A lézervágó szolgáltatások árképzése: amit a vállalkozások nem mondanak el

Mi az a lézervágási szolgáltatás, és hogyan működik

Elgondolkodott már valaha azon, hogyan készítik a gyártók azokat az összetett fémdarabokat lehetetlenül tiszta élekkel? A válasz a lézervágási szolgáltatásban rejlik – egy olyan gyártási folyamatban, amely koncentrált fényenergiát használ anyagok hibátlan, sebészi pontosságú levágására. Ellentétben a hagyományos vágási módszerekkel, amelyek fizikai pengékre vagy csiszoló erőkre támaszkodnak, a lézerrel történő vágás a nyers anyagokat tisztán termikus energiával alakítja át kész alkatrészekké.

Lényegében a lézervágási szolgáltatás hozzáférést biztosít ipari felszerelésekhez amelyeket a legtöbb vállalkozás és magánszemély nem tud megengedni magának. Ezek a szolgáltatások kezelik a tervezési fájlok előkészítésétől kezdve egészen a végső vágásig minden lépést, így a precíziós lézervágás elérhetővé válik hobbihasználók, vállalkozók és nagyvállalati gyártók számára egyaránt.

A lézervágás technológiája hogyan működik

Tehát mi is az a lézeres vágás pontosan? Képzeljük el, ahogy a napfényt egy nagyítóüvegen keresztül fókuszáljuk – most pedig szorozzuk meg ezt az intenzitást ezerszer. Egy lézeres vágó gép egy rezonátorban hoz létre koherens fénysugarat, ahol a fotonok tükrök között verődnek vissza, amíg elég intenzívvé nem válnak ahhoz, hogy áthaladjanak egy félig áteresztő felületen.

Itt válik izgalmassá a dolog. Amikor a lézerközeg elektronjai fotonenergiát nyelnek el, magasabb energiaszintre ugranak. Ahogy visszatérnek az alacsonyabb szintre, azonos fotonokat bocsátanak ki lavinaszerű hatásban. Az Xometry műszaki dokumentációja szerint ezt a folyamatot, amelyet gerjesztett emissiónak neveznek, a pontos vágás lehetővé tételéhez szükséges fókuszált, koherens nyaláb létrehozására használják.

A nyaláb optikai szálakon vagy tükörsorozaton halad keresztül, mielőtt egy fókuszáló lencsén áthalad. Ez a lencse az összes energiát egy apró pontba koncentrálja – néha emberi hajszálnál is kisebb méretűvé. Ezen a fókuszpontban a hőmérséklet olyan drasztikusan megemelkedik, hogy az anyag azonnal megolvad vagy elgőzölög. Ezt követően egy gázáramlat (általában nitrogén, argon vagy oxigén) eltávolítja az olvadt anyagot, így tiszta vágás keletkezik.

Számítógéppel vezérelt motorok mozgatják a vágófejet vagy a munkadarabot előre programozott utasítások, az úgynevezett G-kód alapján. Ez lehetővé teszi a lézernél, hogy összetett alakzatokat vágjon ki ismételhető pontossággal, amire a kézi módszerek egyszerűen képtelenek.

Miért fontos a pontosság az anyagok vágásánál

Lehet, hogy azt gondolja: „Tényleg ennyire fontos a pontosság?” Vegye figyelembe, hogy ha lézert használ autóipari tartók vagy elektronikai házak vágására, akkor még a legkisebb eltérés is oda vezethet, hogy az alkatrészek nem illeszkednek megfelelően egymáshoz.

A modern lézeres vágás olyan szűk tűréshatárokat ér el, mint a +- 0,005 hüvelyk, lehetővé téve olyan alkatrészek gyártását, amelyek minimális utómegmunkálással vagy beállítással illeszkednek egymáshoz.

Ez a pontossági szint több együttesen működő tényezőből ered:

- Nem-kontakt folyamat: Mivel nincs fizikai szerszám, amely megérintené az anyagot, így nincs szerszámkopás, amely befolyásolná a pontosságot

- Minimális hőhatású zóna: A koncentrált energia a hődeformációt a közvetlen vágási területre korlátozza

- Számítógépes vezérlés: A digitális pontosság kiküszöböli az emberi hibát a vágási folyamatból

- Állandó sugárminőség: Ellentétben a mechanikus vágóélekkel, amelyek idővel elkopnak, a lézer intenzitása stabil marad

Az eredmény? Olyan alkatrészek, amelyek méretpontossága független attól, hogy egy prototípust vagy tízezer darabos sorozatot gyártanak. Pontosan ez az egységesség teszi a lézeres vágást elengedhetetlen technológiává az élvonalbeli iparágakban – az űriptól kezdve az orvosi eszközökig.

A lézervágási technológiák típusai magyarázattal

Most, hogy már érti, hogyan működik a lézeres vágás, itt van valami, amit a szolgáltatók többsége eleinte nem mond el: nem minden lézer egyformán hatékony. A lézertípus, amelyet egy vállalkozás használ, jelentősen befolyásolja, milyen anyagokat tud vágni, milyen gyorsan dolgozik, és végül mennyit fog fizetnie. Ezeknek a különbségeknek az ismerete erősebb pozícióba helyezi Önt árajánlatkérésnél.

Három fő lézertechnológia uralja az ipart: a CO2-lézerek, a szálas lézerek és az Nd:YAG-lézerek. Mindegyik adott alkalmazásokban jeleskedik, és annak ismerete, hogy melyik technológia felel meg projektjének, segít abban, hogy megtalálja a legmegfelelőbb lézert anyaga kivágásához.

CO2-lézerek szerves anyagokhoz

A CO2-lézereket évtizedek óta használják alapvető eszközként a lézeres vágásban és gravírozásban. Ezek a gázlézerek elsősorban szén-dioxid keverékét használják egy 10,6 mikrométeres hullámhosszúságú lézersugár előállítására, amely tökéletesen elnyelődik szerves és nem fémes anyagokban.

Mit jelent ez az Ön projektje szempontjából? Ha fával, akrillal, bőrrel, szövettel vagy műanyagokkal dolgozik, a CO2-technológia kiváló eredményeket ér el. A hosszabb hullámhossz kiválóan kölcsönhatásba lép ezekkel az anyagokkal, tiszta éleket és sima felületeket eredményezve, amelyeket a rövidebb hullámhosszú lézerek alig tudnak utolérni.

Itt van a kompromisszum, amiről tudnia kell: a CO2 lézerek összetettebb hűtőrendszereket igényelnek, és nagyobb karbantartást igényelnek az újabb technológiákhoz képest. Emellett kevésbé hatékonyak fémből álló anyagok vágásánál, bár megfelelő teljesítménnyel rendelkező gépek vékony acélt és alumíniumot is képesek vágni. Az ADHMT műszaki specifikációi szerint a CO2 rendszerek általában körülbelül 10–15% elektro-optikai átalakítási hatásfokot érnek el, ami hosszú távon magasabb üzemeltetési költségeket jelent.

Ezek ellenére a CO2 továbbra is legyőzhetetlen a reklámtáblák készítésére szakosodott cégek, a faipari vállalkozások és mindenki számára, aki elsősorban nem fémes anyagokat dolgoz fel.

Fiber lézerek fémalkalmazásokhoz

Amikor a lézeres fémvágás az elsődleges szempont, a szálas lézeres vágási szolgáltatások olyan egyértelmű előnyökkel rendelkeznek, amelyek magyarázzák gyors ipari elterjedésüket. Ezek a szilárdtest lézerek optikai szálak segítségével hoznak létre fényt, melyek ritkaföldfém-elemekkel – általában itterbiummal – vannak adagolva, és körülbelül 1,06 mikrométeres hullámhosszúságú sugárzást állítanak elő.

Miért fontos a hullámhossz? A fémek sokkal hatékonyabban nyelik el ezt a rövidebb hullámhosszúságot, mint a CO₂ lézer hosszabb nyalábját. Ennek eredménye gyorsabb vágási sebesség, tisztább élek tükröző anyagokon, például réz- és sárgarézon, valamint jelentősen alacsonyabb üzemeltetési költségek. A szálas lézerek több mint 30%-os elektro-optikai átalakítási hatásfokot érnek el – ez körülbelül háromszorosa a CO₂ rendszerekének.

A fémlézer-vágógép szálas technológiával emellett minimális karbantartást igényel. Nincs gázkeverék, amit pótolni kellene, nincsenek tükrök, amelyeket be kellene állítani, és a szervizelési élettartam meghaladja a 100 000 órát. Nagy volumenű fémgyártás esetén ezek a tényezők közvetlenül alacsonyabb alkatrész-költségekhez vezetnek.

A korlátozás? A szálas lézerek nehezen birkóznak meg az organikus anyagokkal. Az 1,06 μm-es hullámhossz áthalad a tiszta műanyagokon, és rossz eredményt ad fa esetén. Ha a projektjei mind fém, mind nemfém anyagokat érintenek, valószínűleg mindkét technológiára szüksége lesz – ezt érdemes figyelembe venni a lézeres CNC-szolgáltatók értékelésekor.

Speciális alkalmazásokhoz Nd:YAG lézerek

Az Nd:YAG (neodímiummal adalékolt ittrium-alumínium-gránát) lézerek egy speciális szegmensben működnek. Ezek a szilárdtest rendszerek ugyanazt a 1,064 μm-es hullámhosszt állítják elő, mint a szálas lézerek, de más mechanizmussal: neodímium ionokat gerjesztenek fel egy kristályrudat használva villanócsövek vagy lézerdiódák segítségével.

Hol használhatók ki ezek a lézerek? Olyan nehézipari alkalmazásokban, ahol extrém behatolási teljesítményre van szükség. Az Nd:YAG lézerek kiválóan alkalmasak vastag fémlemezek vágására, hegesztési műveletekre, valamint alkalmazhatók durva környezetben. Nagy csúcsteljesítményük miatt fontosak az űrtechnológiában, a védelmi iparban és a hajógyártásban.

A legtöbb szabványos lézeres vágószolgáltatás-kérésnél nem találkozik Nd:YAG technológiával. A karbantartási igények meghaladják a CO2-es és szálas rendszereket, és a vágási költség darabonként magasabb a tipikus gyártási munkákhoz képest. Ugyanakkor ennek a technológiának az ismerete segít felismerni, mikor igényel valóban egy speciális alkalmazás ilyen technológiát, és mikor bonyolítja túl esetlegesen a szolgáltató a projektjét.

Lézertechnológia-összehasonlítás pillantásra

A megfelelő technológia kiválasztása egyszerűbbé válik, ha oldalról oldalra hasonlítja össze a specifikációkat. Ez a táblázat összefoglalja, amit az egyes lézertípusok kínálnak:

| Specifikáció | Co2 laser | Fiber lézer | Nd:YAG Lézer |

|---|---|---|---|

| Hullámhossz | 10,6 μm | 1,06 μm | 1,064 μm |

| Teljesítményi tartomány | 25 W – 20 kW | 20 W – 30 kW+ | 50 W – 6 kW |

| Legjobb anyagok | Fa, akril, műanyagok, bőr, textil, papír | Acél, rozsdamentes acél, alumínium, réz, sárgaréz, titán | Vastag fémek, nagy szilárdságú ötvözetek |

| Vágási sebesség (vékony fém) | Mérsékelt | Nagyon gyors | Mérsékelt - Gyors |

| Hatékonyság | 10-15% | 30%+ | 15-20% |

| Karbantartási szint | Magas (gáz, tükrök, hűtés) | Alacsony (szilárdtestű) | Mérsékelt és magas |

| Tipikus alkalmazások | Kijelzők, gravírozás, csomagolás, textíliák | Fémfeldolgozás, gépjárműipar, elektronikai házak | Repülőgépipar, védelmi ipar, nehézipari hegesztés |

Melyik technológia illik az Ön projektjéhez?

A megfelelő lézertechnológia kiválasztása néhány kulcskérdés megválaszolásán múlik:

- Csak fém alkatrészek? A szálaslézer-vágási szolgáltatások a sebesség, pontosság és költséghatékonyság legjobb kombinációját kínálják

- Fa, akril vagy műanyag? A CO2 technológia továbbra is az arany standard az organikus anyagoknál

- Vegyes anyagok? Keressen olyan szolgáltatókat, akik mind CO2-, mind rostrendszereket üzemeltetnek, vagy tervezze több szállító használatát

- Vastag acéllemezek (25 mm felett)? Érdeklődjön, hogy rendelkezik-e a műhely nagy teljesítményű rost- vagy Nd:YAG-képességgel

Ezen különbségek megértése segít jobb kérdéseket feltenni, amikor kapcsolatba lép a szolgáltatókkal – és felismerni, ha egy műhely eszközkorlátjai nem felelnek meg konkrét igényeinek. Szó esett az igényekről: az anyagkompatibilitás túlmutat a lézertípuson, ami elvezet bennünket a döntő fontosságú kérdéshez, hogy mely anyagok alkalmasak leginkább az egyes vágási módszerekhez.

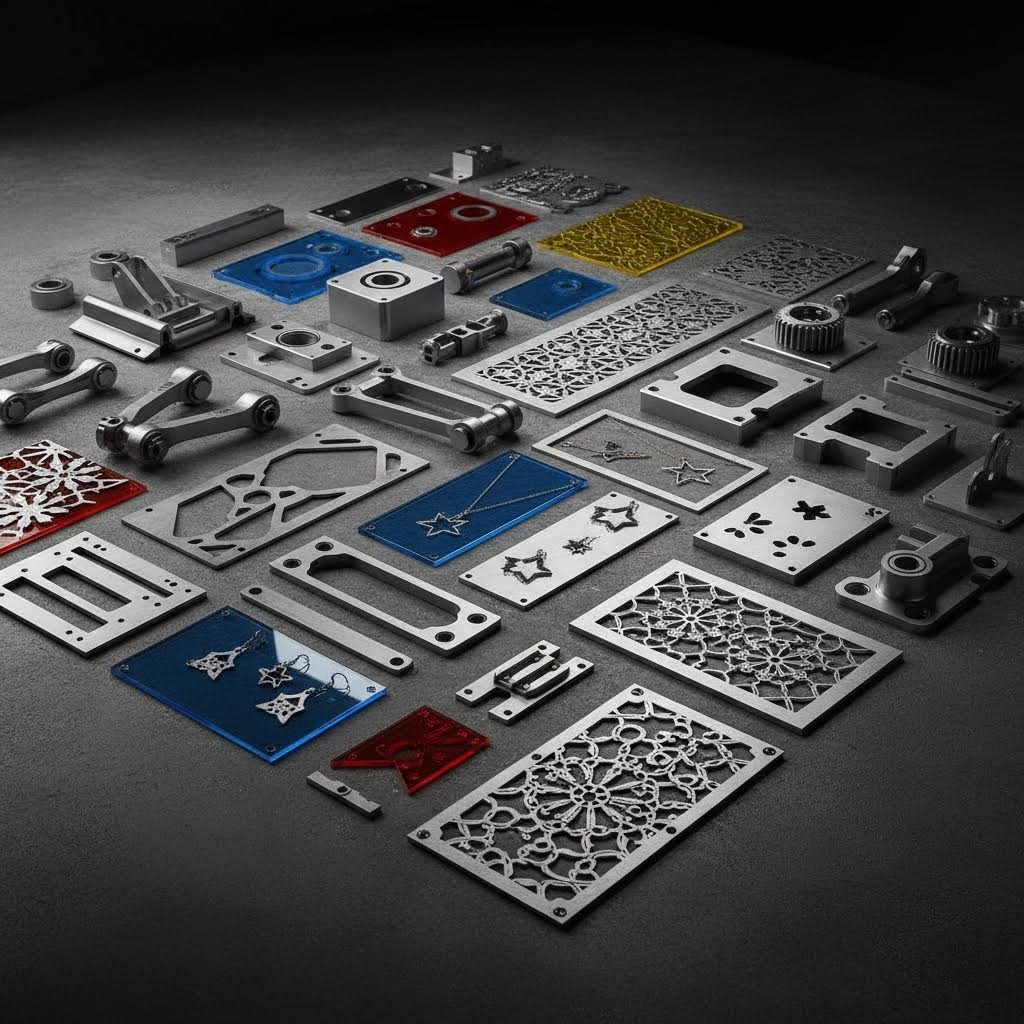

Anyagok, amelyek kompatibilisek a lézervágó szolgáltatásokkal

Itt van valami, amit a legtöbb lézeres vágóüzem nem mond önként: nem minden anyagot, amit hozzájuk visznek, megfelelő eredménnyel lehet feldolgozni. Néhány anyag gyönyörűen vágható, tiszta élekkel és szoros tűrésekkel. Mások olvadnak, torzulnak, vagy mérgező gázokat bocsátanak ki, amelyeket felelős vállalkozások nem dolgoznak fel. Annak ismerete, hogy mely anyagok vághatók lézerrel – és azok konkrét korlátai – megkímél a költséges próbálgatástól.

Az anyag kiválasztása mindenre hatással van, az élminőségtől a darabárakig. A vastagsági képességek és tűrési előírások megértése segít okosabban tervezni, és már eleve pontos árajánlatot kapni.

Fém anyagok és vastagsági képességek

Amikor fémeket kell lézerrel vágnia, a lehetőségek papírvékony lemezektől a súlyos acéllemezekig terjednek. Mindazonáltal minden fém másképp viselkedik a lézersugár alatt, és a vastagságra vonatkozó korlátozások jelentősen eltérhetnek az anyag tulajdonságaitól függően.

A szálas lézerek uralják a fémek lézeres vágását, mivel a fémek hatékonyan elnyelik ezt az 1,06 μm hullámhosszúságot. Szerint SendCutSend anyagspecifikációi , a legtöbb szolgáltató képes azonnali árajánlatot adni legfeljebb 44" x 30" méretű lemezekre, egyéb méretekhez testreszabott árajánlat érhető el.

Itt van, amit tudnia kell a gyakori fémekről és vágási jellemzőikről:

| Fém típus | Maximális vastagság | Élek minősége | Tökéletes alkalmazások |

|---|---|---|---|

| Lágyacél | 0,500" (12,7 mm) | Kiváló – tiszta, oxidmentes élek nitrogén segédgázzal | Tartók, keretek, ipari gépek, járműipari alkatrészek |

| 304 rozsdamentes acél | 0,500" (12,7 mm) | Nagyon jó – vastagabb vágásoknál enyhe oxidáció előfordulhat | Élelmiszeripari berendezések, orvosi eszközök, építészeti panelek |

| 316 rostmentes acél | 0,250" (6,35 mm) | Nagyon jó – korrózióálló élek | Tengerészeti szerelvények, vegyipari berendezések, sebészeti műszerek |

| 5052-es alumínium | 0,500" (12,7 mm) | Jó – vastagabb anyagon enyhe vonalazódás megjelenhet | Kültéri burkolatok, táblák, tengeri alkalmazások |

| 6061 Alumínium | 0,750" (19,05 mm) | Jó – nagyon jó, vágás után hőkezelhető | Szerkezeti alkatrészek, repülőipari alkatrészek, prototípusok |

| Réz | 0,250" (6,35 mm) | Mérsékelt – erősen tükröző, nagy teljesítmény szükséges | Elektromos alkatrészek, hűtőbordák, díszítőelemek |

| Sárgaréz | 0,250" (6,35 mm) | Jó – tiszta vágás megfelelő beállítások mellett | Díszes szerelvények, hangszeralkatrészek, ékszerek |

| Titán 5. osztály | 0,250" (6,35 mm) | Kiváló – minimális hőhatású zóna | Repülőgépipar, orvosi implantátumok, nagyteljesítményű alkatrészek |

Szeretne alumíniumot lézervágni könnyűsúlyú alkalmazásokhoz? Az 5052 és 6061 ötvözetek a legjobb kombinációt kínálják a megmunkálhatóság és szilárdság tekintetében. Vékonyabb lemezek (0,125 hüvelyk alatti) lézervágása esetén a legtöbb szolgáltató ±0,005 hüvelykes tűréshatáron belül képes dolgozni – elegendően pontos ez pontos összeszerelésekhez.

Fontos tudnivaló a fémlapok lézervágásáról: a minimális alkatrész-méretek növekednek a vastagsággal. Míg vékony lemezanyagoknál olyan kis méretű elemek is kivághatók, mint 0,25" x 0,375", vastagabb anyagoknál nagyobb minimális méretek szükségesek – félhüvelykes lemez esetén akár 1" x 1" vagy még több is. Ez a korlátozás hatással van az aprólékos tervekre és kisméretű szerelvények gyártására.

Műanyagok és szerves anyagok útmutatója

Az áttérés fémekről lézervágható műanyagokra más szempontok figyelembevételét igényli. A CO2 lézerek többsége jól kezeli a szerves és polimer anyagokat, de az anyagösszetétel fontosabb szerepet játszik, mint gondolná.

A Laser Cut Supply anyagútmutatója , az akril továbbra is az elegáns, modern alkalmazások első választása, mivel a vágott szél kristálytiszta lesz. A öntött akril (GS) feszültségmentes, és megbízhatóbb a lézerrel való munka során, míg az extrudált változatok (XT) akkor alkalmazhatók jobban, ha a pontos vastagsági tűrések a legfontosabbak.

| Anyag típusa | Maximális vastagság | Élek minősége | Tökéletes alkalmazások |

|---|---|---|---|

| Öntött akril (PMMA) | 0,750" (19 mm) | Kiváló – csiszolt, lángkezelt felület | Hirdetőtáblák, kiállítási elemek, dísztárgyak, világítótestek |

| Nyomott acrilik | 0,500" (12,7 mm) | Nagyon jó – enyhén alacsonyabb átlátszóság, mint az öntött változatnál | Sorozatgyártás, árérzékeny projektek |

| PET-G | 0,250" (6,35 mm) | Jó – enyhe olvadás jelei megjelenhetnek | Ütésálló fedelek, élelmiszer-biztonságos edények |

| Delrin (POM) | 0,250" (6,35 mm) | Jó – tiszta vágás megfelelő sebességbeállítás mellett | Fogaskerekek, csapágyhüvelyek, alacsony súrlódású mechanikus alkatrészek |

| Tölgyfa-plywood | 0,375" (9,5 mm) | Nagyon jó – tiszta élek, enyhe megfeketedés | Szerkezeti modellek, bútorprototípusok, kézműves projektek |

| MDF | 0,250" (6,35 mm) | Kiváló – homogén, ideális marásra | Hirdetőtáblák, belső térdekoráció, sablonok és rögzítők |

| Hullámpapír/Lapréteg | 0,125" (3 mm) | Jó – gyors feldolgozás, tiszta élek | Prototípuskészítés, csomagolás, építészeti modellek |

Figyelmeztetés műanyagokkal kapcsolatban: soha ne feltételezze, hogy egy anyag biztonságosan lézervágható csak azért, mert műanyag. A PVC, a vinil és az ABS fűtés hatására mérgező klór- vagy cianidgázokat bocsát ki. A policarbonát rosszul vágható és egészségkárosító gőzöket termel. A felelős lézeres vágószolgáltatók szigorú tilalmi listákat tartanak fenn – és Önnek is ezt kellene tennie.

Anyagok összeegyeztetése az alkalmazással

A megfelelő anyag kiválasztása nem csupán a vághatóságon múlik – arról is szól, hogy melyik anyagot érdemes vágni az adott felhasználási célból kifolyólag. Az alábbiakban gyakorlati útmutatást adunk közös projekttípusok alapján:

- Ipari alkatrészek és konzolok :Simaacél vagy 304-es rozsdamentes acél a szilárdságért; 6061-es alumínium, ha a súly számít. Egy fémet vágó lézergép ezekkel napi szinten dolgozik

- Táblák és Kijelzők: Öntött akril kiváló átlátszóságért; színes MDF költséghatékony, térfogati táblákhoz

- Prototípuskészítés: Hullámkarton gyors formavizsgálatokhoz; MDF vagy rétegelt lemez funkcionális prototípusokhoz; alumínium gyártás-közelitő teszteléshez

- Dekorációs elemek: A réz és az ónzászló melegséget kölcsönöz; a nyírfa rétegelt lemez természetes esztétikát nyújt; a tükrös akril drámai hatást kelt

- Elektronikai házak: az 5052-es alumínium védelmet biztosít; a porfestékkel bevont acél tartósságot kínál; az akril látható alkatrészekhez alkalmas

Ne feledje, hogy a vágás során eltávolított anyagmennyiséget – azaz a kerf-et – általában 0,1–0,2 mm-es értékben határozzák meg lézervágásnál. Kattintásos illesztésű vagy szűk tűréshatárú alkatrészek tervezésekor ezt figyelembe kell venni a tervezési fájlok elkészítésekor. A tapasztalt szolgáltatók többsége tud tanácsot adni a kerf-hozzáadás mértékéről adott anyagok esetén.

Az anyagok képességeinek megértése lehetővé teszi, hogy kontroll alatt tartsa az árajánlatkéréseket. De még a tökéletes anyagválasztás sem menthet meg egy projektet, ha a tervezési fájlok nincsenek megfelelően előkészítve – ami elvezet minket azokhoz az állomány-előkészítési követelményekhez, amelyek elválasztják a zökkenőmentes projekteket a frusztráló késésektől.

Hogyan készítse elő a fájlokat lézervágáshoz

Kiválasztotta az ideális anyagot, és talált egy ígéretes szolgáltatót. Most pedig elérkezett az a lépés, ahol a legtöbb projekt váratlan késésekbe ütközik: a fájl előkészítése. Bonyolultnak hangzik? Nem kell, hogy az legyen – mégis, ha kihagyja ezeket az alapvető lépéseket, az majdnem biztosan elutasított fájlokhoz, pazarolt időhöz vagy elképzelésétől eltérő alkatrészekhez vezet.

Akár egyedi akril vágást rendel reklámtáblákhoz, akár lézeres fa vágásra keres megoldást kreatív projekthez, az Ön által benyújtott fájl határozza meg mindent. Nézzük meg pontosan, mit igényelnek a lézervágó és CNC rendszerek a tervezett fájloktól.

Lézervágáshoz szükséges fájlformátumok

Íme, mi különbözteti meg a zökkenőmentes megrendeléseket a frusztráló ismételt levelezéstől: a megfelelő fájlformátum használata már a kezdet kezdetén. A Quote Cut Ship tervezési irányelvei szerint a lézervágók nem úgy értelmezik a képfájlokat, ahogyan a tervező szoftvere. Vektoros formátumokra van szükségük, amelyek pontosan meghatározzák a vágási pályákat.

A következő formátumok működnek gyakorlatilag minden lézervágó CNC géppel:

- DXF (Drawing Exchange Format): A lézeres tervezési szolgáltatások univerzális szabványa. Működik az AutoCAD-del, Fusion 360-nal, SolidWorks-szal és a legtöbb CAD programmal. Kiváló pontossági mechanikai alkatrészekhez, ahol a méreti pontosság a legfontosabb

- AI (Adobe Illustrator): Natív formátum az Illustrator felhasználói számára. Megőrzi a rétegeket, színeket és a bonyolult útvonal-információkat. Ideális, ha a tervezés egyszerre vágási és gravírozási műveleteket is tartalmaz

- SVG (Skálázható Vektorgrafika): Nyílt forráskódú formátum, kompatibilis ingyenes szoftverekkel, mint például az Inkscape. Tökéletes hobbihasználatra és alkotók számára, akik professzionális eredményt szeretnének drága szoftver nélkül

- PDF (Hordozható Dokumentum Formátum): Működik, ha vektorprogramokból exportálják, és az útvonalak megmaradnak. Néhány szolgáltató elfogadja a PDF-eket, bár általában a DXF vagy AI jobb kompatibilitást nyújt

Mi a helyzet a JPEG-ekkel és PNG-kel? Ezek a raszteres formátumok képpontokból állnak, nem matematikai útvonalakból. Egy lézeres és CNC rendszer nem tudja követni a képpontrácsot vágáshoz – kizárólag meghatározott vektorvonalakra van szüksége. A raszteres képek alkalmasak fényképek maratására felületeken, de a vágási műveletekhez kizárólag vektoros adatok szükségesek.

Tervezési ajánlott eljárások tiszta vágásokhoz

A megfelelő formátum használata csak a kezdet. Az, hogyan építi fel a tervezést a fájlban, dönti el, hogy az alkatrészek tökéletesen készülnek-e el, vagy drága újrafeldolgozásra van szükség.

A xTool műszaki dokumentációja , a vektorfájl minden részlete konkrét jelentéssel bír a lézervágó számára. Íme, mit kell figyelembe venni:

Vonalak és kitöltések: A vonalak határozzák meg a vágási pályákat – a lézer pontosan ezeket követi az alakzatok kialakításához. A kitöltések (vonalakkal határolt, színnel vagy mintákkal ellátott területek) azt jelzik a lézernek, hogy maratnia kell, nem pedig vágania. Ha ezeket összekeveri, váratlan eredményekkel számolhat.

Kerf-kompenzáció: Ne feledje, hogy a lézer anyagot párologtat, amikor vág, általában 0,1–0,2 mm szélességet eltávolítva. Kattintásra illeszkedő szerelvények vagy pontosan egymásba kapcsolódó alkatrészek esetén állítsa be az útvonalakat a vágási rések felével, hogy megőrizze a pontos végső méreteket.

Legkisebb vonvtörsély: A vonalszélességek adott műveleteket jeleznek a gép számára. Gyakori konvenció, hogy 0,2 pt-es vonalakat használjanak vágáshoz, vastagabb vonalakat (1 pt vagy több) pedig maráshoz. Ellenőrizze a szolgáltató specifikációit – ezek változhatnak a különböző műhelyek között.

Útvonalak közti távolság: Ha a tervezési vonalak túl közel helyezkednek el egymáshoz, a lézer túlégethet, vagy véletlenül belévághat a szomszédos területekre. Tartsa legalább 0,010 inch (0,25 mm) távolságot a kritikus útvonalak között a szerkezeti integritás fenntartása érdekében.

Gyakori hibák, amelyek vágási hibákhoz vezetnek

Még tapasztalt tervezők is beleesnek ezekbe a csapdákba. Az elején való kerülésük időt takarít meg, és elkerüli a gyorsított javítások díjait:

- Nyitott vagy nem összekötött útvonalak: A vágási vonalak szakadásai összezavarják a lézert, ami hiányos alakzatokhoz vagy szabálytalan mozgáshoz vezethet. Használja a szoftver "összekapcsolás" vagy "zárt útvonal" funkcióját az exportálás előtt

- Egymást átfedő vonalak: Ha az útvonalak átfedik egymást, a lézer ugyanazt a területet kétszer vágja el – ez gyengíti az anyagot, égésnyomokat okozhat, vagy durva éleket eredményezhet. Ellenőrizze az esetleges ismétlődéseket a szoftver tisztítóeszközeivel

- Szöveg nem lett körvonalakká alakítva: Az aktív szövegdobozok helytelenül jelenhetnek meg, ha a betűtípus nem érhető el. Alakítsa át az összes szöveget útvonalakká, görbékkel vagy körvonalakká a beküldés előtt

- Az anyagvastagság figyelmen kívül hagyása: A lézervágás egy 2D-s folyamat, de az anyagnak van vastagsága. Az egymásba kapcsolódó alkatrészek, amelyek nem veszik figyelembe az aktuális anyagvastagságot, nem illeszkednek megfelelően

- Helytelen csomópont-elhelyezés: Túl sok csomópont érdes, szaggatott vonalakat hoz létre; túl kevés csomópont pontatlan görbéket eredményez. Egyszerűsítse le a bonyolult útvonalakat, miközben megtartja a szükséges alakzatot

A legtöbb lézeres tervezési szolgáltatás fájlellenőrzést kínál a vágás megkezdése előtt. Használja ki ezt a lehetőséget – néhány percnyi szakértői visszajelzés órákig tartó hibaelhárítástól óvhat meg később.

Megfelelően előkészített fájlok birtokában már képes megérteni, mennyibe kerül valójában a fájlok vágása – és itt válik elengedhetetlenné az átlátható árképzés.

A lézeres vágószolgáltatások árképzésének megértése

Itt van egy dolog, amit a legtöbb lézervágó műhely önkéntelenül nem említ meg: a négyzetméterenkénti ár majdnem semmit sem jelent. Két azonos méretű alkatrész is lehet ugyanabból az anyaglapból – az egyik 15 dollárba, a másik 75 dollárba kerülhet. Mi az oka? A gép által igénybe vett idő. A Fortune Laser árképzési útmutatója szerint az egyetlen legfontosabb tényező, amely a költségeit meghatározza, nem az anyagfelület, hanem az, hogy mennyi ideig dolgozik a lézer az Ön konkrét tervén.

Annak megértése, hogy mi befolyásolja valójában a lézeres vágási költségeket, lehetővé teszi, hogy kontroll alatt tartsd az árajánlatkéréseket. Ahelyett, hogy vakon elfogadnád a számokat, pontosan tudni fogod, melyik tervezési döntések kerülnek pénzbe – és mely optimalizálások takarítanak meg költségeket.

A lézeres vágás elsődleges költségtényezői

Minden lézeres vágási árajánlat egy alapvető képletet követ, akár helyi céggel dolgozol, akár online összehasonlítod a küld-vág-vissza árakat:

Végső ár = (Alapanyagköltségek + Változó költségek + Állandó költségek) × (1 + Haszonkulcs)

Egyszerűen hangzik? Az összetettség ezekben a változó költségekben rejlik. Íme, mi hat valójában a lézeres vágási díjaidra:

- Anyag típusa és vastagsága: Ez kétféleképpen hat az árra: a nyersanyag beszerzési költségére és a vágási nehézségre. A Komacut árképzési elemzése szerint a vastagság megduplázása több mint duplájára növelheti a vágási időt, mivel a lézert sokkal lassabban kell mozgatni tiszta átvágáshoz. Az acélnál drágább a rozsdamentes acél vágása; az alumíniumhoz képest a réz magasabb teljesítménybeállításokat igényel

- A vágás összetettsége és a vágási útvonal hossza: A lézer által megtett teljes lineáris távolság közvetlenül meghatározza a gép időtartamát. Egy 100 kis lyukból álló tervezés drágább, mint egy nagy kivágás, mivel minden lyukhoz külön fúrási pont szükséges, ahol a lézer elkezdi a vágást. A bonyolult, szoros ívekből álló tervek miatt a gépnek le kell lassulnia, ami meghosszabbítja a vágási időt

- Mennyiség és beállítási idő: Minden munkához fix beállítási költségek tartoznak – anyag betöltése, gép kalibrálása, fájl előkészítése. Ezek a költségek az Ön rendelésében szereplő összes alkatrészre eloszlanak, ezért az egységre jutó ár a mennyiséggel jelentősen csökken

- Befejezési követelmények: Másodlagos műveletek, mint például a burkolás, élletörés, menetkészítés vagy porfestés további munkaerő- és speciális berendezésidőt igényelnek. Egy nyers, lézerrel vágott alkatrész olcsóbb, mint amelyik simított éleket vagy beépített szerelvényeket igényel

- Kiszállítási határidő: A sürgős rendelések, amelyek azonos napi vagy hétvégi szállítást igényelnek, általában 20–50%-kal növelik a szabványos árakat. Ha az Ön időbeosztása rugalmas, a szabványos határidő költséghatékonyabb

A fémvágási szolgáltatások általában magasabbak, mint a fa vagy akrilikus anyagok feldolgozása, több oka van ennek a magasabb költségnek az anyagköltségen túlmenően. A fémvágásra alkalmas szálas lézerek drágább berendezéseket igényelnek, és segédgázok, például nitrogén vagy oxigén használata további üzemeltetési költségeket jelent.

Hogyan befolyásolja a tervezési bonyolultság az ajánlatot

Képzeljen el két azonos méretű acél konzolt. Az elsőnek négy egyenes éle és két csavarágya van. A második díszes görbe vonalakkal és tucatnyi íves, bonyolult kivágással rendelkezik. Melyik kerül többe?

A díszesebb konzol akár három-öt szer is többe kerülhet, annak ellenére, hogy ugyanannyi anyagból készül. Íme, miért:

- Fúrási pontok száma: Minden alkalommal, amikor a lézer új vágást kezd, először át kell fúrnia az anyagot. Egy olyan tervezés, amely 50 belső kivágást tartalmaz, 50 fúrást igényel; egy egyszerű téglalap alakú forma csak egyet. Minden egyes fúrás hozzáad néhány másodpercet, ami termelési sorozatok esetén összeadódik.

- Sebességcsökkenés: A bonyolult geometriai alakzatok, szoros ívekkel és éles sarkokkal kényszerítik a vágófejet lassításra. A gép teljes sebességgel haladhat egyenes vonalak mentén, de az összetett minták pontosságának megtartása érdekében gondos, lassú mozgást igényelnek

- Tűréshatár-előírások: A funkcionálisan szükségesnél szigorúbb tűréshatárok megadása növeli a költségeket. A szakmai árképzési adatok szerint a nagyon szoros tűrések betartása lassabb, jobban szabályozott vágási sebességet igényel

A tanulság? Az egyszerű geometriai formák olcsóbbak, mint a művészi tervek. Ha a költségvetés fontosabb, mint az esztétika, az összetett görbék leegyszerűsítése jelentősen csökkentheti a lézervágási árajánlatot

Mennyiségi kedvezmények és tételnagyság-stratégia

Itt válik kiemelkedővé az okos rendelési gyakorlat. Az a beállítási díj, amely 25–50 USD minden munkafolyamatért? Ezt a költséget minden rendelt alkatrészen osztják szét. Tíz darabnál ez 5 USD darabonkénti beállítási költséget jelent; száz darabnál ez csupán 0,50 USD-ra csökken darabonként

A Fortune Laser költségelemzése , a nagy mennyiségű rendelések esetén a kedvezmény akár 70%-ig is elérheti. Ez azért történik, mert:

- A rögzített beállítási költségek több egységre oszlanak el

- A nagykereskedelmi anyagvásárlások jogosultak a szállító által nyújtott kedvezményekre

- A termelési hatékonyság javul az ismétlődő műveletek során

- Csökken a gépek közötti állásidő a feladatok között

Mi a gyakorlati stratégia? Egyesítse igényeit nagyobb, de ritkább rendelésekké, ahelyett, hogy az év során több kisebb rendelést adna le. Ha előreláthatólag hasonló alkatrészekre lesz szüksége idővel, akkor azok együttes megrendelése jelentősen megtakarítást eredményez a darabonkénti vásárláshoz képest.

Hogyan becsülje meg projektjének költségvetését

Lézeres vágásra vonatkozó azonnali árajánlat kérése előtt durván becsülheti a költségeket, ha értékeli ezeket a tényezőket a tervezettel szemben:

- Számítsa ki a teljes vágási távolságot: Mérje vagy becsülje meg a szükséges vágás lineáris hüvelybe eső hosszát. A nagyobb távolság több gép-időt jelent

- Számolja meg a fúrásokat: Minden belső kivágás, lyuk vagy különálló alakzat hozzáadja a fúrási időt. Egyszerűsítsen, ahol lehetséges

- Vegye figyelembe az anyaghatékonyságot: Kompozit elrendezés – a részek egymás közelében történő elhelyezése csökkenti a hulladékot. Az hatékony elrendezések kevesebb anyagot használnak, és csökkenthetik a költségeket

- Vegye figyelembe a másodlagos műveleteket: Szüksége lesz-e letörésre, hajlításra vagy bevonatra? Mindegyik növeli az összes költséget

Sok online szolgáltatás jelenleg olyan lézeres vágásra vonatkozó azonnali árkalkulációs eszközöket kínál, amelyek másodpercek alatt kiszámítják az árakat a feltöltött CAD-fájlokból. Ezek a rendszerek elemzik a tervezés bonyolultságát, az anyagigényeket és a mennyiséget, hogy pontos becslést adjanak – bár előfordulhat, hogy nem észlelik azokat a költséges tervezési hibákat, amelyeket egy emberi ellenőr jelezne.

Amikor közvetlen közelben lézeres vágási szolgáltatást keres, kérdezze meg a szolgáltatóktól, hogy nyújtanak-e gyártásra tervezés (DFM) visszajelzést. Ez a szakértői áttekintés lehetőséget teremthet a költségek csökkentésére anélkül, hogy funkcióban kellene engedni – néha jelentősen. Néhány, tapasztalt gyártó által javasolt tervezési módosítás gyakran többet takarít meg, mint bármilyen áralku.

Miután megértette az árképzés alapelveit, felmerülhet benned, hogyan viszonyul a lézeres vágás az alternatív módszerekhez – és mikor válik valóban gazdaságosabbá az adott projektje számára egy másik eljárás.

Lézeres vágás és egyéb vágási módszerek

Tehát úgy döntött, hogy vágott alkatrészekre van szüksége – de tényleg lézeres vágást kellene használnia? Íme, amit a legtöbb szolgáltató nem mond el nyíltan: a lézeres vágás nem mindig a legjobb választás. Néha vízsugaras, CNC maró vagy plazmavágás jobb eredményt hoz alacsonyabb költséggel az Ön konkrét alkalmazásához.

Annak megértése, hogy mikor melyik technológia különösen hatékony, segít megalapozott döntések meghozatalában, ahelyett, hogy elfogadná bármit, amit éppen elérhetővé tesz egy üzlet. A Wurth Machinery összehasonlító elemzése szerint a rossz CNC marószerszám kiválasztása több ezer anyagpazarlással és elvesztegetett idővel járhat.

Nézzük meg pontosan, hogy projektje követelményeinek megfelelően mikor melyik vágási módszer a legalkalmasabb.

Technológiai összehasonlítás pillantásra

Mielőtt részletekbe mennénk, az alábbi összehasonlító táblázat gyors tájékoztatást nyújt arról, melyik technológia felel meg leginkább az Ön projektjének:

| Gyár | Lézeres vágás | Vízjetes felvágás | CNC útvonalakasztás | Plazma vágás |

|---|---|---|---|---|

| Precíziós szintező | +/– 0,005″ (kiváló) | +/– 0,009″ (nagyon jó) | +/– 0,005″ (kiváló) | +/– 0,020″ (mérsékelt) |

| Az anyagi összeegyeztethetőség | Fémek, műanyagok, fa, szövet (nem PVC) | Szinte bármi – fémek, kő, üveg, kompozitok | Fa, műanyagok, kompozitok, puha fémek | Csak vezetőképes fémek |

| Élek minősége | Kiváló - minimális utómunka szükséges | Jó - enyhén érdesebb, nincsenek bemarások | Nagyon jó - eltávolítás után használható | Mérsékelt - gyakran szükséges tisztítás |

| Vágási Sebesség | Nagyon gyors (akár 2500 IPM) | Lassú (3-4x lassabb, mint a plazmavágás) | Mérsékelt | Gyors vastag fémeken |

| Költséghatékonyság | A leggazdaságosabb vékony anyagoknál | Magasabb üzemeltetési költségek, berendezés ára kb. 195 ezer USD | Mérsékelt - jó fához/műanyagokhoz | Legalacsonyabb költség vastag acélhez (~90 ezer USD rendszer) |

| Vastagsági korlátok | Akár 0,5-0,75 hüvelyk (az anyagtól függően) | 6 hüvelyk felett fémeknél | Az anyag merevségétől függően változik | 1 mm-től 150 mm-ig acélnál |

| Hőhatásövezet | Minimális megfelelő beállításokkal | Nincs - hideg vágási eljárás | Minimális - mechanikai eljárás | Jelentős – akár 30 000 °C-ig |

Lézeres és vízsugaras vágás összehasonlítása

Mikor érdemes a vízsugaras vágást választani a lézervágással szemben? A válasz három esetre redukálódik: vastag anyagok, hőérzékeny alkalmazások és szokatlan típusú anyagok.

A SendCutSend gyártási útmutatója szerint a vízsugaras vágás nagy nyomású, abrasív gránittal kevert vizet használ, amellyel szinte bármilyen anyagot – acéltól kövön át üvegig – meg lehet vágni. A fő előny? Zéró hőhatás. Nincs torzulás, nincs keményedés, és nincsenek hőtől érintett zónák, amelyek ronthatják az anyag tulajdonságait.

Válassza a vízsugaras vágást, ha:

- Olyan vastag fémeket vágsz, amelyeknél a 0,5 hüvelyknél (kb. 12,7 mm) lézerek hatékonyan nem tudnak behatolni

- A hő okozta károsodást feltétlenül el kell kerülni – az űrrepülési alkatrészek gyakran ilyen igényűek

- Olyan anyagok, mint a szénszálas kompozit, a G10 vagy a fenolgyanta rétegeződnének le hőterhelés hatására

- Kövek, kerámiák vagy üveg vágása, amelyeket a lézerek egyszerűen nem tudnak feldolgozni

- A lézervágás helyett acél alternatívákat kell választani, ha olyan vastag anyagokkal dolgozunk, amelyek túl vastagok a szálas lézerekhez

Tartsd meg a lézervágást, ha:

- A sebesség számít – az ipari lézeres vágás 3–4-szer gyorsabb, mint a vízsugaras vágás összehasonlítható anyagoknál

- Bonyolult tervek esetén szigorú tűréshatárok és tiszta élek szükségesek

- Korlátozott költségvetés áll rendelkezésre – a vízsugaras vágás üzemeltetési költségei jelentősen magasabbak

- 0,25 hüvelyknél vékonyabb anyagok feldolgozása szükséges – itt a lézeres vágás kiváló teljesítményt nyújt

A vízsugaras vágás piaca gyorsan növekszik, és 2034-re több mint 2,39 milliárd dollárra becsülik. Ez a növekedés a hidegvágási képességek iránti növekvő igényt tükrözi az űr- és az orvosi iparban, ahol a hőhatások elfogadhatatlanok.

Mikor előnyösebb a CNC marás

A CNC lézeres vágás és a CNC marás közös vonása a számítógéppel vezérelt pontosság, de a vágási mechanizmus alapvetően különböző. A marás egy forgó szerszámot használ, amely fizikailag távolítja el az anyagot – képzeljen el egy ipari méretű marót, amelyet pontos digitális koordináták vezérelnek.

Bizonyos anyagok és alkalmazások esetén a marás valójában jobban teljesít, mint a lézeres vágás:

- Kompozitok és műanyagok: Az olyan anyagok, mint az HDPE, ABS és Delrin, gyakran jobb felületminőséget eredményeznek maráskor, mint lézeres vágáskor. Nincs olvadás vagy hő okozta torzulás

- Vastag faanyagok: Bár a lézerek gyönyörűen vágnak fát, a CNC-marás vastag rétegelt lemezt és tömör fát képes megvágni égetés vagy színeződés nélkül

- Másodlagos műveletek: A marás lehetővé teszi menetvágást, süllyesztést és egyéb furatműveleteket egyetlen beállításban – a lézerek nem képesek ezek elvégzésére

A SendCutSend eljárásösszehasonlítása , a CNC-marás +/- 0,005 hüvelykes tűréshatárt tart fenn, miközben sok műanyagnál tisztább éleket hagy, mint a termikus vágási módszerek.

A kompromisszum? A belső sarkoknak ki kell bírniuk a maróbetét átmérőjét – általában 0,125 hüvelyk minimális rádiusz. Azon tervek, amelyek tökéletesen éles belső sarkokat igényelnek, lézert vagy vízsugaras vágást igényelnek helyette. A részeknek kis rögzítőfülekre is szükségük van a vágás során a mozgás megakadályozásához, amelyek enyhe nyomokat hagyhatnak, amelyek kézi utómunkát igényelhetnek.

Plazmavágás: A nehéz acél bajnoka

A közelemben keres plazma vágást? Ez a technológia egy speciális területet ural: a vastag vezetőképes fémeket, ahol a sebesség és a költségek fontosabbak, mint a pontosság.

A plazmavágás során elektromos ív és tömörített gáz használható a fémek olvadására és átfúvására 30.000 °C-os hőmérsékleten. A Trotec technológia összehasonlítása a plazma rendszerek mindent feldolgozhatnak, az 1 mm-es vékony laptól a 150 mm-es hajólemezig.

A plazma akkor kiváló, ha:

- Acél lézer vágás követelményei meghaladják a 0,5" vastagság - plazma fenntartja a sebességet, ahol a lézerek drámaian lelassulnak

- A strukturális acélgyártás előnyt élvez a gyártási mennyiségnek a szélesszerűsítésnél

- A költségvetési korlátok kedvez a kisebb berendezési költségnek (a vízgéptároló rendszerek körülbelül fele)

- A nehéz berendezéseknek, a hajógyáraknak vagy az építőipari alkalmazásoknak gyors vágásokra van szükségük

A plazmát akkor kerülje, ha:

- A pontosság számít – a tűrések +/- 0,020 hüvelyegben vagy szélesebbek

- Nemfém anyagok vágása szükséges – a plazma csak vezetőképes anyagokon működik

- A hőhatás problémás – az intenzív ív jelentősen befolyásolja a szomszédos anyagot

- Tiszta élek szükségesek – a plazmavágás általában másodlagos köszörülést vagy letörést igényel

Sok sikeres gyártóüzem párosítja a plazma- és lézertechnológiát – a plazma a vastag acélt vágja, amivel a lézerszisztémák küzdenek, míg a lézerek pontosságot nyújtanak vékonyabb anyagokhoz és bonyolult mintákhoz

A megfelelő technológia kiválasztása projekthez

Miután mind a négy technológiát összehasonlítottuk, hogyan döntsön valójában? Kezdje ezekkel a kérdésekkel:

- Milyen anyagot vág? Fémek esetén lézer vagy plazma javasolt; kompozitokhoz vízsugaras vágás szükséges lehet; fa és műanyag jól vágható marással

- Milyen vastag az anyag? 0,5 hüvelyeg alatti fém esetén lézer ajánlott; 1 hüvelyeg feletti acél esetén a plazma előnyösebb; nagyon vastag anyagokhoz vízsugaras vágás szükséges

- Milyen pontosságra van szüksége? A szűk tűrések (+/- 0,005") lézeres vagy CNC marást igényelnek; lazább specifikációk több lehetőséget nyitnak

- Fontos a hőhatás? Légiközlekedési, orvosi és hőérzékeny alkalmazások esetén gyakran vízsugaras vágás szükséges

- Mennyi a költségvetése? A lézer általában a legköltséghatékonyabb megoldás vékony anyagokhoz; vastag acél esetén a plazmavágás előnyösebb

Amikor lézervágó szolgáltatásokat keres, olyan szolgáltatókat keressen, akik több technológiát is kínálnak. Ez a rugalmasság biztosítja, hogy projektjét az optimális eljáráshoz illesszék, ne pedig kényszerítsék arra a felszerelésre, amivel éppen rendelkezik a műhely.

E technológiák közötti különbségek megértése lehetővé teszi, hogy okosabb kérdéseket tegyen fel, és felismerje, ha egy szolgáltató javaslata valóban a projektjének kedvez – szemben azzal, amikor egyszerűen csak a rendelkezésre álló berendezéseikhez próbálják igazítani Önt. A teljes folyamathoz érve nézzük végig pontosan, mi történik attól kezdve, hogy feltölti tervezési fájljait, egészen a kiszállításig.

A teljes lézervágó szolgáltatás munkafolyamata

Kiválasztotta az anyagot, előkészítette a fájlokat, és összehasonlította az árakat. De mi történik valójában a „beküldés” kattintás és a kész alkatrészek megérkezése között? A legtöbb lézeres vágószolgáltató homályban hagyja ezt a folyamatot – elküldi a fájlokat, bizonytalan ideig vár, és reméli, hogy az érkező termék megfelel az elvárásainak.

A teljes munkafolyamat megértése segít előre jelezni az időkereteket, korán felismerni a lehetséges problémákat, és ellenőrizni a minőséget az alkatrészek megérkezésekor. Akár lézeres vágó szolgáltatásokat keres a közelében, akár online szolgáltatóval dolgozik, minden szakmai vállalkozás hasonló sorrendet követ a rendeléstől a kézbesítésig.

Az árajánlat és rendelés folyamata

A Happy Eco News elemzése a lézeres vágás időkereteiről , minden vágási munka sokkal korábban kezdődik, mintsem hogy a gép működésbe lendülne – a fájl elkészítésével kezdődik. Egy jól előkészített, a vágási specifikációkhoz igazított CAD-terv olyan, mint egy előny a versenyben, amely még a késlekedés megjelenése előtt lefaragja az időt.

Íme a tipikus munkafolyamat a kezdeti kapcsolattól a gyártás megkezdéséig:

- Fájl beküldése: Feltölti vektoros tervezési fájljait (DXF, AI, SVG) a szolgáltató portálján keresztül vagy e-mailben. A legtöbb precíziós lézeres vágószolgáltatás elfogadja a szabványos CAD formátumokat, és egyértelmű feltöltési specifikációkat biztosít

- Tervezet áttekintése és DFM-visszajelzés: Egy tapasztalt gyártó átvizsgálja a fájlokat lehetséges problémákra – például átfedő pályákra, minimális elemméretekre, vágáskompenzációs igényekre. A minőségi szolgáltatók jeleznek minden problémát, és javaslatokat tesznek a javításra, mielőtt elkezdődne a vágás

- Árajánlat készítése: Az anyag típusától, vastagságától, a vágás bonyolultságától és a mennyiségtől függően a gyár kiszámítja a gépórákat, és elkészíti az árképzést. Néhány „lézeres vágószolgáltatás közel hozzám” lehetőség azonnali online árajánlatot kínál; másoknak 12–24 órára van szükségük egyéni gyártási becsléshez

- Anyagkiválasztás megerősítése: Ellenőrzi az ötvözet, méret és felületminőség konkrét követelményeit. Ha a szükséges lemezvastagság, fokozat vagy ötvözet nincs raktáron, a beszerzési késések hatással lehetnek az ütemtervre

- Megrendelés megerősítése és fizetés: Miután elfogadta az árajánlatot és teljesítette a fizetést, a megrendelése a gyártási sorba kerül

Mi lepi meg leginkább az első alkalommal vásárlókat? A tervezési felülvizsgálati szakasz jelentős időt vehet igénybe, ha a fájlok javításra szorulnak. A szakmai munkafolyamat-elemzések szerint az összetett minták, rendkívül szűk tűrések vagy szokatlan geometriák elkerülhetetlenül több időt igényelnek a feldolgozásban és vágásban egyaránt. Ha a fájl formátumkonverzióra, javításokra vagy további mérnöki munkára szorul, az időzítő már fut, anélkül hogy az első vágás megtörtént volna.

A rétegek rendezett szerkezetű, pontos méretekkel rendelkező DXF vagy DWG formátumú fájlok jelentik a különbséget. Minél tisztább és gyártásra készebb a terve, annál gyorsabban jut el képernyőről lemezre.

Gyártási és átfutási idő befolyásoló tényezők

Amint a megrendelés gyártásba kerül, több változó is meghatározza, mennyi idő múlva kerülnek a lézerrel vágott alkatrészek a birtokába. Ezeknek a tényezőknek az ismerete segít reális elvárásokat kialakítani – és azonosítani azokat a lehetőségeket, amelyekkel szükség esetén felgyorsítható a kézbesítés.

A tervezési bonyolultság közvetlenül befolyásolja a vágási időt. Az egyszerű geometriai formák kevés belső kivágással gyorsan feldolgozhatók. A tucatnyi lyukat, szoros íveket vagy részletes mintákat tartalmazó összetett tervek lassabb vágási sebességet és több döfőpontot igényelnek – mindegyik másodperceket ad hozzá, amelyek az ön megrendelése során összeadódnak.

Az anyag elérhetősége kritikus szerepet játszik. A gyártási ipar forrásai szerint, ha a szükséges anyag nincs raktáron, beszerzési késésekkel kell számolnia. Olyan beszállítókkal való együttműködés előnyös, akik jelentős készletet tartanak fenn – így nincs várakozás a szállításra, és nem akadályozza le a munkát az sem, hogy a megfelelő anyag valaki más raktárában van.

A megrendelés mennyisége befolyásolja a gyártási ütemezést. Az ismételt feladatok profitálnak az előre beállított gépparaméterekből – amint a beállítások elkészültek, a termelés folyamatosan halad, anélkül hogy állandó újra kalibrálás miatt meg kellene állni. Azonban a több anyagot, vastagságot vagy tervváltozatot igénylő feladatok futtatása között gépi újraállítást igényelnek, csökkentve ezzel a hatékonyságot.

A műhely terheltsége határozza meg a sorban elfoglalt pozíciót. A lézeres vágóüzemekben ritkán állnak ocsmán gépek. A beosztások tele vannak, és még a leggyorsabb szálas lézer sem segít, ha az Ön megrendelése sorban áll. Sürgősségi megrendelések esetleg beszivároghatnak, de ez teljesen az aktuális terheléstől függ. Minél korábban foglalja le a helyét, annál nagyobb az esélye, hogy egyeztethető legyen az üzem gyártási ablakával.

Amikor lézeres vágás keresésénél „közel hozzám” lehetőségeket keres, érdeklődjön az aktuális átfutási időkről a megrendelés előtt. A szabványos teljesítés általában 5–10 munkanap; sürgősségi szolgáltatással ez akár 1–3 napra is csökkenthető, de magasabb áron.

Minőségellenőrzés és szállítás

A munka nem ér véget azzal, hogy az utolsó vágás elkészül. A professzionális lézeres vágószolgáltatások olyan ellenőrzési szakaszokat is tartalmaznak, amelyek megerősítik, hogy alkatrészei megfelelnek a specifikációknak a szállítás előtt.

Milyen minőségi eredményekre számíthat?

- Él kialakítás: A megfelelően vágott lézeres alkatrészek tiszta, sima élekkel rendelkeznek, amelyek minimális utómegmunkálást igényelnek. Fémek vágása nitrogén segédgázzal oxidmentes éleket eredményez; oxigénnel segített vágásnál enyhe oxidáció jelentkezhet, amely könnyen eltávolítható

- Méretei pontosság: A szabványos tűrések többnyire +/- 0,005 hüvelykben vannak. Pontosabb lézervágási szolgáltatások szigorúbb specifikációkat is képesek betartani, ha szükséges, bár ez általában befolyásolja az árakat

- Felület állapota: A minőségi szolgáltatók védik az anyag felületét a kezelés során. Olyan alkatrészeket kell várni, amelyeken nincsenek karcolások, horpadások vagy kezelési nyomok a látható felületeken

A másodlagos műveletek meghosszabbítják az időkeretet. A szakmai fordulóidő-elemzések szerint sok alkatrész közvetlenül a befejező folyamatokba kerül – csavarozás, porfestés, polírozás vagy másodlagos megmunkálás. Még az egyszerű tevékenységek, mint a védőfólia felhelyezése is lelassíthatja a szállítást, ha kézzel végzik, vagy alvállalkozóra van szükség. Ezeknek a szakaszoknak a figyelembe vétele az egyik leggyakoribb hiba a fordulóidő becslésekor.

Az alkatrészek ellenőrzése a kézbesítéskor:

- Ellenőrizze a kritikus jellemzők méreti pontosságát csúszómérővel vagy passzív/működőképtelen sablonokkal

- Ellenőrizze az élek minőségét – a lézerrel vágott élek simák legyenek, túlzott salak- vagy megmunkálási maradványok nélkül

- Győződjön meg arról, hogy a mennyiség megegyezik a rendelésével

- Vizsgálja meg szállítási sérüléseket, mielőtt aláírná a kézbesítési nyugtát

- Próbaverje össze a kritikus szerkezeteket, ha az alkatrészek más, már meglévő komponensekhez kell illeszkedjenek

A legtöbb megbízható szolgáltató garanciát vállal munkájára, és újra gyártja azokat az alkatrészeket, amelyek nem felelnek meg a megállapodott specifikációknak. Rögzítsen minden problémát azonnal fényképekkel a kézhezvétel után – ez egyszerűsíti a megoldást, ha korrekcióra van szükség.

Miután teljes egészében megértette az átfogó munkafolyamatot, most már fel tudja vállalni a folyamat magabiztos kezelését. De hogyan ismerheti fel, hogy melyik szolgáltató tartja valóban be ezeket a minőségi ígéreteket? A képességek értékelése a megrendelés előtt megelőzi a költséges csalódásokat későbbi szakaszokban.

Hogyan válasszon megfelelő lézervágó szolgáltatót

Egy olyan fém lézeres vágószolgáltatás megtalálása, amely gyorsan kínálatot ad és pontosan vág, egyszerűnek tűnik – egészen addig, amíg rá nem jövünk, hogy hány vállalkozó ígér sokat, de keveset teljesít. A probléma? A szolgáltatók többsége felületesen nézve hasonló. Mindannyian ígérik a pontosságot, sebességet és versenyképes árakat. De hogyan különítheti el az igazán alkalmas gyártókat azoktól, akik hetekig hagyják várakozni Önt olyan alkatrészekre, amelyek mégsem illenek pontosan?

A Steelway Laser Cutting szolgáltatói útmutatója szerint a megfelelő partnerrel való együttműködéshez konkrét képességekre vonatkozó célzott kérdéseket kell feltenni – nem pedig homályos biztosítékokat elfogadni. Nézzük meg részletesen, mit érdemes figyelembe venni a projekt átadása előtt.

Értékelendő kulcsfontosságú képességek

Amikor egy 'lézervágó közel hozzám' kifejezést használva keres, vagy online szolgáltatókat hasonlít össze, ezek a szempontok választják el a profi műhelyeket azoktól, amelyek nehezen birkóznak meg az Ön igényeivel:

- Felszerelések minősége és technológiai típusok: Milyen lézerrendszerekkel rendelkezik a műhely? Egy száltechnológiát használó lemezvágó lézer másképp kezeli a fémeket, mint a szerves anyagokhoz készült CO2-es rendszerek. Érdeklődjön konkrétan a gépek márkájáról, teljesítményéről és arról, mikor frissítették utoljára a berendezéseket. A szakmai irányelvek szerint a legjobb fém lézervágó szolgáltatók honlapjukon részletesen közlik ezt az információt, így azonnal tudhatja, hogy képesek-e kezelni az Ön specifikációit

- Anyagválaszték és vastagságkezelési lehetőségek: Képesek feldolgozni az Ön által megadott anyagot a szükséges vastagságban? Az alumínium lézervágása más képességeket igényel, mint az acélé. Győződjön meg róla, hogy rendelkezésre áll – vagy gyorsan beszerezhető – az Ön által szükséges ötvözet és lemezvastagság. Az a szolgáltató, amely csőlézervágási szolgáltatást is kínál, kiterjeszti a tervezési lehetőségeit a lapos lemezek határán túlra

- Teljesítési határidőre vonatkozó garanciák: Vállalja a bolt az adott szállítási időszakot? A homályos „általában néhány héten belül kerül kiszállításra” válaszok potenciális ütemezési kaosszal járhatnak. A professzionális CNC lézeres vágószolgáltatások konkrét határidőket közölnek, és proaktívan kommunikálnak, ha probléma merül fel

- Minőségi tanúsítványok: Az ISO 9001 alapminőség-irányítási rendszert határoz meg. Gépjárműipari alkalmazások esetén IATF 16949 tanúsítvány jelentősen magasabb szintet képvisel – ez a gépjárműgyártás és -kiszolgáló alkatrészek globálisan elismert minőségirányítási rendszere. Ezzel a tanúsítvánnyal rendelkező vállalatok igazolják dokumentált folyamataikat, folyamatos fejlesztési protokolljaikat és ellátási lánc-kockázat-kezelésüket, amelyek gyakran hiányoznak az általános gyártóktól

- DFM-támogatás elérhetősége: Nyújt-e a szolgáltató gyártásra való tervezési visszajelzést? A tapasztalt gyártók felfedezik a költséges tervezési hibákat még a megmunkálás megkezdése előtt. Ez az iránymutatás gyakran több pénzt takarít meg, mint bármilyen áralku – azonosítja a felesleges bonyolultságot, anyagváltási lehetőségeket javasol, vagy figyelmeztet a toleranciaspecifikációkra, amelyek növelik a költségeket anélkül, hogy funkcionális előnyt jelentenének

- Kommunikációs reakcióidő: Milyen gyorsan válaszolnak az árajánlatkérésekre? A megmunkálási iparág legjobb gyakorlatai szerint egy lézeres vágó szolgáltató azonnal képes lehet becsült árat közölni, de ha részletes kérdésekre órákon belül, nem pedig napokon belül kap választ, az jelzi, hogyan kommunikálnak majd a teljes gyártási folyamat során

Olyan autóipari alkalmazásoknál, ahol a lézeres vágás kiegészíti az alakító műveleteket, ezek a tényezők még fontosabbá válnak. A futómű-csavarok, felfüggesztési pontok és szerkezeti alkatrészek tanúsított minőségirányítási rendszereket és gyors iterációs képességet igényelnek. Olyan gyártók, mint Shaoyi (Ningbo) Metal Technology bemutatja, mit kell keresni: IATF 16949 tanúsítvány, átfogó DFM támogatás, 12 órás árajánlat-készítési idő és 5 napos gyors prototípuskészítés, amely felgyorsítja a fejlesztési ciklusokat.

Miért fontosak a gyors prototípuskészítési képességek

Íme egy dolog, amit sok vevő addig figyelmen kívül hagy, amíg problémává nem válik: milyen gyorsan tudja a beszállító elkészíteni a prototípusalkatrészeket?

A termékfejlesztés ritkán halad egyenes vonalban. Tervez, prototípust készít, tesztel, problémákat talál, újra tervez, majd ismét prototípust készít. Minden iterációs ciklus, amely heteket vesz igénybe napok helyett, meghosszabbítja a piacra kerülési időt – és lehetővé teszi a versenytársak számára, hogy felzárkózzanak.

A lézeres csővágó szolgáltatások és síklemez-feldolgozási kapacitások, amelyek támogatják a gyors prototípuskészítést, több előnnyel is járnak:

- Gyorsabb tervezési érvényesítés: Fizikai alkatrészek kézhez vétele napokon belül, hetek helyett, lehetővé teszi a mérnökök számára, hogy ellenőrizzék az illeszkedést, formát és funkciót, mielőtt gyártószerkezetekbe fektetnének

- Alacsonyabb iterációs költségek: A gyors átfutási idő azt jelenti, hogy korán észreveszik a problémákat, amikor a módosítások költsége alacsony. Egy tervezési hiba felfedezése a termelési szerszámok elkészülte után drasztikusan megnöveli a javítási költségeket

- Versenyképes rugalmasság: Amikor a piaci lehetőségek rövidek, az idő számít. Azok a szolgáltatók, amelyek 5 napos prototípuskészítést kínálnak, olyan fejlesztési időt rövidítenek le, amit a hagyományos vállalkozások hónapokra nyújtanak ki

Amikor lézeres fémvágó szolgáltatásokat értékel ki termékfejlesztéshez, kérdezzen konkrétan a prototípusok szállítási idejéről, külön a termelési ütemezéstől. Néhány vállalkozás kitűnő nagy volumenű sorozatgyártásban, de nehézségei vannak a prototípuskészítéshez szükséges gyors átfutási idő rugalmasságával

Figyelmeztető jelek szolgáltató kiválasztásakor

Tudni, mit kell keresni, csak a feladat fele. A figyelmeztető jelek felismerése segít elkerülni az olyan partnerek kiválasztását, amelyek határidők kimaradásához, minőségi problémákhoz vagy költségtúllépéshez vezetnek

Legyen óvatos, ha a következőkkel találkozik:

- Pontatlan árazás projekt-specifikus adatok nélkül: A szakmai iránymutatás szerint óvatosan kell bánni az olyan lézeres vágószolgáltatókkal, amelyek a kezdetektől fogva alacsony, azonnali árral kínálnak előnyöket, de nem világosak az Ön specifikus lézeres vágási projektek pontos árával kapcsolatban. A megalapozott árajánlatokhoz elengedhetetlen az anyag, vastagság, mennyiség és bonyolultság ismerete.

- Képességek dokumentálatlansága: Ha egy vállalkozás nem tudja megadni lézereinek típusát, teljesítményszintjét vagy a maximálisan feldolgozható anyagvastagságot, akkor lehetséges, hogy hiányzik a szakértelme a nehéz feladatok kezeléséhez. A professzionális CNC lézeres vágószolgáltatások egyértelműen dokumentálják és közlik specifikációikat.

- Minőségi tanúsítványok hiánya: Pontossági alkalmazásokhoz – különösen az autóiparban vagy a repülésgyártásban – a tanúsítvánnyal nem rendelkező vállalkozások felesleges kockázatot jelentenek. Az ISO és IATF tanúsítványok megszerzése jelentős beruházást és folyamatos megfelelést igényel, ami az üzemeltetés komolyságát bizonyítja.

- Nem kínál DFM-visszajelzést: Azok a boltok, amelyek egyszerűen elkészítik bármit, amit küld, gyártási szempontból történő tervezési átvizsgálás nélkül, esetlegesen technikailag helyes alkatrészeket szállítanak, amelyek azonban nem úgy működnek, ahogyan szánták. A minőségi szolgáltatók mérnöki átvizsgálásba fektetnek be szolgáltatásaik részeként

- Gyenge kommunikációs minták: A lassú válaszok az idézési fázisban általában arra utalnak, hogy a termelési problémák fellépésekor is lassabb lesz a reakcióidő. Ha alapvető kérdésekre való válaszolás napokig tart, képzelje el az idegességet, amikor időfüggő szállításokra vár

- Nincsenek ügyfélreferenciák vagy ajánlások: A szolgáltató értékelési kritériumai , kérjen ajánlásokat más ügyfelektől, valamint érdeklődjön a fémlézeres vágókapacitások és azon technológia iránt, amely a szolgáltató szolgáltatásait meghajtja. Az ajánlások megadásának vonakodása a korábbi ügyféltapasztalatok problémáira utalhat

Szolgáltató alkalmasságának értékelése saját specifikus igényeihez

A „legjobb” szolgáltató kizárólag a projekt igényeitől függ. Egy olyan műhely, amely tökéletesen alkalmas nagy sorozatgyártásra, csalódást okozhat, ha rugalmas prototípusgyártásra van szüksége. Egy olyan szolgáltató, amely vékonyfalú díszítőmunkákban jeleskedik, nehezen boldogulhat szerkezeti alkatrészekkel, amelyek szigorú tűrésekhez kötöttek.

A döntés meghozatala előtt őszintén értékelje:

- Mennyiségi igényeit: Egyszeri prototípusokra, kis sorozatokra vagy folyamatos termelésre van szüksége? Illessze igényeit a műhely működési specialitásához

- Anyagspecializáció: Egyes szolgáltatók kizárólag fémekre koncentrálnak; mások vegyes anyagú projekteknél jeleskednek. Győződjön meg róla, hogy szakértelmük illeszkedik a vágandó anyaghoz

- Másodlagos műveleti igények: Ha alkatrészeinek hajlításra, hegesztésre, porfestésre vagy szerelvénybeszerelésre van szüksége, az integrált szolgáltatásokat nyújtó szolgáltatók leegyszerűsítik a logisztikát és csökkentik a kezelésből eredő sérülések kockázatát

- Földrajzi szempontok: Folyamatos kapcsolatok esetén a helyi szolgáltatók lehetővé teszik a helyszíni látogatásokat, gyorsabb szállítást és egyszerűbb kommunikációt. Egyszeri projektekhez az online lézeres vágószolgáltatások versenyelőnyt kínálhatnak a távolság ellenére.

A gyártási ipar ajánlásai szerint ideális esetben a fém lézeres vágás szolgáltatója évtizedek tapasztalattal rendelkezik, valamint a legfejlettebb lézeres vágó technológiával dolgozik, amely az összesféle lézeres vágási projekt kezelésére tervezett, korszerű létesítményekben áll rendelkezésre.

Az elején időt szánni a lehetséges szolgáltatók alapos értékelésére megakadályozza a frusztrációt, amit a projekt közben történő váltás okozhat. Néhány óra befektetése a gondos felmérésbe hetekig tartó késéseket és ezrekre rúgó pazarlást takarít meg, ha a rossz partner nem képes teljesíteni.

Miután meghatározta a szolgáltató-kiválasztási szempontokat, fontos megérteni, hogy a különböző iparágak hogyan alkalmazzák valójában a lézeres vágó technológiát, így saját projektek lehetőségei is jobban átláthatóvá válnak.

Gyakori alkalmazási területek lézeres vágó szolgáltatásokhoz

Valaha elgondolkodott már azon, hogy miért bukkan fel a lézeres megmunkálás egyre több iparágban? A kocsija futóművét tartó konzoloktól kezdve egy butik kirakatában lévő bonyolult ékszerig, a lézeres vágótechnológia több terméket érint, mint ahogy az emberek gondolnák. Az Accurl iparági elemzése szerint a lézeres vágótechnológia sokoldalúsága új lehetőségeket nyitott a gyártás, a kreativitás és a pontosság terén szinte minden termelési ágazatban.

Ezeknek a valós alkalmazásoknak a megértése segít felismerni a saját projektekhez kapcsolódó lehetőségeket – akár mérnök, aki járműipari alkatrészeket tervez, akár építész, aki dekoratív paneleket határoz meg, vagy akár egy hobbi-szinten saját darabokat gyártó szakember.

Ipari és autóipari alkalmazások

Amikor a legnagyobb pontosság és ismételhetőség a fontos, a lézeres vágás olyan eredményeket képes produkálni, amelyeket más módszerek nehezen tudnak utolérni. A nehézipar nap mint nap támaszkodik erre a technológiára olyan alkatrészek gyártásához, amelyeknek nehéz körülmények között kell megbízhatóan működniük.

Autóipari gyártás az egyik legnagyobb alkalmazási ágazat. Az iparági dokumentáció szerint a lézervágás kulcsfontosságú eszköz a bonyolult alkatrészek és a személyre szabott termékek gyártásához az autógyártásban. A lézeres fémvágó mindent feldolgoz:

- Alvázkonkolok és rögzítőlemezek: A szögek pontos elhelyezését és a méretmeghatározás következetes pontosságát igénylő szerkezeti alkatrészek több ezer egységben

- Felfüggesztési alkatrészekhez: A jármű biztonságának és kezelési teljesítményének biztosítása érdekében pontos előírásokat kell betartaniuk a alkatrészekre

- Belső díszítő alkatrészek: Ékszer elemek, amelyek kombinálják az esztétikai vonzerejet a funkcionális követelményekkel

- Hőpajzsok és védőburkolatok: Bonyolult formák, amelyek szorosan illeszkednek a motor alkatrészei köré

Mi teszi a lézeres vágást különösen értékesnek az autóipari alkalmazásokban? A technológia zökkenőmentesen integrálható a fémnyomtatási műveletekkel. A lézerrel vágott üres részek közvetlenül a formáláshoz használt nyomtatópreszekbe kerülnek, a lézeres vágás pedig a nyomtatás utáni befejezési műveleteket kezeli. Ez az integráció felgyorsítja a fejlesztési ciklusokat - a gyártók, mint például a Shaoyi (Ningbo) Metal Technology kihasználja az 5 napos gyors prototípusgyártási lehetőségeket, amelyek lézeres vágást és sajtolást kombinálnak, így hónapokig tartó folyamatokat hetekre sűrítenek.

Repülőgépgyártás még szigorúbb pontossági követelményeket támaszt. Az űr- és légiipari szakértők szerint a könnyű, nagy szilárdságú anyagok iránti igény felülmúlhatatlan. A rozsdamentes acél lézervágása olyan alkatrészeket eredményez, amelyek szigorú tűréshatárokat teljesítenek, miközben megőrzik a szerkezeti integritást – kritikus fontosságú, amikor minden alkatrész pontosan úgy kell működjön, ahogy tervezték, hiszen életek múlnak rajta.

Elektronika és házak egy további jelentős ipari alkalmazás:

- Szerver vázas és rackbe szerelhető tokok: Pontos szellőzési minták és csatlakozókivágások

- Vezérlőpanel-felületek: Tiszta nyílások kijelzők, kapcsolók és jelzők számára

- EMI-védettség: Vezetőképes házak, amelyek szoros tűrésekkel rendelkeznek az elektromágneses kompatibilitás érdekében

- Hűtőbordák rögzítőlemezei: Hőkezelési alkatrészek kritikus lyukelhelyezéssel

A rozsdamentes acél lézervágása minimális hődeformáció mellett ideálissá teszi ezt a technológiát olyan házak gyártásához, amelyek méretstabilitást kell hogy megőrizzék, miközben érzékeny elektronikát foglalnak magukba.

Építészeti és tájékoztató rendszerek alkalmazásai

Sétáljon végig bármely modern épületen, és lézervágott elemekbe ütközik – gyakran anélkül, hogy tudatában lenne. A építőipari dokumentációk szerint a lézervágás képessége arra, hogy vastag acéllapokon pontos vágásokat hozzon létre, nélkülözhetetlenné teszi a technológiát az építőiparban, így kombinálva szilárdságot és esztétikai vonzerőt, amelyet különösen keresnek a modern építészetben.

- Dekoratív homlokzati panelek: Bonyolult geometriai minták, amelyek az épületek homlokzatait műalkotásokká változtatják

- Magánéletvédelmi rácsok és helyiséghatárolók: Egyedi minták, amelyek a fényáteresztést a látványos elválasztással ötvözik

- Útmutató jelzés: Térdimenziós betűk és szimbólumok alumíniumból, acélból vagy akrilból vágva

- Lépcsőkorlátok és korlátok: Dekoratív fémalkotások, amelyek a biztonságot látványos megjelenéssel ötvözik

- Világítótestek: Összetett alakzatok, amelyek megvilágításkor jellegzetes árnyékmintákat hoznak létre

Az egyedi lézeres marás további dimenziót ad az építészeti alkalmazásokhoz. Logók, minták és textúrák gravírozhatók közvetlenül fém- vagy üvegfelületekre, így tartós védjegyek jönnek létre, amelyek évtizedekig ellenállnak a környezeti hatásoknak.

Kreatív és prototípusgyártási felhasználások

A lézervágás az ipari alkalmazásokon túl lehetővé tette a pontossági gyártást kreatív személyek, tervezők és termékfejlesztők számára is. Ami korábban drága szerszámozást és minimális rendelési mennyiséget igényelt, ma már bármilyen méretben elérhető.

Ékszerészet és díszítőművészet a lézervágás finom részletességű munka elvégzésére való képességét mutatja be. A szakmai források szerint az ékszeriparban a lézervágás pontossága egyszerű fémdarabból műalkotást varázsol, kiemelve a technológia és kreativitás ötvözetét a modern ékszertervezésben. A lézervágó képes kezelni:

- Bonyolult medálterveket: Olyan részleteket, amelyeket hagyományos fémmegmunkálással lehetetlen lenne elérni

- Egyedi monogramok és személyre szabott darabok: Egyszeri gyártású alkotások, szerszámberuházás nélkül

- Szereléshez szükséges alkatrészek: Pontosan illeszkedő elemek, amelyek tökéletesen passzolnak egymáshoz

Termékprototípus-készítés talán a legátalakítóbb alkalmazás új termékeket fejlesztő vállalkozások számára. A 3ERP prototípus-készítési útmutatója szerint a lemezlasergépelés lehetővé teszi bonyolult prototípusoktól kezdve nagy léptékű gyártási alkatrészekig minden elkészítését sebességgel, pontossággal és sokoldalúsággal.

Miért olyan fontos a gyors prototípuskészítés? Gondoljunk a termékfejlesztési ciklusra:

- Alakellenőrzés: A fizikai alkatrészek olyan illeszkedési problémákat tárhatnak fel, amelyeket a CAD modellek nem mutatnak

- Funkcionális tesztelés: Valódi anyagok valós körülmények között teszik láthatóvá a tervezési gyengeségeket

- Érdekelt felek jóváhagyása: A döntéshozók jobban reagálnak a fizikai mintákra, mint a renderelésekre

- Gyártásra való felkészültség: A korai prototípusok az eszközinverzió előtt azonosítják a gyártási kihívásokat

A műanyag alkatrészek lézeres vágása kiegészíti a fém prototípuskészítést – akrylházak, PETG fedelek és Delrin mechanikus alkatrészek mindegyike gyorsan prototípusként létrehozható CO2 lézeres technológiával.

Bajnok- és makeralalkalmazások robbanásszerűen nőttek, amikor egyre elérhetőbbek lettek a „lézeres marás szolgáltatásaim közelében” lehetőségek:

- RC járművek alkatrészei: Könnyű alumínium és szénrost alkatrészek

- Kosztümös páncél és kellékek: EVA hab és akryl elemek

- Egyedi szerszámok és sablonok: Pontos rögzítőkészülékek műhelyprojektekhez

- Művészeti telepítések: Összetett geometriai szobrok és falikompozíciók

- Makettezés: Építészeti modellek, diorámák és kiállítási darabok

A szakmai dokumentáció szerint a lézer-technológia alkalmazása kreatív területeken nemcsak kibővíti a lehetőségeket, hanem új médiumok és technikák feltárását is lehetővé teszi, tovább tolva azt, ami elérhetőnek tekinthető.

Alkalmazások és technológia összevetése

Különböző alkalmazások különböző lézertechnológiákat és szolgáltatási megközelítéseket részesítenek előnyben:

- Nagy volumenű gépjárműgyártás: Szál-lézeres vágási szolgáltatások minőségirányítási rendszerrel (ISO vagy IATF 16949 tanúsítvánnyal)

- Építészeti fémmunkák: Olyan szolgáltatók, akik másodlagos felületkezelést is nyújtanak, például porfestést vagy kefézett felületet

- Elektronikai házak: Olyan boltok, amelyek szűk tűréshatárok betartására képesek és hardverbeszerelési szolgáltatásokat is nyújtanak

- Ékszer és finom részletek: Pontos rendszerek vékony anyagokon kivitelezhető bonyolult mintákhoz

- Gyors prototípuskészítés: Gyors átfutást biztosító szolgáltatók, akik 5 nap vagy gyorsabb határidővel szállítanak

- Barkácsprojektek: Könnyen elérhető online szolgáltatások alacsony minimális rendelési mennyiséggel

Az a sokoldalúság, amely az ipari lézeres vágástól – például autócsomagtartó alkatrészekhez – egészen az egyedi lézergravírozásig terjed személyre szabott ajándékokhoz, bemutatja, miért vált ez a technológia elengedhetetlenné szinte minden gyártási szektorban. Akár tízezer tartót gyárt, akár egyetlen prototípust, a lézeres vágás pontosságot, ismételhetőséget és hozzáférhetőséget kínál, amire a hagyományos módszerek egyszerűen nem képesek.

Gyakran ismételt kérdések a lézervágó szolgáltatásokkal kapcsolatban

1. Mennyibe kerül a lézervágó szolgáltatás?

A lézeres vágási szolgáltatás költségei a gépóra, az anyag típusa, vastagsága és a tervezés bonyolultsága alapján változnak. A tipikus óradíjak 60–150 USD között mozognak. Az egyszerű geometriai vágások kevesebbe kerülnek, mint az összetett minták, mivel a bonyolultabb dizájnov több fúrási pont és lassabb vágási sebesség szükséges. A nagyobb mennyiségű megrendelés jelentősen csökkenti darabárban a költségeket, mivel a beállítási díjak több alkatrész között oszlanak el. Az online szolgáltatók gyakran az feltöltött CAD-fájlok alapján azonnali árajánlatot adnak, míg egyedi projektek esetén részletes becsléshez 12–24 óra szükséges lehet.

milyen gyakran kell karbantartani egy lézervágót?

A lézeres vágógépek karbantartási gyakorisága a használat intenzitásától és a feldolgozott anyagoktól függ. Műanyagok feldolgozása esetén az optikai elemeket és síneket minden 4–6 hetente tisztítani kell. Fa anyagok, például MDF vagy rétegelt lemez vágása esetén a karbantartási időszak 2–3 hétre rövidül a nagyobb lerakódás miatt. A szálas lézerek minimális karbantartást igényelnek a CO₂ rendszerekhez képest, mivel nincs gázkeverék vagy tükrök beállítása. A szakmai szolgáltatók általában szigorú karbantartási ütemtervet tartanak fenn a vágás minőségének állandó biztosítása érdekében.

3. Mennyibe kerül óránként a lézeres vágás?

A lézeres vágás óradíja általában 60–150 USD között mozog, a gép típusától, teljesítményszintjétől és a műhely költségeitől függően. A fémet feldolgozó szálas lézerek magasabb díjat szabhatnak ki, mint a szerves anyagokat vágó CO2 rendszerek. Azonban az óradíjak nem mondják el a teljes történetet – egy 100 USD/óra díjú, de gyorsabb gép kevesebbe kerülhet ugyanazért a munkáért, mint egy lassabb, 75 USD/óra díjú gép. A teljes projekt költségéhez hozzáadódnak az anyagköltségek, a beállítási díjak, valamint másodlagos műveletek, például a burkolás eltávolítása vagy porfestés.

4. Milyen fájlformátumokat fogadnak el a lézeres vágási szolgáltatások?

A legtöbb lézeres vágószolgáltatás vektoralapú formátumokat fogad el, beleértve a DXF, AI, SVG és PDF formátumokat. A DXF fájlok univerzálisan működnek minden CAD-programban, és kiváló pontosságot biztosítanak mechanikus alkatrészekhez. Az Adobe Illustrator fájlok megőrzik a rétegeket és az összetett útvonal-információkat, amelyek ideálisak kombinált vágáshoz és gravírozáshoz. Az SVG nyílt forráskódú kompatibilitást kínál ingyenes szoftverekkel, mint az Inkscape. Raszteres formátumok, például JPEG és PNG csak gravírozási műveletekhez használhatók – a vágáshoz vektoros útvonalak szükségesek, amelyek pontosan meghatározzák a vágási vonalakat.

5. Milyen anyagokat tudnak feldolgozni a lézeres vágószolgáltatások?

A lézeres vágás különféle anyagokat dolgozhat fel, attól függően, milyen típusú lézert használnak. A szálas lézerek kiemelkedően alkalmasak fémek, például acél, rozsdamentes acél, alumínium, réz, sárgaréz és titán vágására akár 19 mm vastagságig. A CO2 lézerek szerves anyagokat, mint fa, akril, bőr, textil és számos műanyag feldolgozására alkalmasak. Bizonyos anyagok azonban veszélyesek lézeres vágásnál – a PVC, a vinil és az ABS mérgező gázokat bocsát ki hevítés hatására. Az IATF 16949 minősítéssel rendelkező szolgáltatók, mint a Shaoyi Metal Technology, átfogó anyagválasztékot kínálnak dokumentált minőségi folyamatokkal, igényes autóipari alkalmazásokhoz.

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —

Kis szeletek, magas szabványok. Gyors prototípuskészítési szolgáltatásunk gyorsabbá és egyszerűbbé teszi az ellenőrzést —