Metal Laser Cutting Services Decoded: From File Upload To Finished Part

Understanding Metal Laser Cutting Technology

What happens when you focus intense light energy onto a piece of steel? You get one of the most precise cutting methods available in modern manufacturing. Metal laser cutting services transform raw sheet metal into intricate components using nothing more than concentrated light—no physical blade ever touches the material.

Laser cutting is a fabrication process that uses a high-power laser beam, directed through optics and computer numerical control (CNC), to melt, burn, or vaporize material along a programmed path, leaving behind a high-quality finished edge.

How Focused Light Transforms Metal Fabrication

Imagine concentrating sunlight through a magnifying glass, then multiplying that intensity thousands of times. That's essentially what is laser cutting in its simplest form. A laser beam—typically under 0.32 mm (0.0125 inches) in diameter at its narrowest point—delivers enough energy to slice through steel, aluminum, and other metals with remarkable accuracy. Some systems achieve kerf widths as small as 0.10 mm (0.004 inches), depending on material thickness.

Unlike mechanical cutting methods that rely on physical contact, cutting with a laser removes material through thermal energy. A high-pressure jet of gas—either inert nitrogen for clean edges or oxygen to accelerate the cutting of steel—blows away molten material from the cut path. The result? Smooth, precise edges without the mechanical stress that traditional cutting imparts.

The Science Behind Precision Metal Cutting

How does a machine generate such powerful light? The physics involves a fascinating process called stimulated emission. Inside the laser resonator, electrons absorb energy and jump to higher energy states. When these excited electrons return to lower states, they release photons—particles of light—with identical properties. These photons bounce between mirrors inside the laser tube, multiplying rapidly until the beam becomes intense enough to escape through a partially reflective mirror.

This coherent beam then travels through fiber optic cables or a series of mirrors to a focusing lens. The lens concentrates all that energy into a tiny point, creating temperatures high enough to melt or vaporize metal instantly. Computer numerical control guides the cutting head along precisely programmed paths, following instructions generated from your CAD design files.

From Light Beam to Finished Part

Metal laser cutting has become essential across manufacturing because it solves problems other methods cannot. Need intricate patterns in thin stainless steel? Laser metal cutting handles it effortlessly. Require tight tolerances on aluminum brackets? The technology delivers consistently. From automotive components to architectural panels, manufacturers rely on these services for their combination of speed, precision, and versatility.

When you use a laser to cut metal, you're leveraging decades of photonics research refined for industrial applications. The technology continues advancing, with newer fiber laser systems offering improved efficiency and the ability to cut reflective materials that challenged earlier machines. Understanding these fundamentals helps you communicate more effectively with service providers and make informed decisions about your fabrication projects.

Laser Technology Types and Their Capabilities

So you understand how laser cutting works—but which type of laser for cutting machine applications actually suits your project? This question trips up many engineers and procurement managers because the answer isn't straightforward. Different laser technologies excel in different scenarios, and choosing the wrong one can mean slower production, higher costs, or subpar edge quality.

Let's break down the three primary metal cutting laser machine technologies you'll encounter when sourcing fabrication services.

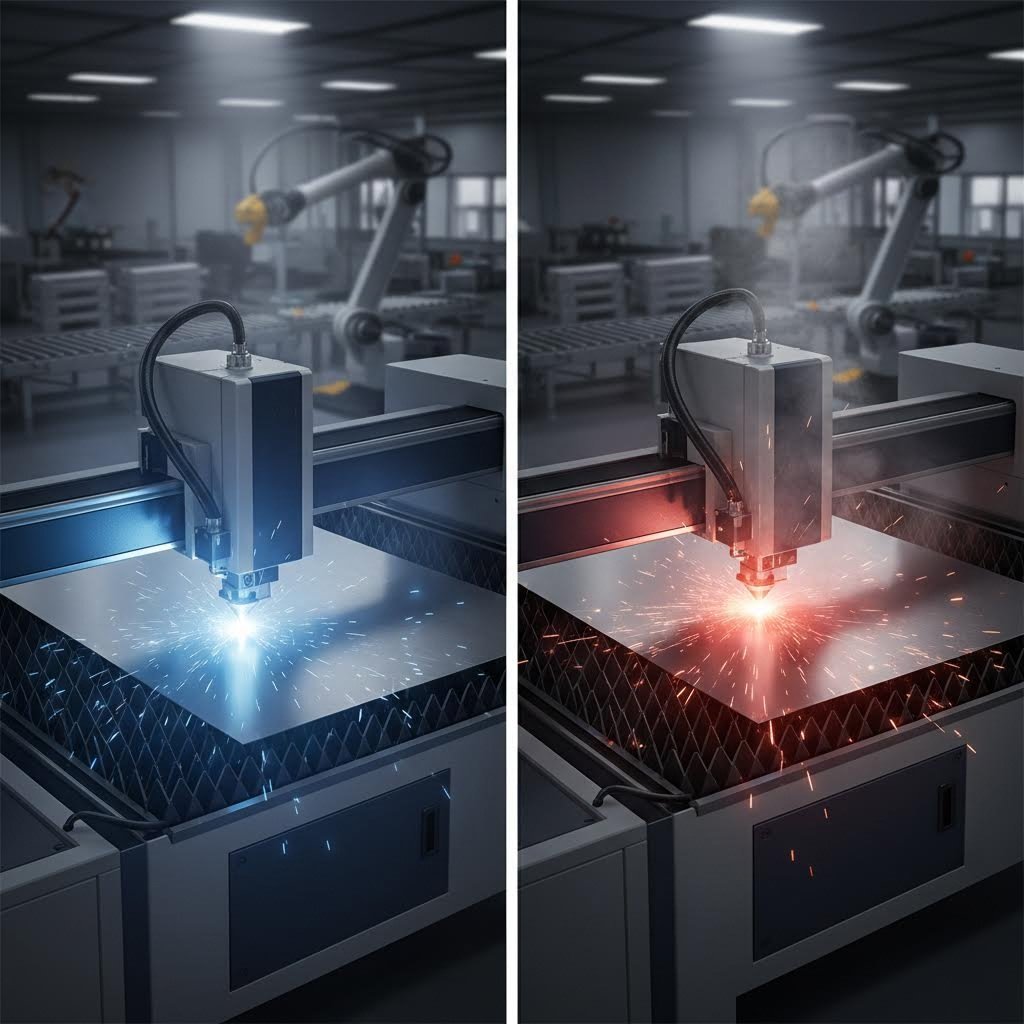

Fiber Lasers vs CO2 Lasers Explained

The two dominant technologies in sheet metal laser cutting machine applications are fiber lasers and CO2 lasers. Understanding their fundamental differences helps you evaluate quotes and capabilities more effectively.

Fiber lasers use solid-state technology with optical fibers doped with rare-earth elements like ytterbium. Energy from semiconductor laser diodes travels through fiber optic cables, exciting ytterbium ions that release near-infrared photons at a wavelength of 1.064 micrometers. This compact design eliminates the need for complex mirror alignment systems, resulting in lower maintenance requirements and higher reliability.

CO2 lasers generate their beam differently. Electrical discharge excites carbon dioxide gas inside a sealed tube, producing far-infrared light at a wavelength of 10.6 micrometers. This longer wavelength requires mirrors to direct the beam path since it cannot travel through fiber optic cables. While this adds complexity, CO2 systems remain valuable for specific applications.

A third option, Nd:YAG lasers, offers ultra-high precision for specialty applications like jewelry, electronics, or microfabrication. However, these systems are limited to thinner materials and represent a niche choice compared to fiber and CO2 technologies.

Power and Wavelength Differences That Matter

Why does wavelength matter so much? It directly affects how metals absorb laser energy—and absorption determines cutting efficiency.

Fiber lasers' shorter 1.064-micrometer wavelength creates a beam that can be focused into a spot roughly 10 times smaller than a CO2 laser's beam. This concentrated energy delivers higher power density at the cutting point, enabling faster processing speeds and finer detail work. According to research from Laser Photonics, aluminum absorbs seven times more radiation from a fiber laser than from a CO2 laser with equivalent power output.

Energy efficiency tells another compelling story. Fiber lasers convert up to 42% of electrical input into laser light, while CO2 systems manage only 10-20% efficiency. This translates directly to lower operating costs—a critical consideration for high-volume production runs.

Power ranges differ significantly between technologies:

- Entry-level systems (500W–1.5kW): Handle thin sheets up to 3mm

- Mid-range systems (3kW–6kW): Cover most industrial cutting applications

- High-power systems (10kW–40kW): Cut very thick plates and maximize production speed

Matching Laser Technology to Your Material

Here's where the "best laser for cutting" question gets practical. Neither technology wins universally—optimal choice depends entirely on what you're cutting.

Fiber lasers dominate when processing:

- Reflective metals like aluminum, copper, and brass

- Stainless steel and mild steel at high speeds

- Thin to medium thickness materials requiring precision

- High-volume production where speed and efficiency matter

CO2 lasers excel for:

- Mixed-material workshops handling both metals and non-metals

- Applications requiring exceptionally smooth edge finishes

- Thicker non-metallic materials like wood, acrylic, and textiles

- Projects where initial equipment cost outweighs long-term operating expenses

For a laser cutting machine metal processing specifically, fiber technology has largely become the industry standard. Its superior efficiency with reflective metals, faster cutting speeds on thin materials, and lower maintenance requirements make it the practical choice for most fabrication shops.

| Category | Fiber Laser | CO2 Laser | Nd:YAG Laser |

|---|---|---|---|

| Best Materials | Steel, stainless steel, aluminum, copper, brass | Metals, wood, acrylic, plastics, textiles | Thin metals, jewelry, electronics |

| Typical Thickness Range | Up to 25mm (power dependent) | Up to 25mm for metals; thicker for non-metals | Up to 6mm |

| Cutting Speed | Up to 3x faster than CO2 on thin metals | Moderate; excels on thicker materials | Slower; precision-focused |

| Edge Quality | Excellent on metals; clean, burr-free | Superior on non-metals; smooth finish | Very high precision edges |

| Energy Efficiency | 35-42% electrical conversion | 10-20% electrical conversion | Moderate |

| Maintenance | Low; solid-state design | Higher; gas tube and mirror replacement | Moderate |

| Ideal Applications | Automotive, aerospace, electronics, high-volume production | Signage, furniture, mixed-material shops | Microfabrication, medical devices |

| Lifespan | Up to 100,000 hours | 20,000-30,000 hours | Varies by application |

When evaluating a co2 laser cut metal machine versus fiber alternatives, consider your production mix. If you're exclusively cutting metals—especially reflective ones—fiber technology offers clear advantages in speed, efficiency, and long-term cost. However, shops handling diverse materials might find CO2's versatility justifies its higher operating expenses.

The best laser for cutting your specific parts ultimately depends on three factors: material type, thickness requirements, and production volume. Armed with this understanding, you're better positioned to evaluate service providers and ensure your projects land on the right equipment.

Material Compatibility and Thickness Guidelines

Now that you understand which laser technology suits different applications, the next critical question emerges: can it actually cut your material? Not all metals behave the same under a laser beam. Some absorb energy efficiently and cut cleanly. Others reflect most of that energy back toward the machine, creating challenges that require specific techniques to overcome.

Let's explore which materials work best for laser cutting of metal sheets—and where you might encounter limitations.

Steel and Stainless Steel Cutting Parameters

Carbon steel remains the workhorse material for metal laser cutting services. Its iron-carbon composition absorbs laser energy readily, making it one of the easiest metals to process. When oxygen assist gas is used, an exothermic reaction occurs—the oxygen actually burns the heated steel, adding energy to the cut and enabling faster processing speeds.

Stainless steel laser cutting presents slightly different characteristics. The chromium content that provides corrosion resistance also affects how the material responds to thermal processing. Laser cutting SS typically requires nitrogen assist gas instead of oxygen to prevent oxidation along the cut edge, preserving that clean, corrosion-resistant surface finish.

Here's what current fiber laser systems can handle:

- Carbon steel: Up to 6mm with 500W systems; up to 20mm with 3000W; up to 40mm with 10kW+ systems

- Stainless steel: Up to 3mm with 500W; up to 10mm with 3000W; up to 50mm with 10kW+ systems

- Quality cutting note: Maximum thickness doesn't equal quality cutting—expect optimal edge quality at roughly 60% of maximum capacity

For laser cut stainless steel applications requiring bright, oxide-free edges, staying within the quality cutting range matters significantly. A 3000W system might technically cut 12mm stainless, but edge quality deteriorates noticeably above 8mm.

Aluminum and Reflective Metal Considerations

Ever wonder why aluminum laser cutting was once considered problematic? Reflective metals like aluminum, copper, and brass behave very differently under laser irradiation. Their smooth surfaces and high thermal conductivity create two significant challenges.

First, these materials bounce a portion of the laser energy back toward the cutting head, reducing efficiency and potentially damaging optical components. Second, their excellent thermal conductivity pulls heat away from the cutting zone rapidly, making consistent penetration more difficult to achieve.

Modern fiber lasers have largely solved these challenges through:

- Pulsed cutting mode: Delivers energy in short, controlled bursts rather than continuous waves

- Anti-reflection protection: Advanced systems include back-reflection monitoring and automatic shutdown

- Optimized parameters: Adjusted peak power, pulse frequency, and focus position for reflective materials

When you need to laser cut aluminum components, material preparation also matters. Surface contaminants—oil, oxidation, film coatings, or moisture—increase reflection and reduce cut quality. Clean surfaces improve absorption and reduce back-reflection risks.

Aluminium laser cutting thickness capabilities with fiber lasers:

- 500W systems: Up to 2mm maximum

- 1000W systems: Up to 3mm maximum

- 3000W systems: Up to 8mm maximum

- 10kW+ systems: Up to 40mm with proper anti-reflection protection

Copper and brass follow similar patterns but present even greater reflectivity challenges. High-purity copper, often used in electrical applications, requires careful parameter tuning and may benefit from pulsed cutting modes even on thinner gauges.

Material Thickness Limits and Why They Exist

Why do thickness limitations exist at all? Three interrelated factors determine whether a laser can successfully cut through a given material thickness: laser power, material thermal properties, and beam focus characteristics.

Higher power delivers more energy to the cutting zone. According to industry data, the cutting speed of 10kW laser cutting machines is more than twice that of 6kW systems when processing 3-10mm stainless steel. For 20mm thick stainless, 12kW systems cut 114% faster than 10kW machines.

But power alone doesn't tell the whole story. Material reflectivity determines how much of that power actually gets absorbed. Thermal conductivity affects how quickly heat dissipates from the cutting zone. And beam focus depth limits how deeply the laser can maintain cutting intensity.

| Material Type | 500W Max | 1000W Max | 3000W Max | 6000W Max | Quality Considerations |

|---|---|---|---|---|---|

| Carbon Steel | 6mm | 10mm | 20mm | 25mm+ | Oxygen assist enables bright surface cutting; nitrogen for oxide-free edges |

| Stainless Steel | 3mm | 5mm | 10mm | 16mm | Quality cutting reliable below 12mm with 6kW; nitrogen required for clean edges |

| Aluminum | 2mm | 3mm | 8mm | 12mm | Requires anti-reflection protection; clean surfaces essential |

| Copper | 2mm | 3mm | 8mm | 10mm | Most challenging reflective metal; pulsed mode often necessary |

| Brass | 2mm | 3mm | 8mm | 12mm | Zinc content can produce fumes; proper ventilation required |

Stainless laser cutting and aluminum processing share a critical consideration: the gap between maximum cutting thickness and quality cutting thickness. A machine might technically pierce through 16mm stainless steel, but edge quality, cutting speed, and consistency may suffer considerably above 12mm. When requesting quotes, always specify whether you need maximum capacity or quality-focused processing.

Some materials simply aren't suited for laser cutting regardless of power. Galvanized steel releases zinc oxide fumes requiring specialized ventilation. Certain coated metals can produce toxic gases. And extremely thick plates—beyond 50mm even for high-power systems—may be better suited for plasma or waterjet cutting methods, which we'll explore in the next section.

The Complete Laser Cutting Process Explained

You've selected your laser technology and confirmed your material works for the process. But what actually happens after you submit your design files? Many customers treat laser cut services as a black box—files go in, parts come out. Understanding the journey from CAD file to finished component helps you communicate more effectively with fabricators, anticipate potential issues, and make design decisions that reduce cost and lead time.

Let's walk through each stage of the precision laser cutting workflow.

From CAD File to Cut Part

Every project begins with your design file. Most laser cut services accept several formats, but some work better than others for efficient processing.

- Design file preparation and submission: Prepare your part geometry in vector format—DXF and DWG files work universally, while STEP and IGES formats preserve 3D information useful for parts requiring secondary bending operations. Avoid submitting raster images like JPG or PNG since these cannot define precise cutting paths. Include separate layers for different operations if your part requires engraving, scoring, or through-cutting.

- File review and DFM feedback: Experienced fabricators don't just run your file immediately. They review geometry for manufacturability issues: features too small for the material thickness, holes positioned too close to edges, or internal corners that need radius adjustments. This design-for-manufacturing (DFM) feedback catches problems before they become expensive mistakes on the cutting bed. According to industry practice, this early collaboration reduces errors and shortens overall production time.

- Material selection and sourcing: Once geometry is confirmed, material gets specified. This includes not just the metal type but the specific alloy grade, thickness tolerance, and surface finish requirements. Shops either pull from existing inventory or order material to match your specifications. Lead time often depends more on material availability than actual cutting time.

- Machine programming and path optimization: Your approved design converts into machine-readable code. The programmer selects cutting parameters—laser power, cutting speed, assist gas pressure, and focus position—matched to your specific material and thickness combination. This step directly impacts edge quality and cutting efficiency.

- The cutting operation: Your parts finally reach the laser bed. The focused beam follows programmed paths, melting or vaporizing material while assist gas clears the cut zone. Modern systems monitor the process in real-time, adjusting parameters if they detect inconsistencies. A single sheet might contain dozens of parts cut in one operation.

- Quality inspection: Finished parts undergo dimensional verification against your original specifications. Critical features get measured using calibrated instruments. Visual inspection catches edge quality issues, surface marks, or incomplete cuts that could affect part function.

- Secondary operations and packaging: Many laser cut parts require additional processing—deburring sharp edges, tapping holes, or applying protective finishes. Parts are then cleaned, packaged to prevent damage during shipping, and documented for traceability.

Understanding Nesting and Material Optimization

One stage deserves special attention because it significantly affects both cost and sustainability: nesting optimization.

When a fabricator receives multiple parts—or multiple copies of the same part—they don't cut them one at a time in the center of individual sheets. Instead, specialized software arranges all parts on shared sheets like puzzle pieces, minimizing the space between components and maximizing how many parts come from each sheet.

This nesting process matters because you're typically paying for material by the sheet, not by individual part area. Efficient nesting can mean the difference between needing four sheets versus five sheets for the same order quantity. For laser tube cutting services processing cylindrical stock, similar optimization arranges parts along the tube length to reduce waste.

Smart nesting also considers cutting path efficiency. Parts arranged to share common cut lines reduce total cutting time. The software calculates optimal sequences that minimize head travel between cuts, further reducing production time without sacrificing laser cutting precision.

The Quality Checkpoints That Ensure Precision

Quality control in laser fabrication happens at multiple stages, not just at the end. Understanding these checkpoints helps you specify the right level of inspection for your application.

Pre-production verification confirms material certifications match specifications before cutting begins. This matters especially for aerospace, medical, or certified applications where material traceability is mandatory.

In-process monitoring uses sensors to track cutting consistency in real-time. Modern systems detect plasma generation, back-reflection, and pierce completion—pausing automatically if parameters drift outside acceptable ranges.

Post-cut inspection verifies dimensional accuracy and edge quality. First-article inspection—carefully measuring the first part from each setup—catches programming errors before they propagate through an entire production run.

Turnaround times for laser cut parts vary considerably based on complexity, material availability, and secondary operation requirements. Simple parts from stock material might ship within 2-3 business days. Complex projects requiring DFM iteration, special material sourcing, and multiple secondary operations could extend to 2-3 weeks. When lead time is critical, communicate your deadline early—many shops offer expedited processing for time-sensitive projects.

With the complete process now clear, you might wonder how laser cutting stacks up against alternative methods. When does plasma, waterjet, or mechanical cutting make more sense? Let's compare the options.

Laser Cutting Compared to Alternative Methods

Here's a truth most fabricators won't tell you upfront: laser cutting isn't always the best choice. Sounds surprising coming from an article about metal laser cutting services, right? But understanding when alternative cutting methods outperform laser technology helps you make smarter decisions—and ultimately get better results for your specific project.

Four primary metal cutting services compete for your business: laser cutting, waterjet cutting, plasma cutting, and electrical discharge machining (EDM). Each technology has carved out niches where it excels. Let's compare them honestly.

Laser Cutting vs Waterjet and Plasma Methods

Laser cutting brings precision and speed to thin and medium-thickness metals. The focused beam produces clean edges with minimal kerf—often requiring no secondary finishing. CNC laser cutting systems excel at intricate patterns, tight tolerances, and high-volume production runs where consistency matters.

But what happens when your material is six inches thick? Or when heat distortion would ruin your part?

Waterjet cutting uses high-pressure water mixed with abrasive particles to slice through virtually any material—including metals up to 24 inches thick for rough cuts. Because waterjet is a cold-cutting process, it produces no heat-affected zone (HAZ). This matters enormously for aerospace components, specialty alloys, or any application where thermal stress could compromise material integrity.

The trade-off? Waterjet runs slower than laser or plasma. It also generates more mess from the abrasive slurry and requires higher maintenance. Yet when accuracy and material preservation are priorities, waterjet often wins.

Plasma cutting uses electrically ionized gas to generate intense heat—slicing through thick steel quickly and economically. If you're searching for "plasma cutting near me" for heavy structural steel work, plasma delivers. It handles thicker materials than laser and costs less per cut, especially in high volumes.

However, plasma introduces significant heat to the material, causing potential warping in thinner sheets. Edge quality is rougher than laser or waterjet, often requiring secondary cleanup. For precision parts or heat-sensitive materials, plasma falls short.

When Alternative Cutting Methods Make More Sense

Let's be direct about when laser cutting is NOT your best option:

- Very thick materials (over 25mm): Plasma or waterjet handle thick plates more efficiently than most machine cutter metal systems using laser technology

- Heat-sensitive applications: Aerospace alloys, hardened steels, or materials prone to thermal distortion benefit from waterjet's cold-cutting process

- Reflective metals at extreme thicknesses: While fiber lasers handle aluminum well, very thick copper or brass may process better with waterjet

- Ultra-precision micro-features: EDM achieves tolerances down to ±0.001 inches on conductive materials—tighter than most laser systems

- Budget-constrained thick steel projects: When cutting laser metal isn't cost-effective, plasma delivers faster results at lower cost for structural steel cutting services

Electrical Discharge Machining (EDM) deserves mention for specialized applications. EDM uses electrical discharges to erode conductive materials with extreme precision. It's slower than other methods—often the slowest of all four—but produces exceptional edge finish on materials up to 12 inches thick. For complex geometries requiring particular edge finishes, EDM remains valuable despite its speed limitations.

Choosing the Right Technology for Your Project

So how do you decide? Consider these six factors:

- Material type: What metal are you cutting? Conductive materials only work with EDM. Reflective metals require fiber laser or waterjet. Non-metals need CO2 laser or waterjet.

- Thickness requirements: Thin to medium sheets favor laser. Thick plates point toward plasma or waterjet.

- Precision needs: Tolerances under ±0.005" typically require laser or EDM. Structural tolerances allow plasma.

- Edge quality expectations: Display-quality edges demand laser or waterjet. Hidden structural components tolerate plasma's rougher finish.

- Heat-affected zone concerns: Any heat sensitivity eliminates plasma and limits laser. Waterjet becomes the clear choice.

- Cost considerations: Plasma offers lowest cost per cut for thick steel. Laser balances speed and precision economically. Waterjet and EDM command premium pricing.

| Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting | EDM |

|---|---|---|---|---|

| Precision Tolerance | ±0.003" to ±0.005" | ±0.003" to ±0.005" | ±0.015" to ±0.030" | ±0.001" to ±0.002" |

| Material Compatibility | Most metals; limited non-metals | Any material | Conductive metals only | Conductive materials only |

| Typical Thickness Range | Up to 25mm (metal) | Up to 24" (rough cut) | Up to 50mm+ | Up to 12" |

| Edge Quality | Excellent; minimal finishing | Smooth, satin finish | Good; may need cleanup | Very smooth; little finishing |

| Heat-Affected Zone | Small but present | None (cold process) | Significant | Very small |

| Cutting Speed | Fast on thin materials | Slower | Very fast on thick steel | Slowest |

| Relative Cost | Moderate | Higher | Lowest | Highest |

| Best Applications | Sheet metal, precision parts, high volume | Thick materials, heat-sensitive alloys | Structural steel, thick plates | Micro-precision, complex geometries |

The honest answer to "which is best?" is: it depends entirely on your project requirements. A manufacturer offering steel cutting services might recommend plasma for your 2-inch structural plates while steering your thin aluminum enclosures toward cnc laser cutting. That versatility in approach—matching technology to application—often indicates a knowledgeable partner.

When you understand these trade-offs, conversations with fabricators become more productive. You can ask informed questions, evaluate recommendations critically, and ensure your parts end up on the right equipment. Now let's examine how your design choices directly influence both cost and quality outcomes.

Design Best Practices for Laser Cut Parts

You've selected the right cutting technology for your material. Now comes a step that separates smooth projects from frustrating delays: preparing your design files correctly. The geometry you submit directly determines whether your parts cut cleanly, fit together accurately, and arrive on schedule—or whether they bounce back for revisions that eat into your timeline.

Understanding why certain design rules exist helps you make informed decisions rather than blindly following specifications. Let's explore the guidelines that genuinely matter for sheet metal laser cutting success.

Design Rules That Reduce Cost and Improve Quality

Every design rule in laser cutting traces back to physical constraints: the beam diameter, material behavior under heat, and structural integrity of the finished part. When you understand these relationships, you can push boundaries intelligently rather than playing it too safe or risking failure.

- Minimum feature size: No internal geometry should be smaller than 0.015 inches (0.38mm), according to industry standards. Why? The laser beam has a physical diameter, and features smaller than this threshold cannot maintain dimensional accuracy. For laser cut sheet metal applications, the practical minimum is typically 50% of your material thickness—a 2mm sheet requires holes at least 1mm in diameter.

- Hole-to-edge distance: Position holes at least one material thickness away from edges. Closer placement weakens the remaining material web, risking deformation during cutting or failure during part use. For a laser cutter sheet metal project using 3mm steel, keep holes at least 3mm from any edge.

- Internal corner radius: Sharp 90-degree internal corners are physically impossible with laser cutting. The beam creates a natural radius equal to approximately half the kerf width—typically 0.05mm to 0.5mm depending on material and power. Design internal corners with explicit radii matching or exceeding this natural limit to avoid stress concentrations.

- Tab and slot design: When designing interlocking parts, size tabs slightly narrower than slots to account for kerf. A common approach: design tabs 0.1mm to 0.2mm undersize. This creates a snug press-fit without requiring force that could damage thin materials.

- Minimum cut width: Slots and narrow cuts should be at least as wide as the material thickness. Narrower cuts trap heat, potentially welding the cut closed or causing warping in adjacent material.

| Design Feature | Recommended Minimum | Why It Matters |

|---|---|---|

| Internal geometry | ≥0.015" (0.38mm) absolute; ≥50% material thickness | Beam diameter limits achievable precision on small features |

| Hole-to-edge distance | ≥1x material thickness | Prevents edge deformation and structural weakness |

| Internal corner radius | ≥0.5x kerf width (typically 0.05-0.5mm) | Eliminates stress concentrations; matches natural beam geometry |

| Tab width for slots | Slot width minus 0.1-0.2mm | Compensates for kerf to create proper interference fit |

| Minimum slot/cut width | ≥1x material thickness | Prevents heat buildup and potential re-welding of cut edges |

| Text/lettering height | ≥3mm for cut-through; ≥1mm for engraving | Maintains legibility and structural integrity of letter forms |

Common Mistakes That Increase Lead Time

Some design errors trigger immediate file rejections. Others slip through initial review only to cause problems on the cutting bed. Knowing these pitfalls helps you avoid the back-and-forth that delays production.

- Open contours: If your vector paths don't form closed shapes, the laser cannot determine what's inside versus outside. As design guides recommend, review your file in outline mode to catch gaps where lines don't quite connect. Even a 0.01mm gap creates an open contour.

- Duplicate or overlapping lines: When the laser encounters the same path twice, it cuts that line twice—potentially burning through adjacent material or creating unwanted marks. Clean your file by selecting all geometry and using your CAD software's merge or weld function.

- Pre-compensating for kerf: Here's a counterintuitive one. Many designers try to adjust their dimensions to account for material removed by the laser. Don't. Professional sheet metal laser cutter services apply kerf compensation automatically during programming. If you've already adjusted your file, your parts will be oversized or undersized.

- Text not converted to outlines: Fonts in CAD files don't transfer reliably between systems. If you submit a file with live text, the fabricator's software may substitute a different font—or fail to read it entirely. Always convert text to paths or outlines before submission.

- Floating geometry: Letters like "O," "A," or "R" contain internal shapes that will fall out when cut unless connected by bridges. This "stencil" approach applies to any design with holes inside other shapes. Without bridges, you lose those center pieces during cutting.

- Pre-nested files for quantity orders: Uploading a file containing multiple copies of the same part seems efficient, but it actually limits optimization. Submit single-part files and specify quantities separately—this allows the fabricator's nesting software to arrange parts more efficiently across sheets.

Optimizing Your Design for Laser Cutting Success

Beyond avoiding mistakes, several proactive choices improve outcomes when laser cutting steel sheet or other metals.

File format selection matters. Vector formats define geometry mathematically, allowing infinite scaling without quality loss. DXF remains the universal standard for laser cutting steel sheet and other materials. DWG works equally well. For parts requiring bending, STEP or IGES files preserve 3D information that helps fabricators plan forming operations.

Avoid bitmap formats—JPG, PNG, BMP—entirely. These pixel-based files cannot define the precise cutting paths a laser sheet metal cutter requires. If you only have a raster image, it must be vectorized first using software like Inkscape or Adobe Illustrator's image trace function.

- Use inch units at 1:1 scale: While metric works fine, inch-based files at actual size reduce conversion errors and interpretation questions.

- Place all geometry on a single layer: Multiple layers complicate processing. Flatten your design unless separate layers indicate different operations (cutting vs. engraving).

- Remove construction geometry: Delete any reference lines, notes, or auxiliary geometry that shouldn't be cut. Hidden layers still export in some file formats.

- Specify tolerances where critical: If certain dimensions require tighter control than standard ±0.005" capability, note these clearly in accompanying documentation.

For laser cut cnc machine processing, these preparation steps directly translate to faster quoting, fewer revision cycles, and on-time delivery. A well-prepared file might process through review in hours; a problematic one could bounce back multiple times over days.

Material selection also influences design constraints. Standard thicknesses—1mm, 1.5mm, 2mm, 3mm—are readily available and pre-calibrated on most equipment. According to fabrication specialists, non-standard thicknesses often require minimum order quantities, special sourcing, and extended lead times that significantly increase costs.

When your design follows these guidelines, you've removed the most common friction points from the fabrication process. Your files process faster, your quotes come back quicker, and your parts arrive matching your intent. With design fundamentals covered, let's examine how different industries leverage these capabilities for specific applications.

Industry Applications for Metal Laser Cutting

Ever wonder why metal laser cutting services appear in everything from the car you drive to the smartphone in your pocket? The technology's combination of precision, speed, and versatility has made it indispensable across virtually every manufacturing sector. But each industry brings unique demands—different tolerances, specialized certifications, specific material requirements, and vastly different production volumes.

Let's explore how industrial laser cutting adapts to meet these diverse needs.

Automotive and Transportation Applications

The automotive industry was among the first to embrace laser cutting at scale. Traditional stamping and die-cutting methods simply couldn't keep pace with modern production demands or accommodate the complexity of contemporary vehicle designs.

Today, a metal laser cutter processes a remarkable range of automotive components:

- Chassis and structural components: Frame brackets, cross members, and reinforcement plates requiring consistent tolerances across thousands of units

- Body panels and trim: Door components, pillar reinforcements, and decorative trim pieces with complex contours

- Suspension parts: Control arm brackets, spring mounts, and stabilizer bar components where precision affects vehicle handling

- Interior metalwork: Seat frames, dashboard brackets, and console mounting hardware

- Exhaust system components: Heat shields, mounting brackets, and flanges requiring specific alloy processing

Lightweighting has emerged as a particularly compelling application. Manufacturers increasingly swap heavy conventional steel for aluminum and high-strength steel alloys to boost fuel efficiency, reduce costs, and improve sustainability. Custom metal laser cutting enables the intricate weight-reduction patterns—honeycomb structures, strategically placed cutouts—that shave pounds without sacrificing structural integrity.

Volume requirements in automotive are demanding. A single vehicle platform might require millions of identical brackets annually, with tolerances held within ±0.005" across every single piece. IATF 16949 certification—the automotive quality standard—governs supplier qualification, requiring documented process controls and traceability from raw material to finished part.

Precision Requirements Across Industries

Aerospace applications push laser cutter for metal capabilities to their limits. When components spend hours exposed to extreme temperatures and atmospheric forces, every cut matters. Aerospace titanium laser cutting demands specialized techniques—argon shielding gas instead of nitrogen, pulsed cutting modes to manage heat, and tolerances often tighter than ±0.003".

Common aerospace applications include:

- Helicopter propeller surface components

- Structural airframe brackets and fittings

- Engine mounting hardware

- Interior cabin structural elements

- Lightweight lattice structures for weight optimization

NADCAP certification—the aerospace industry's quality accreditation—audits everything from gas purity to machine calibration to material traceability. A blue or purple edge on titanium? That indicates oxidation and often means an automatic part rejection.

Electronics manufacturing presents opposite challenges—components are miniature rather than massive. The precision of fiber lasers enables manufacturers to cut printed circuit boards (PCBs), flexible circuit boards (FPCs), and intricate enclosure patterns with micron-level accuracy.

Typical electronics applications include:

- EMI shielding enclosures and covers

- Heat sink fins and thermal management components

- Connector housings and mounting plates

- Device chassis and internal frameworks

- Battery contact springs and terminals

Architectural and signage applications prioritize aesthetics alongside function. A laser metal cutter produces decorative panels, building facades, custom signage, and artistic metalwork with the clean edges that powder coating and painting demand. Both CO2 and fiber lasers serve this market—fiber for metal panels, CO2 for mixed-material projects combining metal with acrylic or wood elements.

From Prototypes to Production Runs

Custom metal cutting requirements vary dramatically by industry stage. Early-stage development might need five prototype brackets for testing. Production ramp-up requires hundreds. Full manufacturing demands thousands monthly with guaranteed consistency.

Industrial equipment manufacturing illustrates this progression well. A machine builder might start with laser-cut prototype brackets, iterate through several design revisions, then scale to production quantities—all using the same laser cutting process but with different optimization priorities at each stage.

Key industrial equipment applications include:

- Machine frames and structural housings

- Conveyor system components

- Guard panels and safety enclosures

- Control panel enclosures

- Custom mounting brackets and adapters

Defense and military applications require equipment that functions reliably in extreme environments. The MIL-STD-130 standard mandates durable, legible equipment identification—and laser cutting produces the reliable, high-quality components that meet these specifications.

Marine and shipbuilding applications face similar durability requirements. Laser cutters produce hull components, deck fittings, and custom replacement parts for vessel maintenance. The technology's ability to cut custom replacement parts for older vessels extends equipment lifespan cost-effectively.

What unites these diverse applications? The fundamental value proposition of metal laser cutting services: consistent precision at production speeds, with the flexibility to handle everything from one-off prototypes to million-unit production runs. Whether you're building aircraft, automobiles, or industrial machinery, the technology adapts to your specific requirements.

Understanding how different industries leverage these capabilities helps you communicate your own requirements more effectively. But how do all these factors—material, volume, precision, certification—translate into actual pricing? Let's examine the cost drivers that shape laser cutting quotes.

Understanding Laser Cutting Pricing Factors

Here's the question everyone asks first: "How much will this cost?" Yet laser cutting charges rarely break down into simple per-square-foot pricing. Why? Because a simple rectangle and an intricate bracket cut from identical material sheets can have vastly different costs. The real driver isn't area—it's machine time.

Understanding what influences your laser cutting quote helps you make design decisions that balance budget with performance. Let's decode the pricing formula most fabricators use.

What Drives Laser Cutting Costs

Nearly every provider calculates pricing using a foundational formula:

Final Price = (Material Costs + Variable Costs + Fixed Costs) × (1 + Profit Margin)

Each component deserves examination because your choices directly affect them.

- Material type and grade: The base cost of raw materials varies dramatically. Standard carbon steel costs less than stainless steel, which costs less than aerospace-grade aluminum or specialty alloys. A laser cutting machine for sheet metal processes all these materials—but your material choice establishes the cost floor before any cutting begins.

- Material thickness: This factor often surprises customers. According to industry pricing guides, doubling material thickness can more than double cutting time and cost. Thicker materials require slower cutting speeds, higher laser power, and more assist gas consumption. A 6mm steel plate doesn't cost twice as much as 3mm—it may cost three times as much to cut.

- Cut distance and pierce count: The total linear distance the laser travels directly determines machine time. But here's a hidden cost driver: every time the laser starts a new cut, it must first pierce through the material. A design with 100 small holes costs more than one large cutout covering the same area because of cumulative piercing time.

- Part complexity: Intricate designs with tight curves and sharp corners force the machine to slow down. Complex geometries increase cutting time and require more precise control. Simpler shapes—even covering the same area—cut faster and cost less.

- Quantity and setup costs: Most services charge setup fees covering operator time for loading material, calibrating the machine, and preparing your file. These fixed costs spread across all parts in an order. Result? Per-part pricing drops significantly as quantity increases. High-volume discounts can reach 70% compared to single-part pricing.

- Tolerance requirements: Specifying tolerances tighter than functionally necessary is a common source of added cost. Holding ±0.002" requires slower, more controlled cutting than standard ±0.005" tolerances. Only specify tight tolerances where your application genuinely requires them.

- Secondary operations: Services beyond cutting—bending, tapping, hardware insertion, deburring, powder coating—add separate charges. Each operation requires additional labor, equipment, and handling.

- Turnaround time: Urgent jobs command premium pricing. Rush orders require schedule disruption, overtime labor, and expedited material sourcing. Standard lead times cost less than emergency turnarounds.

How Design Choices Affect Your Quote

You have more control over custom laser cutting costs than you might realize. Strategic design decisions can significantly reduce your final price without sacrificing functionality.

Use the thinnest material possible. This single choice often delivers the largest cost reduction. If structural analysis confirms 2mm steel meets your requirements, don't specify 3mm "just to be safe." The cutting time difference translates directly to savings.

Simplify geometry where possible. Can that decorative curve become a straight line? Can multiple small holes consolidate into fewer larger openings? Reducing cut distance and pierce count lowers machine time.

Clean your design files. Duplicate lines, hidden objects, and construction geometry create problems. Automated quoting systems may charge for every line—including duplicates. Manual review catches these issues but adds labor cost. Submit clean files to avoid both problems.

Order strategically. Consolidating needs into larger, less frequent orders spreads setup costs across more parts. If you'll need 50 brackets over six months, ordering all 50 at once costs less than five separate orders of 10.

Ask about in-stock materials. Choosing materials your fabricator already stocks eliminates special order fees and reduces lead time. Custom cut metal from standard inventory ships faster and costs less than specialty sourcing.

Evaluating Service Providers Beyond Price

The lowest quote isn't always the best value. Consider what you're actually comparing:

- DFM feedback: Does the provider review your design for manufacturability issues? Catching a costly design problem before cutting saves more than the cheapest quote.

- Quality systems: Certified quality management (ISO 9001, IATF 16949 for automotive) indicates controlled processes and consistent results. Rework and rejection costs can quickly exceed initial quote differences.

- Communication responsiveness: How quickly do they answer questions? A provider who responds in hours rather than days keeps your project moving.

- Secondary operation capabilities: If your parts need bending, finishing, or assembly, a full-service provider eliminates coordination headaches and shipping between multiple vendors.

- File preparation assistance: Some shops charge extra for fixing file errors; others include basic cleanup. Understanding what's included prevents surprise charges.

Machine hourly rates typically range from $60 to $120 depending on equipment capability and location. But hourly rate alone doesn't determine value—a more expensive machine cutting twice as fast may deliver lower per-part costs than a budget operation.

When evaluating your laser cutting quote, look beyond the bottom line. Understand which cost drivers apply to your project, consider how your design choices influence pricing, and assess the total value each provider offers. This informed approach leads to better outcomes than simply choosing the lowest number.

Beyond Cutting and Complete Fabrication Services

Your laser-cut parts just came off the machine. Now what? For most projects, cutting is only the beginning. The flat profiles emerging from a steel laser cutting service rarely function as finished products—they need forming, fastening, finishing, and often assembly before they're ready for installation or shipment.

Understanding how laser cutting and subsequent operations integrate helps you plan projects more effectively, reduce lead times, and avoid the coordination headaches that come from managing multiple vendors. Let's explore what happens after the laser stops firing.

Secondary Operations That Complete Your Parts

Imagine designing a bracket that mounts with bolts, attaches to a formed panel, and accepts threaded inserts. The laser cuts the flat profile—but that's only about 30% of the total fabrication work. Secondary operations transform flat cutouts into functional components.

Common post-cutting operations include:

- Bending and forming: Press brakes transform flat laser-cut blanks into three-dimensional shapes. Bend lines etched during cutting guide accurate positioning. According to industry practice, fabricators often integrate laser cutting with forming services, using RADAN nesting software to maximize efficiency before parts move to bending operations.

- Tapping: While laser cutting creates pilot holes, threading those holes requires a separate tapping operation. Design files should export only the pilot hole diameter—if thread geometry is included in the DXF, no material remains for the tap to cut.

- Hardware insertion: PEM nuts, standoffs, studs, and captive fasteners get pressed into laser-cut holes. Proper hole sizing during the cutting stage ensures reliable installation without material distortion.

- Countersinking and counterboring: Flush-mount fasteners require recessed holes that laser cutting alone cannot produce. CNC machining or dedicated countersink tooling creates these features after cutting.

- Deburring: While laser edges are typically cleaner than plasma or shearing, some applications—especially those with hand contact—require edge softening. Tumbling, vibratory finishing, or manual deburring removes any remaining sharpness.

- Welding: MIG, TIG, and spot welding join laser-cut components into assemblies. Clean laser edges produce superior weld quality compared to mechanically cut parts.

- Milling and lathe operations: Precision features beyond laser capabilities—tight-tolerance bores, machined surfaces, complex 3D geometries—require additional CNC machining.

When laser and CNC capabilities work together, manufacturers can produce parts that neither technology could create alone. This integration of laser and cnc processes expands what's possible while maintaining the speed advantages of laser cutting for appropriate features.

Finishing Options for Professional Results

Raw metal rarely goes directly into service. Environmental exposure, aesthetic requirements, and functional specifications typically demand protective or decorative finishes. Understanding your options helps you specify the right treatment for your application.

- Powder coating: This versatile finish provides a tough, durable exterior in virtually any color, texture, or metallic effect. The electrostatically applied powder cures under heat, creating a finish more resistant to chipping than conventional paint. Powder coating works excellently on steel and aluminum laser-cut parts.

- Anodizing: Particularly effective for aluminum, anodizing strengthens the naturally occurring oxide layer that protects against corrosion. The process also enables dyeing, allowing colored finishes that penetrate the surface rather than sitting on top. UV resistance improves significantly compared to painted surfaces.

- Metal plating: Zinc, nickel, chrome, and other plating options provide corrosion resistance, wear resistance, or specific aesthetic effects. Galvanizing—zinc coating through hot-dip or electrogalvanizing processes—remains particularly popular for steel fabrications exposed to weather.

- Bead blasting: This abrasive process creates uniform matte surface textures while removing minor imperfections. Bead blasting prepares surfaces for subsequent coating or creates the final finish for applications where a satin appearance is desired.

- Hot blackening: Black oxide treatment stabilizes iron-based alloy surfaces, preventing rust while creating a distinctive matte black appearance. Automotive parts, tools, and firearms commonly receive this finish.

- Polishing: For stainless steel, brass, or chrome-plated parts, polishing uses controlled friction to eliminate minor scratches and achieve mirror or brushed finishes. No additional coating is required for inherently corrosion-resistant materials.

Each finishing option has specific preparation requirements. Powder coating demands clean, oil-free surfaces. Anodizing requires precise alloy specifications. Plating needs proper surface activation. Communicating your finishing requirements early helps fabricators optimize their laser cutting and preparation processes accordingly.

Streamlining Your Manufacturing Workflow

Here's where vendor selection becomes strategic. You could source laser cutting from one shop, send parts to another for bending, ship to a third for finishing, and coordinate assembly yourself. Or you could work with an integrated provider who handles the entire workflow under one roof.

The advantages of consolidation are compelling:

- Reduced lead time: Parts don't wait for shipping between operations. According to industry experience, combining fabrication and assembly under one roof delivers unmatched efficiency.

- Lower logistics costs: Fewer shipments mean reduced freight charges and packaging waste.

- Better communication: A single point of contact coordinates all operations, eliminating the game of telephone between multiple vendors.

- Integrated quality control: Problems discovered during secondary operations can be traced back and corrected without finger-pointing between suppliers.

- Economies of scale: Consolidated purchasing power typically translates to better material pricing passed on to customers.

For precision laser cutting services in automotive applications, integrated capabilities become even more critical. Chassis components, suspension brackets, and structural parts often require certified processes at every stage—cutting, forming, welding, and finishing. IATF 16949-certified manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate how comprehensive DFM support and rapid prototyping capabilities complement precision cutting services. Their 5-day rapid prototyping and 12-hour quote turnaround exemplify the responsiveness that streamlined operations enable.

When evaluating cnc laser cutting services or tube laser cutting services, ask about integrated capabilities. Can they handle the bending your parts require? Do they offer in-house finishing? Can they perform assembly and testing? The answers reveal whether you're getting a cutting vendor or a complete manufacturing partner.

For production volumes ranging from prototypes to mass production, working with providers who control the entire workflow eliminates the coordination burden that slows projects and introduces quality risks. The cutting operation may take hours—but coordinating between three different vendors can add weeks to your timeline.

With metal laser cutting services positioned within this broader manufacturing context, you're ready to evaluate potential partners more strategically. What should you look for when selecting a service provider? Let's examine the criteria that separate excellent partners from adequate ones.

Selecting the Right Metal Laser Cutting Partner

You've explored the technology, understood the process, and identified how laser cutting fits your project requirements. Now comes the decision that determines whether your experience is seamless or frustrating: choosing the right service provider. Not all metal laser cutting service providers deliver equal value—and the cheapest quote rarely tells the whole story.

Let's build a practical framework for evaluating your options and making a confident selection.

Is Laser Cutting Right for Your Project

Before searching for a laser cutting service near me, confirm that laser cutting genuinely fits your application. The wrong technology choice wastes time and money regardless of how excellent your chosen provider might be.

Run through this decision checklist:

- Material compatibility: Is your material laser-cuttable? Steel, stainless steel, aluminum, copper, brass, and most common alloys work well. Some coated or treated materials may produce toxic fumes or cut poorly.

- Thickness feasibility: Does your material thickness fall within practical laser cutting ranges? For most metals, that means under 25mm. Thicker materials may require plasma or waterjet instead.

- Precision requirements: Do you need tolerances tighter than ±0.003"? Standard laser cutting delivers ±0.005" reliably. Tighter specifications may require EDM or post-cut machining.

- Heat sensitivity: Will your material or application tolerate a small heat-affected zone? If thermal distortion is absolutely unacceptable, waterjet cutting eliminates this concern entirely.

- Quantity alignment: Laser cutting excels from single prototypes through high-volume production. However, extremely high volumes of simple parts might benefit from stamping or die-cutting economics.

- Secondary operation needs: Does your project require bending, finishing, or assembly? Factor these requirements into your provider search from the start.

If laser cutting checks these boxes, you're ready to evaluate providers. If not, consider alternative cutting methods covered earlier in this guide.

What to Look for in a Service Provider

When you search for laser cutting services near me or metal laser cutting services near me, dozens of options may appear. How do you distinguish excellent partners from adequate ones? Focus on these evaluation criteria:

Certifications and quality systems: Industry certifications indicate controlled processes and consistent results. According to manufacturing experts, asking about regulatory compliance should be among your first questions. Key certifications to look for include:

- ISO 9001: General quality management system certification

- IATF 16949: Automotive industry quality standard—essential for chassis, suspension, or structural components

- AS9100: Aerospace quality management certification

- NADCAP: Special process accreditation for aerospace applications

DFM support and communication: Does the provider review your designs for manufacturability issues? Industry guidance emphasizes that good customer service and open communication throughout the process are essential for success. Providers offering DFM feedback catch costly problems before cutting begins—saving more than any quote difference.

Equipment capabilities: What laser technology do they operate? Fiber lasers handle reflective metals better than CO2 systems. High-power machines cut thicker materials faster. Ask about their equipment and whether it matches your material and thickness requirements.

Material capabilities and sourcing: Can they work with your specific material? Leading services support steel, stainless steel, tool steel, aluminum, brass, bronze, copper, and titanium. Verify they can source your required alloy grade or accept customer-supplied material.

Quote turnaround: How quickly do they respond? In fast-moving projects, a 12-hour quote turnaround versus a 5-day response can determine whether you meet your deadline. For automotive manufacturing seeking precision metal components, manufacturers like Shaoyi demonstrate the value of rapid quote turnaround and certified quality systems—their IATF 16949 certification and 12-hour quote response exemplify what to expect from top-tier partners.

Secondary operation capabilities: If your parts need bending, finishing, or assembly, integrated providers eliminate coordination headaches. Ask specifically about:

- Press brake forming and bending

- Tapping, hardware insertion, and fastener installation

- Finishing options: powder coating, anodizing, plating

- Assembly and kit packaging

Taking the Next Step with Confidence

Armed with these evaluation criteria, you can approach your search for a laser cutter service near me or laser metal cutting near me strategically rather than randomly. Here are the questions that separate informed buyers from those who simply accept the first quote:

Questions to ask prospective providers:

- What file formats do you accept, and do you provide DFM feedback?

- What certifications does your facility hold?

- What laser technology do you use for my specific material?

- Can you handle my required secondary operations in-house?

- What is your typical turnaround time for projects like mine?

- Do you offer expedited processing if needed?

- How do you handle quality inspection and documentation?

Red flags to avoid:

- Unwillingness to discuss equipment or capabilities

- No DFM review or design feedback offered

- Vague or inconsistent communication

- No quality certifications relevant to your industry

- Reluctance to provide references or sample work

- Quotes that seem dramatically lower than competitors without clear explanation

As industry experts recommend, do everything in your power to learn about your supplier—from company history to capabilities to quality systems. If feasible, schedule a facility visit to see their operation firsthand.

The right metal laser cutting service partner doesn't just execute your files—they collaborate on improving your designs, communicate proactively about timeline and quality, and deliver parts that meet your specifications consistently. Whether you need rapid prototyping or automated mass production, the evaluation framework above helps you identify providers who will contribute to your project's success rather than simply processing orders.

Your search for the ideal fabrication partner starts with understanding what you need—and ends with finding a provider whose capabilities, certifications, and communication style match those requirements. With the knowledge from this guide, you're equipped to make that decision confidently.

Frequently Asked Questions About Metal Laser Cutting Services

1. What materials can be laser cut?

Metal laser cutting services handle a wide range of materials including carbon steel, stainless steel, aluminum, copper, brass, and specialty alloys. Fiber lasers excel with reflective metals like aluminum and copper, while CO2 lasers work well for mixed-material applications. Material thickness capabilities depend on laser power—modern fiber lasers cut steel up to 40mm and stainless steel up to 50mm with high-power systems. Some materials like galvanized steel require specialized ventilation due to fume production.

2. How much does laser cutting cost?

Laser cutting pricing depends on multiple factors: material type and thickness, cut distance and pierce count, part complexity, quantity, tolerance requirements, and turnaround time. Thicker materials cost significantly more due to slower cutting speeds. High-volume orders benefit from setup cost distribution, with discounts reaching up to 70% compared to single-part pricing. Machine hourly rates typically range from $60 to $120 depending on equipment capability and location.

3. What is the difference between fiber laser and CO2 laser cutting?

Fiber lasers use solid-state technology with a 1.064-micrometer wavelength, offering higher energy efficiency (35-42% conversion), faster cutting on thin metals, and superior performance with reflective materials like aluminum and copper. CO2 lasers generate a 10.6-micrometer wavelength beam, excelling at mixed-material cutting including non-metals like wood and acrylic. Fiber lasers require less maintenance and last up to 100,000 hours, while CO2 systems typically need tube replacement after 20,000-30,000 hours.

4. How accurate is laser cutting?

Metal laser cutting achieves precision tolerances of ±0.003" to ±0.005" depending on material and equipment. The laser beam diameter is typically under 0.32mm, with kerf widths as small as 0.10mm. This precision makes laser cutting ideal for intricate patterns, tight-tolerance brackets, and components requiring consistent dimensional accuracy across high-volume production runs. For tolerances tighter than ±0.003", EDM or post-cut machining may be required.

5. What file formats are accepted for laser cutting?

Most laser cutting services accept vector file formats including DXF (the universal standard), DWG, STEP, and IGES. Vector formats define geometry mathematically, enabling precise cutting paths. Avoid raster images like JPG or PNG as they cannot define accurate cut lines. For best results, submit files at 1:1 scale with geometry on a single layer, convert text to outlines, and remove duplicate lines or construction geometry. IATF 16949-certified manufacturers like Shaoyi offer comprehensive DFM support to review files before production.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —