Metal Stamp Dies Decoded: From Raw Steel To Precision Parts

What Are Metal Stamp Dies and Why They Matter

Ever wondered how manufacturers produce thousands of identical metal parts with perfect precision? The answer lies in a specialized tool that sits at the heart of modern manufacturing: metal stamp dies. These precision instruments transform flat sheet metal into everything from automotive body panels to tiny electronic connectors—and understanding them is essential for anyone involved in production, engineering, or procurement.

Defining Metal Stamp Dies in Modern Manufacturing

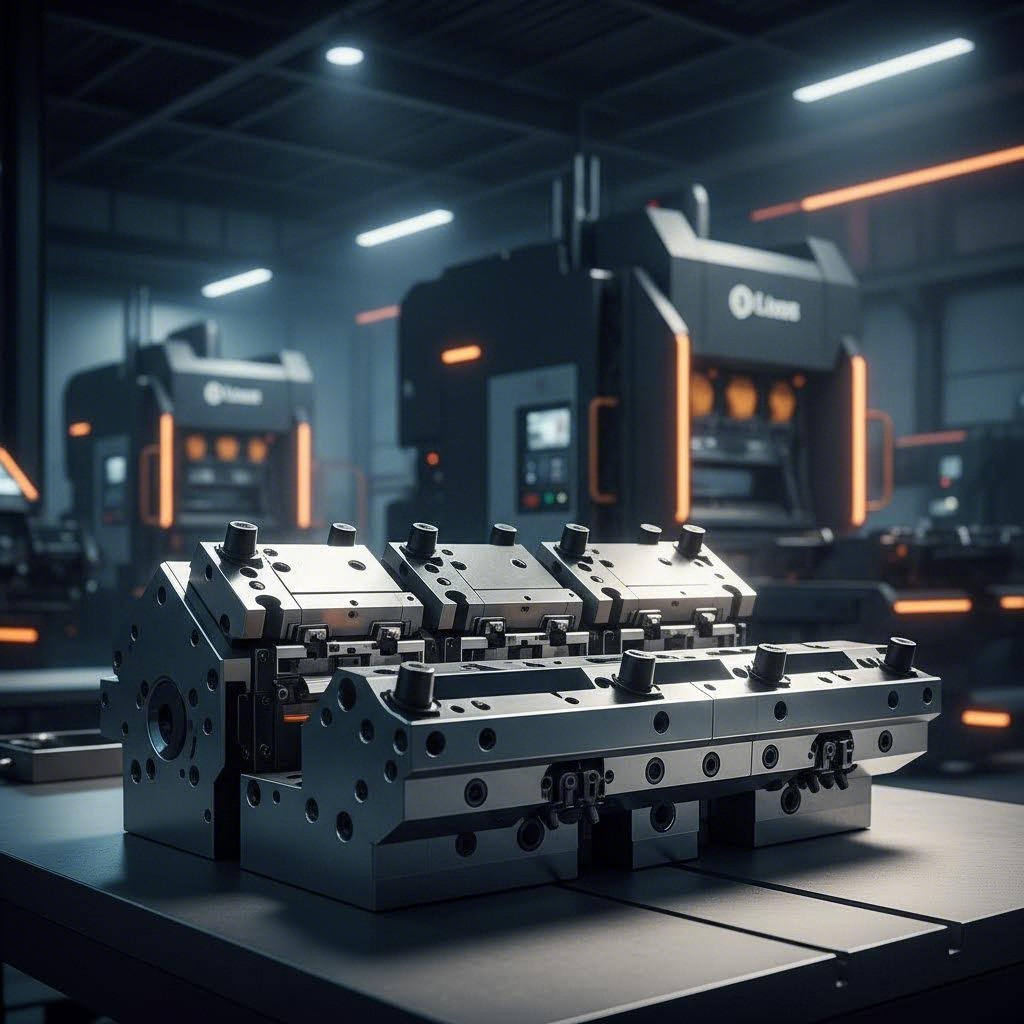

A metal stamp die is a custom-built precision tool designed to cut, bend, or shape sheet metal into a specific form. Think of it as a highly engineered mold that uses tremendous force from a stamping press to transform raw material into finished components. According to industry experts, these tools are typically constructed from special types of hardenable steel called tool steel, though some incorporate carbide or other wear-resistant materials for demanding applications.

Stamping is classified as a cold-forming operation—no external heat is intentionally applied during the process. However, friction generates significant heat during cutting and forming, so stamped parts often exit the die quite warm. The sheer variety of these tools is remarkable: they range from palm-sized dies producing microelectronics to massive 20-foot-square assemblies that stamp entire automobile body sides.

Metal stamping dies serve two fundamental purposes. Industrial stamping dies handle high-volume production, capable of cycling as fast as 1,500 strokes per minute while producing one or more piece parts per cycle. Marking and branding dies, on the other hand, focus on identification—imprinting serial numbers, logos, or part codes onto components for traceability.

Why Die Selection Impacts Your Production Success

Choosing the right die isn't just a technical decision—it directly affects your bottom line. The wrong selection can lead to excessive scrap rates, frequent maintenance downtime, and inconsistent part quality. Conversely, a well-matched die delivers:

- High efficiency – producing large quantities of parts quickly and accurately

- Consistency and precision – ensuring every stamped component meets exact specifications

- Cost-effective production – reducing per-part costs significantly over the die's lifespan

Whether you're working with a standard die for common applications or commissioning custom tooling for specialized parts, the selection process requires balancing multiple factors: material compatibility, production volume, tolerance requirements, and budget constraints.

This guide will take you on a comprehensive journey through the world of dies and stamping—from understanding the different types and how they're manufactured, to selecting the right solution for your specific application. Whether you're a newcomer seeking foundational knowledge or an experienced professional looking to deepen your expertise, you'll find practical insights to inform your next project decision.

Types of Metal Stamp Dies Explained

Now that you understand what metal stamp dies are and why they matter, let's explore the specific categories you'll encounter in manufacturing. Each stamping die type operates differently and excels in particular applications—knowing when to use each one can dramatically impact your production efficiency and cost-effectiveness.

Progressive Dies for Continuous Production

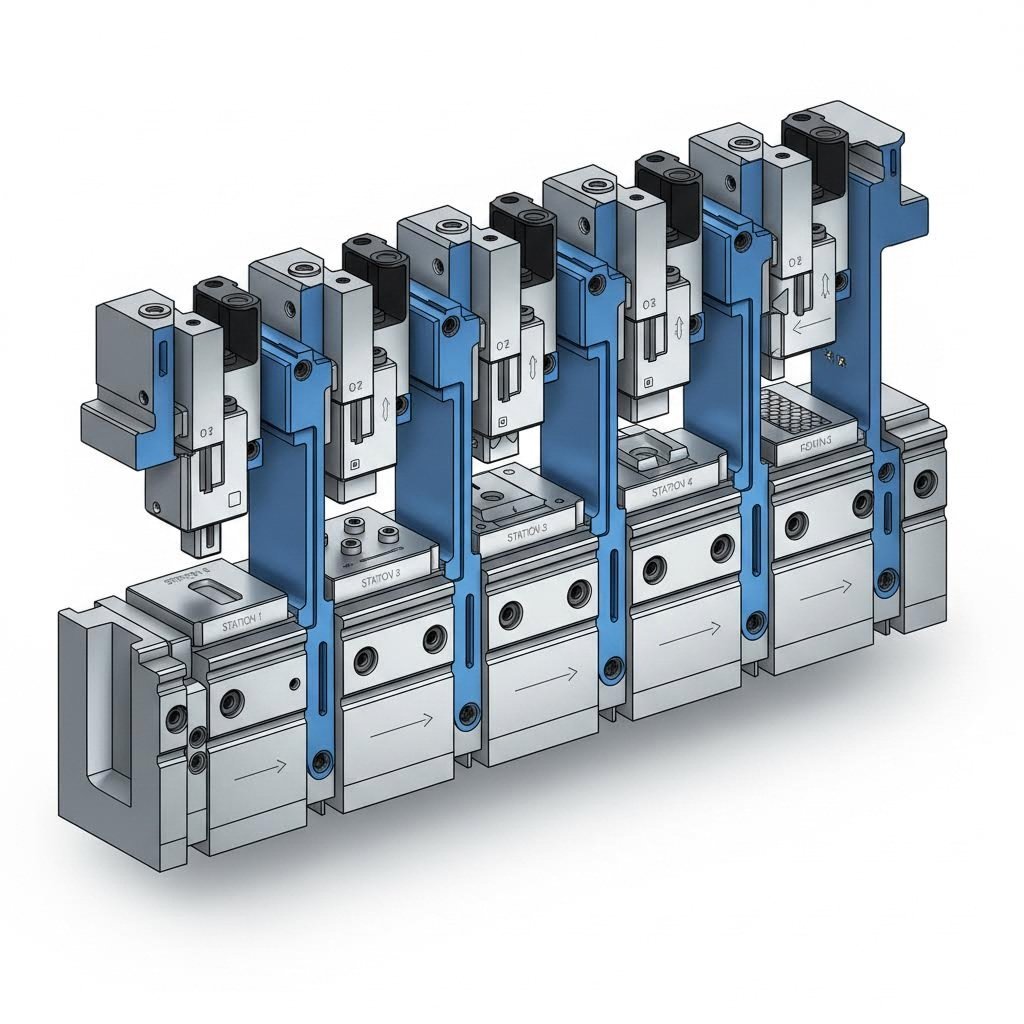

Imagine an assembly line where sheet metal travels through multiple stations, with each stop adding another operation until a finished part emerges at the end. That's exactly how progressive dies work. These sophisticated tools consist of multiple stations arranged in sequence, with each station performing a specific operation—cutting, bending, punching, or forming—as the metal strip advances through the die-stamping machine.

What makes progressive dies so powerful? According to industry experts at Durex Inc., they offer exceptional efficiency and are capable of producing large volumes of parts quickly while ensuring uniformity across all components. Progressive die manufacturers design these tools to cycle incredibly fast—some operating at speeds exceeding 1,000 strokes per minute.

Progressive dies are ideal when you need:

- High-volume production runs (typically 10,000+ parts)

- Complex parts requiring multiple sequential operations

- Consistent quality across every stamped component

- Lower per-part costs over large quantities

The automotive industry relies heavily on progressive dies for manufacturing brackets, clips, and structural components. Electronics manufacturers use them for producing intricate connectors and terminals. However, the initial tooling investment can be substantial, so they're most cost-effective when production volumes justify the upfront expense.

Transfer and Compound Die Applications

What happens when your parts are too large or complex for progressive dies? That's where transfer dies step in. In transfer die stamping, individual workpieces are mechanically or manually moved from one stamping station to the next—like an artisan moving a project between specialized workbenches.

As Worthy Hardware explains, transfer die stamping allows more flexibility in part handling and orientation, making it suitable for intricate designs and shapes. This method can incorporate various operations—punching, bending, drawing, and trimming—in a single production cycle. It's particularly valuable for aerospace and heavy machinery sectors where complex assemblies demand precision at scale.

Compound dies take a different approach entirely. Rather than moving parts through stations, they perform multiple operations in a single stroke. Imagine cutting, bending, and embossing all happening simultaneously—that's the compound die advantage. This integration significantly reduces production time and enhances productivity by completing multiple processes in one pass.

When should you choose compound dies? Consider them for:

- Medium-sized, intricate components

- Applications requiring exceptional precision on flat parts

- Situations where minimizing tooling and setup costs matters

- Production runs where material efficiency is critical

Marking and Branding Die Varieties

Not all sheet metal stamping dies focus on shaping parts—some exist purely for identification. Marking dies imprint serial numbers, logos, date codes, or other traceability information directly onto metal components. In industries like automotive, aerospace, and medical devices, this identification is often mandatory for quality control and regulatory compliance.

Embossing dies create raised or recessed patterns on metal surfaces, serving both functional and aesthetic purposes. They're commonly used for decorative elements, branding, and even grip enhancement on handles or controls. The die and stamping process for marking applications typically requires less force than forming operations but demands exceptional surface finish quality to produce crisp, readable impressions.

Comparing Die Types at a Glance

Choosing between die stamping methods can feel overwhelming. This comparison table breaks down the key differences to help you match the right solution to your application:

| Type | Operation Method | Best For | Volume Range | Complexity Level |

|---|---|---|---|---|

| Progressive Die | Sequential stations; strip advances automatically | High-speed production of uniform parts | High (10,000+) | Medium to High |

| Transfer Die | Parts transferred between separate stations | Large, complex parts; intricate assemblies | Medium to High | High |

| Compound Die | Multiple operations in single stroke | Precise flat parts; medium production runs | Low to Medium | Medium |

| Marking Dies | Single impression for identification | Logos, serial numbers, traceability codes | Any volume | Low |

| Blanking Die | Cuts specific shapes from sheet | Preparing raw materials for further processing | Any volume | Low |

Understanding these distinctions helps you communicate more effectively with suppliers and make informed decisions about your tooling investments. But knowing what type of die you need is just the beginning—how these tools are actually manufactured reveals even more about what separates good tooling from great tooling.

How Metal Stamp Dies Are Manufactured

So you've selected the right die type for your application—but have you ever wondered what happens behind the scenes to transform a concept into a precision tool capable of stamping millions of identical parts? The dies manufacturing process is a fascinating journey that combines advanced engineering, specialized machining, and rigorous quality control. Understanding this process helps you appreciate why custom metal stamping dies command the investment they do—and why quality tooling delivers returns for years.

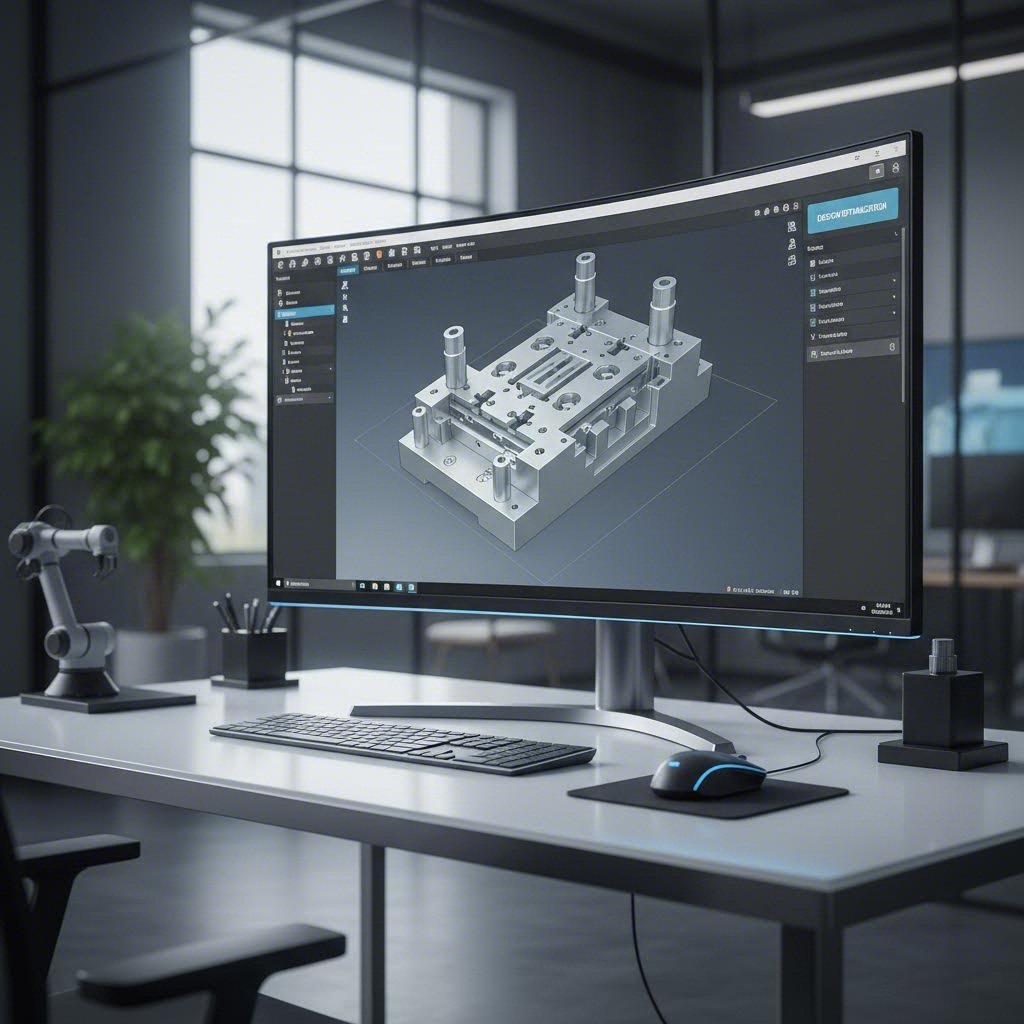

From Design Concept to CAD Model

Every metal stamping die design begins with a vision of the finished part. Engineers analyze the component's geometry, material properties, and production requirements before touching any software. But here's where modern technology transforms the process: computer-aided design (CAD) software allows engineers to draft and refine digital models with extraordinary precision.

According to Frontier Metal Stamping, this digital-first approach ensures accuracy and allows manufacturers to test virtual simulations before physical production begins. Engineers can identify potential interference issues, optimize material flow, and refine tooling geometry—all without cutting a single piece of steel.

But CAD modeling is just the beginning. Modern stamping die manufacturing increasingly relies on CAE (Computer-Aided Engineering) simulation to predict real-world performance. As Keysight's research explains, sheet metal forming simulation enables virtual die try-outs that identify defects before costly physical prototyping. This capability is particularly valuable because:

- Part and process design defects often emerge only during first physical trials—when corrections are time-consuming and expensive

- Advanced high-strength steels and aluminum alloys exhibit challenging springback behaviors that simulation can predict

- Process parameters like press speed, blank holder force, and lubrication can be optimized virtually

Think of CAE simulation as a crystal ball for die designers. It reveals how metal will flow, where wrinkles might form, and whether springback will push tolerances out of specification—all before any steel is machined.

Machining and Heat Treatment Processes

Once the digital design is finalized, skilled diemakers transform raw tool steel into precision components through a carefully orchestrated sequence of operations. Here's how the machining dies process typically unfolds:

- Rough Machining – CNC milling removes bulk material to establish approximate shapes, leaving allowance for finishing operations

- Wire EDM (Electrical Discharge Machining) – For intricate profiles and tight internal corners, wire EDM uses electrical sparks to cut hardened steel with exceptional precision—achieving tolerances as tight as ±0.0001 inches

- Heat Treatment – Die components undergo hardening processes to achieve optimal wear resistance, typically reaching 58-62 HRC on the Rockwell scale for cutting edges

- Precision Grinding – Surface and cylindrical grinding operations achieve final dimensional accuracy and superior surface finishes

- Finishing and Polishing – Critical surfaces receive hand polishing or specialized finishing to ensure smooth material flow during stamping operations

Heat treatment deserves special attention. This process transforms relatively soft tool steel into wear-resistant surfaces capable of withstanding millions of stamping cycles. The specific heat treatment recipe—temperatures, soak times, quenching media, and tempering cycles—varies based on the steel grade and application requirements. Get it wrong, and the die may crack under stress or wear prematurely. Get it right, and you've created tooling that delivers consistent performance for years.

ITD precision stampings and similar high-specification applications demand particularly stringent control over these processes. When tolerances are measured in thousandths of an inch, every machining operation must be executed flawlessly.

Quality Verification and Testing

Sounds complex? It is—which is why quality verification runs throughout the entire manufacturing process, not just at the end. After machining, the die components are assembled and undergo rigorous testing to ensure everything functions correctly.

Engineers verify that the metal stamping die design translates into real-world performance by:

- Measuring critical dimensions using coordinate measuring machines (CMMs)

- Checking surface finishes against specifications

- Verifying hardness at multiple locations on cutting and forming surfaces

- Running sample parts and comparing them to design intent

- Making necessary adjustments to optimize performance and longevity

This final testing phase often reveals opportunities for fine-tuning. Perhaps a forming radius needs slight adjustment to eliminate a subtle wrinkle. Maybe the timing between stations in a progressive die requires optimization. These refinements transform good tooling into exceptional tooling.

The stamping die manufacturing process represents a significant investment in engineering expertise, precision equipment, and quality materials. But understanding what goes into creating these tools helps explain why they're capable of producing millions of consistent, high-quality parts—and why material selection for both the die and the workpiece deserves equally careful consideration.

Material Selection and Compatibility Guide

You've seen how metal stamp dies are manufactured—but here's a question that separates successful stamping operations from frustrating ones: what materials should you use? This applies both to the die itself and the metal you're stamping. Get this pairing wrong, and you'll face premature wear, inconsistent parts, and costly downtime. Get it right, and your tooling delivers reliable performance for millions of cycles.

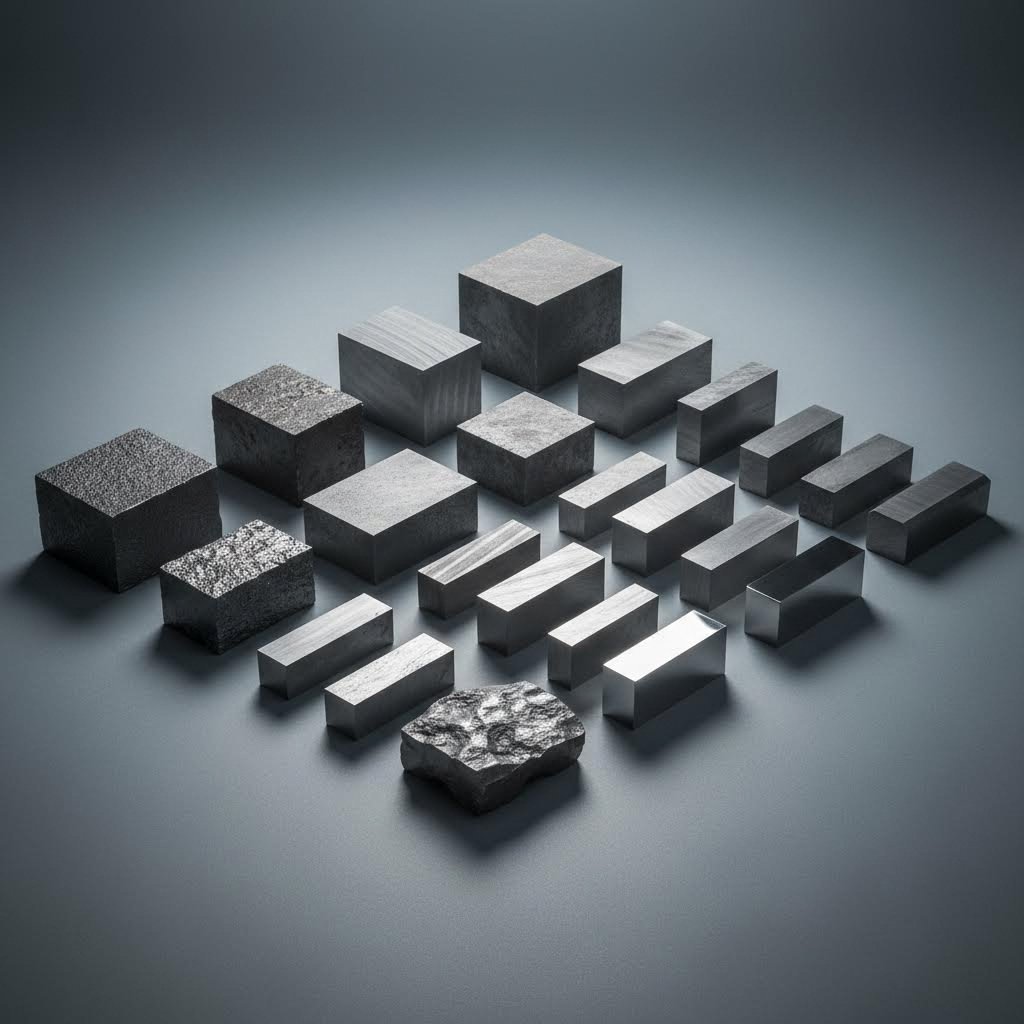

Tool Steel Selection for Die Construction

Why does die material matter so much? Consider this: cutting edges on steel stamping dies may cycle over a million times, each stroke generating friction and heat. The steel must resist wear, maintain dimensional stability, and withstand repeated impact—all while holding precise cutting edges.

According to SteelPro Group, die steel is classified into three primary categories: cold work, hot work, and plastic mold steels. Each serves distinct applications:

- Cold Work Steels (D2, A2) – Ideal for stamping operations at room temperature. D2 offers exceptional wear resistance with hardness reaching 58-62 HRC, while A2 provides better toughness and dimensional stability during heat treatment

- Hot Work Steels (H13) – Designed for applications involving elevated temperatures. H13 maintains its hardness and strength even when exposed to heat from high-speed operations or warm forming processes

- Specialty Grades (S7) – When impact resistance is critical, S7 steel delivers outstanding toughness under shock loading conditions

The Rockwell hardness scale (HRC) provides a standardized way to compare die materials. For most steel stamping tools, cutting components are heat-treated to 58-62 HRC—hard enough to resist wear yet tough enough to avoid chipping. A steel stamper working with abrasive materials might specify the higher end of this range, while applications requiring impact resistance may target slightly lower hardness for improved toughness.

Heat treatment transforms these steels into high-performance tooling. The process typically involves heating to 800°C-1050°C, rapid cooling to form a hard martensitic structure, then tempering at 150°C-650°C to balance hardness with toughness. Some manufacturers also use carbide inserts at high-wear locations, extending die life significantly in demanding applications.

Matching Dies to Your Workpiece Material

Imagine trying to cut butter with a plastic knife versus a sharp metal blade—the tool must match the task. The same principle applies when selecting sheet metal dies for different workpiece materials. Each metal brings unique characteristics that influence die design, clearances, and expected tool life.

According to JV Manufacturing, understanding material properties is essential because they directly affect component quality and production efficiency. Here's what you need to consider for common metals:

| Workpiece Material | Key Characteristics | Die Design Considerations |

|---|---|---|

| Mild Steel | Good formability, moderate strength | Standard clearances; versatile die materials work well |

| Stainless Steel | High strength, work hardens quickly | Requires harder die steel; tighter clearances; increased lubrication |

| Aluminum Alloys | Lightweight, excellent formability, gummy when cut | Polished die surfaces essential; wider clearances prevent galling |

| Copper/Brass | Excellent conductivity, soft and ductile | Moderate die hardness sufficient; watch for material buildup on tooling |

| Specialty Alloys | High strength-to-weight ratio, thermal resistance | Premium die materials required; specialized coatings often beneficial |

Beyond material type, three workpiece properties critically affect how you design your metal punch and die set:

- Thickness – Thicker materials require greater press tonnage and larger die clearances. A metal die punch cutting 0.020" steel needs different specifications than one cutting 0.125" plate

- Hardness – Harder workpiece materials accelerate die wear. When stamping high-strength steels, expect shorter maintenance intervals and consider premium die materials or coatings

- Ductility – Highly ductile materials like copper bend easily without cracking, allowing tighter forming radii. Brittle materials demand gentler forming operations and larger bend radii

The relationship between workpiece and die materials creates a balancing act. Metal punches and dies working with abrasive or hardened materials wear faster, driving up maintenance costs and potentially affecting part quality over time. Manufacturers can extend operational life by selecting materials that minimize wear while meeting performance requirements.

Hardened tool steel—particularly D2 for cold work applications—can significantly extend the lifespan of your tooling. Many modern dies also feature carbide cutting and forming components, offering enhanced strength and wear resistance for high-performance applications where standard options fall short.

Understanding these material relationships helps you make informed decisions about tooling investments. But even with perfect material selection, you'll need to specify appropriate tolerances and understand what lifespan to expect from your dies—topics that directly impact both part quality and total cost of ownership.

Technical Specifications and Tolerance Standards

You've selected your die type and matched materials correctly—but here's where many projects stumble: specifying tolerances that balance precision against cost. Over-specifying leads to unnecessary expense, while under-specifying creates quality problems downstream. Understanding tolerance classes, lifespan expectations, and certification standards helps you communicate requirements clearly and evaluate stamping die manufacturers effectively.

Understanding Tolerance Classes and Standards

What tolerance can you actually achieve with precision die and stamping operations? The answer depends on several factors, but according to industry guidelines from Alekvs, standard dimensional tolerances for holes or edges can often be held to ±0.002" in high-precision applications. However, these capabilities come with important caveats.

Tolerances typically loosen based on:

- Material type – Softer materials like aluminum allow tighter control than springy stainless steels

- Part geometry – Complex shapes with multiple bends accumulate more variation than simple flat parts

- Material thickness – Thinner gauges generally hold tolerances better than heavy plate

- Production volume – High-speed operations may sacrifice slight precision for throughput

Standard steel gauges come with defined thickness tolerances, and while these can be tightened, doing so typically drives up cost. When specifying requirements for stamping die components, consider whether standard tolerances actually meet your functional needs—many applications don't require the tightest specifications available.

| Die Type | Typical Tolerance Range | Best Achievable | Cost Impact |

|---|---|---|---|

| Progressive Die | ±0.003" to ±0.005" | ±0.001" | Moderate to High |

| Compound Die | ±0.002" to ±0.004" | ±0.001" | Moderate |

| Transfer Die | ±0.005" to ±0.010" | ±0.002" | High |

| Blanking Die | ±0.002" to ±0.005" | ±0.001" | Low to Moderate |

Here's a practical insight: tightening tolerances beyond what your application requires doesn't improve part function—it just increases tooling cost and production time. Work with your manufacturing die supplier to determine the loosest tolerances that still meet functional requirements.

Die Lifespan Expectations by Application

How long should your tooling last? Lifespan expectations vary dramatically based on die type, material choices, and production intensity. A well-designed and properly maintained progressive die stamping thousands of mild steel parts might deliver 1-2 million cycles before requiring major maintenance. The same die working with abrasive stainless steel might need attention after 500,000 cycles.

Key factors affecting die longevity include:

- Die material quality – Premium tool steels and carbide inserts extend service life significantly

- Workpiece material – Harder, more abrasive materials accelerate wear on cutting edges

- Production speed – Higher cycling rates generate more heat and friction

- Maintenance practices – Regular inspection and timely sharpening prevent catastrophic failures

- Lubrication – Proper lubricant selection reduces friction and extends tool life

The relationship between precision requirements and cost deserves careful attention. Tighter tolerances demand harder die materials, more frequent maintenance, and slower production speeds—all adding expense. Metal stamping die manufacturers can help you find the sweet spot where quality meets budget.

Quality Certifications That Matter

When evaluating a stamping dies manufacturer, certifications provide objective evidence of quality management capabilities. According to Interstate Specialty Products, ISO certifications demonstrate a commitment to quality that goes beyond marketing claims—they prove the company uses an approved quality management system with documented policies, processes, and procedures.

Two primary standards matter most:

- ISO 9001:2015 – Defines attributes of a quality management system supporting continuous improvement while meeting customer and regulatory requirements. This certification applies broadly across manufacturing industries

- ISO 13485:2016 – Specifically addresses quality management for medical devices and related services, covering the entire product life cycle with increased regulatory requirements

ISO certified companies follow the plan-check-do-act (PCDA) model and demonstrate effectiveness, efficiency, and responsiveness. For customers, partnering with certified suppliers can deliver increased performance, reduced waste, greater efficiency, and more reliable deliveries.

Beyond ISO standards, automotive applications often require IATF 16949 certification—an even more stringent quality framework specifically designed for automotive supply chains. When your stamped components must meet OEM specifications, working with certified suppliers reduces risk and ensures consistent quality.

Understanding these technical specifications empowers you to communicate requirements clearly and evaluate supplier capabilities objectively. But even the best tooling eventually encounters problems—knowing how to troubleshoot common die issues can save significant time and money when challenges arise.

Troubleshooting Common Die Problems

Even the most precisely manufactured metal stamp dies eventually encounter performance issues. Whether you're seeing inconsistent parts, excessive burrs, or accelerated wear, understanding what's going wrong—and why—can mean the difference between a quick fix and costly production delays. This troubleshooting guide covers the problems that experienced stamping professionals encounter most frequently, along with practical solutions to get your operations back on track.

Common Wear Patterns and Their Causes

Have you noticed that your stamper dies wear unevenly, with some areas showing significant damage while others look nearly new? This inconsistent wear pattern is one of the most common issues in stamping operations, and according to DGMF Mold Clamps, it typically stems from several root causes:

- Machine tool alignment issues – When upper and lower turret mounting seats aren't properly aligned, uneven stress distribution accelerates wear on one side

- Insufficient die precision – If the original die design or machining accuracy doesn't meet requirements, wear patterns will be inconsistent from the start

- Worn guide bushings – Guide components that have deteriorated through long-term use cause misalignment between punch and die

- Improper clearances – When the gap between cutting edges isn't optimized for the material being stamped, excessive friction develops

- Inadequate lubrication – Failure to lubricate moving components during operation leads to rapid, uneven wear

What happens when die stamped parts start showing quality issues? Often, the problem traces back to blade wear. Cutting edges naturally dull over time, but several factors accelerate this degradation: poor die material selection, inadequate surface treatment, structural rigidity problems that cause bite marks, and delayed blade sharpening.

Alignment and Deformation Troubleshooting

Alignment problems can be frustrating because they often develop gradually. Your stamp dies might produce perfect parts for months, then slowly drift out of specification as wear accumulates. Here's how to identify and correct alignment issues:

Warning signs of misalignment:

- Uneven burr formation on opposite sides of stamped parts

- Asymmetric wear visible on punch or die surfaces

- Increasing dimensional variation in parts over time

- Unusual noise or vibration during stamping operations

To prevent and correct alignment issues, regularly use an alignment mandrel to check and adjust the machine tool turret and mounting base. Replace worn guide bushings promptly, and ensure proper clearance between stamp and die components. For thin, narrow rectangular dies—where alignment problems are most pronounced—consider using full-guide-range tooling that maintains alignment throughout the stroke.

Material deformation problems often accompany alignment issues. When blanks aren't flat or exhibit warping, the stamping process can't produce consistent results. According to industry best practices, the plate should be flat without deformation before entering the die, and forming processes should be positioned as far from clamps as possible to minimize induced stresses.

Burr Formation and How to Eliminate It

Burrs—those unwanted raised edges on die stamped parts—signal that something in your process needs attention. According to DR Solenoid, burr formation typically results from one of these factors:

- Blunt cutting edges – Worn or damaged blades can't make clean cuts

- Improper clearances – Gaps that are too large, too small, or uneven create burrs

- Press precision problems – Slider stroke that isn't perpendicular to the worktable, or rail gaps that are too large

- Installation errors – Upper and lower dies that aren't concentrically installed

- Inadequate stamping oil – Standard machine oils lack the extreme-pressure properties required for clean cutting

The solutions are often straightforward: sharpen cutting edges regularly, verify clearances match your material specifications, and use stamping-specific lubricants formulated with appropriate additives for your workpiece material.

Preventive Maintenance Best Practices

The best way to troubleshoot problems? Prevent them from occurring in the first place. According to Keneng Hardware, proactive maintenance dramatically extends die life while preventing costly unplanned downtime.

Recommended inspection and maintenance intervals:

- Before each production run – Inspect cutting edges, check alignment, verify lubrication systems

- After each production run – Clean die surfaces, remove debris and metal shavings, check for wear or damage

- Weekly – Apply rust inhibitors to exposed surfaces, verify clearances, inspect springs and guide pins

- Monthly – Comprehensive dimensional inspection, hardness verification at wear points, documentation review

Maintenance checklist essentials:

- Clean die components thoroughly using appropriate solvents

- Lubricate all moving parts to reduce friction and prevent galling

- Maintain sharp cutting edges—dull tooling creates burrs and accelerates wear

- Store dies in clean, dry environments with controlled humidity

- Optimize setup parameters including clearance, tonnage, and feed rates

- Document optimal settings for reference in future production runs

- Train operators on proper handling to avoid dents, scratches, and damage

When restoration becomes necessary, skilled technicians can weld and machine worn areas back to specification, apply heat treatment to restore hardness, and add specialized coatings like TiN or DLC for enhanced wear resistance. Following repair, conduct rigorous quality assurance testing—including dimensional inspections and trial production runs—before returning dies to full production.

Regular maintenance isn't just about preventing breakdowns; it's about protecting your investment. Well-maintained stamping tooling produces consistent, high-quality parts while maximizing return on your tooling investment. Understanding these troubleshooting fundamentals positions you to maintain reliable operations—but what about the financial side of die ownership?

Cost Factors and Economic Considerations

You've learned how to troubleshoot common problems and maintain your tooling—but here's the question that often determines whether a project moves forward: how much will this actually cost? Understanding the economics of metal stamp dies helps you budget accurately, negotiate effectively, and make decisions that optimize total cost of ownership rather than just upfront price.

Key Cost Drivers in Die Manufacturing

When you request a quote for custom metal stamping services, what factors determine the number you'll see? According to Manor Tool, metal stamping pricing includes several interconnected elements: tooling and die investment, material requirements, part complexity, quality control documentation, estimated annual usage, and shipping costs. Together, these determine your total cost per part.

Here's what drives die pricing specifically:

- Complexity – A simple blanking die costs far less than a progressive die with multiple stations performing sequential operations. Each additional feature—piercing, bending, forming, embossing—adds engineering time and machining operations

- Size – Larger dies require more raw material, bigger machine tools, and often specialized handling equipment. A palm-sized die versus a 20-foot assembly represents dramatically different investments

- Material selection – Premium tool steels like D2 or carbide inserts cost more than standard grades but deliver longer service life. The tradeoff between upfront investment and maintenance frequency matters significantly

- Tolerance requirements – Tighter specifications demand more precise machining, additional quality verification steps, and often slower production speeds. Avoid arbitrarily specifying ±0.001" when ±0.005" meets functional requirements

- Production volume expectations – Higher volumes justify premium die materials and more sophisticated designs that reduce per-part costs over time

Die design complexity deserves special attention. Some components can be formed in a single die strike, while more complex parts require progressive stamping tool and die setups that use multiple stations to create detailed features efficiently. Experienced designers plan the production sequence to balance quality, speed, and material usage—and this engineering expertise contributes to tooling cost.

Balancing Investment Against Production Volume

Here's a counterintuitive reality: metal stamping isn't ideal for prototypes or low-volume runs. The upfront investment in metal stamping tooling often exceeds the cost of traditional machining for small batches. However, once production reaches around 10,000+ parts per month, the tooling cost becomes far more economical.

Think of it this way: a custom metal stamping die might cost $15,000 to $50,000 or more depending on complexity. If you're producing only 500 parts, that tooling investment adds $30-$100 per part before material and production costs even enter the equation. But spread that same investment across 100,000 parts, and tooling adds only $0.15-$0.50 per piece.

The relationship between upfront die investment and per-part costs follows a simple principle: the more parts you run through a high-quality die, the lower your cost per part. For the best value, order parts in the highest feasible quantities to spread tooling and setup costs across the entire production volume.

When evaluating a custom metal stamp die investment, consider the complete production lifecycle:

- Initial tooling cost – One-time investment in die design and manufacturing

- Setup costs per run – Press preparation, die installation, and first-article inspection

- Per-part production cost – Material, press time, and direct labor

- Maintenance and refurbishment – Periodic sharpening, replacement of wear components, and major overhauls

- Die replacement – Eventually, even well-maintained tooling reaches end of life

Quality matters for long-term economics. According to Manor Tool, dies manufactured overseas often use lower-grade steel that wears faster and produces inconsistent parts. Many U.S. stamping companies avoid accepting imported dies because they can't maintain required production quality. Investing in reliable, domestic tooling ensures repeatable quality, predictable costs, and long-term production success.

Rapid Prototyping Before Production Tooling

What if you need to test your design before committing to production tooling? Rapid prototyping options let you validate form, fit, and function without the full die investment. According to Custom Metal Pro, CNC or laser cutting shops can often deliver prototypes in 3-10 days—a fraction of production tooling timelines.

This approach offers several advantages:

- Test design assumptions before expensive tooling commitments

- Identify potential forming problems early when changes are inexpensive

- Validate material selection and surface finish requirements

- Confirm dimensional requirements actually support assembly and function

However, remember that prototype parts made through machining or laser cutting may not perfectly replicate stamped characteristics. Springback behavior, surface finish, and edge quality can differ between processes. Use prototypes for concept validation, but expect some refinement when transitioning to production stamping.

Lead Time Variables to Plan For

Beyond cost, timing often determines project success. How long should you expect to wait for custom metal stamping tooling? Lead times vary dramatically based on complexity and manufacturer capabilities.

Typical lead time ranges:

- Simple blanking dies – 2-4 weeks

- Moderate complexity progressive dies – 4-8 weeks

- Complex multi-station tooling – 8-16 weeks or more

- Production parts after tooling approval – 2-6 weeks depending on volume

Several factors can extend your timeline beyond these estimates:

- Design changes after engineering approval

- Material availability issues for specialty alloys

- Quality certification requirements for regulated industries

- First-article inspection and approval processes

- Shipping logistics, especially for international suppliers

Working with suppliers who maintain in-house capabilities—from design through finishing—can significantly accelerate the overall cycle. When a single supplier handles everything, handoffs between vendors disappear, and communication becomes simpler.

Understanding these cost factors and lead time variables positions you to make informed decisions about your tooling investments. But knowing the economics is only part of the equation—selecting the right die type for your specific application and finding the right manufacturing partner requires a systematic approach that we'll explore next.

Selecting the Right Die for Your Application

You understand the economics and lead times—but how do you actually navigate from your production requirements to the right die type and manufacturing partner? This is where many buyers struggle, facing a maze of technical options without a clear framework for decision-making. Let's change that with a systematic approach that matches your specific needs to the optimal solution.

Matching Die Type to Your Application

Think of die selection as answering a series of questions, each narrowing your options until the right choice becomes clear. Start with your application fundamentals, then layer in production realities and budget constraints.

Step 1: Define your application type

What are you actually trying to accomplish? Your answer points toward specific die categories:

- Cutting operations only (blanking, piercing, trimming) → Start with blanking or compound dies

- Forming operations (bending, drawing, embossing) → Consider forming dies or compound dies

- Multiple sequential operations → Progressive dies become strong candidates

- Large parts with complex geometry → Transfer dies handle what progressive dies cannot

- Identification and traceability → Marking dies for logos, serial numbers, or codes

Step 2: Consider your workpiece material

According to Zintilon's engineering guidance, material properties profoundly influence die design and selection. Ask yourself:

- What material are you stamping (mild steel, stainless, aluminum, copper, specialty alloys)?

- What's the material thickness range?

- How does the material's hardness and ductility affect formability?

- Does the material exhibit significant springback that requires compensation?

High-strength steels and aluminum alloys—increasingly common for automotive lightweighting—require higher press tonnages and specialized tooling. Ensure any supplier you consider can handle your specific material requirements.

Step 3: Quantify your production volume

Production volume often determines which die type makes economic sense:

| Annual Volume | Recommended Approach | Rationale |

|---|---|---|

| Under 1,000 parts | CNC machining or laser cutting | Tooling investment doesn't justify stamping |

| 1,000 - 10,000 parts | Simple blanking or compound dies | Moderate tooling cost spreads across volume |

| 10,000 - 100,000 parts | Compound or basic progressive dies | Efficiency gains justify tooling investment |

| 100,000+ parts | Progressive or transfer dies | High-speed production maximizes ROI |

Step 4: Specify tolerance requirements

Don't over-specify. Tighter tolerances drive up costs without improving function if your application doesn't require them. Review your functional requirements and specify the loosest tolerances that still work.

Step 5: Establish budget constraints

Be realistic about your total budget including tooling, production, maintenance, and potential design iterations. Sometimes a simpler die with slightly higher per-part costs makes more sense than a complex progressive die with lower piece prices but massive upfront investment.

Evaluating Die Manufacturers and Partners

Once you've identified what you need, finding the right die assembly manufacturer becomes critical. Not all suppliers offer the same capabilities, and the gap between adequate and excellent can dramatically impact your production success.

Certification requirements

For automotive stamping dies and other demanding applications, certifications signal genuine capability rather than just marketing claims. According to TÜV SÜD, IATF 16949 certification specifically addresses automotive quality requirements that general ISO 9001 certification doesn't cover—including defect prevention, supply chain variation reduction, and customer-specific requirements.

As the Shaoyi supplier selection guide emphasizes, a supplier claiming to be "IATF compliant" without holding actual certification hasn't undergone the rigorous third-party audits that guarantee adherence to the standard. Always request current certificates and verify their validity.

Key evaluation criteria for die manufacturers:

- Quality certifications – IATF 16949 for automotive applications; ISO 9001 minimum for general manufacturing. For example, Shaoyi maintains IATF 16949 certification for their automotive stamping die capabilities, meeting OEM-level quality requirements

- Engineering support – Can they optimize your design for manufacturability? Strong suppliers provide DFM feedback that improves quality while reducing costs

- CAE simulation capabilities – Advanced suppliers use simulation to predict and prevent defects before physical production. This capability—offered by manufacturers like Shaoyi—identifies potential forming problems, springback issues, and tooling interference virtually

- Prototyping speed – When you need to validate designs quickly, rapid prototyping matters. Some manufacturers deliver prototype parts in as little as 5 days, accelerating your development cycle significantly

- In-house tooling capabilities – Suppliers who maintain dies internally can respond to problems quickly. Sending tooling out for repair can take days or weeks; an internal tool shop often fixes issues in hours

- Press capacity range – Verify they have appropriate tonnage for your material and geometry. Automotive applications often require presses from 100 to 600+ tons

- First-pass approval rates – This metric reveals process maturity. High-performing suppliers achieve first-pass approval rates above 90%, reducing iteration cycles and time to production

Questions to ask potential suppliers:

- What is your current rejection rate, and can you document it?

- Do you offer complete PPAP documentation for automotive applications?

- What simulation tools do you use for virtual die try-outs?

- Can you handle our project from prototype through mass production?

- What is your average lead time from design approval to first article?

- How do you manage die maintenance and refurbishment?

Custom Metal Die Stamp Considerations

When your application requires a custom metal stamper rather than off-the-shelf solutions, several additional factors come into play for metal parts stamping success:

- Design collaboration – The best outcomes emerge when supplier engineering teams work alongside your designers from the concept stage, not after drawings are finalized

- Material sourcing – For custom automotive metal stamping, verify your supplier has relationships with reliable material mills and can secure allocation even during market volatility

- Scalability – Your volumes may grow. Ensure your partner can scale from initial runs to full production without requiring new tooling investments

- Geographic considerations – While offshore suppliers may offer lower piece prices, factor in lead times, communication challenges, shipping costs, and supply chain risks for a complete total landed cost analysis

The gap between suppliers who merely quote low prices and those who deliver reliable, high-quality tooling can mean the difference between a smooth production launch and costly delays. For automotive stamping die applications specifically, partnering with manufacturers who understand OEM requirements—and can demonstrate proven capabilities through certifications, simulation tools, and documented quality metrics—reduces risk while improving outcomes.

With a clear framework for die selection and supplier evaluation in hand, you're positioned to make confident decisions. But the stamping industry continues evolving—understanding where technology is headed helps you prepare for future opportunities and make investments that remain relevant as capabilities advance.

Making Confident Die Decisions

You've journeyed through the complete landscape of metal stamp dies—from understanding fundamental concepts to evaluating suppliers and troubleshooting common problems. Now it's time to synthesize these insights into actionable steps that move your projects forward. Whether you're exploring options for the first time or optimizing existing operations, the decisions you make about tooling will shape your production success for years to come.

Key Takeaways for Die Selection Success

Throughout this guide, several critical decision points have emerged that separate successful stamping operations from frustrating ones:

The right metal stamping die isn't the cheapest option or the most sophisticated—it's the one that matches your specific application requirements, production volumes, and quality standards while delivering the lowest total cost of ownership.

Here's what matters most when making your selection:

- Match die type to application – Progressive dies excel at high-volume production of complex parts; compound dies deliver precision for medium runs; transfer dies handle large, intricate assemblies

- Material compatibility drives longevity – Premium tool steels and proper heat treatment extend die life dramatically, especially when stamping abrasive or high-strength materials

- Specify tolerances wisely – Over-specifying wastes money; under-specifying creates quality problems. Define functional requirements first, then determine the loosest tolerances that work

- Volume determines economics – Stamping makes economic sense above 10,000 parts annually; below that threshold, alternative processes often cost less

- Supplier capabilities matter – Certifications like IATF 16949, CAE simulation tools, and documented quality metrics separate reliable partners from risky vendors

Emerging Trends Shaping the Future

The precision stamping industry continues evolving rapidly. According to Step Metalwork's industry analysis, several trends are reshaping what's possible with custom metal stampings:

Advanced materials are expanding possibilities

Demand for high-strength steels, aluminum alloys, and titanium continues growing—particularly in automotive and aerospace applications where weight reduction matters. These materials require more sophisticated die designs and harder tool steels, but they enable components that were previously impossible to manufacture cost-effectively.

Simulation-driven design is becoming standard

As Altair's research indicates, simulation-driven design for manufacturing (SDfM) delivers insights directly into the hands of product designers, allowing design flaws to be detected and corrected early. This approach reduces trial-and-error cycles, prevents costly mold trial defects, and accelerates time to production. Virtual die try-outs can now predict material flow, springback behavior, and potential forming problems before any steel is machined.

Automation and Industry 4.0 integration

Modern stamping operations increasingly incorporate robotics, real-time monitoring, and data analytics. These technologies improve consistency, reduce human error, and enable predictive maintenance that prevents unplanned downtime. When you're evaluating a metal stamping tool supplier, ask about their automation capabilities and digital integration.

Faster prototyping accelerates development

The gap between concept and production continues shrinking. Some manufacturers now deliver prototype parts in days rather than weeks, enabling rapid design iteration before committing to production tooling. This capability is particularly valuable when developing new products for competitive markets where time-to-market determines success.

Your Next Steps Forward

Where do you go from here? Your path depends on where you are in the process:

If you're still researching options:

- Document your application requirements thoroughly—part geometry, material, volumes, tolerances

- Identify whether you need industrial stamping dies for production or marking dies for identification

- Consider whether a number stamp set or custom marking die best serves your traceability needs

- Research potential suppliers and verify their certifications match your industry requirements

If you're ready to request quotes:

- Prepare complete drawings with material specifications and tolerance callouts

- Specify annual volume expectations and potential growth projections

- Ask suppliers about their CAE simulation capabilities and first-pass approval rates

- Request references from customers with similar applications

- Evaluate total cost of ownership, not just piece price

If you're optimizing existing operations:

- Implement preventive maintenance schedules to extend die life and reduce unplanned downtime

- Review your stamping set parameters—clearances, tonnage, feed rates—for optimization opportunities

- Consider whether advanced die materials or coatings could reduce maintenance frequency

- Evaluate whether simulation tools could improve your design-to-production process

For those seeking to accelerate automotive production with certified manufacturing partners, Shaoyi offers a comprehensive solution. Their engineering team combines IATF 16949 certification with advanced CAE simulation for defect prevention, delivering rapid prototyping in as little as 5 days and maintaining a 93% first-pass approval rate. Whether you need precision stamping dies for new programs or tooling optimization for existing production, their automotive stamping die capabilities provide cost-effective, high-quality tooling tailored to OEM standards.

The stamp die decisions you make today will influence your production quality, costs, and competitiveness for years to come. Armed with the knowledge from this guide—understanding die types, manufacturing processes, material selection, troubleshooting techniques, and supplier evaluation criteria—you're positioned to make those decisions with confidence.

Frequently Asked Questions About Metal Stamp Dies

1. What are the different types of stamping dies?

The main types include progressive dies for high-volume continuous production, transfer dies for large complex parts, compound dies for simultaneous multiple operations, and marking dies for identification purposes. Progressive dies cycle through sequential stations at speeds up to 1,500 strokes per minute, while transfer dies move individual workpieces between separate stations for intricate assemblies. Compound dies perform cutting, bending, and forming in a single stroke, making them ideal for medium-sized components requiring exceptional precision.

2. How much does custom metal stamping cost?

Custom metal stamping die costs range from $15,000 to $50,000+ depending on complexity, size, material selection, and tolerance requirements. Key cost drivers include die complexity, premium tool steel grades, tight tolerance specifications, and production volume expectations. While upfront tooling investment is significant, per-part costs decrease dramatically with volume—spreading a $30,000 die across 100,000 parts adds only $0.30 per piece versus $60 per piece for 500 parts. Manufacturers like Shaoyi offer IATF 16949-certified tooling with rapid prototyping in 5 days to help validate designs before full production investment.

3. How long do metal stamping dies last?

Well-designed progressive dies stamping mild steel can deliver 1-2 million cycles before major maintenance, while the same die working with abrasive stainless steel might need attention after 500,000 cycles. Die longevity depends on tool steel quality, workpiece material hardness, production speed, maintenance practices, and proper lubrication. Premium tool steels like D2 heat-treated to 58-62 HRC significantly extend service life, and carbide inserts at high-wear locations can further enhance durability for demanding applications.

4. What tolerances can metal stamping achieve?

High-precision metal stamping operations can hold dimensional tolerances of ±0.002 inches for holes and edges, with some applications achieving ±0.001 inches. However, achievable tolerances vary based on material type, part geometry, material thickness, and production volume. Softer materials like aluminum allow tighter control than springy stainless steels, and complex shapes with multiple bends accumulate more variation. Specifying the loosest tolerances that meet functional requirements helps control costs without sacrificing quality.

5. What certifications should I look for in a stamping die manufacturer?

ISO 9001:2015 certification demonstrates a documented quality management system, while IATF 16949 is essential for automotive applications—covering defect prevention, supply chain variation reduction, and OEM-specific requirements. ISO 13485:2016 addresses medical device manufacturing standards. Beyond certifications, evaluate CAE simulation capabilities for virtual die try-outs, first-pass approval rates (top performers exceed 90%), in-house tooling capabilities, and rapid prototyping options. Verified certifications from third-party audits provide objective evidence of genuine manufacturing capability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —