ปลดล็อกสมรรถนะ: การลดน้ำหนักชิ้นส่วนยานยนต์ด้วยการตีขึ้นรูป

สรุปสั้นๆ

การลดน้ำหนักชิ้นส่วนยานยนต์ด้วยกระบวนการขึ้นรูปแบบฟอร์จจิ้งเป็นกลยุทธ์การผลิตที่สำคัญในการสร้างชิ้นส่วนที่มีความแข็งแรงมากขึ้น น้ำหนักเบาลง และทนทานยิ่งขึ้น โดยการใช้วัสดุอย่างอลูมิเนียมและเหล็กกล้าความแข็งแรงสูงขั้นสูง กระบวนการฟอร์จจิ้งจะผลิตชิ้นส่วนที่มีโครงสร้างเม็ดเกรนที่เหนือกว่าและอัตราส่วนความแข็งแรงต่อน้ำหนักที่ดีขึ้น วิธีการนี้มีความจำเป็นอย่างยิ่งในการลดมวลรวมของยานพาหนะ ซึ่งส่งผลโดยตรงต่อประสิทธิภาพการใช้เชื้อเพลิงที่ดีขึ้น การเพิ่มประสิทธิภาพด้านพลวัตของรถ และการลดการปล่อยมลพิษ โดยไม่กระทบต่อความปลอดภัยหรือสมรรถนะ

'เหตุผล' และ 'สิ่งที่เป็น' ของการลดน้ำหนักยานยนต์ด้วยการฟอร์จจิ้ง

การลดน้ำหนักรถยนต์คือแนวทางการออกแบบที่มีเป้าหมายในการลดน้ำหนักรวมของรถอย่างมีกลยุทธ์ เพื่อเพิ่มประสิทธิภาพและสมรรถนะของรถ แนวคิดนี้ได้กลายเป็นหัวใจสำคัญของวิศวกรรมยานยนต์ในยุคปัจจุบัน อันเนื่องมาจากข้อกำหนดด้านการปล่อยมลพิษที่เข้มงวด และความต้องการของผู้บริโภคที่ต้องการประหยัดน้ำมันมากขึ้น ตามงานวิจัยจากสถาบันต่างๆ เช่น มหาวิทยาลัย RWTH Aachen การออกแบบรถยนต์ให้เบาลงถือเป็นเทคโนโลยีหลักในการลดการสิ้นเปลืองเชื้อเพลิงและการปล่อยก๊าซ CO2 ในขณะเดียวกันยังช่วยเพิ่มสมรรถนะการขับขี่และความสะดวกสบาย โดยรถที่มีน้ำหนักเบากว่าจะใช้พลังงานน้อยลงในการเร่งความเร็วและรักษาระดับความเร็ว ส่งผลให้เกิดการเพิ่มประสิทธิภาพอย่างมีนัยสำคัญ

ข้อดีของการลดน้ําหนักของรถยนต์ ยกยาวไปนอกจากการประหยัดน้ํามัน รถที่เบากว่าจะแสดงให้เห็นการควบคุมที่ดีขึ้น ความเร็วเร่งเร็วขึ้น และระยะทางเบรกที่สั้นลง ส่งผลให้ประสบการณ์การขับขี่ปลอดภัยและตอบสนองได้มากขึ้น สําหรับรถไฟฟ้า (EV) การเบาลงเป็นสิ่งสําคัญยิ่งกว่า เพราะมันสามารถชดเชยน้ําหนักที่สําคัญของแบตเตอรี่และขยายระยะทางของรถไฟฟ้า การ ปรับปรุง ความ ง่ายดาย ของ การ ใช้ หม้อ หม้อ หม้อ หม้อ

นี่คือที่ที่การปลอมแปลงมีบทบาทสําคัญ การสลักเป็นกระบวนการผลิตที่ทําให้โลหะมีรูปร่าง โดยใช้แรงกดที่ตั้ง การ ปั่น ทํา ให้ โลหะ มี รูป แบบ ที่ เหมาะ กับ ภาพ ของ ส่วน ไหน กระบวนการนี้กําจัดขุมขวางและสร้างส่วนประกอบที่แข็งแรงและทนทานมากกว่าคณะที่หล่นหรือแปรรูป ความแข็งแรงที่เกิดขึ้นในตัวนี้ ทําให้วิศวกรสามารถออกแบบชิ้นส่วนที่บางและเบาขึ้น โดยไม่เสียสละความสมบูรณ์แบบของโครงสร้าง ทําให้การโกหกเป็นทางออกที่เหมาะสมสําหรับการผลิตชิ้นส่วนที่มีความเครียดสูงสําหรับอุตสาหกรรมรถยนต์

วัสดุสําคัญสําหรับส่วนประกอบเบาๆที่โกหก

การเลือกวัสดุเป็นสิ่งพื้นฐานที่มีผลต่อความสำเร็จของการผลิตชิ้นส่วนยานยนต์ที่มีน้ำหนักเบาด้วยกระบวนการตีขึ้นรูป เป้าหมายคือการค้นหาวัสดุที่มีอัตราส่วนความแข็งแรงต่อน้ำหนักสูง มีความทนทาน และมีต้นทุนที่เหมาะสม วัสดุหลักสองประเภทที่นิยมใช้ในด้านนี้ ได้แก่ โลหะผสมอลูมิเนียม และเหล็กกล้าความแข็งแรงสูงขั้นสูง (AHSS)

โลหะผสมอลูมิเนียม: อลูมิเนียมได้กลายเป็นวัสดุหลักสำหรับการลดน้ำหนักรถยนต์ ข้อได้เปรียบหลักของมันคือความหนาแน่นต่ำ—ประมาณหนึ่งในสามของเหล็ก—เมื่อผสมกับโลหะอื่นและผ่านกระบวนการตีขึ้นรูปจะได้ความแข็งแรงที่ยอดเยี่ยม บริษัทผู้ผลิตที่ทำกระบวนการตีขึ้นรูปจึงเริ่มลงทุนเพิ่มขึ้นในการผลิตอลูมิเนียมเพื่อตอบสนองความต้องการนี้ ชิ้นส่วนอลูมิเนียมที่ตีขึ้นรูป เช่น ข้อต่อเพลาล้อ ชุดควบคุม และโครงล้อ สามารถลดน้ำหนักส่วนที่ไม่ได้รับแรงสั่นสะเทือน (unsprung mass) ของรถได้อย่างมาก ซึ่งช่วยปรับปรุงคุณภาพการขับขี่และความคล่องตัว กระบวนการนี้ยังช่วยให้สามารถสร้างรูปทรงที่ซับซ้อนได้ โดยออกแบบให้มีทั้งน้ำหนักเบาและความแข็งแรงสูง ทำให้เป็นสิ่งจำเป็นสำหรับโครงรถและระบบกันสะเทือนในยานยนต์สมัยใหม่

เหล็กกล้าความแข็งแรงสูงขั้นสูง (AHSS): แม้ว่าอลูมิเนียมจะเป็นวัสดุที่นิยมใช้ แต่เหล็กกล้ายังคงเป็นวัสดุสำคัญในอุตสาหกรรมการผลิตรถยนต์ เหล็กกล้าความแข็งแรงสูงขั้นสูง (AHSS) และเหล็กกล้าไมโครอัลลอยด์ มีความต้านทานแรงดึงที่ยอดเยี่ยม ทำให้ออกแบบชิ้นส่วนที่มีหน้าตัดบางลงได้ แต่ยังคงผ่านมาตรฐานด้านความปลอดภัยและสมรรถนะอย่างเข้มงวด ชิ้นส่วนเครื่องยนต์และระบบส่งกำลังที่สำคัญ เช่น เพลาข้อเหวี่ยงและก้านสูบ มักผลิตจากเหล็กกล้าความแข็งแรงสูงที่ผ่านกระบวนการตีขึ้นรูป วัสดุเหล่านี้สามารถทนต่อแรงกดมหาศาลและอุณหภูมิสูง จึงมั่นใจได้ในเรื่องความน่าเชื่อถือของระบบส่งกำลัง ซึ่งไม่สามารถยอมให้เกิดข้อผิดพลาดได้

เพื่อให้การเปรียบเทียบชัดเจนยิ่งขึ้น ตารางด้านล่างสรุปลักษณะสำคัญของวัสดุหลักที่ใช้ในงานตีขึ้นรูปรถยนต์

| วัสดุ | คุณสมบัติหลัก | ข้อดี | การใช้งานที่นิยมตีขึ้นรูป |

|---|---|---|---|

| โลหะผสมอลูมิเนียม | ความหนาแน่นต่ำ ทนต่อการกัดกร่อนได้ดี มีความสามารถในการขึ้นรูปที่ดี | ลดน้ำหนักได้อย่างมาก ปรับปรุงการทรงตัว (มวลที่ไม่รองรับน้ำหนักต่ำลง) | ชิ้นส่วนระบบกันสะเทือน (แขนควบคุม, ข้อต่อ), ชิ้นส่วนโครงถัง, กรอบล้อ, แบริ่งแกนโช้คอัพ |

| เหล็กความแข็งสูง | มีความต้านทานแรงดึงสูงมาก ทนต่อการเหนื่อยล้าได้ดี และคุ้มค่าด้านต้นทุน | มีความแข็งแรงสูง เหมาะสำหรับชิ้นส่วนรับน้ำหนักสำคัญ ทนทาน | ชิ้นส่วนเครื่องยนต์ (เพลาข้อเหวี่ยง ก้านสูบ), ฟันเฟืองเกียร์, เพลาขับ, ชิ้นส่วนพวงมาลัย |

กระบวนการและเทคโนโลยีการตีขึ้นรูปหลัก

กระบวนการตีขึ้นรูปไม่ใช่วิธีการที่ใช้ได้กับทุกกรณี มีเทคนิคต่าง ๆ ที่นำมาใช้เพื่อผลิตชิ้นส่วนที่หลากหลายตามความต้องการของอุตสาหกรรมยานยนต์ การเลือกวิธีการขึ้นอยู่กับความซับซ้อนของชิ้นส่วน วัสดุที่ใช้ และปริมาณการผลิตที่ต้องการ วิธีการหลัก ได้แก่ การตีขึ้นรูปแบบแม่พิมพ์ปิด การตีขึ้นรูปแบบแม่พิมพ์เปิด และการตีขึ้นรูปแบบความแม่นยำสูง

การตีขึ้นรูปแบบแม่พิมพ์ปิด (Closed Die Forging): นี่คือกระบวนการตีขึ้นรูปที่พบบ่อยที่สุดสำหรับชิ้นส่วนยานยนต์ โดยในวิธีนี้ ชิ้นงานโลหะจะถูกวางไว้ระหว่างแม่พิมพ์สองชิ้น ซึ่งมีลักษณะตรงตามรูปร่างของชิ้นส่วนที่ต้องการ เมื่อแม่พิมพ์กดเข้าหากัน โลหะจะไหลและเติมเต็มช่องว่าง ทำให้ได้ชิ้นส่วนที่มีรูปร่างชัดเจนและมีความแม่นยำด้านมิติสูง กระบวนการนี้เหมาะสำหรับการผลิตชิ้นส่วนจำนวนมาก เช่น ลูกสูบต่อ ฟันเฟือง และชิ้นส่วนระบบกันสะเทือน ที่ต้องการความแข็งแรงและความสม่ำเสมอสูง

การตีขึ้นรูปแบบแม่พิมพ์เปิด: ในการตีขึ้นรูปแบบแม่พิมพ์เปิด ชิ้นงานจะถูกขึ้นรูปโดยใช้แม่พิมพ์เรียบหรือแม่พิมพ์ที่มีรูปร่างง่าย ซึ่งไม่ได้ล้อมรอบชิ้นงานทั้งหมด ผู้ปฏิบัติงานจะจัดตำแหน่งหรือปรับชิ้นงานเพื่อให้ได้รูปร่างตามต้องการ แม้ว่าวิธีนี้จะมีความแม่นยำน้อยกว่าการตีขึ้นรูปแบบแม่พิมพ์ปิด แต่ก็มีความยืดหยุ่นสูงและเหมาะสมสำหรับการผลิตชิ้นส่วนขนาดใหญ่ที่มีรูปร่างเรียบง่าย เช่น เพลา หรือสำหรับการขึ้นรูปเบื้องต้น (preforms) ก่อนเข้าสู่กระบวนการตีขึ้นรูปขั้นสูง

การตีขึ้นรูปแบบความแม่นยำสูง (รูปร่างใกล้เคียงชิ้นงานจริง) เมื่อเทคโนโลยีก้าวหน้า ความแม่นยำในการตีขึ้นรูปก็พัฒนาตามไปด้วย เช่น การตีขึ้นรูปแบบความแม่นยำสูงหรือใกล้เคียงรูปร่างสุดท้าย (near-net shape forging) ซึ่งผลิตชิ้นส่วนที่มีขนาดใกล้เคียงกับขนาดสุดท้ายที่ต้องการมาก เทคนิคนี้ช่วยลดความจำเป็นในการกลึงเพิ่มเติม จึงประหยัดทั้งวัสดุ เวลา และต้นทุน โดยเฉพาะอย่างยิ่งมีความสำคัญต่อการผลิตชิ้นส่วนที่ซับซ้อนและละเอียด เช่น เฟืองเกียร์และชิ้นส่วนดิฟเฟอเรนเชียล ที่ต้องการค่าความคลาดเคลื่อนที่แคบมาก

การดำเนินกระบวนการตีขึ้นรูปขั้นสูงเหล่านี้ต้องอาศัยความเชี่ยวชาญอย่างมากและอุปกรณ์เฉพาะทาง ตัวอย่างเช่น ผู้ให้บริการอย่าง เทคโนโลยีโลหะเส้าอี้ เชี่ยวชาญด้านการตีขึ้นรูปแบบร้อนที่ได้รับการรับรองตามมาตรฐาน IATF16949 สำหรับภาคยานยนต์ โดยให้บริการตั้งแต่การทำต้นแบบจนถึงการผลิตจำนวนมาก บริษัทเฉพาะทางประเภทนี้มีบทบาทสำคัญในห่วงโซ่อุปทาน ช่วยให้ผู้ผลิตรถยนต์สามารถใช้ประโยชน์จากศักยภาพของการลดน้ำหนักชิ้นส่วนผ่านกระบวนการตีขึ้นรูปได้อย่างเต็มที่

การประยุกต์ใช้งานและประโยชน์ในยานยนต์สมัยใหม่

การใช้ชิ้นส่วนตีขึ้นรูปที่มีน้ำหนักเบาถูกนำมาใช้อย่างแพร่หลายในเกือบทุกระบบสำคัญของยานยนต์สมัยใหม่ โดยการแทนที่ชิ้นส่วนหล่อหรือชิ้นส่วนที่ผ่านการกลึงซึ่งมีน้ำหนักมากกว่า ด้วยชิ้นส่วนตีขึ้นรูปที่มีน้ำหนักเบากว่าแต่แข็งแรงกว่า ทำให้ผู้ผลิตสามารถลดน้ำหนักรวมได้ ซึ่งส่งผลให้เกิดการเพิ่มประสิทธิภาพที่ชัดเจน แอปพลิเคชันเหล่านี้มักจะกระจุกตัวอยู่ในพื้นที่ที่ต้องรับแรงกดสูงและแรงกระทำแบบเป็นรอบ

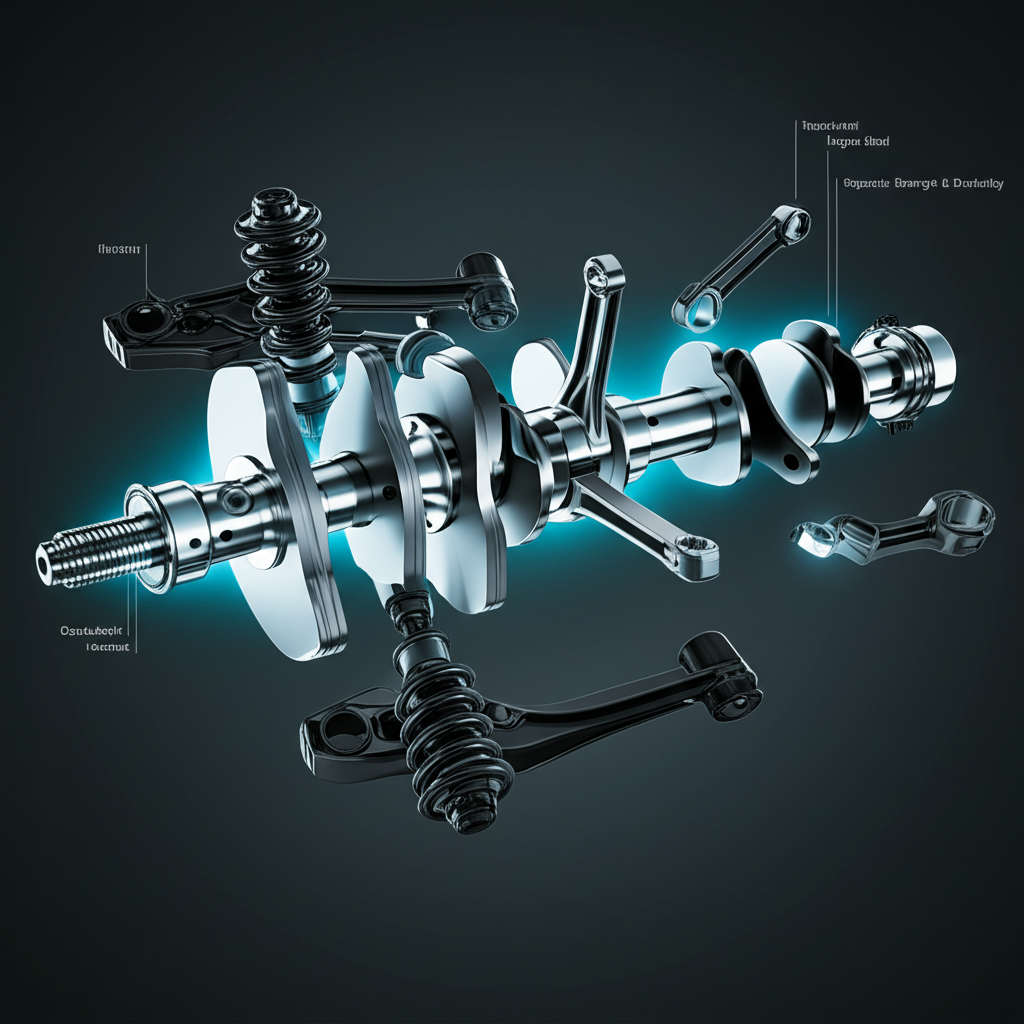

- เครื่องยนต์และระบบส่งกำลัง: หัวใจหลักของยานยนต์ได้รับประโยชน์อย่างมากจากการตีขึ้นรูป เพลาข้อเหวี่ยง ลูกสูบต่อ และเพลากล้องลูกเบี้ยว ล้วนถูกตีขึ้นรูปจากเหล็กที่มีความแข็งแรงสูง เพื่อทนต่อแรงสุดขีดจากกระบวนการเผาไหม้และการหมุน การลดน้ำหนักของชิ้นส่วนที่หมุนและเคลื่อนที่แบบไป-มาเหล่านี้ ช่วยลดแรงเฉื่อย ทำให้เครื่องยนต์ตอบสนองได้รวดเร็วขึ้นและทำงานได้มีประสิทธิภาพมากขึ้น

- แชสซีและระบบกันสะเทือน: นี่คือพื้นที่หลักสำหรับการตีขึ้นรูปอลูมิเนียม ส่วนประกอบต่างๆ เช่น แขนควบคุม (control arms), ข้อต่อพวงมาลัย (steering knuckles), และโครงย่อย (subframes) มักจะถูกตีขึ้นรูปจากโลหะผสมอลูมิเนียม การลดน้ำหนักส่วนที่ "ไม่ได้รับการรองรับจากช่วงล่าง" (unsprung weight) ซึ่งเป็นมวลที่ไม่ได้รับการรองรับจากช่วงล่าง ทำให้ล้อสามารถติดตามผิวถนนได้อย่างมีประสิทธิภาพมากขึ้น ส่งผลให้การทรงตัว การยึดเกาะถนน และความสะดวกสบายขณะขับขี่ดียิ่งขึ้น

- ระบบส่งกำลัง: เฟือง เพลาส่งกำลัง และข้อต่อเพลา (universal joints) ถูกตีขึ้นรูปเพื่อให้มีความแข็งแรงและทนต่อการเหนื่อยล้าสูงสุด การลดน้ำหนักของชิ้นส่วนเหล่านี้ช่วยลดมวลที่หมุน ซึ่งจะช่วยเพิ่มอัตราเร่งและประสิทธิภาพโดยรวมของระบบส่งกำลัง เพลาแบบกลวง (Hollow shafts) ที่สร้างขึ้นผ่านกระบวนการตีขึ้นรูปพิเศษ เป็นตัวอย่างที่ยอดเยี่ยมของการออกแบบเพื่อเพิ่มประสิทธิภาพในด้านนี้

- ระบบเบรก: คาลิปเปอร์เบรกแบบตีขึ้นรูปมีความแข็งแกร่งและน้ำหนักเบา ช่วยปรับปรุงการตอบสนองของระบบเบรกและการระบายความร้อน ความแข็งแรงของชิ้นส่วนเหล่านี้ทำให้ไม่เกิดการยืดหยุ่นภายใต้แรงดันสูง จึงให้แรงเบรกที่สม่ำเสมอและเชื่อถือได้

การตีขึ้นรูปเทียบกับวิธีอื่น: การเปรียบเทียบความแข็งแรงและน้ำหนัก

เมื่อเลือกวิธีการผลิตสำหรับชิ้นส่วนยานยนต์ที่สำคัญ วิศวกรมักจะเปรียบเทียบการตีขึ้นรูปกับการหล่อและการกลึง แม้ว่าวิธีแต่ละอย่างจะมีข้อดีในสถานการณ์ของตนเอง แต่การตีขึ้นรูปมีข้อได้เปรียบทางด้านโลหะวิทยาที่ชัดเจน โดยเฉพาะอย่างยิ่งสำหรับชิ้นส่วนที่ต้องการความแข็งแรงและความน่าเชื่อถือสูง

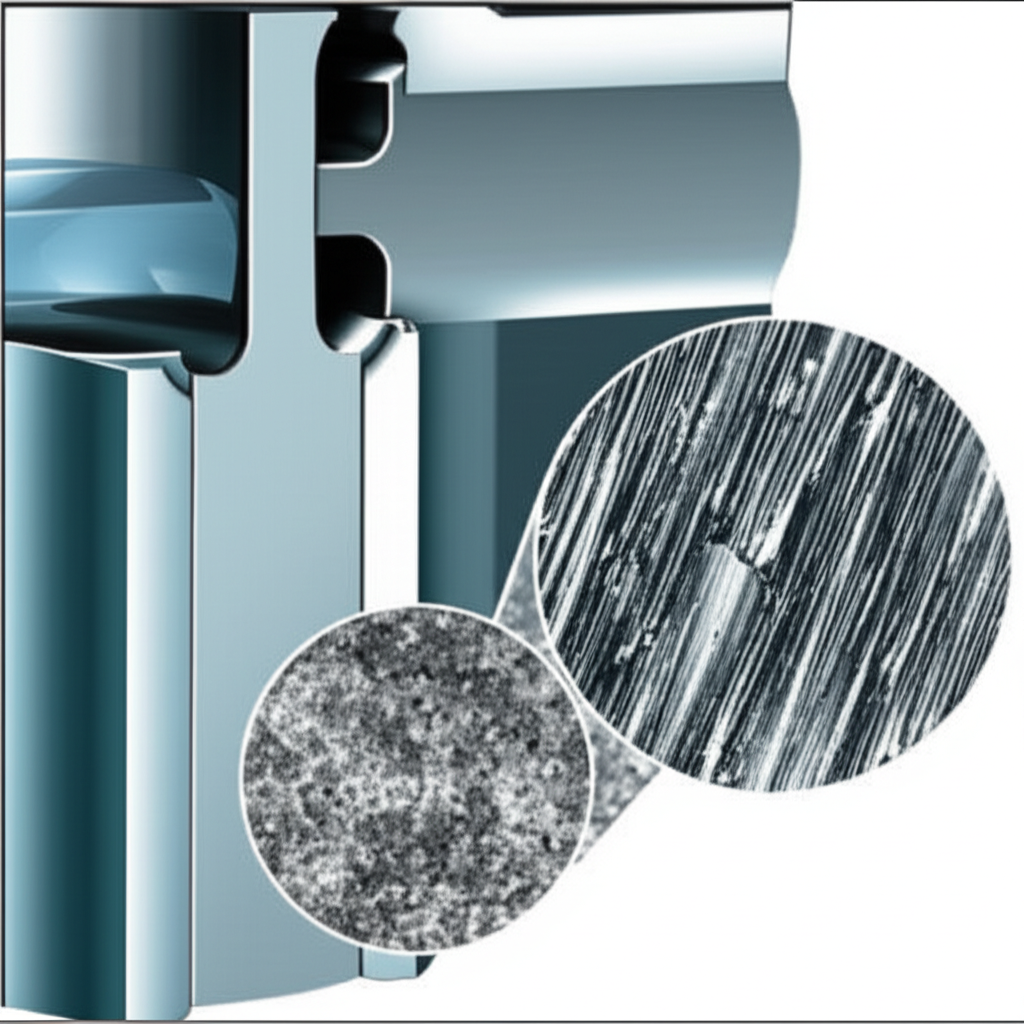

ข้อได้เปรียบหลักของการตีขึ้นรูปคือผลที่เกิดกับโครงสร้างเม็ดเกรนภายในของโลหะ โดยแรงกดมหาศาลในกระบวนการตีขึ้นรูปจะช่วยปรับปรุงความละเอียดของเม็ดเกรนและบังคับให้เกรนไหลตามรูปร่างของชิ้นส่วน ส่งผลให้เกิดการไหลต่อเนื่องของเม็ดเกรน ซึ่งทำให้ชิ้นส่วนมีความแข็งแรงต่อแรงดึง ความเหนียว และความต้านทานต่อแรงกระแทกและการล้าได้อย่างยอดเยี่ยม ในทางตรงกันข้าม การหล่อเกี่ยวข้องกับการเทโลหะเหลวลงในแม่พิมพ์ ซึ่งอาจทำให้โครงสร้างเม็ดเกรนมีลักษณะสุ่มมากขึ้น และอาจมีโพรงอากาศแฝงอยู่ภายใน ทำให้วัสดุมีความแข็งแรงน้อยกว่าโดยธรรมชาติ ส่วนการกลึงซึ่งเป็นการตัดแต่งชิ้นส่วนจากก้อนโลหะสำเร็จรูป (บิลเล็ต) นั้น จะไม่สร้างการไหลของเม็ดเกรนเลย แต่กลับตัดขวางผ่านแนวเม็ดเกรนเดิม ซึ่งอาจก่อให้เกิดจุดความเครียดและทำให้ชิ้นส่วนมีแนวโน้มที่จะเสียรูปหรือแตกหักภายใต้แรงประลัยมากขึ้น

ความเหนือกว่าเชิงโครงสร้างนี้คือเหตุผลที่ชิ้นส่วนแบบปลอมะลึกมีความแข็งแรงมากกว่าชิ้นส่วนที่ผ่านการกลึงหรือหล่อจากวัสดุและขนาดเดียวกันอย่างมีนัยสำคัญ ความแข็งแรงที่เพิ่มขึ้นนี้ทำให้สามารถออกแบบในสิ่งที่เรียกว่า "การออกแบบเพื่อลดน้ำหนัก" ได้ โดยชิ้นส่วนที่ปลอมะลึกสามารถออกแบบให้ใช้วัสดุน้อยลง และดังนั้นจึงมีน้ำหนักเบากว่า แต่ยังคงมีสมรรถนะเกินกว่าชิ้นส่วนที่หนักกว่าซึ่งผลิตด้วยวิธีอื่น สำหรับการใช้งานที่ต้องคำนึงถึงความปลอดภัยเป็นพิเศษ เช่น ชิ้นส่วนระบบกันสะเทือนและพวงมาลัย ความน่าเชื่อถือและความแข็งแรงที่ได้จากการปลอมะลึกทำให้เป็นทางเลือกที่ดีกว่า แม้ว่าต้นทุนเครื่องมือเริ่มต้นสำหรับการปลอมะลึกอาจสูงกว่า แต่ความทนทานในระยะยาวและความสามารถในการลดมวลมักทำให้เป็นทางออกที่มีประสิทธิภาพที่สุดสำหรับการประยุกต์ใช้งานยานยนต์สมรรถนะสูง

คำถามที่พบบ่อย

1. วัสดุใดบ้างที่ใช้ในการลดน้ำหนักยานยนต์

วัสดุหลักประกอบด้วยโลหะผสมอลูมิเนียมขั้นสูงและเหล็กกล้าความแข็งแรงสูง อลูมิเนียมเป็นที่นิยมเนื่องจากมีความหนาแน่นต่ำ และมักใช้ในชิ้นส่วนโครงรถและระบบกันสะเทือน เหล็กกล้าความแข็งแรงสูงถูกใช้สำหรับชิ้นส่วนเครื่องยนต์และชิ้นส่วนระบบส่งกำลังที่ต้องการความทนทานและความต้านทานต่อการเหนื่อยล้าสูง วัสดุอื่นๆ เช่น โลหะผสมแมกนีเซียมและคาร์บอนไฟเบอร์คอมโพสิตก็ถูกใช้เช่นกัน แต่อลูมิเนียมและเหล็กที่ผ่านกระบวนการตีขึ้นรูป (forged) เป็นที่นิยมมากที่สุดสำหรับชิ้นส่วนโครงสร้าง

2. ชิ้นส่วนเครื่องยนต์ใดบ้างที่ควรตีขึ้นรูป

ชิ้นส่วนเครื่องยนต์ที่ต้องรับแรงกด ความร้อน และการโหลดแบบไซเคิลควรตีขึ้นรูปเพื่อให้มีความน่าเชื่อถือสูงสุด ซึ่งรวมถึงชิ้นส่วนสำคัญ เช่น เพลาข้อเหวี่ยง ก้านสูบ ลูกสูบ และเพลาลูกเบี้ยว การตีขึ้นรูปช่วยให้มั่นใจได้ว่าชิ้นส่วนเหล่านี้มีความแข็งแรงและความต้านทานต่อการเหนื่อยล้าที่จำเป็นต่อการทนต่อสภาพแวดล้อมที่รุนแรงภายในเครื่องยนต์

3. มีกี่ประเภทของกระบวนการตีขึ้นรูป และมีอะไรบ้าง

วิธีการหลักที่พิจารณาในบทความคือการสลักแบบพิมพ์ (หรือสลักแบบปิด), การสลักแบบเปิด, และการสลักแบบแม่นยํา ในภาครถยนต์ การสลักแบบฉลากเป็นสิ่งที่พบได้มากที่สุดในการผลิตชิ้นส่วนที่ซับซ้อนและแข็งแรงสูงในปริมาณมาก และการสลักความแม่นยําเป็นเทคนิคที่ก้าวหน้าที่ใช้ในการลดการแปรรูปหลังให้น้อยที่สุด ประเภทหลักอื่น ๆ ที่ไม่ได้รายละเอียดที่นี่รวมถึงการเหมืองเย็นและเหมืองแหวนม้วนที่ไม่มีรอยต่อ

4. ส่วนที่โกหกแข็งแรงกว่าส่วนที่ทําด้วยเครื่องจักรไหม

ใช่ ส่วนที่โกหกแข็งแรงกว่ามาก กระบวนการโกหกสร้างการไหลของเมล็ดพันธุ์ต่อเนื่องที่ตามรูปร่างของชิ้นส่วน, เพิ่มความสมบูรณ์แบบโครงสร้าง, ความยืดหยุ่น, และความทนทานต่อความเหนื่อยล้า. การแปรรูปตัดผ่านโครงสร้างเมล็ดธรรมชาติของโลหะ ซึ่งสามารถสร้างจุดอ่อน ความแข็งแรงที่สูงกว่านี้ทําให้ส่วนประกอบที่โกหกสามารถทําให้เบากว่าส่วนที่ทําด้วยเครื่องจักร ในขณะที่ยังคงให้ผลงานที่ดีและทนทาน

ผลิตจำนวนน้อย แต่มีมาตรฐานสูง บริการสร้างต้นแบบอย่างรวดเร็วของเรามาพร้อมกับการตรวจสอบที่เร็วขึ้นและง่ายขึ้น —

ผลิตจำนวนน้อย แต่มีมาตรฐานสูง บริการสร้างต้นแบบอย่างรวดเร็วของเรามาพร้อมกับการตรวจสอบที่เร็วขึ้นและง่ายขึ้น —