Laser Cut Aluminum Panel Secrets: From Alloy Choice To Flawless Install

Understanding Laser Cut Aluminum Panels and Their Applications

Have you ever wondered how architects create those stunning geometric facades or how designers achieve impossibly intricate patterns in metal railings? The answer often lies in laser cut aluminum panels—precision-crafted sheets that have revolutionized modern fabrication across countless industries.

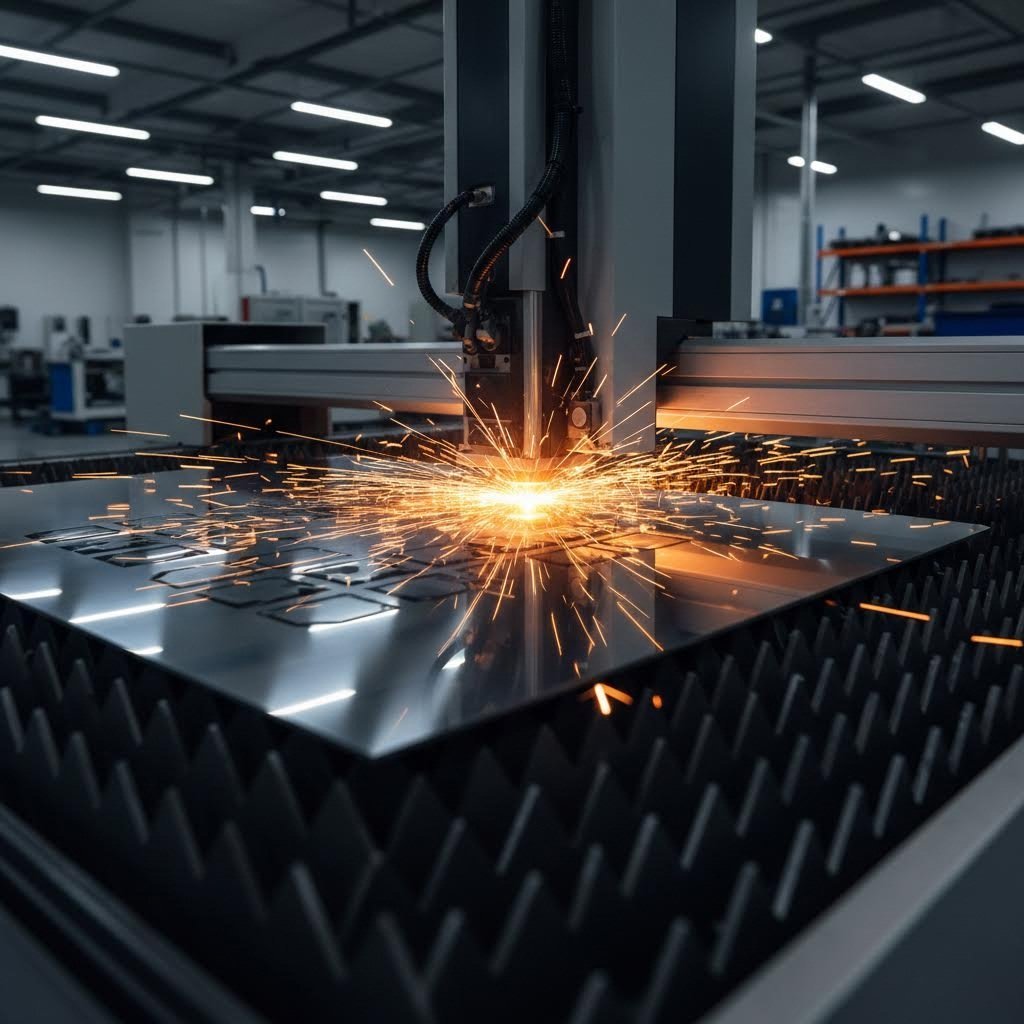

A laser cut aluminum panel is essentially an aluminum sheet that has been shaped using a high-powered laser beam to create precise cuts, patterns, or openings. Unlike traditional mechanical cutting methods, this technology uses focused light energy to melt, burn, or vaporize material along programmed paths. The result? Clean edges, complex geometries, and remarkable consistency that manual methods simply cannot match.

These panels have become indispensable in three primary sectors: architectural design, industrial manufacturing, and decorative applications. From privacy screens gracing urban balconies to ventilation covers in precision machinery, laser cut metal panels serve both functional and aesthetic purposes with equal effectiveness.

Precision Meets Versatility in Modern Fabrication

What makes aluminum laser cutting so transformative? Consider this: a laser cutter for metal can achieve tolerances as tight as 0.1mm while processing intricate designs that would take hours—or prove impossible—with traditional tools. This precision opens doors for designers and engineers who previously faced significant limitations.

Laser cut panels excel in applications requiring:

- Complex geometric patterns with consistent repeatability

- Fine details and tight tolerances impossible with punch presses or plasma cutters

- Minimal material distortion during the cutting process

- Clean, burr-free edges that often require little to no post-processing

Whether you're specifying components for an architectural facade or selecting decorative elements for interior design, understanding how these panels are made—and which materials work best—gives you a significant advantage in achieving your project goals.

From Raw Sheet to Finished Panel

The journey from a flat aluminum sheet to a finished laser cut aluminum panel involves careful material selection, precise file preparation, and skilled fabrication. Throughout this article, you'll discover vendor-neutral technical guidance covering everything from alloy specifications to installation best practices.

Aluminum has emerged as the preferred material for laser cut panels primarily due to its exceptional weight-to-strength ratio and natural corrosion resistance. These properties make it ideal for both indoor decorative applications and demanding outdoor architectural installations where durability matters.

This comprehensive resource will walk you through alloy selection criteria, thickness specifications, the complete manufacturing process, finishing options, and practical installation guidelines. Whether you're an architect specifying facade panels, a fabricator expanding your capabilities, or a homeowner exploring custom railing options, you'll find actionable information to guide your decisions.

Ready to dive deeper into the world of laser cut metal? Let's start by examining which aluminum alloys deliver the best results for your specific application.

Aluminum Alloy Selection Guide for Laser Cutting Projects

Choosing the right aluminum alloy for your laser cut aluminum panel project isn't just about picking whatever's available—it's about matching material properties to your specific performance requirements. With multiple alloy options on the market, understanding their distinct characteristics can mean the difference between a panel that performs flawlessly for decades and one that fails prematurely.

Let's break down the four most commonly specified alloys for laser cutting applications: 5052, 6061, 3003, and 7075. Each brings unique advantages depending on whether you prioritize corrosion resistance, structural strength, formability, or cost efficiency.

Why 5052 H32 Dominates Panel Applications

When fabricators and architects specify aluminum for decorative panels, privacy screens, or architectural facades, 5052 aluminum consistently emerges as the top choice. Why does this particular alloy dominate the market?

The 5052 aluminum properties make it exceptionally versatile. This alloy contains magnesium and chromium additions that deliver superior corrosion resistance—critical for outdoor applications exposed to rain, humidity, and even salt air. The H32 temper designation indicates that 5052-H32 has been strain-hardened and then stabilized, giving it enough ductility for cold working operations like bending without cracking.

Here's what makes 5052 sheet particularly attractive for laser cut panels:

- Excellent weldability: Panels requiring assembly or mounting hardware can be welded without compromising structural integrity

- Outstanding formability: Complex bends and curves are achievable without material failure

- Superior corrosion resistance: Performs exceptionally well in marine and outdoor environments

- Cost-effective: Delivers high performance at a reasonable price point compared to aerospace-grade alloys

For decorative railing panels, garden screens, or facade elements, aluminum 5052 provides the ideal balance of workability and durability. Its availability in thicknesses ranging from 0.040" to 0.500" means you can source 5052 aluminum plate for structural applications or thinner gauges for lightweight decorative pieces.

Matching Alloy Properties to Project Requirements

While 5052 H32 handles most general-purpose applications beautifully, certain projects demand different material characteristics. Structural components requiring maximum strength might call for 6061 or 7075, while budget-conscious projects with minimal performance demands could use 3003.

The following comparison table provides a quick reference for selecting the right alloy based on your project priorities:

| Alloy Grade | Corrosion Resistance | Formability | Weldability | Typical Applications | Laser Cutting Suitability |

|---|---|---|---|---|---|

| 3003 | Good | Excellent | Excellent | General sheet metal, HVAC components, cookware | Good - softer material, clean cuts |

| 5052 H32 | Excellent | Very Good | Excellent | Marine applications, decorative panels, architectural facades, fuel tanks | Excellent - optimal for most panel applications |

| 6061 T6 | Good | Moderate | Good | Structural components, aircraft frames, bridges, machinery parts | Very Good - heat-treated strength with clean edges |

| 7075 T6 | Moderate | Poor | Poor | Aerospace components, high-performance bicycle frames, sporting equipment | Good - requires careful parameter control |

Notice how 6061 T6 aluminum offers approximately 32% higher ultimate strength than 5052, making it ideal for load-bearing structural applications. The heat treatment process gives 6061 enhanced tensile and fatigue strength, which is why you'll find it in aircraft frames and bridge components. However, this strength comes at a cost—6061 requires larger bend radii and special tooling, making it less practical for designs requiring tight curves.

At the top of the strength spectrum sits 7075 T6, with nearly twice the tensile strength of 6061. This aerospace-grade alloy contains significant amounts of zinc, magnesium, and copper, delivering durability closer to titanium than standard aluminum. The tradeoff? It's essentially non-weldable and nearly impossible to bend at typical sheet metal radii, limiting its use to individual high-strength components rather than fabricated assemblies.

When evaluating alloys for your laser cut aluminum panel project, consider these density and strength implications:

- Weight-critical applications: All aluminum alloys share similar density (~2.7 g/cm³), but higher-strength alloys like 7075 allow thinner material for equivalent structural performance

- Structural panels: Yield strength directly impacts how much load a panel can support; 6061 and 7075 excel where structural integrity matters most

- Decorative applications: When appearance trumps structural demands, 5052's superior corrosion resistance and formability make it the practical choice

Understanding these material characteristics empowers you to specify the right alloy from the start—avoiding costly redesigns or premature panel failures. Now that you know which alloys perform best for different applications, let's examine how material thickness affects both cut quality and structural capability.

Material Thickness and Gauge Specifications Explained

Ever picked up two aluminum sheets that looked identical but felt completely different in your hands? That difference likely comes down to gauge—a specification that determines not just weight and rigidity, but also what's possible in terms of laser cutting complexity and structural performance.

When specifying 5052 aluminum sheet metal for your project, understanding the gauge system becomes essential. Here's the counterintuitive twist that trips up many newcomers: larger gauge numbers actually indicate thinner material. This backwards logic traces back to 19th-century metalworking practices, where gauge measured the number of drawing operations rather than a direct thickness measurement.

Standard Gauge Options and Their Ideal Uses

The American Wire Gauge (AWG) system—also called Brown & Sharpe gauge—serves as the definitive standard for aluminum and other non-ferrous metals. Each gauge corresponds to a specific thickness, weight, and set of practical applications. Selecting the wrong gauge can compromise either structural integrity or aesthetic refinement, depending on which direction you miss.

Here are the most commonly specified gauges for laser cut aluminum panel applications:

- 22 Gauge (0.025" / 0.64mm): Ultra-lightweight decorative elements, ornamental wall art, and intricate patterns where structural demands are minimal

- 20 Gauge (0.032" / 0.81mm): Light-duty signage, decorative accents, and indoor applications requiring fine detail work

- 18 Gauge (0.040" / 1.02mm): General-purpose decorative panels, HVAC covers, and moderate-weight applications balancing detail capability with durability

- 16 Gauge (0.051" / 1.29mm): Popular choice for railing infill panels, privacy screens, and architectural elements requiring enhanced rigidity

- 14 Gauge (0.064" / 1.63mm): Structural decorative panels, outdoor screens, and applications demanding significant wind load resistance

- 11 Gauge (0.091" / 2.30mm): Heavy-duty structural panels, industrial guards, and load-bearing architectural elements

When sourcing 5052 h32 aluminum for decorative screens or railing panels, 16 gauge aluminium sheet consistently emerges as the sweet spot. This thickness delivers enough rigidity to prevent oil-canning (that wavy distortion you see in thin panels) while remaining light enough for practical installation. A 16-gauge 5052 h32 aluminum sheet weighs approximately 0.715 lbs/ft²—manageable for most mounting systems while providing solid structural performance.

For projects requiring slightly heavier material, 063 aluminum sheet (roughly 14 gauge at 0.063" thickness) offers increased durability for outdoor installations exposed to wind loads or occasional impacts. The alum 5052 h32 temper designation ensures this thicker material still maintains adequate formability for bending mounting flanges or creating dimensional profiles.

Thickness Limitations in Laser Cutting

Material thickness doesn't just affect structural performance—it fundamentally changes what's achievable during the laser cutting process itself. Understanding these relationships helps you specify designs that are actually manufacturable.

According to industry specifications, fiber lasers effectively cut aluminum ranging from 0.5mm to approximately 25mm, though most decorative panel applications fall well within the thinner end of this spectrum. Here's how thickness impacts your project:

Cut Quality and Edge Finish: Thinner materials (22-18 gauge) produce exceptionally clean edges with minimal heat-affected zones. As thickness increases beyond 6mm, edge quality typically decreases unless operators slow cutting speeds and increase laser power—adding cost and processing time. For aluminum 5052 h32 panels destined for visible architectural applications, staying within the 16-14 gauge range optimizes both edge quality and structural performance.

Design Complexity: The relationship between material thickness and achievable detail follows a simple rule—thinner stock allows finer features. Minimum cut width (kerf) typically runs 0.2-0.4mm for thin aluminum, meaning intricate patterns with tight spacing become impossible as material thickness increases. If your design includes delicate filigree work, specify lighter gauges; if structural demands require heavier stock, simplify pattern complexity accordingly.

Heat-Affected Zone (HAZ) Considerations: Aluminum's high thermal conductivity rapidly disperses heat from the cutting zone. While this property helps minimize distortion, thicker materials retain more heat energy, potentially affecting temper in the immediate cut area. For 5052 h32 aluminum sheet applications where post-cutting bending is required, consider how HAZ might influence formability near cut edges.

Sheet Size and Cutting Capabilities: Most industrial laser cutting systems accommodate standard aluminum sheet sizes of 4' × 8' (1.2m × 2.4m) or 5' × 10' (1.5m × 3m). Larger machines can process oversized panels, but availability and pricing vary significantly. When designing panels that approach maximum sheet dimensions, consider how thickness affects material handling—a full-size 11-gauge aluminum sheet becomes substantially more difficult to position and process than the same dimensions in 18 gauge.

For railing infill panels and decorative screens, these thickness considerations directly impact both visual appeal and long-term performance. A panel that's too thin will flex noticeably when touched or buffeted by wind; one that's too thick adds unnecessary weight to your structure while potentially limiting design intricacy. The 5052 h32 aluminum sheet in 16 or 14 gauge typically provides the optimal balance for most architectural and decorative applications.

With gauge specifications and thickness limitations now clear, let's examine the complete manufacturing process—from your initial design file through final quality inspection.

The Complete Laser Cutting Process for Aluminum Panels

You've selected your alloy and specified the perfect gauge—now what? The journey from concept to finished laser cut aluminum panel involves several critical stages that many service providers assume you already understand. Sounds complex? It doesn't have to be. Breaking down the manufacturing process reveals clear steps where informed decisions directly impact your final results.

Whether you're submitting files for the first time or looking to optimize your workflow, understanding each phase helps you avoid costly rejections, reduce revision cycles, and achieve panels that match your exact specifications.

Design File Preparation and Format Requirements

Here's a truth that surprises many first-time buyers: a laser that cuts metal can only follow precise vector paths—not images. That stunning pattern you've created in Photoshop? It won't work. Laser cutting of metal sheets requires vector-based files where every line represents a defined cutting path the machine can trace.

According to American Laser Cutter, the most critical step is submitting proper vector files. Accepted formats include:

- AI (Adobe Illustrator): Industry standard for complex designs with multiple cut and engrave layers

- DXF (AutoCAD): Ideal for technical drawings and CAD-generated designs

- PDF (vector-exported only): Acceptable when properly exported from vector software—not saved from raster images

Raster formats like JPEG, PNG, or TIFF cannot be used for cutting because they're composed of pixels rather than mathematical paths. Even a high-resolution image that appears sharp on screen offers nothing a laser sheet metal cutter can follow.

Before submitting your design, run through this essential checklist:

- Convert all text to outlines: Fonts must be converted to vector shapes so the cutter reads them as geometry, not editable text that might display incorrectly

- Use consistent line colors and weights: Typically red indicates cut lines and blue designates engrave areas—check with your fabricator for their specific conventions

- Remove duplicates and hidden geometry: Overlapping lines cause double cuts that damage material and waste time

- Verify scale and dimensions: Always design at 1:1 scale (actual size) and confirm whether your fabricator expects inches or millimeters

- Ensure closed paths: Open vector paths result in incomplete cuts—every shape must form a closed loop

One often-overlooked detail involves kerf width—the material removed by the laser beam itself. This cut width typically measures 0.2-0.4mm for aluminum, which means your finished dimensions will differ slightly from drawn dimensions. For precision-critical applications, experienced designers offset cut lines by half the kerf width to maintain exact final measurements. When designing interlocking components or panels that must align precisely, ignoring kerf compensation leads to parts that don't quite fit.

From Vector Art to Precision Cuts

Once your files are properly prepared, understanding the complete manufacturing workflow helps you anticipate timelines and identify where specifications matter most. A laser cutting machine aluminum processes your design through distinct phases, each affecting final quality.

- Design Creation: Develop your pattern using vector software like Adobe Illustrator, AutoCAD, or similar programs. Complex curves should be simplified to reduce unnecessary anchor points that slow processing and potentially overheat materials. According to Eagle Metalcraft, excessive small nodes or micro details can cause quality issues.

- File Optimization: Clean up geometry by removing duplicate lines, closing open paths, and organizing layers. Specify which lines are cuts versus engraves using your fabricator's color conventions. For laser cut sheet metal projects, verify minimum spacing between cut lines—generally at least twice the material thickness to prevent distortion.

- Material Selection: Your fabricator pulls the specified alloy (typically 5052 H32 for decorative panels) in the requested gauge. Material must be flat with deviations under 0.1mm per meter for accurate results. Warped or bowed aluminum leads to alignment issues and inconsistent cuts.

- Laser Cutting: The sheet loads onto the cutting bed, and high-powered fiber lasers trace your design paths. Cutting parameters—power, speed, and assist gas pressure—are calibrated for your specific alloy and thickness. Laser cutting metal sheet generates intense localized heat that the beam's narrow focus contains to the immediate cut area.

- Quality Inspection: Finished panels undergo dimensional verification and visual inspection. Fabricators check edge quality, confirm tolerances (typically ±0.1mm for precision work), and identify any defects from the cutting process.

- Finishing: Depending on specifications, panels may proceed to secondary operations like deburring, bending, anodizing, or powder coating before final packaging and shipment.

Understanding how heat affects your laser cut metal sheets proves particularly important for aluminum panels. The heat-affected zone (HAZ) describes the material immediately adjacent to cut edges where high temperatures alter microstructure and mechanical properties. While aluminum's excellent thermal conductivity quickly disperses heat—minimizing HAZ width compared to steel—the effect still deserves consideration.

For decorative panels, HAZ typically remains cosmetically invisible and structurally insignificant. However, if your design requires post-cutting operations like bending near cut edges or welding attachment points, the altered material in the HAZ may behave differently than the parent metal. Fabricators can adjust laser parameters—slower speeds, pulsed cutting modes, or nitrogen assist gas—to minimize HAZ when critical applications demand it.

Common file preparation mistakes that cause rejections include submitting photos or logos saved as PDF (still raster inside), forgetting to outline text, misaligned layers, artwork with embedded images instead of paths, and overlapping duplicate lines on shared edges. Catching these issues before submission saves significant time and revision costs.

With your panels now cut to specification, the next consideration involves how different finishing options affect both appearance and long-term durability.

Design Applications From Railings to Decorative Wall Art

Imagine walking up to a building where sunlight filters through intricate geometric patterns, casting ever-changing shadows across the entryway. Or picture a residential balcony transformed by a privacy screen featuring delicate botanical silhouettes. These aren't architectural fantasies—they're everyday applications of laser cut decorative metal panels that blend artistry with functionality.

The versatility of a laser cut aluminum panel extends far beyond simple utility. From statement-making facade elements to subtle interior accents, these precision-crafted pieces serve purposes that traditional materials simply cannot achieve. Let's explore the applications reshaping how designers, architects, and homeowners approach both indoor and outdoor spaces.

Architectural Privacy Screens and Facade Elements

According to Viva Railings, metal screen facades have become increasingly popular in modern architecture because they accomplish multiple objectives simultaneously—improving aesthetics, controlling sunlight, and increasing privacy while acting as protective barriers against weather.

Laser cut screens excel in exterior applications where traditional solid barriers would create unwanted visual heaviness or block natural light entirely. Consider how the Sterling Park Safety Center uses perforated metal panel systems to enclose exterior staircases—from inside, the detailed perforations create a sense of motion, while from outside, they add dynamic visual interest to the building's facade.

Weather resistance becomes a critical consideration for outdoor installations. This is precisely why 5052 aluminum dominates architectural facade applications—its natural corrosion resistance handles rain, humidity, and even coastal salt air without degradation. When properly finished with powder coating or anodizing, laser cut metal screens maintain their appearance for decades with minimal maintenance.

Sun control represents another powerful application. At facilities like Braintree South Middle School, varied perforations allow sunlight to filter into building interiors without creating blinding glare. As the sun moves throughout the day, the patterns shift, creating what designers call an "ever-changing sun scape" that brings buildings to life.

Railing Infill Panels That Transform Spaces

Perhaps no application showcases laser cut metal art better than railing infill panels. These functional elements protect stairways, balconies, and decks while serving as opportunities for creative expression that traditional balusters cannot match.

The Kerrie Kelly x Feeney LaserCut Collection exemplifies this trend, offering nine intricate panel designs inspired by architectural icons, global textures, and timeless patterns. Designed for both indoor and outdoor applications, these metal railing panels empower architects, builders, and designers to elevate spaces effortlessly.

Wildlife and nature-inspired designs have proven particularly popular for residential railing applications. Imagine metal cut out designs featuring:

- Delicate leaf patterns that echo surrounding landscaping

- Mountain silhouettes for properties with scenic views

- Geometric abstractions that complement modern architecture

- Wildlife scenes—birds, deer, or fish—that connect interiors with natural settings

Railing infill panels must meet specific building codes regarding opening sizes and structural requirements, making material selection and gauge specification critical. The combination of precision laser cutting with appropriately specified aluminum alloys ensures panels that satisfy both aesthetic ambitions and safety regulations.

Applications by Sector

The breadth of laser cut aluminum panel applications becomes clearer when organized by market sector. Each environment presents unique requirements and opportunities.

Residential Applications:

- Railings and balustrades: Custom infill panels for decks, staircases, and balconies that reflect personal style

- Garden screens and fencing: Privacy barriers that filter light and add visual interest to outdoor living spaces

- Wall decor: Laser cut metal wall decor pieces ranging from small accent art to dramatic full-wall installations

- Room dividers: Freestanding or suspended screens that define spaces without blocking light flow

Commercial Applications:

- Facade panels: Building-scale installations that control sunlight, add branding opportunities, and create distinctive exteriors

- Signage: Dimensional logos and wayfinding elements with clean edges and professional finish

- Room dividers: Acoustic and visual separation in open-plan offices, restaurants, and hospitality venues

- Canopy systems: Overhead shade structures with custom perforations for filtered light effects

Industrial Applications:

- Ventilation covers: Protective grilles that allow airflow while preventing debris or finger access

- Machine guards: Safety enclosures that provide visibility while protecting operators from moving components

- Equipment screening: Aesthetic covers for HVAC units, utility areas, and mechanical rooms

- Walkway barriers: Separation between pedestrian and vehicle areas with both safety and wayfinding functions

Indoor Versus Outdoor Considerations

While the same laser cut metal screens might work beautifully in both environments, material selection and finishing requirements differ significantly based on exposure conditions.

Indoor installations enjoy protection from UV exposure, precipitation, and temperature extremes. This expanded flexibility allows for thinner gauges, broader finish options, and even more delicate pattern designs. Laser cut metal wall decor for interior spaces can incorporate intricate details that would prove impractical outdoors.

Outdoor applications demand more robust specifications:

- Material selection: 5052 aluminum provides superior corrosion resistance essential for exterior longevity

- Gauge requirements: Heavier gauges (14-16) resist wind loads and accidental impacts better than decorative-weight material

- Finish durability: Powder coating or anodizing protects against UV degradation and moisture penetration

- Mounting considerations: Thermal expansion requires appropriate fastening systems and spacing

Interior panels also offer acoustic benefits that exterior installations cannot provide. Perforated metal panels installed on ceilings help control sound reverberation while concealing unsightly mechanical elements. This dual functionality makes laser cut aluminum panels particularly valuable in restaurants, offices, and public spaces where noise management matters.

The creative possibilities continue expanding as designers push boundaries with custom imagery. FotoFacade systems, for instance, use halftone dot patterns to recreate photographs or graphics on metal surfaces—transforming functional panels into genuine art installations that serve practical purposes while making powerful visual statements.

With applications ranging from subtle decorative accents to building-defining architectural elements, the next consideration involves how post-processing and finishing options enhance both appearance and durability.

Post-Processing and Finishing Options for Aluminum Panels

Your laser cut aluminum panel emerges from the cutter with clean edges and precise geometry—but that's rarely the end of the story. The finishing process you select determines not just how your panel looks, but how it performs over years of service. Whether you need vibrant color matching for a branded installation or maximum corrosion resistance for coastal exposure, understanding your options empowers better decisions.

Think of finishing as the protective armor that shields your investment. Raw aluminum cut surfaces, while initially clean, remain vulnerable to oxidation, scratching, and environmental degradation. The right finish transforms a functional panel into a durable, visually refined element that maintains its appearance through decades of use.

Surface Finishing Options That Enhance Durability

When it comes to aluminium laser cutting projects, four primary finishing methods dominate the market. Each offers distinct advantages depending on your application requirements, budget constraints, and aesthetic goals.

Anodizing stands apart as more than a simple coating—it's an electrochemical conversion process that transforms the aluminum surface into aluminum oxide, creating a layer that's integral to the metal itself rather than sitting on top. According to PTSMAKE's finishing guide, this anodic layer can rank just below diamond on the Mohs hardness scale for Type III hardcoat applications. The process creates a porous surface that accepts dyes, allowing for vibrant, fade-resistant colors that become part of the metal.

For laser cutting aluminum applications destined for architectural facades or marine environments, anodizing typically adds 5% to 15% to total part cost but delivers exceptional value through extended service life. Type II anodizing creates decorative finishes in thicknesses of 0.0002" to 0.001", while Type III hardcoat anodizing exceeds 0.001" for maximum wear resistance.

Powder coating offers broader versatility across materials and color options. This process electrostatically applies dry powder particles that are then heat-cured into a durable finish. Unlike anodizing, powder coating works on virtually any metal substrate and provides thicker protective layers—typically 2-6 mils compared to anodizing's thinner films.

The tradeoffs? Powder coating sits on the surface rather than integrating with it, making it more susceptible to chipping under severe impact. However, it excels at hiding minor surface imperfections and offers essentially unlimited color matching capabilities, including metallics, textures, and custom RAL specifications.

Brushed finishes create directional grain patterns through mechanical abrasion, delivering a sophisticated industrial aesthetic popular in modern architectural applications. This process doesn't add protective coating but can be combined with clear anodizing for durability.

Mill finish refers to aluminum in its as-manufactured state—clean but uncoated. While economical, mill finish cut aluminum provides minimal protection and typically suits only indoor applications or situations where panels receive subsequent finishing elsewhere.

Color and Texture Customization Methods

The following comparison helps match finishing methods to specific project requirements:

| Finish Type | Durability Rating | Color Options | Cost Level | Best Applications |

|---|---|---|---|---|

| Type II Anodizing | Excellent (10-20 years) | Wide range, dye-based | Medium | Decorative panels, signage, consumer products |

| Type III Hardcoat Anodizing | Superior (20+ years) | Limited (gray/black tones) | High | Industrial guards, aerospace, high-wear applications |

| Powder Coating | Very Good (15-20 years) | Unlimited, custom matching | Medium-High | Architectural facades, outdoor furniture, branded elements |

| Brushed + Clear Coat | Good (5-10 years) | Natural metallic only | Low-Medium | Interior design, modern industrial aesthetic |

| Mill Finish | Fair (variable) | Natural aluminum only | Lowest | Interior panels, temporary installations, pre-finishing |

Edge quality considerations deserve special attention when selecting finishes. Laser-cut edges on aluminum cut panels typically emerge clean and oxide-free, but different finishes interact with these edges differently. Anodizing builds up uniformly on cut edges, sometimes creating slightly different coloration where the oxide layer meets exposed grain structure. Powder coating tends to be thinner on sharp edges—a phenomenon called "edge pull-back"—which can leave these areas more vulnerable to corrosion over time.

For panels where edge appearance matters, request edge-breaking or light deburring before finishing. This slight radius allows coatings to adhere more uniformly and prevents the thin coverage that sharp corners experience.

Welding and Fabrication Considerations

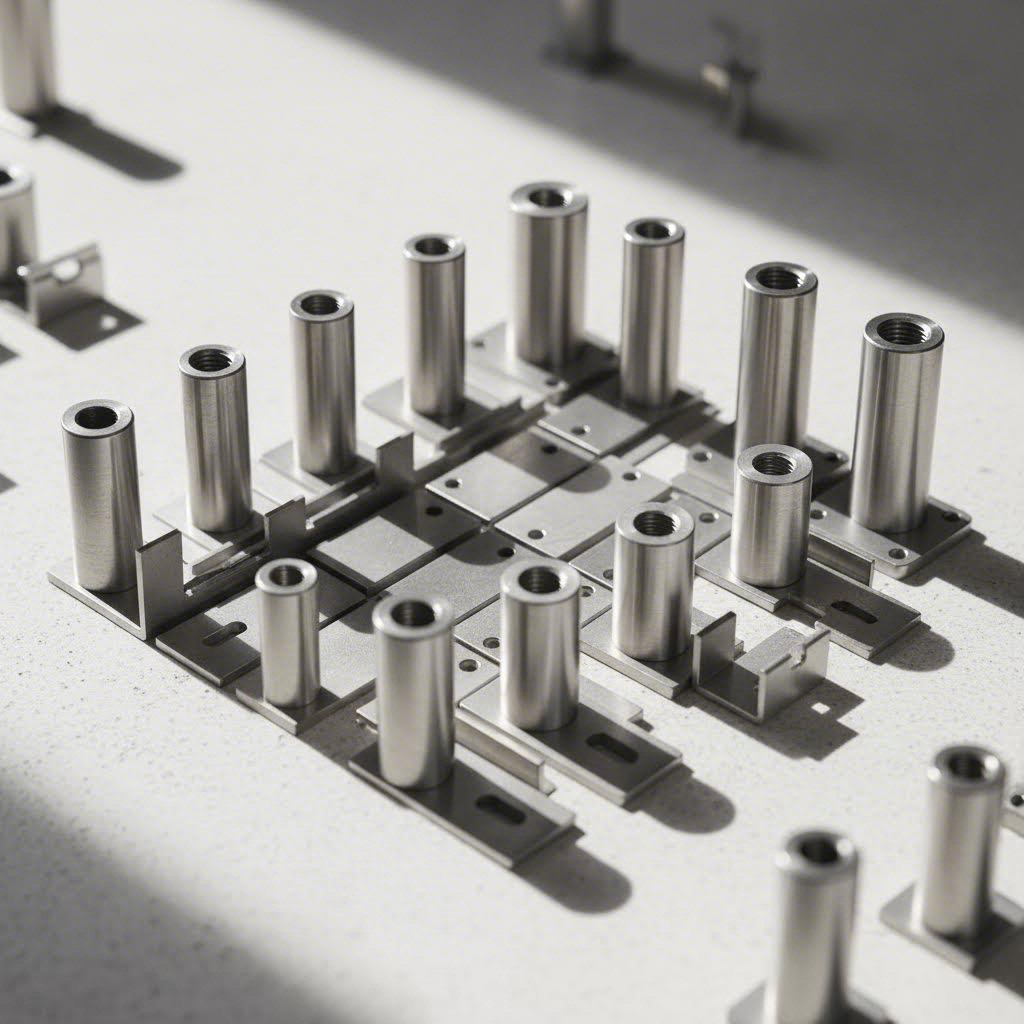

Many laser cut aluminum panel projects require assembly—whether attaching mounting hardware, joining multiple sections, or integrating structural elements. When welding 5052 aluminum, certain considerations ensure strong, reliable joints.

The 5052 alloy responds well to both MIG and TIG welding processes. According to SendCutSend's material guide, proper surface preparation is essential: abrade the surface to remove the oxide layer and ensure both the work area and shielding gas remain completely dry. Recommended filler metals include 1100, 4043 (most crack-tolerant), and 4047.

Bending 5052 aluminum for mounting flanges or dimensional profiles works reliably thanks to the H32 temper's balance of strength and ductility. The alloy's thermal conductivity helps distribute heat during welding, reducing warpage compared to materials where heat stays localized and causes uneven expansion.

When panels require welded attachments, plan finishing sequences carefully. Anodizing after welding produces the most consistent appearance, as the process treats both parent material and weld zones uniformly. Powder coating applied post-welding covers any discoloration from the welding process while providing uniform protection across the entire assembly.

With finishing options now clear, understanding how to properly mount and install your panels ensures long-term performance matches your investment in quality materials and finishes.

Installation Guidelines and Structural Requirements

You've invested in beautifully finished laser cut aluminium panels—now comes the moment of truth. How you mount these pieces determines whether they'll perform flawlessly for decades or develop problems within months. Proper installation isn't just about aesthetics; it's about structural integrity, code compliance, and accounting for the physical forces your panels will encounter.

Whether you're installing a railing panel on a residential deck, mounting decorative wall art in a commercial lobby, or positioning freestanding privacy screens in a garden, each application demands specific hardware and techniques. Let's explore what successful installation requires.

Mounting Methods for Different Panel Applications

The right mounting approach depends on your specific application, substrate material, and whether the installation is interior or exterior. According to Lightwave Laser, while fabricators typically don't offer installation services, they can provide recommended hardware for wall and ceiling applications along with technical support.

Here are the primary mounting hardware options and their appropriate uses:

- Standoffs: Create dimensional separation between panels and mounting surfaces—ideal for laser cut wall panels where shadow effects enhance visual depth. Available in various diameters and projection lengths for sheet rock, concrete, or wood substrates

- Channel molding: Hardwood frames (typically maple or walnut) that accept 1/2" or 3/4" panel edges—perfect for finished interior installations where raw edges should remain hidden

- Dowel pins: Join adjacent panels together, particularly useful for 1/2" to 3/4" panels without borders where seamless pattern continuation matters

- Z-clips: Simple, cost-effective mounting for wall applications where panels lay relatively flat against surfaces

- Through-bolts: Direct fastening for metal panel railing installations where structural connection to posts is required

- Concealed clips: Hidden mounting systems that leave panel faces completely unobstructed—common in architectural facade applications

For railing infill panels, mounting typically involves securing panels within a frame system or directly to posts using through-bolts with appropriate spacers. The metal cut out pattern shouldn't interfere with mounting points—experienced designers position solid areas specifically where fasteners will penetrate.

Wall-mounted decorative panels benefit from standoff systems that create depth and drama. When sunlight or artificial lighting hits cut metal panels mounted away from walls, the resulting shadows become part of the design itself. Standoffs also allow airflow behind panels, preventing moisture accumulation in exterior applications.

Structural Considerations for Load-Bearing Installations

When your laser cut aluminum panel serves structural purposes—as in railing systems or protective barriers—proper engineering becomes essential. Panel thickness and alloy selection directly impact load-bearing capacity.

Consider these structural factors:

- Wind load resistance: Exterior panels must withstand local wind pressure requirements; heavier gauges (11-14) provide greater rigidity

- Impact resistance: Railings face potential human contact loads; building codes typically specify 200 lbs concentrated load requirements

- Span limitations: Unsupported panel spans depend on thickness—16-gauge aluminum may span 24" between supports, while 11-gauge extends to 36" or more

- Connection strength: Mounting hardware must transfer loads to structural elements without yielding or pulling through panel material

Thermal Expansion Considerations: Here's a factor many installers overlook until problems emerge. According to Fairview Architectural, aluminum expands and contracts with temperature changes—and installations that don't accommodate this movement develop serious issues.

When panels are mounted rigidly without expansion allowance, temperature fluctuations cause "oil canning"—that wavy, wrinkled appearance on flat surfaces. Even worse, repeated expansion and contraction at rigid connection points eventually weakens the material, potentially causing cracks or joint failures.

Proper installation techniques address thermal movement through:

- Slotted mounting holes that allow lateral panel movement

- Appropriate gaps between adjacent panels (typically 1/8" per 4 feet of panel length)

- Floating connection systems that secure panels while permitting thermal travel

- Avoiding tight panel-to-panel contact that prevents expansion relief

Darker-colored panels experience greater temperature swings than light colors, amplifying expansion effects. Coastal and desert installations with extreme daily temperature ranges require particularly careful attention to thermal accommodation.

Code Compliance: Architectural installations—especially railings—must meet local building codes. Key requirements typically include maximum opening sizes (often 4" spheres cannot pass through), minimum heights (36" for residential, 42" for commercial), and structural load ratings. Your panel design and mounting system must satisfy these requirements; verify specifications with local authorities before finalizing installations.

The relationship between panel thickness, alloy selection, and structural performance creates a matrix of considerations. Thicker panels in higher-strength alloys like 6061-T6 handle greater loads but weigh more and cost more. For most decorative railing applications, 5052-H32 in 14 or 16 gauge provides adequate strength while keeping weight manageable and costs reasonable.

With installation fundamentals covered, understanding cost factors and ordering strategies helps you optimize your project budget while achieving professional results.

Cost Factors and Smart Ordering Strategies

Ever wondered why two seemingly similar laser cut aluminum panel quotes differ by 40% or more? The answer lies in understanding the multiple variables that drive pricing—and knowing which ones you can control. Whether you're ordering custom cut metal for a single architectural feature or sourcing production quantities for a commercial project, strategic decisions at the specification stage dramatically impact your final costs.

Unlike commodity products with fixed pricing, custom cut sheet metal involves layered cost components that interact in sometimes surprising ways. A design tweak that seems minor might slash cutting time in half, while a material upgrade that appears modest could double your bottom line. Let's break down exactly what influences pricing and how to optimize your order for maximum value.

Factors That Influence Panel Pricing

According to industry pricing analysis, sheet metal laser cutter costs depend on several interconnected factors. Understanding each component helps you make informed tradeoffs between performance requirements and budget constraints.

Here are the primary cost drivers for laser cut products:

- Material Grade and Thickness: Aluminum pricing varies significantly by alloy—5052 typically costs $2.00-$4.00/kg, while aerospace grades like 7075 command premium pricing. Thicker materials require more power and slower cutting speeds, compounding costs beyond just material weight

- Panel Size and Quantity: Larger panels utilize more material but may actually cost less per square foot due to reduced handling. Quantity discounts typically begin at 10-25 pieces, with significant per-unit savings at 100+ quantities

- Design Complexity: Simple shapes require minimal design time ($20-$100), while complex geometries needing 2-4 hours of CAD work can add $40-$400. Custom prototypes requiring 5+ hours push design costs to $100-$500 or more

- Cutting Time: Laser cutter sheet metal operations typically charge $50-$150/hour. Intricate patterns with numerous cut paths take exponentially longer than simple shapes—a panel with 500 individual cuts may cost 10x more than one with 50 cuts at identical dimensions

- Finishing Requirements: Post-processing adds $5-$15/m² for deburring, $10-$25/m² for powder coating, and variable costs for anodizing or specialized treatments. Each additional operation multiplies handling and processing time

- Lead Time: Rush orders typically incur 15-30% premiums. Standard lead times of 2-3 weeks offer baseline pricing, while expedited 3-5 day turnaround commands significant surcharges

Setup costs deserve special attention because they're often fixed regardless of quantity. According to the same pricing data, material positioning, laser calibration, and testing typically consume 20-30 minutes at $20-$50/hour—meaning setup alone can add $6.67-$29.17 to every order. This fixed cost explains why small-quantity orders carry higher per-piece pricing.

Optimizing Your Order for Cost Efficiency

Smart specification and ordering practices can reduce total project costs by 20-40% without compromising quality. The key lies in optimizing before you submit files, not after quotes arrive.

Design Optimization Strategies:

According to metal fabrication experts, clarifying and simplifying your design yields substantial savings. Consider these approaches:

- Simplify complex curves: A right angle cuts faster than a curved corner without adding functional value—evaluate whether decorative complexity justifies added cutting time

- Eliminate redundant features: If one fastener hole secures your panel adequately, two add unnecessary cutting time and potential failure points

- Optimize nesting efficiency: Panel dimensions that nest efficiently within standard sheet sizes (4'×8' or 5'×10') minimize material waste—adjusting dimensions slightly can sometimes improve yield dramatically

- Reduce total cut length: Cutting time directly correlates with total path length. Simplifying patterns or enlarging openings reduces both time and cost

Material Selection for Value:

Resist the temptation to over-specify. Custom cut aluminium sheet in 5052-H32 handles most decorative and architectural applications beautifully—upgrading to 6061 or 7075 adds cost without benefit unless structural calculations specifically require higher strength. Similarly, 16-gauge material often performs identically to 14-gauge for decorative panels while reducing both material and cutting costs.

Batch Ordering Benefits:

Volume purchasing offers multiple cost advantages beyond simple material discounts. Setup costs amortize across more pieces, cutting programs run continuously without repositioning, and finishing operations process efficiently in batches. If your project timeline allows, combining multiple panel designs into a single order often reduces total cost compared to separate purchases.

File Preparation That Reduces Revisions:

Every design revision costs time and potentially money. Before submitting custom cut aluminum files:

- Triple-check dimensions and verify units (inches vs. millimeters)

- Confirm all text is converted to outlines

- Remove hidden layers and duplicate geometry

- Verify minimum feature sizes meet fabricator capabilities

- Include clear notes about material, finish, and quantity requirements

For complex projects or high-volume production, working with manufacturers offering comprehensive Design for Manufacturability (DFM) support proves invaluable. Expert review catches potential issues before cutting begins, suggesting modifications that improve both quality and cost-effectiveness. Manufacturers like Shaoyi (Ningbo) Metal Technology provide 12-hour quote turnaround with detailed DFM feedback—allowing you to optimize designs rapidly rather than discovering problems after production begins.

For automotive and industrial applications requiring IATF 16949-certified quality, rapid prototyping capabilities prove particularly valuable. The ability to validate designs with physical samples within 5 days—before committing to production quantities—prevents costly mistakes and accelerates development timelines. This combination of quick response and expert guidance helps buyers optimize both design specifications and order strategies for maximum value.

Minimum order quantities vary significantly between fabricators. Some specialize in one-off custom pieces while others focus on production volumes. Matching your project scale to the right manufacturing partner prevents paying premium pricing for services designed for different volumes. Don't hesitate to request quotes from multiple sources—the right fit often delivers both better service and better pricing.

With cost factors clearly understood, the final consideration involves selecting the right manufacturing approach for your specific project requirements and scale.

Choosing the Right Path for Your Aluminum Panel Project

You've absorbed the technical knowledge—alloy properties, gauge specifications, manufacturing processes, finishing options, and installation requirements. Now comes the moment that determines whether your project succeeds: translating that knowledge into actionable decisions tailored to your specific situation.

Whether you're a homeowner ordering a single decorative railing panel or an architect specifying hundreds of facade elements, the decision framework remains consistent. Match your requirements to the right materials, processes, and manufacturing partners. Get this alignment right, and your laser cut aluminum panels will perform beautifully for decades.

Matching Your Project to the Right Manufacturing Partner

Not every fabricator serves every project type equally well. According to Metal Works Inc., choosing the right fabrication partner directly impacts project timelines, costs, and final quality. The wrong partner can stall your journey to market, while the right one saves time and money without sacrificing quality.

When evaluating potential partners for your laser cut metal panel project, consider these critical factors:

- Design expertise: Does the fabricator offer DFM (Design for Manufacturability) guidance? Partners who review your files and suggest optimizations catch problems before cutting begins

- Comprehensive capabilities: Can they handle laser cutting, finishing, and assembly in-house? Outsourcing secondary operations adds cost and delays

- Equipment quality: Modern laser cutter aluminum systems deliver tighter tolerances and faster processing than dated machinery—ask about equipment age and capabilities

- Turnaround speed: Quality rapid prototyping can deliver parts in 3-5 days, while production quantities require different timeline planning

For DIY enthusiasts and small-scale projects, online laser cutting services offer accessible entry points. You'll upload vector files, select materials and quantities, and receive finished panels shipped to your door. These services work well for straightforward decorative pieces where standard alloys and finishes meet your needs.

Commercial and architectural applications demand more. When searching for "laser cut metal panels near me," prioritize fabricators with architectural project experience, code compliance knowledge, and finishing capabilities that match your specifications. Large-scale facade projects benefit from partners offering project management support alongside fabrication services.

For automotive and industrial applications requiring certified quality standards, manufacturers with IATF 16949 certification—like Shaoyi (Ningbo) Metal Technology—deliver the documented quality systems these sectors demand. Their combination of 5-day rapid prototyping for design validation and automated mass production capabilities serves projects spanning from initial concept through volume manufacturing.

Key Takeaways for Successful Panel Projects

After exploring every aspect of custom laser cut metal panels, certain decision points emerge as critical. Here's your condensed buyer's guide:

Alloy Selection: For most decorative and architectural applications, 5052-H32 aluminum delivers the optimal balance of corrosion resistance, formability, and weldability. Reserve 6061-T6 for structural applications demanding higher strength, and consider 7075 only when aerospace-grade performance justifies significantly higher costs and fabrication complexity.

Thickness Requirements: 16-gauge (0.051") handles the majority of railing panels and decorative screens effectively. Step up to 14-gauge (0.064") for outdoor installations facing wind loads or impact risks. Use lighter gauges only for purely decorative interior pieces where structural demands are minimal.

Finishing Needs: Powder coating offers unlimited color options and good durability for most applications. Choose anodizing when maximum corrosion resistance matters—particularly for marine environments or high-wear surfaces. Don't skip finishing for exterior installations; unprotected aluminum cut edges will oxidize over time.

Volume Considerations: Single pieces and small quantities favor online services with low minimums. Production volumes benefit from dedicated manufacturing partners offering quantity pricing and consistent quality. Prototype before committing to large orders—validating designs with physical samples prevents costly mistakes.

The most successful laser cut panel projects balance design ambition with practical manufacturing constraints. The most intricate pattern means nothing if it can't be fabricated reliably, finished durably, and installed properly. Start with function, then layer in aesthetics within achievable parameters.

For DIY and Small-Scale Users:

Your path typically involves online quoting platforms where you upload files and receive instant pricing. Focus on getting your vector files right the first time—proper preparation eliminates revision costs. Standard 5052 aluminum in common gauges keeps material costs reasonable. Simple powder coat finishes in stock colors avoid custom finishing premiums.

For Commercial and Architectural Applications:

Invest time in partner selection. Request samples demonstrating cut quality and finish options. Verify code compliance capabilities for railing and facade applications. Confirm lead times align with construction schedules. For complex projects, manufacturers with rapid prototyping capabilities allow you to validate designs physically before committing to production quantities—potentially saving thousands in rework costs.

The laser cut panel industry continues evolving, with fiber laser technology enabling ever-finer details and faster processing. What seemed impossible a decade ago now ships routinely. This expanding capability means your design ambitions face fewer technical barriers than ever—provided you match those ambitions with appropriate material selections, realistic tolerances, and capable manufacturing partners.

Your next step? Define your project requirements clearly, prepare proper vector files, and reach out to fabricators whose capabilities align with your needs. Armed with the knowledge from this guide, you're positioned to specify confidently, order strategically, and achieve results that transform your spaces exactly as envisioned.

Frequently Asked Questions About Laser Cut Aluminum Panels

1. How much does it cost to laser cut aluminum?

Laser cutting aluminum typically costs $1 to $3 per inch or $75 to $150 per hour, depending on material thickness, design complexity, and order quantity. Key cost factors include alloy grade, cutting time, panel size, and finishing requirements. Design optimization can reduce costs by 20-40%—simplifying curves, reducing total cut paths, and nesting panels efficiently within standard sheet sizes minimizes waste and cutting time. Working with manufacturers offering DFM support helps identify cost-saving opportunities before production begins.

2. How thick can laser cut aluminum?

Fiber lasers effectively cut aluminum ranging from 0.5mm (0.020 inches) to approximately 25mm (1 inch), though most decorative panel applications use thinner gauges. Common specifications include 16 gauge (0.051 inches) for railing panels and privacy screens, and 14 gauge (0.064 inches) for outdoor installations requiring wind load resistance. Thicker materials require slower cutting speeds and higher laser power, which increases processing costs and may affect edge quality.

3. Can you laser cut an aluminium composite panel?

Laser cutting aluminum composite panels (ACM) is virtually impossible due to the vastly different properties of the two primary materials—aluminum facing and polyethylene core. The power and temperature required to cut through each material differ significantly, making traditional laser cutting impractical. For composite materials, alternative cutting methods like CNC routing or waterjet cutting are typically recommended instead.

4. What is the best aluminum alloy for laser cut panels?

5052-H32 aluminum dominates panel applications due to its exceptional corrosion resistance, excellent weldability, and superior formability. This alloy contains magnesium and chromium additions that make it ideal for outdoor architectural facades, marine environments, and decorative applications. For structural components requiring higher strength, 6061-T6 offers 32% greater tensile strength, while 7075-T6 delivers aerospace-grade performance for specialized high-stress applications.

5. What file format is needed for laser cutting aluminum panels?

Laser cutting requires vector-based files where every line represents a defined cutting path. Accepted formats include AI (Adobe Illustrator), DXF (AutoCAD), and vector-exported PDF files. Raster formats like JPEG, PNG, or TIFF cannot be used because they're composed of pixels rather than mathematical paths. Before submitting, convert all text to outlines, remove duplicate geometry, ensure closed paths, and verify scale at 1:1 actual size.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —