Laser Cutting Steel Decoded: From Parameter Setup To Perfect Edges

Understanding Laser Cutting Steel Fundamentals

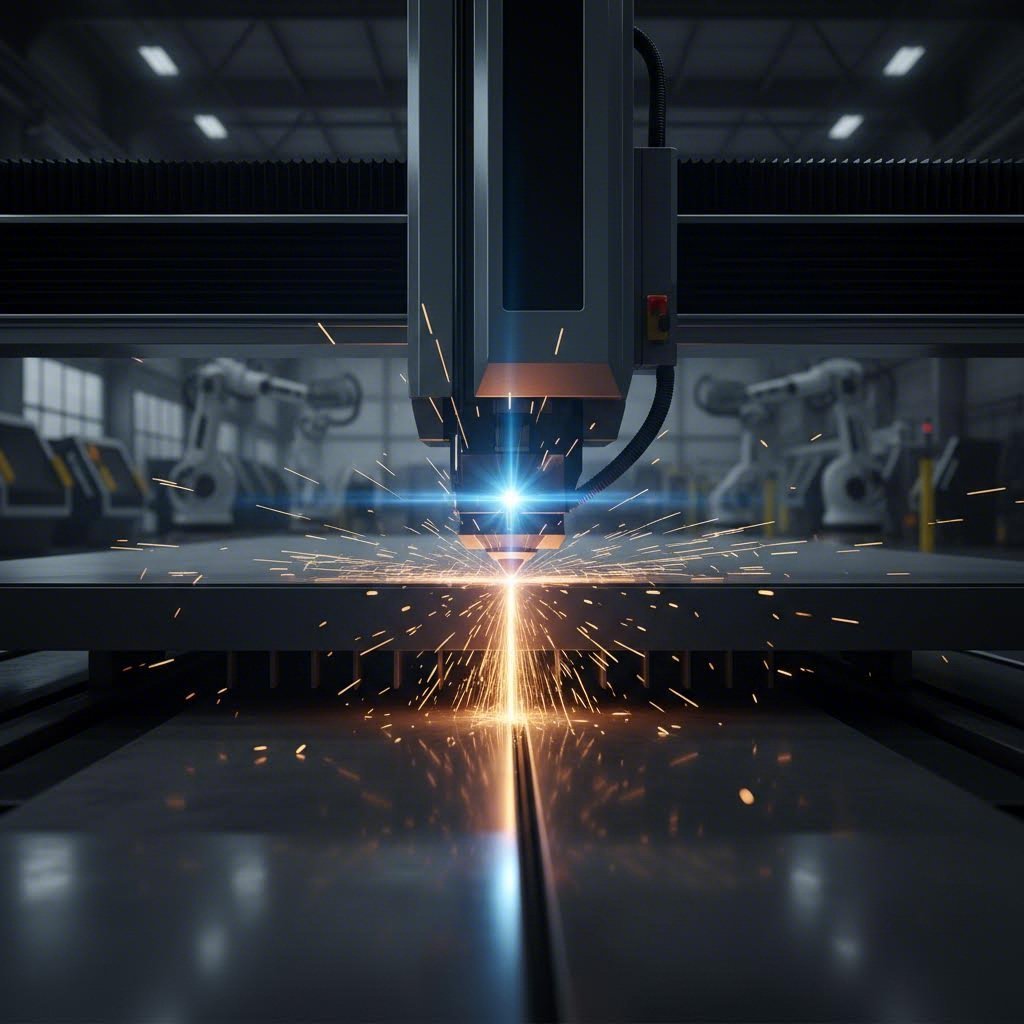

Imagine channeling the intensity of focused light to slice through solid steel with surgical precision. That is exactly what happens in modern metal fabrication facilities every day. Laser cutting steel has emerged as the definitive precision manufacturing method, replacing older techniques like plasma and oxy-fuel cutting across industries ranging from automotive to aerospace.

But what actually happens when that beam meets metal? And why does steel respond so uniquely to this process compared to other materials? Whether you are evaluating laser cutting services for a project or simply want to understand the technology driving modern manufacturing, this guide breaks down everything from the fundamental science to practical parameter selection.

Why Steel Demands Precision Cutting Technology

Steel is not just any metal. With melting points reaching approximately 5198°F according to Moore Machine Tools, it demands substantial energy input for effective processing. Yet steel also absorbs laser energy efficiently, making it an ideal candidate for laser metal cutting applications.

The thermal conductivity of steel creates a unique advantage. Unlike highly conductive metals such as aluminum or copper, steel retains heat in the localized cutting zone rather than dissipating it rapidly throughout the workpiece. This characteristic allows a laser metal cutting machine to maintain consistent cut quality while minimizing the heat-affected zone surrounding each cut.

Traditional cutting methods struggle to match what a laser that cuts metal achieves. Mechanical shearing creates material distortion. Plasma cutting leaves rough edges requiring secondary finishing. Laser cutting, by contrast, delivers edge squareness, dimensional accuracy, and surface finish quality that increasingly makes it the default choice for precision steel components.

The Science Behind Laser-Steel Interaction

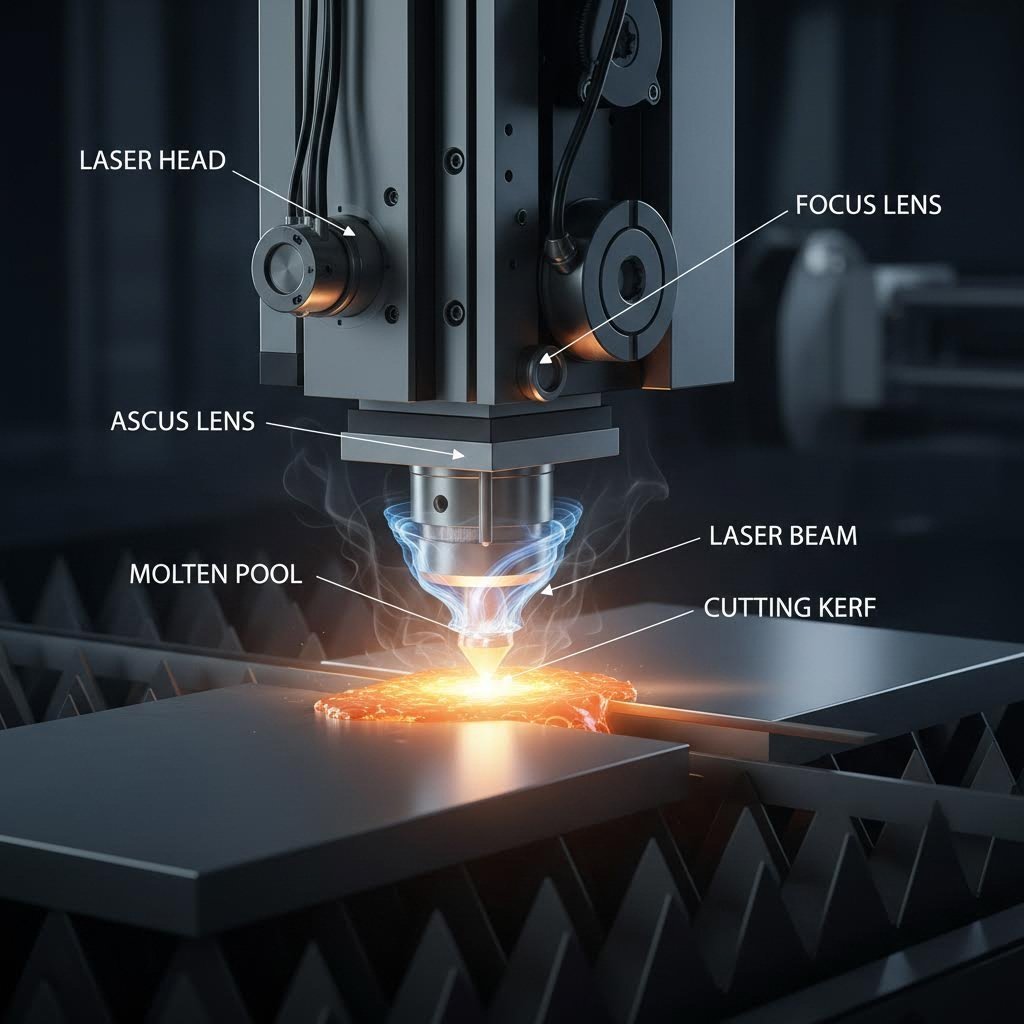

At its core, laser cutting metal is a thermal process. A focused laser beam concentrates photonic energy onto a tiny spot on the steel surface. When photons strike the material, they transfer their energy to the steel's atoms and molecules, causing rapid temperature increases in that localized area. The steel melts, and in some cases partially vaporizes, while an assist gas jet expels the molten material to create a clean kerf.

According to TWI Global, there are three major varieties of this process:

- Fusion cutting: Uses inert gas like nitrogen to expel molten steel without chemical reaction

- Flame cutting: Uses oxygen as assist gas, creating an exothermic reaction that adds energy to the process

- Remote cutting: Partially vaporizes thin materials using high-intensity beams without assist gas

The fibre laser has revolutionized this process for steel applications. These solid-state lasers generate beams through optical fibers, delivering higher wall-plug efficiency and requiring less maintenance than traditional CO2 systems. Modern fibre laser systems can achieve kerf widths as narrow as 0.004 inches, enabling intricate designs that would be impossible with conventional cutting methods.

Throughout this guide, you will learn how to select appropriate parameters for different steel types, understand the capabilities and limitations of various laser technologies, troubleshoot common cutting problems, and evaluate service providers or equipment for your specific applications. The goal is straightforward: giving you the actionable knowledge that bridges the gap between oversimplified overviews and technical manuals written for engineers.

Fiber Laser vs CO2 Technology for Steel

So you understand how laser energy interacts with steel. But here is where the real decision-making begins: which laser technology actually delivers the best results for your steel cutting applications? The fiber laser cutting machine has fundamentally transformed metal fabrication since capturing 60% of the market by 2025, yet CO2 systems still hold their ground in specific scenarios. Understanding why requires diving into the physics of how each technology works.

Fiber Laser Advantages for Steel Processing

The fiber laser generates its beam through a solid-state medium, delivering light at approximately 1064nm wavelength. This shorter wavelength matters enormously for steel processing because metals absorb it far more efficiently than the 10,600nm wavelength produced by CO2 systems. The result? A fiber laser cutter can cut thin to medium gauge steel at speeds reaching 100 meters per minute while consuming roughly 70% less energy.

Consider what this means in practical terms. According to EVS Metal's 2025 technology analysis, fiber laser systems achieve throughput rates up to 277 parts per hour compared to just 64 parts per hour for equivalent CO2 systems. That productivity differential translates directly into faster turnaround times and lower per-part costs.

Maintenance represents another compelling advantage. The fiber laser machine uses a monolithic configuration where the beam travels through protected fiber optic cable, completely shielded from contaminants. According to Esprit Automation, maintenance of a CO2 laser cutting head takes between 4-5 hours weekly compared to less than half an hour for fiber systems. The consumables list shrinks dramatically too. Fiber laser CNC systems primarily require nozzle and protective window replacements, while CO2 lasers need regular mirror cleaning, bellows replacement, and beam realignment.

For reflective metals like aluminum and copper, fiber lasers prove essential. The shorter wavelength experiences far less reflection, enabling efficient cutting of materials that would damage CO2 oscillators through back-reflection. While this guide focuses on steel, understanding this capability matters if your work involves mixed metal processing.

When CO2 Lasers Still Make Sense

Despite fiber laser dominance in most steel applications, CO2 laser metal cutting maintains specific advantages worth understanding. The longer wavelength interacts differently with thick steel sections, often producing superior edge quality on materials exceeding 20-25mm thickness. Some fabricators report that CO2 systems deliver cleaner, more consistent cuts on heavy plate where edge finish takes priority over cutting speed.

CO2 lasers also excel when processing non-metallic materials. If your operation handles mixed substrates including wood, acrylic, leather, or textiles alongside steel, a CO2 system provides versatility that fiber lasers cannot match. The 10,600nm wavelength gets readily absorbed by organic materials, making CO2 the default choice for signage, display, and mixed-material fabrication shops.

Additionally, the established service network for CO2 technology offers advantages in regions where fiber laser expertise remains limited. Operator training typically requires only one week for CO2 systems versus 2-3 weeks for fiber, though this differential matters less as fiber technology becomes standard.

| Specification | Fiber Laser | CO2 Laser |

|---|---|---|

| Cutting Speed (thin steel) | Up to 100 m/min | 20-40 m/min |

| Energy Efficiency | Up to 50% wall-plug efficiency | 10-15% wall-plug efficiency |

| Hourly Energy Cost | $3.50-4.00 | $12.73 |

| Weekly Maintenance Time | Less than 30 minutes | 4-5 hours |

| Annual Maintenance Cost | $200-400 | $1,000-2,000 |

| Optimal Steel Thickness | Under 20mm (superior speed) | Over 25mm (superior edge quality) |

| Maximum Steel Thickness | Up to 100mm (high-power systems) | Up to 25mm+ (standard systems) |

| Reflective Metal Capability | Excellent (aluminum, copper, brass) | Limited (reflection risks) |

| Non-Metal Cutting | Not suitable | Excellent (wood, acrylic, textiles) |

| Machine Uptime | 95-98% | 85-90% |

| 5-Year Total Cost of Ownership | ~$655,000 | ~$1,175,000 |

The financial implications deserve emphasis. According to EVS Metal, fiber laser cutting systems typically achieve 12-18 month payback periods compared to 24-30 months for CO2 equipment. Over five years, total cost of ownership savings exceed $520,000 for comparable systems. These numbers explain why fiber laser adoption has accelerated so dramatically across the fabrication industry.

For most steel-focused operations, the choice has become clear. Fiber laser technology delivers faster cutting speeds, lower operating costs, reduced maintenance burden, and superior efficiency across the thickness ranges that dominate general fabrication work. However, understanding steel types and their unique responses to laser processing becomes equally critical for achieving optimal results, which we explore next.

Steel Types and Their Cutting Behaviors

Here is something most guides overlook entirely: not all steel behaves the same under a laser beam. The steel laser cutting parameters that produce flawless edges on mild steel can create disastrous results on stainless or tool steel. Understanding these material-specific differences separates successful cuts from expensive scrap.

Why does this matter so much? Each steel type brings unique combinations of carbon content, alloying elements, thermal conductivity, and surface reflectivity to the cutting process. According to LYAH Machining, these differences directly impact tool wear rates, heat management requirements, and achievable edge quality. When you laser cut metal sheets without accounting for material type, you are essentially guessing at parameters rather than engineering optimal results.

Mild Steel Cutting Characteristics

Mild steel laser cutting represents the most forgiving application in steel processing. With carbon content typically ranging from 0.05% to 0.25%, mild steel offers excellent malleability and ductility that translates into predictable cutting behavior. The material melts cleanly, ejects consistently, and produces oxide-free edges when cut with nitrogen assist gas.

What makes mild steel so cooperative? Its relatively low tensile strength compared to stainless steel means the laser beam encounters less resistance during the cutting process. According to LYAH Machining, mild steel enables higher machining speeds and reduces production time compared to harder steel grades. The material also generates less heat during cutting, extending nozzle and lens life while reducing the frequency of maintenance interventions.

Key considerations for mild steel cutting include:

- Surface preparation: Remove heavy mill scale, oil, and contaminants before cutting. Light mill scale often burns away during the cutting process, but heavy scale can cause inconsistent penetration.

- Assist gas recommendations: Oxygen creates faster cutting speeds through an exothermic reaction but leaves an oxidized edge. Nitrogen produces clean, oxide-free edges suitable for welding or painting without additional preparation.

- Expected edge quality: Smooth, straight edges with minimal dross when parameters are properly set. Mild steel tolerates wider parameter windows than harder grades.

- Heat-affected zone: Relatively narrow due to the material's lower hardness and predictable thermal response.

For structural applications, automotive components, and general fabrication work, mild steel remains the go-to material precisely because of these forgiving characteristics. The laser cutting of metal sheets in mild steel grades achieves excellent results across a wide range of equipment and skill levels.

Stainless Steel Reflectivity Challenges

Stainless steel demands an entirely different approach. Containing a minimum of 10.5% chromium along with nickel, molybdenum, and other alloying elements, stainless steel presents unique challenges that catch unprepared operators off guard. The same properties that provide excellent corrosion resistance create complications during laser processing.

The primary challenge? Reflectivity. Smooth stainless steel surfaces reflect a significant portion of laser energy rather than absorbing it for cutting. According to DP Laser, the smoother the material surface, the lower the laser absorption rate. This means polished stainless steel grades require more power and slower speeds to achieve equivalent cuts compared to mild steel of the same thickness.

Work hardening compounds the difficulty. Stainless steel rapidly hardens during processing, which according to LYAH Machining leads to increased tool wear and requires more robust cutting parameters. A laser cutter for stainless steel must deliver sufficient power density to overcome this hardening effect while maintaining consistent edge quality.

Key considerations for stainless steel cutting include:

- Surface preparation: Ensure surfaces are clean and free from protective films. Some operators lightly scratch polished surfaces to improve initial absorption, though this step is rarely necessary with modern high-power fiber lasers.

- Assist gas recommendations: Nitrogen is strongly preferred for stainless steel to maintain corrosion resistance at the cut edge. Oxygen creates an oxidized edge that compromises the material's inherent corrosion resistance.

- Expected edge quality: Clean, bright edges with nitrogen assist. Requires tighter parameter control than mild steel to prevent dross formation.

- Heat management: Enhanced cooling strategies may be necessary. The material retains heat longer, increasing the risk of edge discoloration and warping on thin sections.

When comparing these materials, the contrast becomes striking. Where mild steel practically cuts itself with properly set parameters, stainless steel demands precision. According to LYAH Machining, cutting stainless steel costs significantly more due to harder material, faster tool wear, and more intensive post-processing requirements to maintain corrosion resistance and aesthetic quality.

Carbon Steel and Tool Steel Considerations

Carbon steel occupies the middle ground between mild and stainless grades. With carbon content ranging from 0.30% to over 1.0% for high-carbon varieties, these steels offer increased hardness and strength but require adjusted cutting parameters. Higher carbon content affects how the material responds to rapid heating and cooling during the laser cutting process.

Key considerations for carbon steel cutting include:

- Surface preparation: Similar to mild steel but pay extra attention to rust and heavy scale on stored materials. Carbon steel oxidizes more readily than stainless grades.

- Assist gas recommendations: Oxygen provides excellent cutting speeds through the exothermic reaction. Nitrogen works well for applications requiring weld-ready edges.

- Expected edge quality: Good to excellent depending on carbon content. Higher carbon grades may show slight hardening at the cut edge.

- Heat-affected zone: Can be more pronounced than mild steel. The rapid heating and cooling may create a hardened zone adjacent to the cut that affects subsequent machining operations.

Tool steel represents the most demanding category for laser cutting. These highly alloyed steels contain tungsten, molybdenum, vanadium, and other elements that provide extreme hardness and wear resistance. While laser cutting tool steel is possible, the thermal conductivity variations and alloy composition create unpredictable behavior that often makes alternative cutting methods more appropriate for thick sections.

Key considerations for tool steel cutting include:

- Surface preparation: Thorough cleaning is essential. Any surface contamination affects energy absorption unpredictably.

- Assist gas recommendations: High-purity nitrogen protects the cut edge from oxidation that would compromise the material's intended properties.

- Expected edge quality: Achievable with proper parameters on thin gauge material. Thick sections may require alternative methods.

- Thickness limitations: More restrictive than softer grades. Tool steel's hardness and thermal properties limit practical laser cutting to thinner sections.

Lessons from Reflective Metal Processing

Interestingly, the challenges encountered with stainless steel share characteristics with laser cut aluminum and aluminium laser cutting applications. Both materials exhibit higher surface reflectivity than carbon steels, requiring operators to understand how surface properties affect energy absorption.

According to DP Laser, the lower the resistivity of a material, the lower the absorption of laser light. This principle explains why aluminum poses even greater challenges than stainless steel, and why fiber laser technology with its shorter 1070nm wavelength has become essential for processing these reflective materials efficiently.

Understanding steel grades before selecting cutting parameters is not optional. It is fundamental to achieving consistent, high-quality results. The differences between mild steel, stainless steel, carbon steel, and tool steel affect every aspect of the cutting process from power settings to assist gas selection to achievable edge quality. With this material-specific knowledge established, we can now examine how to dial in the exact parameters that transform these general principles into precise, repeatable cuts.

Cutting Parameters and Process Variables

You understand steel types now. But here is where the rubber meets the road: translating that material knowledge into actual machine settings. Every laser cutting machine for metal operates on the same fundamental principle, yet dialing in the right parameters separates clean, profitable cuts from expensive scrap and rework.

Think of parameter selection as a three-legged stool. Laser power, cutting speed, and steel thickness form an interdependent relationship where changing one variable demands adjustments to the others. Add assist gas selection, focus position, and kerf compensation into the mix, and you begin to see why experienced operators command premium rates. Let us break down each variable so you can approach any metal laser cutting machine with confidence.

Power and Speed Relationships Explained

The fundamental relationship works like this: thinner materials require less power and tolerate faster cutting speeds, while thicker materials demand more power and slower traverse rates. Sounds simple, right? The complexity emerges when you realize that optimal parameters occupy a surprisingly narrow window for each material and thickness combination.

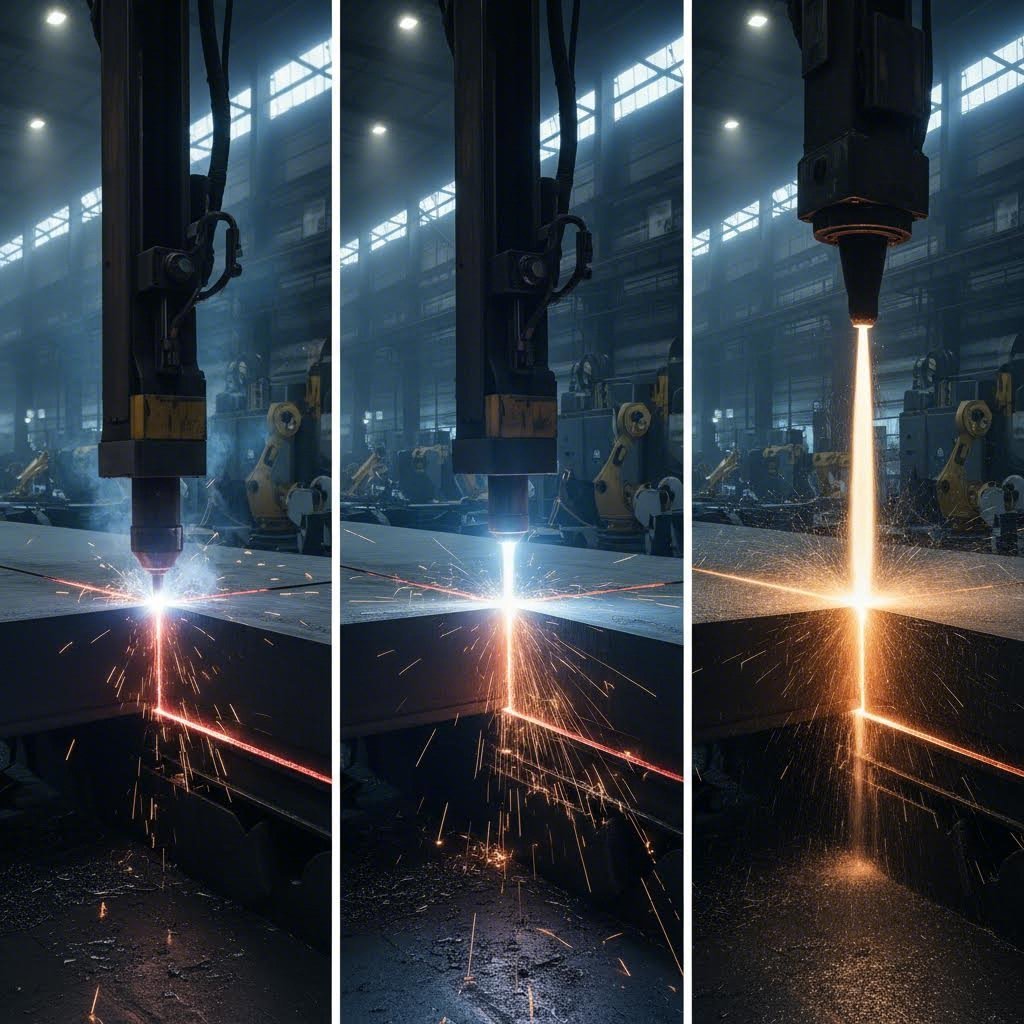

Consider what happens when power exceeds the optimal range. According to Prestige Metals, only so much power can be applied to the material before too much burning occurs, resulting in a poor cut. This limitation explains why cutting thin steel with oxygen assist gas produces similar speeds whether you are using a 1500W or 6000W laser. The exothermic reaction from oxygen burning iron creates its own speed ceiling.

Nitrogen-assisted cutting follows different rules. Here, power becomes the determining factor in cutting speed because the nitrogen serves only as a shielding gas rather than contributing energy through chemical reaction. More power truly equals more speed in nitrogen cutting applications.

Real-world data from Varisigns illustrates these relationships clearly:

- 1500W with air assist: Cuts 1mm carbon steel at approximately 16.6 m/min, but only 1.2 m/min at 5mm thickness

- 12000W with oxygen: Achieves 4.2 m/min on 20mm carbon steel, dropping to 1.0 m/min at 40mm

- High-power systems (40000W+): Can process carbon steel exceeding 100mm, though at significantly reduced speeds

Notice the pattern? Speed degrades exponentially as thickness increases. Doubling the material thickness does not simply halve the cutting speed. It reduces speed by far greater margins because the laser must deliver sufficient energy density through the entire material depth while the assist gas must expel an increasingly larger volume of molten material.

| Material Thickness | Power Requirement | Relative Speed | Assist Gas Effect |

|---|---|---|---|

| Thin gauge (under 3mm) | Low to medium (1500-4000W) | Very fast (10-30+ m/min) | Nitrogen enables 3-4x faster speeds than oxygen |

| Medium gauge (3-12mm) | Medium to high (4000-12000W) | Moderate (2-10 m/min) | Oxygen and nitrogen speeds converge |

| Heavy plate (12-25mm) | High (12000W+) | Slow (0.5-2 m/min) | Oxygen typically faster due to exothermic assist |

| Ultra-thick (25mm+) | Very high (20000W+) | Very slow (under 1 m/min) | Oxygen preferred for energy contribution |

CNC laser cutting systems automate much of this parameter selection through material databases and cutting recipes. Modern laser CNC machine controllers store optimized parameters for common material and thickness combinations, reducing operator guesswork. However, understanding the underlying relationships remains essential for troubleshooting cuts that fall outside normal parameters or when processing non-standard materials.

Assist Gas Selection for Optimal Results

Your choice between oxygen and nitrogen affects far more than just cutting speed. It fundamentally changes the chemistry of the cutting process and determines whether your finished edges are ready for immediate use or require secondary processing.

Oxygen performs approximately 60 percent of the cutting work on steel according to Prestige Metals. The oxygen reacts with iron in an exothermic reaction that releases additional energy through heat and light. This burning process adds cutting power but creates an oxide layer on the cut edge. For powder coating or welding applications, this oxide surface typically requires removal, particularly on steels thicker than 14 gauge.

Nitrogen operates as a shielding gas, preventing oxidation rather than participating in the cutting reaction. The result is an edge that emerges oxide-free, highly receptive to powder coat paint, and ready for welding without additional preparation. According to Prestige Metals, nitrogen cutting generally eliminates the need for any secondary operations on the cut edge.

The trade-off? Gas consumption. Oxygen cutting consumes 10 to 15 times less gas than nitrogen processing. As material thickness increases, nitrogen consumption climbs further, making the cost differential more pronounced for heavy plate applications.

| Factor | Oxygen Assist | Nitrogen Assist |

|---|---|---|

| Cutting mechanism | Exothermic reaction adds energy | Shielding only, no chemical reaction |

| Speed on thin steel | Power-limited ceiling | 3-4x faster with adequate power |

| Speed on thick steel | Generally faster | Slower due to pure laser energy reliance |

| Edge quality | Oxidized surface, may require cleaning | Clean, oxide-free, weld-ready |

| Gas consumption | Low (baseline) | 10-15x higher than oxygen |

| Best applications | Thick plate, cost-sensitive production | Stainless steel, aluminum, painted parts |

For stainless steel and aluminum, nitrogen is essentially mandatory. Oxygen would compromise the corrosion resistance that makes stainless steel valuable, and would create problematic oxide formation on aluminum surfaces.

Focus Position and Kerf Width Considerations

Focus position determines where the laser beam reaches its smallest, most energy-dense point relative to the material surface. Proper focus positioning ensures maximum energy concentration exactly where cutting occurs. Even small deviations from optimal focus create wider kerfs, rougher edges, and increased dross formation.

According to DW Laser, kerf width varies based on laser type, material properties, laser power settings, and cutting thickness. For materials under 1mm thick, cuts can be extremely fine and smooth. However, kerf width increases with material thickness and power level, requiring compensation in part programming to maintain dimensional accuracy.

Modern laser cutting machines handle kerf compensation through software that automatically adjusts cutting paths based on measured kerf width. Operators input material type and thickness, and the system calculates appropriate compensation values. For external contours, the software increases dimensions by half the kerf width. For internal features like holes, it decreases dimensions by the same amount.

Key kerf compensation practices include:

- Measure actual kerf width by cutting test samples and using precision measuring tools like micrometers

- Adjust compensation values when switching between material types or thicknesses

- Calibrate regularly since laser performance changes over time and affects kerf consistency

- Consider cutting method differences as fusion cutting and flame cutting may require different compensation settings

Nozzle condition indirectly affects kerf width as well. According to DW Laser, while the nozzle does not physically determine kerf size, it plays a crucial role in the cutting process that influences the final kerf dimensions. Worn or damaged nozzles create inconsistent gas flow that affects cut quality and dimensional accuracy.

With these parameter fundamentals established, you can now evaluate laser steel cutting machine capabilities against your specific requirements. Understanding how power, speed, assist gas, and focus interact enables meaningful conversations with service providers and informed equipment purchasing decisions. Next, we examine the thickness limitations that define what laser cutting can and cannot accomplish on steel materials.

Steel Thickness Capabilities and Limitations

So you have dialed in your parameters and selected the right assist gas. But here is a question that catches many people off guard: can your laser actually cut through the steel thickness you need? Understanding thickness limitations saves you from wasted time, rejected parts, and the frustration of discovering mid-project that your chosen cutting method cannot deliver.

Sheet metal laser cutting excels within specific thickness windows. Push beyond those limits, and quality degrades rapidly. Stay within the sweet spot, and you achieve the precision, speed, and edge quality that make laser cutting the preferred method for modern fabrication. Let us examine exactly where those boundaries fall.

Thickness Limits by Laser Power Class

Laser power directly determines how thick you can cut, but the relationship is not linear. According to LD Laser Group, optimal cutting quality occurs at 60-80% of maximum rated thickness, with diminishing results beyond these ranges. This means a laser rated for 30mm maximum mild steel cutting actually delivers best results at 18-24mm.

Here is how capabilities break down across common power classes:

- Low power (1-2kW): Ideal for laser cutting steel sheet up to 12mm mild steel. These systems dominate thin gauge sheet metal laser cutting applications where speed on light materials matters more than maximum thickness capability.

- Medium power (4-6kW): Handles laser cutting metal sheet up to 25mm mild steel effectively. According to IVY CNC, 6kW systems achieve favorable edge quality up to 20mm.

- High power (8-12kW): Pushes into 30mm mild steel territory. According to LD Laser Group, modern 12kW fiber lasers can cut mild steel up to 30mm with acceptable quality.

- Ultra-high power (20kW+): Specialized systems reaching beyond 50mm for mild steel, though practical applications at these extremes require careful evaluation of cost versus alternative methods.

Different steel types shift these limits significantly. According to LD Laser Group, stainless steel cutting maxes out at 25mm for grade 304 and 20mm for grade 316L using high-power systems. The higher nickel content in 316L reduces laser absorption efficiency, creating a lower practical ceiling despite identical machine capabilities.

| Power Class | Mild Steel Max | Stainless Steel Max | Optimal Quality Range |

|---|---|---|---|

| 1-2kW | 12mm | 6-8mm | Under 8mm |

| 4-6kW | 25mm | 12-15mm | Under 16mm |

| 8-12kW | 30mm | 20-25mm | Under 24mm |

| 20kW+ | 50mm+ | 30mm+ | Application dependent |

For laser cut metal sheets in thin gauge applications, even modest 1500W systems deliver exceptional results. According to Leapion, a 1500W laser effectively cuts 12mm thick carbon steel but only about 4mm of aluminum due to different physical properties. This highlights why material type matters as much as raw power when evaluating thickness capabilities.

When Steel Gets Too Thick for Lasers

Imagine trying to cut 35mm mild steel on a 6kW fiber laser. What happens? The machine might technically pierce and traverse the material, but the results tell a different story. Edge quality deteriorates dramatically. Dross accumulates on the bottom surface. The heat-affected zone widens significantly. And cutting speeds drop to a crawl that makes the process economically questionable.

According to LD Laser Group, industry practices typically recommend maintaining cutting thicknesses between 16mm to 20mm for peak production efficiency and consistent quality output. Materials beyond 20mm often require reduced cutting speeds and increased laser power, potentially compromising edge quality and production rates.

The laser cutting machine sheet metal sweet spot falls into three distinct zones:

- Thin gauge sheet metal (under 6mm): This is where laser cut sheet metal applications truly shine. Cutting speeds reach their maximum, edge quality remains excellent, and laser cutting delivers unmatched precision for intricate patterns, tight tolerances, and high-volume production. A laser cutting machine sheet metal setup in this range achieves the fastest cycle times and lowest cost per part.

- Medium thickness structural components (6-20mm): Laser cutting remains highly competitive. Quality stays consistent with proper parameter selection, though speeds reduce noticeably compared to thin materials. Most fabrication shops handle this range routinely for brackets, structural members, and machine components.

- Thick plate limitations (over 20mm): Here the trade-offs become significant. According to IVY CNC, cutting speed decreases proportionally as material thickness increases, with efficiency dropping more rapidly beyond certain thickness thresholds. Edge quality becomes more variable, requiring tighter process control and potentially secondary finishing operations.

Why does quality degrade at thickness extremes? Several factors converge. The laser beam must maintain sufficient energy density through the entire material depth. Molten material must be expelled from an increasingly deep and narrow channel. Heat accumulates in the cutting zone, affecting edge metallurgy. And assist gas struggles to reach the bottom of deep cuts effectively.

According to IVY CNC, optimizing cutting parameters can increase maximum cutting thickness by up to 20% while maintaining cut quality. However, this optimization requires expertise, testing, and acceptance of reduced throughput. For materials significantly beyond optimal ranges, alternative methods like plasma cutting or waterjet often deliver better results at lower cost.

Understanding these limits serves a practical purpose: it helps you select the right cutting method for each application. Laser cutting steel sheet in thin to medium gauges offers unbeatable precision and speed. But recognizing when steel gets too thick for efficient laser processing prevents costly mistakes and guides you toward the most appropriate fabrication approach. With thickness capabilities clearly mapped, the next step is comparing laser cutting against the alternative methods that may better serve heavy plate applications.

Comparing Laser to Alternative Steel Cutting Methods

Here is a truth that commercial sites rarely share: laser cutting steel is not always the best choice. Sounds counterintuitive after five chapters explaining laser technology, right? But understanding when plasma, waterjet, or mechanical shearing outperforms laser cutting transforms you from someone who defaults to one method into someone who selects the optimal solution for each application.

According to Wurth Machinery, choosing the wrong CNC cutter can cost thousands in wasted material and lost time. The goal is matching cutting technology to your specific requirements rather than forcing a single method onto every job. Let us examine each alternative honestly so you can make informed decisions.

Laser vs Plasma for Steel Fabrication

Plasma cutting uses an electrical arc and compressed gas to melt and blast through conductive metals. If you are cutting half-inch steel plate or thicker, plasma often delivers the best combination of speed and cost efficiency. The metal cutter machine comparison becomes especially interesting at thickness extremes.

Where does plasma excel? According to Wurth Machinery, plasma cutting dominates when working with thick conductive metals while keeping costs manageable. Their testing showed excellent performance on steel plates over one inch thick, precisely where laser cutters struggle to penetrate efficiently.

Key advantages of plasma for steel cutting include:

- Lower equipment costs: According to Tormach, a complete plasma system starts under $16,000 while comparable laser or waterjet systems cost tens of thousands more

- Superior thick material speed: Plasma cuts one-inch steel approximately 3-4 times faster than waterjet at roughly half the operating cost per foot

- Operational flexibility: Works on any conductive material without the reflection concerns that affect laser processing

- Lower barrier to entry: Simpler operation and maintenance compared to laser systems

However, plasma creates larger heat-affected zones than laser cutting and produces rougher edge quality. For structural steel fabrication, heavy equipment manufacturing, and shipbuilding applications where tight tolerances matter less than throughput speed, plasma represents the smarter choice over laser.

When should you choose laser over plasma? For thin sheets requiring precise, intricate cuts. The focused laser beam creates exceptionally clean edges with minimal post-processing. According to Wurth Machinery, laser cutting proves far superior for holes smaller than material thickness, intricate patterns and fine details, and parts requiring minimal finishing. If your sheet metal cutting machine requirements involve precision on thin gauge materials, laser remains the clear winner.

When Waterjet Beats Laser Cutting

Waterjet cutting uses high-pressure water mixed with abrasive to cut virtually any material without heat. That means no warping, no hardening, and no heat-affected zones whatsoever. When thermal damage must be avoided, waterjet becomes the only viable option among metal cutting machines.

According to Wurth Machinery, the waterjet market is projected to reach over $2.39 billion by 2034, reflecting growing recognition of its unique capabilities. The cutting metal machine comparison shifts dramatically when heat sensitivity enters the equation.

Waterjet stands out when:

- Heat-sensitive materials are involved: Hardened tool steels, tempered components, and materials that would lose properties from thermal exposure require cold cutting processes

- Material versatility matters: The abrasive waterjet cuts through virtually any material except tempered glass and diamonds, making it the most versatile option

- Edge metallurgy must remain unchanged: No heat-affected zone means material properties remain consistent right to the cut edge

- Thick materials need precision: Waterjet maintains consistent accuracy through thick sections where laser edge quality degrades

The trade-offs? According to Tormach, waterjet cutting can be messy due to the garnet abrasive, and consumable costs run higher than other methods. Equipment investment typically reaches around $195,000 compared to $90,000 for comparable plasma systems. Best applications include aerospace components, stone and glass cutting, and food processing equipment.

Comprehensive Method Comparison

Choosing the right steel cutting machine requires weighing multiple factors simultaneously. This comparison table synthesizes the key differences based on testing data from Wurth Machinery and Tormach:

| Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting | Mechanical Shearing |

|---|---|---|---|---|

| Edge Quality | Excellent on thin materials | Good, rougher than laser | Excellent, smooth finish | Good for straight cuts |

| Heat-Affected Zone | Small, localized | Large, significant | None (cold process) | None (mechanical) |

| Optimal Thickness Range | Under 20mm (best under 12mm) | Over 12mm (excels at 25mm+) | Any thickness with consistency | Thin sheet, straight lines only |

| Precision Tolerances | ±0.1mm achievable | ±0.5-1.0mm typical | ±0.1-0.25mm typical | ±0.25mm for clean sheets |

| Operating Costs | Moderate (gas, power) | Lower (consumables, power) | Higher (abrasive, water) | Lowest (blade wear only) |

| Equipment Investment | $150,000-500,000+ | $16,000-90,000 | $195,000+ | $10,000-50,000 |

| Material Limitations | Reflective metals challenging | Conductive metals only | Virtually unlimited | Thin sheet metal only |

| Complex Geometry | Excellent | Good | Excellent | Straight cuts only |

Making the Right Choice for Your Application

The honest recommendation depends entirely on your specific requirements. A cnc metal cutting machine selection should follow this decision framework:

Choose laser cutting when: You need precision on thin to medium gauge steel, complex geometries, small features, or high-volume production where edge quality matters. The metal cutting laser delivers unmatched accuracy for parts under 12mm thick.

Choose plasma cutting when: Your work involves thick plate steel, cost sensitivity is high, and edge finish tolerances are relaxed. Structural fabrication and heavy equipment manufacturing typically favor plasma.

Choose waterjet cutting when: Heat damage cannot be tolerated, material versatility matters, or you need precision through thick sections. Aerospace, medical, and specialty material applications often require waterjet.

Choose mechanical shearing when: You need high-speed straight cuts on thin sheet metal with minimal investment. Simple blanking operations favor this lowest-cost option.

According to Wurth Machinery, many successful shops eventually incorporate multiple technologies, starting with the system that addresses their most common projects. Plasma and laser often pair well, with waterjet adding unmatched versatility for specialty work.

Understanding these alternatives positions you to make genuinely informed decisions rather than defaulting to laser cutting for every application. Sometimes the best laser cutting advice is knowing when not to use it. With this comparative foundation established, the next step is addressing what happens when cuts do not go as planned and how to troubleshoot common laser cutting problems.

Troubleshooting Common Steel Cutting Problems

So you have compared cutting methods and selected laser for your application. But what happens when that supposedly perfect cut comes off the table with dross clinging to the bottom edge, burrs that catch your fingers, or parts warped beyond tolerance? Every laser cutter for metal operator faces these moments. The difference between frustration and resolution lies in understanding what causes each problem and how to fix it.

According to Fortune Laser, every cutting error is a symptom pointing to a root cause, whether it is in the machine's settings, its delicate optics, or its mechanical parts. Think like a technician, and you transform problems into solved issues rather than recurring headaches. Let us diagnose the most common steel cutting defects and their corrective actions.

Diagnosing Dross and Burr Problems

Dross and burr formation rank among the most frequent complaints with any metal laser cutter. That stubborn residue clinging to the bottom of your cut, or those sharp raised edges requiring manual removal, both trace back to specific process imbalances.

What causes dross formation? According to Fortune Laser, when assist gas pressure is too low, molten material fails to clear the cut path completely. Instead of being expelled, it resolidifies on the bottom surface. Similarly, cutting speed mismatches create dross issues. Too slow, and excess heat melts more material than the gas stream can remove. Too fast, and incomplete penetration leaves partially molten residue.

Burrs present a related but distinct challenge. According to Senfeng Laser, factors such as thicker materials, insufficient air pressure, or mismatched feed speeds can cause some molten slag to solidify and form burrs that stick to the bottom of the workpiece. This requires additional deburring work, resulting in extra labor hours and increased costs.

Root causes and corrective actions for dross and burr issues:

- Insufficient assist gas pressure: Increase pressure incrementally until molten material clears consistently. Too low pressure allows dross to cling; too high pressure can create turbulence and wavy cuts.

- Speed-power imbalance: If cutting too fast, reduce speed or increase power. If cutting too slow, increase speed to reduce heat accumulation. According to Fortune Laser, finding the sweet spot for your specific material and thickness eliminates most quality issues.

- Incorrect focus position: An unfocused beam diffuses energy, creating wider, weaker cuts with increased dross. Verify the beam focuses on or slightly below the material surface for cleanest results.

- Nozzle condition: A damaged, dirty, or clogged nozzle creates chaotic gas flow that ruins cut quality. Visually inspect daily, ensuring the nozzle is clean, centered, and free of nicks or spatter.

- Wrong nozzle size: Using a nozzle opening too large for the job reduces gas pressure at the cut, causing dross accumulation. Match nozzle diameter to material thickness and cutting requirements.

When evaluating work from a laser metal cutter service provider, examine the bottom edge carefully. Clean cuts should show minimal to no dross, requiring no secondary grinding or filing. If you consistently receive parts needing deburring, the provider's parameters need adjustment.

Preventing Heat Distortion in Steel Parts

Heat distortion represents a more complex challenge than surface defects. When parts come off the metal cutting laser machine warped or dimensionally inaccurate, the intense localized heating from laser processing has caused differential expansion and contraction that permanently deformed your component.

According to Sheet Metal Industries, distortion arises when intense heat generated by the laser beam causes localized expansion and contraction in the metal. The result is unwanted warping or dimensional deviation that can affect component fit or performance.

Common causes of heat distortion include:

- Excessive heat input: Too much power or too slow cutting speeds concentrate thermal energy in the material

- Poor material support: Inadequate fixturing allows thermal stresses to translate into physical movement during cutting

- Cutting sequence issues: Cutting patterns that concentrate heat in one area before moving elsewhere create localized stress concentrations

- Material thickness mismatches: Thin materials distort more readily than thick sections under equivalent heat input

Prevention strategies focus on thermal management. According to Sheet Metal Industries, engineers calibrate power, speed, and focus to balance cut quality with minimal heat input, reducing the risk of expansion or contraction stresses forming in the material. The heat-affected zone (HAZ) directly correlates with distortion risk. A smaller HAZ means less material undergoes thermal cycling that creates warping stresses.

According to Senfeng Laser, the smaller the heat-affected zone, the better the cutting quality. This principle applies equally to structural integrity and dimensional stability.

Comprehensive Troubleshooting Checklist

Before concluding that your laser cutting machine metal has a serious problem, run through this systematic checklist. Most issues resolve through these checks:

-

Parameter adjustments:

- Verify laser power matches material type and thickness requirements

- Confirm cutting speed falls within optimal range for the application

- Check that power and speed are balanced rather than individually optimized

-

Nozzle condition:

- Inspect for damage, contamination, or spatter buildup daily

- Confirm nozzle is properly centered over the beam path

- Replace worn nozzles before quality degradation becomes visible

-

Focus calibration:

- Verify focus position is correctly set for material thickness

- Check for lens contamination that could diffuse the beam

- Inspect mirrors in the optical path for dirt or damage

-

Assist gas pressure:

- Confirm gas type matches application requirements (oxygen vs nitrogen)

- Verify pressure settings are appropriate for material and thickness

- Check for leaks or restrictions in gas delivery system

According to Fortune Laser, if adjusting these primary factors does not solve the issue, the problem might be mechanical, like vibrations from a worn-out belt or bearing. Motion system issues create wavy lines, inconsistent dimensions, and quality variations across the cutting bed.

Quality Assessment Criteria for Evaluating Service Providers

When you cannot troubleshoot directly because you are outsourcing laser cut machine work, knowing how to evaluate received parts becomes essential. These criteria help you assess whether a provider delivers acceptable quality:

Edge roughness: According to Senfeng Laser, during laser cutting, diagonal marks may appear on the cut surface. The smaller the marks, the smoother the cutting surface and the better the cutting quality. Run your finger along cut edges. Quality cuts feel smooth with minimal texture.

Dimensional accuracy: Measure critical dimensions against specifications. The cutting gap, or kerf, affects final part size. Consistent and accurate kerf width is crucial for ensuring parts fit together as intended. Request tolerance specifications from providers and verify compliance through measurement.

Perpendicularity: According to Senfeng Laser, vertical angle refers to how straight the cut is in relation to the material. Examine cut edges with a square. The thicker the workpiece, the harder it is to maintain cutting perpendicularity, so evaluate accordingly.

Heat-affected zone inspection: Look for discoloration adjacent to cut edges. Excessive discoloration indicates thermal damage that may affect material properties. For critical applications, metallurgical testing may be warranted to verify HAZ extent and its impact on component performance.

These assessment skills serve you whether you are evaluating a potential new supplier, verifying quality from an existing provider, or troubleshooting your own laser cutting operations. Understanding what constitutes quality and recognizing departures from acceptable standards positions you to demand better results and identify root causes when problems arise. With troubleshooting fundamentals established, the next step examines how proper design and material preparation can prevent many of these issues before they occur.

Design and Preparation for Optimal Results

You have mastered troubleshooting techniques for when cuts go wrong. But what if you could prevent most problems before they ever happen? That is exactly what proper design and material preparation accomplish. The decisions you make before steel ever touches a laser cutting table directly determine whether parts come off clean and accurate or require costly rework.

Think of it this way: a sheet metal laser cutter can only execute what your design file tells it to do. Feed it geometry that violates physical constraints, and even the most sophisticated laser cutter for sheet metal produces disappointing results. Feed it well-prepared material with optimized designs, and quality practically takes care of itself.

Design Rules for Laser-Cut Steel Parts

Design for manufacturability sounds like engineering jargon, but the principles are surprisingly straightforward. Every feature you add to a part either supports successful cutting or works against it. Understanding these relationships transforms your designs from technically correct drawings into parts that cut efficiently and perform reliably.

According to MakerVerse, kerf width typically ranges from 0.1 mm to 1.0 mm depending on material and cutting parameters. This means features smaller than your kerf width simply cannot exist. The laser beam consumes that material completely. Plan minimum feature sizes accordingly, and verify your service provider's actual kerf width for the specific material and thickness you are using.

Hole-to-edge distances represent one of the most commonly violated design rules. According to SendCutSend, holes should be placed at least one times their diameter from an edge, and slots at least 1.5 times their width away from edges or other cut features. Push closer than these minimums, and you risk tearing, deformation, or complete feature loss during cutting or subsequent forming operations.

Essential design guidelines for laser sheet metal cutter applications:

- Minimum hole diameter: Keep hole diameters and bridging widths no less than 50% of material thickness. For a 0.125 inch thick part, this means 0.0625 inch minimum between features.

- Preferred bridging: For strength and cut quality, design wall thickness or bridging at 1x to 1.5x material thickness rather than the absolute minimum.

- Cutting geometry spacing: According to MakerVerse, space cutting geometry at least two times the sheet thickness apart to avoid distortion from heat accumulation.

- Bend radius considerations: If parts will undergo forming, use consistent radii with consistent bend orientations. Varying these means repositioning parts more often, increasing labor time and cost.

- Tool access for bending: When designing for subsequent bending operations, leave enough clearance for bending tools to access corners at 90 degrees from the bend line.

What about tolerances? According to SendCutSend, cut tolerances for most materials run plus or minus 0.005 inches. This means any given cut feature or perimeter geometry may vary by that amount in either the X or Y axis. When designing tight-tolerance features like slots, always consider the worst-case scenario where finished dimensions land at the negative end of that tolerance range.

T-slots deserve special attention since they combine multiple design considerations. The goal is creating an opening that allows a nut to slide in at its narrowest point, then engage the slot walls when rotated. SendCutSend recommends adding 0.01 inch to the nut width at its narrowest point, ensuring reliable function without excessive looseness.

Material Preparation Best Practices

Even the most carefully designed part fails if material preparation falls short. Surface conditions directly affect laser energy absorption, cut consistency, and edge quality. A machine to cut metal performs best when starting with properly prepared material.

Mill scale presents the most common preparation challenge for hot-rolled steel. According to The Fabricator, removing mill scale is quite difficult even with a powerful laser because the scale's ablation threshold is very high. Thick mill scale on heavy plate may require multiple laser passes, making mechanical removal more efficient for high-volume operations.

Material preparation requirements for optimal sheet metal laser cutting machine results:

- Mill scale removal: Light scale on thin material often burns away during cutting. Heavy scale on thick plate should be removed mechanically before processing to ensure consistent penetration.

- Surface cleanliness: Remove oils, lubricants, and protective films. According to The Fabricator, oils are transparent to laser light and must be vaporized by heating the base metal beneath them, which affects process consistency.

- Rust treatment: Surface rust changes absorption characteristics unpredictably. Remove rust before cutting to maintain consistent parameters across the sheet.

- Material flatness: Warped or bowed sheets create focus variations across the cutting area. Use flat material or plan for reduced quality in distorted areas.

- Protective film handling: Some materials arrive with protective plastic film. Decide whether to cut through the film (adds debris) or remove it first (exposes surface to contamination).

According to The Fabricator, laser cleaning systems are gaining traction for surface preparation, using thermal shock effects to remove rust, scale, and organic coatings without chemicals or consumables. For operations processing significant volumes, dedicated laser cleaning prior to cutting may prove more efficient than manual preparation methods.

Setting Realistic Expectations

Commercial service providers often mention tolerances and edge quality standards without explaining what they actually mean in practice. Understanding these specifications helps you communicate requirements effectively and evaluate delivered parts fairly.

According to MakerVerse, dimensional tolerances represent the allowable deviation in a part's dimensions due to variations in the cutting process. These tolerances exist because no cutting process is perfect. Thermal expansion, mechanical precision, material variations, and process dynamics all introduce small deviations from nominal dimensions.

What should you expect from quality laser cutting?

- Dimensional accuracy: Plus or minus 0.005 inch is standard for most sheet metal laser cutter operations. Tighter tolerances are achievable but may require premium pricing.

- Edge perpendicularity: Thinner materials maintain better perpendicularity. As thickness increases, slight taper becomes increasingly difficult to prevent.

- Surface finish: Expect striation marks on cut edges. According to MakerVerse, various finishing techniques can enhance properties like corrosion resistance and aesthetic appeal if raw edge finish is unacceptable.

- Heat-affected zone: Some metallurgical change adjacent to the cut is unavoidable. The extent depends on power, speed, and material properties.

Armed with these design principles and preparation standards, you can create parts optimized for laser cutting while setting realistic expectations for the results. This knowledge also positions you to evaluate potential manufacturing partners effectively, which brings us to selecting the right service provider or equipment for your specific requirements.

Selecting the Right Manufacturing Partner

You have absorbed the technical fundamentals, understood material behaviors, and learned how to design parts that cut cleanly. Now comes the decision that determines whether all that knowledge translates into successful parts: choosing who actually performs the work. Whether you are evaluating a cnc laser cutting machine purchase or selecting a service provider, the criteria that separate exceptional partners from adequate ones deserve careful examination.

The question many buyers ask first is straightforward: how much is a laser cutter, or what will service cost per part? But starting with price puts the cart before the horse. According to Wrightform, choosing the right steel laser cutting service is critical to ensuring your project meets quality, budget, and timeline expectations. Price matters, but it matters most when compared against capability, reliability, and total value delivered.

Evaluating Laser Cutting Service Providers

When vetting potential partners, you need answers to specific questions that reveal whether they can actually deliver what your project requires. According to Wrightform, laser cutting involves high-precision work that requires specialized equipment, experienced operators, and efficient processes. Generic promises mean little without evidence of relevant capability.

Start with equipment and material capabilities. Not all providers handle the same thickness ranges or material types. High-power fiber lasers can cut thicker and more reflective materials than traditional CO2 lasers, though suitability depends on many factors. Ask specifically about your material type and thickness, and request examples of similar work.

Key questions to ask any potential cnc laser cutter service provider:

- What materials and thicknesses can you handle? Confirm they routinely process your specific steel grades at required thicknesses. According to Wrightform, providers should specify whether they work with stainless steel, aluminum, or mild steel in the thickness you need.

- What precision tolerances can you achieve? Clarify their cutting accuracy and ability to produce clean edges without burrs. Industries requiring tight tolerances like aerospace or medical demand verification.

- Do you offer prototyping services? Prototyping allows you to validate designs before committing to full-scale production, invaluable for fine-tuning specifications and ensuring component compatibility.

- How do you optimize material usage? Efficient nesting through advanced CAD/CAM software saves costs and reduces waste. Ask whether they recycle product waste as well.

- What are your turnaround times? Verify standard production timelines and whether rush orders are available. Some providers ship within a day or two for urgent jobs.

- What file formats do you accept? Standard formats include DXF and DWG for CAD designs. Some providers work with PDFs or even hand-drawn sketches and offer design review services.

- Do you provide finishing and assembly services? A one-stop shop offering deburring, polishing, painting, or assembly saves logistics hassles and coordination time.

- What quality control processes do you use? Quality assurance should involve regular inspections, dimensional verification, and material flaw checking.

- What experience do you have with similar projects? A company familiar with your industry's standards anticipates needs better. Cutting for architectural features differs significantly from automotive components.

- Can you handle flexible order sizes? Whether you need one-off prototypes or high-volume production, reliable providers accommodate varying quantities without requiring you to switch partners.

Certifications provide objective evidence of capability. For automotive steel components, IATF 16949 certification carries particular weight. According to SGS, this automotive quality management system standard ensures consistent processes that meet the demanding requirements of chassis, suspension, and structural component manufacturing. If your steel parts feed into automotive supply chains, working with IATF 16949-certified partners reduces qualification headaches and ensures traceability throughout production.

The industrial laser cutter equipment itself matters, but the people operating it matter more. Ask about operator experience and training. According to Wrightform, experienced operators combined with advanced technology deliver results that equipment specifications alone cannot guarantee.

From Prototype to Production Scaling

Here is where many projects stumble: the transition from successful prototypes to reliable production volumes. A provider who delivers excellent one-off samples may struggle when orders scale to thousands of parts per month. Evaluating scalability before you need it prevents painful mid-project partner switches.

Consider the full manufacturing workflow beyond just cutting. Many steel components require secondary operations like stamping, bending, welding, or assembly. Integrated manufacturing partners who handle multiple processes under one roof streamline workflows dramatically compared to coordinating between separate cutting, forming, and finishing vendors.

When researching laser cutting machine price or fiber laser cutting machine price for in-house equipment, factor in the total cost of ownership beyond the initial purchase. An industrial laser cutting machine requires trained operators, regular maintenance, consumables inventory, and facility modifications. For many operations, outsourcing to capable service providers delivers better economics than equipment ownership, at least until volumes justify dedicated capacity.

Key factors when evaluating production scaling capability:

- Equipment redundancy: Multiple machines mean your production does not halt if one system requires maintenance

- Automation capabilities: Automated material handling and lights-out operation enable consistent high-volume throughput

- Quality systems: Statistical process control and documented inspection procedures maintain consistency across production runs

- Supply chain integration: Partners who stock common materials or maintain vendor relationships reduce lead time variability

- Design for manufacturability support: Comprehensive DFM feedback before cutting begins prevents costly design iterations after production starts

For automotive and structural steel applications where precision cutting feeds into stamping or assembly operations, integrated manufacturing partners deliver particular value. Consider partners like Shaoyi (Ningbo) Metal Technology, who combine IATF 16949-certified quality with capabilities spanning rapid prototyping through automated mass production for chassis, suspension, and structural components. Their 5-day rapid prototyping and 12-hour quote turnaround exemplify the responsiveness that keeps projects moving without sacrificing quality standards.

DFM support deserves emphasis because it multiplies the value of everything covered in this guide. When manufacturing engineers review your designs before cutting begins, they identify potential issues with tolerances, feature spacing, material preparation, and downstream operations. This proactive approach costs far less than discovering problems after parts are cut and prevents the troubleshooting scenarios we covered earlier.

Making Your Final Decision

With evaluation criteria established, the selection process becomes more systematic. Request quotes from multiple providers, but compare more than just laser cutter for steel pricing. Evaluate response time, technical questions asked during quoting, and willingness to discuss your specific application needs.

The best partners ask questions before quoting. They want to understand your tolerance requirements, surface finish expectations, and end-use applications. This curiosity indicates genuine interest in delivering successful parts rather than simply processing orders.

Consider starting relationships with smaller prototype orders before committing to production volumes. This trial period reveals communication patterns, actual versus quoted turnaround times, and real-world quality levels. The investment in a test run pays dividends through avoided problems on critical production orders.

Throughout this guide, you have gained the knowledge to understand laser cutting steel at a fundamental level, select appropriate technologies and parameters, design parts optimized for laser processing, troubleshoot problems when they arise, and now evaluate manufacturing partners effectively. This comprehensive foundation positions you to achieve the precision edges and reliable results that make laser cutting the preferred method for modern steel fabrication.

Frequently Asked Questions About Laser Cutting Steel

1. How much does it cost to get steel laser cut?

Steel laser cutting costs vary based on material thickness, complexity, and volume. Most jobs incur setup fees of $15-30, with labor rates around $60 per hour for additional work. For precision automotive and structural components, IATF 16949-certified manufacturers like Shaoyi Metal Technology offer competitive pricing with 12-hour quote turnaround and comprehensive DFM support to optimize costs before cutting begins.

2. How thick of steel can a laser cut?

Laser cutting thickness depends on power level. Low-power 1-2kW systems cut up to 12mm mild steel effectively. Medium 4-6kW lasers handle up to 25mm, while high-power 12kW+ systems can process 30mm or more. For optimal quality, manufacturers recommend staying at 60-80% of maximum rated thickness. Stainless steel limits run lower due to reduced laser absorption efficiency.

3. What is the difference between fiber laser and CO2 laser for cutting steel?

Fiber lasers use 1064nm wavelength that steel absorbs efficiently, achieving cutting speeds up to 100 m/min on thin materials with 70% less energy consumption. CO2 lasers operate at 10,600nm wavelength and excel on thick steel over 25mm with superior edge quality. Fiber systems require less than 30 minutes weekly maintenance versus 4-5 hours for CO2, making them the dominant choice for most steel fabrication work.

4. What materials cannot be cut on a laser cutter?

Standard laser cutters cannot safely process PVC, polycarbonate, Lexan, or materials containing chlorine that release toxic gases when heated. For metals, highly reflective materials like polished copper and brass pose challenges for CO2 lasers due to back-reflection risks, though modern fiber lasers handle these materials effectively. Always verify material compatibility with your service provider before processing.

5. Should I use oxygen or nitrogen assist gas for laser cutting steel?

Oxygen performs approximately 60% of cutting work through exothermic reaction, making it faster for thick steel but leaving oxidized edges requiring cleaning. Nitrogen produces oxide-free, weld-ready edges ideal for stainless steel, painted parts, and applications requiring immediate secondary operations. Nitrogen costs 10-15x more in gas consumption, so choice depends on edge quality requirements versus operating budget.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —