การตัดแผ่นโลหะด้วยเลเซอร์: แก้ไขข้อบกพร่อง ลดต้นทุน และเลือกให้ถูกต้อง

เหตุใดการตัดด้วยเลเซอร์จึงเป็นวิธีที่นิยมสำหรับการผลิตโลหะ

คุณเคยเห็นมีดร้อนๆ ลากผ่านเนยไหม? ตอนนี้ลองจินตนาการถึงความแม่นยำแบบไม่ต้องออกแรงเช่นเดียวกัน แต่ใช้กับเหล็ก อลูมิเนียม หรือไทเทเนียม นั่นคือสิ่งที่เกิดขึ้นในการดำเนินงานตัดแผ่นโลหะด้วยเลเซอร์ ซึ่งแสงที่มีความเข้มข้นจะเปลี่ยนวัตถุดิบให้กลายเป็นชิ้นส่วนที่มีรูปร่างสมบูรณ์ภายในไม่กี่วินาที

แล้วการตัดด้วยเลเซอร์คืออะไรกันแน่? มันคือกระบวนการผลิตแบบลบเนื้อวัสดุ ที่ใช้ ลำแสงเลเซอร์กำลังสูงเพื่อหลอมละลาย , เผา หรือทำให้โลหะระเหยไปตามเส้นทางที่ถูกโปรแกรมไว้อย่างแม่นยำ ผลลัพธ์คือ รอยตัดที่สะอาด ลวดลายซับซ้อน และค่าความคลาดเคลื่อนที่วิธีการกลไกแบบดั้งเดิมไม่สามารถทำได้ ไม่ว่าคุณจะผลิตชิ้นส่วนสำหรับอากาศยานหรือแผงสถาปัตยกรรม เทคโนโลยีนี้ก็ให้ผลลัพธ์ที่สม่ำเสมอ ทำซ้ำได้ ส่งมอบความเร็วและประสิทธิภาพอย่างเหนือชั้น

แสงที่มีความเข้มข้นเปลี่ยนโลหะดิบให้กลายเป็นชิ้นส่วนที่มีความแม่นยำได้อย่างไร

การเดินทางจากแผ่นดิบสู่ชิ้นงานสำเร็จรูปเริ่มต้นขึ้นที่แหล่งกำเนิดเลเซอร์เอง เมื่อรังสีเลเซอร์กระทบพื้นผิวโลหะ จะทำให้วัสดุร้อนอย่างรวดเร็วจนถึงจุดหลอมเหลว จากนั้นกระแสก๊าซช่วยตัดที่มีความเข้มข้น—โดยทั่วไปคือก๊าซไนโตรเจนหรือออกซิเจน—จะเป่าเอาวัสดุที่หลอมละลายออกไป ทำให้เกิดรอยตัดที่เรียบและแม่นยำ

เครื่องตัดด้วยเลเซอร์เครื่องแรกสำหรับการใช้งานในอุตสาหกรรมปรากฏขึ้นครั้งแรกในช่วงต้นทศวรรษ 1960 โดยได้รับการพัฒนาโดยคุณคุมาร์ ปาเทล ที่ห้องปฏิบัติการเบลล์ โดยใช้เทคโนโลยีคาร์บอนไดออกไซด์ (CO2) นับแต่นั้น เทคโนโลยีนี้ได้พัฒนาไปอย่างมาก ในปัจจุบัน เลเซอร์ไฟเบอร์ขั้นสูงได้เข้ามาแทนที่ระบบ CO2 สำหรับการตัดโลหะด้วยแสงเลเซอร์ เนื่องจากให้พลังงานที่สูงกว่า ประสิทธิภาพการใช้พลังงานที่ดีกว่า และประสิทธิภาพที่เหนือกว่าเมื่อทำงานกับวัสดุที่สะท้อนแสง

ต่างจากการตัดด้วยวิธีกลที่อาศัยการสัมผัสและการใช้แรง เทคนิคการตัดแผ่นโลหะด้วยแสงเลเซอร์สามารถบรรลุความแม่นยำได้ด้วยพลังงานความร้อนที่มีความเข้มข้นสูง—สามารถควบคุมความคลาดเคลื่อนได้แน่นหนาถึง ±0.1 มม. ในขณะที่ไม่เกิดการสึกหรอของเครื่องมือเลย

หลักฟิสิกส์ที่อยู่เบื้องหลังการตัดโลหะอย่างสะอาดและแม่นยำ

เหตุใดการตัดโลหะด้วยเลเซอร์จึงได้ผลดีมาก? คำตอบอยู่ที่หลักการทางวิทยาศาสตร์สำคัญหลายประการที่ทำงานร่วมกัน:

- การดูดซึมน้ำ: โลหะชนิดต่าง ๆ ดูดซับความยาวคลื่นของเลเซอร์ที่แตกต่างกัน เลเซอร์ไฟเบอร์เหมาะสำหรับการตัดเหล็กกล้าและอลูมิเนียม เพราะโลหะเหล่านี้ดูดซับพลังงานโฟตอนได้อย่างมีประสิทธิภาพ

- ความสามารถในการนําไฟฟ้า โลหะนำความร้อนออกไปจากริมเขตที่ตัดได้อย่างรวดเร็ว ทำให้วัสดุรอบข้างไม่ได้รับผลกระทบและขอบตัดมีความสะอาด

- ความแม่นยำของระบบควบคุมตัวเลขด้วยคอมพิวเตอร์ (CNC): เทคโนโลยีระบบควบคุมตัวเลขด้วยคอมพิวเตอร์ (CNC) ควบคุมหัวตัดให้เคลื่อนที่ตามเส้นทางที่ถูกโปรแกรมไว้ล่วงหน้า ทำให้มั่นใจได้ว่าทุกการตัดตรงตามข้อกำหนดของแบบดิจิทัลอย่างผิดพลาดน้อยที่สุด

หัวตัดเคลื่อนที่ด้วยความแม่นยำสูง ติดตามรูปทรงเรขาคณิตที่ซับซ้อน ซึ่งเป็นไปไม่ได้ด้วยเครื่องมือแบบดั้งเดิม กระบวนการนี้จึงเหมาะสำหรับทุกอย่างตั้งแต่การออกแบบเครื่องประดับที่ละเอียดอ่อน ไปจนถึงโครงสร้างสถาปัตยกรรมขนาดใหญ่ — ทุกการใช้งานที่ความแม่นยำมีความสำคัญ

สำหรับอุตสาหกรรมที่ต้องการความแม่นยำสูงและรูปทรงซับซ้อน เทคโนโลยีนี้ได้กลายเป็นมาตรฐานทองคำ มันเร็วกว่าวิธีการเชิงกล ให้ขอบที่สะอาดกว่าการตัดด้วยพลาสมา และสามารถจัดการกับการออกแบบที่ซับซ้อนซึ่งจะเป็นความท้าทายสำหรับวิธีการอื่นๆ พร้อมที่จะเข้าใจว่าเลเซอร์แต่ละประเภทต่างกันอย่างไรหรือไม่? ต่อไปนี้เราจะมาสำรวจกัน

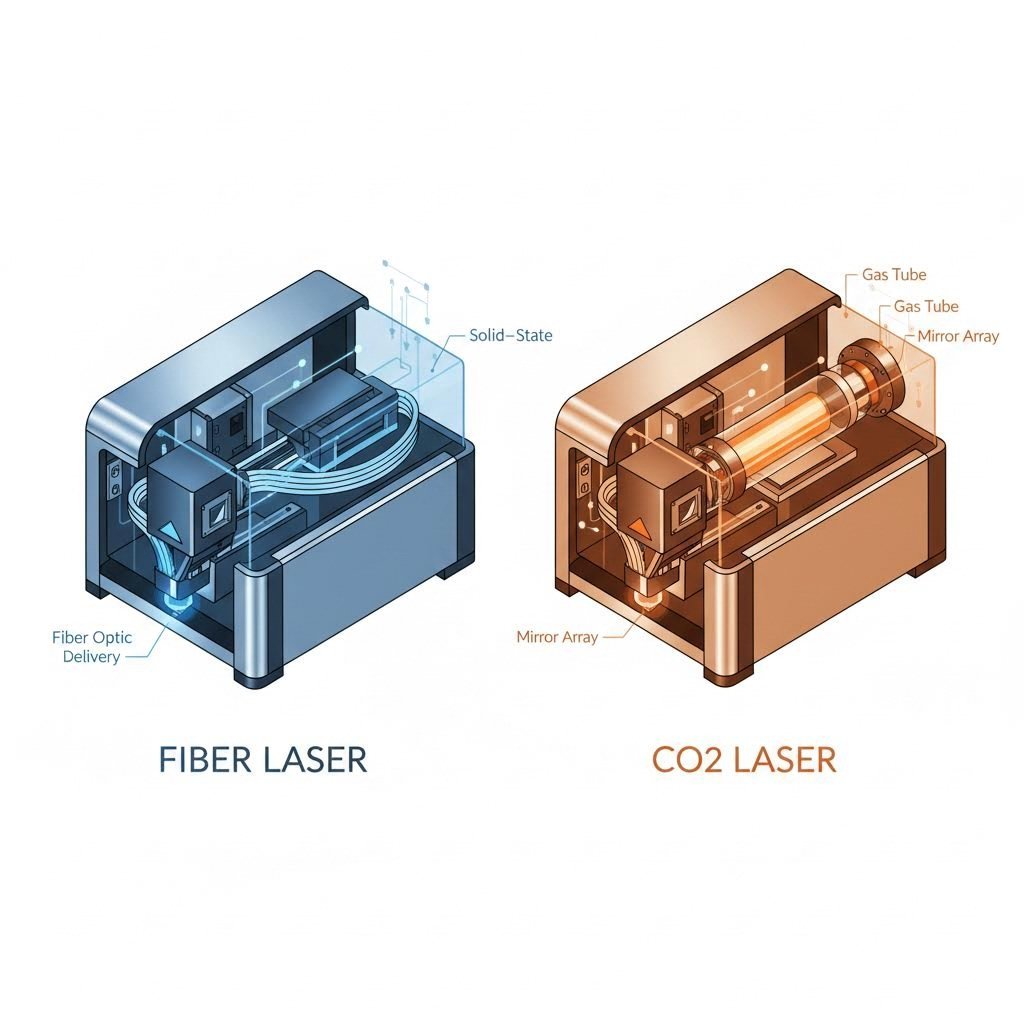

เปรียบเทียบเทคโนโลยีเลเซอร์ไฟเบอร์ กับ เลเซอร์ CO2

การเลือกระหว่างเทคโนโลยีเลเซอร์ไฟเบอร์และเลเซอร์ CO2 อาจดูน่าสับสน—โดยเฉพาะเมื่อทั้งสองฝ่ายต่างมีผู้สนับสนุนที่แข็งขัน ความจริงก็คือ: ไม่มีตัวใดตัวหนึ่งที่ "ดีกว่า" โดยทั่วไป ทางเลือกที่เหมาะสมที่สุดของคุณขึ้นอยู่กับสิ่งที่คุณกำลังตัด ความหนาของวัสดุ และความต้องการในการผลิตของคุณ

เรามาดูความแตกต่างพื้นฐานกัน เครื่องตัดไฟเบอร์เลเซอร์ ใช้เทคโนโลยีแบบสเตตัสแข็ง โดยสร้างแสงผ่านไดโอดเลเซอร์ที่ส่งผ่านสายไฟเบอร์ออปติกซึ่งเติมด้วยธาตุหายาก ซึ่งจะผลิตความยาวคลื่นประมาณ 1.064 ไมโครเมตร — สั้นพอที่จะถูกดูดซับได้อย่างมีประสิทธิภาพโดยโลหะส่วนใหญ่ เลเซอร์ CO2 ในทางกลับกัน ใช้หลอดบรรจุก๊าซคาร์บอนไดออกไซด์เพื่อสร้างลำแสงที่ความยาวคลื่น 10.6 ไมโครเมตร ความยาวคลื่นที่ยาวกว่านี้มีปฏิสัมพันธ์กับวัสดุแตกต่างออกไป ทำให้ระบบ CO2 เหมาะสมกว่าสำหรับวัสดุที่ไม่ใช่โลหะ

ช่องว่างด้านประสิทธิภาพระหว่างเทคโนโลยีเหล่านี้มีขนาดค่อนข้างมาก เลเซอร์ไฟเบอร์แปลงพลังงานไฟฟ้าเป็นแสงเลเซอร์ได้ที่ประสิทธิภาพประมาณ 35% ในขณะที่ระบบ CO2 ทำได้เพียง 10-20% สิ่งนี้หมายความอย่างไรในทางปฏิบัติ? เลเซอร์ไฟเบอร์ใช้พลังงานประมาณหนึ่งในสามของระบบ CO2 สำหรับงานตัดที่เทียบเท่ากัน — ซึ่งแปลตรงไปยังต้นทุนการดำเนินงานที่ต่ำกว่าและผลกระทบต่อสิ่งแวดล้อมที่ลดลง

| ข้อมูลจำเพาะ | ไลเซอร์ไฟเบอร์ | เลเซอร์ co2 |

|---|---|---|

| ความยาวคลื่น | 1.064 ไมโครเมตร | 10.6 ไมโครเมตร |

| ประสิทธิภาพในการใช้พลังงาน | ~35% | 10-20% |

| การใช้พลังงาน | ต่ำกว่า (ประมาณ 1/3 ของ CO2) | สูงกว่า |

| ความต้องการในการบํารุงรักษา | ขั้นต่ำ—ไม่มีกระจกหรือหลอดก๊าซ | ปกติ — การจัดแนวกระจก, การเปลี่ยนก๊าซ |

| ความเข้ากันได้กับโลหะสะท้อนแสง | ยอดเยี่ยม (อลูมิเนียม ทองแดง ทองเหลือง) | แย่ — เสี่ยงต่อความเสียหายจากแสงสะท้อนกลับ |

| ความเร็วสำหรับวัสดุบาง (<6 มม.) | เร็วขึ้นได้ถึง 3 เท่า | ช้ากว่า |

| ประสิทธิภาพสำหรับวัสดุหนา (>20 มม.) | ประสิทธิภาพลดลง | คุณภาพขอบดีกว่า |

| อายุการใช้งาน | สูงสุดถึง 100,000 ชั่วโมง | 20,000-30,000 ชั่วโมง |

| การลงทุนเบื้องต้น | ต้นทุนเริ่มต้นสูงกว่า | ต้นทุนเริ่มต้นต่ำกว่า |

ข้อได้เปรียบของเลเซอร์ไฟเบอร์สำหรับโลหะสะท้อนแสง

คุณเคยลองตัดอลูมิเนียมหรือทองแดงด้วยเลเซอร์ CO2 ไหม? มันอันตรายมาก โลหะที่มีการสะท้อนสูงเหล่านี้สามารถสะท้อนลำแสงเลเซอร์กลับเข้าสู่ระบบออปติก ซึ่งอาจทำลายเลนส์และกระจกที่มีราคาแพงได้ ตามรายงานของ งานวิจัยของ Laser-ing การตัดวัสดุด้วยเลเซอร์ CO2 ที่มีคุณสมบัติสะท้อนแสงจำเป็นต้องมีการเตรียมพิเศษ—มักจะต้องเคลือบผิวด้วยวัสดุดูดซับแสงเพื่อป้องกันการสะท้อนย้อนกลับที่อาจเป็นอันตราย

เครื่องตัดด้วยไฟเบอร์เลเซอร์แก้ปัญหานี้ได้อย่างชาญฉลาด การออกแบบแบบโซลิดสเตตและระบบส่งผ่านด้วยไฟเบอร์ออปติกสามารถจัดการกับวัสดุสะท้อนแสงได้โดยไม่มีความเสี่ยงจากการสะท้อนย้อนกลับที่พบในระบบ CO2 เลเซอร์ไฟเบอร์ถูกดูดซึมได้ง่ายบนพื้นผิวอลูมิเนียม ทองแดง และทองเหลือง ทำให้เป็นทางเลือกที่ดีที่สุดสำหรับโรงงานที่ต้องทำงานกับวัสดุเหล่านี้ ระบบ CNC เลเซอร์ไฟเบอร์รุ่นใหม่สามารถประมวลผลสแตนเลสสตีลได้อย่างมีประสิทธิภาพด้วยความเร็วสูงสุดถึง 20 เมตรต่อนาทีในแผ่นบาง—ซึ่งเป็นข้อได้เปรียบที่สำคัญต่อผลผลิต

สำหรับโลหะที่มีความหนาน้อยกว่า 6 มม. ช่องว่างด้านประสิทธิภาพจะยิ่งชัดเจนมากขึ้น ลำแสงที่ถูกโฟกัสของเครื่องตัดเลเซอร์ไฟเบอร์แบบ CNC จะสร้างจุดที่เล็กลง ทำให้สามารถตัดได้อย่างแม่นยำสูงขึ้นและเร็วกว่า ซึ่งทำให้เทคโนโลยีไฟเบอร์กลายเป็นทางเลือกหลักในอุตสาหกรรมต่างๆ เช่น อุตสาหกรรมยานยนต์ การบินและอวกาศ และการผลิตอิเล็กทรอนิกส์ ที่ต้องการความแม่นยำสูงในการตัดแผ่นโลหะบาง

เมื่อใดที่เลเซอร์ CO2 ยังคงเหมาะสม

แม้เทคโนโลยีไฟเบอร์จะมีข้อได้เปรียบ แต่เลเซอร์ CO2 ยังไม่หายไปจากตลาด—and for good reason เมื่อคุณต้องตัดวัสดุที่มีความหนาเกิน 20 มม. ระบบ CO2 มักให้คุณภาพผิวขอบที่เรียบเนียนกว่า ความยาวคลื่นที่ยาวกว่าช่วยกระจายความร้อนได้อย่างสม่ำเสมอมากขึ้น จึงลดพื้นผิวขรุขระจากการตัดแผ่นหนา

เลเซอร์ CO2 ยังทำงานได้ดีในสภาวะที่ใช้วัสดุผสมกัน หากร้านของคุณต้องแปรรูปไม้ อคริลิก เส้นใยผ้า และพลาสติก ควบคู่ไปกับโลหะ การใช้ระบบ CO2 จะให้ความหลากหลายที่เลเซอร์ไฟเบอร์ไม่สามารถเทียบได้ เครื่องเดียวกันที่ใช้ตัดสแตนเลส ก็สามารถแกะสลักหนัง หรือตัดไม้อัดได้ — ความยืดหยุ่นที่มีค่ามากสำหรับร้านผลิตชิ้นงานตามสั่ง

พิจารณาปัจจัยเหล่านี้เมื่อตัดสินใจ:

- ประเภทวัสดุ: งานโลหะล้วนเหมาะกับไฟเบอร์; งานวัสดุหลากหลายอาจควรใช้ CO2

- ช่วงความหนา: วัสดุบาง (ต่ำกว่า 6 มม.) เหมาะกับไฟเบอร์; งานแผ่นหนาอาจได้ประโยชน์จาก CO2

- กรอบเวลาด้านงบประมาณ: ไฟเบอร์มีต้นทุนเริ่มต้นสูงกว่า แต่ให้ค่าใช้จ่ายในการดำเนินงานที่ต่ำกว่าในระยะยาว

- ปริมาณการผลิต: การตัดโลหะปริมาณมากจะได้เปรียบเรื่องความเร็วและประสิทธิภาพของไฟเบอร์อย่างเต็มที่

สรุปคือ เลเซอร์ไฟเบอร์ได้กลายเป็นตัวเลือกหลักสำหรับการผลิตชิ้นส่วนโลหะโดยเฉพาะอย่างยิ่งในงานที่ตัดวัสดุความหนาบางถึงปานกลาง โดยจุดเด่นของเลเซอร์ไฟเบอร์ที่มีทั้งความเร็ว ประสิทธิภาพ และความสามารถในการตัดโลหะสะท้อนแสงได้ดี ทำให้ยากที่จะมีเทคโนโลยีอื่นมาเทียบชั้น อย่างไรก็ตาม เลเซอร์ CO2 ยังคงมีบทบาทสำคัญในงานที่ต้องการความหลากหลายของวัสดุ หรืองานที่เชี่ยวชาญในการตัดแผ่นโลหะหนา การเข้าใจข้อกำหนดเฉพาะของงานที่ใช้งานจริงคือกุญแจสำคัญในการตัดสินใจลงทุนอย่างถูกต้อง

คู่มือการเลือกวัสดุสำหรับทุกประเภทของโลหะ

ไม่ใช่ทุกโลหะที่ตอบสนองต่อลำแสงเลเซอร์เหมือนกัน การเข้าใจพฤติกรรมของแต่ละวัสดุเมื่อเผชิญกับพลังงานความร้อนที่มีความเข้มข้นสูง คือสิ่งที่ทำให้เกิดความแตกต่างระหว่างการตัดที่สมบูรณ์แบบ กับการเกิดข้อบกพร่องที่น่าหงุดหงิด ไม่ว่าคุณจะกำลังทำงานกับเหล็กกล้าคาร์บอนทั่วไป หรือโลหะผสมที่มีคุณสมบัติสะท้อนแสงซึ่งตัดยาก คู่มือนี้จะให้ข้อมูลเชิงลึกในแต่ละประเภทของโลหะเพื่อให้คุณ เพิ่มประสิทธิภาพการตัดเหล็กด้วยเครื่องเลเซอร์ และสามารถจัดการกับวัสดุใด ๆ ได้อย่างมั่นใจ

ก่อนที่จะลงลึกในรายละเอียด นี่คือการเปรียบเทียบที่ครอบคลุม เพื่อช่วยให้คุณระบุแนวทางที่เหมาะสมสำหรับการตัดแผ่นโลหะด้วยเลเซอร์ในวัสดุประเภทต่างๆ ได้อย่างรวดเร็ว

| ประเภทโลหะ | เลเซอร์ที่แนะนำ | ช่วงความหนาทั่วไป | ความเร็วในการตัด | คุณภาพของรอยตัด | ปัญหา ที่ มี อยู่ บ่อย |

|---|---|---|---|---|---|

| เหล็กกล้าคาร์บอน | ไฟเบอร์หรือ CO2 | 0.5 มม. - 25 มม. | เร็วด้วยแก๊สออกซิเจนช่วยเสริม | ยอดเยี่ยม | เกิดออกซิเดชันที่ขอบ และการเกิดคราบผิว |

| เหล็กกล้าไร้สนิม | ไฟเบอร์ (แนะนำ) | 0.5 มม. - 20 มม. | ปานกลาง | ดีมากด้วยไนโตรเจน | เกิดสีเปลี่ยนจากโซนที่ได้รับความร้อน |

| อลูมิเนียม | เฉพาะไฟเบอร์ | 0.5 มม. - 15 มม. | เร็วบนวัสดุบาง | ดีถึงดีเยี่ยม | การสะท้อนแสงสูง การเกิดแตกร้าว |

| ทองเหลือง | เฉพาะไฟเบอร์ | 0.5mm - 8mm | ปานกลาง | ดี | การสะท้อนแสง ไอระเหยของสังกะสี |

| ทองแดง | เส้นใยเท่านั้น (กำลังสูง) | 0.5 มม. - 6 มม. | ช้ากว่า | ปานกลางถึงดี | การสะท้อนแสงและการนำความร้อนได้ดีมาก |

| ไทเทเนียม | ไฟเบอร์ (แนะนำ) | 0.5 มม. - 12 มม. | ปานกลาง | ใช้งานได้ดีเยี่ยมกับแก๊สเฉื่อย | เกิดการออกซิเดชัน ต้องใช้แก๊สอาร์กอนป้องกัน |

พารามิเตอร์การตัดเหล็กกล้าและคุณภาพที่คาดหวัง

เหล็กกล้ายังคงเป็นวัสดุหลักในการผลิตอุตสาหกรรม—and ด้วยเหตุผลที่ดี ทั้งเหล็กคาร์บอนและเหล็กสเตนเลสสามารถตัดได้อย่างสวยงามด้วยพารามิเตอร์ที่เหมาะสม ทำให้เหมาะสำหรับโรงงานที่เพิ่งเริ่มใช้เทคโนโลยีเลเซอร์

เหล็กคาร์บอน: วัสดุชนิดนี้อาจเป็นโลหะที่ตัดด้วยเลเซอร์ได้ง่ายที่สุด เมื่อใช้ออกซิเจนเป็นแก๊สช่วยตัด จะเกิดปฏิกิริยาเอกโซเทอร์มิกที่เพิ่มพลังงานในการตัดขึ้นตามจริง ตามคู่มือเทคนิคของ ADHMT การตัดที่ได้รับการช่วยจากออกซิเดชันนี้ทำให้สามารถประมวลผลเหล็กกล้าคาร์บอนได้ที่ความเร็วสูงขึ้นและตัดแผ่นที่หนาขึ้นกว่าโลหะส่วนใหญ่ ข้อเสียคือ? จะมีชั้นออกไซด์บางๆ เกิดขึ้นที่ขอบที่ตัด ซึ่งยอมรับได้ในงานโครงสร้างส่วนใหญ่ แต่จำเป็นต้องทำความสะอาดหากนำไปใช้ในชิ้นส่วนที่ต้องการความแม่นยำ

เหล็กไม่ржаมี การใช้เครื่องตัดด้วยเลเซอร์กับเหล็กสเตนเลสจำเป็นต้องมีความแม่นยำมากกว่าเดิม เนื่องจากปริมาณโครเมียมที่ทำให้เหล็กสเตนเลสมีความต้านทานการกัดกร่อน ก็ยังก่อให้เกิดปัญหาโซนที่ได้รับผลกระทบจากความร้อน (HAZ) ด้วย เมื่ออุณหภูมิสูงเกินไปบริเวณรอบรอยตัด จะสังเกตเห็นการเปลี่ยนสี เช่น สีน้ำเงินหรือสีทอง ซึ่งบ่งชี้ว่าความสามารถในการต้านทานการกัดกร่อนลดลง

ทางแก้คืออะไร? ใช้ก๊าซไนโตรเจนช่วย เนื่องจากต่างจากออกซิเจน ไนโตรเจนจะสร้างบรรยากาศเฉื่อยที่ป้องกันการเกิดออกซิเดชัน และทำให้ขอบตัดสะอาดและสว่างสดใส สำหรับการตัดเหล็กสเตนเลสด้วยเลเซอร์ ควรพิจารณาปรับพารามิเตอร์ดังนี้:

- แผ่นบาง (ต่ำกว่า 3 มม.): ความเร็วสูง พลังงานปานกลาง ก๊าซไนโตรเจนที่ความดัน 10-15 บาร์

- แผ่นกลาง (3-10 มม.): ความเร็วลดลง พลังงานเพิ่มขึ้น ก๊าซไนโตรเจนที่ความดัน 15-20 บาร์

- แผ่นหนา (10 มม. ขึ้นไป): ความเร็วต่ำ พลังงานสูงสุด ก๊าซไนโตรเจนบริสุทธิ์ที่ความดัน 20 บาร์ขึ้นไป

การตัดโลหะสะท้อนแสงโดยไม่ทำลายอุปกรณ์ของคุณ

คุณสามารถตัดอลูมิเนียมด้วยเลเซอร์ได้หรือไม่? ได้อย่างแน่นอน—แต่ต้องใช้อุปกรณ์ที่เหมาะสมเท่านั้น อลูมิเนียม เหล็กกล้า และทองแดง มีความท้าทายเฉพาะตัว เนื่องจากพื้นผิวที่สะท้อนแสงได้สูงสามารถสะท้อนพลังงานเลเซอร์กลับเข้าสู่ระบบออปติกได้ สำหรับเลเซอร์ CO2 การสะท้อนย้อนกลับนี้อาจทำให้เกิดความเสียหายอย่างรุนแรงต่อเลนส์และกระจก นั่นจึงเป็นเหตุผลที่ทำให้เลเซอร์ไฟเบอร์กลายเป็นสิ่งจำเป็นสำหรับวัสดุเหล่านี้

การตัดด้วยเลเซอร์สำหรับอลูมิเนียม: หรือ การวิจัยของ Accumet ยืนยันว่า เลเซอร์ไฟเบอร์ที่ทำงานที่ความยาวคลื่นสั้นกว่า เหมาะสมกว่ามากสำหรับการแปรรูปโลหะที่สะท้อนแสงได้ดี เมื่อคุณตัดอลูมิเนียมด้วยเลเซอร์ ความสามารถในการนำความร้อนสูงของวัสดุจะทำให้ความร้อนกระจายตัวออกจากบริเวณที่ตัดอย่างรวดเร็ว ซึ่งหมายความว่า คุณจะต้องใช้กำลังไฟที่สูงกว่าเมื่อเปรียบเทียบกับเหล็กที่มีความหนาเท่ากัน

เพื่อความสำเร็จในการตัดอลูมิเนียมด้วยเลเซอร์ โปรดคำนึงถึงประเด็นต่อไปนี้:

- ใช้ก๊าซช่วยเหลือชนิดไนโตรเจนเพื่อให้ได้ขอบที่สะอาด ปราศจากออกไซด์

- เพิ่มความเร็วในการตัดแผ่นบาง เพื่อลดการสะสมความร้อน

- คาดว่าจะมีการเกิดเครื่องหมายริ้วรอยที่ขอบด้านล่าง ซึ่งเป็นผลตามธรรมชาติจากคุณสมบัติความร้อนของอลูมิเนียม

- พิจารณาการทำเตรียมผิวก่อนสำหรับวัสดุที่ถูกออกซิไดซ์อย่างหนัก

สายสลัดและทองแดง: วัสดุเหล่านี้ทำให้เทคโนโลยีเลเซอร์ไฟเบอร์ต้องทำงานใกล้ขีดจำกัด โดยทองแดงมีคุณสมบัติสะท้อนแสงสูงมาก (มากกว่า 95% สำหรับบางช่วงคลื่น) และนำความร้อนได้ดีเยี่ยม ทำให้เป็นโลหะทั่วไปที่ตัดได้ยากที่สุด คู่มือของ Longxin Laser ระบุว่าจำเป็นต้องใช้เลเซอร์ไฟเบอร์กำลังสูง—โดยทั่วไป 6 กิโลวัตต์ขึ้นไป—เพื่อการประมวลผลทองแดงอย่างมีประสิทธิภาพ

ทองเหลืองมีปัญหาเพิ่มเติมคือ เนื้อสังกะสี เมื่อเลเซอร์ทำให้ทองเหลืองกลายเป็นไอ จะปล่อยไอสังกะสีที่ต้องมีการดูดระบายออกอย่างเหมาะสม ห้ามตัดทองเหลืองโดยไม่มีการระบายอากาศที่เพียงพอ เพราะไอที่เกิดขึ้นมีอันตรายต่อสุขภาพอย่างแท้จริง

ไทเทเนียม: วัสดุเกรดการบินและอวกาศนี้ต้องได้รับความเคารพอย่างยิ่ง ไทเทเนียมเกิดการออกซิไดซ์ได้ง่ายที่อุณหภูมิสูง และการปนเปื้อนจากออกซิเจนหรือไนโตรเจนสามารถทำให้คุณสมบัติทางกลเสื่อมลงได้ ทางแก้ไขคือการใช้แก๊สอาร์กอนป้องกัน ซึ่งเป็นแก๊สเฉื่อยที่ช่วยปกป้องบริเวณตัดจากการปนเปื้อนของบรรยากาศ

สำหรับการตัดไทเทเนียม ต้องแน่ใจว่า:

- ใช้แก๊สช่วยเหลืออาร์กอนคุณภาพสูง (99.99% หรือดีกว่า)

- ใช้แผ่นป้องกันแก๊สด้านหลังสำหรับชิ้นงานที่หนา

- ควบคุมความเร็วในระดับปานกลางเพื่อรักษากล coverage ของแก๊สป้องกัน

- พื้นผิววัสดุสะอาด ปราศจากน้ำมันหรือสิ่งปนเปื้อน

การเข้าใจลักษณะเฉพาะของวัสดุแต่ละชนิดจะเปลี่ยนแนวทางการทำงานของคุณจากแบบลองผิดลองถูกไปสู่ความแม่นยำอย่างเป็นระบบ โลหะแต่ละชนิดมีลักษณะเฉพาะของตนเอง แต่ด้วยพารามิเตอร์และการเลือกอุปกรณ์ที่เหมาะสม คุณสามารถบรรลุผลลัพธ์คุณภาพระดับมืออาชีพได้กับโลหะผสมอุตสาหกรรมทุกประเภท ต่อไปนี้ เราจะพาเดินผ่านกระบวนการตัดอย่างครบถ้วน—ตั้งแต่การออกแบบดิจิทัลจนถึงชิ้นส่วนสำเร็จรูป

การแยกย่อยกระบวนการตัดด้วยเลเซอร์อย่างสมบูรณ์

คุณได้เลือกวัสดุและเทคโนโลยีเลเซอร์ที่เหมาะสมแล้ว—ต่อไปควรทำอย่างไร? การเข้าใจขั้นตอนทั้งหมดตั้งแต่ไฟล์ดิจิทัลไปจนถึงชิ้นงานสำเร็จรูปจะช่วยลดความไม่แน่นอน และรับประกันผลลัพธ์ที่มีคุณภาพสูงและสม่ำเสมอทุกครั้ง มาติดตามแต่ละขั้นตอนของเครื่องตัดด้วยเลเซอร์สำหรับโลหะ ตั้งแต่เปิดโปรแกรมออกแบบ ไปจนถึงขณะที่ชิ้นส่วนหลุดออกจากแผ่นโลหะ

จากแบบดิจิทัล สู่ชิ้นงานจริงในไม่กี่นาที

การตัดที่แม่นยำทุกครั้งเริ่มต้นจากไฟล์ CAD ที่เตรียมอย่างดี ให้ถือว่าเป็นแบบแปลนที่บอกเครื่องตัดด้วยเลเซอร์สำหรับโลหะของคุณอย่างชัดเจนว่าควรเคลื่อนที่ไปที่ใด และต้องทำอะไร ตามเอกสารทางเทคนิคของ Komacut ไฟล์ CAD จะต้องประกอบด้วยเส้นวงปิด เสถียรภาพของขนาดที่เหมาะสม และลบเลเยอร์ที่ไม่จำเป็นออก เพื่อให้มั่นใจในความแม่นยำและการทำงานของเครื่องอย่างราบรื่น

ไฟล์ CAD แบบใดถือว่าพร้อมใช้งานกับเครื่องตัดด้วยเลเซอร์? ตรวจสอบสิ่งต่อไปนี้ก่อนส่งแบบของคุณไปยังเครื่องตัดด้วยเลเซอร์สำหรับแผ่นโลหะ:

- เวกเตอร์ปิด: เส้นตัดทั้งหมดต้องสร้างเป็นลูปที่สมบูรณ์และต่อเนื่องกัน—เส้นที่เปิดอยู่จะทำให้เครื่องสับสน

- มาตราส่วนที่ถูกต้อง: ตรวจสอบว่าหน่วยของแบบร่างตรงกับมิติในโลกจริง (แหล่งที่มาของข้อผิดพลาดที่พบบ่อยและมีค่าใช้จ่ายสูง)

- เรขาคณิตที่สะอาด: ลบเส้นซ้ำ เส้นจุดลอย และเส้นทางที่ทับซ้อนกัน

- การจัดระเบียบเลเยอร์: แยกเส้นตัดออกจากเส้นแกะสลักและเรขาคณิตอ้างอิง

- การชดเชยความกว้างตัด (Kerf compensation): คำนึงถึงความกว้างการตัดของเลเซอร์ (โดยทั่วไป 0.1-0.3 มม.) ในการกำหนดมิติของคุณ

เมื่อไฟล์ของคุณเรียบร้อยแล้ว กระบวนการตัดด้วยเครื่องเลเซอร์สำหรับแผ่นโลหะจะดำเนินตามลำดับที่คาดเดาได้:

- ขั้นตอนที่ 1 - การนำเข้าไฟล์: ซอฟต์แวร์ CAM อ่านแบบของคุณและสร้างเส้นทางการเดินเครื่อง

- ขั้นตอนที่ 2 - การกำหนดพารามิเตอร์: การตั้งค่ากำลัง ความเร็ว และก๊าซจะสอดคล้องกับประเภทและความหนาของวัสดุของคุณ

- ขั้นตอนที่ 3 - การโหลดแผ่นวัสดุ: วัสดุถูกจัดตำแหน่งบนเตียงตัดและปรับให้ตรงกับจุดอ้างอิง

- ขั้นตอนที่ 4 - การเจาะทะลุ: เลเซอร์รวมพลังงานเพื่อเจาะผ่านพื้นผิววัสดุ สร้างจุดเริ่มต้นในการตัด

- ขั้นตอนที่ 5 - การดำเนินการตามเส้นทาง: หัวตัดเคลื่อนที่ตามเส้นทางที่โปรแกรมไว้ โดยหลอมละลายและเป่าวัสดุออกไป

- ขั้นตอนที่ 6 - การแยกชิ้นส่วน: ชิ้นส่วนที่เสร็จสมบูรณ์จะหลุดออกมาเอง หรือยังคงติดอยู่กับแท็บเพื่อให้ถอดออกได้ง่าย

ขั้นตอนการเจาะควรได้รับความสนใจเป็นพิเศษ ต่างจากการตัดแบบต่อเนื่อง ขั้นตอนการเจาะต้องใช้พลังงานเลเซอร์ที่เข้มข้นเพื่อทะลุผ่านพื้นผิวเริ่มต้นของวัสดุ การศึกษาแสดงให้เห็นว่าก๊าซช่วยเหลือมีบทบาทสำคัญในการขจัดวัสดุที่หลอมละลายออกไปในช่วงนี้—การไหลของก๊าซที่เหมาะสมจะป้องกันไม่ให้รูเจาะอุดตันด้วยเศษวัสดุ

ระบบตัดด้วยเครื่องเลเซอร์รุ่นใหม่มาพร้อมเทคโนโลยีโฟกัสอัตโนมัติและติดตามความสูง โดยระบบเหล่านี้จะปรับระยะโฟกัสอย่างต่อเนื่องขณะหัวตัดเคลื่อนที่ไปบนแผ่นวัสดุ เพื่อชดเชยความไม่สม่ำเสมอและแรงบิดเบี้ยวของพื้นผิวเล็กน้อย หากไม่มีตัวติดตามความสูง แผ่นวัสดุที่ไม่เรียบอาจทำให้จุดโฟกัสคลาดเคลื่อนไปหลายมิลลิเมตร—ซึ่งเพียงพอที่จะทำให้คุณภาพขอบเสียหาย หรือทำให้การตัดล้มเหลวโดยสิ้นเชิง

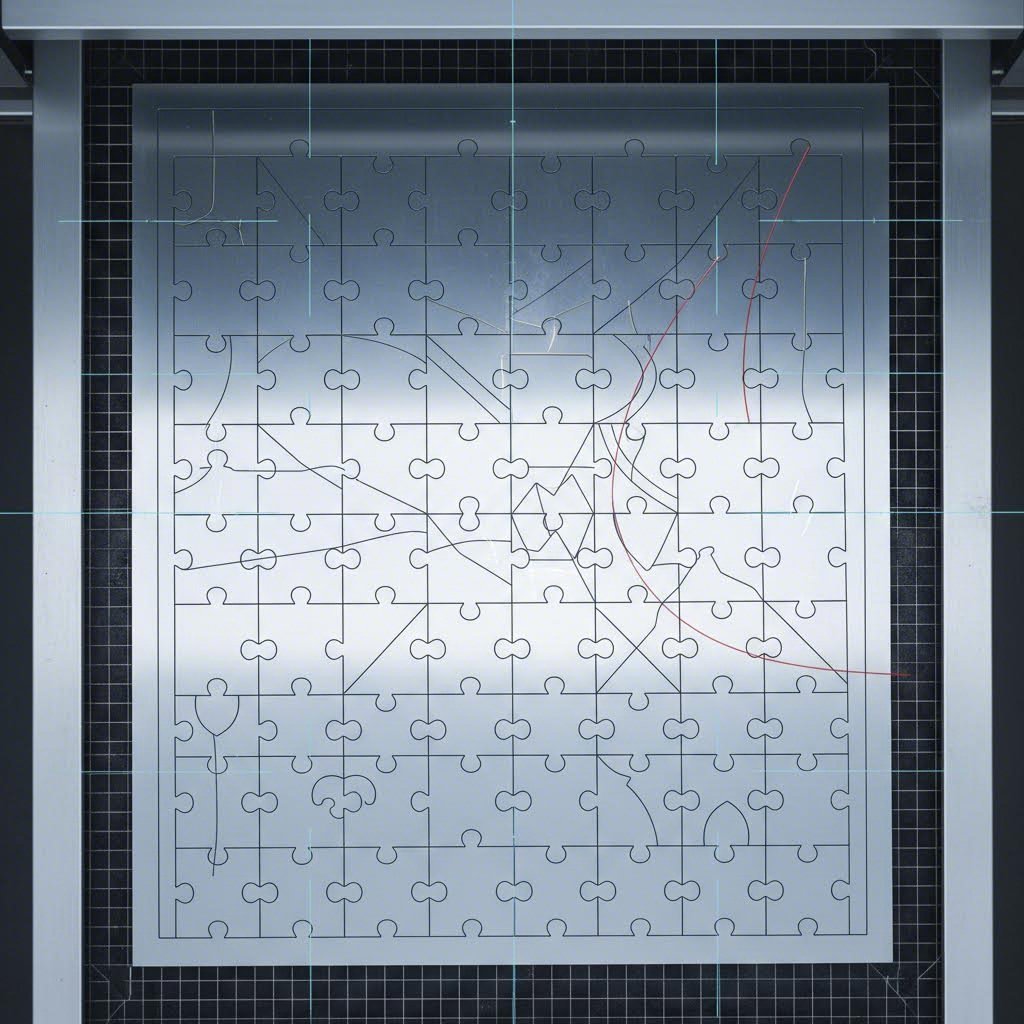

กลยุทธ์การวางรูปแบบที่ลดของเสียจากวัสดุให้น้อยที่สุด

นี่คือสิ่งที่ผู้ประกอบการอัจฉริยะแยกตัวเองออกจากกลุ่มอื่น: การเพิ่มประสิทธิภาพการเรียงชิ้นงาน (nesting optimization) ลองนึกภาพว่าคุณกำลังแก้ปริศนา โดยแต่ละช่องว่างระหว่างชิ้นงานนั้นหมายถึงเงินที่สูญเปล่า ซอฟต์แวร์การเรียงชิ้นงานขั้นสูงจะวิเคราะห์รูปทรงเรขาคณิตของชิ้นงานคุณ และจัดเรียงลงบนแผ่นวัสดุเพื่อลดเศษวัสดุให้น้อยที่สุด

เครื่องมือการเรียงชิ้นงานระดับมืออาชีพพิจารณาปัจจัยต่าง ๆ ที่มากกว่าการวางตำแหน่งชิ้นงานเพียงอย่างเดียว พวกมันคำนึงถึงทิศทางของเสี้ยมในวัสดุที่สำคัญ พิจารณาเส้นทางการตัดเพื่อลดเวลาเคลื่อนที่ และหมุนชิ้นงานเพื่อให้จัดเรียงได้มีประสิทธิภาพมากขึ้น การจัดเรียงชิ้นงานอย่างเหมาะสมอาจใช้วัสดุได้ถึง 85-90% เมื่อเทียบกับการจัดเรียงด้วยมือซึ่งใช้เพียง 60-70%

เมื่อออกแบบชิ้นส่วนสำหรับเครื่องตัดโลหะด้วยเลเซอร์ของคุณ โปรดคำนึงถึงข้อจำกัดเหล่านี้

- ขนาดชิ้นส่วนต่ำสุด ช่องเว้าภายในควรมีขนาดอย่างน้อย 1.5 เท่าของความหนาของวัสดุ (แผ่นหนา 2 มม. ต้องมีรูขนาดต่ำสุด 3 มม.)

- รัศมีมุมโค้ง ไม่สามารถทำมุมฉากภายในที่แหลมคมได้ — ลำแสงเลเซอร์มีเส้นผ่านศูนย์กลาง จึงเกิดรัศมีตามธรรมชาติขนาด 0.1–0.3 มม.

- ระยะห่างระหว่างชิ้นส่วน เว้นความหนาของวัสดุอย่างน้อยหนึ่งชั้นระหว่างชิ้นงาน เพื่อรักษารูปทรงคงที่ของแผ่น

- การวางแท็บ: แท็บขนาดเล็กที่วางอย่างมีกลยุทธ์จะช่วยยึดชิ้นส่วนให้อยู่กับที่ขณะตัด ป้องกันไม่ให้ชิ้นงานยกตัวขึ้นซึ่งอาจทำให้หัวตัดเสียหาย

ความสัมพันธ์ระหว่างความเร็วและกำลังคือตัวแปรสำคัญสุดท้ายของคุณ ความเร็วในการตัดจะกำหนดระยะเวลาที่เลเซอร์ใช้กับแต่ละจุด—หากช้าเกินไปจะเกิดความร้อนสะสมมากเกินไป และอาจทำให้วัสดุบิดงอได้ แต่ถ้าเร็วเกินไปจะทำให้การตัดไม่สมบูรณ์ สำหรับการใช้งานเครื่องตัดด้วยเลเซอร์กับโลหะ ผู้ปฏิบัติงานจำเป็นต้องปรับสมดุลพารามิเตอร์เหล่านี้ตามความหนาของวัสดุ: แผ่นที่หนากว่าต้องใช้ความเร็วช้าลงและกำลังสูงขึ้น ในขณะที่วัสดุเบากว่าต้องใช้แนวทางตรงกันข้าม

การเลือกแก๊สช่วยเสริมมีความเกี่ยวข้องกันทั้งหมด Oxygen จะทำปฏิกิริยาเอกซ์โซเทอร์มิกกับเหล็กกล้าคาร์บอน สร้างพลังงานตัดเพิ่มเติมและทำให้สามารถตัดด้วยความเร็วที่สูงขึ้นได้ Nitrogen จะให้ขอบตัดที่สะอาดปราศจากออกไซด์ในเหล็กสเตนเลสและอลูมิเนียม ซึ่งเป็นสิ่งสำคัญเมื่อพิจารณาเรื่องความต้านทานการกัดกร่อนหรือความสามารถในการเชื่อม หากเลือกผิด อาจส่งผลให้คุณภาพขอบตัดต่ำ หรือเสียเวลาในการประมวลผลโดยเปล่าประโยชน์

เมื่อคุณตั้งค่าพารามิเตอร์กระบวนการเรียบร้อยแล้ว คุณก็พร้อมที่จะผลิตชิ้นส่วนที่มีคุณภาพสม่ำเสมอและสูง แต่จะเกิดอะไรขึ้นหากสิ่งต่าง ๆ เกิดปัญหา? ต่อไปนี้ เราจะมาดูกลยุทธ์การแก้ไขปัญหาที่จะช่วยให้การดำเนินงานของคุณทำงานได้อย่างราบรื่น

การแก้ไขปัญหาข้อบกพร่องในการตัดและการมีปัญหาด้านคุณภาพทั่วไป

แม้เครื่องตัดเลเซอร์ที่ดีที่สุดสำหรับโลหะก็อาจสร้างข้อบกพร่องที่น่าหงุดหงิดได้ หากพารามิเตอร์หลุดออกจากค่าที่กำหนด ความแตกต่างระหว่างผู้ผลิตมืออาชีพกับผู้ปฏิบัติงานที่ดิ้นรนอยู่คือ การรู้อย่างแน่ชัดว่าปัญหาแต่ละอย่างเกิดจากอะไร — และจะแก้ไขได้อย่างรวดเร็วอย่างไร ไม่ว่าคุณจะกำลังเผชิญกับคราบสะเก็ดเหล็ก (dross) ที่ดื้อดึง เศษคม (burr) มากเกินไป หรือการเปลี่ยนสีที่อธิบายไม่ได้ คู่มือการแก้ปัญหานี้จะให้กรอบการวินิจฉัยเพื่อระบุสาเหตุที่แท้จริงและดำเนินการแก้ไขได้อย่างมีประสิทธิภาพ

นี่คือความจริงที่คู่มืออุปกรณ์ส่วนใหญ่มักไม่บอกคุณ: ปัญหาด้านคุณภาพส่วนใหญ่สามารถตามรอยกลับไปยังตัวแปรเพียงไม่กี่อย่างเท่านั้น หากคุณเชี่ยวชาญในตัวแปรเหล่านี้ คุณจะใช้เวลาน้อยลงในการแก้ไขชิ้นส่วน และมีเวลามากขึ้นในการส่งมอบชิ้นส่วนที่สมบูรณ์แบบ

กำจัดคราบสะเก็ดเหล็กและเศษคมเพื่อให้ได้ขอบที่เรียบร้อย

คราบสะเก็ดเหล็ก (dross) หรือโลหะหลอมเหลวที่เกาะติดอยู่ที่ขอบด้านล่างของการตัดของคุณ เป็นปัญหาที่พบได้บ่อยที่สุดในหมู่ผู้ปฏิบัติงานเครื่องตัดเลเซอร์โลหะ ตามรายงานจาก คู่มือการแก้ปัญหาโดยละเอียดของ DXTech , การเกิดดรอสโดยทั่วไปบ่งชี้ถึงความไม่สมดุลระหว่างความเร็วในการตัด พลังงานเลเซอร์ และแรงดันก๊าซ

เมื่อเครื่องเลเซอร์ที่ใช้ตัดโลหะทิ้งคราบดรอสไว้ ให้ตรวจสอบสาเหตุและแนวทางแก้ไขทั่วไปดังต่อไปนี้:

- อัตราส่วนความเร็ว/พลังงานไม่ถูกต้อง: การตัดเร็วเกินไปจะทำให้วัสดุไม่สามารถหลุดออกไปได้อย่างสมบูรณ์ ส่วนการตัดช้าเกินไปจะทำให้โลหะหลอมเหลวรีบแข็งตัวใหม่ที่ขอบด้านล่าง วิธีแก้ไข: ลดความเร็วสำหรับการตัดที่ไม่สมบูรณ์ เพิ่มความเร็วในกรณีที่เกิดความร้อนสะสมมากเกินไป

- หัวพ่นเสียหายหรือสึกหรอ: หัวพ่นที่สึกหรออย่างไม่สม่ำเสมอจะทำให้การไหลของก๊าซผิดปกติ จนไม่สามารถขจัดสลาแกรมออกได้อย่างเหมาะสม วิธีแก้ไข: ตรวจสอบความตรงศูนย์กลางของหัวพ่น และเปลี่ยนหากช่องเปิดแสดงอาการเสียหายหรือปนเปื้อนที่มองเห็นได้

- แรงดันก๊าซไม่เหมาะสม: แรงดันต่ำเกินไปจะไม่สามารถพัดวัสดุที่หลอมเหลวออกไปได้ ขณะที่แรงดันสูงเกินไปอาจดันสลาแกรมกลับมาติดที่ขอบรอยตัด วิธีแก้ไข: ปรับแรงดันทีละน้อย เริ่มจากคำแนะนำของผู้ผลิต จากนั้นปรับแต่งเพิ่มเติมตามผลลัพธ์ที่ได้

- ตำแหน่งโฟกัสเลเซอร์สูงเกินไป: เมื่อจุดโฟกัสอยู่สูงกว่าตำแหน่งที่เหมาะสม ลำแสงจะกระจายตัวมากเกินไปในเขตตัด วิธีแก้ไข: ปรับลดตำแหน่งโฟกัสตามข้อกำหนดความหนาของวัสดุของคุณ

การเกิดบัร์เป็นปัญหาที่เกี่ยวข้องแต่แตกต่างออกไป ในขณะที่ดรอสมีองค์ประกอบเป็นโลหะหลอมเหลวที่แข็งตัวใหม่ บัร์คือส่วนยื่นแหลมที่เกิดขึ้นเมื่อวัสดุไม่ถูกตัดอย่างเรียบร้อย การศึกษาชี้ให้เห็นว่า ปัญหาบัร์มักเกิดจากปัญหาระบบออพติก มากกว่าการตั้งค่าพารามิเตอร์เพียงอย่างเดียว

สาเหตุทั่วไปของบัร์และวิธีแก้ไข ได้แก่:

- เลนส์ปนเปื้อนหรือเสียหาย: ออพติกสกปรกทำให้ลำแสงเลเซอร์กระเจิง ลดความแม่นยำในการตัด วิธีแก้ไข: ทำความสะอาดเลนส์เป็นประจำด้วยสารทำความสะอาดที่ได้รับอนุมัติและผ้าเช็ดไม่มีเสี้ยน; เปลี่ยนเลนส์ที่มีรอยบุ๋มหรือความเสียหายของเคลือบผิว

- ตำแหน่งโฟกัสไม่ถูกต้อง: แม้การลอยตัวของโฟกัสเพียงเล็กน้อยก็สามารถสร้างคุณภาพขอบที่ไม่สม่ำเสมอได้ วิธีแก้ไข: ตรวจสอบการปรับเทียบโฟกัสด้วยการตัดทดสอบบนวัสดุเศษก่อนเริ่มการผลิต

- หัวพ่นจัดตำแหน่งไม่ตรง: เมื่อหัวพ่นไม่อยู่ตรงกลางกับลำแสงเลเซอร์ การไหลของก๊าซจะไม่สมมาตร ส่งผลให้เกิดครีบหรือสะเก็ดโลหะ (burr) ขึ้นเฉพาะด้านใดด้านหนึ่งเท่านั้น วิธีแก้ไข: ตรวจสอบความร่วมศูนย์ (coaxiality check) และปรับตั้งศูนย์หัวพ่นใหม่

- ความบริสุทธิ์ของก๊าซช่วยเหลือไม่เพียงพอ: ก๊าซที่ปนเปื้อนจะนำออกซิเจนเข้ามาในแนวตัด ซึ่งควรจะต้องปราศจากออกไซด์ วิธีแก้ไข: ตรวจสอบให้มั่นใจว่าความบริสุทธิ์ของก๊าซเป็นไปตามข้อกำหนด (อย่างน้อย 99.5% สำหรับการตัดสแตนเลสโดยใช้ก๊าซไนโตรเจน)

สำหรับการทำงานของเครื่องตัดแผ่นโลหะด้วยเลเซอร์ ปัญหาคุณภาพขอบเช่นนี้ส่งผลกระทบโดยตรงต่อกระบวนการถัดไป ชิ้นงานที่มีครีบมากเกินไปจำเป็นต้องผ่านกระบวนการลบครีบเพิ่มเติม ทำให้เพิ่มต้นทุนแรงงานและยืดระยะเวลาการผลิต ชิ้นงานที่มีดรอส (dross) มากอาจทำให้เกิดปัญหาในการประกอบพอดีหรือการเชื่อม

การป้องกันการบิดงอจากความร้อนในแผ่นบาง

วัสดุที่มีความหนาน้อย (thin gauge) มีความท้าทายเฉพาะตัวสำหรับการใช้งานเครื่องตัดด้วยเลเซอร์ พลังงานความร้อนที่เข้มข้นซึ่งสามารถตัดแผ่นหนาได้อย่างสะอาด กลับอาจทำให้แผ่นบางเสียรูป หมอง หรือแม้แต่ไหม้ทะลุได้ การเข้าใจการจัดการความร้อนจึงเป็นสิ่งสำคัญต่อผลลัพธ์ที่สม่ำเสมอ

การเปลี่ยนสีบริเวณที่ได้รับความร้อน (HAZ) ปรากฏเป็นสีน้ำเงิน สีทอง หรือสีรุ้งตามขอบที่ตัด โดยมองเห็นได้ชัดเจนโดยเฉพาะบนเหล็กกล้าไร้สนิม ตามการวิเคราะห์ทางเทคนิคของ JLC CNC พื้นที่ใกล้เคียงกับรอยตัดดูดซับความร้อนมากพอจนเกิดการเปลี่ยนแปลงทางโลหะวิทยาโดยไม่ละลายจริง ทำให้เกิด HAZ การเปลี่ยนสีที่มองเห็นได้บ่งชี้ถึงการลดลงของความสามารถในการต้านทานการกัดกร่อนในโลหะผสมสเตนเลส

แก้ไขปัญหาการเปลี่ยนสีด้วยกลยุทธ์ต่อไปนี้:

- การป้อนความร้อนมากเกินไป: เลเซอร์ค้างไว้นานเกินไป ทำให้ความร้อนนำเข้าสู่วัสดุรอบข้าง วิธีแก้: เพิ่มความเร็วในการตัดพร้อมรักษากำลังไฟให้เพียงพอเพื่อให้ได้รอยตัดที่สะอาด

- การเลือกแก๊สช่วยผิด: การใช้ออกซิเจนแทนไนโตรเจนกับเหล็กกล้าไร้สนิมจะทำให้เกิดออกซิเดชันซึ่งแสดงออกมาเป็นการเปลี่ยนสี วิธีแก้: เปลี่ยนมาใช้ไนโตรเจนบริสุทธิ์สูงเพื่อให้ได้ขอบที่ปราศจากออกไซด์บนสเตนเลสและอลูมิเนียม

- แรงดันแก๊สไม่เพียงพอ: การไหลที่ไม่เพียงพอจะไม่สามารถระบายความร้อนในโซนตัดได้อย่างมีประสิทธิภาพ วิธีแก้: เพิ่มแรงดันไนโตรเจนเพื่อปรับปรุงการระบายความร้อนและการขจัดสลากพร้อมกัน

- การกระจายความร้อนไม่ดี: การซ้อนแผ่นหรือตัดโดยไม่มีการรองรับที่เพียงพอจะทำให้เกิดการสะสมความร้อน วิธีแก้ไข: ตัดแผ่นเดี่ยวโดยเว้นระยะห่างที่เหมาะสมระหว่างวัสดุกับเตียงตัด

แผ่นบิดงอ อาจเป็นข้อบกพร่องที่น่าหงุดหงิดที่สุดสำหรับผู้ปฏิบัติงานเครื่องเลเซอร์ตัดโลหะ แผ่นเรียบแบนถูกป้อนเข้าไป แต่กลับได้ชิ้นส่วนที่โค้งและบิดเบี้ยวออกมา เกิดอะไรขึ้น?

การบิดงอเกิดขึ้นเมื่อการขยายตัวและหดตัวจากความร้อนสร้างแรงดันภายในที่วัสดุไม่สามารถรองรับได้ในขณะที่ยังคงสภาพเรียบได้ สาเหตุทั่วไปและแนวทางแก้ไข ได้แก่:

- ยึดตรึงไม่เพียงพอ: วัสดุที่ไม่มีการยึดมั่นคงจะเคลื่อนตัวระหว่างการตัดเมื่อเกิดแรงดันจากความร้อน วิธีแก้ไข: ใช้อุปกรณ์ยึดแผ่น โต๊ะสุญญากาศ หรืออุปกรณ์แม่เหล็กเพื่อรักษาตำแหน่งของแผ่นในระหว่างกระบวนการตัดทั้งหมด

- ลำดับการตัดไม่เหมาะสม: การตัดชิ้นส่วนตามลำดับที่ผิดจะทำให้ความร้อนสะสมอยู่ในบางพื้นที่ วิธีแก้ไข: ตั้งโปรแกรมลำดับการตัดให้มีการกระจายความร้อนอย่างสม่ำเสมอทั่วแผ่น เช่น การสลับตัดระหว่างตำแหน่งที่อยู่ห่างกัน แทนที่จะตัดชิ้นส่วนที่อยู่ติดกันต่อเนื่องกัน

- ชิ้นส่วนซ้อนกันอยู่ใกล้เกินไป: ระยะห่างระหว่างชิ้นส่วนที่แคบเกินไปจะทำให้ความร้อนสะสมอยู่ในบริเวณสะพานตัดที่แคบ วิธีแก้ไข: เพิ่มระยะห่างระหว่างชิ้นส่วนให้มีขนาดอย่างน้อย 1.5 เท่าของความหนาของวัสดุ

- ไม่มีช่วงเวลาพักเพื่อระบายความร้อนระหว่างกระบวนการ: การเร่งผลิตโดยไม่หยุดพักระหว่างการตัดจะทำให้ความร้อนไม่สามารถระบายออกได้ วิธีแก้ไข: ควรเว้นช่วงหยุดสั้นๆ ระหว่างการทำงานที่มีการจัดเรียงชิ้นงานซับซ้อน โดยเฉพาะอย่างยิ่งเมื่อทำงานกับโลหะผสมที่ไวต่อความร้อน

ผู้ปฏิบัติงานมืออาชีพแนะนำให้ใช้โหมดเลเซอร์แบบพัลส์หากมีพร้อม โหมดพัลส์จะช่วยให้มีช่วงเวลาพักระบายความร้อนสั้นๆ ระหว่างช่วงการปล่อยพลังงาน ซึ่งช่วยลดการสะสมความร้อนโดยรวมในวัสดุบางได้อย่างมาก

การป้องกันปัญหาด้านคุณภาพที่ดีที่สุดคือ การบำรุงรักษาเชิงป้องกัน ควรทำความสะอาดเลนส์ก่อนที่คราบสกปรกจะก่อให้เกิดปัญหา ตรวจสอบหัวพ่นในตอนเริ่มต้นแต่ละกะงาน และตรวจสอบความบริสุทธิ์ของก๊าซทุกครั้งที่เปลี่ยนถังก๊าซ นิสัยง่ายๆ เหล่านี้จะช่วยตรวจจับปัญหาเล็กๆ ได้ก่อนที่จะกลายเป็นข้อบกพร่องที่สร้างค่าใช้จ่ายสูง ทำให้การดำเนินงานของคุณราบรื่นและลูกค้าพึงพอใจ

ตอนนี้คุณเข้าใจวิธีการวินิจฉัยและแก้ไขข้อบกพร่องในการตัดที่พบบ่อยแล้ว แต่การตัดด้วยเลเซอร์จะเปรียบเทียบกับวิธีอื่นๆ เช่น พลาสมา และวอเตอร์เจ็ท ได้อย่างไร? มาเปรียบเทียบเทคโนโลยีเหล่านี้กันโดยตรง

การตัดด้วยเลเซอร์ เทียบกับพลาสมา วอเตอร์เจ็ท และวิธีการเชิงกล

ด้วยตัวเลือกเครื่องตัดโลหะที่มีอยู่มากมาย คุณจะรู้ได้อย่างไรว่าเทคโนโลยีใดเหมาะสมกับความต้องการเฉพาะของคุณ? คำตอบขึ้นอยู่กับประเภทวัสดุ ความหนาที่ต้องการ ความแม่นยำที่ต้องการ และข้อจำกัดด้านงบประมาณ แต่ละวิธีมีข้อดีที่แตกต่างกันออกไป—และการเข้าใจความแตกต่างเหล่านี้จะช่วยให้คุณตัดสินใจได้อย่างมีข้อมูล ช่วยประหยัดเงินในขณะที่ยังคงได้คุณภาพตามที่โครงการของคุณต้องการ

นี่คือการเปรียบเทียบที่ครอบคลุมของเทคโนโลยีการตัดหลักสี่ประเภทที่ใช้ในงานผลิตสมัยใหม่:

| ข้อมูลจำเพาะ | การตัดเลเซอร์ | การตัดพลาสม่า | การตัดด้วยน้ำแรงดันสูง | เชิงกล (การเฉือน/การตอก) |

|---|---|---|---|---|

| ความแม่นยำ/ความคลาดเคลื่อน | ±0.1 มม. บนวัสดุบาง | ±0.5-1มม. | ±0.1 มม. (±0.02 มม. พร้อมหัวเคลื่อนไหวแบบไดนามิก) | ±0.25-0.5 มม. |

| ช่วงความหนาของวัสดุ | 0.5 มม. - 25 มม. (เหล็ก) | 0 มม. - 38 มม. ขึ้นไป | 0.8 มม. - 100 มม. ขึ้นไป | สูงสุด 25 มม. |

| เขตที่ได้รับผลกระทบจากความร้อน | น้อยมาก (โซนความร้อนที่ได้รับผลกระทบแคบ) | สำคัญ | ไม่มี (การตัดแบบเย็น) | ไม่มี |

| คุณภาพของรอยตัด | ยอดเยี่ยม—เรียบ ปราศจากรอยแตกร้าว | พอใช้—ต้องทำการเจียร | ดีมาก—ไม่มีผลจากความร้อน | ดีสำหรับการตัดตรงเท่านั้น |

| ต้นทุนการดำเนินงาน/ชั่วโมง | ~$20/ชั่วโมง | ~$15/ชั่วโมง | สูงกว่า (ค่าใช้จ่ายของวัสดุขัด) | ต่ำสุด |

| ความเร็ว (วัสดุบาง) | เร็วมาก | ปานกลาง | ช้า | เร็วมาก (รูปทรงง่ายๆ) |

| ความเร็ว (วัสดุหนา) | ปานกลางถึงช้า | เร็ว | ช้า | เร็ว (รูปทรงง่ายๆ) |

| ความเข้ากันของวัสดุ | โลหะ บางชนิดไม่ใช่โลหะ | เฉพาะโลหะที่นำไฟฟ้าเท่านั้น | เกือบทุกวัสดุ | เพียงโลหะ |

| ความสามารถในการสร้างเรขาคณิตที่ซับซ้อน | ยอดเยี่ยม | LIMITED | ยอดเยี่ยม | จำกัดมาก |

จุดที่การตัดด้วยเลเซอร์เหนือกว่าทางเลือกทุกอย่าง

เมื่อความแม่นยำมีความสำคัญสูงสุด เครื่องตัดด้วยเลเซอร์อุตสาหกรรมสามารถให้ผลลัพธ์ที่เทคโนโลยีอื่นๆ ไม่สามารถเทียบเคียงได้ ตามการวิเคราะห์ทางเทคนิคของ Xometry พลังงานที่ถูกควบแน่นจากลำแสงเลเซอร์จะสร้างรอยตัด (kerf) ที่แคบประมาณ 0.5 มม. เมื่อเทียบกับ 1-2 มม. สำหรับการตัดด้วยพลาสม่า รอยตัดที่แคบกว่านี้ทำให้เกิดความทนทานที่แน่นขึ้น และเปิดโอกาสให้ออกแบบรายละเอียดซับซ้อนมากขึ้นโดยตรง

พิจารณาเหตุผลที่ทำให้เครื่องตัดเลเซอร์อุตสาหกรรมเป็นตัวเลือกอันดับแรกสำหรับงานที่ต้องการความแม่นยำ:

- ความแม่นยำยอดเยี่ยม: การตัดด้วยเลเซอร์สามารถบรรลุค่าความทนทานได้ที่ ±0.1 มม. บนวัสดุบาง ซึ่งแม่นยำมากกว่าการตัดด้วยพลาสม่าที่ ±0.5 มม. ถึงห้าเท่า สำหรับชิ้นส่วนที่ต้องการพอดีแน่นหรือขนาดที่แม่นยำอย่างยิ่ง ความแตกต่างนี้มีความสำคัญอย่างยิ่ง

- ผิวเรียบที่สะอาด เครื่องตัดด้วยเลเซอร์แบบ CNC ผลิตขอบที่เรียบและปราศจากเศษตกค้าง ซึ่งมักไม่จำเป็นต้องผ่านกระบวนการตกแต่งเพิ่มเติม ขณะที่ขอบที่ตัดด้วยพลาสม่ามักต้องผ่านการเจียรเพื่อลบสแล็กและการผิวที่หยาบจากการตัด

- เรขาคณิตซับซ้อน: รูขนาดเล็ก มุมที่แหลมคม และลวดลายซับซ้อน ซึ่งไม่สามารถทำได้ด้วยวิธีพลาสมาหรือเครื่องจักรทั่วไป กลายเป็นเรื่องปกติสำหรับระบบเลเซอร์ เครื่องหมายที่เน้นความแม่นยำนี้สามารถทำงานรายละเอียดที่วิธีตัดแบบกว้างไม่สามารถทำได้

- ความหลากหลายของวัสดุ: ต่างจากพลาสมาที่ต้องใช้วัสดุนำไฟฟ้า เทคโนโลยีการตัดด้วยเลเซอร์สามารถตัดโลหะรวมถึงพลาสติก เซรามิก และคอมโพสิตบางชนิดได้ตามความต้องการ

- ความเร็วในการตัดแผ่นบาง: สำหรับวัสดุที่มีความหนาน้อยกว่า 6 มม. การตัดด้วยเลเซอร์มีความเร็วสูงกว่าวิธีอื่นๆ อย่างมาก การทดสอบโดย Wurth Machinery ยืนยันว่าระบบเลเซอร์โดดเด่นเมื่อต้องการความแม่นยำและความเร็วร่วมกันในการทำงานกับแผ่นโลหะตั้งแต่บางจนถึงปานกลาง

หมวดหมู่เครื่องตัดแผ่นโลหะได้เปลี่ยนแปลงไปอย่างมากด้วยเทคโนโลยีเลเซอร์ ที่ซึ่งการเจาะและการเฉือนแบบดั้งเดิมต้องใช้อุปกรณ์ต่างกันสำหรับแต่ละรูปร่าง ระบบเลเซอร์เพียงชุดเดียวสามารถตัดรูปทรงเกือบทุกแบบจากไฟล์ CAD เดียวกันได้ ความยืดหยุ่นนี้ช่วยลดเวลาเตรียมงานและค่าใช้จ่ายด้านอุปกรณ์ตัดลงอย่างมาก โดยเฉพาะอย่างยิ่งมีคุณค่าสูงสำหรับงานผลิตตามสั่งหรือการพัฒนาต้นแบบ

สำหรับผู้ผลิตที่ใช้เครื่องตัดเหล็กในสภาพแวดล้อมที่มีความหลากหลายสูงแต่ปริมาณการผลิตต่ำ เทคโนโลยีเลเซอร์ให้ความยืดหยุ่นที่เหนือกว่า เพียงเปลี่ยนไฟล์ออกแบบของคุณ เครื่องตัดโลหะก็สามารถผลิตชิ้นส่วนที่แตกต่างกันได้โดยไม่ต้องปรับแต่งเครื่องจักร

เมื่อใดที่ควรใช้พลาสมาหรือวอเตอร์เจ็ท

แม้ว่าการตัดด้วยเลเซอร์จะมีข้อได้เปรียบในเรื่องความแม่นยำ แต่เทคโนโลยีอื่นๆ ยังคงจำเป็นสำหรับการประยุกต์ใช้งานเฉพาะด้าน การเข้าใจว่าเมื่อใดควรเลือกใช้พลาสมาหรือน้ำตัด (waterjet) แทนเลเซอร์ จะช่วยให้คุณหลีกเลี่ยงการจ่ายเงินเกินสำหรับฟังก์ชันที่ไม่จำเป็น หรือประสบปัญหากับอุปกรณ์ที่ไม่สามารถรองรับความต้องการของคุณได้

ข้อดีของการตัดด้วยพลาสม่า:

การตัดด้วยพลาสมามีข้อดีเมื่อต้องประมวลผลโลหะตัวนำไฟฟ้าที่มีความหนา โดยข้อมูลจากอุตสาหกรรมระบุว่าเครื่องตัดพลาสมาสามารถตัดแผ่นโลหะได้หนาถึง 38 มม. ซึ่งมากกว่าขีดจำกัดสูงสุดประมาณ 25 มม. ของระบบเลเซอร์ส่วนใหญ่ สำหรับงานผลิตโครงสร้างเหล็ก การผลิตอุปกรณ์หนัก หรือการต่อเรือ พลาสมายังคงเป็นทางเลือกที่เหมาะสม

พิจารณาการตัดด้วยพลาสมาเมื่อ:

- ความหนาของวัสดุเกิน 20 มม. เป็นประจำ

- ข้อกำหนดด้านคุณภาพขอบอยู่ในระดับปานกลาง (สามารถทำกระบวนการเพิ่มเติมหลังการผลิตได้)

- งบประมาณลงทุนจำกัด — ระบบพลาสม่ามีต้นทุนต่ำกว่าอุปกรณ์เลเซอร์ที่มีสมรรถนะเทียบเท่ากันอย่างมาก

- ต้นทุนการดำเนินงานสำคัญกว่าความแม่นยำ — พลาสม่าใช้ต้นทุนประมาณ 15 ดอลลาร์สหรัฐต่อชั่วโมง เทียบกับ 20 ดอลลาร์สหรัฐต่อชั่วโมงสำหรับเลเซอร์

- ชิ้นส่วนจะถูกเชื่อมอยู่แล้ว ทำให้การขัดขอบเป็นส่วนหนึ่งของขั้นตอนการทำงานตามปกติอยู่แล้ว

ข้อดีของการตัดด้วยเจ็ทวอเตอร์:

เทคโนโลยีตัดแบบวอเตอร์เจ็ทมีตำแหน่งที่โดดเด่นในฐานะวิธีการตัดที่เย็นจริงๆ เพียงวิธีเดียว โดยการผสมน้ำแรงดันสูงกับอนุภาคขัดผิว วอเตอร์เจ็ทสามารถตัดวัสดุโดยไม่เกิดความร้อน จึงกำจัดโซนที่ได้รับผลกระทบจากความร้อน การบิดงอจากความร้อน และการเปลี่ยนแปลงทางโลหะวิทยาออกไปได้อย่างสิ้นเชิง

การวิจัยตลาด คาดการณ์ว่าอุตสาหกรรมการตัดด้วยวอเตอร์เจ็ทจะมีมูลค่าเกิน 2.39 พันล้านดอลลาร์สหรัฐภายในปี 2034 จากความต้องการในการประมวลผลวัสดุที่ไวต่อความร้อน เมื่อคุณต้องการรักษาคุณสมบัติของวัสดุให้คงเดิมอย่างครบถ้วน วอเตอร์เจ็ทคือคำตอบที่วิธีการตัดด้วยความร้อนไม่สามารถทำได้

เลือกการตัดด้วยเจ็ทน้ำเมื่อ:

- โซนที่ได้รับผลกระทบจากความร้อนถือว่าไม่สามารถยอมรับได้ — ชิ้นส่วนอากาศยาน อุปกรณ์ทางการแพทย์ หรือวัสดุที่ผ่านการอบความร้อน

- ความหนาของวัสดุเกิน 25 มม. ในขณะที่ความแม่นยำยังคงมีความสำคัญ

- ต้องการตัดวัสดุที่ไม่ใช่โลหะ เช่น หิน กระจก คอมโพสิต ยาง หรือผลิตภัณฑ์อาหาร

- มีข้อกังวลเกี่ยวกับโลหะสะท้อนแสง—เครื่องตัดด้วยน้ำสามารถจัดการทองแดงและทองเหลืองได้โดยไม่มีความเสี่ยงจากการสะท้อนกลับ

- คุณสมบัติของวัสดุต้องคงเดิม—ไม่เกิดการแข็งตัว ไม่มีความเครียด และไม่เปลี่ยนสี

วิธีการเชิงกล (การตัดด้วยกรรไกรและการเจาะ):

อย่ามองข้ามการตัดด้วยวิธีการเชิงกลแบบดั้งเดิมสำหรับงานที่เหมาะสม การตัดด้วยกรรไกรและการเจาะยังคงเป็นทางเลือกที่เร็วที่สุดและประหยัดที่สุดสำหรับการผลิตจำนวนมากของชิ้นงานรูปทรงง่าย เมื่อคุณผลิตชิ้นส่วนยึด แผ่นเปล่า หรือรูปทรงพื้นฐานจำนวนหลายพันชิ้น วิธีการเชิงกลจะให้ต้นทุนต่อชิ้นที่ต่ำที่สุด

ควรใช้วิธีการตัดเชิงกลเมื่อ:

- รูปร่างมีความเรียบง่าย—เส้นตรง รูมาตรฐาน สี่เหลี่ยมพื้นฐาน

- ปริมาณการผลิตมีจำนวนมาก—ต้นทุนแม่พิมพ์ถูกเฉลี่ยออกในชิ้นงานหลายพันชิ้น

- ความเร็วสำคัญกว่าความซับซ้อน—ระบบเชิงกลทำงานได้เร็วกว่าวิธีการใดๆ ที่ใช้ความร้อน

- ความหนาของวัสดุอยู่ภายในขีดจำกัดของเครื่องมือ

สรุปแล้ว เลเซอร์ตัดครองตลาดงานตัดแผ่นความแม่นยำระดับบางถึงกลางที่คุณภาพผิวตัดและรูปร่างเรขาคณิตมีความสำคัญ พลาสมาเหมาะกับการตัดแผ่นหนาอย่างคุ้มค่าเมื่อความแม่นยำในระดับปานกลางเพียงพอ ส่วนวอเตอร์เจ็ทช่วยกำจัดปัญหาความร้อนสำหรับวัสดุที่ไวต่อความร้อน และวิธีการเชิงกลยังคงเป็นตัวเลือกชั้นนำสำหรับชิ้นงานรูปทรงง่ายที่ต้องผลิตจำนวนมาก ร้านงานแปรรูปโลหะที่ประสบความสำเร็จหลายแห่งในท้ายที่สุดจะลงทุนในเทคโนโลยีหลายประเภท—แต่ละแบบใช้ตามงานที่เหมาะสมที่สุด

การเข้าใจข้อแลกเปลี่ยนเหล่านี้ระหว่างเทคโนโลยีต่างๆ จะช่วยให้คุณพร้อมตัดสินใจขั้นตอนสำคัญต่อไป ได้แก่ โครงการของคุณจะมีค่าใช้จ่ายจริงเท่าใด และปัจจัยใดบ้างที่กำหนดราคาตัดด้วยเลเซอร์

ปัจจัยด้านต้นทุนและกลยุทธ์การกำหนดราคาสำหรับโครงการตัดโลหะ

นี่คือคำถามที่ทำให้วิศวกรและผู้จัดการโครงการหลายคนสับสน: "ราคาตัดเลเซอร์ต่อตารางฟุตอยู่ที่เท่าไร?" ฟังดูสมเหตุสมผลใช่ไหมครับ แต่จริงๆ แล้วนี่คือจุดเริ่มต้นที่ผิด ปัจจัยสำคัญที่สุดที่กำหนดค่าใช้จ่ายในการตัดด้วยเลเซอร์ของคุณ ไม่ใช่ขนาดพื้นที่ของวัสดุ แต่เป็นเวลาเครื่องที่ต้องใช้ในการตัดแบบเฉพาะของคุณ ชิ้นงานรูปสี่เหลี่ยมธรรมดา กับแผงตกแต่งซับซ้อนที่ทำจากแผ่นเดียวกัน อาจมีราคาแตกต่างกันมาก

การเข้าใจกลไกการกำหนดราคาที่แท้จริงจะช่วยให้คุณควบคุมงบประมาณโครงการได้อย่างมีประสิทธิภาพ อ้างอิงจาก คู่มือการกำหนดราคาอย่างละเอียดของ Fortune Laser ผู้ให้บริการส่วนใหญ่คำนวณต้นทุนโดยใช้สูตรพื้นฐานนี้:

ราคาสุดท้าย = (ต้นทุนวัสดุ + ต้นทุนผันแปร + ต้นทุนคงที่) × (1 + อัตรากำไร)

มาดูกันว่าแต่ละองค์ประกอบหมายถึงอะไรต่อกระเป๋าเงินของคุณ และคุณสามารถมีอิทธิพลต่อแต่ละข้อได้อย่างไร

เข้าใจสิ่งที่ขับเคลื่อนต้นทุนการตัดด้วยเลเซอร์

มีปัจจัยหลัก 5 ประการที่ส่งผลโดยตรงต่อใบเสนอราคาที่คุณจะได้รับสำหรับชิ้นงานที่ตัดด้วยเลเซอร์ การรู้จักปัจจัยเหล่านี้จะช่วยให้คุณคาดการณ์ต้นทุนก่อนส่งแบบ และระบุโอกาสในการประหยัดค่าใช้จ่ายได้

ประเภทและความหนาของวัสดุ: สิ่งนี้มีผลต่อราคาของคุณสองประการ ได้แก่ ต้นทุนวัตถุดิบเอง และระดับความยากในการตัด การวิจัยจาก Komacut ยืนยันว่าวัสดุที่หนากว่าต้องใช้พลังงานมากกว่าและต้องใช้ความเร็วตัดที่ช้ากว่า การเพิ่มความหนาของวัสดุเป็นสองเท่าอาจทำให้เวลาตัดและต้นทุนเพิ่มขึ้นมากกว่าสองเท่า เนื่องอเลเซอร์จะต้องเคลื่อนที่ช้าลงอย่างมากเพื่อให้ได้รอยตัดที่สะอาด

เวลาเครื่องจักร (ปัจจัยที่สำคัญที่สุด): นี่คืออัตราค่าบริการต่อชั่วโมงของเครื่องตัดเลเซอร์ คูณด้วยระยะเวลาที่ต้องใช้ในการทำงานของคุณ อัตราค่าเครื่องโดยทั่วไปอยู่ในช่วง 60 ถึง 120 ดอลลาร์ต่อชั่วโมง ขึ้นอยู่กับความสามารถของอุปกรณ์ เวลาเครื่องจักรรวมถึง:

- ระยะทางการตัด: เส้นทางเชิงเส้นทั้งหมดที่เลเซอร์เดินทาง — เส้นทางที่ยาวขึ้นหมายถึงเวลามากขึ้น

- จำนวนการเจาะ: ทุกครั้งที่เลเซอร์เริ่มการตัดครั้งใหม่ จะต้องเจาะทะลุผ่านวัสดุก่อน การออกแบบที่มีรูขนาดเล็ก 100 รูจะมีต้นทุนสูงกว่าชิ้นงานที่มีการตัดออกขนาดใหญ่เพียงชิ้นเดียว เนื่องจากเวลาการเจาะสะสม

- ประเภทการใช้งาน: การตัด (ผ่านวัสดุทั้งหมด) ใช้เวลานานที่สุด การทำเครื่องหมายผิว (ความลึกบางส่วน) เร็วกว่า ส่วนการแกะสลักมักจะมีการกำหนดราคาต่อตารางนิ้ว

ความซับซ้อนของการออกแบบ: การออกแบบที่ซับซ้อนพร้อมเส้นโค้งแน่นและมุมแหลมจะทำให้เครื่องต้องทำงานช้าลง ส่งผลให้เวลาในการตัดรวมเพิ่มขึ้น ตามเอกสารทางเทคนิคของ A-Laser การตัดแหวนเรียบง่ายที่มีระยะทางเชิงเส้นรวม 300 มม. จะทำได้เร็วกว่าการตัดรูปทรงซับซ้อนที่มีระยะทางรวมเท่ากัน 300 มม. เนื่องจากการตัดรายละเอียดจำเป็นต้องใช้ความเร็วเลเซอร์ที่ช้ากว่า

ข้อกำหนดด้านความคลาดเคลื่อนและการตรวจสอบ: การระบุความคลาดเคลื่อนที่แคบเกินกว่าที่จำเป็นโดยหน้าที่ใช้งานจริง เป็นสาเหตุหนึ่งที่ทำให้ต้นทุนเพิ่มขึ้นอย่างพบได้บ่อย การควบคุมความคลาดเคลื่อน ±0.025 มม. จำเป็นต้องใช้ความเร็วในการตัดที่ช้ากว่าและควบคุมอย่างระมัดระวังมากกว่าเมื่อเทียบกับ ±0.127 มม. ขณะที่การตรวจสอบตาม AQL หรือการยืนยันชิ้นส่วนทุกชิ้น (100%) จะเพิ่มต้นทุนแรงงานอย่างมีนัยสำคัญ เมื่อเทียบกับการตรวจสอบชิ้นแรกและชิ้นสุดท้ายตามมาตรฐาน

กระบวนการทำงานเพิ่มเติม: บริการเพิ่มเติมนอกเหนือจากการตัดขั้นต้น เช่น การดัด การทากเกลียว การใส่อุปกรณ์เสริม การพาวเดอร์โค้ท หรือการผ่านกรรมวิธีผิว (passivation) จะมีการคิดราคาแยกต่างหาก วิธีการตกแต่งสำเร็จนี้เพิ่มทั้งต้นทุนและระยะเวลาดำเนินการให้กับโครงการของคุณ

อย่าลืมต้นทุนที่แฝงอยู่ซึ่งมักทำให้ผู้ซื้อหลายคนประหลาดใจ:

- ใบรับรองวัสดุ: ใบรับรองแหล่งที่มาของวัสดุสำหรับการใช้งานในอุตสาหกรรมการบินหรือการแพทย์

- ข้อกำหนดการตรวจสอบพิเศษ: รายงานการวัดด้วยเครื่อง CMM หรือเอกสารแสดงมิติ

- บรรจุภัณฑ์แบบกำหนดเอง: กล่องเจลแพก ถาดเฉพาะ หรือข้อกำหนดบรรจุภัณฑ์เฉพาะที่มากกว่าการบรรจุแบบมาตรฐาน

- ค่าบริการสั่งด่วน: การเร่งดำเนินการโดยทั่วไปจะเพิ่มราคา 25-50% จากราคาปกติ

การปรับแต่งการออกแบบของคุณเพื่อการผลิตที่คุ้มค่าต้นทุน

ข่าวดีก็คือ ในฐานะผู้ออกแบบหรือวิศวกร คุณมีอำนาจควบคุมราคาสุดท้ายได้อย่างมาก กลยุทธ์เหล่านี้จะช่วยให้คุณลดต้นทุนได้โดยไม่ต้องเสียประสิทธิภาพการทำงาน—ทำให้มีงบประมาณเหลือไปใช้กับสิ่งที่สำคัญจริงๆ

- ทำให้รูปทรงเรียบง่ายขึ้น: เมื่อเป็นไปได้ ให้ลดเส้นโค้งซับซ้อน และรวมรูเล็กหลายๆ รูให้เป็นช่องขนาดใหญ่แทน สิ่งนี้จะช่วยลดระยะทางในการตัดและลดขั้นตอนการเจาะที่ใช้เวลานาน

- ใช้วัสดุที่บางที่สุดเท่าที่เป็นไปได้: นี่คือกลยุทธ์การลดต้นทุนที่มีประสิทธิภาพสูงสุดเพียงหนึ่งเดียว วัสดุที่หนาขึ้นจะทำให้เวลาในการทำงานของเครื่องเพิ่มขึ้นแบบทวีคูณ—ควรตรวจสอบเสมอว่าวัสดุเบอร์บางกว่าสามารถรองรับข้อกำหนดด้านโครงสร้างของคุณได้หรือไม่

- ทำความสะอาดไฟล์ออกแบบของคุณ: ลบเส้นซ้ำ เส้นที่ซ่อนอยู่ และโน้ตสำหรับงานก่อสร้างออกก่อนส่งมอบ ระบบประเมินราคาอัตโนมัติจะพยายามตัดทุกอย่าง—เส้นที่ซ้ำกันจะทำให้ต้นทุนของฟีเจอร์นั้นเพิ่มขึ้นเป็นสองเท่าโดยตรง

- มาตรฐานความหนาของวัสดุ: การใช้วัสดุขนาดมาตรฐานจะช่วยกำจัดค่าธรรมเนียมการสั่งพิเศษและลดระยะเวลาการผลิต สอบถามผู้ให้บริการของคุณว่ามีวัสดุใดบ้างที่เก็บไว้ในสต็อก

- ออกแบบเพื่อการจัดเรียงอย่างมีประสิทธิภาพ: ชิ้นส่วนที่สามารถจัดเรียงติดกันได้อย่างแน่นหนาโดยมีช่องว่างน้อยที่สุด จะช่วยลดของเสียจากวัสดุ ควรพิจารณาหมุนหรือพลิกชิ้นส่วนเพื่อให้สามารถวางบนแผ่นขนาดมาตรฐานได้อย่างมีประสิทธิภาพมากขึ้น

- จัดกลุ่มชิ้นส่วนที่คล้ายกันเพื่อผลิตพร้อมกัน: รวมคำสั่งซื้อเข้าด้วยกันเพื่อกระจายต้นทุนการตั้งค่าไปยังจำนวนหน่วยที่มากขึ้น โครงการตัดเลเซอร์แบบเฉพาะตัวจะได้รับประโยชน์อย่างมากจากการผลิตจำนวนมาก—ส่วนลดสำหรับคำสั่งซื้อปริมาณมากอาจสูงถึง 70%

เรื่องของขนาดเศรษฐกิจ (economy of scale) ควรได้รับความสนใจเป็นพิเศษ ทุกๆ งานมีต้นทุนคงที่สำหรับการตั้งค่า เช่น การโหลดวัสดุ การปรับเทียบเครื่องจักร และการเตรียมไฟล์ เมื่อคุณสั่งผลิตชิ้นส่วน 10 ชิ้น ต้นทุนเหล่านี้จะถูกแบ่งไปยังชิ้นส่วนเพียง 10 หน่วย แต่หากสั่งผลิต 1,000 ชิ้น ต้นทุนการตั้งค่าเดียวกันนี้จะถูกกระจายไปยัง 1,000 หน่วย ทำให้ต้นทุนต่อชิ้นลดลงอย่างมาก การวิเคราะห์ในอุตสาหกรรมแสดงให้เห็นว่า การรวมคำสั่งซื้อให้มีปริมาณมากขึ้นและสั่งน้อยครั้งลงนั้น มักจะให้คุณค่าที่ดีที่สุด

คุณอาจสงสัยว่าราคาเครื่องตัดเลเซอร์จะอยู่ที่เท่าไร หากคุณกำลังพิจารณาความสามารถในการผลิตเองภายในองค์กร โดยทั่วไป เครื่องตัดเลเซอร์ไฟเบอร์ระดับเริ่มต้นจะมีราคาเริ่มต้นประมาณ 20,000 ดอลลาร์สหรัฐสำหรับระบบที่พื้นฐาน ขณะที่อุปกรณ์ระดับการผลิตจะมีราคาตั้งแต่ 100,000 ถึง 500,000 ดอลลาร์สหรัฐขึ้นไป สำหรับการดำเนินงานส่วนใหญ่ คำถามจึงไม่ใช่แค่ "เครื่องตัดเลเซอร์ราคาเท่าไร" แต่คือ ปริมาณงานของคุณเพียงพอที่จะคุ้มทุนจากการลงทุนด้านอุปกรณ์หรือไม่ เมื่อเทียบกับการจ้างผู้เชี่ยวชาญภายนอกที่มีอุปกรณ์และความชำนาญอยู่แล้ว

เมื่อพิจารณาเรื่องพื้นฐานด้านการกำหนดราคาเสร็จสิ้นแล้ว ยังมีอีกหนึ่งปัจจัยที่สำคัญอย่างยิ่งก่อนที่คุณจะเริ่มต้นกระบวนการตัดโลหะ นั่นคือ ความปลอดภัย ขั้นตอนและมาตรการที่เหมาะสมจะช่วยปกป้องทั้งผู้ปฏิบัติงานและอุปกรณ์ — มาดูกันว่าการดำเนินงานอย่างรับผิดชอบต้องมีอะไรบ้าง

มาตรการด้านความปลอดภัยและแนวทางปฏิบัติที่ดีที่สุดสำหรับการตัดโลหะ

มีบางสิ่งที่โบรชัวร์อุปกรณ์ส่วนใหญ่มักจะไม่กล่าวถึงโดยละเอียด นั่นคือ การตัดโลหะด้วยเลเซอร์มีอันตรายจริงที่ต้องได้รับการให้เกียรติและเคารพ เราพูดถึงระบบเลเซอร์ระดับคลาส 4 ซึ่งสามารถทำลายดวงตาหรือผิวหนังได้ทันที ไอระเหยของโลหะที่มีโลหะหนักพิษเจือปน และอุณหภูมิที่สูงพอจะทำให้วัสดุลุกไหม้ได้ การเข้าใจความเสี่ยงเหล่านี้ และการนำมาตรการควบคุมที่เหมาะสมมาใช้ จะช่วยปกป้องผู้ปฏิบัติงาน อุปกรณ์ และธุรกิจของคุณ

ตามที่ มาตรฐาน ANSI Z136.1 —เอกสารหลักฐานพื้นฐานสำหรับโปรแกรมความปลอดภัยเลเซอร์ในอุตสาหกรรม—สถานที่ที่ดำเนินการเครื่องตัดโลหะด้วยเลเซอร์กำลังสูง จำเป็นต้องจัดการทั้งอันตรายจากลำแสง (การบาดเจ็บที่ตาและผิวหนัง) และอันตรายที่ไม่ใช่จากลำแสง (ไฟฟ้าช็อต ไฟไหม้ และมลภาวะทางอากาศ) มาดูกันว่าการดำเนินงานอย่างรับผิดชอบจำเป็นต้องทำอะไรบ้าง

การป้องกันผู้ปฏิบัติงานจากอันตรายของเลเซอร์และไอระเหยโลหะ

ระบบตัดด้วยเลเซอร์ในอุตสาหกรรมส่วนใหญ่จะถูกจัดอยู่ในระดับ Class 1 ในระหว่างการทำงานปกติ เนื่องจากเลเซอร์จะถูกปิดล้อมอย่างสมบูรณ์ และประตูที่มีระบบล็อกป้องกันการเปิดเผยรังสี อย่างไรก็ตาม ภายในระบบที่ปิดล้อมเหล่านี้มีเลเซอร์ระดับ Class 3B หรือ Class 4 ซึ่งสามารถก่อให้เกิดอันตรายร้ายแรงได้ เมื่อมีการเปิดฝาครอบเพื่อดำเนินการบำรุงรักษาหรือแก้ไขปัญหา ผู้ปฏิบัติงานจะเผชิญความเสี่ยงจากการสัมผัสรังสีโดยตรง

ข้อกำหนดด้านการป้องกันส่วนบุคคล:

- แว่นตาสำหรับป้องกันเลเซอร์: จำเป็นต้องใช้ทุกครั้งที่มีการปลดระบบล็อกป้องกันของตู้ครอบ เลเซอร์ เลนส์แว่นตาต้องได้รับการประเมินค่าให้เหมาะสมกับความยาวคลื่นเฉพาะ—1.06 ไมโครเมตร สำหรับเลเซอร์ไฟเบอร์ และ 10.6 ไมโครเมตร สำหรับระบบ CO2 แว่นนิรภัยทั่วไปไม่สามารถป้องกันได้เลย

- เครื่องแต่งกายป้องกัน: การสวมเสื้อแขนยาวและชุดทำงานที่เหมาะสมจะช่วยป้องกันการสัมผัสผิวหนังระหว่างขั้นตอนการบำรุงรักษา ต้องสวมถุงมือทนความร้อนเมื่อจัดการกับวัสดุที่เพิ่งตัดหรือพื้นผิวร้อน

- ถุงมือทนการขีดข่วน: จำเป็นอย่างยิ่งเมื่อถอดชิ้นส่วนที่มีขอบคม หรือจัดการเศษวัสดุที่มีลักษณะแหลมคมจากเตียงตัด

- การป้องกันระบบทางเดินหายใจ: จำเป็นเมื่อระบบระบายอากาศไม่สามารถควบคุมการสัมผัสไอระเหยได้อย่างเพียงพอ โดยเฉพาะระหว่างการบำรุงรักษาภายในห้องตัด

นอกจากอันตรายจากเลเซอร์โดยตรงแล้ว ไอควันที่เกิดขึ้นระหว่างการตัดด้วยเลเซอร์ในอุตสาหกรรมยังก่อให้เกิดความเสี่ยงต่อสุขภาพอย่างร้ายแรง งานวิจัยจาก Camfil APC ยืนยันว่าการตัดด้วยเลเซอร์และพลาสม่าผลิตไอโลหะที่มีองค์ประกอบอันตราย เช่น ตะกั่ว นิกเกิล โครเมียม และปรอท อนุภาคขนาดเล็กเหล่านี้ลอยอยู่ในอากาศและอาจถูกลดเข้าไปโดยไม่รู้ตัว ทำให้เกิดปัญหาทางเดินหายใจและผลกระทบต่อสุขภาพในระยะยาว

อันตรายเฉพาะวัสดุควรได้รับความสนใจเป็นพิเศษ:

- เหล็กเคลือบสังกะสี: วัสดุชุบสังกะสีจะปล่อยไอออกไซด์ของสังกะสีออกมาขณะตัด ซึ่งเป็นสาเหตุของ "ไข้ไอน้ำโลหะ" การดูดไอระเหยออกอย่างเหมาะสมจึงเป็นสิ่งจำเป็น

- เหล็กไม่ржаมี มีโครเมียมที่เมื่อระเหยจะกลายเป็นสารประกอบโครเมียมหกขั้ว ซึ่งเป็นสารก่อมะเร็งที่ต้องควบคุมการสัมผัสอย่างเข้มงวด

- สีเหล็ก: เนื้อสังกะสีสร้างความเสี่ยงจากไอระเหยในลักษณะเดียวกับเหล็กชุบสังกะสี

- โลหะสะท้อนแสง: อลูมิเนียมและทองแดงมีความเสี่ยงจากการสะท้อนกลับ ซึ่งอาจทำให้ชิ้นส่วนออปติคัลเสียหาย และอาจทำให้ผู้ปฏิบัติงานได้รับพลังงานลำแสงที่กระจายออกมาหากระบบป้องกันถูกทำลาย

ข้อกำหนดของสถานที่สำหรับการดำเนินงานตัดด้วยเลเซอร์อย่างปลอดภัย

การปฏิบัติงานเครื่องตัดเหล็กด้วยเลเซอร์อย่างปลอดภัยต้องอาศัยมากกว่าเพียงอุปกรณ์ป้องกันส่วนบุคคล—สถานที่ของคุณเองจะต้องมีการควบคุมทางวิศวกรรมที่เหมาะสม แนวทางความปลอดภัยในการใช้เครื่องตัดเลเซอร์ของมหาวิทยาลัยคาร์เนกีเมลลอน ระบุว่าอุปกรณ์สามารถใช้งานได้เฉพาะในพื้นที่ที่มีการระบายอากาศดี โดยมีการเปลี่ยนถ่ายอากาศอย่างน้อย 15 ครั้งต่อชั่วโมง

ข้อกำหนดการควบคุมสิ่งแวดล้อม:

- ระบบดูดควันเฉพาะทาง: ระบบปรับอากาศมาตรฐานไม่สามารถควบคุมไอโลหะได้อย่างมีประสิทธิภาพ จำเป็นต้องใช้อุปกรณ์ดูดฝุ่นและไอระเหยแบบเฉพาะที่มาพร้อมกับตัวกรองแบบคาร์ทริดจ์ประสิทธิภาพสูง เพื่อดักจับอนุภาคก่อนที่จะปนเปื้อนในสภาพแวดล้อมการทำงาน

- ระบบดับเพลิง: เครื่องตัดเลเซอร์สามารถติดตั้งได้เฉพาะในพื้นที่ที่มีระบบดับเพลิงที่เพียงพอเท่านั้น ต้องมีถังดับเพลิงชนิด CO2 หรือผงเคมีแห้งวางอยู่ใกล้กับอุปกรณ์ โดยขนาดถังต้องไม่เกิน 5 ปอนด์ เพื่อให้สามารถเข้าถึงได้อย่างรวดเร็ว

- ระบบล็อกความปลอดภัยสำหรับการระบายอากาศ: ต้องเปิดใช้งานระบบควบคุมการระบายอากาศก่อนเริ่มดำเนินการตัดด้วยเลเซอร์ สถานที่จำนวนมากจะเชื่อมโยงระบบระบายอากาศเข้ากับวงจรเปิดใช้งานเลเซอร์ เพื่อป้องกันการใช้งานหากไม่มีการไหลของอากาศที่เพียงพอ

- สภาพแวดล้อมในการทำงานที่สะอาด: การสะสมของฝุ่นและเศษวัสดุบริเวณอุปกรณ์ตัดสามารถสร้างความเสี่ยงต่อการเกิดเพลิงไหม้ได้ การทำความสะอาดตะแกรงตัดและพื้นที่โดยรอบเป็นประจำจึงเป็นสิ่งที่ต้องปฏิบัติอย่างเคร่งครัด

ข้อกำหนดขั้นตอนการปฏิบัติงาน:

- การตรวจสอบความปลอดภัยก่อนเริ่มงาน: ก่อนเริ่มการตัดในแต่ละครั้ง ผู้ปฏิบัติงานต้องตรวจสอบสภาพอุปกรณ์ กำจัดสิ่งไวไฟออกจากพื้นที่โดยรอบ ยืนยันว่ามีเครื่องดับเพลิงพร้อมใช้งาน และตรวจสอบให้มั่นใจว่าระบบระบายอากาศทำงานอย่างถูกต้อง

- ต้องมีผู้ดูแลอยู่ตลอดเวลา: ห้ามทิ้งเครื่องตัดเลเซอร์โดยไม่มีผู้ดูแลเด็ดขาด การรวมกันของอุณหภูมิสูงและเศษวัสดุที่ติดไฟได้ ทำให้มีความเสี่ยงเกิดเพลิงไหม้จริง ซึ่งต้องสามารถตอบสนองได้ทันที

- ขั้นตอนการหยุดฉุกเฉิน: ผู้ปฏิบัติงานต้องทราบวิธีหยุดการทำงานทันทีเมื่อเกิดไฟไหม้หรือพบปัญหาทางกลไก ห้ามปล่อยให้ระบบความปลอดภัยถูกข้ามไปเด็ดขาด

- การตรวจสอบวัสดุ: ก่อนทำการตัด ต้องตรวจสอบให้มั่นใจว่าวัสดุเหมาะสมกับกระบวนการแปรรูปด้วยเลเซอร์ วัสดุบางชนิด เช่น ชั้นเคลือบ กาว หรือวัสดุคอมโพสิต อาจปล่อยไอพิษร้ายแรงเมื่อถูกทำให้ระเหยด้วยความร้อน

การฝึกอบรมและการรับรอง:

บริการตัดด้วยเลเซอร์แบบแม่นยำขึ้นอยู่กับผู้ปฏิบัติงานที่ได้รับการฝึกอบรมอย่างเหมาะสม ข้อกำหนดในการฝึกอบรมรวมถึงหลักการพื้นฐานด้านความปลอดภัยในการใช้เลเซอร์ ขั้นตอนการปฏิบัติงานเฉพาะอุปกรณ์ การป้องกันและรับมือเหตุเพลิงไหม้ และมาตรการฉุกเฉิน ควรจัดเก็บเอกสารยืนยันการผ่านการฝึกอบรมสำหรับบุคลากรทุกคน

กิจกรรมการบำรุงรักษานำความเสี่ยงเพิ่มเติมมาด้วย การทำความสะอาดเลนส์และการเปลี่ยนหัวพ่นทำให้ผู้ปฏิบัติงานต้องสัมผัสกับพลังงานลำแสงตกค้าง ชิ้นส่วนออปติกที่ปนเปื้อน และระบบไฟฟ้าแรงสูง ควรให้เฉพาะบุคลากรที่ผ่านการฝึกอบรมเท่านั้นดำเนินการเหล่านี้ โดยปฏิบัติตามขั้นตอนล็อกเอาต์/แท็กเอาต์ และใช้อุปกรณ์ป้องกันส่วนบุคคล (PPE) ที่เหมาะสม

สรุปคืออะไร? ความปลอดภัยไม่ใช่สิ่งที่เพิ่มเข้าไปในการตัดด้วยเลเซอร์อย่างแม่นยำ—แต่เป็นพื้นฐานสำคัญของการดำเนินงานอย่างยั่งยืน สิ่งอำนวยความสะดวกที่ให้ความสำคัญกับการควบคุมที่เหมาะสมจะช่วยปกป้องคนงาน หลีกเลี่ยงเหตุการณ์ที่ก่อให้เกิดค่าใช้จ่ายสูง และรักษาระดับคุณภาพการผลิตอย่างต่อเนื่องตามที่ลูกค้าคาดหวัง เมื่อมีมาตรการด้านความปลอดภัยที่ชัดเจนแล้ว คุณก็พร้อมสำหรับการตัดสินใจขั้นสุดท้าย: ควรลงทุนซื้ออุปกรณ์เอง หรือร่วมมือกับบริการระดับมืออาชีพ?

การเลือกระหว่างการลงทุนในอุปกรณ์และการใช้บริการระดับมืออาชีพ

คุณได้เชี่ยวชาญเทคโนโลยี เข้าใจวัสดุ และรู้วิธีการปรับลดต้นทุนอย่างมีประสิทธิภาพแล้ว—ตอนนี้มาถึงคำถามสำคัญที่ทุกธุรกิจที่กำลังเติบโตต้องเผชิญ: คุณควรลงทุนซื้อเครื่องตัดโลหะด้วยเลเซอร์ของตัวเอง หรือควรร่วมมือกับบริการตัดโลหะด้วยเลเซอร์ที่มีอุปกรณ์และผู้เชี่ยวชาญอยู่แล้ว? การตัดสินใจนี้จะกำหนดการจัดสรรเงินทุน ความยืดหยุ่นในการดำเนินงาน และตำแหน่งการแข่งขันของคุณในระยะยาว

ไม่มีคำตอบเดียวที่ใช้ได้กับทุกกรณี ตามการวิเคราะห์อุตสาหกรรมของ GF Laser , แนวทางที่ดีที่สุดขึ้นอยู่กับปริมาณ งบประมาณ ความต้องการวัสดุ และกลยุทธ์ทางธุรกิจในระยะยาวของคุณ โดยการดำเนินงานที่ประสบความสำเร็จหลายแห่งมักเริ่มต้นจากการจ้างภายนอก จากนั้นจึงนำความสามารถมาดำเนินเองภายในองค์กรเมื่อความต้องการเพิ่มขึ้น ในขณะที่บางแห่งเลือกใช้โมเดลผสมผสานอย่างถาวร โดยใช้พันธมิตรภายนอกเพื่อรองรับงานที่มากเกินไปหรืองานเฉพาะทาง

กรอบการตัดสินใจระหว่างซื้ออุปกรณ์เองกับจ้างภายนอกสำหรับการดำเนินงานของคุณ

การเป็นเจ้าของเครื่องตัดโลหะด้วยเลเซอร์มีเหตุผลทางการเงินเมื่อใด? และเมื่อใดที่การค้นหาคำว่า "บริการตัดด้วยเลเซอร์ใกล้ฉัน" จะให้คุณค่าที่ดีกว่า? มาดูปัจจัยที่ทำให้การตัดสินใจเอียงไปทางใดทางหนึ่งกัน

ปัจจัยที่สนับสนุนการลงทุนอุปกรณ์ภายในองค์กร

- ปริมาณสูง ความต้องการสม่ำเสมอ: หากคุณผลิตชิ้นส่วนเดียวกันหรือคล้ายกันทุกวัน การประหยัดต่อชิ้นจะสะสมได้อย่างรวดเร็ว การตัดด้วยความถี่สูงสามารถรับรองการลงทุนในสินทรัพย์ได้

- การออกแบบเฉพาะที่ต้องการความลับ: เมื่อการป้องกันทรัพย์สินทางปัญญาเป็นสิ่งสำคัญ การเก็บรักษาการออกแบบที่ละเอียดอ่อนไว้ภายในองค์กรจะช่วยลดความเสี่ยงจากการเปิดเผยข้อมูลให้กับบุคคลที่สาม

- ความต้องการในการทำซ้ำอย่างรวดเร็ว: ทีมพัฒนาผลิตภัณฑ์ได้รับประโยชน์จากการสร้างต้นแบบในวันเดียวกัน การมีอุปกรณ์ภายในสถานที่ช่วยให้สามารถดำเนินการวงจรออกแบบ-ทดสอบ-แก้ไขได้อย่างรวดเร็ว โดยไม่ต้องรอใบเสนอราคาและระยะเวลาจัดส่งจากภายนอก

- ข้อกำหนดด้านการควบคุมการผลิต: การเป็นเจ้าของอุปกรณ์ทำให้คุณมีอำนาจควบคุมอย่างเต็มที่เกี่ยวกับการจัดกำหนดการ มาตรฐานคุณภาพ และการเปลี่ยนแปลงลำดับความสำคัญ โดยไม่ต้องแข่งขันกับลูกค้ารายอื่นเพื่อใช้เวลาเครื่องจักร

- การลดต้นทุนในระยะยาว: แม้จะมีการลงทุนเริ่มต้นสูง (เลเซอร์ไฟเบอร์ระดับการผลิตจากผู้ผลิตเช่น Trumpf มีราคาเกิน 600,000 ดอลลาร์สหรัฐ) แต่การดำเนินงานที่มีปริมาณสูงอย่างต่อเนื่องมักจะสามารถลดต้นทุนต่อชิ้นในระยะยาวได้

ปัจจัยที่สนับสนุนการจ้างงานบริการจากภายนอก

- ความต้องการที่แปรผันหรือคาดการณ์ไม่ได้: เมื่อความต้องการตัดของคุณมีการเปลี่ยนแปลงอย่างมาก การจ้างงานจากภายนอกจะช่วยให้คุณสามารถขยายหรือลดขนาดการผลิตได้โดยไม่ต้องแบกภาระอุปกรณ์ที่ว่างงานในช่วงเวลาที่ชะลอตัว

- ความต้องการวัสดุที่หลากหลาย: ผู้ให้บริการตัดโลหะด้วยเลเซอร์แบบกำหนดเองมีระบบเลเซอร์หลายประเภทที่เหมาะสมกับวัสดุต่างๆ การเข้าถึงเลเซอร์ไฟเบอร์ เลเซอร์ CO2 และระดับพลังงานที่แตกต่างกันผ่านผู้ให้บริการรายเดียวนั้นคุ้มค่ากว่าการลงทุนซื้อเครื่องจักรหลายเครื่อง

- ข้อจำกัดด้านเงินทุน: การหลีกเลี่ยงการซื้อเครื่องจักรที่มีมูลค่าหลายแสนบาทช่วยรักษากำลังเงินสดไว้สำหรับความสำคัญทางธุรกิจอื่น ๆ ไม่ต้องผ่อนชำระเครื่องจักร ไม่ต้องคำนวณค่าเสื่อมราคา

- การเข้าถึงความเชี่ยวชาญและเทคโนโลยีขั้นสูง: บริการระดับมืออาชีพจะลงทุนในอุปกรณ์ล่าสุดและจ้างผู้ปฏิบัติงานที่มีประสบการณ์ คุณได้รับประโยชน์จากศักยภาพเหล่านี้โดยไม่ต้องใช้เวลาเรียนรู้หรือแบกรับภาระด้านการฝึกอบรม

- ลดความซับซ้อนในการดำเนินงาน: การไม่ต้องดูแลเครื่องจักร ไม่ต้องจัดเก็บวัสดุสิ้นเปลือง ไม่ต้องฝึกอบรมผู้ปฏิบัติงาน และไม่ต้องกังวลเรื่องความปลอดภัย จะช่วยทำให้การดำเนินงานของคุณง่ายขึ้น ปล่อยให้ผู้เชี่ยวชาญเป็นผู้จัดการความซับซ้อนแทน

- ความต้องการก๊าซช่วยพิเศษ: การตัดสแตนเลสหรืออลูมิเนียมปริมาณมากต้องใช้ก๊าซไนโตรเจนในปริมาณมาก ซึ่งจำเป็นต้องติดตั้งถังก๊าซแบบถาวร ทำให้มีต้นทุนโครงสร้างพื้นฐานเพิ่มเติมนอกเหนือจากราคาเครื่องเลเซอร์เอง

กำลังสงสัยเกี่ยวกับ "เครื่องตัดเลเซอร์ใกล้ฉัน" สำหรับโปรเจกต์ครั้งคราวใช่ไหม? พื้นที่ในเมืองใหญ่ส่วนใหญ่มีผู้ให้บริการหลายรายที่เสนอระยะเวลาดำเนินการที่รวดเร็ว สำหรับงานเฉพาะทางหรืองานที่ต้องการความแม่นยำสูง อย่าจำกัดการค้นหาตามพื้นที่ทางภูมิศาสตร์—ค่าจัดส่งมักจะน้อยมากเมื่อเทียบกับความแตกต่างด้านความสามารถระหว่างผู้ให้บริการ

ภาคยานยนต์และอุตสาหกรรมเป็นตัวขับเคลื่อนความต้องการ

การเข้าใจว่าอุตสาหกรรมต่างๆ ใช้ประโยชน์จากเทคโนโลยีการตัดด้วยเลเซอร์อย่างไร จะช่วยทำให้เห็นภาพชัดเจนว่าวิธีใดเหมาะสมกับสถานการณ์ของคุณ แอปพลิเคชันเหล่านี้ครอบคลุมตั้งแต่ชิ้นส่วนโครงสร้างขนาดใหญ่ไปจนถึงชิ้นส่วนประกอบที่ต้องการความแม่นยำสูง—แต่ละประเภทมีข้อกำหนดที่แตกต่างกัน ซึ่งส่งผลต่อการตัดสินใจว่าจะผลิตเองหรือจ้างผลิตภายนอก

ชิ้นส่วนแชสซีและระบบกันสะเทือนยานยนต์

ภาคยานยนต์ถือเป็นหนึ่งในผู้บริโภคเครื่องตัดเลเซอร์ความแม่นยำสูงรายใหญ่ที่สุด อุปกรณ์ยึดตัวถัง จุดยึดระบบกันสะเทือน และชิ้นส่วนเสริมโครงสร้าง ต้องการความทนทานตามเกณฑ์ที่เข้มงวดและคุณภาพที่สม่ำเสมอในชิ้นส่วนจำนวนหลายพันชิ้นที่เหมือนกัน งานดังกล่าวมักให้ความสำคัญกับพันธมิตรการผลิตมืออาชีพที่รวมการตัดด้วยเลเซอร์เข้ากับกระบวนการอื่นๆ เช่น การขึ้นรูปโดยใช้แรงกดและการขึ้นรูปแบบพิเศษ

สำหรับการใช้งานยานยนต์ที่ต้องการมาตรฐานคุณภาพตามการรับรอง IATF 16949 การร่วมมือกับผู้ผลิตที่มีความชำนาญมักเป็นทางเลือกที่เหมาะสมกว่าการพัฒนาศักยภาพภายในองค์กร บริษัทอย่าง Shaoyi (Ningbo) Metal Technology แสดงให้เห็นว่าพันธมิตรการผลิตมืออาชีพสามารถผสานการตัดด้วยเลเซอร์ เข้ากับการขึ้นรูปโลหะและการประกอบความแม่นยำได้อย่างไร เพื่อมอบโซลูชันชิ้นส่วนครบวงจร ตั้งแต่การผลิตต้นแบบอย่างรวดเร็วภายใน 5 วัน ไปจนถึงการผลิตจำนวนมากแบบอัตโนมัติ แนวทางแบบบูรณาการนี้ช่วยสนับสนุนการออกแบบเพื่อความสามารถในการผลิต (DFM) และการเสนอราคาอย่างรวดเร็ว ซึ่งยากที่จะทำซ้ำได้ด้วยอุปกรณ์ภายในองค์กรเพียงอย่างเดียว

ชิ้นส่วนโครงสร้างอากาศยาน:

ส่วนประกอบทางอากาศยานต้องการความแม่นยำสูงพิเศษและการตรวจสอบแหล่งที่มาของวัสดุได้อย่างละเอียด เกณฑ์การรับรองอันเข้มงวดของอุตสาหกรรม—เช่น AS9100, NADCAP และคุณสมบัติเฉพาะด้านวัสดุ—มักทำให้การจ้างผู้ให้บริการเฉพาะทางจากภายนอกเป็นทางเลือกที่เหมาะสมกว่าการพยายามดำเนินการรับรองภายในองค์กร ส่วนประกอบเหล่านี้โดยทั่วไปเกี่ยวข้องกับโลหะผสมพิเศษ เช่น ไทเทเนียม และอลูมิเนียมเกรดพิเศษ ซึ่งจะได้ประโยชน์จากการมีผู้ให้บริการที่มีความชำนาญลึกในด้านวัสดุ

แผงสถาปัตยกรรมและองค์ประกอบตกแต่ง

การใช้งานด้านสถาปัตยกรรมแสดงศักยภาพเชิงศิลปะของเครื่องตัดด้วยเลเซอร์ ไม่ว่าจะเป็นแผงผนังด้านนอกที่ซับซ้อน หน้าจอกั้นตกแต่ง และป้ายบอกทางแบบปรับแต่งพิเศษ ซึ่งรวมเอาความต้องการด้านความงามเข้ากับประสิทธิภาพเชิงโครงสร้าง โครงการเหล่านี้มักเกี่ยวข้องกับการออกแบบที่มีเพียงชิ้นเดียวหรือผลิตจำนวนจำกัด ทำให้การจ้างภายนอกเป็นทางเลือกที่เหมาะสมกว่า เพราะต้นทุนการตั้งค่าและระยะเวลาในการเรียนรู้ไม่คุ้มค่ากับการลงทุนอุปกรณ์สำหรับงานตกแต่งที่เกิดขึ้นเพียงบางครั้ง

ตัวเรือนเครื่องมือความแม่นยำ

อุปกรณ์ทางการแพทย์ เครื่องมือวิทยาศาสตร์ และกล่องอิเล็กทรอนิกส์ ต้องการค่าความคลาดเคลื่อนที่แคบที่สุดซึ่งสามารถทำได้ด้วยการตัดด้วยเลเซอร์ การใช้งานเหล่านี้มักต้องการกระบวนการรอง เช่น การขึ้นรูป การใส่อุปกรณ์ฮาร์ดแวร์ การตกแต่งผิว ซึ่งจะได้ประโยชน์จากการทำงานร่วมกับผู้ให้บริการครบวงจรที่มีความสามารถแบบบูรณาการ

แนวทางแบบผสมผสานควรได้รับการพิจารณาอย่างจริงจัง หลายองค์กรมีอุปกรณ์สำหรับงานหลักที่มีปริมาณสูง ขณะเดียวกันก็ยังคงรักษาความสัมพันธ์กับผู้ให้บริการภายนอกสำหรับงานที่เกินกำลังการผลิต วัสดุเฉพาะทาง หรือความสามารถที่เหนือกว่าระบบภายในองค์กร โมเดลนี้รวมข้อได้เปรียบด้านต้นทุนของการเป็นเจ้าของอุปกรณ์เข้ากับความยืดหยุ่นของการจ้างช่วง ทำให้สามารถปรับตัวตามความผันผวนของความต้องการได้ โดยไม่ต้องปฏิเสธงานหรือแบกภาระกำลังการผลิตที่เกินจำเป็น

ไม่ว่าคุณจะเลือกเส้นทางใด จงจำไว้ว่าการตัดสินใจเกี่ยวกับการตัดด้วยเลเซอร์ไม่ใช่ถาวร เริ่มต้นจากสถานการณ์ปัจจุบันของคุณ แล้วพัฒนาต่อไปตามการเติบโตของธุรกิจของคุณ ผู้ผลิตที่ประสบความสำเร็จคือผู้ที่ประเมินแนวทางของตนเองอย่างสม่ำเสมอ เพื่อให้แน่ใจว่ากลยุทธ์การผลิตของตนสอดคล้องกับความต้องการของตลาดที่เปลี่ยนแปลงและเทคโนโลยีที่ก้าวหน้า

คำถามที่พบบ่อยเกี่ยวกับการตัดแผ่นโลหะด้วยเลเซอร์

1. สามารถตัดแผ่นโลหะด้วยเครื่องตัดเลเซอร์ได้หรือไม่

ได้ เครื่องตัดเลเซอร์สามารถประมวลผลโลหะต่างๆ ได้อย่างมีประสิทธิภาพ รวมถึงเหล็ก สเตนเลส อลูมิเนียม ไทเทเนียม ทองเหลือง และทองแดง โดยมีความแม่นยำสูง เลเซอร์ไฟเบอร์รุ่นใหม่สามารถควบคุมค่าความคลาดเคลื่อนได้แคบถึง ±0.1 มม. บนวัสดุบาง ทำให้เหมาะสำหรับการใช้งานในอุตสาหกรรมยานยนต์ อากาศยาน และงานสถาปัตยกรรม สำหรับโลหะสะท้อนแสง เช่น อลูมิเนียมและทองแดง เลเซอร์ไฟเบอร์มีความจำเป็นเพราะสามารถจัดการวัสดุเหล่านี้ได้โดยไม่มีความเสี่ยงจากการสะท้อนย้อนกลับที่อาจทำลายระบบ CO2

2. การตัดโลหะด้วยเลเซอร์มีค่าใช้จ่ายเท่าใด

การตัดเหล็กด้วยเลเซอร์โดยทั่วไปมีค่าใช้จ่ายอยู่ที่ 13-20 ดอลลาร์ต่อชั่วโมงของเวลาเครื่องจักร อย่างไรก็ตาม ราคาจริงของคุณขึ้นอยู่กับประเภทและหนาของวัสดุ ความซับซ้อนของการตัดและระยะทางรวม ปริมาณ (ค่าใช้จ่ายในการตั้งค่าจะถูกกระจายไปยังคำสั่งซื้อขนาดใหญ่) และข้อกำหนดด้านคุณภาพของขอบ ชิ้นส่วนที่เรียบง่ายจะมีค่าใช้จ่ายต่ำกว่าการออกแบบที่ซับซ้อนมากจากแผ่นเดียวกัน ส่วนลดสำหรับปริมาณมากสามารถลดได้สูงถึง 70% สำหรับคำสั่งซื้อจำนวนมาก และการปรับแต่งออกแบบของคุณให้มีรูปทรงเรียบง่ายและใช้วัสดุบางลงจะช่วยลดต้นทุนได้อย่างมีประสิทธิภาพ

3. วัสดุใดบ้างที่ไม่สามารถตัดด้วยเครื่องตัดเลเซอร์ได้

เครื่องตัดเลเซอร์มาตรฐานไม่สามารถแปรรูปพีวีซี เลกซาน พอลิคาร์บอเนต และวัสดุสไตรีนบางชนิดได้อย่างปลอดภัย เนื่องจากการปล่อยก๊าซพิษ สำหรับโลหะ เลเซอร์ CO2 มีปัญหาในการตัดวัสดุที่สะท้อนแสงได้ดี เช่น อลูมิเนียม ทองแดง และทองเหลือง ซึ่งวัสดุเหล่านี้จำเป็นต้องใช้เทคโนโลยีเลเซอร์ไฟเบอร์ นอกจากนี้ โลหะเคลือบบางชนิดและคอมโพสิตจะปล่อยก๊าซอันตรายเมื่อระเหย จึงจำเป็นต้องตรวจสอบวัสดุก่อนตัดและต้องมีระบบระบายอากาศที่เหมาะสม

4. ต่างกันอย่างไรระหว่างเลเซอร์ไฟเบอร์กับเลเซอร์ CO2 สำหรับการตัดโลหะ

เลเซอร์ไฟเบอร์ทำงานที่ความยาวคลื่น 1.064 ไมโครเมตร โดยมีประสิทธิภาพพลังงาน 35% เหมาะอย่างยิ่งสำหรับการตัดโลหะที่สะท้อนแสง และต้องการการบำรุงรักษาน้อยมาก พร้อมอายุการใช้งานสูงสุดถึง 100,000 ชั่วโมง เลเซอร์ CO2 ใช้ความยาวคลื่น 10.6 ไมโครเมตร มีประสิทธิภาพ 10-20% และไม่สามารถตัดโลหะที่สะท้อนแสงได้อย่างปลอดภัย เลเซอร์ไฟเบอร์ใช้พลังงานประมาณหนึ่งในสามของระบบ CO2 สำหรับงานเดียวกัน และสามารถตัดวัสดุบางได้เร็วกว่าถึง 3 เท่า ทำให้เป็นทางเลือกที่ดีกว่าสำหรับงานผลิตโลหะโดยเฉพาะ

5. ฉันควรซื้อเครื่องตัดด้วยเลเซอร์ หรือจ้างบริการจากผู้เชี่ยวชาญด้านนอก

เลือกใช้อุปกรณ์ภายในองค์กรสำหรับความต้องการที่มีปริมาณสูงและคงที่ งานออกแบบเฉพาะที่ต้องการความลับ และความต้องการในการทำต้นแบบอย่างรวดเร็ว ให้จ้างภายนอกเมื่อความต้องการผันแปร คุณต้องการความสามารถด้านวัสดุที่หลากหลาย หรือต้องการรักษาเงินทุนไว้ หลายองค์กรมีการดำเนินงานที่ประสบความสำเร็จโดยใช้โมเดลแบบผสมผสาน—การเป็นเจ้าของอุปกรณ์สำหรับงานหลัก พร้อมทั้งร่วมมือกับผู้ผลิตที่ได้รับการรับรอง IATF 16949 เช่น Shaoyi สำหรับชิ้นส่วนยานยนต์เฉพาะทางที่ต้องการกระบวนการขึ้นรูปและตัดแต่งแบบบูรณาการ

ผลิตจำนวนน้อย แต่มีมาตรฐานสูง บริการสร้างต้นแบบอย่างรวดเร็วของเรามาพร้อมกับการตรวจสอบที่เร็วขึ้นและง่ายขึ้น —

ผลิตจำนวนน้อย แต่มีมาตรฐานสูง บริการสร้างต้นแบบอย่างรวดเร็วของเรามาพร้อมกับการตรวจสอบที่เร็วขึ้นและง่ายขึ้น —