Metal Cut Services Decoded: 9 Specs Your Fabricator Won't Explain

Understanding Metal Cut Services in Modern Manufacturing

When you need a metal component for your next project, have you ever wondered what actually happens behind the scenes? Metal cut services represent a foundational manufacturing process where larger pieces of material are precisely separated into smaller pieces or custom-shaped parts. Whether you're an engineer specifying components, a procurement professional sourcing suppliers, or a buyer evaluating options, understanding these services can mean the difference between project success and costly mistakes.

In modern manufacturing, metalcut operations have evolved far beyond simple sawing. Today's precision metal cutting encompasses everything from traditional mechanical methods to advanced thermal technologies guided by computerized controls. Each approach offers distinct benefits and limitations that directly impact your project's quality, timeline, and budget.

What Metal Cut Services Actually Include

Think of metal cutting services as an umbrella term covering multiple specialized processes. At its core, a cut service separates material through either mechanical force, thermal energy, or high-velocity particle erosion. According to industry standards, these methods can be fundamentally divided into two categories:

- Mechanical Cutting (Sawing, Shearing): Uses physical force or abrasion with minimal heat-affected zones, reducing the risk of material warping

- Thermal/Erosion Cutting (Laser, Plasma, Waterjet): Employs intense heat or accelerated abrasive particles for superior geometric complexity and narrower cuts

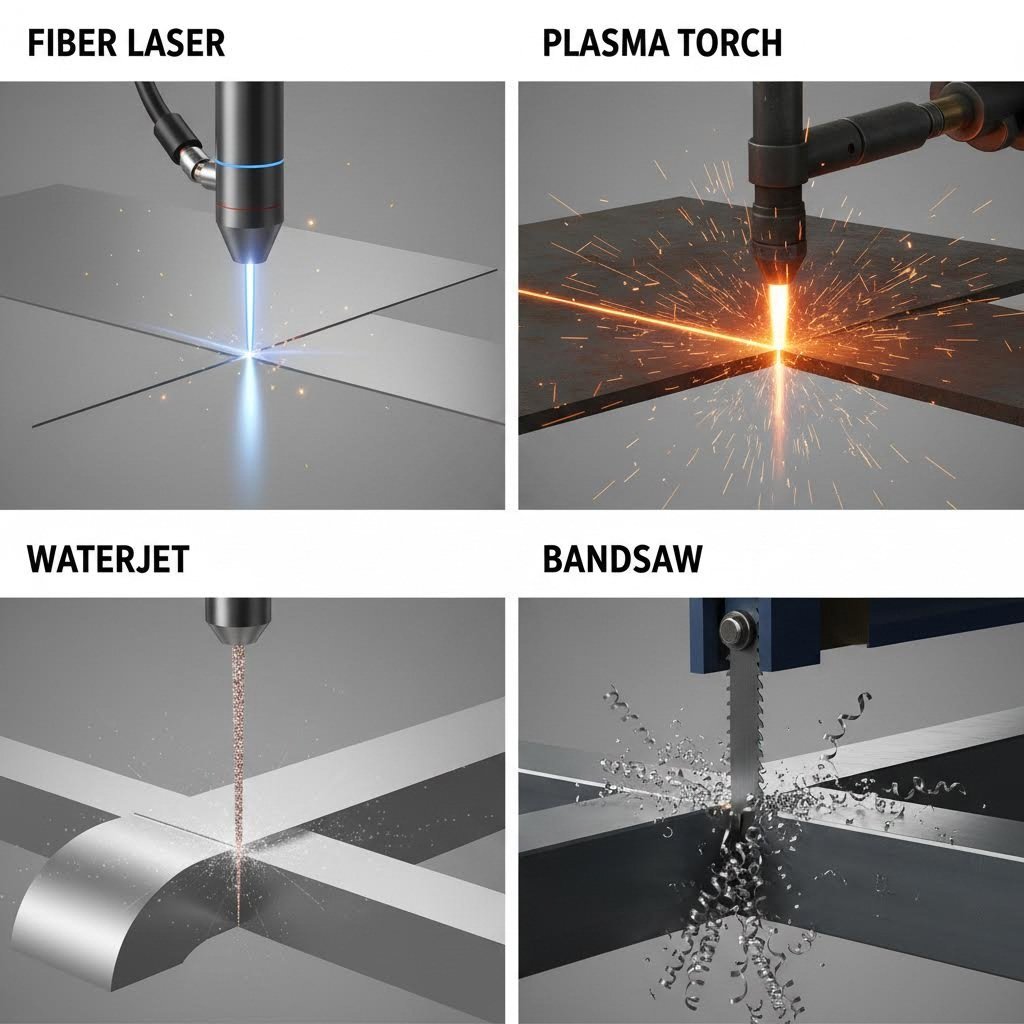

The main categories of metal cutting services you'll encounter include:

- Laser Cutting: High-precision cuts using focused light beams with CNC controls

- Plasma Cutting: Fast processing of thick conductive materials using superheated gas

- Waterjet Cutting: Cold cutting technique using pressurized water, ideal for heat-sensitive materials

- Sawing Operations: Band saw and circular saw methods for various cross-sections

- CNC Machining: Computer-controlled precision cutting for complex geometries

Why Understanding Cutting Methods Matters for Your Project

Here's the reality: your fabricator might not explain why they recommend one method over another. Yet this choice directly affects your project outcomes. Steel cutting services using plasma technology deliver speed for thick materials, while laser systems offer tighter tolerances for thin gauge components. Production cutting services must balance precision requirements against budget constraints.

Quality assurance becomes critical when selecting providers. ISO certification serves as your baseline indicator that a manufacturer maintains consistent processes and documentation. For specialized applications like aerospace or automotive components, additional certifications may be required to ensure traceability and compliance with industry-specific standards.

Throughout this article, you'll discover the nine specifications your fabricator typically won't explain—from tolerance grades and material compatibility to equipment capabilities and cost factors. By the end, you'll have the knowledge to ask the right questions and make informed decisions for your metal cutting projects.

Primary Metal Cutting Methods and Their Applications

Ever stood in front of a fabrication shop wondering why they're quoting laser cutting for your project while another suggests plasma? You're not alone. The truth is, each cutting technology excels in specific scenarios, and understanding these differences can save you thousands in material costs and production time. Let's break down the four primary methods you'll encounter when sourcing laser metal cutting services or other cutting technologies.

Laser Cutting Technology Explained

Laser cutting uses an intensely focused beam of light to melt, burn, or vaporize material along a programmed path. But here's what most fabricators won't tell you—there are two fundamentally different laser technologies, and choosing the wrong one can compromise your results.

Fiber Lasers generate light through optical fibers doped with rare-earth elements like ytterbium. According to Superstar Laser's 2025 industry analysis, fiber lasers operate at a 1.06 micrometer wavelength—ten times shorter than CO2 lasers. This shorter wavelength is absorbed far more efficiently by metals, making fiber lasers the undisputed champion for steel plasma cutting services alternatives and general metal fabrication.

CO2 Lasers use a gas mixture as the lasing medium, producing light at 10.6 micrometers. This longer wavelength excels with organic materials like wood, acrylic, and leather but struggles with reflective metals. The beam is largely bounced off surfaces of copper, brass, and aluminum, wasting significant energy.

When should you specify each? Consider these practical guidelines:

- Fiber laser: Sheet metal fabrication, automotive parts, industrial components, stainless steel, aluminum, and brass processing

- CO2 laser: Signage, crafts, wood products, acrylic displays, and mixed-material projects

If you're searching for "laser cut stainless steel near me," you'll want a fabricator running fiber laser equipment. The speed advantage is dramatic—a 4kW fiber laser slices through 1mm stainless steel at speeds exceeding 30 meters per minute, while a comparable CO2 system achieves only 10-12 meters per minute.

Plasma vs Waterjet Cutting Comparison

Beyond laser cutting metal fabrication, two other thermal and erosion-based methods dominate industrial applications. Understanding when each shines helps you avoid costly over-specification or quality compromises.

Plasma cutting uses an electrical arc and compressed gas to melt and blast through conductive metals. It's the workhorse of heavy fabrication, particularly for CNC plasma cutting services handling thick steel plate. According to Wurth Machinery's testing data, plasma cutting 1-inch steel runs 3-4 times faster than waterjet, with operating costs roughly half as much per linear foot.

Waterjet cutting takes a completely different approach. High-pressure water mixed with abrasive garnet particles erodes material without generating heat. This cold cutting process eliminates heat-affected zones, warping, and material hardening—critical considerations for aerospace components or heat-sensitive alloys.

Here's when each method proves most appropriate:

- Plasma excels: Structural steel fabrication, heavy equipment manufacturing, shipbuilding, and projects where ½" to 2"+ thickness is common

- Waterjet excels: Stone and glass cutting, aerospace components requiring no thermal distortion, food processing equipment, and multi-material stacks

The waterjet market is experiencing significant growth, projected to reach over $2.39 billion by 2034, driven by demand for heat-free cutting in precision industries.

Complete Cutting Method Comparison

Before requesting quotes, use this comparison table to match your project requirements with the optimal cutting technology:

| Factor | Fiber Laser | CO2 Laser | Plasma | Waterjet |

|---|---|---|---|---|

| Material Compatibility | Metals (steel, stainless, aluminum, brass, copper) | Organics (wood, acrylic, leather, fabric), some metals | Conductive metals only | Virtually any material except tempered glass |

| Thickness Range | 0.5mm to 25mm+ (with high-power systems) | Up to 25mm steel; excels in thin non-metals | 3mm to 50mm+ (optimal above 12mm) | Up to 200mm+ depending on material |

| Precision Tolerance | ±0.05mm to ±0.1mm | ±0.1mm to ±0.3mm | ±0.5mm to ±1.5mm | ±0.1mm to ±0.25mm |

| Edge Quality | Excellent; minimal burr, ready for finishing | Good to excellent on compatible materials | Rougher; may require secondary finishing | Smooth, no heat-affected zone |

| Cutting Speed | Very fast on thin metals | Moderate; slower on metals than fiber | Fast on thick conductive metals | Slowest overall |

| Relative Cost | Higher equipment cost; lower operating cost | Lower equipment cost; higher operating cost | Lowest equipment cost; moderate operating cost | Highest equipment cost; high abrasive consumption |

| Heat-Affected Zone | Minimal | Moderate | Significant | None |

Traditional Sawing Methods

Don't overlook conventional sawing when thermal cutting isn't necessary. Band saws and circular saws remain cost-effective solutions for straight cuts, bar stock, and tube processing. They generate no heat-affected zones and handle large cross-sections that would challenge even high-power laser systems.

Sawing proves particularly valuable for:

- Cutting round bar, tube, and structural shapes to length

- Processing extremely thick plate where thermal methods struggle

- Budget-conscious projects with simple geometry

- Materials sensitive to thermal stress

Now that you understand the primary cutting technologies, the next critical consideration is matching these methods to specific sawing operations and equipment specifications. Understanding equipment capabilities helps you evaluate whether a fabricator can actually handle your project requirements.

Specialized Sawing Operations and Equipment Capabilities

You've probably seen fabricators list sawing services on their websites—cutoff sawing, plate sawing, contour sawing—but what do these terms actually mean for your project? Unlike laser and plasma cutting where the technology itself defines capabilities, sawing operations are categorized by the type of cut and material configuration they handle. Understanding these distinctions helps you specify the right service and evaluate whether a shop can actually deliver what you need.

Sawing Categories and When to Use Each

Think of sawing operations as specialized tools in a toolbox. Each serves a distinct purpose, and using the wrong one wastes time and money. Here's what separates these categories:

- Cutoff Sawing: The most common steelcutting operation, cutoff sawing produces straight, perpendicular cuts through bar stock, tubing, and structural shapes. According to DoALL Sawing Products, horizontal bandsaws with their long blade design excel at these straight cuts through hard materials like steel and aluminum. This is your go-to for cutting raw materials to length before secondary processing.

- Notch & Shape Sawing: When your project requires complex profiles—think notches, angles, or custom shapes cut into structural members—this specialized operation comes into play. Fabrication mitering saws with swiveling heads or swiveling vises create precise angled cuts essential for frame assemblies and structural connections.

- Plate Sawing: Thick plate materials demand specialized equipment. Steel plate cutting services for materials exceeding 4 inches often utilize heavy-duty horizontal saws with dual-column designs that maintain blade stability through massive cross-sections. These production saws feature enclosed box designs for enhanced safety during demanding steel cuts.

- Contour Sawing: Need curved patterns or intricate shapes? Vertical contouring saws—also called vertical bandsaws—make detailed cuts through softer materials like aluminum and low-carbon steel. The vertical blade orientation allows operators to guide material through complex paths, similar to how a scroll saw works in woodworking.

Companies like True Steel & Cutting Inc. and similar specialized fabricators often maintain multiple sawing stations configured for different operations. This specialization matters because switching between operation types on a single machine creates inefficiencies and potential accuracy issues.

Understanding Equipment Specifications

When reviewing fabricator capabilities, you'll encounter specifications that seem cryptic without context. Here's how to decode the numbers that actually determine whether a shop can handle your project:

Throat Size: This measurement indicates the maximum distance from the blade to the saw frame's vertical support. A 20-inch throat means the saw can accommodate workpieces up to 20 inches wide. For plate sawing operations, throat capacity directly limits maximum material width.

Cutting Capacity (Round/Square): Fabricators typically list maximum cutting capacity for round bar and square stock separately. A saw rated for 12-inch round may only handle 10-inch square because corners extend further from center than circular profiles.

Blade Size and Type: Larger blade diameters allow deeper cuts, while blade thickness affects cut width (kerf) and stability. According to KBR Build's industrial guide, thicker blades reduce flex during cutting, producing straighter cuts—but require more powerful motors to operate effectively.

Motor Power: Research indicates that motors with at least 3 kW output are essential for optimal performance in demanding cold cutting service applications. Higher wattage translates to faster cutting speeds and the ability to maintain consistent feed rates through tough materials without bogging down.

Automation Level: Production saws range from manual to fully automatic operation. Semi-automatic machines require operator intervention between cuts, while fully automatic systems can process multiple workpieces from programmed cut lists—critical for high-volume steel plate cutting services where cycle time impacts project economics.

Understanding these specifications empowers you to ask targeted questions when evaluating fabricators. Does their throat size accommodate your largest parts? Can their motor power maintain efficient cutting through your material thickness? These details separate shops that can genuinely serve your needs from those that will struggle with your project requirements.

With sawing operations clarified, the next essential consideration is matching cutting methods to specific materials and thickness ranges—a decision that directly impacts both cut quality and project costs.

Materials and Thickness Specifications for Metal Cutting

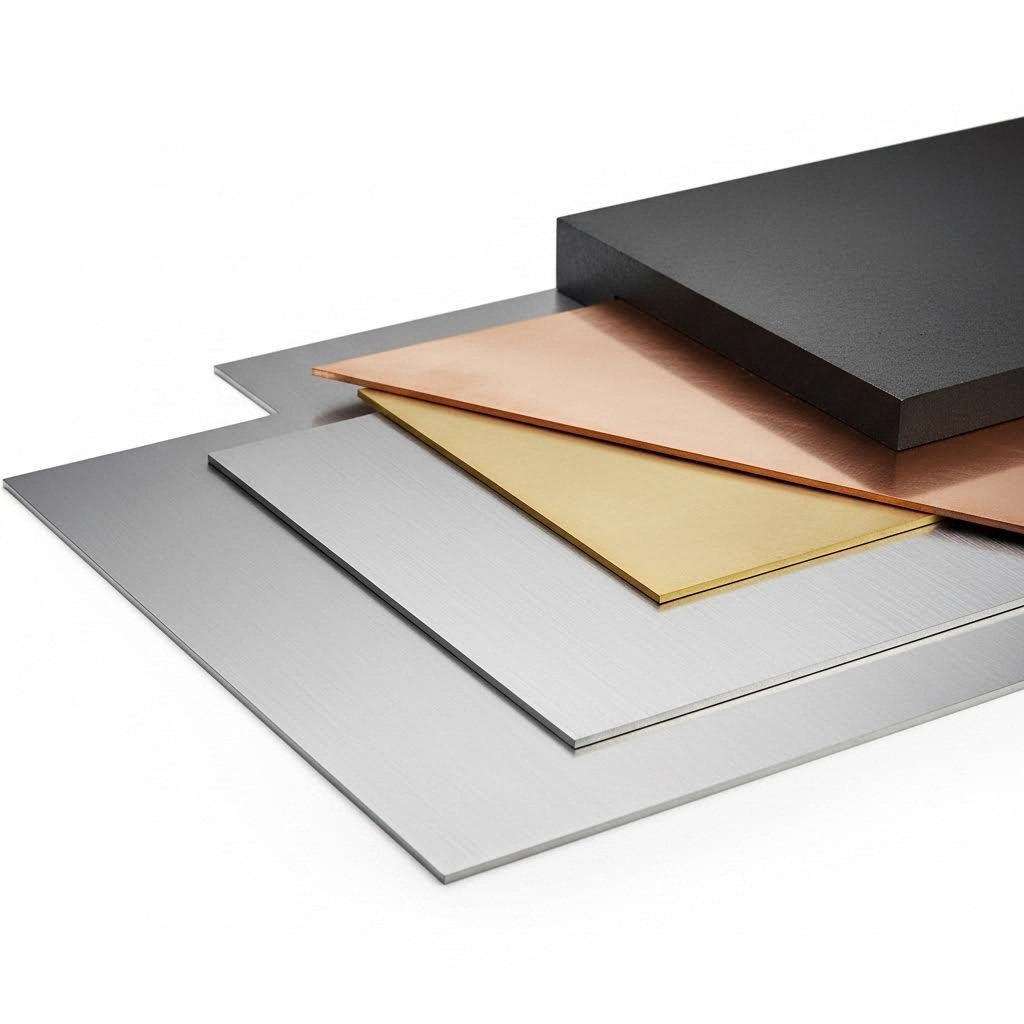

Ever submitted a cutting project only to discover your fabricator can't process your chosen material—or worse, they tried anyway and ruined expensive stock? Material compatibility isn't just a checkbox; it's the foundation of successful metal cut products. Different metals respond dramatically differently to heat, abrasion, and mechanical force. Understanding these relationships helps you specify the right cutting method from the start.

Here's what many fabricators won't explain upfront: the metal you're cutting fundamentally determines which technology will deliver acceptable results. Reflective metals like copper bounce laser energy. Heat-sensitive alloys warp under plasma. Hardened steels destroy saw blades prematurely. Let's decode the material-method relationships that drive professional sheet metal cutting services decisions.

Material Compatibility by Cutting Method

Each metal brings unique physical properties that interact differently with cutting technologies. Thermal conductivity, reflectivity, melting point, and hardness all influence which method produces optimal results.

Carbon and Mild Steel: The most forgiving material for cutting, steel works well with virtually every method. Laser cutting excels for thin gauge steel sheet cutting, while plasma dominates thicker plate. According to Longxin Laser's cutting guide, a 3kW fiber laser handles carbon steel up to 22mm thickness, making it the preferred choice for most steel cutting services.

Stainless Steel: Higher chromium content increases reflectivity and requires more power than carbon steel. Fiber lasers handle stainless efficiently, though you'll need approximately 20-30% more power compared to mild steel at equivalent thicknesses. Waterjet cutting eliminates heat-affected zones entirely—critical for food-grade or medical applications where metallurgical changes are unacceptable.

Aluminum: This lightweight metal presents challenges across multiple technologies. High thermal conductivity means heat dissipates quickly, requiring higher power settings for laser cutting. Aluminum's reflective surface can damage CO2 laser optics, making fiber lasers the safer choice. For thick aluminum plate, waterjet cutting often proves most practical since it eliminates the slag adhesion issues common with plasma.

Copper and Brass: These highly reflective metals were historically problematic for laser cutting. Modern high-power fiber lasers (6kW+) now process copper effectively, though edge quality requires careful parameter tuning. As noted by 3ERP's cutting comparison, plasma cutting works well on brass and copper since both are electrically conductive, though waterjet remains the premium choice for applications requiring zero thermal distortion.

Specialty Alloys: Titanium, Inconel, and other high-performance alloys demand special consideration. According to Sintel's fabrication guide, waterjet cutting is ideal for titanium and specific aluminum alloys where heat sensitivity is paramount. These materials often require cold cutting approaches to preserve their engineered properties.

Thickness Ranges and Limitations

Sounds complex? Here's the practical reality: thickness determines method viability more than any other factor. What works beautifully at 3mm may fail completely at 25mm.

The industry distinguishes between two general categories:

- Sheet Metal Cutting: Generally refers to materials under 6mm (approximately 1/4 inch). Laser cutting dominates this range due to speed, precision, and edge quality advantages.

- Plate Cutting: Materials 6mm and thicker fall into plate territory. Plasma and waterjet become increasingly competitive as thickness increases, with plasma offering speed advantages and waterjet delivering superior edge quality without heat effects.

Laser power directly correlates with thickness capability. Reference data from industry specifications shows dramatic differences:

- 1.5kW fiber laser: Carbon steel to 14mm, stainless to 6mm, aluminum to 5mm

- 6kW fiber laser: Carbon steel to 25mm, stainless to 16mm, aluminum to 16mm

- 12kW+ fiber laser: Carbon steel to 40mm+, stainless to 40mm, aluminum to 40mm

The following table provides a comprehensive reference for matching materials to cutting methods based on typical thickness capabilities:

| Material Type | Recommended Primary Method | Alternative Method | Typical Max Thickness | Key Considerations |

|---|---|---|---|---|

| Carbon/Mild Steel | Fiber Laser (thin); Plasma (thick) | Waterjet, Sawing | Laser: 40mm; Plasma: 50mm+; Waterjet: 200mm+ | Most versatile; all methods work well |

| Stainless Steel | Fiber Laser | Waterjet, Plasma | Laser: 40mm; Waterjet: 150mm+ | Requires 20-30% more laser power than carbon steel |

| Aluminum | Fiber Laser (thin); Waterjet (thick) | Plasma (with limitations) | Laser: 40mm; Waterjet: 200mm+ | High thermal conductivity; avoid CO2 laser |

| Copper | Waterjet; High-power Fiber Laser (6kW+) | Plasma | Laser: 12mm; Waterjet: 100mm+ | Highly reflective; requires specialized parameters |

| Brass | Fiber Laser; Waterjet | Plasma | Laser: 16mm; Waterjet: 100mm+ | Good conductivity supports plasma; laser preferred for precision |

| Titanium | Waterjet | Fiber Laser (with assist gas control) | Waterjet: 150mm+; Laser: 25mm | Heat-sensitive; waterjet preserves material properties |

| Inconel/Superalloys | Waterjet | EDM, Fiber Laser | Waterjet: 100mm+ | Extremely hard; cold cutting prevents work hardening |

Material Properties That Affect Cutting Results

Beyond simple compatibility, material properties influence final quality in ways that impact your project's success:

Thermal Conductivity: Metals that rapidly dissipate heat (aluminum, copper) require higher power settings or slower speeds. This affects both cutting costs and edge quality. High conductivity metals may show more pronounced heat-affected zones along cut edges with thermal methods.

Reflectivity: Shiny metals bounce laser energy back toward the cutting head. Modern fiber lasers handle this better than older technologies, but reflectivity still matters for edge quality and cutting speed on materials like polished stainless or copper.

Hardness: Tool steels and hardened alloys challenge mechanical cutting methods. Saw blade wear accelerates dramatically, increasing per-piece costs. Thermal and waterjet methods often prove more economical despite higher hourly rates.

When specifying metalcut products for your project, consider not just whether a method can cut your material, but how material properties will affect edge finish, dimensional accuracy, and secondary processing requirements. A fabricator who understands these relationships can guide you toward the most cost-effective approach for your specific application.

Material selection and thickness requirements establish what's possible—but precision tolerances determine whether results meet your functional requirements. Understanding tolerance specifications helps you avoid over-specifying (and overpaying) while ensuring parts actually fit and function as designed.

Precision Tolerances and Quality Control Standards

You've selected your cutting method and verified material compatibility—but here's the question that separates successful projects from costly rework: what tolerance does your application actually require? Many buyers either over-specify precision (paying premium prices for accuracy they don't need) or under-specify (receiving parts that won't fit their assemblies). Understanding tolerance specifications empowers you to make informed decisions that balance performance with budget.

In metal cutting context, precision refers to how closely a finished dimension matches the specified target value. When a drawing calls for a 100mm dimension with ±0.1mm tolerance, acceptable parts measure anywhere from 99.9mm to 100.1mm. But here's what fabricators rarely explain: different cutting technologies achieve vastly different tolerance ranges, and those capabilities directly influence your method selection.

Precision Tolerances by Cutting Technology

Each cutting method has inherent accuracy limitations based on its physical principles. Thermal processes introduce heat distortion variables. Mechanical methods face blade deflection and wear factors. Understanding these baseline capabilities helps you match technology to requirements—not the other way around.

According to Davantech's machining tolerance analysis, here are typical tolerance ranges by process:

- CNC Milling (3-axis): ±0.05mm to ±0.1mm—excellent for precision metal cutter applications requiring tight dimensional control

- CNC Turning: ±0.02mm to ±0.05mm—achieves superior accuracy for rotational components

- 5-Axis CNC Milling: ±0.02mm or better—the premium choice for complex aerospace and medical geometries

- Laser Cutting: ±0.1mm to ±0.2mm for standard work; high-precision systems achieve ±0.05mm on thin materials

- Waterjet Cutting: ±0.1mm to ±0.25mm—impressive accuracy without heat-affected zones

- Plasma Cutting: ±0.5mm to ±1.5mm—fastest for thick materials but lower precision than alternatives

- Sheet Metal Bending: ±0.2mm to ±0.5mm—secondary forming operations add tolerance stack-up

- Grinding: ±0.002mm to ±0.005mm—reserved for ultra-precision finishing operations

Reference data from Komacut's tolerance guide provides additional detail for sheet metal operations. Their testing shows laser cutting achieves linear tolerances of ±0.12mm for materials between 0.5mm and 2mm thickness, with hole diameter tolerances holding ±0.08mm under high-precision conditions.

These figures reveal a critical insight: if your application demands tolerances tighter than ±0.1mm, laser cutting alone may not suffice. You might need secondary machining, grinding operations, or entirely different primary processes. Companies offering comprehensive tooling services often combine cutting with precision finishing to achieve specifications that no single process can deliver independently.

When High Precision Matters Most

Not every project requires ultra-tight tolerances. Imagine you're fabricating decorative panels—±0.5mm variation won't affect aesthetics or function. But consider a precision shaft bearing housing where ±0.02mm determines whether components seize or spin freely. Context determines specification requirements.

High-precision tolerances become critical in these scenarios:

- Mating Assemblies: Parts designed to fit together require coordinated tolerances. A press-fit connection might specify H7/p6 interference fit—demanding micron-level control

- Motion Systems: Slides, bearings, and rotating components amplify dimensional errors into performance problems

- Medical Devices: According to industry specifications, medical implants often require ±0.005mm or better tolerances

- Aerospace Components: Safety-critical applications typically specify ±0.005mm to ±0.02mm tolerance ranges

- Optical and Micro-Mechanical Parts: Precision reaches the micron range (±0.001mm to ±0.005mm) for specialized applications

Here's a practical guideline: specify the loosest tolerance that meets functional requirements. Tighter tolerances always cost more—they demand slower cutting speeds, more rigid fixturing, temperature-controlled environments, and additional inspection time. When carbide tool services inc. or similar precision machining providers quote jobs, tolerance specifications often represent the largest cost variable.

Quality Control Processes That Ensure Accuracy

Precision tolerances mean nothing without verification. According to Superior Manufacturing's quality control analysis, effective quality assurance involves checking and verifying that products meet design requirements throughout the fabrication process—not just at final inspection.

Professional fabricators employ multiple inspection methods:

- Coordinate Measuring Machines (CMM): Computer-controlled probes measure three-dimensional geometry against CAD models, detecting deviations with micron-level accuracy

- Optical Comparators: Project part profiles onto calibrated screens for visual comparison against tolerance bands

- Go/No-Go Gauges: Simple binary verification tools for critical dimensions in high-volume production

- Surface Roughness Testers: Measure Ra (roughness average) values to verify finish specifications

- Statistical Process Control (SPC): Track dimensional trends across production runs to detect drift before parts exceed tolerance limits

The significance of ISO certification cannot be overstated when precision matters. ISO 9001 certification indicates a manufacturer maintains documented quality management systems with consistent processes. For machine tool repair and high-precision applications, look for fabricators who provide CMM reports on request and maintain calibrated inspection equipment. As noted by quality experts, working with experienced fabricators who understand process-specific tolerances makes a substantial difference in part precision and quality.

Material type also influences achievable tolerances. Softer metals like aluminum machine to tight tolerances more easily than hardened steels. Thin walls and complex geometries may experience deflection during cutting, limiting practical precision. Tool and die repair operations often require tolerances that push beyond standard cutting capabilities—necessitating specialized grinding or EDM finishing.

Understanding tolerance capabilities helps you communicate requirements effectively—but translating those requirements into production-ready files introduces another set of specifications most fabricators won't explain upfront.

How to Prepare Your Metal Cutting Project

You've selected your cutting method, verified material compatibility, and specified tolerances—but here's where many projects stall: file preparation. Submitting a poorly formatted design file can delay your quote by days, introduce errors that waste expensive material, or result in parts that don't match your intent. Yet most fabricators simply list accepted file formats without explaining what makes a submission production-ready.

The reality is that your digital file serves as the manufacturing blueprint. Every line, dimension, and layer translates directly into machine instructions. Understanding file requirements and design considerations upfront eliminates the back-and-forth revisions that frustrate both engineers and fabricators.

File Formats and Design Requirements

When you submit a project for metal cutting, your fabricator's software must interpret your design and convert it into machine-readable code. Different file formats carry different information—and choosing the wrong one can strip away critical details.

Common Accepted Formats:

- DXF (Drawing Exchange Format): The universal standard for 2D cutting paths. According to Datum Alloys' preparation guide, DXF files should contain clean 2D drawings without title blocks, dimension lines, or extra notes. One component per file, with no overlapping or duplicate geometry.

- DWG (AutoCAD Drawing): Native AutoCAD format carrying similar 2D vector information as DXF. Ensure you're submitting drawing geometry only—not 3D model data that requires conversion.

- STEP (Standard for the Exchange of Product Data): The preferred format for 3D parts requiring CNC machining. STEP files preserve solid geometry, enabling fabricators to extract cutting paths and verify manufacturability.

- PDF Drawings: Useful as supplementary documentation showing dimensions, tolerances, and notes—but not for direct machine programming. Include PDFs alongside vector files for complete communication.

Critical File Preparation Rules:

Sounds straightforward? Here's where projects commonly fail:

- Convert text to outlines: Active text boxes in your design software don't translate to cutting paths. In Illustrator, use "convert to outlines." In CAD programs, look for "explode" or "expand" commands. If you can edit text by clicking on it, it needs conversion.

- Ensure continuous paths: All cut lines must be complete and unbroken. Dashed lines, broken paths, or gaps require cleanup before cutting. Lasers and waterjets follow continuous vectors—they can't interpret stylized line types.

- Export at 1:1 scale: Always submit files at actual size. As emphasized by industry best practices, scale mismatches lead to parts cutting too small or too large. Print your design at 100% scale to verify dimensions before submission.

- Eliminate duplicates and overlays: Overlapping geometry causes machines to cut the same path twice, damaging edges and wasting time. Check for stacked lines or copied elements occupying identical positions.

- Remove floating cutouts: Internal shapes that aren't connected to the main part will fall away during cutting. Either submit these as separate designs or add bridging tabs to retain them.

If you've converted files from raster images (JPG, PNG, BMP), verify all dimensions carefully. Raster-to-vector conversion often introduces scaling errors or approximated curves that don't match your original intent.

Preparing Your Project for Metal Cutting

Beyond file formatting, successful project preparation involves design optimization and clear communication. Following a systematic preparation process prevents costly revisions and accelerates production.

- Finalize material selection and thickness: Confirm your material type, grade, thickness, and any surface finish requirements before creating final drawings. Cutting parameters vary by material—changing specifications after submission often requires complete re-quoting.

- Review geometry for manufacturability: Check that internal corners include appropriate radii for your cutting method. According to Modus Advanced's DFM engineering guide, sharp internal corners require specialized tooling and add 50-100% to programming time. Specify the largest radius your design can accommodate.

- Verify minimum feature sizes: Each cutting technology has minimum hole diameters, slot widths, and detail sizes it can reliably produce. Features too small for the selected process will either fail to cut correctly or produce poor edge quality. As noted by SendCutSend's guidelines, features below minimum thresholds may not be retained.

- Create clean vector files: Export your design in accepted formats (DXF, DWG, or STEP) following the formatting rules above. Run path cleanup tools to eliminate duplicates and verify continuous geometry.

- Prepare supplementary documentation: Include a dimensioned PDF drawing showing critical tolerances, surface finish callouts, and any special requirements. Note which features are most critical for function.

- Specify secondary operations: If your parts require bending, welding, powder coating, or other post-cut processing, flag these requirements early. Secondary operations affect cutting approach—for example, parts destined for bending may need specific grain orientation.

- Submit and review the quote: When you receive your quote, verify that the fabricator has interpreted your requirements correctly. Confirm material, quantity, tolerances, and any DFM feedback before authorizing production.

How DFM Support Prevents Costly Mistakes

Design for Manufacturability (DFM) represents a systematic approach to optimizing parts for efficient production. According to manufacturing engineering research, effective DFM implementation can reduce manufacturing costs by 15-40% and cut lead times by 25-60% compared to non-optimized designs.

Comprehensive DFM support from your fabricator identifies potential issues before production begins:

- Geometry conflicts: Features that can't be produced with selected methods, like sharp internal corners in laser cutting or undercuts in single-setup machining

- Tolerance stack-up: When multiple tight tolerances compound across a part, achieving all specifications simultaneously may become impractical

- Material waste optimization: Nesting parts efficiently on sheet stock reduces material consumption and per-piece costs

- Process selection guidance: Recommending alternative methods when your initial choice creates unnecessary complexity or cost

A fabricator offering machine tool servicing and CNC machine repair services often brings deeper process knowledge to DFM reviews. They understand how equipment capabilities, tooling limitations, and setup requirements affect what's practically achievable—insights that pure design engineers may lack.

When evaluating fabricators, ask whether they provide DFM feedback as part of their quoting process. Providers offering tool grinding service or carbide tool services typically maintain in-house expertise that translates into more thorough design reviews. This upfront investment in communication prevents the rework cycles that delay projects and inflate budgets.

With your files prepared and design optimized, the next consideration becomes how different industries apply these principles—because aerospace components, automotive parts, and construction elements each carry unique requirements that shape fabricator selection.

Industry Applications and Sector-Specific Requirements

Here's a reality check: the same 6mm stainless steel plate cut to identical dimensions might pass quality inspection for a restaurant equipment project—yet fail catastrophically for an aerospace bracket application. Why? Because different industries impose dramatically different requirements beyond simple dimensional accuracy. Material certifications, traceability documentation, and specialized tolerances vary enormously between sectors, and your fabricator's capabilities must align with your industry's expectations.

Understanding these sector-specific requirements helps you ask the right questions before committing to a provider. Whether you're sourcing components in Cincinnati metal fabricating hubs or exploring metal cutting Perth specialists across the globe, the certification frameworks remain consistent within each industry.

Aerospace and Automotive Component Requirements

When parts literally keep people alive—whether in aircraft at 35,000 feet or vehicles traveling at highway speeds—quality standards escalate dramatically. Both aerospace and automotive sectors have developed rigorous certification systems that govern every aspect of metal cutting and fabrication.

Aerospace Requirements:

Aerospace manufacturing operates under AS9100 certification, which builds upon ISO 9001 with additional requirements specific to flight-critical applications. According to Dynamic Metals' aerospace compliance analysis, this certification system represents a significantly more demanding version of standard quality management.

- Complete Material Traceability: Every piece of metal must be tracked from arrival through final delivery. When a customer requests information about a particular aluminum batch six months after delivery, documentation must include heat treatment records, chemical analysis certificates, and physical test results.

- Certified Supplier Requirements: Raw materials must come from approved aerospace-grade suppliers with their own certification chains. This isn't just about purchasing from reputable vendors—documentation proving certification status must accompany every material lot.

- Extended Record Retention: Keep all quality records for at least seven years. Some aerospace customers require even longer retention periods, particularly for flight-critical components.

- Comprehensive Testing Protocols: Testing goes beyond basic strength checks to include specialized dimensional verification, metallurgical analysis, and non-destructive examination using calibrated equipment operated by trained personnel.

- Risk Management Systems: AS9100 emphasizes prevention over correction. Fabricators must maintain systems to identify potential failures, assess risks, and implement preventive measures before problems occur.

The aerospace certification process typically requires 12-18 months of preparation. Common obstacles include incomplete documentation systems, insufficient traceability protocols, and inadequate employee training records.

Automotive Requirements:

The automotive industry relies on IATF 16949 certification—a quality management framework developed by the International Automotive Task Force. According to Xometry's certification overview, this standard distills information from ISO 9001 into guidelines specifically designed for automotive manufacturers and their supply chains.

- Defect Reduction Focus: IATF 16949 certification signifies that an organization limits defects in products while reducing waste and wasted effort. This isn't just about catching problems—it's about preventing them systematically.

- Binary Certification Status: Unlike tiered systems, IATF 16949 certification is binary—a company is either certified or not. There are no partial compliance levels.

- Supply Chain Integration: Suppliers, contractors, and customers throughout the automotive supply chain increasingly require IATF 16949 registration. Without certification, collaboration opportunities shrink dramatically.

- Internal and External Auditing: The certification process involves both internal audits and external verification covering organizational context, leadership, planning, support systems, operations, performance evaluation, and improvement processes.

- Continuous Improvement Requirements: Beyond initial certification, manufacturers must demonstrate ongoing improvement in quality metrics, defect rates, and process efficiency.

For precision laser cutting Cincinnati fabricators and sheet metal Cincinnati specialists serving automotive clients, IATF 16949 certification often determines whether they can compete for contracts. The investment in certification infrastructure pays dividends through access to major automotive supply chains.

Construction and Structural Applications

Construction and structural fabrication operate under different—but equally important—quality frameworks. While tolerances may be looser than aerospace specifications, safety implications remain critical. Structural failures endanger lives and carry enormous liability exposure.

Structural Steel Requirements:

According to the American Institute of Steel Construction (AISC), construction steel cutting must meet specific surface quality standards depending on application:

- Thermally Cut Edges Under Tensile Stress: Surfaces should have roughness values not exceeding 1,000 μin as defined in ASME B46.1. These edges experience the highest loading and require the finest finish.

- Mechanically Guided Thermal Cuts: Edges not subjected to calculated tensile stress require roughness not greater than 2,000 μin—still demanding, but acknowledging lower stress exposure.

- Hand-Guided Thermal Cuts: For non-stressed edges, hand-guided cutting may produce roughness up to 1/16 inch—significantly more lenient than mechanically guided work.

- Notch and Gouge Limitations: All thermally cut edges must be free of notches and reasonably free of gouges. Occasional gouges up to 3/16 inch deep are permitted, but deeper defects require welded repair following specific procedures.

Compression Joint Requirements:

AISC specifications mandate that compression joints depending on contact bearing must have bearing surfaces prepared by milling, sawing, or other suitable means. Importantly, friction sawing and cold sawing processes meet the required 500 μin surface roughness limitation—confirming that cold-sawing equipment produces fully satisfactory cuts for structural applications.

Reentrant Corner Standards:

Structural cope cuts require smooth transitions at reentrant corners. AISC recommends an approximate minimum radius of ½ inch, with the primary emphasis on avoiding square-cut corners that create stress concentrations. Radius transitions may be created by drilling with common-diameter drill sizes not less than ¾ inch.

- AWS D1.1 Compliance: Welded repairs to cutting defects must observe applicable requirements from AWS D1.1/D1.1M, including low-hydrogen electrodes not exceeding 5/32 inch diameter

- Mill Certificate Requirements: Material certifications documenting chemical composition and mechanical properties must accompany structural steel throughout fabrication

- Inspection and Testing: Visual inspection, dimensional verification, and sometimes non-destructive testing verify that fabricated components meet design requirements

General Manufacturing Considerations

Beyond specialized aerospace, automotive, and construction requirements, general manufacturing applications still benefit from systematic quality approaches:

- ISO 9001 Baseline: Even without industry-specific certifications, ISO 9001 demonstrates that a fabricator maintains documented quality management systems with consistent processes

- Material Certification Levels: Request appropriate mill test reports (MTRs) documenting material properties—essential for any application where material performance matters

- First Article Inspection: For production runs, require documented first article inspection confirming that initial parts meet all specifications before full production proceeds

- Statistical Process Control: Ongoing production benefits from SPC monitoring that detects process drift before parts exceed tolerance limits

When evaluating fabricators for your specific industry, certification status provides the most reliable indicator of capability alignment. A laser cutting Cincinnati provider with IATF 16949 certification has already demonstrated the systems, documentation, and quality culture that automotive applications demand. Similarly, AS9100-certified shops have invested in the traceability infrastructure and testing capabilities aerospace requires.

Understanding industry requirements establishes quality expectations—but equally important is understanding how these requirements translate into project costs and timelines. The next consideration addresses the pricing factors and delivery expectations that complete your fabricator evaluation.

Cost Factors and Project Timeline Expectations

You've specified your material, selected a cutting method, and verified your fabricator's certifications—but here's the question that often catches buyers off guard: why does the same part cost dramatically different amounts from different providers? Metal cutting pricing isn't arbitrary, yet most fabricators deliver quotes without explaining the underlying cost structure. Understanding what drives pricing empowers you to optimize designs for budget efficiency and evaluate quotes on equal footing.

Beyond cost, timeline expectations represent another opaque area. When you need CNC plasma cutting services near me urgently, how do you distinguish between fabricators who can genuinely deliver fast turnaround versus those who promise speed but consistently miss deadlines? Let's decode both pricing factors and realistic timeline expectations.

Cost Factors in Metal Cutting Services

Metal cutting costs accumulate from multiple sources, and each fabricator weighs these factors differently based on their equipment, overhead, and business model. According to industry pricing analysis, the primary cost drivers include:

- Material Type and Cost: Different metals carry vastly different base prices. Aluminum and stainless steel typically cost more than mild steel or iron. A standard 4×8 ft mild steel sheet (2mm thick) runs approximately $60–$120, while equivalent stainless steel costs significantly more per kilogram ($1.50–$3.00/kg versus $0.50–$1.00/kg for mild steel).

- Material Thickness: Thicker sheets require more cutting power, slower speeds, and longer machine time. Cutting 1-inch plate takes 3-4 times longer than thin gauge material, directly multiplying per-piece costs.

- Design Complexity: Simple rectangular shapes cut faster than intricate geometries with tight curves and numerous pierce points. Complex designs require slower cutting speeds and more careful programming. Design preparation costs range from $20–$100 for simple shapes to $100–$500+ for custom prototypes requiring 5+ hours of CAD work.

- Quantity and Volume: Setup costs spread across larger orders reduce per-piece pricing. Single prototypes might cost 50% more per unit than 100-piece production runs. High-volume orders may qualify for material discounts and batch processing efficiencies.

- Precision Requirements: Tighter tolerances demand slower cutting speeds, more sophisticated equipment, additional inspection time, and potentially secondary finishing operations. Specifying ±0.05mm when ±0.2mm would suffice can inflate costs by 30-50%.

- Setup and Calibration Time: Every job requires material positioning, machine calibration, and initial testing—typically 15-30 minutes at labor rates of $20–$50/hour. This fixed cost impacts small orders disproportionately.

- Post-Cutting Operations: Deburring, polishing, bending, or painting add significant costs. A 1 m² laser-cut part with deburring and painting might add $15–$40 beyond base cutting costs.

- Lead Time Requirements: Rush orders requiring priority scheduling or overtime work typically carry 15-30% surcharges. When steel cutters near me can't accommodate your timeline, expedite fees become unavoidable.

Calculating Cutting Costs

Laser cutting costs are often calculated based on cutting speed, material type, and thickness. According to reference data, machines typically charge hourly rates between $50–$150. For perspective, cutting a 1-meter straight line on 2mm thick mild steel might take only seconds—but complex geometries with intricate details require slower speeds and substantially more time.

Here's a practical example breakdown:

| Cost Component | Simple Part | Complex Part |

|---|---|---|

| Material (1mm stainless, 300×300mm) | $8–$15 | $8–$15 |

| Design/Programming | $20–$40 | $80–$200 |

| Machine Time | $10–$25 | $40–$100 |

| Setup/Calibration | $10–$20 | $15–$30 |

| Post-Processing | $5–$10 | $20–$50 |

| Total Range | $53–$110 | $163–$395 |

This comparison illustrates why design optimization matters—reducing complexity can cut costs by 50% or more without compromising functionality.

Understanding Project Timelines

Timeline expectations in metal cutting vary enormously based on project scope, fabricator capacity, and current workload. According to industry workflow analysis, the quote-to-delivery process involves multiple sequential stages, each adding time to your project.

Typical Timeline Components:

- Quote Turnaround: Standard providers typically require 24-72 hours for detailed quotes. However, quote turnaround times vary dramatically between providers—some industry leaders offer same-day or even faster response. For instance, manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate what's possible with optimized systems, delivering 12-hour quote turnaround that significantly accelerates project initiation.

- Design Review and DFM: 1-3 days for straightforward projects; complex geometries requiring manufacturability adjustments may extend this phase to a week or more.

- Material Procurement: Standard materials typically ship within 1-3 days. Specialty alloys, unusual thicknesses, or certified materials may require 2-4 weeks lead time from mills.

- Production Scheduling: Queue position depends on fabricator workload. High-capacity shops may slot your job within days; constrained facilities might quote 2-3 week lead times before cutting begins.

- Cutting Operations: Actual cutting time ranges from hours for simple jobs to days for complex, high-volume orders.

- Secondary Operations: Bending, welding, finishing, and inspection add 1-5 days depending on complexity and certification requirements.

- Shipping: Ground freight adds 1-5 days domestically; international shipping requires additional planning.

Accelerating Development with Rapid Prototyping

When standard timelines don't meet development needs, rapid prototyping services offer accelerated alternatives. According to industry research on metal rapid prototyping, these services bridge the gap between digital concepts and physical products, enabling teams to create functional metal parts at a fraction of traditional time and cost.

Rapid prototyping proves most valuable during early development stages when designs are still evolving and agility matters more than high-volume production. Key scenarios include:

- Design Iteration: Modify CAD files and receive new parts in days, bypassing financial penalties of altering hardened tools

- Functional Validation: Verify mechanical performance under real-world conditions before committing to production tooling

- Bridge Production: Produce small batches (1–50 units) for immediate assembly while waiting for production-grade dies

Lead times for different rapid prototyping methods vary considerably:

- Metal 3D Printing: 3–7 business days

- CNC Machining: 7–12 business days

- Sheet Metal Fabrication: 3–14 business days

- Investment Casting: 2–6 weeks

Industry-leading manufacturers demonstrate what's achievable with optimized rapid prototyping infrastructure. Companies like Shaoyi offer 5-day rapid prototyping capabilities, enabling automotive development teams to compress validation cycles dramatically. This speed advantage becomes particularly valuable when CNC repair near me or CNC repair services near me can't deliver replacement components fast enough to avoid production downtime.

When evaluating fabricators, ask specifically about their fastest possible turnaround for your project type. The gap between standard lead times and expedited capabilities often spans weeks—and understanding this range helps you plan contingencies for time-critical projects.

For organizations requiring consistent access to fast-turnaround cutting services, establishing relationships with multiple qualified providers creates supply chain resilience. When your primary CNC machine repair service near me experiences capacity constraints, pre-qualified alternatives prevent project delays from cascading into production shutdowns.

Understanding cost structures and timeline realities prepares you for productive fabricator conversations—but translating this knowledge into effective provider selection requires systematic evaluation criteria that separate capable partners from underqualified shops.

Choosing the Right Metal Cutting Service Provider

You've absorbed the technical specifications, understood material compatibility, and grasped tolerance requirements—but here's where knowledge transforms into action: selecting the right fabricator. When you're searching for where can i get metal cut or evaluating a metal cut service near me, the decision extends far beyond price comparison. According to Dr. Shahrukh Irani's industry analysis, too often businesses treat job shops as interchangeable, choosing the lowest price or fastest turnaround—only to face delays and reworks due to poor quality.

The gap between a mediocre fabricator and an excellent one often remains invisible until problems emerge. What sounded good in the quote frequently turns out to be overpromising. Your challenge is evaluating potential partners before committing—not after discovering capability gaps mid-project.

Key Criteria for Evaluating Service Providers

Systematic evaluation separates informed decisions from hopeful guesses. According to industry consulting experience, job shops vary enormously in capabilities, attention to detail, quality control, customer service, and more. Here's a structured approach to assessment:

- Verify Certifications and Quality Systems: Start with documentation. ISO 9001 certification indicates baseline quality management systems. For automotive applications, IATF 16949 certification is non-negotiable. Aerospace work demands AS9100. According to Cypress Fabrication's requirements guide, certifications from organizations like ASME, DNV, AISC, and ABS help ensure finished products meet safety and quality standards.

- Assess Equipment Capabilities: Match your project requirements against actual equipment specifications. What's their maximum cutting thickness? Do they operate fiber lasers, plasma systems, or waterjets appropriate for your material? Ask for equipment lists and verify capabilities align with your needs—not just current projects, but potential future requirements.

- Evaluate Quality Control Processes: According to Wiley Metal's evaluation guidance, quality isn't achieved by inspection after the fact—it's the result of defining and following rigorous procedures that dictate how each job is done. Ask about Weld Procedure Specifications, CMM inspection capabilities, and statistical process control systems.

- Review Experience and Track Record: Look for demonstrated expertise with your specific materials and applications. Request references from similar projects. A company with years of experience in your field has likely encountered and solved problems that newer providers haven't faced.

- Confirm Turnaround Capabilities: Standard lead times matter less than actual delivery performance. Ask about on-time delivery rates and what systems they use to maintain schedules. Discuss expedite capabilities for urgent situations.

- Examine Communication and Customer Service: Responsiveness during the quoting process often predicts production communication quality. Do they answer technical questions thoroughly? Do they provide DFM feedback proactively? According to industry experts, good customer service requires a deep commitment to putting the customer first in everything.

- Investigate Problem Resolution Policies: Ask directly: what happens if something goes wrong? Reputable fabricators stand behind their work and want the opportunity to correct issues while understanding root causes to prevent recurrence.

Certification verification isn't just paperwork—it's your primary indicator that a manufacturer maintains documented quality systems, calibrated equipment, trained personnel, and consistent processes. Never assume certification status; always request current certificates and verify validity with issuing bodies when stakes are high.

Questions to Ask Before Ordering

Beyond evaluation criteria, specific questions reveal fabricator capabilities that marketing materials often obscure. According to welding industry best practices, smart, probing questions help assess competence before trusting a shop with your business:

- What certifications do your operators hold? For welding, expect AWS certification by reputable organizations. For CNC operations, ask about training programs and recertification policies.

- How do you ensure consistent quality across production runs? Listen for mentions of documented procedures, inspection protocols, and statistical monitoring—not just "we're very careful."

- What experience do you have with my specific materials? Some alloys pose challenges that only experience teaches. A shop familiar with your materials has already learned the parameter adjustments and techniques required.

- What cutting technologies do you operate? Verify they have appropriate methods for your material and thickness. A shop with only plasma capability cannot deliver laser-quality edges regardless of promises.

- What's your typical quote turnaround time? This reveals operational efficiency. Industry leaders demonstrate what's possible—manufacturers like Shaoyi (Ningbo) Metal Technology deliver 12-hour quote turnaround, while others require days or weeks.

- Can you support rapid prototyping needs? Development projects require speed. Providers offering 5-day rapid prototyping capabilities enable faster iteration cycles than those requiring weeks for first articles.

- What DFM support do you provide? Comprehensive Design for Manufacturability feedback prevents costly revisions. Ask whether they review designs proactively or simply build what's submitted.

DIY Considerations vs. Professional Cut Services

For some projects, you might consider handling cutting internally or using hobbyist-grade equipment. Here's an honest assessment of when professional cut services justify their cost:

Professional services make sense when:

- Tolerances tighter than ±0.5mm are required

- Material thickness exceeds hobbyist equipment capacity

- Volume justifies setup and programming costs

- Certifications or traceability documentation are mandatory

- Edge quality affects function or appearance

- You lack time or expertise for equipment operation and maintenance

DIY or local services may suffice when:

- Simple cuts on thin, common materials

- Prototype quantities where imperfections are acceptable

- Non-critical applications with loose tolerances

- Educational or hobby projects where learning matters more than results

When searching for where to get metal cut locally, consider that tool service providers, tool repair centers, and machine tool repair services sometimes offer cutting capabilities alongside their primary operations. These shops may provide cost-effective solutions for straightforward work, though they typically lack the certifications and volume capacity of dedicated fabrication facilities.

Finding Quality Standards That Match Your Needs

Your industry and application determine which quality standards matter most. For general manufacturing, ISO 9001 provides adequate assurance. For automotive supply chains, IATF 16949 certification represents the quality benchmark that separates qualified suppliers from those excluded from major programs.

IATF 16949-certified manufacturers like Shaoyi demonstrate the comprehensive quality systems automotive applications demand—combining rigorous process control, complete traceability, and continuous improvement methodologies. Their integration of 12-hour quote turnaround, 5-day rapid prototyping, and comprehensive DFM support illustrates how certification infrastructure translates into operational capability.

For precision applications beyond automotive—aerospace, medical, and high-performance industrial components—certification requirements escalate further. Yet the evaluation principles remain consistent: verify credentials, assess capabilities, confirm experience, and establish communication expectations before production begins.

By applying the systematic evaluation approach outlined in this article, you'll transform from a buyer who simply accepts quotes into a partner who selects fabricators strategically. The nine specifications your fabricator won't explain—cutting methods, sawing operations, material compatibility, tolerance capabilities, file requirements, industry certifications, cost factors, timeline expectations, and provider evaluation criteria—now equip you to ask informed questions and make decisions that deliver project success.

Frequently Asked Questions About Metal Cut Services

1. How much does metal cutting cost?

Metal cutting costs range from $0.50 to $2 per linear inch depending on material type, thickness, and cutting method. Hourly rates typically fall between $50-$150 for laser cutting. Key cost factors include material type (stainless steel costs 3x more than mild steel), design complexity, quantity ordered, precision tolerances required, and post-processing needs like deburring or finishing. Simple parts may cost $53-$110 while complex geometries can reach $163-$395. Rapid prototyping services from IATF 16949-certified manufacturers like Shaoyi offer competitive pricing with 12-hour quote turnaround to help you budget accurately.

2. Will a hardware store cut metal for you?

Hardware stores offer limited metal cutting services, primarily for pipes and basic materials using simple tools. For precision metal cutting requiring specific tolerances, complex geometries, or specialized materials like stainless steel, aluminum alloys, or titanium, professional fabrication shops are necessary. These facilities operate fiber lasers achieving ±0.05mm tolerances, CNC plasma systems for thick plate, and waterjets for heat-sensitive applications. Professional services also provide material certifications, quality documentation, and DFM support that hardware stores cannot offer.

3. How to get a piece of metal cut?

To get metal cut professionally, start by preparing your design files in DXF, DWG, or STEP format at 1:1 scale with continuous paths and no overlapping geometry. Specify your material type, thickness, tolerance requirements, and quantity. Submit files to fabricators for quotes—industry leaders like Shaoyi provide 12-hour quote turnaround with comprehensive DFM feedback. For thin sheet metal under 6mm, laser cutting delivers the best precision. For thick plate over 12mm, plasma or waterjet cutting proves more practical. Always verify fabricator certifications match your industry requirements before ordering.

4. What is the difference between laser cutting and plasma cutting?

Laser cutting uses focused light beams achieving ±0.05mm to ±0.1mm tolerances with excellent edge quality, ideal for thin materials under 25mm. Plasma cutting employs superheated gas, delivering ±0.5mm to ±1.5mm tolerances at faster speeds for thick conductive metals up to 50mm+. Laser excels for precision sheet metal fabrication and intricate geometries. Plasma offers 3-4x faster cutting speeds on 1-inch steel at roughly half the operating cost. Fiber lasers handle steel, stainless, aluminum, and brass efficiently, while plasma requires electrically conductive materials only.

5. What certifications should I look for in a metal cutting service provider?

ISO 9001 certification indicates baseline quality management systems for general manufacturing. Automotive applications require IATF 16949 certification—a rigorous standard ensuring defect reduction and supply chain integration. Aerospace work demands AS9100 certification with complete material traceability and 7+ year record retention. Construction projects should verify AISC or AWS D1.1 compliance. Always request current certificates and verify validity. IATF 16949-certified manufacturers like Shaoyi demonstrate comprehensive quality systems combining process control, traceability, rapid prototyping capabilities, and DFM support that precision applications demand.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —