How To Use A Die Without Stripping Threads: 7 Steps That Work

What Is a Threading Die and Why It Matters

Picture this: you're in the middle of a repair project when you discover a bolt with completely stripped threads. Or maybe you need a custom-length threaded rod for a fabrication project, but no hardware store carries the exact size. These situations happen more often than you'd think, and that's exactly where knowing how to use a die becomes invaluable.

What Is a Threading Die and When Do You Need One

Before diving in, let's clear up a common mix-up. If you searched expecting information about die cutting machines for crafts or paper, you're in the wrong place. We're talking about threading dies—precision metalworking tools used in machine shops, garages, and home workshops everywhere.

A threading die is a hardened steel tool designed to cut external threads onto cylindrical metal stock, transforming a plain rod into a functional bolt or threaded fastener.

This die tool features multiple cutting edges arranged in a circular pattern. When rotated around a metal rod, it progressively cuts spiral grooves that form precise threads. According to Travers Tool, dies are applied to specific rod diameters to create threads of exact size and pitch.

Threading Die vs Tap - Understanding the Key Difference

Understanding the difference between tap and die is essential before starting any threading project. Here's the simple breakdown:

- Dies create external threads on rods, bolts, and screws (the male component)

- Taps create internal threads inside holes for nuts and sockets (the female component)

When comparing die vs tap applications, think of it this way: a die makes the screw, while a tap makes the hole the screw goes into. Both tools work together, which is why you'll often find them sold as a set. So what is a tap and die set? It's a comprehensive toolkit containing both types of threading tools in various sizes, typically including handles and wrenches for operation.

Why Every DIYer and Machinist Needs Dies in Their Toolkit

Threading dies open up countless possibilities for repairs and custom fabrication. Common applications include:

- Creating custom-length bolts for unique projects

- Repairing damaged or rusty threads on existing fasteners

- Matching specific thread sizes for vintage equipment restoration

- Converting plain rod stock into threaded components

By the end of this guide, you'll master the complete process—from selecting the right die type to cutting clean threads without stripping. You'll learn proper preparation techniques, lubrication strategies, and troubleshooting methods that separate amateur attempts from professional results.

Step 1 Choose the Right Die Type for Your Project

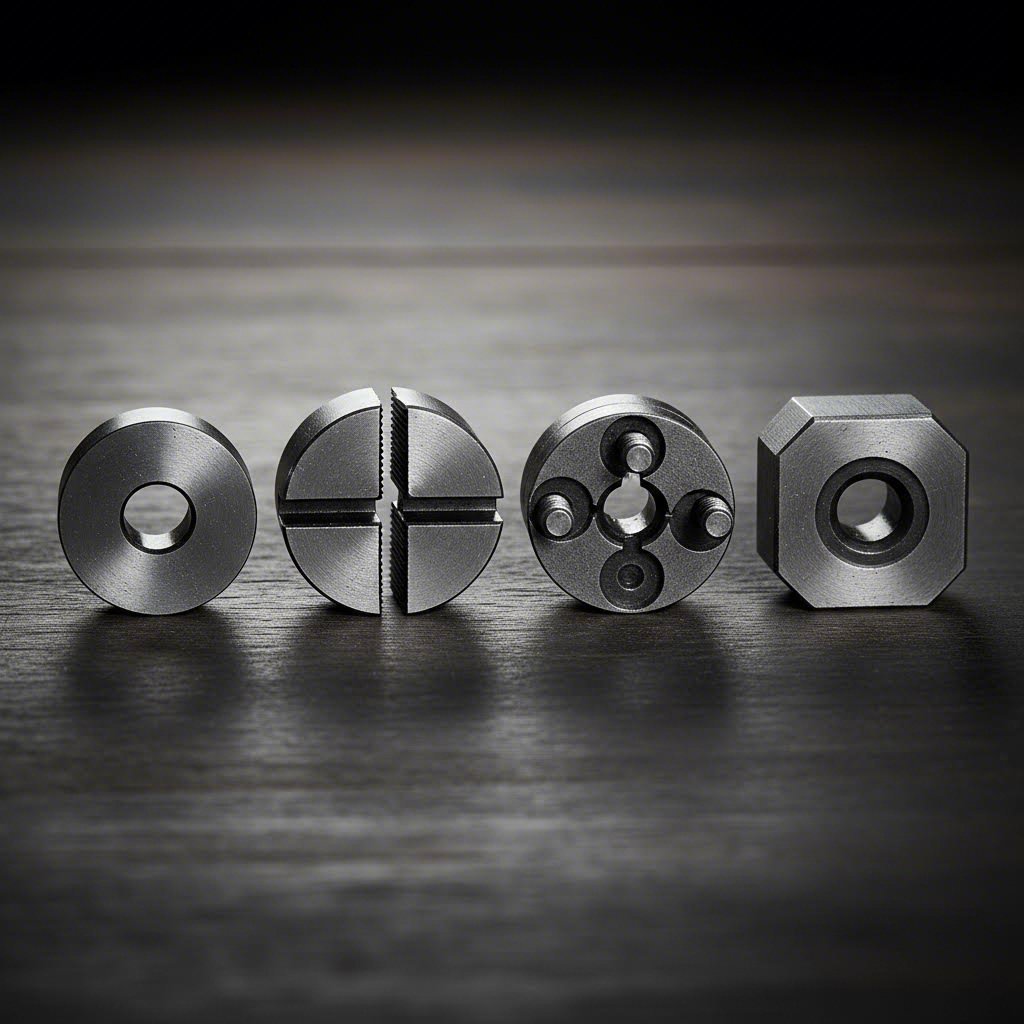

Ever stood in front of a wall of threading dies at the hardware store, completely overwhelmed by the options? You're not alone. Selecting the correct die from your tap die set can make the difference between clean, precise threads and a frustrating mess. Let's break down the four main types so you'll know exactly which threading die matches your project.

Solid Dies for Standard Threading Projects

Solid dies are the workhorses of any set of die tools. These fixed-size threading dies feature a single-piece construction with no adjustable components. According to NIKOPAS, solid thread cutting dies work best for small-diameter and pitch threads where precision is paramount.

When should you reach for a solid die? They're your go-to choice for:

- Standard bolt and fastener creation

- Projects requiring consistent, repeatable threads

- Situations where the rod diameter matches specifications exactly

The main limitation? Zero adjustability. If your rod stock is slightly oversized, a solid die won't compensate—you'll need to choose a different type from your die set.

Split and Adjustable Dies for Precision Control

Need more flexibility? Split dies and adjustable dies give you control that solid options simply can't match.

Split Dies feature a gap cut through one side, allowing slight diameter adjustment via a set screw. This makes them ideal for fine-tuning thread depth or accommodating rod stock that's slightly off-spec. As noted in threading industry resources, split thread cutting dies consist of fixed and adjustable parts specifically designed for cutting larger threads with greater precision.

Adjustable Dies take this concept further with multiple cutting edges that can be independently positioned. These excel when working with:

- Worn or oversized stock that needs custom fitting

- Projects requiring threads looser or tighter than standard

- Repair work on existing threaded components

When consulting a die and tap chart, you'll notice adjustable dies often cover a small range rather than a single fixed size. This versatility makes them valuable additions to any serious machinist's toolkit.

Hex Dies for Confined Workspace Applications

Working in tight spaces where a standard die stock handle won't fit? Hex dies solve this problem elegantly. Designed with a hexagonal exterior, they accept socket wrenches and ratchets instead of traditional handles.

You'll appreciate hex dies when threading in:

- Automotive engine compartments

- Tight mechanical assemblies

- Any situation requiring a low-profile approach

Quick Reference: Die Type Comparison

| Die Type | Best Use Case | Adjustability | Skill Level Required |

|---|---|---|---|

| Solid Die | Standard threading, consistent results | None | Beginner |

| Split Die | Fine-tuning thread depth | Limited (via set screw) | Intermediate |

| Adjustable Die | Worn/oversized stock, custom fits | Full range adjustment | Intermediate to Advanced |

| Hex Die | Confined spaces, ratchet operation | Varies by design | Beginner to Intermediate |

Reading Die Markings Like a Pro

Here's where many beginners get stuck. Those cryptic numbers stamped on every thread die actually tell you everything you need to know—once you understand the code.

Metric Dies display markings like "M8 x 1.25." The "M" indicates metric standard, "8" represents the nominal diameter in millimeters, and "1.25" shows the thread pitch (distance between threads in mm).

Imperial Dies use fractional sizing like "1/4-20." The "1/4" indicates the nominal diameter in inches, while "20" represents threads per inch (TPI).

When building your thread tap die collection, always verify that your rod stock diameter matches the die specifications. A quick reference to a die and tap chart prevents costly mistakes before you start cutting. Most quality tap die sets include sizing charts to eliminate guesswork.

With the right die selected, you're ready to prepare your materials and workspace—the critical foundation for clean, professional threads.

Step 2 Prepare Your Materials and Workspace

You've selected the perfect die for your project. Now comes the step that separates frustrating failures from flawless threads: proper preparation. Rushing this phase is the single biggest mistake beginners make. Spend an extra five minutes here, and you'll save yourself from stripped threads and wasted materials.

Preparing Your Metal Stock for Clean Threads

Here's something most guides overlook: your rod diameter matters more than you think. For metric threads, the rod should be 0.1-0.2mm smaller than the finished thread size. Why? The die needs material to cut into, but too much stock causes binding and poor thread formation.

Before the die touches metal, you need to chamfer the rod end. Using a file or grinder, create a 45-degree bevel around the rod's edge. This chamfer serves two critical purposes:

- Helps the die center itself on the workpiece

- Allows cutting teeth to engage gradually rather than all at once

According to Mechanical Elements, thread dies have an entry side with relief in the cutting threads—reduced height teeth designed for starting the cut. Your chamfer works together with this relief to ensure straight thread initiation.

Essential Tools Beyond the Die Itself

Wondering what you'll need beyond the die? A complete tap set or threading setup requires several supporting tools. Gather everything before starting:

- Die stock/handle – Provides leverage and control for turning the die

- Appropriate die – Matched to your desired thread size and pitch

- Cutting fluid – Essential for lubrication (we'll cover this in depth next)

- Bench vise – Secures the workpiece rigidly during threading

- File for chamfering – Creates the lead-in bevel on rod ends

- Measuring tools – Calipers or micrometers to verify rod diameter

- Clean rags – For wiping away chips and debris

If you're working with a tap and die drill bit set, ensure your tapping sets include the correct pilot drill sizes. While this applies more to internal threading, having complete taps tools organized prevents mid-project scrambling.

Setting Up Your Workspace for Threading Success

Securing your workpiece properly is non-negotiable. Clamp the rod in a bench vise with enough length exposed for your threading needs plus about an inch extra. The critical requirement? The rod must be perfectly vertical.

Here's a trick from experienced machinists: use a square or level against the rod before tightening the vise completely. Even a slight angle at the start compounds into a disaster as you cut deeper. As noted in the Mechanical Elements guide, getting a die started truly straight is often the hardest part of the entire process.

Cleanliness matters more than you'd expect. Metal chips, dust, and debris cause rough threads and premature die wear. Wipe down your rod with a clean rag before starting. Keep your work area clear so fallen chips don't contaminate your cutting fluid or workpiece.

Special Considerations for Stainless Steel and Hard Materials

Planning to thread stainless steel? This is where forum users consistently struggle, and for good reason. Stainless work-hardens during cutting, meaning it gets harder the more you work it. The solution requires adjusting your entire approach:

- Slower speed – Turn the die stock deliberately, never rushing

- More lubricant – Apply cutting fluid generously and frequently

- Lighter pressure – Let the die cut at its own pace

- Frequent reversals – Break chips more often to prevent binding

A tap die drill approach for hard materials requires patience above all else. Forcing the die generates heat, which work-hardens the stainless further, creating a vicious cycle that ends with broken dies or ruined workpieces.

With your workspace organized and materials properly prepared, you're ready to tackle the next critical decision: selecting and applying the correct cutting fluid for your specific material.

Step 3 Select and Apply the Correct Cutting Fluid

Here's a secret that separates professional machinists from frustrated beginners: lubrication isn't optional—it's essential. Skip this step, and you'll end up with rough threads, overheated dies, and shortened tool life. Master it, and you'll produce clean, precise threads every single time.

Why Lubrication Makes or Breaks Thread Quality

When a die cuts into metal, tremendous friction builds at the cutting edges. Without proper lubrication, this friction generates heat that can damage both your workpiece and your threading tools. According to TTP Hard Drills, using the right lubricant can extend your tool life up to four times while preventing chip welding—especially critical when working with stainless steel or aluminum.

Proper cutting fluid delivers four key benefits:

- Reduces friction between the die's cutting edges and the workpiece

- Prevents overheating that causes work-hardening and tool damage

- Produces cleaner threads with smoother surface finishes

- Extends die life by reducing wear on cutting edges

Think of cutting fluid as insurance for your tap and die set for metal. A small investment in proper lubrication protects your tools and guarantees better results on every thread tap operation.

Matching Cutting Fluids to Your Metal Type

Not all metals respond the same way to cutting fluids. Using the wrong lubricant—or none at all—leads to problems ranging from gummy threads to broken dies. Here's your material-specific guide:

| Material | Recommended Lubricant | Application Frequency | Special Notes |

|---|---|---|---|

| Mild Steel | Cutting oil or tapping fluid | Before starting, reapply every 2-3 rotations | Standard approach works well |

| Stainless Steel | Sulfur-based cutting oil or cutting paste | Generously before starting, reapply frequently | Prevents work-hardening; never cut dry |

| Aluminum | Kerosene, WD-40, or light cutting oil | Before starting and as needed | Prevents chip welding to die teeth |

| Brass | Light oil or dry | Minimal application needed | Machines easily; avoid heavy lubricants |

| Cast Iron | Dry or light oil | Optional, apply sparingly | Produces powdery chips; fluid can create paste |

For stainless steel—the material that gives beginners the most trouble—a high-performance cutting paste is ideal. These formulations withstand high temperatures and form a lasting film that prevents the work-hardening that ruins so many threading attempts. When using a tap with thread operations on challenging materials, never underestimate lubricant importance.

Application Techniques for Optimal Results

Knowing which lubricant to use is only half the equation. How you apply it matters just as much. Follow this proven technique:

- Apply generously before starting – Coat the chamfered end of your rod and the die's cutting surfaces

- Reapply during cutting – Every few rotations, add more fluid to the cutting zone

- Don't let it dry out – Fresh lubricant should always be present at the cut thread taps interface

- Clear chips first – Before reapplying, brush away metal shavings so fluid reaches cutting edges

A thin, even layer is usually enough for most materials. However, stainless steel is the exception—apply liberally and keep it wet throughout the entire tap thread process.

Alternatives When Proper Cutting Fluid Isn't Available

Caught without proper cutting fluid? These alternatives can work in a pinch, though dedicated cutting oils always perform better:

- Motor oil – Works for mild steel, though not ideal

- 3-in-1 oil – Acceptable for light-duty threading

- Vegetable oil – Emergency option for aluminum only

- Soapy water – Provides minimal lubrication for brass

Avoid using these substitutes on stainless steel or hardened materials. The consequences—broken dies and ruined workpieces—far outweigh the cost of proper cutting fluid. If you're investing in a quality tap and die set for metal, invest in proper lubricants too.

With the correct cutting fluid selected and applied, you're ready for the most critical phase: positioning your die and beginning the actual thread-cutting process.

Step 4 Position the Die and Begin Cutting Threads

You've prepared your materials, selected the right lubricant, and secured your workpiece. Now comes the moment of truth: actually cutting those threads. This is where technique matters most. Get it right, and you'll produce professional-quality threads. Get it wrong, and you'll understand why so many beginners end up with stripped, cross-threaded disasters.

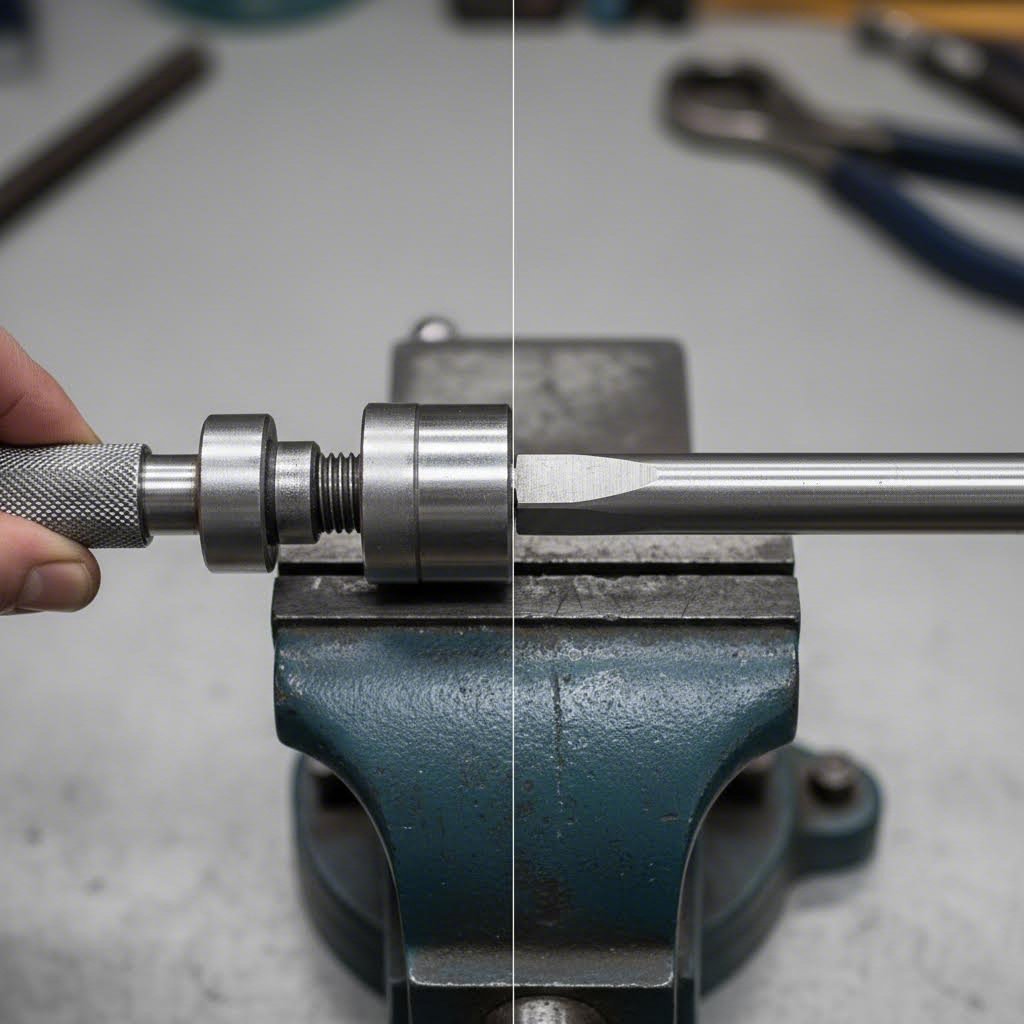

Orienting Your Die Correctly Every Time

Here's a detail that trips up nearly every first-timer: dies have a right side and a wrong side. Install it backward, and you'll fight the tool instead of letting it work for you.

Look closely at your die. One side features a slight taper or chamfer on the cutting teeth—this is the lead-in side. The opposite side has teeth that cut at full depth immediately. When learning how to use a tap and die set, this orientation rule is fundamental:

- The tapered/chamfered side must face the workpiece

- This allows cutting teeth to engage gradually

- The taper guides the die onto center as you begin

According to Tameson, the process of threading with a die involves ensuring the die handle is square with the workpiece, and the lead-in angle creates the centered start that makes this possible. If you're asking "how do you use a tap and die set correctly?"—proper orientation is your first answer.

The Half-Turn-Back Technique for Clean Threads

This single technique separates amateur attempts from professional results. It's called the half-turn-back method, and once you master it, you'll never produce rough or binding threads again.

Here's how it works: as you cut threads, metal chips accumulate in the die's flutes. If these chips pack tightly, they prevent clean cutting and can even break your die. The solution? Periodically reverse direction to break and clear chips.

Follow this step-by-step cutting sequence for optimal results:

- Apply cutting fluid to both the chamfered rod end and the die's cutting surfaces

- Position the die's tapered side against the chamfered rod end

- Apply firm downward pressure while turning clockwise (for standard right-hand threads)

- Complete one-half to one full rotation forward, maintaining steady pressure

- Reverse direction one-quarter turn to break the chips

- Continue forward again, repeating this forward-and-back rhythm

- Reapply lubricant every few rotations to keep cutting surfaces wet

- Continue until desired thread length is achieved

When using tap and die tools, this rhythm becomes second nature. Think of it as "two steps forward, one step back"—though the actual ratio is more like "half-turn forward, quarter-turn back." The brief reversal clears chips without losing your progress.

Maintaining Perpendicular Alignment Throughout

Starting perpendicular is important. Staying perpendicular throughout the entire cut? That's what produces truly professional threads.

As Midland Tool notes, threading with dies requires clean, consistent cuts—and consistency demands unwavering alignment. Here's how to maintain it:

- Watch both hands equally – Uneven pressure causes the die to tilt

- Keep elbows close to your body – This centers your force over the workpiece

- Check alignment frequently – Step back and visually verify perpendicularity

- Don't force it – If the die wants to walk to one side, stop and realign

The first few threads are critical. Once the die has cut several complete threads, it will self-guide along the established path. But those initial cuts determine everything. If you're wondering how do I use a tap and die set without cross-threading, the answer lies in these first careful rotations.

Handling the M3 Stainless Steel Challenge

Small-diameter stainless steel threading—particularly M3 and similar sizes—represents the ultimate test of technique. Forum discussions consistently highlight this as where beginners fail most often. The material work-hardens quickly, the small die is fragile, and there's almost no margin for error.

If you're using a tap and die set on M3 stainless, modify your approach:

- Extra-slow rotation – Half the speed you'd use on mild steel

- Frequent reversals – Quarter-turn back after every quarter-turn forward

- Abundant lubrication – Reapply sulfur-based cutting oil constantly

- Minimal pressure – Let the die cut at its own pace

- Feel the resistance – Stop immediately if cutting force increases dramatically

That last point deserves emphasis. When threading any material, you'll develop a feel for proper cutting. The die should produce a steady, moderate resistance with each forward turn. If resistance suddenly spikes, something's wrong—usually chip buildup or misalignment. Stop immediately, reverse to clear chips, check your angle, and proceed more carefully.

Recognizing Proper Cutting vs. Forcing

How do you know if you're cutting properly or just forcing metal? Pay attention to these signals:

| Sign of Proper Cutting | Sign of Forcing/Problems |

|---|---|

| Steady, consistent resistance | Sudden increase in resistance |

| Small, curly metal chips forming | No chips or powdery residue only |

| Smooth rotation rhythm | Jerky, catching motion |

| Die stays centered on workpiece | Die wants to walk or tilt |

| Cutting sounds clean and consistent | Squealing, grinding, or silence |

If you encounter any warning signs, stop cutting. Reverse the die completely off the workpiece, clear accumulated chips, add fresh lubricant, and examine your progress. Sometimes a simple chip clearance solves everything. Other times, you may need to adjust your technique or verify alignment before continuing.

Mastering these cutting fundamentals transforms threading from a frustrating gamble into a reliable skill. With your die properly oriented and your technique dialed in, you're ready to complete the threading process and verify your work meets professional standards.

Step 5 Complete the Threading and Check Your Work

You've started cutting and established a rhythm with the half-turn-back technique. Now comes the satisfying part: completing those threads and verifying they'll actually work. This is where thread tapping transitions from technique to finished product—and where attention to detail separates usable threads from frustrating failures.

Controlling Thread Depth and Quality

How do you know when you've cut enough thread? Unlike drilling a hole to a specific depth, thread dies require you to track progress visually and by feel. Here's the straightforward approach:

For full-length threads, continue the cutting process until the die has traveled the entire required distance along your rod. Watch the die's position relative to your workpiece—when it reaches your target length, you're ready to reverse off.

Reversing requires patience. Turn the die counterclockwise steadily, maintaining the same controlled pace you used while cutting. Rushing this step can damage the threads you just created. The die should back off smoothly through the fresh threads without catching or binding.

Here's a tip from experienced machinists: mark your desired thread length on the rod with a marker or tape before starting. This visual reference eliminates guesswork and prevents over-threading, which wastes material and can weaken the rod at transition points.

Thread Chasing vs Creating New Threads

Here's a distinction that most guides completely overlook: there's a significant difference between creating new threads and chasing existing ones.

Creating new threads is what we've discussed so far—cutting spiral grooves into smooth metal rod stock. This requires full cutting engagement, proper lubrication, and the complete half-turn-back technique. The die removes material with every forward rotation.

Thread chasing, by contrast, involves cleaning or restoring threads that already exist but have become rusty, dirty, or slightly damaged. According to Mechanical Malarkey, thread chasers aren't designed for cutting new threads—only for cleaning rusty or damaged ones. Taps and thread dies can often substitute for dedicated chasers, but the technique differs significantly.

When using a die to chase existing threads:

- Apply much less pressure—you're cleaning, not cutting

- The die follows existing thread paths rather than creating new ones

- Lubrication remains important but primarily for rust penetration

- Resistance should feel minimal compared to cutting fresh threads

Why does this matter? If you're restoring a bolt with damaged threads, treating it like a fresh cutting job can make things worse. You'll remove more material than necessary and potentially create an undersized thread that won't hold properly. A complete thread tap and die set gives you options for both scenarios—just adjust your technique accordingly.

Finishing Techniques for Professional Results

Your threads are cut. But are they good enough? Professional machinists rarely stop after a single pass. Consider these finishing techniques to elevate your work:

The Second Pass Method: Run the die through your freshly cut threads a second time with minimal pressure. This light finishing pass cleans up any rough spots and produces smoother, more consistent thread surfaces. Some machinists apply fresh cutting fluid for this pass, while others run it nearly dry—both approaches work.

The Test Fit Check: This is your ultimate quality verification. Thread a matching nut onto your newly created threads. As noted by BAER Tools, you should always be able to rely on a thread—it must work seamlessly with its mating component.

What should proper tap threads feel like during testing? Use this quality checkpoint list:

- Smooth engagement—the nut should start threading by hand without forcing

- Consistent resistance—no tight spots or loose sections along the length

- Full thread contact—the nut should sit flush when fully threaded

- No wobble—properly cut threads create a snug, centered fit

- Easy removal—backing the nut off should feel as smooth as threading on

If your test nut binds partway down, you've likely got debris in the threads or a slight alignment issue mid-cut. Clean the threads thoroughly with a brush and retry. Persistent binding may indicate cross-threading that requires starting over with fresh stock.

Fine-Tuning Thread Fit with Adjustable Dies

What if your test nut is too tight or too loose? This is exactly when adjustable thread dies prove their value.

For threads that are too tight (nut won't thread smoothly):

- Open the adjustable die slightly using its set screws

- Run another pass to remove a small additional amount of material

- Test fit again and repeat if necessary

For threads that are too loose (nut wobbles or feels sloppy), you have fewer options with the same workpiece. Prevention is key here—when in doubt, start with a slightly tighter die setting and open up only as needed. A loose thread can't be tightened, but a tight thread can always be opened slightly with another pass.

This adjustability is precisely what makes a quality thread tap and die set worth the investment. Fixed dies work perfectly when everything goes right, but adjustable options give you recovery paths when dimensions aren't quite perfect.

With your threads complete and verified, you're producing professional-quality work. But what happens when things don't go according to plan? Next, we'll tackle the troubleshooting strategies that solve the most common threading problems.

Step 6 Troubleshoot Common Threading Problems

Even with perfect technique, things go wrong. Maybe you rushed the start, or the material was harder than expected, or that cutting fluid bottle was emptier than you realized. Whatever the cause, threading problems share a silver lining: most are fixable, and all are preventable once you understand what went wrong.

Let's diagnose the symptoms you're experiencing and get you back on track. Understanding how to use tap and die tools includes knowing what to do when they don't cooperate.

Fixing Cross-Threaded Starts

Cross-threading is the most common problem beginners face, and it's almost always caused by one thing: starting at an angle instead of perpendicular to the workpiece.

You'll know you've cross-threaded when:

- The die suddenly feels like it's fighting you after a few turns

- A test nut won't thread past the first few rotations

- Visible threads appear crooked or uneven

- The die wobbles noticeably during cutting

The fix depends on how far you've gone. If you've only cut one or two threads, stop immediately. Remove the die completely, examine the damage, and consider whether the workpiece is salvageable. Often, you can file off the damaged start and create a fresh chamfer slightly further down the rod.

For severe cross-threading, you may need fresh stock. As one experienced mechanic discovered when dealing with a cross-threaded shock mount, sometimes the only solution is cutting new threads entirely—a process that requires patience but delivers reliable results.

Prevention is straightforward: take your time during initial engagement. Apply firm downward pressure while turning, use a square to verify alignment before starting, and never let an impact wrench start threads for you.

Solving Stripped and Shallow Thread Problems

Stripped or shallow threads present differently than cross-threading. Here, the threads form but don't engage properly—they're either too shallow to grip a nut or so worn they strip immediately under load.

Two primary culprits cause this issue:

Incorrect Rod Diameter: If your stock is undersized, the die can't cut deep enough to create full thread engagement. Before blaming your technique, measure your rod with calipers. The diameter should match your die specifications within tight tolerances—typically the nominal thread size minus 0.1-0.2mm for metric dies.

Worn Die Cutting Edges: Dies don't last forever. Dull cutting teeth produce shallow, poorly-formed threads regardless of your technique. Inspect your die under good lighting. Look for:

- Rounded or chipped cutting edges

- Visible wear patterns on the teeth

- Rust or corrosion on cutting surfaces

- Debris packed into the flutes that won't brush out

The solution? If rod diameter is the issue, source properly-sized stock. If your die is worn, replacement is usually more practical than attempting to sharpen hardened steel cutting edges. Quality tap and die set uses depend on maintaining sharp, undamaged tools.

Addressing Rough or Torn Threads

When threads come out rough, torn, or have a ragged appearance, the problem almost always traces back to lubrication or speed—usually both.

Rough threads tell you that metal was torn rather than cleanly cut. This happens when:

- Cutting fluid was insufficient or absent

- You turned the die too fast

- Chips weren't cleared frequently enough

- The die overheated during cutting

The fix is simple in concept but requires discipline: slow down and lubricate more. If you're using a tap and die set on steel, reapply cutting oil every two to three rotations. For stainless steel, lubricate constantly—there's essentially no such thing as too much cutting fluid on this material.

The half-turn-back technique becomes critical here. Those quarter-turn reversals break chips before they pack into the flutes and cause tearing. If you've been skipping this step, that's likely your problem.

Preventing Die Breakage on Hard Materials

A broken die represents the worst-case scenario. Not only have you lost an expensive tool, but broken pieces may be lodged in your workpiece. This almost exclusively happens when forcing a die through material that's too hard or when technique breaks down.

Warning signs that you're approaching die failure:

- Dramatically increased resistance that doesn't ease with chip clearing

- Squealing or grinding sounds during cutting

- The die handle becomes difficult to grip due to transmitted force

- No visible chips forming despite continued rotation

If you experience any of these signs, stop immediately. Forcing through will break something—either the die or your patience when you have to start over anyway.

For hard materials like stainless steel, prevention requires adjusted expectations. You cannot rush threading on work-hardening materials. Using tap and die set tools on stainless means accepting slower progress, more frequent lubricant application, and lighter cutting pressure throughout.

Complete Threading Troubleshooting Reference

| Problem | Likely Cause | Solution | Prevention |

|---|---|---|---|

| Cross-threaded start | Die started at an angle | File off damaged threads, create new chamfer, restart with careful alignment | Verify perpendicular alignment before cutting; never use power tools to start threads |

| Stripped or shallow threads | Undersized rod or worn die | Verify rod diameter; inspect and replace worn dies | Measure stock before starting; maintain dies properly |

| Rough or torn threads | Insufficient lubrication or cutting too fast | Run a second pass with heavy lubrication at slower speed | Apply cutting fluid generously; maintain half-turn-back rhythm |

| Die binding mid-cut | Chip buildup in flutes | Reverse completely, clear chips, add lubricant, continue | More frequent reversals during cutting |

| Broken die | Forcing through hard material or misalignment | Extract broken pieces; use proper die for material hardness | Never force; match die to material; use adequate lubrication |

| Threads too tight | Die set too small or insufficient passes | Open adjustable die slightly; run additional finishing pass | Start with adjustable dies on critical projects |

| Threads too loose | Oversized stock or die opened too far | Limited options—may require new stock | Verify measurements; start with tighter die settings |

Special Focus: Conquering Stainless Steel Threading

Forum discussions consistently identify stainless steel as the material that defeats beginners most often. The reason? Stainless work-hardens during cutting. Every rotation that generates excessive heat makes the next rotation harder. This creates a vicious cycle that ends with broken dies, stripped threads, or abandoned projects.

When learning how to tap and die stainless successfully, modify every aspect of your approach:

- Speed: Cut at half the pace you'd use on mild steel—maybe slower

- Lubrication: Use sulfur-based cutting oil or paste; reapply constantly

- Pressure: Light and steady; let the die do the work

- Reversals: Quarter-turn back after every quarter-turn forward

- Chip clearing: Remove the die completely every few threads to clear chips

- Cooling breaks: If the die feels warm, stop and let everything cool

The tap and die set usage on stainless demands patience above all else. Rushing guarantees failure. Taking twice as long as you think necessary usually produces success.

With troubleshooting knowledge in your toolkit, you're equipped to handle whatever threading challenges arise. But prevention beats repair every time—and proper die maintenance ensures your tools perform consistently for years to come.

Step 7 Maintain Your Dies for Long-Term Performance

You've mastered the technique. Your threads come out clean and precise. But here's what separates hobbyists from serious craftspeople: how you treat your tools after the work is done. A professional tap and die set represents a significant investment, and proper maintenance ensures those precision-ground cutting edges perform flawlessly for years—not months.

Cleaning Dies After Every Use

Metal chips are your die's worst enemy after the job is complete. Those tiny shavings left in the flutes don't just sit there—they attract moisture, promote rust, and can damage cutting edges during storage. According to Hi-Spec Tools, always cleaning your tap and die set after use prevents rust and extends tool life significantly.

Here's the cleaning sequence that protects your investment:

- Remove chips immediately—use a soft brush to clear debris from flutes and cutting surfaces while the tool is still accessible

- Wipe away cutting fluid residue—old lubricant becomes gummy and attracts dust

- Soak stubborn buildup—for packed chips, a few minutes in mild soap solution loosens grime

- Dry thoroughly—any remaining moisture becomes tomorrow's rust

- Apply a light coat of oil—a thin protective film prevents corrosion between uses

What are tap and die sets used for if they can't cut cleanly? Neglected dies develop dull edges faster, produce rougher threads, and eventually become unreliable. Those five minutes of post-job maintenance pay dividends across dozens of future projects.

Proper Storage to Prevent Damage and Rust

Where you store your dies matters almost as much as how you clean them. Tossing precision tools into a drawer with other hardware guarantees damaged cutting edges and shortened tool life.

Ideal storage conditions include:

- Cool, dry environment—humidity accelerates corrosion on hardened steel

- Stable temperature—avoid areas with extreme fluctuations

- Away from direct sunlight—UV exposure degrades protective oil films

- Organized cases or holders—prevents tools from contacting each other

A good quality tap and die set typically comes in a fitted case for exactly this reason. Each die has its own compartment, preventing the cutting edges from banging against other tools. If your tap and die kit lacks proper organization, consider investing in a dedicated storage solution—foam-lined toolboxes or magnetic holders work well.

For long-term storage, add silica gel desiccant packets to absorb ambient moisture. This simple addition costs almost nothing but dramatically reduces rust formation during months between uses.

Complete Maintenance Checklist

Before putting your tap die sets away, run through this quick verification:

- All metal chips removed from flutes and cutting surfaces

- Cutting fluid residue wiped clean

- Tools completely dry—no moisture in recessed areas

- Light oil coating applied to all metal surfaces

- Each tool returned to its designated storage position

- Cutting edges not contacting other metal objects

- Storage area protected from humidity and temperature extremes

- Desiccant packets fresh and positioned near tools

When to Replace Rather Than Sharpen

Here's a question that comes up frequently: can you sharpen worn dies instead of replacing them? Technically, yes. Practically? Most users should simply replace worn tools.

Die sharpening requires specialized equipment and expertise. The cutting edges are precision-ground at specific angles, and amateur sharpening attempts usually make things worse. As Jarvis Cutting Tools explains, if there's chipping, cracking, or excessive wear—and if sharpening doesn't restore performance—replacement is the smart choice. When repair costs approach new tool prices, investing fresh makes better sense.

So how do you know when replacement is necessary? Inspect your dies regularly for these warning signs:

- Dull cutting edges—threads require excessive force to cut

- Chipped or broken teeth—visible damage on cutting surfaces

- Rust or corrosion—pitting that compromises cutting precision

- Inconsistent thread quality—clean technique still produces rough results

- Visible wear patterns—shiny spots where metal has worn away

A worn die doesn't announce itself dramatically—it just gradually produces inferior work. If you're following proper technique but threads keep coming out rough or shallow, your tools are likely the problem.

The Value of Professional-Grade Tooling

When building or upgrading your threading toolkit, quality matters more than quantity. A smaller set of precision-manufactured dies outperforms a large collection of bargain tools every time.

What distinguishes professional tap and die set options from budget alternatives? Material quality tops the list—high-speed steel (HSS) holds its edge far longer than softer alloys. Precision grinding creates consistent cutting geometry. And quality control ensures every die in the set performs to specification.

For industrial and automotive applications, precision standards become even more critical. Professional manufacturing environments rely on certified tooling that delivers consistent results across thousands of operations. Companies like Shaoyi demonstrate what professional-grade die manufacturing looks like—their IATF 16949 certified stamping die solutions use CAE simulation for defect-free results, with rapid prototyping capabilities and a 93% first-pass approval rate. While their focus is industrial stamping dies rather than hand threading tools, the same precision manufacturing standards apply: quality tooling produces quality results.

Whether you're threading bolts in your garage or specifying dies for production manufacturing, the principle holds: invest in quality tools, maintain them properly, and they'll deliver professional results for years to come.

With your threading dies properly maintained and stored, you've completed the full circle—from selecting the right tool through cutting clean threads to preserving your investment for future projects. Now it's time to consider where these skills can take you next.

Master Threading and Expand Your Metalworking Skills

You've made it through the complete journey—from understanding what a threading die actually does to troubleshooting problems and maintaining your tools. That's no small accomplishment. But mastering how to use a die is really just the beginning of your metalworking capabilities.

Your Threading Skills Roadmap

Let's recap the core techniques you've developed through this guide. You now understand how to:

- Select the right die type—matching solid, split, adjustable, or hex dies to your specific project needs

- Prepare materials properly—chamfering rod ends and verifying correct stock diameter

- Apply appropriate lubrication—choosing cutting fluids matched to your material type

- Execute proper cutting technique—using the half-turn-back method for clean, consistent threads

- Troubleshoot common problems—diagnosing and fixing issues before they ruin your workpiece

- Maintain your tools—protecting your investment for years of reliable performance

These fundamentals apply whether you're creating a single replacement bolt or threading dozens of custom fasteners. The technique scales; only the patience required changes.

Advancing to Challenging Materials

Ready to push your skills further? The natural progression moves from mild steel toward increasingly demanding materials.

Stainless steel represents the first significant challenge. As discussed in the troubleshooting section, work-hardening requires slower speeds, heavier lubrication, and lighter pressure. Master stainless, and you'll handle most common threading scenarios confidently.

Titanium alloys push the boundaries even further. According to research from Yunchi Titanium, titanium's low thermal conductivity causes rapid heat buildup during threading, while its high chemical activity can cause adhesion between the tool and workpiece. Professional machinists often use staggered tooth taps and dies, combining high-speed steel for initial cutting with carbide tools for finishing passes. If you're working with titanium, expect to invest in specialized tooling and significantly more patience.

Building Your Complete Threading Toolkit

External threading with dies is only half the equation. What is a tap and die kit truly used for? Creating complete threaded connections—both the bolt and the hole it threads into.

Learning how to use a tap set opens the complementary skill of internal threading. The techniques overlap significantly: proper lubrication, the half-turn-back chip-clearing method, and perpendicular alignment all apply. If you've mastered dies, taps will feel familiar.

Beyond basic tapping, consider expanding your knowledge of thread standards. According to SSM Alloys, metric threads (ISO standard with 60° thread angles) and imperial threads (UNC/UNF standards) differ in measurement systems, tolerance grades, and precision levels. Understanding these differences—plus specialized standards like pipe threads—lets you tackle any threading project with confidence.

Complementary skills worth developing include:

- Screw taps for internal thread creation

- Thread gauges for verifying pitch and diameter

- Drill and tap operations for complete hole-threading workflows

- Thread identification for matching unknown fasteners

Patience and proper technique matter far more than expensive tools. A beginner with a quality entry-level set who follows correct procedures will outperform an impatient expert with professional equipment every time.

Before tackling critical projects, practice on scrap material. Thread a few test pieces, verify them with nuts, and build muscle memory for the cutting rhythm. Those practice runs cost almost nothing but save expensive mistakes on parts that matter.

Threading is a fundamental metalworking skill that unlocks countless possibilities. Custom bolts for restoration projects. Replacement fasteners for obsolete equipment. Threaded rods cut to exact specifications. Repair work that saves components others would discard. Once you know how to use taps and dies confidently, you'll find applications everywhere—and the satisfaction of creating precision threads never gets old.

Frequently Asked Questions About Using Threading Dies

1. How do you use a die?

To use a threading die, first chamfer your rod end at 45 degrees and secure it vertically in a vise. Place the die's tapered side against the workpiece, apply cutting fluid generously, then turn clockwise while applying firm downward pressure. Use the half-turn-back technique—rotate forward one-half turn, then reverse a quarter turn to break chips. Continue this rhythm, reapplying lubricant every few rotations until you reach your desired thread length.

2. Which side of the die to use?

The tapered or chamfered side of the die must face your workpiece. This side has relief-cut teeth designed to start the threading process gradually. You can identify it by looking for the side with slightly shorter teeth or the side where the manufacturer's markings are stamped. Starting with the wrong side up makes thread initiation difficult and often causes cross-threading.

3. What do you use a die set for?

A die set creates external threads on cylindrical metal stock, transforming plain rods into bolts, threaded fasteners, or custom threaded components. Common uses include creating custom-length bolts, repairing damaged or rusty threads on existing fasteners, matching specific thread sizes for vintage equipment restoration, and converting plain rod stock into threaded components for fabrication projects.

4. How to use a tap and die set to rethread?

For rethreading damaged threads, use thread chasing technique rather than full cutting. Apply light lubricant, position the die on the existing threads, and turn with minimal pressure—the die follows existing thread paths rather than cutting new material. This cleans rust, debris, and minor damage without removing excess metal. For severely damaged threads, you may need to cut fresh threads using standard technique.

5. What is the difference between a tap and a die?

Dies create external threads on rods and bolts (the male component), while taps create internal threads inside holes for nuts and sockets (the female component). Think of it this way: a die makes the screw, while a tap makes the hole the screw goes into. Both tools work together in threading operations, which is why they're commonly sold as complete tap and die sets.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —