Laser For Cutting Aluminum: Why Your Edges Look Terrible

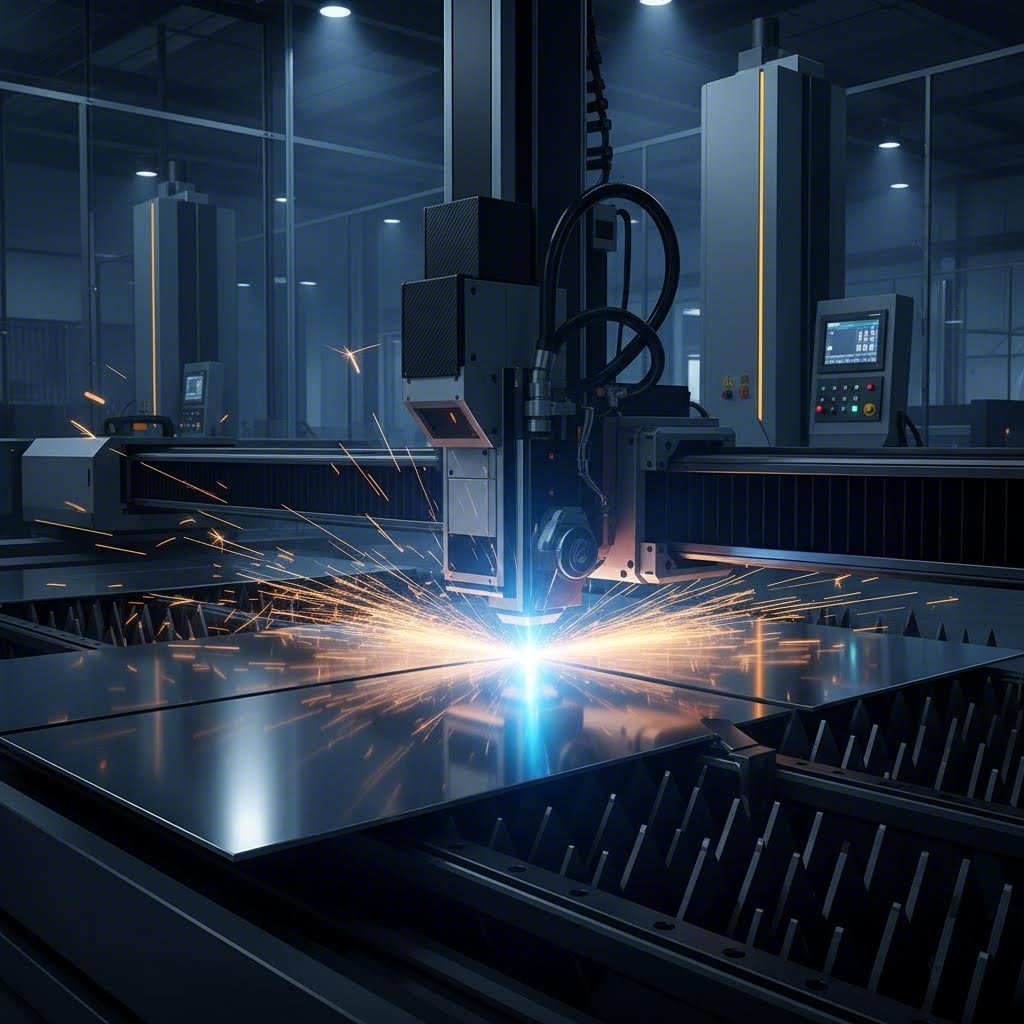

Understanding Laser Technology for Aluminum Fabrication

Laser cutting for aluminum uses a highly focused beam of light to slice through aluminum sheets with remarkable precision. This technology has transformed metal fabrication by delivering clean edges, tight tolerances, and the ability to create complex geometries impossible with traditional methods. But here's the catch: aluminum doesn't behave like steel under a laser beam, and that difference is exactly why your edges might look terrible.

Can you laser cut aluminum? Absolutely. However, this material presents unique challenges that demand specialized approaches. Unlike carbon steel or stainless steel, aluminum possesses high reflectivity and exceptional thermal conductivity. These properties can scatter the laser beam, dissipate heat too quickly, and even reflect dangerous levels of energy back into the machine's optics. Understanding these characteristics is the first step toward achieving professional-grade results.

Why Aluminum Demands Specialized Laser Technology

When you're laser cutting aluminum, you're essentially working against the material's natural properties. Aluminum's thermal conductivity means heat disperses rapidly away from the cutting zone, requiring higher power densities to maintain an effective cut. Additionally, the material's low viscosity when molten can lead to poor edge quality if parameters aren't precisely dialed in.

According to TWI Global, aluminum's reflectivity doesn't come entirely from the sheet surface—it's caused by the formation of a molten pool which can be highly reflective. This means simply coating the surface won't eliminate the problem. As a general rule, adding alloying elements reduces reflectivity, so pure aluminum is actually harder to process than common 5000 series alloys.

Aluminum reflects laser energy at rates significantly higher than steel, and its thermal conductivity disperses heat up to five times faster. These two properties working together are precisely why aluminum laser cutting requires fundamentally different parameters than steel cutting.

The Reflectivity Challenge Explained

All metals reflect CO2 laser beams until a certain power density threshold is reached. With aluminum, this threshold is considerably higher. The real danger? A reflected laser beam can travel back through the beam delivery optics and into the laser itself, potentially causing significant damage to your equipment.

Modern laser cutting machines designed for aluminum cutting typically include what manufacturers call an "aluminum cutting system." This is actually a back reflection protection system that detects when too much laser radiation is bouncing back through the optics. When triggered, it automatically stops the laser before major damage occurs. Without this protection, processing aluminum carries genuine risk to your investment.

Beyond cutting applications, laser marking aluminium and laser aluminium engraving face similar reflectivity challenges, though at lower power levels. The same principles of wavelength selection and proper machine configuration apply across these aluminum processing techniques.

Throughout this guide, you'll learn how to select the right equipment for your aluminum fabrication needs, optimize cutting parameters for clean edges, and troubleshoot common defects. This is vendor-neutral technical guidance focused on helping you understand the science behind successful aluminum laser cutting—whether you're running a production facility or a small fabrication shop.

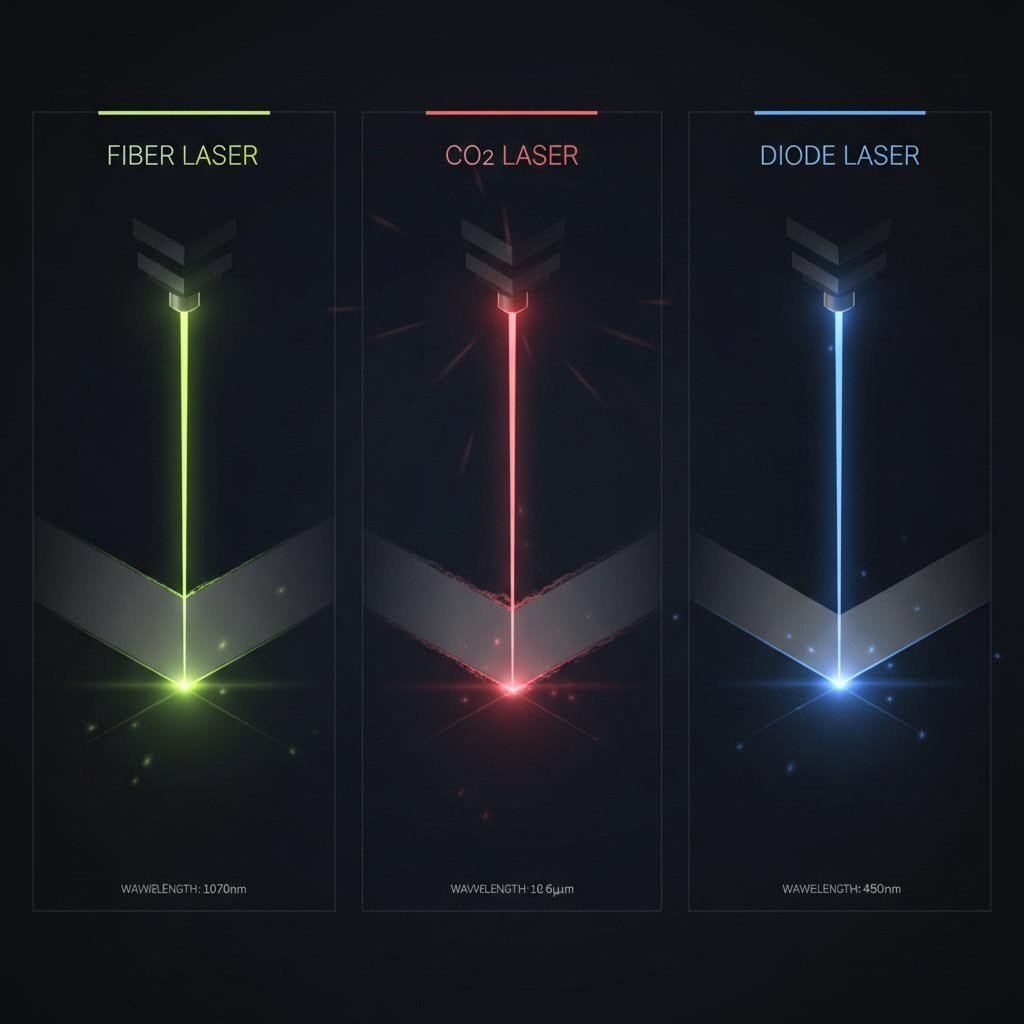

Fiber vs CO2 vs Diode Lasers for Aluminum

Choosing the right laser technology for aluminum fabrication isn't just about picking the most powerful option—it's about matching wavelength characteristics to aluminum's unique material properties. The laser type you select directly determines your cut quality, processing speed, and long-term operating costs. Let's break down exactly how CO2, fiber, and diode lasers perform when cutting this challenging reflective metal.

Fiber vs CO2 Lasers for Reflective Metals

Fiber laser cutting aluminum has become the dominant approach in modern fabrication shops, and there's solid science behind this shift. According to LS Manufacturing's technical analysis, fiber lasers possess an electro-optical conversion efficiency exceeding 30%, significantly greater than traditional CO2 laser technology. This efficiency advantage translates directly into lower power consumption and reduced cooling system demands.

But efficiency isn't the only reason fiber laser metal cutting dominates aluminum applications. The real advantage lies in wavelength absorption. Fiber lasers operate at approximately 1064nm (1μm), which aluminum absorbs far more readily than the 10.6μm wavelength produced by CO2 lasers. This higher absorption rate means more energy goes into cutting rather than reflecting back toward your optics.

CO2 laser cut aluminum applications haven't disappeared entirely. These systems can still deliver smooth cut surfaces on extremely thick aluminum plates—typically 15mm and above—where the longer wavelength creates improved coupling with the metal plasma. However, their electro-optical conversion efficiency of roughly 10% results in significantly higher power consumption. You'll also face ongoing costs for laser gas and reflector replacements that fiber systems simply don't require.

Diode lasers represent the entry-level option for metal laser cutting, but they come with significant limitations for aluminum work. While these systems offer the most affordable upfront investment, their lower power output restricts them to thin materials and slower processing speeds. For hobbyists or occasional prototype work on thin aluminum sheet, a diode laser might suffice. For production environments, you'll quickly outgrow these capabilities.

Why Wavelength Matters for Aluminum

Imagine shining a flashlight at a mirror versus a matte surface. The mirror reflects most of the light, while the matte surface absorbs it. Aluminum behaves similarly with laser wavelengths—but the degree of reflection varies dramatically based on the specific wavelength used.

At the 10.6μm wavelength of CO2 lasers, aluminum reflects a substantial portion of the beam energy. This reflection doesn't just waste power; it creates genuine equipment risk. That reflected energy can travel back through your beam delivery system and damage optical components or even the laser source itself.

Fiber laser cutters operating at 1064nm experience significantly better energy coupling with aluminum's surface. The material absorbs more of the incoming energy, creating a more stable and efficient cutting process. Modern high-power fiber systems from manufacturers like IPG incorporate proprietary anti-reflection technology that monitors and regulates reflected light, essentially optimizing safety and stability during the aluminum cutting process.

A fibre laser cutter also produces a highly focused beam with excellent beam quality. This allows for narrower kerfs and smaller heat-affected zones—critical factors when you need sharp edges and smooth cross-sections on precision aluminum components.

| Specification | Fiber Laser | CO2 Laser | Diode Laser |

|---|---|---|---|

| Wavelength | 1064nm (1μm) | 10,600nm (10.6μm) | 800-980nm |

| Aluminum Absorption Rate | High | Low to Moderate | Moderate |

| Maximum Thickness Capability | Up to 25mm+ (high power) | Up to 20mm+ (thick plate advantage) | Up to 3mm |

| Edge Quality on Aluminum | Excellent | Good (better on thick plates) | Fair |

| Electrical Efficiency | 30%+ wall plug efficiency | ~10% wall plug efficiency | ~25% wall plug efficiency |

| Cutting Speed (thin/medium sheets) | Very Fast | Moderate | Slow |

| Relative Equipment Cost | Moderate to High | Moderate | Low |

| Ongoing Operating Costs | Low | High (gas, reflectors, energy) | Low |

| Back-Reflection Risk | Managed with built-in protection | Higher risk | Moderate risk |

When should you consider each laser metal cutting machine type? Here's practical guidance based on real-world production requirements:

- Fiber laser for metal cutting: Choose this when processing aluminum sheets up to 12mm thick at production volumes. The combination of speed, edge quality, and low operating costs delivers the best return on investment for most fabrication operations.

- CO2 laser systems: Consider these primarily if you're already running an established CO2 operation and occasionally process thick aluminum plates above 15mm. For new equipment purchases, fiber technology typically makes more financial sense.

- Diode lasers: Best suited for hobbyists, prototyping thin materials, or shops with minimal aluminum cutting requirements. Don't expect production-level throughput or thick material capability.

The bottom line? For the vast majority of aluminum cutting operations—especially materials below 12mm—fiber lasers deliver overwhelming advantages in efficiency, quality, and operating cost. This explains why leading fabrication companies have standardized on fiber technology for their aluminum processing needs.

Understanding laser technology selection is just the starting point. Your next consideration involves matching laser power to your specific material thickness requirements—a critical decision that directly impacts both equipment investment and processing capability.

Power Requirements and Equipment Selection Guide

So you've decided fiber laser technology is the right choice for your aluminum cutting needs. But here's where many fabricators make costly mistakes: selecting the wrong wattage for their material thickness requirements. Underpowered machines struggle to penetrate thicker aluminum, while overpowered systems waste capital on capabilities you'll never use. Let's map exactly what power levels you need for specific aluminum thicknesses.

Matching Laser Power to Material Thickness

When it comes to metal laser cutting machine selection, power directly determines your maximum cutting thickness and processing speed. According to Accurl's technical documentation, the relationship between laser power and aluminum cutting capability follows predictable patterns that should guide your equipment decisions.

Here's the practical breakdown based on industry data:

- 500W-1000W fiber lasers: Handle aluminum up to 3mm thick. A 1000W system delivers maximum thickness of 3mm for aluminum, making these entry-level options suitable for thin sheet work.

- 1500W fiber lasers: Extend capability to approximately 4mm aluminum thickness. This represents the sweet spot for small fabrication shops handling general-purpose work.

- 2 kW laser cutting machine: Reaches aluminum up to 6mm thick. A 2000W system provides excellent versatility for medium-duty production environments.

- 3000W-4000W fiber lasers: Push aluminum cutting thickness to 8-10mm respectively. These mid-range industrial systems handle structural components and thicker architectural panels.

- 6000W and above: Achieve aluminum thicknesses of 15mm or more, though you'll rarely need this capability outside specialized heavy industrial applications.

Sounds straightforward? Here's the nuance most equipment guides miss: maximum cutting thickness isn't the same as optimal cutting thickness. A 2kW laser might technically cut 6mm aluminum, but edge quality and processing speed improve dramatically when you operate below maximum capacity. For production work, aim for equipment rated 20-30% above your typical material thickness.

Consider a packaging equipment manufacturer mentioned in Kirin Laser's case studies who brought aluminum cutting in-house using a 1500W fiber laser. They consistently cut 2mm aluminum cleanly with minimal cleanup, achieving excellent results because they weren't pushing their equipment to its limits.

Investment Considerations by Production Scale

How much is a laser cutting machine? The honest answer depends on your production requirements, desired features, and quality expectations. Laser cutting machine price varies dramatically based on several interconnected factors rather than just wattage alone.

Based on current market analysis from STYLECNC's equipment overview, here's how pricing tiers generally break down:

- Entry-level systems ($6,000-$15,000): Include basic CO2 sheet metal cutters and beginner fiber laser systems. Desktop fiber laser options fall into this category, suitable for hobbyists and small shops with occasional aluminum cutting needs.

- Mid-range professional systems ($18,000-$36,000): Cover enthusiast and professional-grade metal laser cutting machines with power options from 1500W to 4000W. These systems include features like autofocus cutting heads and industrial control software.

- Industrial/enterprise systems ($36,000-$100,000+): Represent production-grade equipment with high wattage options (6000W to 40000W), larger bed sizes, automation features, and comprehensive support packages.

Beyond wattage, several factors significantly affect equipment cost:

- Bed size: A standard 5x10 foot cutting table costs less than larger format machines. Match bed size to your typical sheet dimensions.

- Automation features: Auto-feeding systems, rotary attachments for tube cutting, and material handling automation add substantial cost but dramatically improve throughput.

- Laser source brand: Premium brands like IPG command higher prices than domestic alternatives like Raycus or MAX, though quality differences have narrowed considerably.

- Control system sophistication: Advanced CNC controllers with better nesting software and user interfaces cost more but improve material utilization and operator efficiency.

- Brand positioning: Established manufacturers with proven support networks typically price higher than newer market entrants.

For hobbyists and small shops exploring aluminum cutting, a small metal laser cutter or table laser cutting machine offers an accessible entry point. These compact systems won't match industrial throughput, but they enable prototype work and small-batch production without massive capital investment. A metal laser cutting machine for home use typically falls in the $6,000-$15,000 range for fiber-based systems capable of handling thin aluminum sheets.

The key is matching your investment to realistic production needs. A shop processing 3mm aluminum panels for signage doesn't need a 6kW industrial system. Conversely, an aerospace subcontractor cutting 10mm structural components can't rely on an entry-level desktop unit. Evaluate your typical material thickness, production volume, and growth trajectory before committing capital.

With power requirements and equipment tiers understood, your next consideration involves the specific aluminum alloys you'll be processing—because not all aluminum cuts the same way.

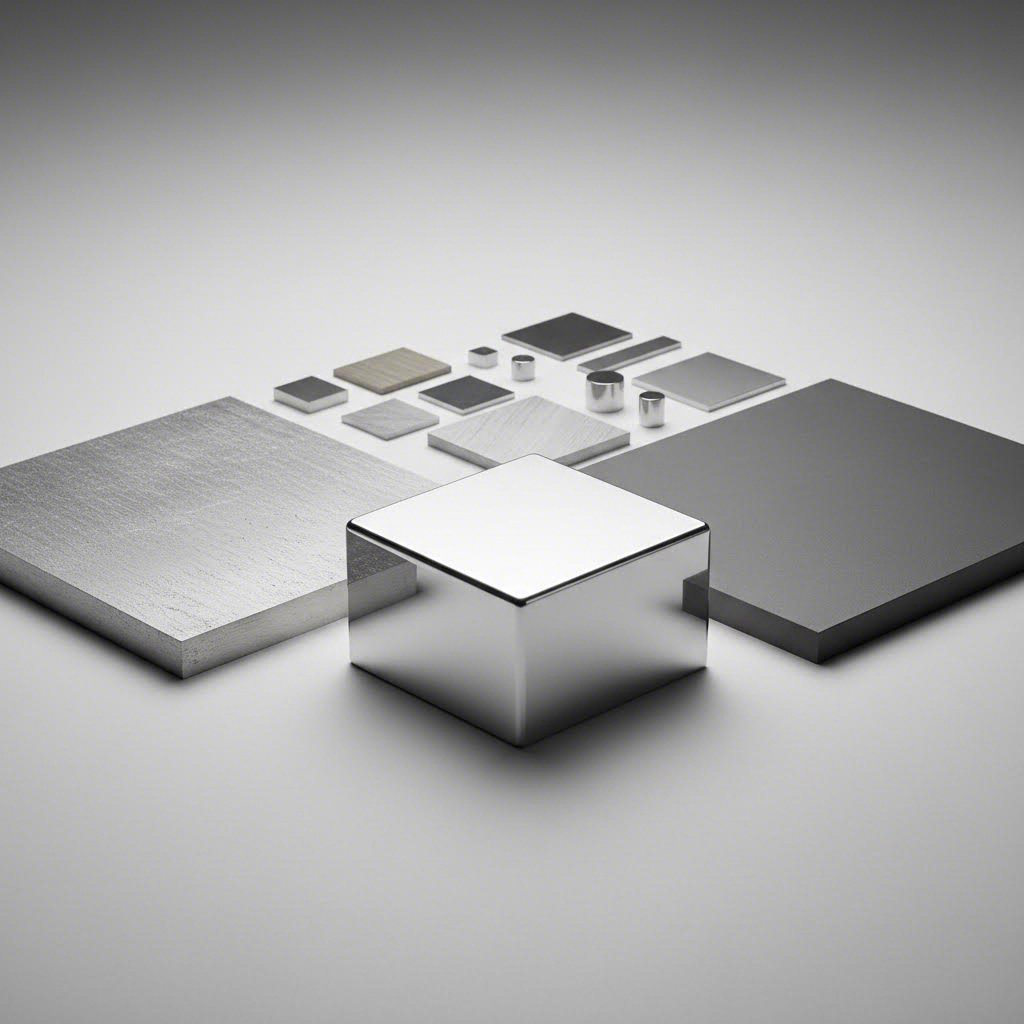

Aluminum Alloy Variations and Cutting Performance

Here's something most laser cutting guides completely overlook: not all aluminum behaves the same under a laser beam. The specific alloy you're cutting dramatically affects edge quality, parameter requirements, and processing speed. If you've been using identical settings for every aluminum sheet that hits your cutting table, you're likely leaving quality and efficiency on the table.

Aluminum alloys contain different combinations of elements—copper, magnesium, silicon, zinc—that alter thermal conductivity, melting characteristics, and surface finish potential. Understanding these differences is the key to achieving consistently clean edges across your entire material inventory.

Alloy Selection Impact on Cut Quality

When cutting aluminum sheet metal, the alloy series tells you almost everything you need to know about how the material will respond to your laser. Let's examine the four most common alloys you'll encounter in aluminium laser cutting operations:

6061 Aluminum: This workhorse alloy is alloyed primarily with magnesium and silicon, offering excellent all-around machinability. According to Xometry's technical resources, 6061 is among the common aluminum grades processed by laser cutting due to its favorable characteristics. You'll find it delivers predictable cut quality with standard parameters, making it ideal for operators developing their baseline settings. Applications range from structural components to general fabrication work.

5052 Aluminum: Marine-grade applications favor this magnesium-alloyed series for its exceptional corrosion resistance and weldability. When you laser cut aluminium in the 5052 series, expect slightly different behavior than 6061—the higher magnesium content affects how heat disperses through the material. Post-cut welding operations benefit from 5052's excellent weldability, making it popular for boat hulls, fuel tanks, and marine fittings.

7075 Aluminum: Here's where things get interesting. This zinc-alloyed aerospace grade provides exceptional strength—SendCutSend notes it's strong enough to replace steel in many structural applications while remaining significantly lighter. However, 7075 requires more careful handling during fabrication. Heat buildup must be controlled to prevent localized softening of the T6 temper, and the alloy's hardness can affect tool and nozzle wear over time.

3003 Aluminum: When you need maximum formability and clean edges on decorative work, 3003 delivers. This highly formable alloy contains manganese as its primary addition, creating excellent workability characteristics. Signage, architectural panels, and applications requiring post-cut bending typically use 3003 for its predictable behavior.

Aerospace vs General Purpose Aluminum Considerations

The fundamental difference between aerospace alloys like 7075 and general-purpose options like 6061 comes down to strength—and the trade-offs that strength creates. Aerospace aluminum achieves its exceptional tensile properties through heat treatment (the T6 designation), and excessive thermal input during cutting can degrade these properties.

When you laser cut aluminum sheet in 7075-T6, keep thermal exposure low. Prolonged heat during cutting or post-processing can reduce the carefully achieved T6 hardness. This means faster cutting speeds with adequate power become critical—you want efficient material removal without dwelling too long in any area.

According to PART MFG's aluminum machining guide, the 7xxx series provides exceptional strength but requires careful handling due to its susceptibility to stress corrosion cracking. For laser cutting specifically, this translates to parameter adjustments that minimize heat-affected zones while still achieving complete penetration.

General-purpose alloys like 6061 and 5052 offer more forgiving processing windows. You have greater latitude to adjust speed and power without dramatically affecting mechanical properties or edge quality. This makes them excellent choices for developing your cutting parameters before tackling more demanding aerospace materials.

| Alloy | Typical Applications | Relative Cutting Difficulty | Speed Adjustment vs Baseline | Edge Quality Expectations |

|---|---|---|---|---|

| 6061-T6 | Structural components, general fabrication, machinery parts | Easy (baseline reference) | Standard parameters | Excellent—smooth, consistent edges |

| 5052-H32 | Marine applications, fuel tanks, pressure vessels | Easy to Moderate | 5-10% slower than 6061 | Very Good—clean edges, excellent for welding |

| 7075-T6 | Aerospace structures, high-stress components, motorsports | Moderate to Difficult | 10-15% faster to reduce heat input | Good—requires heat management for best results |

| 3003-H14 | Signage, decorative panels, HVAC, formable parts | Easy | Standard to 5% faster | Excellent—very clean, minimal burr |

Notice how alloy composition directly affects thermal conductivity? Alloys with higher thermal conductivity disperse heat faster, requiring either more power or adjusted speed to maintain an effective cutting zone. The 5000 series alloys (like 5052) with their magnesium content handle heat slightly differently than silicon-magnesium 6000 series alloys.

For production environments cutting aluminum metal, maintaining separate parameter libraries for each alloy saves significant troubleshooting time. Document your optimal settings for 6061 first—it's the most forgiving—then adjust based on the specific alloy characteristics outlined above. When you switch from cutting a 6061 structural part to a 7075 aerospace component, those documented adjustments ensure consistent quality without trial-and-error iterations.

Understanding alloy behavior gives you the foundation for consistent cuts. But knowing what speed and power settings to use is only half the equation—the next step is mastering the complete parameter optimization process for achieving truly clean aluminum edges.

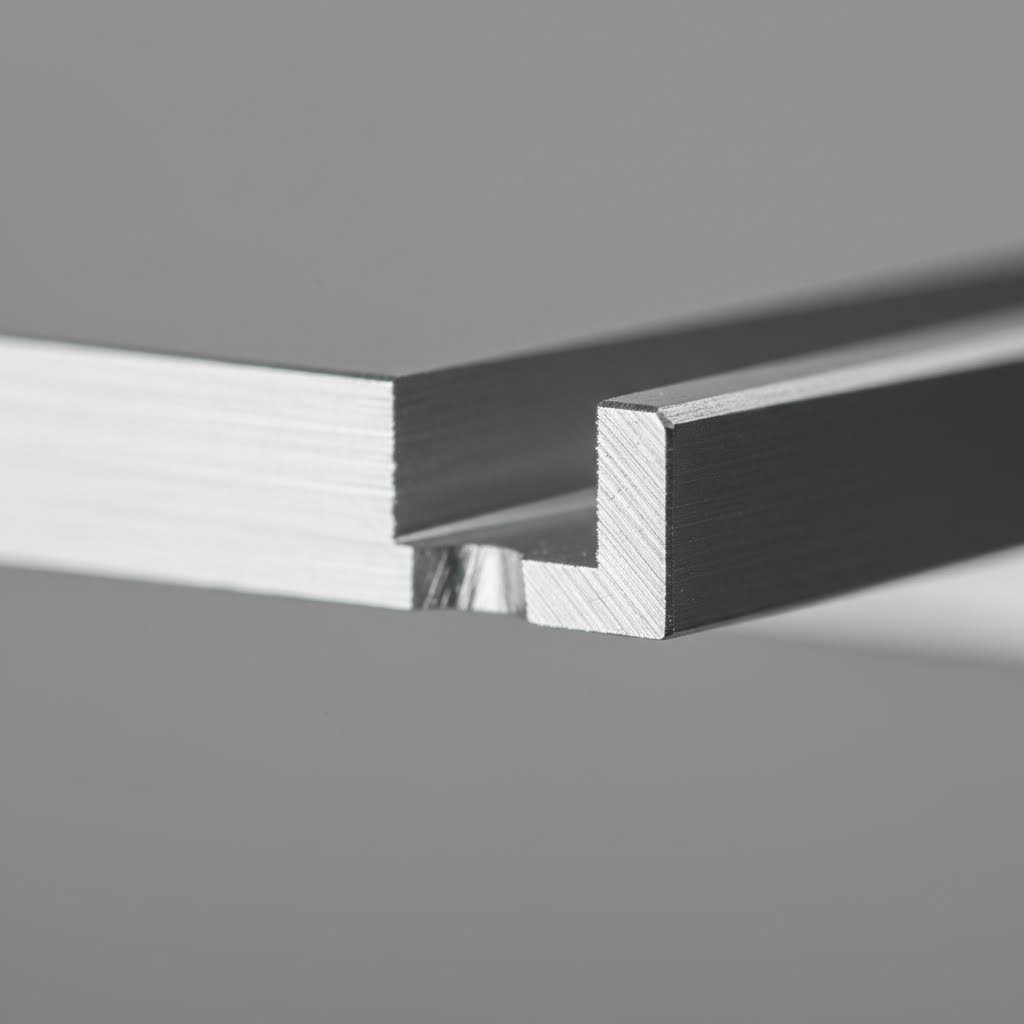

Optimizing Cut Parameters for Clean Edges

You've selected the right laser technology, matched power to your material thickness, and understand how different alloys behave. Now comes the part where most operators struggle: dialing in the exact parameters that separate professional-grade edges from the rough, burred mess that sends parts to the scrap bin. A laser cutter for metal is only as good as its parameter settings—and aluminum demands precision that generic manufacturer defaults rarely deliver.

Four critical variables control your cut quality: power percentage, cutting speed, pulse frequency, and focal point position. These aren't independent settings you can adjust in isolation. Change one, and you'll likely need to compensate with another. Understanding these relationships is what separates operators who consistently produce clean aluminum cuts from those who fight their machines on every job.

Dialing In Your First Aluminum Cut

Think of parameter optimization like tuning a musical instrument. Each string (or variable) affects the overall sound, and getting one right while ignoring others produces poor results. Your laser cutting machine for metal works the same way—power, speed, and focus must harmonize for clean sheet metal laser cutting.

Power Percentage: This controls how much energy your laser delivers to the material. Too little power, and you won't achieve complete penetration—leaving you with incomplete cuts or excessive dross on the bottom edge. Too much power creates excessive heat, widening your kerf and potentially causing edge burn or warping on thin sheets. For aluminum, you'll typically run at 80-95% of your machine's rated power for the thickness you're cutting.

Cutting Speed: Speed determines how long the laser dwells on each point of the cut path. Faster speeds reduce heat input but risk incomplete penetration. Slower speeds ensure complete cuts but can create excessive heat-affected zones and rough edges. According to Accurl's technical guidance, the laser beam's speed and power must be carefully managed to ensure a clean cut, considering aluminum's thermal conductivity and reflective nature.

Pulse Frequency: This setting controls how the laser energy is delivered—continuous wave versus pulsed operation. Higher frequencies create smoother cuts but deliver more total heat. Lower frequencies reduce heat input but can create a more textured edge. For aluminum, moderate to high pulse frequencies generally produce the best balance of edge quality and heat management.

Focal Point Position: Perhaps the most overlooked variable, focal position determines where maximum beam intensity occurs relative to the material surface. For aluminum's reflective surface, proper focus is absolutely critical. If your focal point sits too high or too low, you're essentially fighting the material's natural tendency to scatter laser energy. Most laser cutter for sheet metal applications on aluminum position the focal point at or slightly below the material surface.

Speed vs Power Trade-offs Explained

Here's where laser cutting metal becomes both science and art. Increase your cutting speed, and you'll need to compensate with higher power to maintain complete penetration. Decrease speed, and you can reduce power—but you'll add heat to the cut zone. Finding the optimal balance depends on your specific material thickness, alloy, and quality requirements.

Imagine running too fast with insufficient power: the laser begins the cut but fails to penetrate completely. You'll see incomplete separation or heavy dross clinging to the bottom edge. Now imagine the opposite—too slow with excessive power: the laser dwells too long, creating a wider kerf, rough edges, and potential heat distortion on thin sheets.

The sweet spot exists where you're moving just fast enough to minimize heat input while delivering just enough power for clean, complete penetration. This balance point shifts based on material thickness and alloy composition, which is why documented parameter libraries for each material become invaluable.

Assist Gas Selection and Pressure Requirements

Your assist gas choice fundamentally affects edge quality when using a laser cutter sheet metal setup for aluminum. According to Accurl's nitrogen cutting guide, nitrogen is particularly valued in settings where the final product demands a pristine finish with minimal post-processing—and aluminum is exactly that type of material.

Nitrogen: The premium choice for aluminum cutting. Nitrogen, being an inert gas, does not react with the molten metal, preventing oxidation and discoloration. Your cut edges remain shiny, smooth, and oxide-free. This matters for visible components, parts requiring welding, or any application where post-cut finishing adds cost and time. Typical nitrogen pressure requirements for aluminum range from 150-250 PSI depending on material thickness.

Compressed Air: A cost-effective alternative when edge appearance isn't critical. Compressed air contains oxygen, which can cause mild oxidation or discoloration on cut edges. For internal components or parts that will receive surface treatment anyway, the cost savings may justify this trade-off. Pressure requirements are generally similar to nitrogen, though some operators run slightly higher pressures to compensate for less efficient material removal.

Beyond gas selection, pressure calibration matters significantly. According to technical data on nitrogen cutting, higher pressures are needed for thicker materials to effectively remove molten aluminum from the cut zone. Insufficient pressure leaves dross adhered to the bottom edge; excessive pressure can cause turbulence that affects cut quality.

Step-by-Step Parameter Optimization Process

Ready to dial in your aluminum cutting parameters? Follow this systematic approach rather than randomly adjusting settings:

- Start with manufacturer baseline settings: Your machine likely includes material libraries with starting parameters for various aluminum thicknesses. These aren't optimized for your specific setup, but they provide a reasonable starting point. Load the appropriate material preset for your thickness and alloy type.

- Perform test cuts on scrap material: Never optimize on production parts. Cut small test pieces—simple straight lines and corners work well—using your baseline parameters. Examine both top and bottom edges for burrs, dross, and edge quality. Listen to the cutting process; a consistent, smooth sound indicates stable cutting conditions.

- Adjust speed first: Speed changes have the most predictable effects on cut quality. If you're seeing incomplete penetration or heavy bottom-side dross, try reducing speed by 5-10% increments. If edges look burned or the heat-affected zone seems excessive, increase speed by similar increments. Document each adjustment and its result.

- Fine-tune power settings: Once speed is optimized, adjust power to refine edge quality. Small power adjustments (2-5%) can significantly impact results without requiring speed changes. The goal is finding the minimum power level that produces complete, clean cuts at your optimized speed.

- Optimize focal position: This final adjustment often makes the difference between good and excellent results. On aluminum's reflective surface, even small focal position errors scatter energy and reduce cut quality. Adjust focus in small increments (0.1-0.2mm) above and below the baseline position, testing each adjustment on scrap. The correct position produces the narrowest kerf width and cleanest edge finish.

This systematic process works because it isolates variables. Adjusting multiple parameters simultaneously makes it impossible to understand which change affected your results. Patience during optimization pays dividends in consistent production quality.

Why Focus Matters More for Aluminum

Aluminum's reflectivity creates a unique challenge for focal position optimization. When your focal point isn't precisely positioned, reflected energy scatters in unpredictable ways. This scattered energy doesn't contribute to cutting—it just adds heat to surrounding areas while reducing cutting efficiency at the intended point.

Unlike steel, where a slightly off-focus beam still couples reasonably well with the material, aluminum punishes focal errors harshly. You'll notice inconsistent cut quality, varying kerf width along the cut path, and edge quality that changes unpredictably. These symptoms often get blamed on power or speed settings when the real culprit is focus position.

Modern laser cutting machine for metal systems include autofocus capabilities that can help maintain consistent focus across warped or uneven sheets. For manual focus systems, verify focal position at the start of each job and whenever you notice cut quality degradation. A quick focus check takes seconds and prevents hours of troubleshooting the wrong variables.

With your parameters optimized for clean aluminum cuts, you're equipped to tackle production work confidently. But even optimized settings can't prevent every problem—which is why understanding how to diagnose and fix common cutting defects becomes your next essential skill.

Troubleshooting Common Aluminum Cutting Defects

You've optimized your parameters, selected the right assist gas, and verified your focal position. Yet somehow, your aluminum parts still come off the cutting table with rough edges, stubborn dross, or inconsistent quality. Sound familiar? Every metal laser cutter operator encounters these frustrations—but the difference between struggling and succeeding lies in systematic troubleshooting rather than random parameter adjustments.

When problems arise during aluminum cutting, they're almost always symptoms pointing to specific root causes. Understanding this cause-and-effect relationship transforms troubleshooting from guesswork into a logical diagnostic process. Let's examine the most common defects you'll encounter and exactly how to fix them.

Solving Burr and Dross Problems

Burrs and dross are the two most frequent complaints when operators laser cut metal sheets in aluminum. They're related but distinct problems with different causes—and confusing them leads to ineffective solutions.

Burr Formation: Those sharp, raised edges clinging to the top or bottom of your cut. Burrs typically indicate an imbalance between cutting speed and power delivery. According to Fortune Laser's troubleshooting guide, if your speed is too high for the power level, the laser won't cut cleanly through the material. The result? Incomplete melting that solidifies as burrs rather than being expelled from the cut zone.

Dross Adhesion: That stubborn solidified metal clinging to the bottom edge of your cut. Dross forms when molten aluminum isn't efficiently removed from the kerf before it re-solidifies. This typically traces back to focal position errors, insufficient assist gas pressure, or contaminated gas supply.

Here's how to diagnose and fix each problem:

Burr Formation Issues:

- Symptoms: Sharp, raised edges on cut parts; rough texture along cut line; inconsistent edge quality

- Common Causes: Excessive cutting speed for available power; insufficient laser power; worn or damaged nozzle affecting gas flow

- Solutions: Reduce cutting speed by 5-10% increments; increase power if operating below optimal range; inspect and replace damaged nozzles; verify assist gas flow is unobstructed

Dross Adhesion Issues:

- Symptoms: Solidified metal beads clinging to bottom edge; uneven buildup along cut path; difficulty removing parts from sheet

- Common Causes: Incorrect focal position (typically too high); insufficient assist gas pressure; contaminated or moisture-laden assist gas; nozzle misalignment

- Solutions: Adjust focal position downward in 0.1mm increments; increase gas pressure by 10-15 PSI; check gas supply for contamination; verify nozzle is centered and undamaged

A laser sheet metal cutter processes aluminum differently than steel, and this distinction matters for troubleshooting. Aluminum's rapid heat dissipation means parameters that work perfectly on one section of a cut can fail on another if the material acts as a heat sink. Larger parts or cuts near sheet edges often behave differently than small, isolated features.

Protecting Your Laser from Reflective Damage

Here's the problem that keeps experienced operators vigilant: back-reflection damage. Aluminum's highly reflective surface can bounce a significant portion of laser energy back through your optical system. According to BCAMCNC's technical guide, the reflected beam may travel back into the laser head, collimation lens, or even the laser source itself—causing protective lens burns, output instability, and premature damage to internal optical components.

Modern fiber laser metal cutter systems include built-in back-reflection protection. These systems monitor reflected energy levels and automatically shut down the laser before critical damage occurs. However, triggering these safety systems still interrupts production and indicates setup problems that need addressing.

Back-Reflection Prevention:

- Symptoms: Sudden laser shutdown during aluminum cutting; inconsistent power output; visible damage to protective lens; system warning messages about reflected energy

- Common Causes: Cutting highly polished aluminum surfaces; incorrect starting pierce parameters; attempting continuous-wave cutting on thick reflective material; contaminated or oily material surface

- Solutions: Use pulsed cutting mode for reflective materials (delivers energy in controlled bursts with cooling periods between pulses); ensure material surface is clean and free of oil or film; verify back-reflection protection is enabled and functioning; consider surface treatment for highly polished materials

Why does pulsed mode work better for reflective metals? As BCAMCNC explains, pulsed cutting delivers energy in short, controlled bursts where each pulse instantly melts a small section. The metal has a moment to cool between pulses, meaning less energy stays on the surface long enough to reflect back. This significantly reduces the risk of dangerous back-reflection while maintaining cutting quality.

Maintenance Considerations for Aluminum Cutting

A metal cutting laser processing aluminum requires more frequent maintenance than one cutting steel. Aluminum vaporizes differently, creating fine particulate that deposits on optical surfaces faster than steel slag. Ignoring this reality leads to progressive quality degradation that operators often misattribute to parameter problems.

Lens Cleaning Frequency: For heavy aluminum cutting, inspect your focus lens daily and clean it as needed—often more frequently than manufacturer guidelines suggest for steel cutting. Aluminum residue bakes onto optical surfaces and becomes increasingly difficult to remove over time. Use proper lens cleaning wipes and solutions; improper cleaning techniques cause more damage than the contamination itself.

Nozzle Inspection Protocol: Your nozzle directs assist gas into the cut zone with precision. According to Fortune Laser's maintenance guidance, a damaged, dirty, or clogged nozzle creates a chaotic gas jet that ruins cut quality. Aluminum spatter accumulates on nozzle tips faster than steel spatter, so visual inspection should happen at least daily during production. Look for:

- Spatter buildup on nozzle tip affecting gas flow

- Nicks or damage to the nozzle opening that distort gas stream

- Misalignment between nozzle and beam path

- Erosion of nozzle opening from extended use

Keep replacement nozzles in stock. When quality problems appear and parameter adjustments don't help, a fresh nozzle often resolves issues that would otherwise require hours of troubleshooting.

Protective Lens Monitoring: The protective lens sits between your cutting optics and the work zone, shielding expensive components from spatter and debris. Aluminum cutting accelerates protective lens contamination. Establish a regular inspection schedule and replace protective lenses before contamination affects beam quality. A damaged protective lens can mask itself as power delivery problems or focal issues.

Systematic troubleshooting combined with proactive maintenance keeps your laser metal cutter producing clean aluminum cuts consistently. But understanding defect prevention is only part of the picture—knowing how industries actually apply these capabilities reveals the full potential of precision aluminum laser cutting.

Industry Applications from Aerospace to Architecture

Now that you understand the technology, parameters, and troubleshooting techniques, you might be wondering: who actually uses laser-cut aluminum, and for what? The answer spans virtually every manufacturing sector where weight reduction, precision, and design flexibility matter. From aircraft components soaring at 40,000 feet to decorative facades transforming urban skylines, laser cut aluminum panels have become indispensable across industries with vastly different requirements.

What makes aluminum cutting via laser so universally appealing? It delivers capabilities that traditional methods simply cannot match—complex geometries cut in a single operation, tight material nesting that minimizes waste, and rapid prototyping that accelerates product development cycles. Let's explore how specific industries leverage these advantages.

From Aircraft Parts to Architectural Facades

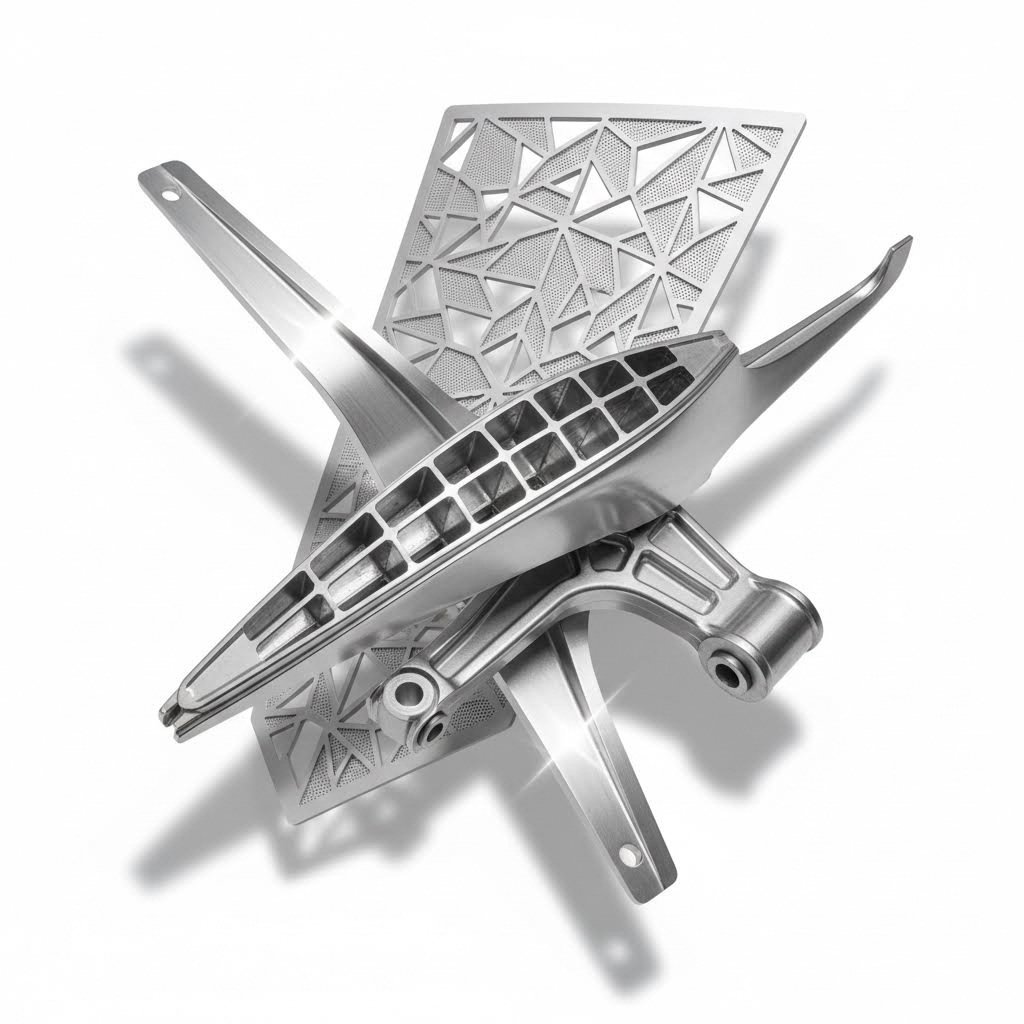

Aerospace Applications: When every gram matters, aluminum becomes the material of choice—and laser cutting becomes the fabrication method that delivers both precision and weight savings. According to Xometry's technical documentation, aerospace represents one of the primary industries utilizing laser cutting for aluminum components. Aircraft manufacturers demand tolerances measured in thousandths of an inch, and fiber lasers consistently deliver.

- Typical parts: Structural brackets, skin panels, bulkhead components, interior trim pieces, heat shields

- Tolerance requirements: ±0.001" to ±0.005" on critical dimensions

- Why laser cutting: Weight optimization through complex geometries; consistent quality across production runs; minimal heat-affected zones preserve material properties in heat-treated alloys like 7075-T6

Automotive Applications: Modern vehicles rely heavily on aluminum for weight reduction without sacrificing structural integrity. Laser cut metal panels appear throughout vehicle construction—from structural components to heat management systems. The automotive sector values laser cutting's ability to produce consistent parts at high volumes with minimal secondary processing.

- Typical parts: Chassis reinforcements, suspension brackets, heat shields, battery enclosures for EVs, interior structural components

- Tolerance requirements: ±0.005" to ±0.010" for structural components; tighter for precision assemblies

- Why laser cutting: High production speeds; excellent repeatability across thousands of parts; ability to cut complex shapes for lightweighting initiatives

Electronics Applications: Aluminum's thermal conductivity makes it ideal for heat management in electronics—and laser cutting enables the intricate features these applications demand. Enclosures, heat sinks, and chassis components all benefit from the precision and clean edges that laser cut decorative metal panels provide.

- Typical parts: Heat sinks with complex fin patterns, RF shielding enclosures, server chassis, LED housings, device bezels

- Tolerance requirements: ±0.003" to ±0.005" for precise fit and thermal contact

- Why laser cutting: Ability to cut intricate cooling patterns; clean edges for electrical grounding; burr-free finish eliminates secondary operations

Signage Applications: When you see illuminated channel letters, dimensional logos, or intricate wayfinding systems, you're often looking at laser cutting signage in aluminum. The combination of material durability and laser precision enables designs that would be impossible or prohibitively expensive with traditional fabrication methods. Beyond aluminum, laser cut steel panels also serve heavy-duty signage applications where additional strength is required.

- Typical parts: Dimensional letters, decorative screens, backlit panels, architectural signage, wayfinding elements

- Tolerance requirements: ±0.010" to ±0.020" (visual applications are more forgiving)

- Why laser cutting: Complex typography and logos cut cleanly; consistent quality for matching multi-piece installations; rapid turnaround for custom work

Architectural Applications: Walk through any modern urban center and you'll encounter laser cut aluminum panels on building facades, privacy screens, and decorative installations. Architects specify these panels because laser cutting enables patterns and perforations that transform flat aluminum sheets into striking visual elements.

- Typical parts: Facade panels, sunscreens and shading elements, decorative screens, balustrade infills, ceiling systems

- Tolerance requirements: ±0.010" to ±0.030" depending on panel size and installation method

- Why laser cutting: Unlimited pattern possibilities; consistent perforations for light and airflow control; large panel capability on industrial-bed machines

Why Industries Choose Laser Over Traditional Cutting

Imagine designing a heat sink with 50 precisely spaced cooling fins, or an architectural screen with thousands of identical perforations. With traditional punching or routing, you're limited by tooling costs, setup time, and geometric constraints. Laser cutting eliminates these barriers—if you can draw it in CAD, you can cut it.

Complex Geometries: Laser cutting follows programmed paths without regard for tool geometry. Internal cutouts, sharp corners, intricate patterns, and organic shapes all process with equal efficiency. This design freedom enables engineers and architects to optimize for function rather than manufacturability.

Tight Nesting for Material Efficiency: Modern nesting software positions parts on aluminum sheets with minimal waste—often achieving 85-90% material utilization. The laser's ability to cut parts close together without tool clearance requirements makes this possible. For expensive aerospace alloys or high-volume production, these material savings directly impact profitability.

Rapid Prototyping Capabilities: Need three different versions of a bracket to test fit and function? With laser cutting, you're looking at hours rather than days. No tooling investment, no setup changes between designs—just load the new CAD file and cut. This speed accelerates product development across every industry that values time-to-market.

Understanding where laser-cut aluminum fits across these industries reveals why mastering this technology matters. Whether you're fabricating aerospace components with micron-level precision or producing architectural panels by the thousands, the fundamentals remain consistent: select the right equipment, optimize your parameters, and maintain systematic quality control.

Making the Right Manufacturing Decisions

You've now covered everything from laser technology selection to parameter optimization, alloy considerations, and troubleshooting techniques. But knowledge without action doesn't improve your cut quality or production efficiency. Whether you're evaluating your first laser cutting machine aluminum purchase, upgrading existing equipment, or refining your current processes, the path forward depends on where you are in your manufacturing journey.

Let's synthesize the key decision factors and translate them into actionable next steps tailored to your specific situation. Can you laser cut aluminium successfully? Absolutely—but success requires matching the right equipment, parameters, and workflows to your production requirements.

Choosing Your Path Forward

Every manufacturing operation faces unique constraints: budget limitations, production volume requirements, material thickness ranges, and quality expectations. Your optimal path depends on honestly assessing these factors rather than chasing specifications you don't need.

For Hobbyists and Small Shops: If you're cutting thin aluminum sheets for prototypes, signage, or small-batch production, an entry-level fiber laser system in the 1000W-1500W range handles materials up to 3-4mm effectively. Focus your investment on a reliable laser source and solid frame construction rather than maximum wattage. A sheet metal laser cutting machine at this level costs significantly less than industrial equipment while still delivering professional edge quality on appropriate materials.

For Growing Fabrication Businesses: When production volume increases and material thickness requirements expand, mid-range systems (2000W-4000W) become the sweet spot. These aluminum laser cutter systems handle the 3-8mm thickness range that covers most commercial applications—from automotive brackets to architectural panels. Prioritize features that improve throughput: autofocus cutting heads, efficient nesting software, and adequate bed size for your typical sheet dimensions.

For High-Volume Production Environments: Industrial-grade fiber lasers (6000W and above) deliver the speed and thick-material capability that production environments demand. According to Qijun Laser's production analysis, today's 6kW fiber lasers cut 3mm mild steel at 35m/minute while holding ±0.15mm positional accuracy—similar performance applies to aluminum with appropriate parameter adjustments. At this level, automation features like automatic loading/unloading systems and real-time monitoring become critical for maximizing return on investment.

Regardless of where you fall on this spectrum, three principles apply universally:

- Fiber laser technology dominates aluminum cutting due to superior wavelength absorption, lower operating costs, and built-in back-reflection protection

- Alloy-specific parameters matter—develop and document optimized settings for each aluminum alloy you process regularly

- Systematic troubleshooting saves time—diagnose problems methodically rather than randomly adjusting parameters

From Prototype to Production

Modern manufacturing rarely relies on a single fabrication process. Laser-cut aluminum components typically integrate with stamped parts, machined features, welded assemblies, and surface treatments. Understanding how laser cutting fits within broader metal fabrication workflows helps you plan for complete product realization rather than isolated cutting operations.

The same laser cutter for aluminum that produces your prototypes can seamlessly scale to production volumes. According to recent manufacturing research, integrated CAD/CAM systems reduce programming time by 65% compared to manual workflows. Design modifications propagate automatically through cutting instructions, ensuring all production files stay synchronized. This continuity removes traditional bottlenecks caused by transitioning between different prototyping and production tools.

For automotive and precision manufacturing applications, laser-cut aluminum components frequently require integration with stamped brackets, precision assemblies, and structural elements. A telecommunications manufacturer case study demonstrated this integration effectively—initial 5-unit prototypes validated heat dissipation patterns, while automated batch processing delivered 5,000 enclosures with ±0.15mm dimensional consistency. The unified workflow eliminated tooling changeovers typically costing 12-18 production hours per design revision.

For automotive-grade aluminum components, partnering with IATF 16949-certified manufacturers ensures your laser-cut parts integrate seamlessly with stamped and assembled components while meeting stringent automotive quality standards.

When your laser cutting machine aluminum setup produces components that must integrate with stamped parts, welded assemblies, or precision machined features, consider partnering with manufacturers who understand complete automotive supply chains. Shaoyi (Ningbo) Metal Technology offers complementary capabilities for custom metal stamping parts and precision assemblies—from 5-day rapid prototyping to automated mass production with IATF 16949-certified quality for chassis, suspension, and structural components.

Optimizing Your Complete Workflow:

- Design for manufacturability: Consider how laser-cut features interact with downstream processes. Edge quality requirements differ for welded joints versus cosmetic surfaces.

- Material utilization: Advanced nesting algorithms achieve 92-97% material usage rates according to recent fabrication reports—the narrow 0.15mm kerf width means parts fit together tighter than plasma or waterjet alternatives.

- Quality verification: Establish inspection protocols that catch issues before parts move downstream. Multispectral sensors and high-speed cameras now run upwards of 200 quality inspections per minute during production.

- Maintenance scheduling: Aluminum cutting demands more frequent lens cleaning and nozzle inspection than steel processing. Build these requirements into your production planning.

The laser cutter aluminum technology you implement today positions your operation for tomorrow's requirements. Whether you're producing prototype components for design validation or running thousands of production parts weekly, the fundamentals remain consistent: select appropriate equipment for your material and volume requirements, optimize parameters systematically, troubleshoot methodically, and maintain your equipment proactively.

Your edges don't have to look terrible. With the right technology selection, properly optimized parameters, and systematic quality control, laser-cut aluminum delivers the precision, consistency, and edge quality that professional fabrication demands. The knowledge you've gained throughout this guide provides the foundation—now it's time to apply it to your specific manufacturing challenges.

Frequently Asked Questions About Laser Cutting Aluminum

1. What type of laser can cut aluminum?

Both CO2 and fiber lasers can cut aluminum, but fiber lasers are the preferred choice for most applications. Fiber lasers operate at a 1064nm wavelength that aluminum absorbs more readily than the 10.6μm wavelength of CO2 lasers. This higher absorption rate means better energy coupling, reduced back-reflection risks, and cleaner cuts. CO2 lasers remain viable for very thick aluminum plates (15mm+), while fiber lasers excel at thin to medium thicknesses with superior speed and edge quality.

2. What is the minimum power to cut aluminum with a laser?

For fiber lasers, a minimum of 500W-1000W handles aluminum up to 3mm thick. A 1500W system extends capability to approximately 4mm, while a 2000W laser reaches 6mm aluminum. For thicker materials, 3000W-4000W systems cut 8-10mm respectively. CO2 lasers require higher minimum power—typically 300W as the baseline, with most aluminum processing operations running 500W or greater for effective cutting performance.

3. How thick can laser cut aluminum?

Laser cutting thickness depends on your equipment's power level. Entry-level 1000W fiber lasers handle up to 3mm aluminum, while industrial 6000W+ systems can process 15mm or thicker material. Mid-range 2000W-4000W systems cover the 6-10mm range that addresses most commercial fabrication needs. Fiber lasers typically achieve maximum thickness up to 25mm with specialized high-power equipment, though edge quality and speed decrease significantly at maximum capacity.

4. How to cut aluminium with laser?

Successful aluminum laser cutting requires proper setup across four key parameters: power percentage (typically 80-95% for the material thickness), cutting speed balanced against power for complete penetration, correct focal point position (at or slightly below the surface), and high-pressure nitrogen assist gas (150-250 PSI) for oxide-free edges. Start with manufacturer baseline settings, test on scrap material, then systematically adjust speed first, fine-tune power, and optimize focal position for best results.

5. What causes burrs and dross when laser cutting aluminum?

Burrs typically result from excessive cutting speed or insufficient laser power—the laser fails to cut cleanly through the material, creating raised edges. Dross adhesion stems from incorrect focal position, insufficient assist gas pressure, or contaminated gas supply preventing proper molten metal removal. Fix burrs by reducing speed or increasing power. Address dross by adjusting focal position downward, increasing gas pressure by 10-15 PSI, and verifying clean gas supply and proper nozzle alignment.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —