Metal Die Press Secrets: From Tonnage Math To Flawless Parts

What Is a Metal Die Press and How Does It Work

Ever wondered how manufacturers transform flat metal sheets into complex automotive body panels or smartphone housings? The answer lies in a powerful piece of equipment that forms the backbone of modern metalworking: the metal die press.

A metal die press is a machine that uses shaped tooling (dies) to cut, form, or shape metal sheets under controlled pressure, utilizing the plastic deformation properties of metal to create precise, repeatable parts.

When you think about it, this process is remarkably elegant. A die press machine applies tremendous force to sandwich metal between specially designed tools, permanently reshaping the material into everything from simple brackets to intricate electronic enclosures. Once the force is removed, the metal retains its new shape - a property manufacturers have leveraged for decades to produce millions of identical parts.

The Core Mechanism Behind Metal Forming

So what is a die cutting machine actually doing when it operates? The fundamental principle involves plastic deformation - the characteristic of metals that allows them to be permanently reshaped without breaking. Unlike elastic materials that spring back, metals hold their new form after the press and die complete their work.

Here's where terminology often causes confusion. While people sometimes use "metal die press" and "stamping press" interchangeably, there's an important distinction. A die press specifically refers to equipment using custom-shaped dies tailored to produce particular parts. General stamping presses, on the other hand, may use standardized tooling for simpler operations. Think of it this way: every metal die press performs stamping, but the die for press operations is what makes each machine specialized for specific components.

From Raw Sheet to Precision Part

Imagine a flat sheet of steel entering the press die system. Within seconds, it emerges as a precisely formed component - perhaps a bracket, a panel, or a decorative trim piece. This transformation happens through several possible operations:

- Cutting and blanking - punching shapes from sheet metal

- Bending - creating angles and curves

- Drawing - forming three-dimensional shapes like cups or containers

- Embossing - adding raised designs or patterns

The applications are everywhere around you. Automotive manufacturers rely on these machines for body panels and structural components. Electronics companies use them for device housings and heat sinks. Even your kitchen appliances contain parts shaped by a die press. According to industry experts, pressing is used across automobiles, electronics, furniture, and home appliances because of its ability to flexibly process metals.

What makes this technology so valuable? Speed and consistency. Once you've created the tooling, a press die can produce thousands of identical parts with remarkable efficiency. This combination of precision, repeatability, and production speed is exactly why metal die presses remain essential equipment in manufacturing facilities worldwide.

Essential Components of a Metal Die Press System

Now that you understand what a metal die press does, let's pop the hood and examine what's actually inside. Knowing these components helps you evaluate equipment, troubleshoot problems, and communicate effectively with tooling suppliers. Think of this as your anatomy lesson for die machines - once you understand how each part functions, the entire system makes much more sense.

Understanding Die Sets and Their Function

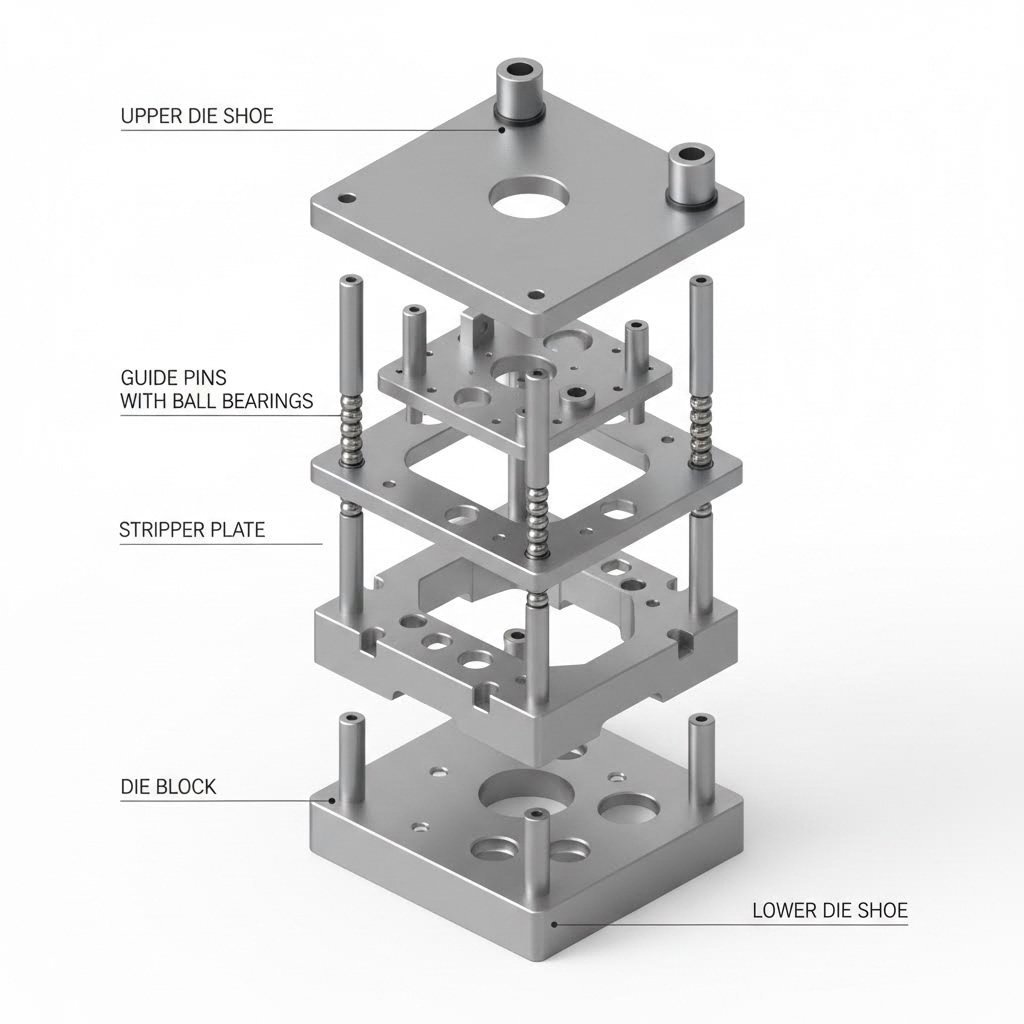

The die set is the heart of every metal die press operation. According to engineering references, a die set consists of a lower shoe (die shoe) and an upper shoe, both machined to be parallel within a few thousandths of an inch. These precision surfaces provide the foundation where all other tooling components are mounted.

Here's what happens during operation: the upper shoe attaches to the press ram (the moving part), while the lower shoe bolts to the stationary press bed. When the ram descends, it brings the punch - the male portion of the tooling - down into the die block, which contains the female cutting or forming surfaces. The metal sheet caught between them gets permanently shaped.

The following components work together to make this happen:

- Die shoes - Steel or aluminum plates that serve as the foundation for mounting all other die components. They must maintain precise parallelism to ensure consistent part quality.

- Die block - A hardened tool steel block attached to the lower shoe containing die buttons, nests, and openings that define the part shape.

- Punch plate - Mounted to the upper shoe, this hardened steel plate holds all punches, pilots, and spring components.

- Die punches - The cutting or forming tools that press into the metal. Available in various nose shapes including round, oblong, square, and custom configurations.

- Die buttons - The counterparts to punches, providing the opposite cutting edge. They typically offset larger than the punch by 5-10% of material thickness to create proper die clearance.

- Strippers - Components that remove the metal sheet from the punch after each stroke. Can be stationary (mounted to the die block) or spring-loaded (attached to the punch plate).

- Back-up plates - Positioned between die blocks and die shoes to prevent punches and dies from becoming embedded in the softer shoe material.

The Role of Die Shoes and Guide Systems

Precision alignment between upper and lower die halves is absolutely critical. Even microscopic misalignment causes uneven wear, burrs on finished parts, and premature tooling failure. This is where guide pins and bushings earn their keep.

Guide pins - also called guide posts - are precision-ground steel pins firmly embedded in the lower shoe. They're manufactured to tolerances within 0.0001 inches (one ten-thousandth of an inch) to ensure exact positioning every single stroke. The upper shoe contains matching bushings into which these pins slide.

You'll encounter two main types of guide systems in press die set configurations:

- Ball-bearing guide pins - These glide on a sequence of ball bearings within an aluminum cage, making die halves easier to separate and reducing friction during high-speed operations. They've become the industry standard for most applications.

- Friction (plain) guide pins - Slightly smaller than their bushing's inner diameter, these provide accurate guidance but require more effort to separate. Still valuable where maximum rigidity is needed.

When selecting die sets for press applications, you'll also choose between open die sets and pillar die sets. Open sets lack guide posts entirely - they're inexpensive but require careful setup and work best for simple parts with loose tolerances. Pillar sets include two or four guide posts, with four-post configurations offering maximum accuracy for heavy gauge materials or large dies.

Key Terminology You Need to Know

When evaluating machine dies or discussing specifications with suppliers, you'll encounter several critical terms:

- Stroke - The distance the press ram travels from its highest to lowest position. Longer strokes accommodate taller dies but may reduce production speed.

- Tonnage - The maximum force the press can apply, measured in tons. This determines what materials and thicknesses you can work with.

- Die clearance - The gap between punch and die button, typically 5-10% of material thickness. Too little clearance causes excessive tool wear; too much creates burrs and rough edges.

- Shut height - The distance between outer surfaces of upper and lower die shoes when the die is fully closed. This must match your press specifications.

Understanding these fundamentals transforms how you approach equipment selection. Rather than feeling overwhelmed by technical specifications, you can now evaluate whether specific die sets match your production requirements - a foundation that becomes essential when calculating tonnage needs for your applications.

Types of Metal Die Presses and Their Applications

With the components covered, here's the next logical question: what actually drives all that force? The answer determines everything from production speed to part quality. Metal die presses fall into three major categories based on their drive mechanism, and choosing the right one can make or break your manufacturing efficiency.

Mechanical vs Hydraulic Press Systems

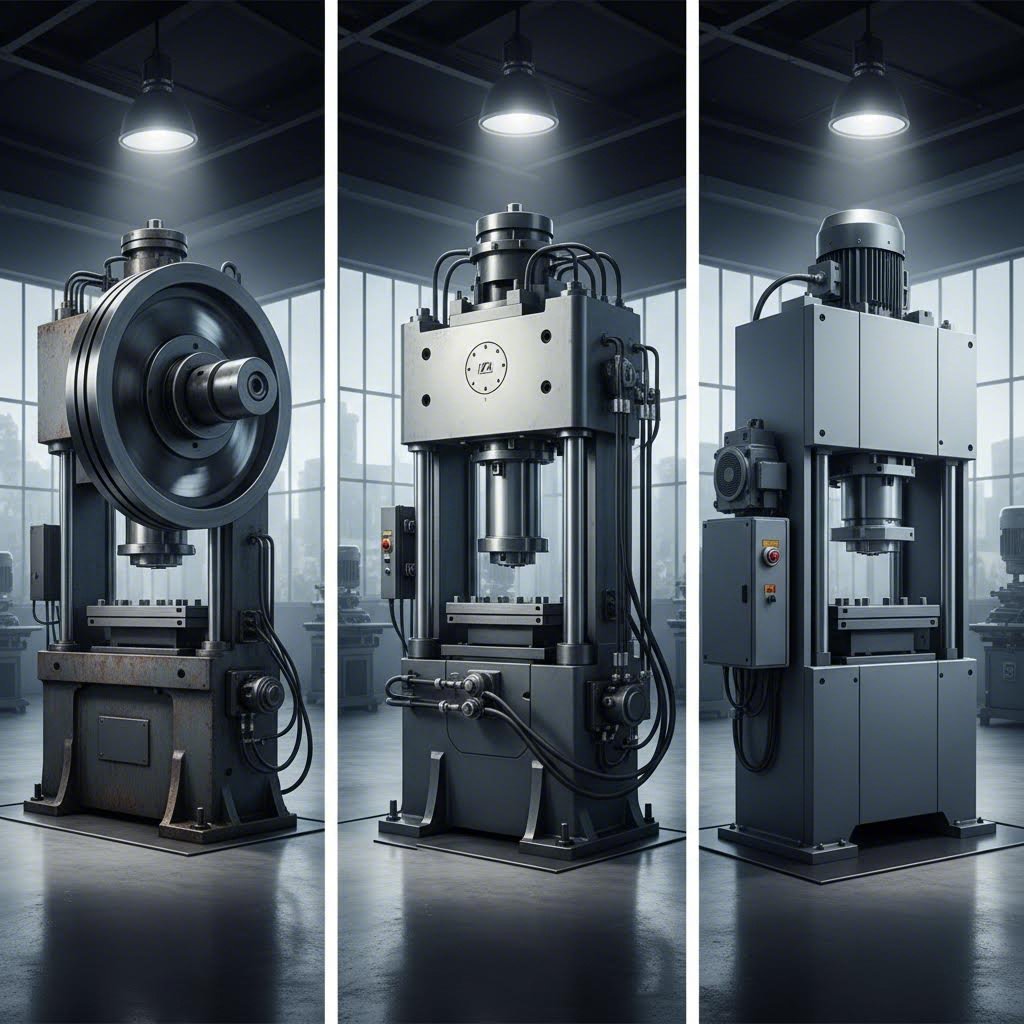

Mechanical presses have dominated manufacturing floors for decades - and for good reason. These machines use a flywheel and crankshaft system to generate force. The flywheel stores rotational energy, which transfers through the crankshaft to drive the ram downward. According to Stamtec's technical comparison, traditional mechanical presses achieve the greatest production speeds, especially when running relatively flat parts with simpler, shallower forming requirements.

What makes mechanical systems so fast? Simplicity. The energy is already stored in the spinning flywheel, ready to release instantly. Die cutting machines using mechanical drives can cycle hundreds of times per minute for high-volume stamping operations. Automotive, appliance, and hardware manufacturers rely heavily on this technology for progressive die operations where speed matters most.

Hydraulic presses take a completely different approach. Instead of stored mechanical energy, they use fluid pressure - typically oil pumped into a cylinder - to move the ram. This design offers something mechanical presses cannot: full tonnage anywhere in the stroke. A hydraulic press die set can apply maximum force whether the ram is at the top, middle, or bottom of its travel.

This flexibility makes hydraulic press dies the preferred choice for deep drawing operations. When forming tanks, cylinders, bowl shapes, or any part requiring significant material flow, the ability to apply consistent pressure throughout the stroke prevents tearing and produces cleaner results. Hydraulic press tooling also excels when operations require a "dwell" - holding pressure at the bottom of the stroke for a period of time.

The tradeoff? Speed. Hydraulic systems simply cannot match the cycling rates of mechanical presses. They're also generally less precise and repeatable, as noted in industry comparisons. However, for complex forming where accuracy matters more than volume, hydraulic systems deliver results that mechanical presses struggle to match.

When Servo Technology Makes Sense

What if you could combine mechanical speed with hydraulic flexibility? That's exactly what servo-driven presses accomplish. These machines replace the traditional flywheel, clutch, and brake with high-capacity servo motors that provide full working energy at any speed - even while dwelling.

The difference is transformative. According to Stamtec's engineering team, servo presses can vary speed throughout the entire stroke - moving quickly through the non-working portion and slowing to optimum forming speeds when engaging the material. This capability has allowed some manufacturers to double their production output.

An industrial die cutting machine with servo technology offers programmable stroke profiles including:

- Deep drawing cycles - Slower forming speeds with full energy

- Multi-pass operations - Multiple forming actions per cycle

- Pendulum mode - Variable stroke lengths (using only 2, 4, or 6 inches of an 8-inch full stroke)

- Simulated link motion - Replicating specialized mechanical press characteristics

The industrial die cut machine powered by servo technology particularly shines in consolidation scenarios. A servo press can often perform more drawing and forming in one station than a traditional mechanical press accomplishes in multiple stations. This means fewer presses, smaller die beds, and reduced floor space requirements.

Of course, servo presses carry higher initial costs. The motors, controls, and programming capabilities represent significant investments. They remain mechanical presses at heart, achieving greatest tonnage capacity near the bottom of the stroke. For applications requiring full tonnage throughout the entire stroke, hydraulic press die configurations still hold advantages.

| Factor | Mechanical Press | Hydraulic Press | Servo Press |

|---|---|---|---|

| Speed Capability | Highest - ideal for high-volume production | Slowest - suited for complex forming | High - approaches mechanical speeds with flexibility |

| Tonnage Availability | Full capacity near bottom of stroke only | Full capacity at any point in stroke | Full capacity near bottom of stroke |

| Precision Level | High accuracy and repeatability | Lower accuracy and repeatability | High accuracy with programmable control |

| Energy Efficiency | Efficient - uses stored flywheel energy | Higher consumption at full capacity | Efficient - full energy at any speed |

| Stroke Flexibility | Fixed stroke length (typically) | Variable stroke length | Fully programmable stroke profiles |

| Initial Cost | Relatively low | Relatively low | Relatively high |

| Best Applications | Progressive dies, blanking, simple forming | Deep drawing, complex forms, dwell operations | Difficult forming, consolidation, variable production |

Selecting between these technologies depends entirely on your production requirements. Running flat automotive stampings at maximum volume? Mechanical presses remain the gold standard. Forming deep cylindrical parts that need careful material flow? Hydraulic press dies deliver the control you need. Want versatility to handle varying part types with excellent speed? Servo technology justifies its higher investment.

Understanding these drive mechanisms puts you in a stronger position when calculating the tonnage requirements and material compatibility for your specific applications - the critical calculations that ultimately determine which press size your operation needs.

Tonnage Calculation and Material Compatibility

You've seen the equipment types. Now comes the question that separates successful operations from costly mistakes: how much force does your application actually require? Getting this calculation wrong creates serious problems. Run a part in an undersized press, and you'll face equipment fatigue, damage, and significant downtime. Force production into an oversized press, and you'll watch efficiency plummet while costs climb. Let's break down the math so you can size your sheet metal die press correctly from the start.

Calculating Your Tonnage Requirements

The fundamental tonnage calculation involves three key variables: the length of cut (perimeter), material thickness, and the material's shear resistance. For punching and trimming operations, the formula looks like this:

Tonnage = Perimeter (mm) × Thickness (mm) × Shear Resistance (kgf/mm²) × Safety Factor (1.1-1.2) ÷ 1000

Sounds straightforward? Here's where it gets interesting. According to the Auto/Steel Partnership's research, old-school rules of thumb that worked decades ago now frequently under-predict tonnage requirements - especially with today's Advanced High-Strength Steels (AHSS). These newer materials offer double the strength of traditional high-strength steels with similar formability, which magnifies any calculation errors.

Consider a practical example from Keyence's machining formulas: piercing SUS304 stainless steel with a 100mm cut perimeter, 3mm thickness, and 53 kgf/mm² shear resistance requires approximately 17.49 tons - assuming a 1.1 safety factor. Change that material to mild steel at 35 kgf/mm², and your requirement drops to roughly 11.5 tons. The material choice dramatically shifts your press dies selection.

The following factors directly affect your tonnage calculation:

- Cut perimeter - The total length of line being trimmed, pierced, or blanked. More complex shapes with longer perimeters demand higher tonnage.

- Material thickness - Thicker stock requires proportionally more force. However, actual cutting involves only 20-50% penetration before breakage occurs, meaning full thickness isn't always engaged.

- Shear resistance - Typically estimated at 60% of tensile strength, though this varies by material microstructure. AHSS grades particularly challenge this assumption.

- Die clearance - Tighter clearances increase friction and force requirements. Your metal die set design directly impacts tonnage needs.

- Cutting method - Shear angles on punches reduce instantaneous force by spreading the cut across the stroke.

- Lubrication - Proper lubrication reduces friction between material cutting dies and workpiece, lowering force requirements.

For bending operations, the calculation shifts. You'll need to factor in bend length, V-die width, material thickness, and tensile strength. A correction coefficient based on the V-width to thickness ratio also applies. Forming and drawing operations become even more complex, requiring consideration of surface area, material flow, and spring-back characteristics.

Material Thickness and Press Capacity

Different metals behave very differently under pressure, and your press dies must accommodate these variations. Here's what you need to know about common materials:

Mild steel remains the most forgiving option for die cutting metal operations. With tensile strengths around 44 kgf/mm² (roughly 430 MPa), it forms predictably and tolerates wider die clearance ranges. Most standard tonnage calculations were developed using mild steel as the baseline.

Stainless steel demands significantly more force - about 20% higher than mild steel for comparable thicknesses. SUS304, for instance, runs 53 kgf/mm² tensile strength. The material also work-hardens during forming, meaning progressive operations may see increasing resistance through each station.

Aluminum presents the opposite challenge. Lower tensile strength (around 10-30 kgf/mm² depending on alloy) means less tonnage is needed, but the material's softness demands tighter die clearances to prevent excessive burring. Your sheet metal die designs need adjustment for aluminum's tendency to gall against tooling surfaces.

Copper and brass fall somewhere in between, with moderate strength and excellent formability. These materials are often selected for electrical components where conductivity matters more than structural strength.

Advanced High-Strength Steels represent the biggest calculation challenge. With tensile strengths reaching 1500 MPa or higher - three to five times mild steel - these materials magnify every estimation error. The Auto/Steel Partnership research documents cases where seemingly small parts requiring modest tonnage actually needed presses twice as large to deliver sufficient energy.

Why Press Sizing Mistakes Are Costly

Undersizing your press creates immediate problems. When peak loads exceed capacity, you risk damaging the frame, ram, bushings, and drive components. Even if damage doesn't occur immediately, running consistently near maximum capacity accelerates wear and leads to premature failures.

But here's what many overlook: tonnage isn't the only consideration. Total energy through the stroke matters equally. A mechanical press might have adequate peak tonnage at bottom dead center, yet stall because its flywheel couldn't store enough energy to complete the forming operation. This happens more frequently with AHSS materials that require sustained force through significant ram travel.

Oversizing creates different problems. That frame bracket example from industry research - a small 6" × 6" AHSS part that theoretically fit a 600-ton press - actually required a 1200-ton press for adequate energy. Running a small die in the center of a 180-inch press bed created ergonomic challenges for operators, slower cycle times, and significantly higher burden rates.

The solution? Move beyond simple rules of thumb. Today's best practice combines finite element analysis (FEA) simulation with accurate material characterization. Software can predict not just peak loads, but force curves through the entire stroke and off-center load distribution. This data helps you select press dies and equipment that match your actual requirements rather than worst-case estimates.

With tonnage requirements understood, the next critical factor is die design itself - particularly how clearances, forming strategies, and tooling choices affect the quality of your finished parts.

Die Design Fundamentals for Quality Results

You've calculated your tonnage requirements and selected your press type. Now comes the factor that ultimately determines whether you produce flawless parts or frustrating rejects: die design. The tooling die you use - its geometry, clearances, and construction - directly controls edge quality, dimensional accuracy, and how long your equipment runs before needing maintenance. Let's examine what separates precision tooling dies from problematic ones.

Die Clearance and Its Impact on Part Quality

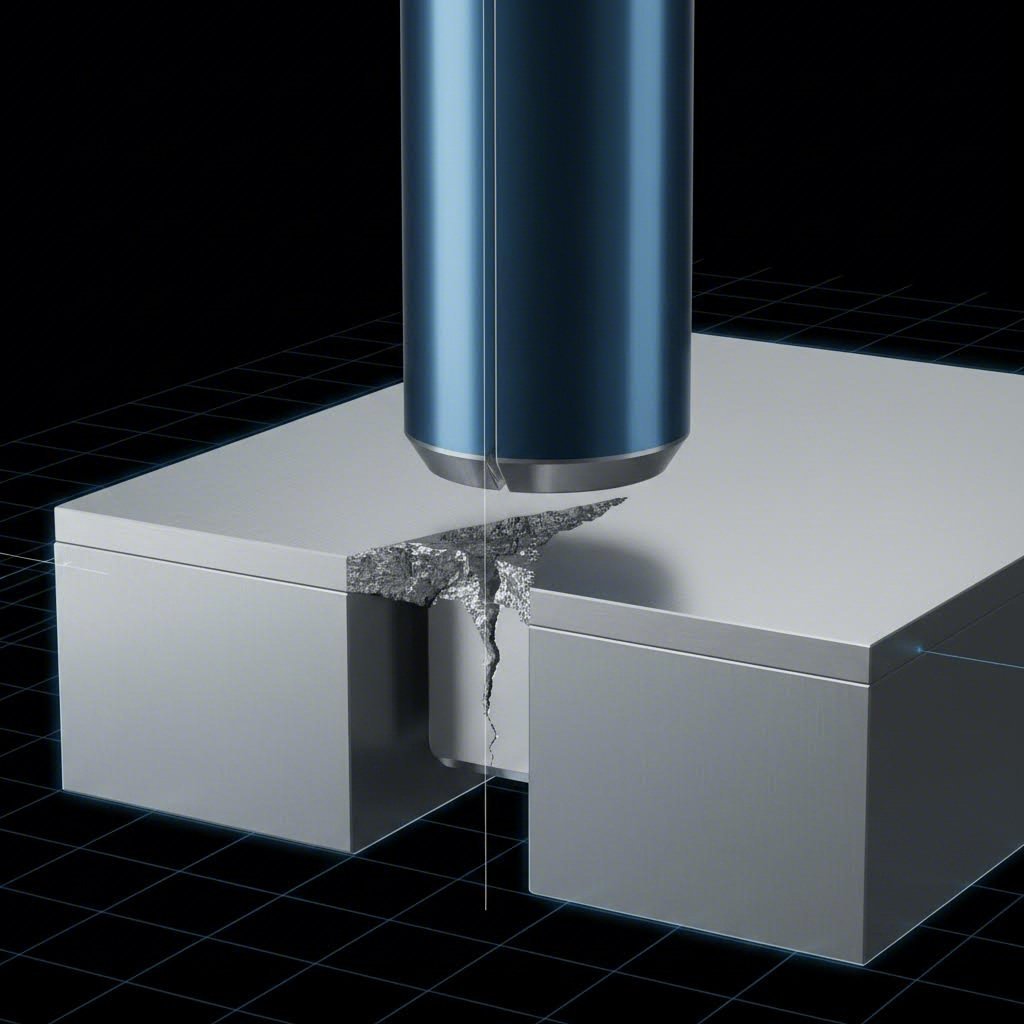

Die clearance - the space between the cutting edge of your punch and the cutting edge of your die button - might seem like a minor detail. It's actually the single most critical factor in punching success. According to Dayton Lamina's extensive research involving over 10,000 clearance tests, optimizing this gap dramatically affects burr height, tool life, and overall hole quality.

Here's what happens during the cut: when your punch penetrates the material, fractures originate at the cutting edges of both the punch and die button - on both the upper and lower surfaces of the sheet. With correct clearance, these fractures connect cleanly, freeing the slug and releasing punching force smoothly.

What happens when clearance is wrong? A common mistake is specifying too-tight clearance, assuming it improves edge quality. The opposite occurs. When clearance is insufficient, the upper and lower fractures essentially miss each other, creating secondary cracks and double breaks. The material also grabs the punch more aggressively, increasing stripping forces and causing abrasive wear that shortens both punch and die button life.

The traditional industry rule of thumb - 5% of stock thickness per side - provides acceptable results for many applications. However, Dayton's Engineered Clearance research demonstrates that significantly increased clearances (up to 28% per side for certain materials) can actually reduce burr height, increase punch life, and improve hole quality. The optimal clearance depends on:

- Stock thickness - Thicker materials generally tolerate wider clearances

- Material tensile strength - Higher-strength steels require different clearance percentages than mild steel

- Hardness ratings - Harder materials (measured in Brinell or Rockwell scales) behave differently during fracture

- Application requirements - Whether you prioritize burnish length, burr height, or tool life

The slugs your pressing die produces tell the story. Optimal die clearance creates slugs with a consistent burnished land approximately one-third of material thickness, plus an even fracture plane aligned with that land. Rough fracture planes with excessive burr indicate too much clearance. Irregular fracture planes with uneven burnish and secondary shear signal insufficient clearance.

Designing for Precision and Longevity

Beyond clearance, several die design principles determine whether your tooling delivers consistent results across thousands - or millions - of cycles. Die cutting presses demand tooling engineered for the specific stresses they'll encounter.

Forming dies face different challenges than cutting dies. When shaping metal through bending, drawing, or embossing, material flow becomes critical. According to PEKO Precision's engineering guidance, effective tool and die design requires deep understanding of both material properties and mechanical processes involved.

Bending dies for sheet metal introduce a phenomenon every designer must address: springback. After the bending force is removed, the material partially returns toward its original shape due to elastic recovery. Research from CHAOERO confirms that springback is influenced by material yield strength, elastic modulus, bend radius, bend angle, and sheet thickness.

The springback compensation formula provides a starting point:

Δθ (over-bend angle) = θ × (E × t) / (2 × σ × R)

Where θ is the target bend angle, E is elastic modulus, t is thickness, σ is yield strength, and R is bend radius. Operators use this to calculate pre-compensation angles for precision bending.

Progressive dies represent the most sophisticated tooling die approach. Multiple operations occur in sequence as material advances through stations in a single press cycle - punching, bending, forming, and trimming all happening within one die set. According to PEKO's analysis, engineers must consider proper alignment of punches and die cavities, the material's strain hardening characteristics, and feed system design ensuring smooth material movement.

Key die design considerations that affect both quality and longevity include:

- Material flow analysis - Predicting how metal will move during forming operations prevents thinning, tearing, and wrinkling. CAE simulation helps optimize blank shape and die geometry before cutting steel.

- Spring-back compensation - Building over-bend angles into bending dies, adjusting punch radii, and optimizing dwell time at bottom of stroke all counteract elastic recovery.

- Wear resistance - Tool steel selection (A2, D2, or alloy steels) based on expected production volume and material being processed. Harder materials demand harder tooling.

- Stripping forces - Designing adequate stripper systems prevents material from sticking to punches during withdrawal. Spring-loaded strippers or ejector-equipped punches reduce slug pulling.

- Pilot systems - Precision pilots ensure accurate material positioning at each progressive station, maintaining tolerances across multi-station operations.

Tolerances and Precision Levels

What precision can you realistically expect from die cutting presses? This depends on tooling quality, press condition, and material consistency. Well-maintained equipment with precision tooling die components typically achieves:

- Dimensional tolerances - ±0.05mm to ±0.1mm for punched features in most applications

- Angular tolerances - ±0.5° for bent features with proper springback compensation

- Positional accuracy - ±0.1mm for feature-to-feature relationships within progressive dies

Higher precision is achievable but requires investment in guide systems, temperature control, and more frequent maintenance intervals. The CHAOERO case studies demonstrate that with optimized tooling and process parameters, stainless steel bending can achieve 90° ±0.5° after springback, while aluminum housing production hits ±0.3° tolerance.

Interchangeable inserts in dies reduce wear impact, allowing reconditioning without replacing entire tools. Regular maintenance practices - cleaning, lubrication, and inspection - extend tooling life significantly. These operational factors matter just as much as initial design, which brings us to the safety considerations and best practices that protect both your people and your equipment.

Safety Considerations and Best Practices

Precision tooling and perfect tonnage calculations mean nothing if an operator gets injured. Metal die press operations involve tremendous forces, rapidly moving components, and pinch points that can cause serious harm in milliseconds. According to OSHA's hazardous energy guidelines, injuries from uncontrolled energy releases during maintenance include electrocution, crushing, cutting, lacerating, amputating, and fracturing body parts. Let's examine the systems and practices that keep your team safe while maintaining productivity.

Essential Safety Systems and Protocols

Every punch and die press operation requires multiple layers of protection. Think of safety systems as a series of barriers - if one fails, others still protect your workers. Modern safeguarding goes far beyond simple guards bolted to the frame.

Machine guarding forms your first line of defense. According to The Fabricator's safety analysis, physical barriers should protect all access points - not just the front of the machine, but the ends of the ram and areas behind the press where backgauges create additional hazards. A gate or fence across the back prevents someone from accessing the rear and being caught by quickly moving components.

Light curtains represent the most popular form of press safeguarding. These optoelectronic devices create an invisible barrier of infrared beams. When anything breaks the beam pattern during operation, the machine stops immediately. Five types serve different applications:

- Basic light curtains - Require the operator to remain outside the protected zone throughout the entire stroke

- Light curtains with muting - Deactivate when the punch is within 0.25 inches of the die shoe, eliminating the hazard point

- Beam blanking curtains - Allow specific beams to be obstructed by workpiece features without triggering a stop

- Programmable light curtains - Accommodate different blanking patterns between cycles for varying part sizes

- Laser-based proximity guards - Mount directly on the ram and monitor machine performance including stopping distance and speed

Two-hand controls require operators to engage both hands simultaneously - and keep them engaged - while the ram moves through its dangerous portion of stroke. This physically prevents hands from entering the die equipment during operation.

Lockout/tagout (LOTO) procedures protect workers during maintenance and die changes. OSHA's LOTO standard (29 CFR 1910.147) requires employers to establish procedures for isolating hazardous energy sources - electrical, mechanical, hydraulic, and pneumatic - before any servicing work begins. Every die cutting tool change, adjustment, or repair demands proper energy isolation.

Maintenance Practices That Prevent Failures

Your die cut tool investment only delivers value when properly maintained. Neglected tooling doesn't just produce bad parts - it creates safety hazards when components fail unexpectedly under load.

Proper die handling starts with dedicated storage. Dies should rest on wooden blocks or padded surfaces, never stacked directly on each other. Upper and lower die shoes should remain bolted together during storage to maintain alignment and protect precision-ground surfaces. Climate-controlled storage prevents rust and corrosion that compromise critical clearances.

Regular inspection catches problems before they cause failures. Check for:

- Wear marks on punches and die buttons indicating clearance issues

- Cracks or chips in cutting edges

- Galling or scoring on guide pins and bushings

- Spring fatigue in strippers and ejectors

- Loosened fasteners throughout the die set

Before starting any production run on your die equipment, work through this pre-operation safety checklist:

- Verify all guards are in place and functioning - test light curtains and proximity sensors

- Confirm lockout/tagout devices have been removed and all personnel are clear

- Inspect the die shoe surfaces for debris, damage, or foreign objects

- Check that the die set is properly bolted to the press bed and ram

- Verify guide pin and bushing alignment through manual cycling

- Test two-hand controls and emergency stop functions

- Confirm material feed systems are clear and properly aligned

- Run several slow-speed test cycles before engaging production speeds

Common Operational Errors and Their Consequences

Understanding what goes wrong helps you prevent it. These mistakes consistently cause injuries and equipment damage:

Bypassing safety devices - Operators sometimes disable light curtains or block-out interlocks to speed production. This eliminates the protection designed to prevent amputations and crushing injuries. No production schedule justifies this risk.

Reaching into the die during cycling - Even experienced operators occasionally attempt to adjust material or remove slugs while the press is running. The ram moves faster than human reflexes can respond.

Improper die setting - Failing to verify shut height, tonnage settings, or die alignment before running creates conditions where tooling can shatter or the press frame can be damaged - sending fragments at dangerous velocities.

Neglecting maintenance intervals - Worn guide bushings allow die halves to shift during operation. Fatigued springs fail to strip material properly. Both conditions lead to unexpected forces that can eject parts or tooling components.

Working alone without safeguards - Someone unfamiliar with the operation can walk around behind a light curtain, accessing hazardous areas the operator cannot see. Physical barriers at machine ends prevent this scenario.

The investment in proper safety systems, training, and maintenance practices protects more than your workers - it protects your production schedule. Injuries cause investigations, downtime, and regulatory scrutiny that far exceed the cost of doing things right from the start. With safety fundamentals established, the next consideration is how your metal die press integrates into broader manufacturing workflows.

Metal Die Press in the Manufacturing Workflow

Your metal die press doesn't operate in isolation. It's one component within a larger production ecosystem - fed by upstream material handling systems and connected to downstream finishing operations. Understanding how these elements work together transforms your perspective from viewing the press as standalone equipment to seeing it as the heart of an integrated manufacturing cell. Let's examine how everything connects.

From Coil to Finished Part

Imagine a 10,000-pound coil of steel arriving at your facility. How does it become thousands of precision components? The journey involves multiple coordinated systems working in perfect synchronization with your die cutting press.

According to The Fabricator's analysis of coil line integration, modern stamping operations achieve their greatest efficiencies when operators can control multiple functions from a single touchscreen. This integration reduces errors and increases efficiencies while minimizing floor space, power sources, and wiring requirements.

A typical coil-fed die cutting press machine setup includes:

- Uncoiler (reel) - Holds the coil and pays out material at controlled rates. Advanced systems can prestage multiple coils on a single mandrel, with the keeper arm automatically aligning the next coil when one is consumed.

- Straightener - Removes the coil set (curvature from being wound) through a series of work rolls. Integrated controls automatically adjust roll positions based on stored tool parameters.

- Feeder - Advances precise lengths of material into the press for each stroke. Feed length, speed, and timing synchronize exactly with press operation.

- Loop control - Maintains a material loop between straightener and feeder, absorbing variations in feed rate and preventing tension from affecting material positioning.

The backbone of any integrated coil line is the control system. Large color touchscreens provide simplified control of prestaging, manufacturing, diagnostics, and troubleshooting. These systems store predefined production parameters for hundreds of dies for machine setups - feed angle, feed rate, pilot release, passline height, stock guide positions, and straightener settings can all be recalled automatically when changing jobs.

This automation dramatically reduces changeover time. Rather than manually adjusting each component, operators recall stored values and the system configures itself. The die cutting manual machine approach - where operators manually thread material and adjust each station - still exists for prototype work and short runs, but high-volume production demands integrated automation.

Integrating Press Operations Into Production Lines

Your cutting press represents just one station in the manufacturing flow. What happens before and after stamping determines overall line efficiency as much as the press operation itself.

Two fundamental approaches exist for moving parts through stamping operations:

Progressive die stamping keeps material as a continuous strip. According to Keysight's stamping process analysis, progressive presses perform sequential operations on a continuous strip of metal within a single press. Multiple operations combine in one die set, enabling high-speed production with reduced part handling and excellent repeatability. This approach excels for smaller parts like brackets and clips produced in high volumes.

Transfer die stamping moves discrete parts between stations. Transfer presses use mechanical fingers, walking beams, or robotic systems to advance parts through multiple operations within the same machine. This method suits complex parts requiring operations that can't be performed while material remains in strip form - such as deep draws that would otherwise interfere with adjacent stations.

The choice between batch production and continuous stamping affects everything from inventory levels to labor requirements:

- Batch production - Run quantities of one part number, then changeover to the next. Works well when changeover times are significant relative to run times, or when downstream operations can't keep pace with stamping speeds.

- Continuous production - Dedicated lines running single part numbers continuously. Eliminates changeover losses but requires sufficient volume to justify the dedicated equipment.

- Flexible cells - Quick-change tooling and integrated controls enable rapid switching between part numbers, approaching continuous efficiency with batch flexibility.

Downstream operations connect directly to press output. Parts may flow to:

- Secondary forming operations for features not achievable in the primary die

- Welding cells that join multiple stampings into assemblies

- Finishing lines for plating, painting, or coating

- Assembly stations where stampings become components in larger products

Quality Control Integration

How do you know every part meets specifications when you're producing hundreds per minute? Modern press cutting dies integrate quality monitoring directly into production rather than relying solely on post-process inspection.

According to Eigen Engineering's quality analysis, precision metal stamping requires detection as an ongoing effort at all stages - not just random testing in different areas. Advanced metal stamping solutions implemented throughout the process deliver consistently quality results.

In-die sensing provides real-time monitoring during every press stroke. Sensors detect:

- Part presence and proper positioning before the press cycles

- Slug ejection verification to prevent double hits

- Material feed accuracy ensuring correct progression

- Force variations indicating tool wear or material changes

These in-die detector systems protect tooling from inadvertent damage caused by slugs, material variation, or wrong feeds. At the end of the process, in-die sensors also verify product conformance before parts leave the press.

Statistical process control (SPC) uses control charts to track the stamping process in real time. Acceptable ranges and critical attributes are assigned to the process, and SPC software notes variances from set norms automatically. This helps process managers identify relevant trends and implement solutions before out-of-tolerance conditions produce scrap.

Coordinate measuring machines (CMM) provide precise dimensional verification within the tightest manufacturing tolerances. CMM data feeds into SPC systems so engineers can view review charts in real time and detect problems requiring immediate intervention.

The integration of these quality systems means problems are caught immediately - often within the first few defective parts rather than after an entire batch has run. When an operator can resolve issues while standing at the press, reviewing diagnostics on the same screen that controls production, response time shrinks from hours to seconds.

Understanding where your metal die press fits within this broader workflow context helps you make better decisions about equipment selection, line layout, and process design. With this manufacturing perspective established, the final consideration is selecting the right equipment and tooling partner to bring your production vision to reality.

Selecting the Right Equipment and Tooling Partner

You've learned about press types, tonnage calculations, die design principles, and workflow integration. Now comes the decision that ties everything together: choosing the right equipment and the right partner to supply your tooling. This choice affects your production capabilities for years - possibly decades. Getting it right means consistent quality, reliable delivery, and a collaborative relationship that solves problems before they reach your production floor. Getting it wrong? Delays, costly rework, and frustration that compounds with every order.

Evaluating Your Production Requirements

Before contacting any supplier, you need clarity on what you're actually trying to accomplish. Sounds obvious? You'd be surprised how many manufacturers skip this step and find themselves with equipment that doesn't match their real needs.

Start with production volume. Are you running prototype quantities - perhaps dozens or hundreds of parts for testing and validation? Or do you need high-volume manufacturing capability producing thousands or millions of components annually? A die cut press machine optimized for short runs looks completely different from one designed for continuous production. Your volume requirements directly influence press tonnage, automation level, and tooling construction.

Part complexity matters equally. Simple blanking operations require straightforward metal stamping die sets. Complex parts with multiple bends, draws, and pierced features demand progressive or transfer dies with significantly more engineering investment. An industrial die cutter handling basic shapes costs a fraction of what sophisticated multi-station tooling requires.

Material specifications introduce another variable. That hydraulic press tooling designed for mild steel may not perform adequately with stainless or aluminum. Advanced high-strength steels require entirely different considerations - from tonnage capacity to die clearances. According to Die-Matic's manufacturer selection guide, one of the most important factors in selecting a metal stamping manufacturer is their experience with the materials you plan to use. Different materials require different handling, tooling, and processes.

Budget constraints shape everything. However, the lowest quote rarely represents the best value. A metal die cutter priced 20% below competitors but requiring twice the maintenance costs you more over its lifetime. Similarly, cheap tooling that needs resharpening every 50,000 cycles costs more than quality dies running 500,000 cycles between services.

What to Look for in a Tooling Partner

When you're ready to evaluate potential suppliers, move beyond price comparisons. The relationship you're building will affect your production success for years. Here are the essential questions to ask:

- What certifications do they hold? For automotive applications, IATF 16949 certification is essential. According to Xometry's certification overview, IATF 16949 is a quality management system built specifically for automotive product manufacturers, focusing on creating consistency, safety, and quality across automotive products. While not legally required, you may find that customers and suppliers won't collaborate with uncertified partners.

- What engineering support do they provide? Can they optimize your part designs for manufacturability? Do they offer prototyping and sampling services to test and refine parts before full-scale production?

- How do they use simulation technology? CAE (Computer-Aided Engineering) simulation predicts forming behavior, identifies potential defects, and optimizes die geometry before cutting any steel. This reduces development risk significantly.

- What is their typical lead time for prototypes versus production tooling? Rapid prototyping capability - some suppliers deliver in as few as 5 days - accelerates your development timeline.

- What is their first-pass approval rate? This metric reveals how often dies produce acceptable parts on the first production run without rework. High rates (90%+ is excellent) indicate robust engineering processes.

- How long have they been in business, and what is their customer retention rate? Long-term customers who keep coming back signal reliability and quality consistency.

- Can they scale with your needs? If your volumes increase - or decrease - can they adapt? Flexibility matters for long-term partnerships.

- What quality control processes are in place? Beyond certifications, ask about inspection equipment, testing protocols, and traceability systems.

Several warning signs should prompt caution when evaluating potential partners. Watch for inconsistent quality across sample parts, poor communication or slow response times, reluctance to share references from existing customers, and lack of investment in modern equipment or technology. These issues rarely improve after you've signed a contract.

Why Certifications and Simulation Matter

IATF 16949 certification deserves special attention for anyone serving the automotive industry. This standard goes beyond general quality management to address automotive-specific requirements including:

- Product safety considerations

- Defect prevention systems

- Reduction of variation and waste

- Continuous improvement frameworks

- Robust traceability throughout production

Certification isn't just a piece of paper. It represents a systematic approach to quality that protects your production schedule and your reputation with your own customers. When evaluating a metal die cutting machine supplier, certification indicates they've invested in processes that minimize your risk.

CAE simulation transforms die development from trial-and-error to predictable engineering. Before any steel is cut, simulation software models material flow, predicts springback, identifies potential thinning or wrinkling, and optimizes blank shapes. This front-end investment prevents costly surprises during tryout - the traditional period when new dies are tested and adjusted to produce acceptable parts.

The combination of robust quality systems and advanced simulation capability produces measurable results. Consider Shaoyi's precision stamping die solutions as an example of these principles in action. Their IATF 16949 certification and advanced CAE simulation deliver a 93% first-pass approval rate - meaning dies produce acceptable parts on the first attempt more than nine times out of ten. Rapid prototyping capability in as little as 5 days accelerates development timelines significantly.

These benchmarks provide concrete reference points when evaluating any supplier. Ask potential partners: what is your first-pass approval rate? How quickly can you deliver prototypes? What simulation tools do you use? Answers below industry leaders like Shaoyi suggest potential quality or capability gaps.

Making Your Final Decision

After gathering information, how do you make the final call? Consider creating a weighted evaluation matrix that scores each potential partner against your priorities. A die cutter for metal focused on automotive applications might weight IATF certification heavily, while a supplier serving electronics might prioritize fine-pitch capability and tight tolerances.

Don't underestimate the value of site visits. Seeing a facility firsthand reveals more than any questionnaire. Is the shop floor organized? Is equipment well-maintained? How do employees interact with each other and with visitors? These observations provide insight into company culture and operational discipline.

Finally, remember that you're selecting a partner, not just a vendor. The best manufacturing relationships involve collaboration, problem-solving, and mutual investment in success. Choose a supplier who demonstrates genuine interest in understanding your challenges - not just one who quotes the lowest price on your die cut press requirements.

The metal die press equipment and tooling you select today will shape your manufacturing capabilities for years ahead. Invest the time to evaluate thoroughly, ask the right questions, and choose partners whose capabilities and culture align with your long-term success.

Frequently Asked Questions About Metal Die Press

1. How much does a metal stamping die cost?

Metal stamping die costs typically range from $500 to $15,000 depending on part complexity, die type, and production requirements. Simple single-punch dies fall on the lower end, while progressive dies with multiple stations command higher prices. However, the per-part cost often drops significantly compared to CNC or manual fabrication methods, making dies cost-effective for volumes exceeding 500 pieces. Working with IATF 16949 certified partners like Shaoyi can optimize tooling investment through CAE simulation that reduces development iterations.

2. What is a die press used for?

A die press transforms flat metal sheets into precision components through cutting, forming, bending, and drawing operations. The machine applies controlled pressure to sandwich metal between specially shaped tooling, permanently reshaping material into parts like automotive body panels, electronic enclosures, brackets, and appliance components. Metal stamping dies with sharp edges perform cutting and blanking, while forming dies shape three-dimensional features through plastic deformation of the metal.

3. What are the different types of press die?

Four main types of press dies exist: compound dies perform multiple operations simultaneously in one stroke; transfer dies move discrete parts between stations using mechanical fingers or robotics; progressive dies perform sequential operations on a continuous metal strip advancing through multiple stations; and single punch dies complete one operation at a time. Each type suits different production volumes, part complexities, and manufacturing requirements.

4. What is the difference between mechanical and hydraulic die presses?

Mechanical presses use flywheel-driven systems for high-speed production, achieving peak tonnage near the bottom of the stroke. They excel at progressive die operations and high-volume stamping. Hydraulic presses apply fluid pressure to generate force, delivering full tonnage anywhere in the stroke. This makes them ideal for deep drawing, complex forming, and operations requiring dwell time. Servo presses combine mechanical speed with programmable flexibility, offering variable stroke profiles for difficult forming applications.

5. How do I calculate tonnage requirements for a metal die press?

Calculate tonnage using this formula: Perimeter (mm) × Thickness (mm) × Shear Resistance (kgf/mm²) × Safety Factor (1.1-1.2) ÷ 1000. Key factors include cut perimeter length, material thickness, shear resistance (approximately 60% of tensile strength), and die clearance. Advanced high-strength steels require careful calculation as traditional rules often under-predict requirements. CAE simulation provides more accurate predictions by modeling force curves throughout the entire stroke.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —