Layer Colors | Use exact RGB values (Red 255,0,0 for cuts; Black 0,0,0 for engraving) | Incorrect colors cause operations to be assigned wrong parameters |

The Material-First Mindset

Every successful laser design starts with a simple question: what am I cutting? Your answer shapes every subsequent decision.

Steel conducts heat rapidly—design with tighter spacing. Acrylic melts cleanly—expect consistent kerf. Plywood varies with grain—test every batch. The material dictates the rules; your job is to follow them.

This material-first approach distinguishes laser cutting designs that work from those that fail. When you understand why plywood requires wider slot tolerances than acrylic, or why aluminum needs more edge distance than steel, you stop memorizing arbitrary rules and start making informed decisions.

According to Komacut's design guide, using standard material thicknesses is one of the easiest ways to optimize the laser cutting process—these materials are more cost-effective, readily available, and your laser is already calibrated for them. Custom thicknesses require special sourcing and calibration that increase both lead times and costs.

From Design to Production: Your Next Steps

You now possess the knowledge to create laser ready templates that cut successfully the first time. But knowledge alone doesn't produce parts—action does. Here's how to move forward:

For Personal Projects:

Start with simple designs that test your understanding. Cut a few test pieces in your chosen material to verify kerf values and minimum feature performance before committing to complex projects. Use the free software options (Inkscape, LaserGRBL) to develop skills without financial pressure.

For Professional Applications:

Complex projects—especially precision metal components for automotive, structural, or mechanical applications—benefit enormously from professional DFM support. According to Impact Fab, working with a fabricator who takes time to discuss your project in detail helps avoid the many possible negative outcomes of leaving anything to chance.

For design for laser cutting projects requiring validated precision, partnering with manufacturers offering comprehensive DFM review catches issues before they become expensive mistakes. Companies like Shaoyi Metal Technology provide the rapid iteration essential for moving confidently from design to prototype—their 12-hour quote turnaround and 5-day prototyping capabilities enable quick validation cycles that keep projects on schedule.

For Continuous Improvement:

Keep a design journal documenting what works and what fails. Note the kerf values you measure for different materials, the minimum features that cut successfully, and the joint parameters that produce tight fits. This personalized reference becomes invaluable as you tackle increasingly complex laser designs.

Final Thoughts

Successful laser cutting begins long before any beam touches material. It starts with understanding that every design decision—from file format selection to feature sizing to kerf compensation—directly impacts whether your parts arrive ready to use or require frustrating rework.

The principles in this guide represent thousands of collective hours of trial, error, and refinement. Apply them consistently, verify your work against the checklists provided, and approach each project with the material-first mindset that separates amateur attempts from professional results.

Your next design awaits. Make it your best one yet.

Frequently Asked Questions About Laser Cutting Design

1. Where can I find free laser cutting designs?

Several reputable websites offer free laser cut files, including Atomm, 3axis.co, Vecteezy, Ponoko, Design Bundles, Thingiverse, and Instructables. These platforms provide SVG, DXF, and other vector formats ready for cutting. When using free files, always verify path closure, check for proper color coding, and confirm dimensions match your material thickness before cutting. Many files require kerf compensation adjustments for precision fits.

2. What software is best for laser cutting designs?

The best software depends on your project complexity and budget. For beginners, Inkscape (free) paired with LaserGRBL works well for basic projects. LightBurn ($60-$120 one-time) offers an excellent balance of design and machine control for serious hobbyists. Adobe Illustrator excels at complex artwork, while Fusion 360 provides parametric capabilities for precision mechanical parts. Choose based on whether you need 2D illustration tools or CAD-style engineering precision.

3. What file format should I use for laser cutting?

DXF is preferred for precision parts and CAD-originated designs due to its exceptional dimensional accuracy. SVG works best for web-based workflows, creative projects, and when using free software like Inkscape. AI files suit Adobe ecosystem users handling complex layering. Regardless of format, ensure all paths are closed, strokes set to 0.1pt, text converted to outlines, and proper RGB color coding applied for cut versus engrave operations.

4. How do I compensate for laser kerf in my designs?

Kerf compensation requires offsetting cut paths based on material removal width. For outer contours, offset paths outward by half the kerf width to maintain correct part size. For inner contours (holes and slots), offset inward by half the kerf. Typical kerf values range from 0.15-0.25mm for metals to 0.25-0.50mm for wood and acrylic. Always run a test cut on your specific material to measure actual kerf before production.

5. What are the minimum feature sizes for laser cutting?

Minimum feature sizes depend on material type and thickness. For metals, hole diameters should be at least 0.25 inches for thin stock (under 0.135 inches) and 0.50 inches for thicker materials. Text height minimums are 0.20 inches for metals and 0.15 inches for thin acrylic. Maintain spacing between cuts at minimum 2x material thickness to prevent heat accumulation and warping. Always verify features meet these thresholds before sending files to production.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —