Nyckelfaktorer vid kostnadsskattning av bilindustrins stansverktyg

TL;DR

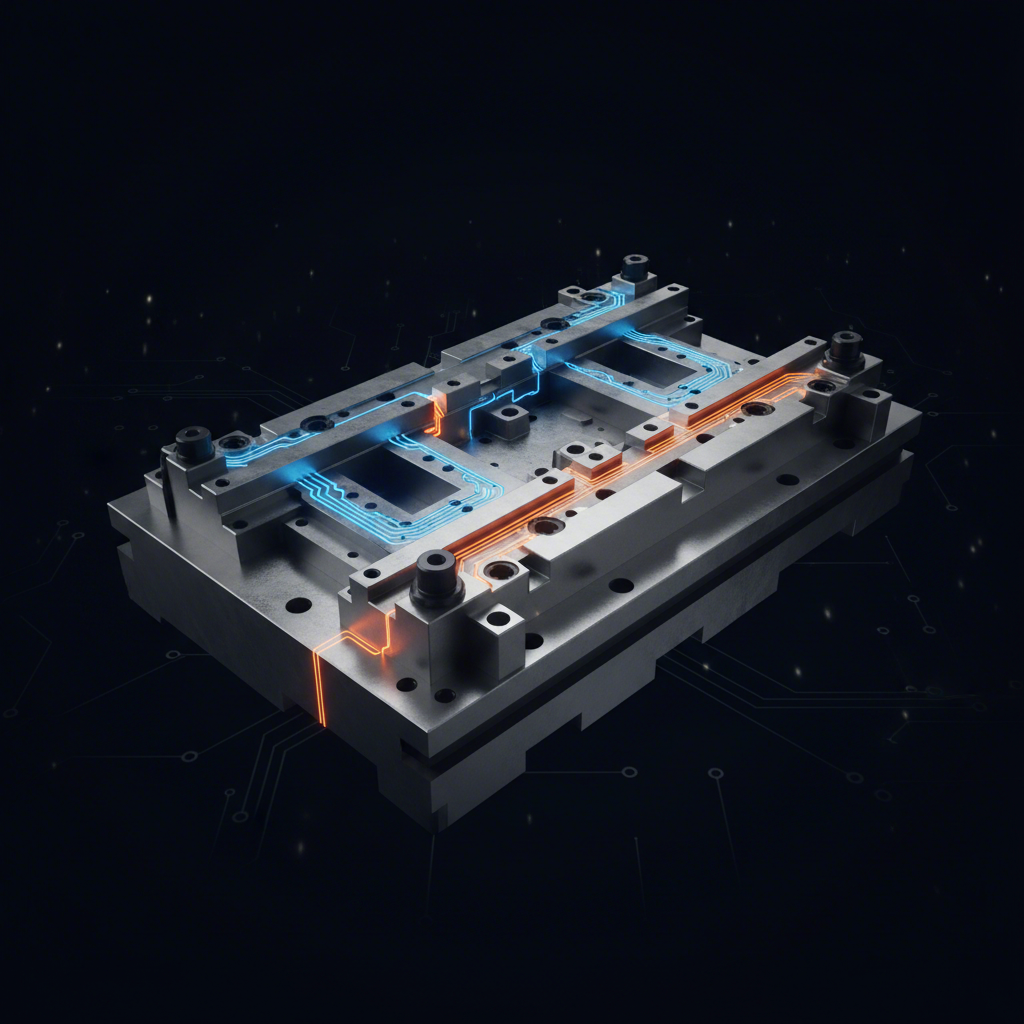

Kostnadsestimeringen för bilstansverktyg varierar kraftigt, från flera tusen dollar för enkla verktyg till över en miljon för komplexa flerstegsverktygsrader. Slutgiltiga priset är inte godtyckligt; det är en beräknad siffra baserad på flera nyckelfaktorer. De viktigaste faktorerna som påverkar kostnaden är delens komplexitet, typ och tjocklek på den formade metallen, den krävda produktionsvolymen samt typen av verktyg, till exempel ett envägsverktyg eller ett mer komplext progressivt verktyg.

Nyckelfaktorer som påverkar stansverktygskostnader

Förståelsen av slutpriset för en bilstansform börjar med en detaljerad analys av de variabler som formar dess design, materialsammansättning och tillverkningsprocess. Dessa faktorer är sammanlänkade, och en förändring i en kan få en kaskadeffekt på de andra, vilket i slutändan påverkar den totala investeringen. För inköpschefer och ingenjörer är en god förståelse av dessa element avgörande för korrekt budgetering och effektiva leverantörsförhandlingar.

Delens komplexitet och design: Detta är förmodligen den mest betydande kostnadsdrivaren. En enkel, platt del som kräver en enda blankningsoperation behöver en relativt billig verktygsform. I motsats till detta kräver en komplex fordonskomponent, som en kroppspanel med djupa dragningar, invecklade konturer och flera genomslag, en sofistikerad progressiv form. Progressiva former utför flera operationer vid olika stationer medan en metallremsa matas igenom. Enligt vissa branschuppskattningar kan varje ytterligare station i en progressiv form öka den totala kostnaden med 8–12 %. Konstruktionsdetaljer som hårda hörn eller strama toleranser kräver också mer robusta och exakt slipade verktyg, vilket ytterligare höjer priset.

Materialtyp och tjocklek: Materialet i det slutgiltiga delen styr vilket material som krävs för själva verktyget. Att stansa standardkallvalsat stål är mindre krävande än att forma höghållfast, lättviktigt aluminium eller avancerade höghållfasta stål (AHSS). Dessa tuffare material orsakar mer slitage och kräver att verktyget konstrueras av hårdare, dyrare verktygsstål. Dessutom kräver tjockare material en mer robust verktygsstruktur och en press med högre tonnage, vilket båda bidrar till högre verktygskostnader.

Produktionsvolym och verktygslivslängd: Den beräknade produktionsvolymen påverkar direkt verktygets design och materialval. För en liten serieproduktion med några tusen delar kan ett mindre slitstarkt, lägrekostnadigt verktyg (så kallat mjukt verktyg) räcka. För massproduktion med hundratusentals eller miljontals delar måste dock verktyget tillverkas av högkvalitativt, slitstarkt verktygsstål som tål långvarig användning utan att försämras. Även om detta ökar den initiala investeringen sänker det kostnaden per del på lång sikt och minimerar driftstopp för underhåll och reparationer.

| Fabrik | Lågkostnadsscenariot (t.ex. enkel fästeplåt) | Högkostnadsscenariot (t.ex. komplex karossdel) |

|---|---|---|

| Komplexitet hos delen | Enkel geometri, få detaljer, envärkesverktyg. | Komplexa konturer, flera hål/böjningar, progressivt verktyg. |

| Material | Standardmässig, tunnväggig läggstål. | Hållfast stål eller tjockväggigt aluminium. |

| Produktionsvolym | Låg volym (under 10 000 delar); mjukverktyg acceptabelt. | Hög volym (över 100 000 delar); kräver härdat verktygsstål. |

| Toleranser | Standardmässiga, generösa toleranser. | Extremt strama, exakta toleranser som kräver avancerad bearbetning. |

För att få en korrekt offert är det avgörande att tillhandahålla potentiella leverantörer med ett omfattande informationspaket. Detta bör inkludera detaljerade CAD-modeller av delen, specifikationer om materialtyp och tjocklek, erforderlig årlig produktionsvolym samt eventuella specifika krav på ytbehandling eller kvalitetskontroll. Ju mer detaljerad informationen är, desto mer exakt blir kostnadsestimeringen.

Vanliga metoder för kostnadsestimering av verktyg

Inom bilindustrins stansbransch är kostnadsestimering av ett nytt verktyg en kritisk uppgift som balanserar precision med hastighet. Företag förlitar sig i allmänhet på två huvudsakliga metodiker: erfarenhetsbaserad 'liknelsemetod' och datadriven 'analytisk metod', som ofta drivs av specialiserad programvara. Valet av metod kan avsevärt påverka offertens noggrannhet och projektets ekonomiska resultat.

Metoden med liknelse, som namnet antyder, innebär att man jämför en ny del med liknande projekt som slutförts tidigare. En erfaren beräknare använder historiska kostnadsuppgifter från ett jämförbart verktyg som baslinje och justerar dem utifrån uppfattade skillnader i storlek, komplexitet eller material. Denna metod är snabb och bygger på värdefull expertintuition. Den har dock betydande nackdelar. En artikel från FormingWorld påpekar att denna metod kan vara mycket onoggrann om subtila men kritiska skillnader mellan den gamla och nya delen inte upptäcks, vilket potentiellt kan leda till stora kostnadsöverskridningar eller förlorade anbud. Faktum är att deras forskning visade att en stor andel verktygstillverkare är kraftigt beroende av denna mindre exakta metod.

Den analytiska eller programbaserade metoden är en mer systematisk ansats. Den innebär att man delar upp verktyget i dess grundkomponenter och beräknar kostnaderna för varje element, inklusive råmaterial, maskintid, arbetstid och värmebehandling. Modern CAD/CAE-programvara automatiserar och förfinar denna process, vilket möjliggör mycket detaljerade och noggranna kostnadsuppdelningar baserat på delens digitala modell. Denna metod minimerar gissningar och ger en transparent, datadriven kostnadsuppskattning. Till exempel kan en komplex verktygsdesign i CAD kräva 40–80 timmars arbete till en sats på 50–100 USD per timme, en kostnad som ett analytiskt system kan beräkna exakt.

Fördelar och nackdelar med uppskattningsmetoder

Likhetmetoden

- Fördelar: Snabb, kräver mindre förhandsanalys, utnyttjar värdefull expertkunskap.

- Nackdelar: Höggradigt subjektiv, benägen att vara felaktig, riskfylld för nya eller mycket komplexa delar, svår att motivera eller granska.

Analytisk/Programvarumetod

- Fördelar: Mycket noggrann och objektiv, ger en detaljerad kostnadsuppdelning, minskar ekonomisk risk, konsekvent mellan olika beräkningar.

- Nackdelar: Mer tidskrävande, kräver specialiserad programvara och skickliga operatörer, kan vara överkomplex för mycket enkla verktyg.

När du utvärderar offerter är det klokt att fråga potentiella leverantörer om deras uppskattningsmetodik. En leverantör som förlitar sig på en robust, analytisk process är mer benägen att erbjuda ett tillförlitligt och konkurrenskraftigt pris, vilket minskar risken för oväntade kostnadshöjningar under projektets gång.

Beprövade strategier för att minska kostnader för stansverktyg

Medan kostnaden för bilstansverktyg kan vara betydande är den inte oföränderlig. Strategiska beslut som tas under faserna för delkonstruktion och leverantörsval kan leda till betydande besparingar utan att kompromissa med kvaliteten. Genom att fokusera på konstruktionsprinciper för tillverkbarhet (DFM) kan tillverkare proaktivt minska verktygets komplexitet och kostnad.

En av de mest effektiva strategierna är att optimera delens design själv. Förenkling av geometrin kan ha en överdimensionerad påverkan på kostnaden. Till exempel kan det att utforma delar med generösa böjradier och undvika djupa, smala kanaler eliminera behovet av extra stationer i en progressiv stansverktyg eller komplexa liftere och kammar. Genom att samarbeta med sin stansningspartner redan i designprocessens tidiga skede kan man låta deras expertis vägleda dessa modifieringar, vilket säkerställer att delen är optimerad för effektiv produktion. Ett annat nyckelområde är att förenkla verktygskraven. Som nämnts i en detaljerad guide av Fecision , kan användning av standardiserade, färdigfabrikerade stanskomponenter istället för specialtillverkade reducera den totala verktygskostnaden med upp till 15–25%.

Materialeffektivitet är en annan avgörande faktor för kostnadsminskning. Genom att förbättra komponentlayouten på metallbandet, en metod som kallas 'tät packning', minimeras mängden skräpmat som uppstår vid varje stansning. Avancerad programvara kan simulera olika layouter för att hitta den mest effektiva placeringen, vilket potentiellt kan minska materialkostnaderna med 5–7 %. Det kanske verkar lite, men vid storserieproduktion blir besparingen betydande. Nedanstående checklista kan hjälpa ingenjörer och konstruktörer att identifiera kostnadsbesparingar innan en design är färdigställd:

- Engagera tidiga leverantörssamarbeten: Diskutera DFM-principer med din stansningsleverantör innan designen är fastlagd.

- Förenkla delgeometrin: Kan skarpa hörn avrundas? Kan flera delar slås ihop till en? Är alla funktioner nödvändiga?

- Ange standardkomponenter: Begär användning av standardverktyg, fjädrar och fästelement där det är möjligt.

- Optimera materialval: Välj det mest kostnadseffektiva material som uppfyller alla prestandakrav. Undvik överdimensionering.

- Planera för effektiv utplacering: Ta hänsyn till hur delens orientering på spolen påverkar materialutnyttjande och spillnivå.

Det är viktigt att analysera de kompromisser som är involverade. Till exempel kan en designändring som förenklar verktygstillverkningen något förändra delens estetik eller kräva en liten ändring i en relaterad komponent. Genom att dock ta hänsyn till den totala tillverkningskostnaden ger ofta dessa små kompromisser betydande ekonomiska fördelar under produktens livstid.

Utöver den initiala offerten: Dolda kostnader och långsiktiga överväganden

Ett vanligt misstag i inköp är att välja leverantör enbart baserat på lägsta initiala pris för stansverktyget. Detta pris utgör ofta bara en bråkdel av den totala ägandekostnaden (TCO). En omfattande kostnadsuppskattning måste ta hänsyn till pågående kostnader, underhåll samt det strategiska värdet med en kompetent tillverkningspartner.

Den mest betydande långsiktiga kostnaden är verktygsmarin underhåll. Stansverktyg är högslitageartiklar som kräver regelbunden service för att upprätthålla delkvaliteten. Detta inkluderar slipning av skärkanter, utbyte av slitna komponenter och rengöring. Enligt Fecision kan verktyg behöva slipsas igen efter 50 000 till 200 000 slag, och de årliga underhållskostnaderna kan ligga på cirka 5–10 % av verktygets ursprungliga inköpspris. Ett billigare, lägre kvalitetsverktyg kommer troligen att kräva mer frekventa och omfattande underhållsinsatser, vilket leder till högre kostnader och ökad maskinplåt under dess livslängd.

Andra kostnader att ta i beaktning inkluderar engångsinkomster (NRE) för initial design och prototypframställning, samt kostnader för frakt och provkörningar. När man väljer en leverantör är det avgörande att se bortom prislappen och utvärdera deras kompetens. Som en artikel från Tillverkaren poängterar att en leverantörs plats, teknisk expertis och interna kapaciteter är avgörande. Ett välutrustat företag kan ofta erbjuda en helhetslösning som inkluderar konstruktion, tillverkning, provkörningar och en tydlig underhållsschema, vilket förhindrar oväntade kostnader i framtiden. Till exempel erbjuder branschledare inom specialverktyg, såsom Shaoyi (Ningbo) Metal Technology Co., Ltd. , omfattande tjänster från CAE-simulering och prototypframställning till massproduktion, vilket säkerställer att långsiktig prestanda och underhåll beaktas redan i den ursprungliga konstruktionen. Att välja en partner med beprövad projekthantering och tekniska certifieringar som IATF 16949 kan avsevärt minska långsiktiga risker och kostnader.

För att säkerställa att du gör en hållbar långsiktig investering bör du ställa följande frågor till potentiella leverantörer:

- Inkluderar er offert konstruktion, prototypframställning och initiala provtillverkningar?

- Vad är den förväntade livslängden för verktyget i termer av slag?

- Vilket underhållsschema rekommenderar ni, och vad är de uppskattade årliga kostnaderna?

- Vilka slitagekomponenter är standard och vilka är anpassade?

- Vad kan ni erbjuda internt när det gäller reparationer och modifieringar?

Vanliga frågor

1. Hur mycket kostar verktyg för plåtformning?

Kostnaden varierar kraftigt beroende på flera faktorer. Ett enkelt verktyg för en enskild operation vid låg volym kan kosta mellan 5 000 och 15 000 USD. I motsats till detta kan ett komplext flerstationsseriedö för en högvolymskomponent för bilindustrin lätt överstiga 100 000 USD, med fullständiga dölinjer för större komponenter som kan kosta hundratusentals dollar.

2. Vad är formeln för kostnadsuppskattning?

Det finns ingen enda universell formel för kalkylering av verktygskostnader för stansning på grund av det stora antalet variabler. Analytiska metoder använder dock en formelbaserad metod som delar upp den totala kostnaden i dess komponenter: Total kostnad = Totala fasta kostnader (t.ex. design, installation) + (Rörlig kostnad per enhet × Antal enheter). Specialiserad programvara använder denna princip för att beräkna kostnader baserat på materialvolym, maskintid, arbetskraft och andra specifika indata från en CAD-modell.

3. Vad är skillnaden mellan die cutting och stansning?

Även om båda processerna formar metall är de skilda från varandra. Metallstansning är en bredare term som inkluderar böjning, formskapning, dragning och perforering av metall, nästan alltid som en kallbearbetningsprocess med rullar eller platser av plåt. Verktygsskärning däremot är främst en skärprocess som används för att skära plåt eller andra material till en specifik form med hjälp av ett verktyg. Stansning kan inkludera skärning, men innefattar även formskapning och formning av metallen, medan verktygsskärning fokuserar på att skära ut delens omkrets.

Lilla partier, höga standarder. Vår snabba prototypservice gör validering snabbare och enklare —

Lilla partier, höga standarder. Vår snabba prototypservice gör validering snabbare och enklare —