Pokrycia CVD vs PVD dla narzędzi: dopasuj metal, maksymalizuj żywotność narzędzia

Decyzja o powłoce, która decyduje o wydajności narzędzia

Wyobraź sobie następującą sytuację: inwestujesz w wysokiej jakości płytki węglikowe, optymalizujesz parametry skrawania i dokładnie dostrojasz ustawienia maszyny. Mimo to Twoje narzędzia zużywają się szybciej niż się spodziewałeś, jakość powierzchni pozostawia wiele do życzenia, a koszt na sztukę ciągle rośnie . Co zostało pominięte? Najczęściej wszystko sprowadza się do jednego kluczowego wyboru — decyzji między technologiami pokryć CVD i PVD.

Zrozumienie różnicy między pokryciem PVD a CVD to nie tylko akademicka ciekawość. To różnica pomiędzy narzędziami, które świetnie sprawdzają się w trudnych warunkach, a tymi, które ulegają przedwczesnemu uszkodzeniu. Znaczenie pokrycia PVD wykracza daleko poza prostą obróbkę powierzchni; reprezentuje strategiczną decyzję wpływającą na całą operację.

Dlaczego wybór powłoki decyduje o wydajności narzędzia

Porównując powłoki CVD i PVD dla narzędzi, wybierasz między dwoma różnymi filozofiami napylania. Każda z tych technologii nanosi ochronne warstwy na narzędzia tnące, ale robi to za pomocą zasadniczo różnych mechanizmów – a te różnice bezpośrednio przekładają się na rzeczywiste cechy użytkowe.

Definicja powłoki PVD opiera się na procesach fizycznych zachodzących w niższych temperaturach, co pozwala zachować ostre krawędzie tnące oraz integralność podłoża. CVD natomiast wykorzystuje reakcje chemiczne w podwyższonej temperaturze, tworząc grubsze i bardziej termoodporne warstwy. Żadna z metod nie jest jednoznacznie lepsza. Każda z nich sprawdza się najlepiej w określonych warunkach obróbki skrawaniem.

Ukryte koszty niewłaściwego wyboru powłoki

Wybór niewłaściwej technologii powłok CVD i PVD wiąże się z większymi kosztami niż tylko zużycie narzędzia. Weź pod uwagę następujące efekty łańcuchowe:

- Wczesne zużycie narzędzia wymuszające awaryjne przestoje maszyn

- Niestabilna jakość powierzchni wymagająca dodatkowych operacji

- Zwiększona ilość odpadów wpływająca na marżę zysku

- Wyższe koszty inwentarza narzędzi spowodowane szybszym zużyciem

Gdy porównuje się wydajność PVD i CVD w różnych materiałach i operacjach, odpowiedni dobór może wydłużyć żywotność narzędzia o 200–400%. Źle dobrany? Wyniki mogą być gorsze niż przy użyciu całkowicie niepowlekanych narzędzi.

Zakres tego porównania

Ten przewodnik stanowi praktyczny materiał warsztatowy do doboru technologii powłok dla konkretnych operacji obróbczych. Zamiast zagłębiać się w teorię metalurgiczną, skupimy się na konkretnych, operacyjnych wskazówkach, które można od razu zastosować.

Znajdziesz szczegółowe oceny popularnych opcji powłok — od TiAlN PVD dla precyzyjnej pracy wysokiej prędkości po Al2O3 CVD do zastosowań w ekstremalnych warunkach temperaturowych. Przeanalizujemy kompatybilność podłoży, zakresy temperatur roboczych, grubość powłok oraz rzeczywiste scenariusze zastosowania. Na końcu będziesz dysponować jasnym schematem decyzyjnym wyboru powłoki maksymalizującej żywotność narzędzi dla Twoich konkretnych materiałów i warunków skrawania.

Jak ocenialiśmy każdą technologię powłok

Zanim przejdziemy do konkretnych rekomendacji powłok, musisz zrozumieć, jak doszliśmy do naszych wniosków. Losowy wybór powłoki osadzanej metodą osiadania z fazy gazowej na podstawie marketingowych zapewnień prowadzi do niestabilnych wyników. Zamiast tego opracowaliśmy systematyczny schemat oceny, który analizuje każdą metodę powłoki pod kątem mierzalnych kryteriów wydajności.

Wyobraź sobie ten schemat jako listę kontrolną przed startem. Gdy zrozumiesz kryteria oceny, zauważysz, dlaczego niektóre powłoki świetnie sprawdzają się w konkretnych zastosowaniach — a inne nie.

Pięć kluczowych czynników oceny powłok

Każda metoda nanoszenia powłoki, niezależnie od tego, czy wykorzystuje proces PVD, czy CVD, musi przejść przez te pięć etapów oceny:

- Zgodność podłoża: Czy temperatura procesu osadzania z fazy gazowej odpowiada materiałowi Twojego narzędzia? Podłoża ze stali szybkotnącej nie wytrzymują takich samych temperatur jak węglik spiekany.

- Zakres temperatury pracy: Jakie temperatury cięcia będą oddziaływać na powłokę? Tokarka ciągła generuje inne obciążenia termiczne niż frezowanie przerywane.

- Wymagania dotyczące grubości powłoki: Ile materiału możesz dodać, nie naruszając geometrii krawędzi? Narzędzia do gwintowania wymagają węższych tolerancji niż płytki do toczenia zgrubnego.

- Właściwości przylegania: Czy powłoka pozostanie przyłączona pod wpływem naprężeń mechanicznych i cykli termicznych? Słabe przyleganie prowadzi do łuszczenia się i przyspieszonego zużycia.

- Wydajność Specyficzna dla Zastosowania: Jak powłoka zachowuje się wobec Twojego konkretnego materiału obrabianego? Obróbka aluminium wymaga innych właściwości niż toczenie stali ulepszanej cieplenie.

Jak dopasowaliśmy powłoki do operacji skrawania

Dopasowanie metod nanoszenia powłok do operacji skrawania wymaga zrozumienia zarówno właściwości powłoki, jak i wymagań danej operacji. Oto, jak przeprowadziliśmy każdą ocenę:

W przypadku toczenia priorytetem była stabilność termiczna i odporność na zużycie. Ciągłe skrawanie generuje utrzymującą się temperaturę na styku narzędzia i przedmiotu obrabianego , przez co właściwości tworzenia bariery termicznej są niezbędne. Proces osadzania opary chemicznej doskonale sprawdza się w tym zakresie, ponieważ tworzy grubsze i bardziej odporne na ciepło warstwy.

W przypadku frezowania i wiercenia ważniejsze były zachowanie ostrości krawędzi i odporność na obciążenia udarowe. Przerwane skrawanie powoduje cykliczne zmiany temperatury i obciążenia mechaniczne. Powłoki nanoszone w niższych temperaturach zachowują pierwotną twardość podłoża i pozwalają na utrzymanie ostrzejszych krawędzi skrawających.

W przypadku gwintowania i kształtowania skupiliśmy się na współczynnikach tarcia i stabilności wymiarowej. Te precyzyjne operacje nie mogą tolerować grubych powłok, które zmieniają geometrię narzędzi.

Zrozumienie wpływu grubości na wydajność

Grubość powłoki to nie tylko specyfikacja — w sposób zasadniczy określa ona sposób działania Twojego narzędzia. Proces CVD zwykle wytwarza powłoki o grubości od 5 do 12 µm, a w niektórych zastosowaniach nawet do 20 µm. Proces PVD natomiast osadza cieńsze warstwy, zazwyczaj w zakresie 2–5 µm.

Dlaczego to ma znaczenie? Rozważ następujące praktyczne implikacje:

- Ostrość krawędzi: Cieńsze powłoki PVD zachowują oryginalną geometrię krawędzi, co jest kluczowe w operacjach wykańczania i pracach precyzyjnych.

- Ochrona termiczna: Grubsze warstwy CVD tworzą lepsze bariery termiczne, niezbędne przy ciągłym cięciu w wysokich temperaturach.

- Rezerwa zużyciowa: Większa grubość powłoki zapewnia więcej materiału do zużycia przed odsłonięciem podłoża.

- Dopuszczalne odchyłki wymiarowe: Narzędzia o ścisłych wymaganiach tolerancji — takie jak narzędzia kształtne i gwintowniki — wymagają cieńszych powłok, aby zachować określone wymiary.

Zrozumienie tych kompromisów związanych z grubością powłoki pomaga w wyborze odpowiedniej technologii powłoki przed przeanalizowaniem indywidualnych składów powłok. Mając już ustanowiony ten schemat oceny, przyjrzyjmy się, jak konkretne powłoki sprawdzają się w rzeczywistych warunkach obróbki.

Powłoka TiAlN PVD do precyzyjnej pracy wysokoprędkościowej

Podczas obróbki stali hartowanych lub stali nierdzewnych w podwyższonych prędkościach jedna powłoka PVD systematycznie przewyższa konkurencję: azotek tytanu i aluminium, czyli TiAlN. Ta powłoka osadzana metodą osiadania fizycznego (PVD) zyskała uznanie jako rozwiązanie pierwszego wyboru dla narzędzi ze stali szybkotnącej oraz operacji cięcia przerywanego, gdzie najważniejsze są ostre krawędzie i stabilność termiczna.

Ale co sprawia, że TiAlN wyróżnia się tak wysoką wydajnością? Kiedy warto wybrać go zamiast innych opcji powłok? Przeanalizujmy szczegóły, aby określić, czy ten materiał powłoki PVD odpowiada Twoim wymaganiom obróbkowym.

Gdzie TiAlN doskonale sprawdza się w nowoczesnej obróbce

Kluczem do sukcesu TiAlN jest jego unikalne zachowanie podczas utleniania. Gdy temperatura cięcia przekracza 700°C, ta technologia powłoki PVD tworzy cienką warstwę tlenku glinu na swojej powierzchni. Ta samogenerowana bariery działa jak osłona termiczna, chroniąc zarówno powłokę, jak i podłożenie przed uszkodzeniem spowodowanym przez wysoką temperaturę.

Rozważ, co dzieje się podczas frezowania wysokoprędkościowego. Twoje narzędzie wielokrotnie wchodzi i wychodzi z obrabianego przedmiotu, powodując cykliczne zmiany temperatury, które zniszczyłyby słabsze powłoki. TiAlN dobrze radzi sobie w takich warunkach, ponieważ proces osadzania parą w próżni (PVD) nakłada powłokę w stosunkowo niskich temperaturach — zazwyczaj pomiędzy 400-500°C. To pozwala zachować pierwotną twardość podłoża i zapobiega uszkodzeniom termicznym, jakie procesy CVD o wyższych temperaturach mogą spowodować w narzędziowych stalach wrażliwych na ciepło.

Wykończenie metodą osadzania parą w próżni (PVD) zachowuje wyjątkowo ostre krawędzie skrawające. Ponieważ powłoki PVD tworzą cieńsze warstwy (zazwyczaj 2-4 µm dla TiAlN), oryginalna geometria krawędzi pozostaje nienaruszona. W przypadku precyzyjnego frezowania i wiercenia, gdzie ostrość krawędzi bezpośrednio wpływa na jakość powierzchni, ta cecha okazuje się nieoceniona.

Zalecane zastosowania i parametry skrawania

TiAlN najlepiej sprawdza się przy obróbce następujących materiałów obrabianych:

- Stale hartowane (45-65 HRC): Twardość cieplna powłoki przekracza 3000 HV w podwyższonej temperaturze, zachowując wydajność cięcia przy obróbce trudnych materiałów.

- Stale nierdzewne: Doskonała odporność na utlenianie zapobiega reakcjom chemicznym między narzędziem a przedmiotem obrabianym, które prowadzą do tworzenia się naddatku.

- Stopy wysokotemperaturowe: Właściwości izolacyjne chronią przed ekstremalnym ciepłem powstającym podczas cięcia stopów nadstopowych niklu.

Pod względem parametrów skrawania narzędzia pokryte TiAlN osiągają optymalne wyniki przy prędkościach powierzchniowych o 20–40% wyższych niż ich odpowiedniki niepowlecane lub powleczone TiN. W zastosowaniach obróbki suchych — gdzie nie stosuje się chłodziwa — ta technologia powłok PVD naprawdę ujawnia swoją wartość, przejmując dodatkowe obciążenie termiczne bez przedwczesnego uszkodzenia.

Typowe zastosowania, w których TiAlN osiąga wyjątkowe rezultaty, to:

- Szybkoobrotowe frezowanie końcowe stali narzędziowych

- Wiercenie w elementach ze stali nierdzewnej

- Przerwane cięcie na hartowanych elementach matryc

- Zastosowania obróbki suchych, gdzie stosowanie chłodziwa nie jest praktyczne

Ograniczenia, o których należy wiedzieć

Żadne rozwiązanie powłokowe nie działa uniwersalnie, a TiAlN ma swoje ograniczenia. Zrozumienie tych ograniczeń pozwala uniknąć niewłaściwego zastosowania.

Zalety

- Doskonała odporność termiczna do 900°C dzięki samoformującej się barierze tlenkowej

- Ostrze o ostrej krawędzi dzięki cienkiej warstwie powłoki osiadanej metodą osadzania par fazy gazowej (PVD)

- Niższa temperatura osadzania (400–500°C) zachowuje integralność podłoża

- Lepsza wydajność w warunkach cięcia przerywanego i zmian temperatury

- Umożliwia wyższe prędkości cięcia oraz możliwość obróbki na sucho

Wady

- Cieńsza warstwa powłoki (2–4 µm) zapewnia mniejszy zapas odporności na zużycie niż alternatywy CVD

- Mniej odpowiedni do intensywnych operacji toczenia przy ekstremalnych obciążeniach mechanicznych

- Może nie dorównywać trwałości powłok CVD w ciągłych aplikacjach toczenia w wysokiej temperaturze

- Wyższy koszt narzędzia w porównaniu z podstawowymi powłokami TiN

Cieńsza warstwa powłoki, która korzystnie wpływa na ostrość krawędzi, staje się wadą podczas agresywnego toczenia wyrywkowego. Jeśli obrabiasz materiał przy dużych głębokościach skrawania, zmniejszony zapas odporności na zużycie oznacza szybsze przebicie powłoki. W takich zastosowaniach warto rozważyć opcje z grubszą powłoką CVD — co prowadzi nas do powłok tlenkowych glinu zaprojektowanych specjalnie do ekstremalnych warunków wysokiej temperatury.

Powłoka Al2O3 CVD do zastosowań przy ekstremalnych temperaturach

Gdy ciągłe operacje skrawania podnoszą temperaturę narzędzi poza zakres, w którym radzi sobie TiAlN, powłoka chemiczna osadzana metodą CVD (Al2O3) wkracza jako mistrz barier cieplnych. Ta technologia osadzania parowego tworzy warstwę o właściwościach ceramicznych, która znosi temperatury przekraczające 1000°C — warunki, które zniszczyłyby większość powłok PVD w ciągu kilku minut.

Jeśli w Twojej warsztacie wykonywane są intensywne operacje toczenia żeliwa lub stali, zrozumienie działania powłok Al2O3 CVD może radykalnie zmienić oczekiwania dotyczące trwałości narzędzi. Przyjrzyjmy się, dlaczego ta technologia osadzania CVD jest preferowanym wyborem w zastosowaniach przy ekstremalnych temperaturach.

Chemia stojąca za doskonałą izolacją cieplną Al2O3

Wyobraź sobie powłokę, która nie tylko odpiera ciepło – ale aktywnie blokuje przenikanie ciepła do podłoża Twojego narzędzia. Dokładnie to osiąga tlenek glinu dzięki swojej unikalnej strukturze krystalicznej. Proces chemicznego osadzania z fazy gazowej (CVD) buduje tę powłokę poprzez wprowadzenie chlorku glinu i dwutlenku węgla do komory reakcyjnej w temperaturach od 900 do 1050°C. W tak wysokich temperaturach zachodzące reakcje chemiczne osadzają czysty Al2O3 bezpośrednio na powierzchni wkładki węglikowej.

Ale tutaj sytuacja staje się interesująca. Nowoczesne urządzenia do powlekania CVD nie nanoszą pojedynczej warstwy Al2O3. Zamiast tego tworzą strukturę wielowarstwową, łącząc różne typy osadzania par fazy gazowej w celu zoptymalizowania wydajności:

- Warstwa podstawowa (TiN lub TiCN): Tworzy silny związek między podłożem węglikowym a kolejnymi warstwami

- Warstwa pośrednia (TiCN): Zwiększa twardość i odporność na zużycie pod barierą termiczną

- Warstwa Al2O3: Zapewnia podstawową ochronę termiczną oraz obojętność chemiczną

- Warstwa wierzchnia (TiN): Umożliwia wykrywanie zużycia poprzez zmianę koloru oraz dodatkową ochronę

Ta architektura wielowarstwowa—osiągalna wyłącznie dzięki osadzaniu par CVD—tworzy system powłok, w którym każda warstwa przyczynia się do konkretnych właściwości. Przewodność cieplna warstwy Al2O3 wynosi zaledwie 25 W/mK w porównaniu do 100 W/mK dla niepowleczonego węgliku. Ta znacząca różnica oznacza, że znacznie mniej ciepła przenika do narzędzia, utrzymując podłoże chłodniejszym i znacznie wydłużając żywotność narzędzia.

Najlepsze zastosowania powłok tlenkowych glinu

W jakich zastosowaniach powłoka Al2O3 metodą CVD przynosi największą wartość? Skup się na następujących głównych obszarach:

Obróbka żeliwa szarego: Stabilność chemiczna tlenku glinu zapewnia odporność na działanie łusek grafitu w żeliwie szarym. Można oczekiwać wydłużenia trwałości narzędzi nawet 3–5 razy w porównaniu do niepowlekanych płytek, szczególnie podczas ciągłych operacji toczenia wykańczającego.

Toczenie stali: Podczas obróbki stali węglowych i stali stopowych przy wysokich prędkościach, bariera termiczna zapobiega zużyciu kruszeniowemu na powierzchni przyłożenia. Ten mechanizm zużycia—spowodowany dyfuzją między gorącą wiórką a powierzchnią narzędzia—niszczy niepowlecane oraz wiele narzędzi powlekanych metodą PVD. Obojętność chemiczna Al2O3 skutecznie blokuje tę dyfuzję.

Długotrwałe produkcje seryjne: Jeśli prowadzisz ciągłe cykle cięcia trwające godzinami zamiast minutami, gruba powłoka CVD (zazwyczaj 8–12 µm łącznie) zapewnia znaczny zapas odporności na zużycie. Twoi operatorzy spędzają mniej czasu na wymianie płytek i więcej czasu na produkcji wiórów.

Urządzenia do osadzania chemicznego z fazy gazowej zaprojektowane do powłok Al2O3 wytwarzają warstwy o wyjątkowej jednolitości — nawet na skomplikowanych geometriach płytek. Ta spójność ma znaczenie, ponieważ nieregularna grubość powłoki prowadzi do przedwczesnego uszkodzenia w miejscach cienkich warstw.

Kiedy CVD przewyższa PVD

Wybór między CVD a PVD nie polega na tym, która technologia jest „lepsza” — chodzi o dopasowanie powłoki do konkretnych warunków pracy. Oto sytuacje, w których powłoki tlenkowe Al2O3 metodą CVD wyraźnie przewyższają alternatywy PVD:

- Utrzymanie wysokich temperatur: Tokarka ciągła generuje stałe nagrzanie w strefie skrawania. Właściwości Al2O3 jako bariery termicznej są szczególnie widoczne, gdy brak cyklicznych zmian temperatury umożliwiających odprowadzenie ciepła.

- Intensywne toczenie z dużymi głębokościami skrawania: Grubsza powłoka CVD zapewnia więcej materiału, który może ulec zużyciu, zanim zostanie odsłonięta podstawa.

- Chemicznie reaktywne materiały obrabiane: Obojętna natura Al2O3 zapobiega reakcjom chemicznym przyspieszającym zużycie.

- Długotrwałe serie produkcyjne: Gdy maksymalizacja czasu między wymianami narzędzi jest ważniejsza niż ostrość krawędzi, trwałość CVD ma przewagę.

Zalety

- Wyjątkowa ochrona termiczna w temperaturach powyżej 1000°C

- Doskonała stabilność chemiczna zapobiega dyfuzji i zużyciu kraterowemu

- Nadzwyczajna odporność na zużycie w operacjach cięcia ciągłego

- Wielowarstwowa struktura łączy barierę termiczną z wytrzymałością mechaniczną

- Grubsze powłoki (8–12 µm) zapewniają większy zapas odporności na zużycie

Wady

- Wyższe temperatury osadzania (900–1050°C) ograniczają wybór podłoży wyłącznie do węglików – stal szybkotnąca nie wytrzymuje tego procesu

- Możliwość wystąpienia naprężeń rozciągających w powłoce, co może zmniejszyć jej odporność na pękanie

- Grubsza powłoka nieco zaokrągla krawędzie skrawające, przez co jest mniej odpowiednia do precyzyjnego wykańczania

- Dłuższe cykle nanoszenia powłoki zwiększają koszt narzędzia w porównaniu z alternatywami PVD

Ograniczenia podłoża zasługują na szczególną uwagę. Ze względu na bardzo wysokie temperatury procesu osadzania chemicznego z fazy gazowej, jedynie podłoża węglikowe mogą wytrzymać takie obciążenie. Jeśli pracujesz z narzędziami ze stali szybkotnącej, stalą kobaltową lub cermetem, Al2O3 CVD nie jest opcją — należy rozważyć alternatywy PVD lub inne składu CVD.

Zrozumienie tych kompromisów pomaga w skutecznym wykorzystaniu Al2O3 tam, gdzie zapewnia największą wartość: w ciągłych operacjach cięcia przy wysokich temperaturach, gdzie ochrona termiczna jest ważniejsza niż ostrość krawędzi. Ale co, jeśli potrzebujesz powłoki, która łączy zalety retencji krawędzi PVD i trwałości CVD? Właśnie wtedy powłoki TiCN — dostępne w obu wariantach procesowych — oferują wyjątkową elastyczność.

Warianty powłoki TiCN dla uniwersalnego obrabiania

Co się dzieje, gdy potrzebujesz powłoki działającej we wielu operacjach i na różnych materiałach, nie zobowiązując się jednak całkowicie do technologii PVD ani CVD? Powłoka tytanu węglikonitrycznego (TiCN) oferuje właśnie taką elastyczność. W przeciwieństwie do powłok ograniczonych do jednej metody napylania, TiCN jest dostępna zarówno w wersji PVD, jak i CVD – każda z nich zapewnia inne właściwości eksploatacyjne dostosowane do specyficznych warunków obróbki.

Ta podwójna dostępność czyni TiCN wyjątkowo położoną w sporze pomiędzy CVD a PVD. Nie chodzi o wybór między technologiami na ślepo, lecz o selekcję konkretnej odmiany TiCN odpowiadającej wymaganiom Twoich procesów. Przyjrzyjmy się, czym różnią się te wersje i kiedy każda z nich daje optymalne rezultaty.

Różnice w wydajności TiCN PVD i TiCN CVD

Z pierwszego spojrzenia powłoki PVD TiCN i CVD TiCN mogą wydawać się wymienne — przecież mają identyczną skład chemiczny. Jednak proces osadzania zasadniczo zmienia sposób działania powłoki na narzędziach.

TiCN PVD osadzane w niższych temperaturach (około 400–500°C) metodami PVD (ang. physical vapour deposition). Powstaje cieńsza warstwa powłoki — zazwyczaj 2–4 µm — o drobnoziarnistej mikrostrukturze. Efekt? Lepsze zachowanie ostrości krawędzi i charakterystyczny brązowo-szary wygląd, który operatorzy łatwo rozpoznają.

CVD TiCN powstaje metodą CVD (ang. chemical vapour deposition) w podwyższonej temperaturze (850–1000°C). Wyższa temperatura procesu pozwala na uzyskanie grubszej warstwy powłoki — zazwyczaj 5–10 µm — o strukturze słupkowej, która zwiększa odporność na zużycie przez tarcie. Można zauważyć nieco inny, srebrno-szary odcień w porównaniu do wersji PVD.

Oto, co oznaczają te różnice w praktyce:

| Cechy | TiCN PVD | CVD TiCN |

|---|---|---|

| Typowa Grubość | 2–4 µm | 5–10 µm |

| Temperatura osadzania | 400–500°C | 850–1000°C |

| Ostrość krawędzi | Doskonałe zachowanie | Umiarkowane zaokrąglenie |

| Rezerwa zużycia | Umiarkowany | Wysoki |

| Opcje podłoża | HSS, węgliki spiekane, cermet | Tylko węglik spiekany |

| Wygląd | Brązowo-szary | Srebrno-szary |

Dopasowanie odpowiednich wariantów TiCN do Twojej operacji

Zrozumienie różnic między PVD a CVD pomaga dopasować odpowiedni wariant TiCN do konkretnych potrzeb obróbki. Weź pod uwagę następujące wytyczne dotyczące zastosowań:

Wybierz TiCN metodą PVD, gdy:

- Operacje gwintowania wymagają precyzyjnej geometrii krawędzi — cienka powłoka nie zmieni wymiarów gwintownika ani frezu gwintowego

- Narzędzia kształtowe wymagają dokładnych profili, które grubszą powłoką można by naruszyć

- Podłoża ze stali szybkotnącej nie wytrzymują wysokich temperatur procesowych CVD

- Przerwane skrawanie generuje uderzenia termiczne, które lepiej znoszą cieńsze i bardziej elastyczne powłoki

Wybierz CVD TiCN, gdy:

- Ciągłe toczenie generuje trwałe zużycie ścierne — grubsza warstwa zapewnia więcej materiału do zużycia

- Obróbka materiałów ściernych, takich jak aluminium o wysokiej zawartości krzemu lub żeliwo z twardymi wtrąceniami

- Wielkość produkcji uzasadnia dłuższe cykle pokrywania i wyższe koszty na narzędzie

- Ostrość krawędzi jest mniej ważna niż maksymalna trwałość narzędzia

Operacje gwintowania i formowania szczególnie korzystają z właściwości zmniejszających tarcie powłoki PVD TiCN. Twardość powłoki (około 3000 HV) w połączeniu z relatywnie niskim współczynnikiem tarcia umożliwia czyste usuwanie wiórów z dolin gwintu. Zapobiega to zatkanju się wiórami, które prowadzi do pękania gwintowników i uszkodzeń gwintu.

Zaleta uniwersalności

Prawdziwą zaletą TiCN jest jego uniwersalność materiałowa. Warianty CVD i PVD sprawdzają się dobrze na szerokim zakresie materiałów obrabianych — od stali węglowych przez stale nierdzewne po stopy nieżelazne. Dzięki temu TiCN stanowi doskonałą powłokę „uniwersalną", gdy Twoja pracownia realizuje różnorodne zlecenia.

Zalety

- Doskonała odporność na ścieranie radzi sobie z trudnymi, intensywnie zużywającymi operacjami

- Dobra smarowność zmniejsza tarcie i poprawia usuwanie wiórów

- Uniwersalne działanie na stalach, stalach nierdzewnych i materiałach nieżelaznych

- Dostępny zarówno w technologii PVD, jak i CVD, zapewnia elastyczność podłoża i zastosowania

- Wyższa twardość niż standardowe powłoki TiN wydłuża żywotność narzędzi

Wady

- Może wymagać specyficznego przygotowania podłoża — czystość powierzchni krytycznie wpływa na przyczepność

- Różnice barw między procesami PVD i CVD mogą utrudniać identyfikację narzędzi

- Wyższa temperatura wersji CVD ogranicza wybór podłoży do węglików

- Żadna z wersji nie dorównuje TiAlN w zastosowaniach ekstremalnie wysokotemperaturowych

Wymóg przygotowania podłoża wymaga szczególnej uwagi. Przyczepność TiCN w dużej mierze zależy od odpowiedniego oczyszczenia i kondycjonowania powierzchni przed naniesieniem powłoki. Zanieczyszczenia lub niewłaściwe przygotowanie prowadzą do odspajania się powłoki — często w najmniej odpowiednim momencie podczas serii produkcyjnej.

Gdy Twoje operacje obejmują różne typy materiałów i warunki skrawania, uniwersalność TiCN czyni ją rozsądnym wyborem asortymentowym. Ale co z zastosowaniami, w których tradycyjne powłoki po prostu nie działają — na przykład frezowanie aluminium bez chłodziwa? Wtedy na scenę wkraczają specjalistyczne powłoki DLC.

Powłoka DLC PVD dla doskonałości w obróbce metali nieżelaznych

Czy kiedykolwiek widziałeś, jak aluminium samo napawa się na narzędziu tnącym w trakcie pracy? Dokuczliwe nacinanie niszczy wykończenie powierzchni, wymusza wcześniejszą wymianę narzędzi i zamienia opłacalne zlecenia w koszmar. Standardowe narzędzia powlekane metodą PVD słabują przy lepkim charakterze aluminium — ale powłoki typu Diamond-Like Carbon (DLC) zostały zaprojektowane specjalnie, by rozwiązać ten problem.

DLC reprezentuje specjalistyczną kategorię materiałów PVD, które zachowują się inaczej niż jakiekolwiek inne powłoki w arsenale narzędziowym. Podczas obróbki materiałów nieżelaznych — szczególnie stopów aluminium i miedzi — ta technologia osadzania PVD zapewnia wydajność, której konwencjonalne powłoki po prostu nie są w stanie dorównać.

Dlaczego DLC dominuje w obróbce aluminium

Tajemnica przewagi DLC w obróbce aluminium tkwi w jego wyjątkowych właściwościach powierzchniowych. Ta technologia wykańczania PVD tworzy warstwę węglową o cechach zadziwiająco podobnych do diamentu naturalnego:

- Ekstremalnie niski współczynnik tarcia: Powłoki DLC osiągają współczynniki tarcia w zakresie 0,05–0,15—znacznie niższe niż TiN (0,4–0,6) lub TiAlN (0,3–0,4). Wióry zsuwają się z powierzchni narzędzia zamiast się przywierać.

- Właściwości antyprzywierne: Skrzepalność aluminium do powierzchni narzędzi znacząco spada. Chemiczna obojętność powłoki zapobiega tworzeniu się wiązań metalicznych, które prowadzą do powstawania narościa.

- Wyjątkowa twardość: Mimo niskiego tarcia, powłoki DLC zachowują twardość w zakresie 2000–5000 HV, w zależności od konkretnej odmiany napylania metalu PVD.

W zastosowaniach lotniczych związanych z obróbką aluminium, te właściwości przekładają się bezpośrednio na mierzalne korzyści. Podczas obróbki stopów aluminium 7075-T6 lub 2024-T3 stosowanych w elementach konstrukcyjnych, narzędzia pokryte powłoką DLC regularnie osiągają chropowatość powierzchni poniżej Ra 0,8 µm bez konieczności dodatkowych operacji polerowania. Technologia materiału PVD skutecznie eliminuje zjawisko mikrozgrzewania, z którym borykają się inne powłoki.

Wyobraź sobie obróbkę aluminium z dużą prędkością bez konieczności ciągłego monitorowania krawędzi. To rzeczywistość działania, jaką umożliwia DLC. Operatorzy skupiają się na produkcji, a nie na pilnowaniu narzędzi pod kątem powstawania naddatku na krawędzi.

Możliwości i ograniczenia cięcia na sucho

Właśnie tutaj DLC naprawdę wyróżnia się spośród konkurencji: zdolność do obróbki na sucho. Podczas gdy większość powłok wymaga chłodzenia strumieniowego przy frezowaniu aluminium, właściwości tarcia DLC pozwalają na efektywną obróbkę na sucho lub z minimalnym smarowaniem (MQL).

Dlaczego to ma znaczenie?

- Wyeliminowanie kosztów utylizacji chłodziwa oraz obciążeń związanych ze zgodnością środowiskową

- Czyściejsze elementy wymagające mniejszego czyszczenia po obróbce

- Zmniejszone koszty konserwacji maszyn spowodowane problemami związanymi z chłodzeniem

- Lepsza widoczność strefy cięcia podczas pracy

Jednak ograniczenia temperaturowe DLC wymagają szczególnej uwagi. Większość powłok DLC zaczyna ulegać degradacji powyżej 350–400 °C — znacznie mniej niż próg 900 °C dla TiAlN. Oznacza to, że nie można doprowadzać do ekstremalnych prędkości skrawania generujących nadmierną ilość ciepła. W przypadku aluminium rzadko występują z tym problemy, ponieważ własne właściwości termiczne materiału zwykle ograniczają praktyczne prędkości skrawania. Operatorzy muszą jednak zdawać sobie sprawę z tego ograniczenia.

Powłoka również słabo działa przy obróbce materiałów żelaznych. Obróbka stali i żeliwa przyspiesza zużycie DLC poprzez dyfuzję węgla w matrycę żelaza. Nigdy nie należy stosować narzędzi pokrytych DLC do cięcia stali — niszczy się powłokę szybciej niż w przypadku narzędzi niepowlekanych.

Analiza kosztów i korzyści inwestycji w DLC

Powłoki DLC są droższe — ich cena jest zazwyczaj 2–3 razy wyższa niż standardowych powłok TiN lub TiAlN. Czy inwestycja jest uzasadniona? To całkowicie zależy od rodzaju wykonywanych zadań.

Zalety

- Zapobiega tworzeniu się przełożeń na stopach aluminium i miedzi

- Umożliwia wydajne toczenie na sucho, eliminując koszty chłodziwa

- Wyjątkowa jakość powierzchni zmniejsza liczbę operacji wtórnych

- Ekstremalnie niski współczynnik tarcia wydłuża żywotność narzędzi w odpowiednich zastosowaniach

- Idealny do obróbki aluminium w przemyśle lotniczym, gdzie kluczowe znaczenie ma integralność powierzchni

Wady

- Nie nadaje się do materiałów żelaznych — stal i żeliwo niszczą powłokę

- Wyższy początkowy koszt (2–3 razy wyższy niż standardowe powłoki) zwiększa inwestycję początkową

- Ograniczenia temperaturowe (maks. 350–400°C) ograniczają zakres parametrów skrawania

- Cieńsze warstwy powłoki (1–3 µm) zapewniają mniejszy zapas odporności na zużycie niż opcje CVD

- Wymaga starannego dopasowania zastosowania — błędny dobór materiału marnuje pieniądze

Dla warsztatów prowadzących znaczącą produkcję aluminium — szczególnie elementów lotniczych — korzyści z powłoki DLC szybko rekompensują wyższą cenę. Zmniejszenie odpadów spowodowanych natarciem, wyeliminowanie kosztów chłodziwa oraz mniejsza liczba operacji wykańczających wtórnych tworzą przekonujący zwrot z inwestycji. Samo ręczne polerowanie jednego elementu konstrukcyjnego lotniczego po obróbce może kosztować więcej pod względem pracy, niż różnica cenowa narzędzi.

Jeśli jednak aluminium stanowi tylko okazjonalną pracę mieszaną z obróbką stali, prowadzenie osobnego zapasu narzędzi pokrytych powłoką DLC dodaje złożoności bez odpowiednich korzyści. W takich przypadkach bardziej praktyczne mogą okazać się uniwersalne powłoki TiCN lub węgliki bez powłoki, mimo gorszej wydajności przy aluminium.

Zrozumienie, gdzie powłoka DLC sprawdza się dobrze — i gdzie nie — kończy naszą ocenę indywidualnych powłok. Teraz jesteś gotowy, by porównać wszystkie te opcje obok siebie, co uczyni wybór szybszym i pewniejszym.

Precyzyjne matryce tłoczące z zoptymalizowaną integracją powłok

Poznałeś już poszczególne technologie powłok — TiAlN do pracy wysokoprędkościowej, Al2O3 do ekstremalnych temperatur, TiCN do zastosowań uniwersalnych oraz DLC do obróbki metali nieżelaznych. Ale pojawia się pytanie, na które często się nie zwraca uwagi: co się dzieje, gdy wybór powłoki jest idealny, ale podstawowy projekt narzędzia podważa jego wydajność?

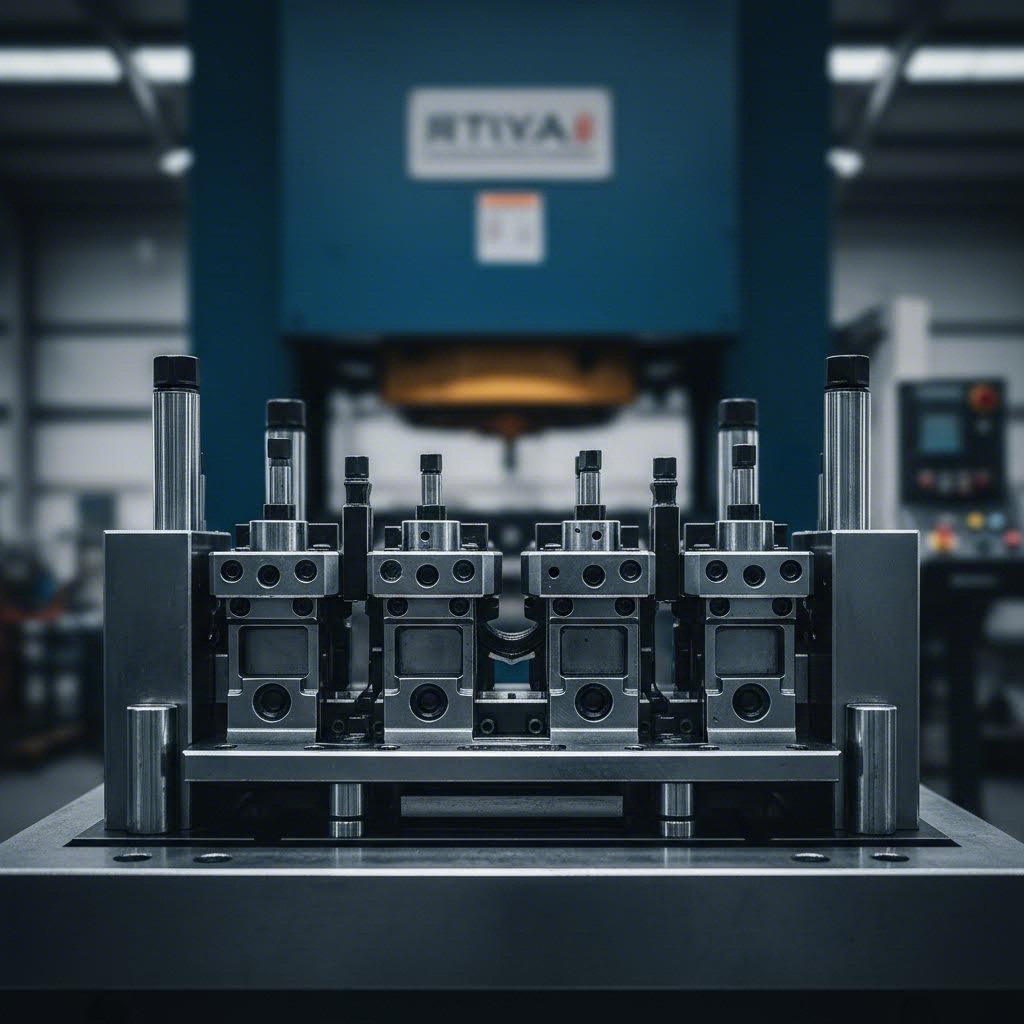

W aplikacjach tłoczni samochodowych sukces powłoki zależy od czegoś więcej niż tylko wybór między powłokami CVD a narzędziami PVD. Sam projekt matrycy — jej geometria, przygotowanie powierzchni oraz precyzja produkcji — decyduje o tym, czy inwestycja w powłokę przyniesie korzyści, czy też powłoka odpadnie po kilku tysiącach cykli.

Zintegrowane rozwiązania powłokowe dla narzędzi produkcyjnych

Zastanów się przez chwilę nad procesem osadzania cienkich warstw w próżni. Niezależnie od tego, czy stosujesz powłokę metalową PVD, czy warstwy CVD, powłoka może działać tylko tak dobrze, jak podłoże, do którego się przylega. Wady powierzchni, niewłaściwe promienie krawędzi oraz strefy o niestabilnej twardości tworzą punkty słabe, w których powłoki ulegają przedwczesnemu uszkodzeniu.

Wykrojniki produkcyjne poddawane są ekstremalnym warunkom — wysokiemu ciśnieniu kontaktowemu, ścieraniu materiału oraz zmęczeniu termicznemu przy każdym suwie. Powłoka CVD może teoretycznie zapewniać doskonałą odporność na zużycie, jednak słabe zaprojektowanie wykrojnika koncentruje naprężenia w określonych punktach, powodując pękanie powłoki już po kilku tygodniach zamiast po kilku miesiącach.

Ta rzeczywistość wymusza potrzebę kompleksowych rozwiązań, w których dobór powłoki jest realizowany równolegle z projektowaniem wykrojnika — a nie jako dodatkowe uzupełnienie. Gdy inżynierowie biorą pod uwagę wymagania dotyczące powłoki już na etapie wstępnego projektowania, mogą:

- Optymalizować promienie krawędzi, aby zapobiec koncentracji naprężeń w powłoce

- Określać odpowiednie zakresy twardości podłoża dla dobrej przyczepności powłoki

- Projektować geometrie powierzchni, które sprzyjają jednolitej grubości powłoki

- Uwzględniać grubość powłoki w końcowych tolerancjach wymiarowych

Zaawansowane procesy powlekania pacvd — warianty osadzania warstw metodą CVD z wykorzystaniem plazmy działającej w niższych temperaturach — poszerzają wybór podłoży dla złożonych geometrii matryc. Jednak te procesy nadal wymagają precyzyjnie wykonanych podłoży o spójnej jakości powierzchni.

Wpływ projektu matrycy na jakość powłoki

Kiedyś zastanawiałeś się, dlaczego identyczne powłoki różnie działają na pozornie podobnych matrycach? Odpowiedź tkwi w tym, co dzieje się przed wejściem do komory powlekarki. Symulacja CAE ujawnia wzorce naprężeń, ścieżki przepływu materiału oraz gradienty termiczne, które bezpośrednio wpływają na to, gdzie powłoki odniosą sukces lub zawiodą.

Weź pod uwagę następujące interakcje między projektem a powłoką:

Geometria krawędzi i naprężenia w powłoce: Ostre narożniki wewnętrzne powodują koncentrację naprężeń w każdej warstwie powłoki. Podczas tłoczenia te skoncentrowane obciążenia przekraczają odporność powłoki na pękanie, powodując powstawanie rys, które rozprzestrzeniają się po powierzchni roboczej. Odpowiednie promienie zaokrągleń — określone za pomocą symulacji — równomiernie rozkładają naprężenia, utrzymując obciążenia w granicach wydajności powłoki.

Wymagania dotyczące jakości powierzchni: Narzędzia PVD i powierzchnie pokryte metodą CVD wymagają określonych zakresów chropowatości podłoża dla optymalnej przyczepności. Zbyt gładka powierzchnia prowadzi do słabej blokady mechanicznej, zbyt chropowata — do nieregularnej grubości powłoki. Specyfikacja powierzchni kierowana przez CAE zapewnia odpowiednią równowagę już przed rozpoczęciem procesu powlekania.

Zarządzanie cieplne: Tłoczenie generuje ciepło w strefach kontaktu. Matryce zaprojektowane z odpowiednim rozkładem masy termicznej zapobiegają powstawaniu gorących punktów, które pogarszają właściwości powłoki. Symulacja identyfikuje te miejsca koncentracji ciepła, umożliwiając inżynierom modyfikację geometrii lub określenie lokalnych odmian powłoki.

Gdy projekt matrycy i wybór powłoki są podejmowane oddzielnie, to gra w ciemno — liczy się szczęście, czy wszystko się ze sobą zgodzi. Gdy natomiast są zintegrowane dzięki inżynierii opartej na symulacjach, podejmujesz świadome decyzje oparte na przewidywanej wydajności.

Osiągnięcie jakości przy pierwszym przebiegu dzięki zoptymalizowanemu narzędziowaniu

Brzmi skomplikowanie? Nie musi tak być — wystarczy współpracować z partnerami, którzy od samego początku projektu integrują te aspekty.

Rozwiązania matryc do precyzyjnego tłoczenia Shaoyi pokazują, jak wygląda optymalizacja powłoki w praktyce. Ich zespół inżynieryjny nie traktuje powłoki jako końcowego etapu; wymagania dotyczące powłoki są wprowadzane już na wstępnym etapie projektowania matryc poprzez zaawansowane symulacje CAE. Rezultat? Narzędzia pozbawione wad i aż 93-procentowa frekwencja akceptacji przy pierwszym przebiegu.

Co czyni tę metodę skuteczną?

- Certyfikowane systemy jakości zgodne z IATF 16949: Zarządzanie jakością na poziomie motoryzacyjnym gwarantuje, że każdy etap procesu — od projektu przez powłokę — spełnia rygorystyczne wymagania dotyczące dokumentacji i śledzenia.

- Szybkie wytwarzanie prototypów: Gotowość narzędzi już w ciągu 5 dni oznacza szybką weryfikację wydajności powłoki zamiast czekania miesiącami na wykrycie niezgodności między projektem a powłoką.

- Wsparcie inżynieryjne w doborze powłoki: Ich zespół pomaga dopasować technologie powłokowe do konkretnego zastosowania tłoczenia, biorąc pod uwagę materiał obrabiany, wielkość produkcji oraz wymagane parametry wydajności.

- Integracja symulacji CAE: Analiza naprężeń i symulacja przepływu materiału wpływają na decyzje dotyczące rozmieszczenia powłoki, zapewniając ochronę tam, gdzie matryce potrzebują jej najbardziej.

Takie kompleksowe podejście eliminuje kosztowny cykl prób i błędów, w którym zakłady odkrywają awarie powłok dopiero po rozpoczęciu produkcji. Zamiast wielokrotnie przerabiać matryce i nanosić ponownie powłoki, otrzymujesz narzędzia działające poprawnie od pierwszej tłoczonej części.

W produkcji samochodowej, gdzie przestoje szybko generują wysokie koszty, zdolność osiągania poprawnych wyników już za pierwszym razem daje znaczącą wartość. Harmonogram produkcji pozostaje nienaruszony, wskaźniki jakości są stabilne, a inwestycje w powłoki rzeczywiście przynoszą zapowiadane wydłużenie żywotności narzędzi.

Gdy projekt matrycy i integracja powłoki są już zrozumiane, możesz przejść do systematycznego porównania wszystkich dostępnych opcji powłok. Poniższa macierz porównawcza zawiera całą omówioną wcześniej wiedzę w formie praktycznego narzędzia, które możesz wykorzystać przy każdej decyzji dotyczącej narzędzi.

Kompletna macierz porównawcza powłok CVD i PVD

Przeanalizowałeś każdą technologię powłok oddzielnie – teraz najwyższy czas zobaczyć je wszystkie na jednym zestawieniu. Gdy stoisz przy szafce z narzędziami i musisz podjąć decyzję między opcjami opartymi na osadzaniu metodą CVD a PVD, potrzebujesz szybkich odpowiedzi. Ta macierz porównawcza zawiera wszystkie informacje w formie przejrzystej i łatwej do skanowania, zaprojektowanej z myślą o rzeczywistych decyzjach.

Nie trzeba już przewijać między kartami specyfikacji ani polegać na pamięci. Niezależnie od tego, czy oceniasz osadzanie chemiczne par (CVD) w porównaniu z osadzaniem fizycznym par (PVD) dla nowego zastosowania, czy weryfikujesz istniejący wybór, te tabele dają kompletny przegląd jednym rzutem oka.

Kompletna macierz porównawcza powłok

Poniższa tabela porównuje wszystkie technologie powłok oceniane w tym poradniku. Przesuwaj się wierszami, aby porównać konkretne cechy, lub kolumnami, aby poznać pełny profil każdej powłoki.

| Typ powłoki | Proces | Zakres grubości | Maksymalna temperatura pracy | Najlepsze materiały obrabianych przedmiotów | Optymalne operacje | Koszt względny |

|---|---|---|---|---|---|---|

| Zintegrowane rozwiązania matryc (różne) | PVD/CVD | Specjalistyczne do konkretnych zastosowań | Zależnie od powłoki | Materiały do tłoczenia w przemyśle motoryzacyjnym | Tłoczenie, kształtowanie, matryce wielostanowiskowe | $$-$$$ |

| TiAlN | PVD | 2–4 µm | 900°C | Stale hartowane, stale nierdzewne, stopy o wysokiej temperaturze topnienia | Frezowanie szybkościowe, wiercenie, cięcie przerywane | $$ |

| Al2O3 (Wielowarstwowy) | CVD | 8-12 µm | 1000°C+ | Żeliwo, stal węglowa, stal stopowa | Obcinanie ciągłe, toczenie zgrubne | $$$ |

| TiCN | PVD | 2–4 µm | 400°C | Stale, stale nierdzewne, metale nieżelazne | Gwintowanie, kształtowanie, frezowanie uniwersalne | $$ |

| TiCN | CVD | 5–10 µm | 450°C | Stale, materiały ścierne | Tokarka ciągła, cięcie ściernym narzędziem | $$-$$$ |

| DLC | PVD | 1-3 µm | 350-400°C | Aluminium, stopy miedzi, metale nieżelazne | Obróbka sucha, aluminium lotnicze, wykańczanie | $$$ |

| TiN (Referencyjny) | PVD | 2–4 µm | 600°c | Stale ogólne, zastosowania łagodne | Zastosowanie uniwersalne, operacje o niskim obciążeniu | $ |

Zauważ, jak różnice między osadzaniem par fizycznych a chemicznych wyraźnie odzwierciedlają się w grubości i temperaturze pracy. Technologie CVD konsekwentnie wytwarzają grubsze warstwy o wyższej odporności na temperaturę, podczas gdy systemy PVD wyróżniają się zachowaniem geometrii krawędzi dzięki cieńszym osadom.

Rekomendacje specyficzne dla operacji w skrócie

Znajomość specyfikacji powłok to jedno — dopasowanie ich do rzeczywistych warunków pracy to zupełnie inne. Ten przewodnik szybkiego odniesienia łączy typowe scenariusze obróbki z zalecanymi wyborami powłok.

Frezowanie wysokoprędkościowe (stal i stal nierdzewna): TiAlN PVD. Samotworząca się bariery tlenkowa radzi sobie z cyklicznym obciążeniem termicznym wynikającym z przerywanej skrawania, zachowując przy tym ostrość krawędzi.

Obróbka ciągła (żeliwo): Al2O3 CVD. Wielowarstwowa bariera termiczna chroni przed długotrwałym działaniem wysokich temperatur oraz ściernym działaniem płatków grafitu.

Operacje gwintowania: PVD TiCN. Cienka powłoka zachowuje krytyczną geometrię gwintu, jednocześnie zmniejszając tarcie, co umożliwia czyste odprowadzanie wiórów.

Obróbka aluminium (aeronautyka): DLC PVD. Nadzwyczaj niska tarcie zapobiega tworzeniu się nadżek, umożliwiając suchą obróbkę z doskonałą jakością powierzchni.

Głębine frezowanie (stal): CVD TiCN lub Al2O3 CVD. Grubsze warstwy powłoki zapewniają rezerwę odporności na zużycie przy intensywnym usuwaniu materiału.

Wykrojniki i matryce do kształtowania: Rozwiązania kompleksowe z optymalizacją powłoki. Projekt matrycy i dobór powłoki muszą być ze sobą zsynchronizowane, aby osiągnąć maksymalną wydajność.

Porównując zastosowania CVD z przypadkami użycia PVD, pojawia się wyraźny wzorzec: systemy CVD dominują w ciągłych operacjach wysokotemperaturowych, podczas gdy systemy PVD świetnie sprawdzają się w precyzyjnych zadaniach wymagających ostrych krawędzi i odporności na szok termiczny.

Szybka tabela kompatybilności podłoży

Oto istotny aspekt, który często pomija się w dyskusjach na temat powłok: nie każda powłoka jest kompatybilna z każdym rodzajem podłoża narzędziowego. Temperatury procesu decydują o kompatybilności, a błędny wybór niszczy inwestycję w narzędzia jeszcze zanim zaczną one cięć metalu.

| Materiał podłoża | TiAlN (PVD) | Al2O3 (CVD) | TiCN (PVD) | TiCN (CVD) | DLC (PVD) |

|---|---|---|---|---|---|

| Złączony twardometal | ✓ Doskonały | ✓ Doskonały | ✓ Doskonały | ✓ Doskonały | ✓ Doskonały |

| Stal szybkotnąca (HSS) | ✓ Dobre | ✗ Niekompatybilny | ✓ Dobre | ✗ Niekompatybilny | ✓ Dobre |

| Cermet | ✓ Dobre | ✗ Niekompatybilny | ✓ Dobre | ✗ Ograniczony | ✓ Dobre |

| Stal narzędziowa (utwardzona) | ✓ Dobre | ✗ Niekompatybilny | ✓ Dobre | ✗ Niekompatybilny | ✓ Dobre |

Wzorzec jest oczywisty: systemy CVD wymagają podłoży z węglika spiekanego ze względu na temperatury procesu przekraczające 850°C. Jeśli używasz narzędzi ze stali szybkotnącej (HSS), opcje zawężają się wyłącznie do technologii PVD.

Kiedy NIE stosować każdego powłokowania

Oto o czym unikają rozmów konkurenci — przeciwwskazania dla każdego typu powłokowania. Zrozumienie, gdzie powłoki zawodzą, zapobiega kosztownym błędom w zastosowaniach.

| Typ powłoki | Nie używać w przypadku | Dlaczego ulega awarii |

|---|---|---|

| TiAlN (PVD) | Ciężkie toczenie z ekstremalnymi głębokościami skrawania; ciągłe toczenie w wysokich temperaturach trwające ponad 20 minut | Cienka warstwa powłoki szybko wyczerpuje zapas na zużycie; brak masy termicznej do długotrwałego oddziaływania ciepła |

| Al2O3 (CVD) | Narzędzia ze stali HSS; dokładne wykańczanie wymagające ostrych krawędzi; skrawanie przerywane z silnym szokiem termicznym | Temperatura procesu niszczy stal HSS; gruba powłoka zaokrągla krawędzie; naprężenia resztkowe mogą powodować pęknięcia pod wpływem udaru |

| TiCN (PVD) | Zastosowania w ekstremalnie wysokich temperaturach powyżej 400°C; ciężkie warunki zużycia przez ścieranie | Ograniczenia temperaturowe ograniczają potencjał prędkościowy; cienka warstwa nie zapewnia wystarczającego zapasu na zużycie przy intensywnym ścieraniu |

| TiCN (CVD) | Narzędzia ze stali HSS; precyzyjne gwintowanie lub formowanie, gdzie geometria krawędzi ma kluczowe znaczenie | Temperatura procesu jest niekompatybilna; grubsza powłoka zmienia wymiary narzędzia poza dopuszczalne tolerancje |

| DLC (PVD) | Obróbka materiałów żelaznych (stal, żeliwo, stal nierdzewna); operacje powyżej 350°C | Węgiel dyfuunduje do matrycy żelaznej, niszcząc powłokę; degradacja termiczna rozpoczyna się w niższych temperaturach niż w przypadku innych rozwiązań |

Ta tabela przeciwwskazań odpowiada na pytania, których może unikać dostawca narzędzi. Gdy dokładnie wiesz, gdzie każda powłoka ulega awarii, dokonujesz świadomych wyborów, które działają zgodnie z oczekiwaniami, a nie odkrywasz ograniczeń podczas produkcji.

Mając te macierze porównawcze, jesteś gotowy, by stworzyć systemowy model decyzyjny dopasowujący odpowiednią technologię powłoki do Twojej konkretnej operacji — właśnie to zapewnia ostatnia sekcja.

Ostateczne rekomendacje dotyczące wyboru powłoki

Zapoznałeś się z danymi technicznymi, przeanalizowałeś macierze porównawcze i wiesz, w jakich obszarach każdy rodzaj powłoki odznacza się najlepszymi właściwościami. Nadchodzi pytanie praktyczne: jak przekuć tę wiedzę na odpowiednią decyzję dla Twojej konkretnej operacji? Odpowiedź tkwi w systematycznym podejściu decyzyjnym, które wyeliminuje domysły i dopasuje technologię powłoki do rzeczywistych wymagań obróbki.

Rozumienie, czym jest powłoka PVD lub czym jest powłoka CVD, jest mniej istotne niż wiedza, która z nich rozwiązuje Twój konkretny problem. Stwórzmy proces decyzyjny, który możesz zastosować przy wyborze dowolnego narzędzia.

Twoja ramy decyzyjne doboru powłoki

Traktuj dobór powłoki jak diagnozowanie usterki — postępuj krok po kroku, eliminując opcje, które nie pasują, aż pojawi się właściwa odpowiedź. Ten priorytetowy schemat decyzyjny poprowadzi Cię dokładnie tym procesem:

- Zidentyfikuj główny materiał przedmiotu obrabianego. Ten pojedynczy czynnik natychmiast eliminuje całe kategorie powłok. Obrabiasz aluminium? DLC przenosi się na szczyt listy, podczas gdy powłoki optymalizowane do żelaza odpadają. Cięcie hartowanej stali? TiAlN i Al2O3 stają się głównymi kandydatami. Materiał obrabiany decyduje, które chemie powłok mogą w ogóle skutecznie działać.

- Określ typ operacji cięcia. Tokarka ciągła a frezowanie przerywane wymagają zasadniczo różnych właściwości powłok. Operacje ciągłe preferują grubsze powłoki CVD o lepszej pojemności cieplnej. Przerywane cięcia potrzebują cieńszych warstw osadzanych metodą osadzania z fazy gazowej (PVD), które wytrzymują cyklowanie termiczne bez pęknięć. Gwintowanie i kształtowanie wymagają powłok wystarczająco cienkich, by zachować krytyczną geometrię narzędzia.

- Oceń wymagania dotyczące temperatury i prędkości. Z jakimi prędkościami skrawania będziesz pracować? Wyższe prędkości generują więcej ciepła, co skłania do wyboru powłok o podwyższonych temperaturach pracy. W tym miejscu kluczowe staje się znaczenie osadzania par fizycznych (PVD) — niższe temperatury procesu PVD zachowują twardość podłoża w zastosowaniach wrażliwych na ciepło, podczas gdy grubsze warstwy CVD zapewniają barierę termiczną przy długotrwałym skrawaniu w wysokich temperaturach.

- Oceń kompatybilność podłoża. Właśnie tutaj wiele błędów popełnia się przy doborze. Materiał podłoża Twojego narzędzia całkowicie ogranicza dostępne opcje powłok. Stal szybkotnąca nie wytrzyma temperatur procesu CVD — punkt kropki. Jeśli pracujesz narzędziami ze stali szybkotnącej (HSS), musisz wybrać wyłącznie spośród opcji PVD, niezależnie od tego, co sugerowałaby aplikacja. Podłoża węglikowe oferują pełną elastyczność w zakresie obu technologii.

- Weź pod uwagę objętość produkcji i cele kosztowe. Powłoka, która wydłuża żywotność narzędzi o 300%, ale kosztuje o 400% więcej, ma sens tylko przy określonych wielkościach produkcji. Oblicz swój koszt na sztukę przy różnych opcjach powłok. Czasem ta „gorsza” powłoka zapewnia lepszą opłacalność w Twojej konkretnej sytuacji.

Dopasowanie Twojej operacji do odpowiedniej technologii

Zastosujmy ten schemat do typowych scenariuszy, z którymi możesz się spotkać:

Scenariusz: toczenie stali w wysokiej serii samochodowej

Analiza drzewa decyzyjnego: materiał stalowy sugeruje TiAlN, TiCN lub Al2O3. Operacja toczenia ciągłego preferuje grubsze powłoki CVD. Wysokie prędkości generują trwałe temperatury – właściwości termoizolacyjne Al2O3 stają się atrakcyjne. Płytki węglikowe pozwalają na pełną elastyczność technologiczną. Wysoka seria uzasadnia inwestycję w droższą powłokę. Rekomendacja: wielowarstwowa powłoka Al2O3 metodą CVD.

Scenariusz: frezowanie konstrukcji aluminiowych w przemyśle lotniczym

Element z aluminium natychmiast wskazuje na DLC. Operacja frezowania z przerywanym skrawaniem sprzyja odporności termicznej PVD na szok cieplny. Umiarkowane temperatury pozostają w zakresie pracy DLC. Frezy z węglików spiekanych są kompatybilne. Wymagania branży lotniczej dotyczące jakości powierzchni uzasadniają wyższy koszt DLC. Rekomendacja: Powłoka DLC metodą PVD z parametrami obróbki na sucho.

Scenariusz: Zróżnicowane operacje gwintowania w warsztacie uniwersalnym

Różne materiały wymagają uniwersalnej powłoki. Gwintowanie wymaga precyzyjnej geometrii krawędzi – tylko cienkie powłoki. Umiarkowane temperatury w całym zakresie materiałów. Dorabiacze HSS dostępne w magazynie wymagają kompatybilności z PVD. Wrażliwość cenowa w zróżnicowanych zleceniach. Rekomendacja: PVD TiCN ze względu na uniwersalność i zachowanie ostrości krawędzi.

Zauważ, że napylanie jonowe i inne odmiany PVD pojawiają się konsekwentnie, gdy najważniejsze są ostrość krawędzi i elastyczność podłoża. Aby prosto określić zalety powłok PVD: niższe temperatury, cieńsze warstwy, szersza kompatybilność podłoży oraz lepsze utrzymanie krawędzi.

Kiedy stosowanie narzędzi niepowlekanych ma sens

Oto wskazówki, których nie znajdziesz w większości dyskusji na temat powłok: czasami brak powłoki jest właściwą odpowiedzią. Rozważ użycie narzędzi bez powłoki, gdy:

- Praca prototypowa o niskiej liczbie sztuk gdy czas realizacji powłoki przekracza terminy projektu

- Obróbka miękkich materiałów (plastików, drewna, miękkiego aluminium), gdzie korzyści z powłoki są minimalne

- Wyjątkowo przerywane operacje gdy przyczepność powłoki narażona jest na nadmierny naprężenie mechaniczne

- Zastosowania wrażliwe na koszty gdzie wydłużenie żywotności narzędzia nie rekompensuje kosztu powłoki

- Programy przeciernia gdzie narzędzia będą ostrzone wielokrotnie — koszty powłokowania rosną w każdej kolejnej iteracji

Niepowlekany węglik spiekany lub HSS pozostaje uzasadnionym wyborem w określonych zastosowaniach. Nie pozwól entuzjazmowi dla powłok zasłonić prostych kalkulacji ekonomicznych.

Następne kroki wdrożeniowe

Optymalne wyniki osiąga się dopiero wtedy, gdy technologia powłoki jest dostosowana zarówno do zastosowania, jak i do jakości podstawowego narzędzia. Nawet najbardziej zaawansowana powłoka na źle zaprojektowanym lub wyprodukowanym narzędziu nadal ulegnie przedwczesnemu uszkodzeniu. Dlatego tak ważne jest współpracowanie z certyfikowanymi partnerami produkującymi narzędzia.

Rozwiązania matryc do precyzyjnego tłoczenia Shaoyi pokazują, jak specyfikacje powłok powinny być dostosowane do projektu matrycy już od początku projektu. Ich procesy certyfikowane według IATF 16949 gwarantują, że wybór powłoki integruje się z symulacją CAE, przygotowaniem podłoża i kontrolą wymiarową — zapewniając współczynnik akceptacji za pierwszym razem na poziomie 93%, co pozwala utrzymać produkcję zgodnie z harmonogramem.

W celu wdrożenia wykonaj następujące kroki:

- Przeanalizuj obecną wydajność narzędzi Zidentyfikuj, które narzędzia ulegają przedwczesnemu uszkodzeniu i dlaczego. Dokumentuj wzorce zużycia, sposoby uszkodzeń oraz warunki pracy.

- Zastosuj ramy decyzyjne. Przeanalizuj pięciokrokowy proces dla każdej problematycznej aplikacji. Udokumentuj swoje rozumowanie w celach archiwalnych.

- Rozpocznij od aplikacji o największym wpływie. Skoncentruj się na ulepszeniach powłok najgorzej działających narzędzi lub tych o najwyższym wskaźniku zużycia.

- Śledź wyniki w sposób systematyczny. Mierz żywotność narzędzia, jakość wykończenia powierzchni oraz koszt na sztukę przed i po zmianie powłoki. Dane potwierdzają decyzje i kierują kolejnymi wyborami.

- Współpracuj z dostawcami skupionymi na jakości. Nie ważne, czy zakupione są powleczone płytki, czy też określone powłoki dla narzędzi specjalnych, współpracuj z partnerami, którzy rozumieją zarówno technologię powłok, jak i integrację projektowania narzędzi.

Różnica między powłokami CVD a PVD dla narzędzi sprowadza się ostatecznie do dopasowania technologii do zastosowania. Mając ten schemat decyzyjny, jesteś w stanie dokonać wyboru maksymalizującego żywotność narzędzia, optymalizującego efektywność obróbki i zapewniającego opłacalność kosztów na sztukę wymaganą przez Twoją operację.

Często zadawane pytania dotyczące powłok CVD i PVD dla narzędzi

1. Jaka jest główna różnica między powłokami PVD i CVD dla narzędzi tnących?

Główna różnica dotyczy metody napylania i temperatury. PVD (osadzanie fizyczne z fazy gazowej) wykorzystuje procesy fizyczne przy niższych temperaturach (400–500°C), tworząc cieńsze powłoki (2–4 µm), które zachowują ostre krawędzie tnące. CVD (osadzanie chemiczne z fazy gazowej) wykorzystuje reakcje chemiczne przy wyższych temperaturach (800–1050°C), tworząc grubsze warstwy (5–12 µm) o lepszych właściwościach barier cieplnych. PVD nadaje się do cięcia przerywanego i podłoży ze stali szybkotnącej (HSS), podczas gdy CVD doskonale sprawdza się w ciągłym toczeniu przy wysokich temperaturach na narzędziach węglikowych.

2. Czy preferujesz płytki tokarskie PVD czy CVD do użytku ogólnego?

Wybór zależy od Twojej konkretnej operacji. W przypadku toczenia stali z ciągłym skrawaniem, płytki CVD z warstwami Al2O3 oferują doskonałą ochronę termiczną i dłuższy okres żywotności. W przypadku uniwersalnego obrabiania różnych materiałów, w tym stali nierdzewnej, oraz przy skrawaniu przerywanym, powłoki PVD TiAlN zapewniają lepsze utrzymywanie ostrości krawędzi i odporność na zmęczenie termiczne. Wiele zakładów utrzymuje oba typy, wybierając je w zależności od tego, czy zadanie priorytetowo wymaga odporności na ciepło (CVD), czy ostrości krawędzi (PVD).

3. Dlaczego powinienem stosować powłoki PVD lub CVD na swoich narzędziach skrawających?

Powłoki przedłużają żywotność narzędzi o 200–400%, gdy są odpowiednio dopasowane do zastosowań. Zmniejszają one tarcie, odpornają na zużycie i zapewniają bariery termiczne chroniące podłoże. Powłoki PVD umożliwiają wyższe prędkości skrawania stali hartowanych przy zachowaniu ostrych krawędzi. Powłoki CVD zapobiegają zużyciu kraterowemu i dyfuzji podczas ciągłego skrawania w wysokich temperaturach. Odpowiednia powłoka zmniejsza koszt na sztukę, minimalizuje wymiany narzędzi i poprawia jakość wykończenia powierzchni.

4. Czy mogę stosować powłoki CVD na narzędziach ze stali szybkotnącej?

Nie, powłoki CVD są niekompatybilne z podłożami ze stali szybkotnącej. Proces CVD odbywa się w temperaturze 850–1050°C, która przekracza temperatury odpuszczania stali HSS i zniszczyłaby twardość oraz integralność strukturalną narzędzia. W przypadku narzędzi HSS należy wybrać powłoki PVD, takie jak TiAlN, TiCN lub DLC, które są napylane w niższych temperaturach (400–500°C), zachowując właściwości podłoża.

5. Która powłoka jest najlepsza do obróbki aluminium bez chłodziwa?

Powłoka DLC (Diamond-Like Carbon) metodą PVD jest optymalnym wyborem do obróbki suchej aluminium. Jej ekstremalnie niski współczynnik tarcia (0,05–0,15) zapobiega powstawaniu przyrostów, które utrudniają pracę przy innych powłokach podczas toczenia aluminium. DLC umożliwia wydajną obróbkę suchą lub z zastosowaniem MQL, eliminuje koszty środków chłodzących i zapewnia wyjątkowo gładkie wykończenie powierzchni poniżej Ra 0,8 µm. Jednak DLC nadaje się wyłącznie do materiałów nieżelaznych i charakteryzuje się niższą odpornością na temperaturę (350–400°C) w porównaniu z innymi rozwiązaniami.

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —

Małe partie, wysokie standardy. Nasza usługa szybkiego prototypowania sprawia, że weryfikacja jest szybsza i łatwiejsza —