Stamping Manufacturing Process Decoded: From Raw Sheet To Finished Part

What Is the Stamping Manufacturing Process

Ever wondered how thousands of identical metal parts—from car door panels to tiny electronic connectors—are produced with remarkable speed and precision? The answer lies in one of manufacturing's most efficient and versatile techniques: the stamping manufacturing process.

Metal stamping is a cold-forming manufacturing process that uses specialized dies and high-force presses to transform flat sheet metal into precisely shaped components through cutting, bending, and forming operations—all without removing material.

Understanding what is metal stamping begins with recognizing its fundamental difference from other metalworking methods. Unlike machining, which cuts away material, or casting, which pours molten metal into molds, stamping reshapes solid metal at room temperature. This cold-forming approach preserves material integrity while enabling incredible production speeds—sometimes producing hundreds of parts per minute.

The Core Mechanics Behind Metal Forming

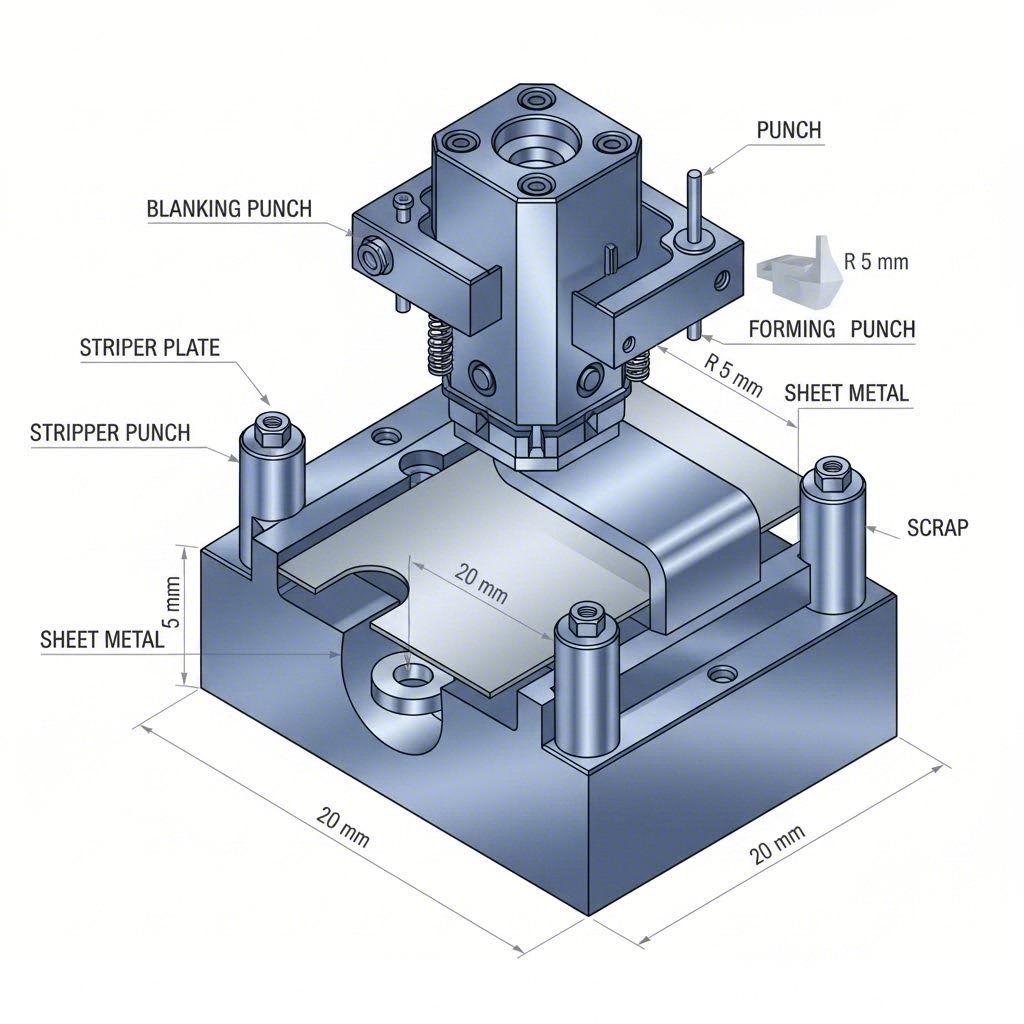

So, what is a stamping operation at its most basic level? Imagine placing a flat sheet of metal between two precisely engineered tools: a punch (the upper component) and a die (the lower component). When the press activates, it drives the punch downward with tremendous force—often measured in tons—causing the metal to plastically deform and take on the shape defined by the tooling.

The mechanics involve three essential elements working in harmony:

- Force application: The stamping press generates controlled pressure, typically ranging from a few tons for small parts to thousands of tons for automotive body panels.

- Tooling precision: Dies and punches are machined to exact specifications, with clearances measured in thousandths of an inch to ensure consistent part quality.

- Material flow: As pressure is applied, the metal undergoes plastic deformation, permanently changing shape while maintaining its structural properties.

This process works because metals exhibit ductility—the ability to deform without fracturing. When force exceeds the metal's yield strength but stays below its breaking point, the material flows into new shapes and retains them once pressure is released. According to National Material Company, this approach offers low costs and faster lead times for both short and long production runs while maintaining consistent quality and dimensional accuracy.

From Flat Sheet to Precision Component

What is stamped metal in practical terms? It's any component that began as a flat sheet or coil and was transformed through metal pressing operations into a functional part. Stamping means applying strategic force through specialized tooling to achieve specific geometric changes—whether that's cutting a precise outline, creating bends at exact angles, or forming complex three-dimensional shapes.

The journey from raw material to finished component typically follows this progression:

- Design and engineering: Engineers define part geometry while considering material properties, die design, and tooling requirements using CAD/CAM software.

- Tooling fabrication: Specialized dies are manufactured, including blanking dies, forming dies, and piercing dies.

- Material preparation: Metal sheets or coils are cut, slit, and leveled to proper dimensions.

- Stamping operations: The press applies force through the dies, performing cutting, bending, or forming operations.

- Finishing: Post-processing steps like deburring, cleaning, and surface treatment complete the part.

Throughout this article, you'll discover the nine essential stamping operations, compare progressive versus transfer die methods, learn how to select the right press type and materials, and understand the quality control strategies that ensure precision results. Whether you're evaluating stamping for a new project or deepening your technical knowledge, this guide bridges foundational concepts with the practical depth needed for informed decision-making.

Nine Essential Stamping Operations and Their Applications

Now that you understand the fundamentals of the stamping process, let's explore the specific operations that transform flat metal into functional components. Each die stamping operation serves a distinct purpose, and knowing when to apply each technique is crucial for achieving optimal results. Think of these nine operations as tools in your manufacturing toolkit—each designed for specific tasks, yet often combined to create complex finished parts.

Cutting Operations Explained

Cutting operations form the foundation of most stamping and pressing sequences. These techniques separate material or create openings, setting the stage for subsequent forming operations.

Blanking is the process of cutting flat shapes from sheet metal where the punched-out piece becomes the finished product. When you're blank stamping metal, precision is paramount—the die must produce clean edges with minimal burr formation. According to Master Products, blanking is extremely similar to punching, except that the punched parts are the product and the remaining sheet metal workpiece is scrap. Typical applications include producing base components for electronics, automotive brackets, and appliance panels. Tooling requires hardened steel dies with precise clearances—typically 5-10% of material thickness—to ensure clean cuts.

Punching (Piercing) creates precisely located holes within the sheet metal workpiece. Unlike blanking, the punched-out material is scrap, and the perforated sheet continues through production. This operation is essential for creating mounting holes, ventilation openings, and connection points. Tooling complexity varies based on hole patterns—simple single-punch dies handle basic applications, while multi-station setups create complex hole arrangements in a single press stroke.

Forming and Shaping Techniques

Once cutting operations establish the basic outline, forming techniques reshape the metal into three-dimensional components. These operations require careful consideration of material properties and springback characteristics.

Bending uses mechanical force to create angular deformation along a specific axis. A press brake applies extreme pressure, producing V-shaped or U-shaped profiles commonly found in brackets, enclosures, and structural frames. Tooling includes matched punch and die sets designed for specific bend angles, with inside bend radii typically ranging from 0.5 to 2 times material thickness depending on the metal's ductility.

Coining represents a high-pressure operation that stamps both sides of the workpiece simultaneously. This technique creates fine surface details, precise thickness control, and sharp definition that other methods cannot achieve. A classic example of stamping using coining is currency production—hence the name. For coining steel and other metals, pressures can reach 5-6 times those used in conventional forming, requiring robust die construction and precise alignment. Applications extend to decorative hardware, precision components, and any part requiring exact dimensional control.

Embossing creates raised or indented patterns by stamping a single side of the workpiece. While stamps and embossers share similarities with coining tools, embossing requires less pressure since it displaces rather than compresses material. Common embossed features include logos, serial numbers, decorative patterns, and branding elements. Tooling consists of matched male and female dies with controlled clearances that determine pattern depth.

Flanging bends edges at a 90-degree angle from the sheet surface, typically around punched holes or along part perimeters. This operation creates smooth rims that eliminate sharp edges, improve structural rigidity, and facilitate assembly. Flanging is essential in manufacturing tanks, pipes, and automotive body panels where edge quality impacts both safety and aesthetics.

Stretching forms protrusions or contours by forcing material into a die cavity while the edges remain clamped. This operation produces complex shapes like automobile door panels and roof sections where material must flow over curved surfaces. Tooling requires draw beads or blank holders to control material flow and prevent wrinkling.

Curling rolls sheet metal edges into cylindrical shapes, creating rounded profiles used for hinges, wire guides, and safety edges. The operation may form complete tubes or partial rolls depending on application requirements. Tooling includes specially contoured dies that progressively shape the material through multiple forming stages.

Grooving cuts channels or grooves into metal sheets without fully penetrating the material. These features serve as fold lines, accommodate O-rings, or create decorative elements. Grooving tooling requires precise depth control to achieve consistent groove profiles without material separation.

| Operation Name | Description | Typical Applications | Tooling Complexity |

|---|---|---|---|

| Blanking | Cutting flat shapes from sheet; punched piece is the product | Base components, brackets, appliance panels | Moderate—requires precise clearances for clean edges |

| Punching | Creating holes or cutouts; punched material is scrap | Mounting holes, ventilation, connection points | Low to Moderate—complexity increases with hole patterns |

| Bending | Angular deformation along a specific axis | Brackets, enclosures, structural frames | Moderate—matched punch/die sets for specific angles |

| Coining | High-pressure stamping on both sides for fine detail | Currency, decorative hardware, precision components | High—requires robust construction for extreme pressures |

| Embossing | Creating raised/indented patterns on one side | Logos, serial numbers, decorative elements | Moderate—controlled clearances for pattern depth |

| Flanging | Bending edges at 90° from sheet surface | Tanks, pipes, automotive panels | Moderate—specialized edge-forming tooling |

| Stretching | Forming contours while edges remain clamped | Automotive doors, roof panels, appliance covers | High—requires draw beads and material flow control |

| Curling | Rolling edges into cylindrical shapes | Hinges, wire guides, safety edges | Moderate to High—progressive shaping stages |

| Grooving | Cutting channels without full penetration | Fold lines, O-ring seats, decorative features | Moderate—precise depth control required |

Understanding these nine operations empowers you to select the right techniques for your specific blank stamping requirements. Many production scenarios combine multiple operations—perhaps blanking followed by bending and flanging—to create finished components efficiently. The key lies in matching operation capabilities to part geometry, production volume, and quality requirements. With this foundation in place, you're ready to explore how these operations are organized into progressive, transfer, and fourslide stamping systems.

Progressive vs Transfer vs Fourslide Stamping Methods

You've mastered the nine essential stamping operations—but how do you organize them into an efficient production system? The answer depends on choosing the right stamping technology for your specific requirements. Three primary methods dominate modern stamping machinery: progressive die, transfer die, and fourslide stamping. Each approach offers distinct advantages, and selecting the wrong one can mean the difference between profitable production stamping and costly inefficiency.

Progressive Die Advantages for High-Volume Runs

Imagine a continuous metal strip feeding through a series of stations, each performing a specific operation—punching, bending, forming—until finished stamped parts emerge at the end. That's progressive die and stamping in action. The strip advances incrementally through the die with each press stroke, and parts remain attached to the carrier strip (called webbing) until the final cutoff operation separates them.

Why does this approach dominate high-volume manufacturing? Consider these key benefits:

- Exceptional speed: Stamping machines running progressive dies can produce hundreds of parts per minute since all operations occur simultaneously across multiple stations.

- Reduced handling: Parts never leave the strip until completion, eliminating transfer mechanisms and reducing labor costs.

- Lower per-unit costs: Once tooling is established, the continuous nature of the process drives down cost-per-piece dramatically at scale.

- Consistent quality: The strip maintains precise positioning throughout, ensuring dimensional repeatability across millions of cycles.

Progressive stamping excels for simple to moderately complex parts—think automotive brackets, electrical connectors, battery contacts, and precision hardware. According to Die-Matic, this method offers production speed, fast cycle times, reduced labor costs, and lower per-unit costs, making it one of the most effective methods for producing large volumes of precision parts quickly and cost-effectively.

However, progressive dies come with trade-offs. The initial tooling investment can be significant—complex dies with multiple stations require extensive engineering and precision manufacturing. Design modifications after tooling completion become costly and time-consuming. Additionally, part geometry is limited by the strip's continuous feed: very deep draws or large components may exceed what progressive stamping machinery can accommodate.

When Transfer Dies Outperform Progressive Systems

What happens when your part requires deeper draws, larger dimensions, or geometric complexity that progressive dies can't handle? Transfer die stamping offers the solution. This method either starts with a pre-cut blank or separates the workpiece from the strip early in the process. Mechanical fingers or transfer mechanisms then move the individual part between separate die stations.

Transfer stamping shines in scenarios where progressive methods fall short:

- Larger parts: Automotive body panels, structural components, and heavy-duty enclosures benefit from transfer die flexibility.

- Complex geometries: When parts require operations from multiple angles or deep forming that would interfere with strip feed, transfer dies provide access.

- Material efficiency: Starting with optimized blanks can reduce scrap compared to continuous strip feeding for certain part shapes.

The trade-off? Transfer stamping typically runs slower than progressive methods since parts must be physically moved between stations. Tooling and handling complexity increase costs for lower-volume runs. Still, for medium to high-volume production of intricate or oversized stamped parts, transfer die systems deliver unmatched capability.

Fourslide stamping takes a completely different approach. Instead of vertical press action, fourslide (or multislide) stamping machines use four or more horizontal tool slides that simultaneously shape metal from multiple directions. This multi-axis forming capability excels at creating complex bends, twists, and three-dimensional shapes that would require multiple operations in conventional stamping machinery.

Fourslide technology proves ideal for:

- Intricate small parts: Electrical connectors, terminals, clips, and fasteners with precise multi-directional bends.

- Wire forms and flat springs: Components requiring complex geometries from thin, flexible materials.

- Reduced secondary operations: Parts that would otherwise need multiple forming steps can often be completed in a single fourslide cycle.

The limitations? Fourslide stamping generally suits smaller parts and thinner materials. It's less effective for heavy-gauge metals or large components, and production volumes typically run lower than progressive die operations.

| Criteria | Progressive Die Stamping | Transfer Die Stamping | Fourslide Stamping |

|---|---|---|---|

| Part Complexity | Simple to moderate; limited by strip feed | High; accommodates deep draws and complex shapes | Very high; multi-directional forming for intricate bends |

| Production Volume | Medium to very high; optimal for mass production | Medium to high; efficient for larger batch runs | Low to medium; suited for specialized components |

| Tooling Cost | High initial investment; lower per-part at volume | Higher due to transfer mechanisms and multiple stations | Moderate; less complex than progressive dies |

| Cycle Time | Fastest; all operations simultaneous | Slower; part transfer between stations | Moderate; depends on forming complexity |

| Best Applications | Automotive brackets, connectors, electrical terminals, precision hardware | Large body panels, structural components, deep-drawn parts | Small connectors, clips, springs, wire forms |

How do you choose the right method? Start by evaluating these decision criteria:

- Part size and geometry: Small, flat parts with moderate complexity favor progressive dies. Large or deep-drawn components point toward transfer systems. Intricate multi-bend small parts suggest fourslide.

- Production volume: High-volume runs justify progressive die tooling investment. Lower volumes may favor fourslide flexibility or transfer die versatility.

- Material thickness: Thin, flexible metals work well across all methods. Heavier gauges may exceed fourslide capabilities.

- Budget constraints: Consider total cost including tooling amortization, per-part costs, and secondary operation requirements.

With your stamping method selected, the next critical decision involves choosing the right press type. Mechanical, hydraulic, and servo presses each bring distinct characteristics that can make or break your production efficiency.

Stamping Press Types and Selection Criteria

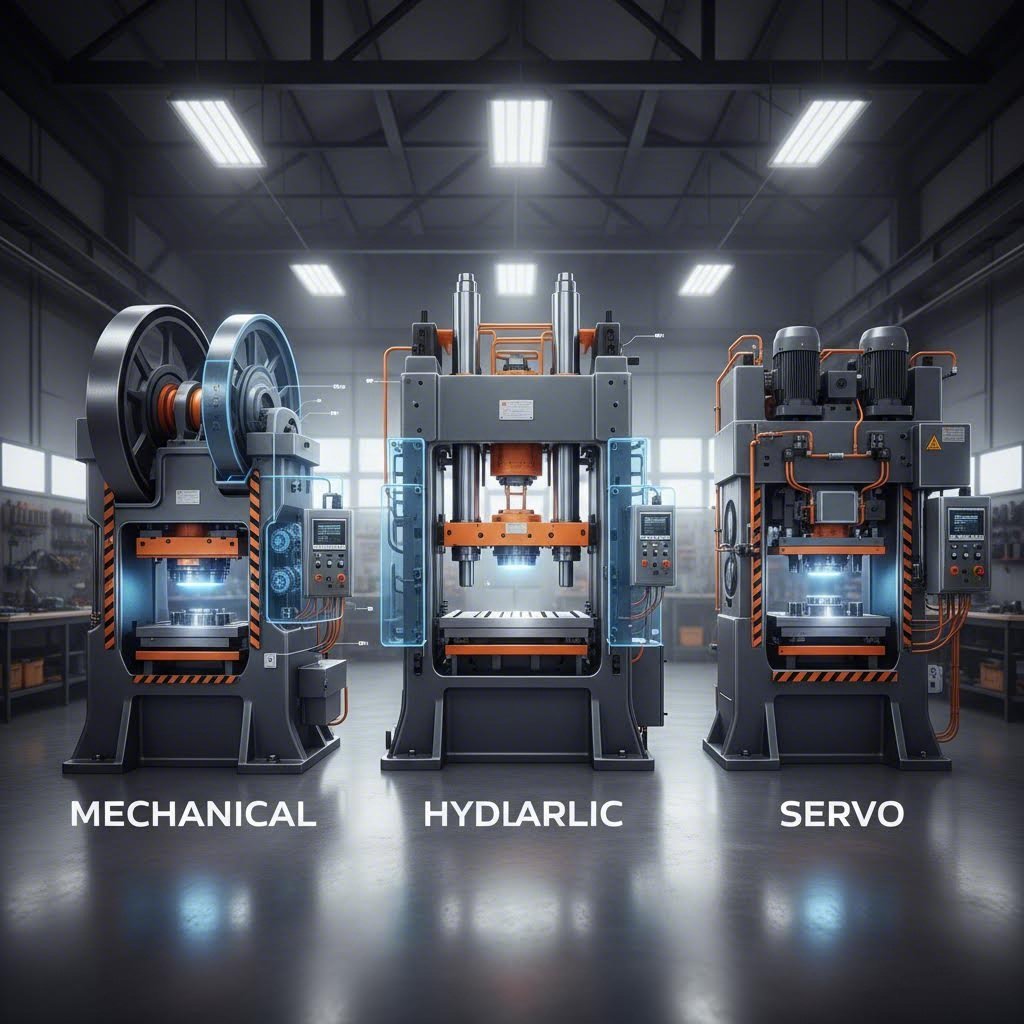

You've selected your stamping method—but what machine will power your production? The stamping press you choose directly impacts cycle speed, part quality, energy consumption, and long-term operational costs. So, what is a stamping press exactly? It's the mechanical heart of any stamping operation: a machine that applies controlled force through tooling to shape metal into finished components. Understanding the differences between mechanical, hydraulic, and servo presses empowers you to match equipment capabilities to your specific manufacturing requirements.

Mechanical Press Speed and Precision Trade-offs

Mechanical stamping presses are often called the workhorses of the industry—and for good reason. These metal stamping presses rely on a flywheel-and-crankshaft mechanism to store rotational energy and convert it into linear force. When the clutch engages, that stored energy drives the ram downward with remarkable speed and consistency.

Here's how it works: an electric motor continuously spins a heavy flywheel, building kinetic energy. During the press stroke, this energy transfers through the crankshaft to the ram, delivering force at the bottom of the stroke. The fixed stroke length and predictable motion profile make mechanical presses ideal for operations requiring speed and repeatability.

According to JVM Manufacturing, mechanical stamping presses are known for their speed and can achieve high strokes per minute, making them ideal for large-scale production runs where time directly impacts profitability.

Pros

- High-speed operation: Cycle rates can exceed 1,000 strokes per minute for smaller presses, maximizing throughput.

- Lower upfront cost: Simpler construction compared to hydraulic or servo alternatives reduces initial investment.

- Proven reliability: Straightforward design translates to less maintenance and easier troubleshooting.

- Energy efficiency at speed: Flywheel momentum recovers energy between strokes during continuous operation.

Cons

- Fixed stroke characteristics: Limited flexibility for varying forming depths or dwell times at bottom dead center.

- Reduced control: Force peaks at the bottom of the stroke rather than remaining constant throughout.

- Limited deep-draw capability: Not ideal for operations requiring sustained pressure through extended forming distances.

A steel stamping press of the mechanical variety excels at high-speed blanking, shallow forming, and repetitive operations where consistent cycle times outweigh flexibility needs. Think electrical terminals, small brackets, and precision hardware produced in millions of units annually.

What about hydraulic metal stamping presses? These machines take a fundamentally different approach. Instead of mechanical energy storage, hydraulic presses use fluid pressure generated by pumps and cylinders to apply force. This design enables variable force application throughout the entire stroke—a critical advantage for deep drawing and complex forming operations.

The hydraulic advantage becomes clear when forming large automotive panels or deep containers. The metal stamping press machine maintains consistent pressure as material flows into the die cavity, preventing thinning and tearing that can occur with mechanical presses' fixed force curves. Adjustable stroke length and programmable pressure profiles add versatility that mechanical systems cannot match.

Pros

- Full-stroke force control: Consistent pressure application from top to bottom of stroke ensures uniform material flow.

- Deep drawing excellence: Ideal for forming containers, enclosures, and automotive body panels requiring extended forming depths.

- Adjustable parameters: Stroke length, speed, and force can be modified without mechanical changes.

- Versatile applications: One press can handle diverse operations by adjusting settings rather than changing equipment.

Cons

- Slower cycle times: Hydraulic systems typically run 10-20 strokes per minute versus hundreds for mechanical presses.

- Higher energy consumption: Continuous pump operation consumes power even during idle periods.

- Maintenance complexity: Hydraulic fluid, seals, and pumps require regular attention and eventual replacement.

Servo Technology Revolutionizing Stamping Control

Servo-driven stamping presses represent the cutting edge of metal forming technology. These advanced machines replace traditional flywheel or hydraulic systems with servo motors that directly control ram movement. The result? Unprecedented flexibility and precision that's transforming what's possible in stamping operations.

Imagine programming the exact motion profile for each operation—accelerating quickly through the approach, slowing precisely during forming, dwelling at bottom dead center for coining operations, then retracting at maximum speed. Servo presses make this customization routine, not exceptional.

As noted by Eigen Engineering, servo presses offer advanced servo motor technology that enables speed, power, and programmability—great for jobs requiring high accuracy such as electronics, medical products, or high-end stamped metal parts.

Pros

- Programmable motion profiles: Customize speed, acceleration, and dwell time for each unique operation.

- Energy efficiency: Motors operate only when needed, reducing power consumption by 30-50% compared to mechanical presses running continuously.

- Superior accuracy: Precise position control enables tighter tolerances and improved part consistency.

- Quick changeover: Digital programming enables rapid setup changes for mixed production environments.

- Reduced noise and vibration: Controlled deceleration minimizes impact forces and workplace noise.

Cons

- Higher initial investment: Advanced servo technology costs significantly more than comparable mechanical presses.

- Technical expertise required: Programming and maintenance demand specialized knowledge.

- Peak speed limitations: Maximum strokes per minute may not match dedicated high-speed mechanical presses.

What about heat generation? Thermal considerations play a critical role in press selection and operation. During high-speed stamping, friction between the die, punch, and workpiece generates significant heat. This thermal energy affects die life, lubricant effectiveness, and part dimensional accuracy.

Mechanical presses running at maximum speed generate the most friction heat due to their rapid cycling. Without adequate cooling or lubrication, die surfaces can reach temperatures that accelerate wear and cause premature failure. Part quality also suffers as thermal expansion affects dimensional consistency.

Hydraulic and servo presses offer advantages here. Their slower operation and controllable forming speeds reduce friction heat generation. Servo presses add the ability to program slower approach speeds through critical forming zones, further minimizing thermal buildup without sacrificing overall cycle efficiency.

How do you match press type to your application? Consider these decision factors:

- Production volume: High-volume, simple operations favor mechanical steel press speed. Lower volumes benefit from hydraulic or servo flexibility.

- Part complexity: Deep draws and complex forming sequences align with hydraulic or servo capabilities. Shallow blanking suits mechanical presses.

- Tolerance requirements: Tight dimensional specifications favor servo press precision.

- Energy costs: Facilities with high electricity rates may benefit from servo energy efficiency despite higher equipment costs.

- Production mix: Shops handling diverse parts benefit from servo programmability for quick changeovers.

With press type determined, your next critical decision involves material selection. Different metals behave uniquely during stamping, and understanding these characteristics ensures both quality results and optimal die life.

Material Selection Guide for Stamped Components

You've selected your press type—now comes a decision that directly impacts part performance, tooling longevity, and manufacturing cost: choosing the right metal for stamping. Each material behaves differently under the tremendous forces involved in stamping operations. Select wisely, and your parts emerge with excellent dimensional accuracy and surface quality. Choose poorly, and you'll battle cracking, excessive springback, or premature die wear.

What makes a metal ideal for stamping? Four key properties determine stampability:

- Ductility: The material's ability to deform plastically without fracturing. Higher ductility allows more aggressive forming operations.

- Yield strength: The stress level where permanent deformation begins. Lower yield strength means easier forming but may sacrifice final part strength.

- Work hardening rate: How quickly a metal becomes harder and less formable as it's deformed. High work hardening can cause problems in multi-stage operations.

- Grain structure: Fine, uniform grains generally improve formability and surface finish compared to coarse or irregular grain patterns.

Understanding these properties helps you predict how each material will perform during blanking, bending, drawing, and other stamping operations. Let's explore the most common metal stamping materials and their unique characteristics.

Steel Grades and Their Stamping Characteristics

Steel dominates the stamping industry for good reason—it combines strength, formability, and cost-effectiveness that few alternatives can match. However, "steel" encompasses dozens of grades, each suited to different applications.

Carbon steel serves as the workhorse of stamped steel production. According to Talan Products, carbon steel is widely used in stamping because it is strong, affordable, and easy to form. Different grades based on carbon content serve specific purposes:

- Low-carbon steel (mild steel): Excellent formability and weldability make this the go-to choice for deep draws, complex bends, and high-volume production. Think automotive brackets, appliance panels, and structural components.

- Medium-carbon steel: Higher strength but reduced ductility. Suitable for parts requiring wear resistance or load-bearing capability.

- High-carbon steel (spring steel): Engineered for resilience and high yield strength, these grades produce springs, clips, and high-stress components that must return to their original shape repeatedly.

High-Strength Low-Alloy (HSLA) steel offers a step up from carbon steel, delivering higher strength with less weight. Automotive and heavy equipment manufacturers favor HSLA when strength-to-weight ratio matters without the cost premium of stainless grades.

Stainless steel metal stamping addresses applications demanding durability and corrosion resistance. As noted by Verdugo Tool & Engineering, stainless steel is highly versatile and compatible with an extensive range of industrial applications—it is not only highly ductile but also strong and can be drawn, formed, and coined easily when annealed. Common grades include:

- 304L stainless: Excellent formability and corrosion resistance for food processing equipment and medical devices.

- 316 stainless: Contains molybdenum for enhanced corrosion resistance in marine or chemical applications.

- 301 stainless: High strength with good ductility—a common choice for springs, clips, and clamps.

- 321 stainless: Titanium-stabilized for high-temperature environments like exhaust and engine components.

Coated steels provide built-in corrosion protection through galvanizing (zinc coating) or other surface treatments. These materials combine carbon steel formability with enhanced environmental resistance for construction and automotive applications.

Aluminum Springback Challenges and Solutions

When weight reduction drives your design requirements, the aluminum stamping process offers an attractive solution. Stamped aluminum delivers excellent strength-to-weight ratios and natural corrosion resistance—critical for aerospace, automotive, and consumer electronics applications.

However, aluminum presents unique challenges. According to Verdugo Tool & Engineering, aluminum alloys create lightweight parts with high levels of strength and stability, but the material is sometimes resistant to forming and drawing. For this reason, care needs to be taken when engineering aluminum parts for manufacturability.

The primary challenge? Springback. Aluminum's elastic recovery after forming causes parts to partially return toward their original flat shape. A bend programmed for 90 degrees might end up at 87 or 88 degrees once the part leaves the die. Managing this requires:

- Overbending: Programming dies to bend slightly past the target angle, compensating for elastic recovery.

- Bottoming or coining: Applying extra pressure at the bottom of the stroke to set the bend permanently.

- Material-specific tooling: Designing dies specifically for aluminum's springback characteristics rather than adapting steel tooling.

- Grade selection: Choosing alloys with lower springback tendencies for critical applications.

Common aluminum grades for stamping include:

- 6061 aluminum (O to T6 tempers): Highly resistant to corrosion with good weldability and relatively high strength for structural applications.

- 2024 aluminum: Superior strength-to-weight ratio makes this grade popular for aerospace components.

- 5052-H32 aluminum: Excellent formability and corrosion resistance ideal for marine environments and automotive manufacturing.

Copper and brass fill specialized roles where electrical or thermal conductivity matters most. These metals offer excellent formability, making them ideal for electrical connectors, terminals, and HVAC components. Beryllium copper combines outstanding electrical conductivity with high strength for precision instruments, while brass (copper-zinc alloy) provides good machinability and corrosion resistance for electrical and decorative applications.

What about specialty alloys? High-performance applications demand exotic materials:

- Inconel: Nickel-chromium superalloys withstanding extreme temperatures for aerospace and chemical processing.

- Titanium: Strong yet lightweight (55% the density of steel), corrosion-resistant for aerospace and marine applications.

- Hastelloy: Nickel-based superalloy for highly demanding environments in chemical processing and defense.

Cold forming versus hot forming—when does each apply? Most stamping occurs as cold forming at room temperature, preserving material properties and achieving excellent surface finish. Hot forming becomes necessary when:

- Material lacks sufficient ductility for cold forming

- Part geometry requires extreme deformation

- Work hardening would cause cracking during multi-stage cold operations

- Specific metallurgical properties require elevated temperatures

Hot stamping (typically 900-950°C for steel) reduces forming forces and enables complex shapes, but adds process complexity and cost. Most commercial stamping operations favor cold forming whenever material properties permit.

| Material | Formability Rating | Typical Thickness Range | Common Applications | Special Considerations |

|---|---|---|---|---|

| Low-Carbon Steel | Excellent | 0.4mm - 6.0mm | Automotive brackets, appliance panels, structural components | Most versatile; excellent deep draw capability |

| Stainless Steel (304, 316) | Good to Excellent | 0.3mm - 4.0mm | Food processing, medical devices, marine hardware | Work hardens quickly; requires proper lubrication |

| HSLA Steel | Good | 0.5mm - 5.0mm | Automotive structural, heavy equipment | Higher strength reduces formability; springback management needed |

| Aluminum (5052, 6061) | Good | 0.5mm - 4.0mm | Aerospace, automotive, electronics enclosures | Significant springback; requires overbending compensation |

| Copper | Excellent | 0.1mm - 3.0mm | Electrical connectors, terminals, heat sinks | Soft material; galling prevention critical |

| Brass | Excellent | 0.2mm - 3.0mm | Electrical components, decorative hardware | Easy to form; good surface finish achievable |

| Spring Steel | Moderate | 0.1mm - 2.0mm | Springs, clips, retaining rings | Limited forming; primarily bending operations |

| Titanium | Moderate | 0.3mm - 3.0mm | Aerospace, medical implants, marine | Requires specialized tooling; galling prone |

Precision capabilities vary significantly by material. Stamped steel typically achieves tolerances of ±0.05mm to ±0.15mm depending on part complexity and thickness. Stainless steel stamping delivers similar precision but requires tighter process control due to work hardening. The aluminum stamping process generally achieves ±0.1mm to ±0.25mm tolerances, with springback compensation being the primary variable.

With material selection complete, your next focus should be the tooling that transforms flat sheet into finished components. Die design fundamentals and maintenance practices directly determine whether your chosen material produces quality parts consistently over millions of cycles.

Tooling and Die Design Fundamentals

You've selected your material—but what transforms that flat sheet into a precision component? The answer lies in tooling: the specialized dies that define every cut, bend, and form your parts will take. Whether you're running a stamping machine for metal brackets or producing millions of electrical connectors, die design fundamentals determine part quality, production speed, and long-term cost efficiency. Understanding these principles helps you communicate effectively with tooling partners and make informed decisions that impact your bottom line.

Think of a stamping die as a precision instrument rather than a simple tool. Every component works in harmony—guide systems maintain alignment, cutting elements separate material cleanly, and forming sections shape metal with micron-level accuracy. When any element falls out of specification, you'll see it immediately in part quality, scrap rates, or unplanned downtime.

Critical Die Components and Their Functions

What's inside a typical stamping die? While metal stamping machines vary in complexity, most dies share these fundamental components:

- Die shoe (upper and lower): These thick steel plates form the foundation of your die set, providing stability and mounting surfaces for all other components. According to Shaoyi Metal Technology, both shoes are machined with tight tolerances to ensure flatness and parallelism—the reference points that prevent misalignment during operation.

- Punch plate (punch retainer): This hardened plate secures cutting and forming punches in precise positions. Dowel pins and heel blocks maintain exact alignment relative to the die openings below.

- Stripper plate: Positioned between the punch and workpiece, this component holds material flat during cutting and strips it from the punch on the upstroke. Spring-loaded strippers provide controlled pressure that prevents part distortion.

- Guide pins and bushings: These precision-ground components ensure the upper and lower die halves align perfectly with every stroke. As noted in industry specifications, guide pins are typically ground to tolerances within 0.0001 inch for high-precision applications.

- Die springs: These specialized springs provide the force needed for stripping, pressure pad operation, and material control. Color-coded by load capacity, die springs must match application requirements precisely—too light and parts stick; too heavy and you risk material damage.

What about die steel selection? The material you stamp directly influences tooling material choices. According to stamping industry research, selecting proper tool steels requires balancing three competing characteristics: toughness, wear resistance, and compressive strength.

Common tool steel grades for machine stamp applications include:

- A2 tool steel: Offers good toughness and wear resistance for general-purpose applications. Contains approximately 5.25% chromium for hardening capability.

- D2 tool steel: High chromium content (12%) delivers excellent wear resistance for stamping abrasive materials like stainless steel and high-strength alloys.

- M2 and M4 high-speed steels: When stamping coated materials or high-strength steel, these grades provide the combination of shock resistance and compressive strength needed for demanding applications.

- CPM-10V: Particle metallurgy process creates superior wear resistance for the most challenging stamping environments.

Heat treatment requirements unlock the full potential of these steel stamping dies. The process follows a precise sequence: preheating to avoid thermal shock, soaking at austenitizing temperatures to restructure the steel's atomic structure, rapid quenching to form martensite, and tempering to balance hardness with toughness. For high-speed tool steels used in metal stamping machines, industry standards call for at least three tempering cycles to bring retained austenite to acceptable levels for stamping operations.

Surface coatings extend die life further by reducing friction, wear, and material pickup. Common options include:

- Titanium nitride (TiN): Applied via physical vapor deposition (PVD), this coating offers excellent wear resistance for precision tooling—though it may encounter difficulties with copper and stainless steel applications.

- Titanium carbonitride (TiCN): Provides greater wear resistance in a narrower application range.

- Chrome nitride (CrN): Good general-purpose coating for diverse stamping applications.

- Thermal diffusion (TD) carbide: Uses carbon from the substrate material to form extremely hard surface layers—ideal for forming applications where precision requirements are less stringent.

Extending Die Life Through Proper Maintenance

Even the best-designed custom metal stamping die requires disciplined maintenance to deliver consistent results over millions of cycles. What factors influence die lifespan?

- Material being stamped: Abrasive materials like stainless steel and HSLA grades accelerate wear compared to mild steel or copper.

- Lubrication practices: Proper lubricant selection and application reduce friction heat and prevent galling between tooling and workpiece.

- Press speed: Higher stroke rates generate more friction heat, accelerating wear and potentially affecting part quality.

- Maintenance quality: Regular inspection and timely intervention prevent minor issues from becoming major failures.

Establish these key maintenance checkpoints for your stamping design and tooling program:

- Pre-shift inspection: Check guide pins for scoring, verify spring condition, confirm proper lubrication, and inspect punch tips for visible wear or chipping.

- Sharpening intervals: Monitor burr height on stamped parts—when burrs exceed specifications, schedule die sharpening. Typical intervals range from 50,000 to 500,000 strokes depending on material and tooling configuration.

- Alignment verification: Use precision indicators to check punch-to-die alignment weekly or after any die change. Misalignment as small as 0.001 inch accelerates wear and degrades part quality.

- Component replacement: Track wear on springs, guide bushings, and stripper components. Replace before failure to avoid unplanned downtime.

- Clearance monitoring: As punches and die buttons wear, clearance increases. Regular measurement ensures parts remain within specification.

How does modern engineering reduce trial-and-error? CAE simulation and advanced stamping design software have transformed die development. As explained by industry experts, Computer-Aided Engineering and Finite Element Analysis software allow designers to simulate the entire stamping process digitally before cutting a single piece of steel.

Using platforms like AutoForm or DYNAFORM, engineers can predict material flow, identify potential forming issues, and optimize die geometry virtually. This approach offers significant advantages:

- Rapid iteration without physical prototyping costs

- Early identification of springback, thinning, or wrinkling issues

- Optimized blank shapes that reduce material waste

- Shortened physical tryout periods

- Higher first-time success rates

The result? Faster development timelines, reduced tooling costs, and dies that perform correctly from the first production run. This simulation-first approach represents the current state of the art in metal stamping equipment development.

With tooling fundamentals established, the next critical consideration is quality control. Understanding how to prevent defects, monitor processes, and achieve consistent dimensional accuracy ensures your investment in precision dies delivers the results your production demands.

Quality Control and Defect Prevention Strategies

You've invested in precision tooling and selected the right materials—but how do you ensure every stamped metal component meets specifications? Quality control separates successful stamping operations from costly failures. Without systematic inspection methods and defect prevention strategies, even the best dies and presses will eventually produce parts that fail to meet customer requirements. The difference between a 95% yield rate and a 99.5% yield rate might seem small, but across millions of parts, it translates to thousands of rejected components and significant financial impact.

Think of quality control as your manufacturing insurance policy. According to Metal Infinity, the dimensional tolerance for precision stamping parts often hovers around ±0.05mm—equivalent to the thickness of two sheets of A4 paper. Without an inspection mechanism, this tiny discrepancy could lead to assembly issues, misaligned screws, or even cause entire equipment to seize up. Understanding where defects originate and how to catch them early protects both your reputation and your bottom line.

Common Defects and Root Cause Analysis

What goes wrong during stamping operations? Recognizing defects and understanding their causes enables you to address problems at their source rather than filtering out bad parts at the end of production.

Burrs form when cutting edges fail to separate material cleanly, leaving raised edges or metal fragments along part perimeters and hole edges. According to HLC Metal Parts, burrs often form when cutting tools fail to cut through the metal completely, leaving some metal on the edge of the part. Root causes include worn or dull tooling, excessive punch-to-die clearance, and improper material selection. Left unchecked, burrs can cut hands, scratch mating surfaces, and cause assembly interference.

Cracks occur when metal is subjected to tensile stress beyond its ductility limits. This deformation failure typically appears in localized areas where high strains or stresses concentrate—particularly at sharp corners, small radii, or heavily formed zones. Contributing factors include:

- Excessive strain during aggressive forming operations

- Material with insufficient ductility for the required deformation

- Improper die design creating stress concentration points

- Cold working material that has already been work-hardened

Wrinkles manifest as irregular corrugations or surface deformations, particularly in thin sheets or curved areas. When blank holder pressure is insufficient or material flow is uncontrolled during drawing operations, excess metal bunches up rather than flowing smoothly into the die cavity. Wrinkles reduce part strength, create poor appearance, and often make metal stamping components unusable.

Springback deviation occurs when formed parts partially return toward their original flat shape after leaving the die. This elastic recovery affects dimensional accuracy, particularly on bend angles. Materials with higher yield strength—stainless steel and aluminum alloys especially—exhibit more pronounced springback that must be compensated for in die design.

Surface scratches and strains result from friction between tooling and workpiece surfaces. Foreign particles trapped between die surfaces, inadequate lubrication, or rough tooling finish all contribute to surface defects. For precision stamping parts destined for visible applications, even minor scratches may cause rejection.

Prevention starts with understanding that most defects trace back to six root causes: excessive strain, improper material selection, worn cutting tools, unreasonable mold design, incorrect stamping parameters, and insufficient lubrication. Addressing these fundamentals eliminates the majority of quality issues before they occur.

Achieving Consistent Dimensional Accuracy

How do you verify that stamped metal components meet specifications throughout production? Quality metal stamping requires systematic inspection at multiple stages, not just final checking.

First-article inspection (FAI) establishes the foundation for quality production. Before each production run, a sample part is produced and inspected comprehensively for dimensions, appearance, and functionality. Only after confirming the first article meets all specifications does mass production begin. This protocol catches setup errors before they multiply across thousands of parts.

In-process monitoring provides real-time quality assurance during production. Key techniques include:

- Patrol inspection: Inspectors regularly sample parts from the production line—typically checking 5 pieces every 30 minutes—to verify process stability.

- Statistical process control (SPC): Continuous recording of dimensional data plotted on control charts (X-bar/R charts) reveals trends before parts exceed tolerance limits. If data shows deviation trends, operators can intervene before producing out-of-spec parts.

- Go/no-go gauging: Simple functional gauges quickly verify critical dimensions without precise measurement, enabling 100% inspection of critical features.

Dimensional inspection methods for precision metal stamping parts include:

- Coordinate Measuring Machines (CMM): Three-axis probe systems measure complex geometries with micron-level accuracy, generating detailed dimensional reports for critical dimensions.

- 2.5D optical measurement: Video measuring systems inspect planar dimensions, hole diameters, and positional accuracy without contacting parts—ideal for delicate components.

- Optical scanning: Advanced 3D scanning captures complete part geometry for comparison against CAD models, quickly identifying deviations across entire surfaces.

- Vernier calipers and micrometers: Traditional hand tools provide quick verification of critical dimensions during production sampling.

Industry certifications validate quality systems and provide assurance to customers. For automotive stamped metal components, IATF 16949 certification represents the gold standard. As noted by OGS Industries, this certification meets all ISO 9001 requirements—and then some—ensuring compliance with lean manufacturing, defect prevention, variance deterrence, and waste reduction. IATF 16949-certified suppliers demonstrate their ability to deliver consistent quality through documented quality management systems, process capability analysis, and continuous improvement practices.

Establish these quality checkpoints throughout your stamping process:

- Incoming material inspection: Verify sheet thickness (typically ±0.05mm tolerance), surface condition, and material composition before production begins.

- First-article approval: Comprehensive dimensional and functional verification before releasing production.

- In-process sampling: Regular patrol inspection with documented sampling plans based on AQL (Acceptable Quality Level) standards.

- Critical dimension monitoring: SPC tracking of key characteristics with immediate response to out-of-control conditions.

- Final inspection: Dimensional verification, visual inspection, and functional testing before packaging.

- Outgoing quality control: Lot sampling and documentation with inspection reports for customer verification.

What tolerances are achievable? With proper process control, precision stamping consistently achieves ±0.05mm to ±0.1mm on critical dimensions. Tighter tolerances to ±0.03mm are possible for specific features with optimized tooling and controlled processes. However, achieving these precision standards requires the complete quality system—from incoming material verification through final inspection—working in harmony.

Quality control in stamping isn't merely about catching defects; it's about building a closed-loop system where inspection data drives continuous improvement. When dimensional data reveals trends, engineers adjust die designs, optimize material selection, and refine operating parameters. This feedback loop transforms quality inspection from a cost center into a competitive advantage.

With quality systems established, you're ready to evaluate how stamping compares against alternative manufacturing methods—and understand when this process delivers the best value for your specific application.

Stamping vs Alternative Manufacturing Methods

You've mastered quality control—but is stamping actually the right choice for your project? Before committing to tooling investment, you need to understand how the sheet metal stamping process stacks up against competing technologies. Each manufacturing method offers distinct advantages, and selecting the wrong one can mean overpaying for low-volume runs or leaving money on the table during mass production.

The truth is, no single manufacturing process dominates every scenario. CNC machining excels at flexibility, laser cutting eliminates tooling costs, casting handles complex geometries, and forging delivers unmatched strength. Understanding where stamped sheet metal outperforms these alternatives—and where it doesn't—empowers you to make decisions that optimize both cost and quality.

Cost Break-Even Analysis for Stamping Projects

When does sheet metal stamping become the economical choice? The answer hinges on volume thresholds, tooling amortization, and per-part cost curves that differ dramatically across manufacturing methods.

CNC machining takes a fundamentally different approach than stamping. According to Zintilon, CNC machining utilizes computer-controlled cutting tools to carve or mill a workpiece into the required shape—a subtractive process that removes material rather than reshaping it. This method shines in specific scenarios:

- Flexibility: No tooling investment means design changes cost nothing beyond programming time.

- Precision: Tight tolerances and complex geometries are achievable regardless of part volume.

- Material versatility: Works with metals, plastics, and composites that stamping cannot handle.

However, CNC machining carries significant drawbacks for production applications. The process is inherently slower—each part requires individual machining time. Material waste increases substantially since you're cutting away rather than reshaping. As Zintilon notes, stamping is highly efficient for high-volume production, running continuously with minimal labor once the die is set up, resulting in low per-unit costs for large production runs.

Laser cutting eliminates tooling entirely, making it attractive for prototypes and low volumes. A focused laser beam cuts intricate 2D profiles directly from sheet metal without dies or punches. The trade-off? Laser cutting remains limited to flat profiles—it cannot form bends, draws, or three-dimensional features. For parts requiring only cutting operations at low to medium volumes, laser cutting often outperforms the sheet metal process economically.

Casting produces complex three-dimensional shapes by pouring molten metal into molds. This approach handles geometries impossible for pressed sheet steel—internal cavities, varying wall thicknesses, and organic shapes. However, casting typically delivers looser tolerances than stamping, requires secondary machining for precision surfaces, and involves higher per-part costs at the volumes where stamping excels.

Forging creates the strongest possible metal components by compressing heated or cold material into shape. Forged parts exhibit superior grain structure and mechanical properties compared to stamped alternatives. The premium comes with a price: forging operations cost significantly more per part and require substantial tooling investment—making this method best suited for high-stress applications where material strength justifies the expense.

So where's the break-even point? According to Switzer Manufacturing, stamping may begin to show cost advantages at annual volumes exceeding 50,000 to 100,000 parts, with the specific crossover point highly dependent on individual part characteristics. Simpler parts with larger features favor stamping at lower volumes because die costs remain modest. Complex parts with intricate details may remain more economical to produce through alternative methods even at 500,000 pieces annually.

The tooling amortization calculation drives this analysis. Imagine a progressive die costing $50,000. At 10,000 parts, that's $5.00 per part just for tooling recovery. At 100,000 parts, the tooling contribution drops to $0.50 per part. At 1,000,000 parts, it becomes essentially negligible at $0.05 per part. Meanwhile, CNC machining maintains constant per-part costs regardless of volume—making the crossover point predictable once you know both cost curves.

| Manufacturing Method | Setup Cost | Per-Part Cost at Volume | Geometric Complexity | Tolerance Capability | Ideal Volume Range |

|---|---|---|---|---|---|

| Sheet Metal Stamping | High ($20,000-$150,000+ for tooling) | Very Low at scale | Moderate; limited to formable shapes | ±0.05mm to ±0.15mm | 50,000+ annually |

| CNC Machining | Low (programming only) | High; constant per part | Very High; complex 3D capable | ±0.01mm to ±0.05mm | 1-10,000 parts |

| Laser Cutting | Very Low (no tooling) | Moderate; depends on complexity | High for 2D; no forming | ±0.1mm to ±0.25mm | 1-50,000 parts |

| Casting | Moderate to High (mold costs) | Moderate | Very High; internal features possible | ±0.25mm to ±1.0mm | 500-100,000 parts |

| Forging | High (die costs) | High | Moderate; limited by die access | ±0.1mm to ±0.5mm | 1,000-500,000 parts |

Design Modifications That Reduce Tooling Costs

Once you've determined that the manufacturing stamping process fits your volume requirements, design for manufacturability (DFM) principles can dramatically reduce both tooling investment and per-part costs. Small design changes often yield significant savings without compromising function.

Minimum bend radii prevent cracking and reduce tooling complexity. As a general rule, inside bend radius should equal at least the material thickness for soft materials like aluminum and copper. For harder materials like stainless steel, specify inside radii of 1.5 to 2 times material thickness. Tighter bends require more sophisticated tooling, increase forming forces, and risk material failure.

Hole-to-edge distances affect both die life and part quality. Position holes at least 1.5 times material thickness from part edges to prevent distortion during blanking. Closer spacing weakens the material between hole and edge, potentially causing tear-out during forming operations or in service.

Hole-to-hole spacing follows similar logic. Maintain at least 2 times material thickness between adjacent holes to preserve material integrity between punches. Closer spacing increases die complexity and reduces tool life.

Draft angles facilitate part ejection from forming dies. While stamping requires less draft than casting or molding, slight angles (typically 1-3 degrees) on vertical walls help parts release cleanly from die cavities without sticking or surface damage.

Material utilization optimization directly impacts per-part costs. The sheet metal stamping design process should consider blank layout efficiency—how many parts can be nested within a sheet or coil width with minimal scrap. Sometimes small dimensional adjustments yield dramatically better material utilization. A bracket that's 98mm wide might use 30% more material per part than one redesigned to 95mm if that dimension improves nesting efficiency.

Feature consolidation reduces die stations and forming operations. Rather than designing separate components that must be assembled, consider whether a single stamped part can incorporate multiple functions. Each eliminated assembly operation saves labor cost and reduces potential quality issues.

Avoid deep draws when possible. Shallow forming operations require less press tonnage, simpler tooling, and run faster than deep draws. If your design requires significant depth, consider whether that depth is functionally necessary or simply an inherited feature from previous manufacturing methods.

These sheet metal press considerations work together. A well-optimized design for the manufacturing stamping process might cost 20-40% less to produce than a functionally identical part designed without DFM principles. The difference compounds across production volumes—savings multiply with every part produced.

Understanding these cost dynamics and design principles positions you to evaluate stamping opportunities accurately. But theory only goes so far. In the next section, we'll explore how these principles apply in one of stamping's most demanding applications: automotive manufacturing, where quality standards, production volumes, and development timelines push the technology to its limits.

Automotive Stamping Applications and Industry Standards

You've explored stamping fundamentals, compared manufacturing methods, and understand cost dynamics—but where does this knowledge face its ultimate test? The automotive industry. No sector pushes metal stamping manufacturing to greater extremes: tighter tolerances, higher volumes, stricter quality requirements, and relentless pressure to accelerate development timelines. Understanding how automotive stamping operates reveals the full potential of stamping manufacturing as a precision production technology.

Consider the scale: a single vehicle contains between 300 and 500 stamped components, from massive body panels to tiny brackets. Multiply that by production volumes reaching millions of vehicles annually, and you begin to grasp why automotive metal stamping demands absolute consistency. A defect rate acceptable in other industries becomes catastrophic when translated across automotive production volumes.

Meeting OEM Quality Standards

What separates automotive stamping from general manufacturing? The answer starts with certification requirements that filter suppliers before a single part is produced.

IATF 16949 certification represents the entry ticket to automotive supply chains. According to industry analysis, while ISO 9001 establishes a baseline for general quality management, it is insufficient for the rigorous demands of automotive OEMs and Tier 1 suppliers. IATF 16949 is the industry standard, specifically designed to prevent defects, reduce variation, and minimize waste in the automotive supply chain.

This certification goes beyond documentation. An IATF-certified supplier has demonstrated systems for:

- Handling safety-critical components with full traceability

- Implementing risk management protocols for parts like brake components and chassis reinforcements

- Maintaining defect prevention rather than defect detection approaches

- Meeting customer-specific requirements from major OEMs

Production Part Approval Process (PPAP) validates that a supplier's metal stamping manufacturing process can consistently produce parts meeting all requirements during actual production runs. This rigorous documentation package—including dimensional results, material certifications, capability studies, and control plans—must be approved before volume production begins.

Advanced Product Quality Planning (APQP) structures the entire development process from concept through production launch. This framework ensures potential issues are identified and resolved during planning rather than discovered during production.

The performance expectations? According to industry benchmarks, top-tier automotive stampers achieve rejection rates as low as 0.01% (100 PPM), while average suppliers hover around 0.53% (5,300 PPM). This gap translates directly to assembly line reliability—the difference between smooth production and costly shutdowns.

High volume metal stamping for automotive applications also demands specific technical capabilities. Press tonnage requirements typically range from 100 to 600+ tons to handle both precision brackets and larger structural components like control arms or subframes. In-house tooling capabilities become critical—when a die breaks during production, sending it out for repair can take days or weeks, while internal tool shops often fix issues in hours.

Suppliers like Shaoyi Metal Technology exemplify how modern stamping die providers address these demanding requirements. Their IATF 16949-certified facility utilizes presses up to 600 tons, enabling production of critical safety components with OEM-level precision. Advanced CAE simulation capabilities allow their engineering team to predict material flow, identify potential forming issues, and optimize die geometry before cutting steel—reducing trial-and-error and accelerating time to production.

Accelerating Development with Rapid Prototyping

Automotive development cycles have compressed dramatically. Vehicle programs that once spanned five years now complete in three. This acceleration creates intense pressure on stamping manufacturing timelines—tooling that previously had 18 months for development must now be production-ready in half that time.

Rapid prototyping bridges the gap between design concepts and production validation. According to industry experts, rapid prototyping quickly delivers cost-efficient models that help trim days, weeks, or months off standard development timelines. When product designers don't have time for endless hypothesizing, prototypes built to mirror final products with exceptional accuracy enable faster decision-making.

The benefits extend beyond speed:

- Design validation: Physical prototypes reveal issues that CAD models miss—fit problems, unexpected springback, assembly interference.

- Process refinement: Testing forming sequences on prototype tooling identifies optimal parameters before production die investment.

- Customer approval: OEMs can evaluate actual parts rather than making decisions based solely on drawings and simulations.

- Risk reduction: Catching design flaws during prototyping costs a fraction of discovering them during production launch.

Consider the practical impact: production metal stamping suppliers with integrated prototyping capabilities can deliver initial samples in as little as five days. This speed enables multiple design iterations within timeframes that previously allowed only one—dramatically improving final part quality while compressing overall development schedules.

Shaoyi's approach demonstrates how leading suppliers integrate rapid prototyping with production stamping. Their engineering team delivers prototype tooling capable of producing 50 parts within days, allowing customers to validate designs before committing to full production dies. This prototype-to-production capability—combined with a 93% first-pass approval rate—reduces the costly iterations that plague stamping programs managed by multiple disconnected suppliers.

The automotive stamping landscape continues evolving. Lightweighting initiatives drive increased use of high-strength steels and aluminum alloys that demand more sophisticated forming techniques. Electric vehicle platforms introduce new component geometries and material requirements. Throughout these changes, the fundamental requirements remain: precision tooling, certified quality systems, and suppliers capable of moving seamlessly from concept through high-volume production.

For manufacturers evaluating stamping partners, the automotive sector provides a useful benchmark. Suppliers meeting automotive requirements—IATF 16949 certification, proven PPAP processes, integrated prototyping capabilities, and documented quality metrics—bring that same rigor to every project. Whether your application involves automotive volumes or more modest production runs, partnering with automotive-qualified suppliers ensures your stamping program benefits from the industry's most demanding standards.

With automotive applications illustrating stamping's full potential, you're ready to synthesize everything covered into actionable guidance for your specific project. The final section provides a decision framework to help you evaluate whether stamping fits your requirements and how to select the right manufacturing partner.

Making the Right Stamping Decisions for Your Project

You've journeyed through the complete stamping manufacturing process—from fundamental mechanics to automotive-grade quality systems. Now comes the critical question: how do you translate this knowledge into successful project execution? Whether you're launching a new product or optimizing existing production, the decisions you make at the outset determine outcomes for years to come.

The truth is, metal stamping success rarely depends on a single brilliant decision. Instead, it emerges from systematically addressing interconnected factors: selecting materials that match application demands, choosing process types aligned with volume and complexity, matching press capabilities to forming requirements, and implementing quality systems that deliver consistent results. Miss any element, and you'll encounter problems that could have been prevented.

Your Stamping Project Evaluation Checklist

Before engaging potential suppliers or committing to tooling investment, work through these essential decision criteria. Each question builds on insights from the previous chapters, creating a comprehensive framework for project evaluation.

- Volume assessment: What annual quantities do you require? Metal stamping typically becomes cost-effective above 50,000 pieces annually, though simpler parts may break even at lower volumes. If you need fewer than 10,000 parts, consider whether CNC machining or laser cutting offers better economics.

- Material requirements: Does your application demand specific properties—corrosion resistance, electrical conductivity, high strength-to-weight ratio? Match material selection to functional requirements first, then verify stampability. Remember that aluminum requires springback compensation while stainless steel work-hardens quickly.

- Geometric complexity: Evaluate whether your part geometry suits progressive dies (moderate complexity, high volume), transfer dies (larger parts, deep draws), or fourslide systems (intricate small parts). Complex geometries increase tooling costs but may consolidate multiple components into one.

- Tolerance specifications: Define critical dimensions and acceptable tolerances early. Precision stamping achieves ±0.05mm on critical features, but tighter tolerances increase tooling complexity and inspection requirements. Specify only what function truly requires.

- Quality certifications needed: Determine whether your industry mandates specific certifications. Automotive applications require IATF 16949-certified suppliers. Medical and aerospace sectors have their own standards. Selecting certified suppliers upfront prevents qualification delays later.

- Development timeline: How quickly must you reach production? Rapid prototyping capabilities—some suppliers deliver initial samples in as few as 5 days—dramatically compress development cycles. Factor prototype iterations into your schedule.

- Secondary operations: Identify post-stamping requirements: plating, welding, assembly, heat treatment. Suppliers offering integrated secondary operations reduce logistics complexity and quality handoff risks.

- Total cost analysis: Look beyond per-part pricing. Include tooling amortization, scrap rates, quality costs, and development expenses in your calculations. A slightly higher per-part cost from a supplier with 99%+ quality may cost less overall than a lower quote with 5% rejection rates.

According to Larson Tool & Stamping, vetting potential suppliers should explore several critical areas: quality certifications, measurable performance objectives, reinvestment in capabilities, supply chain relationships, workforce training programs, and facility organization. Any well-run stamping company should have this information readily available—if they don't, consider it a warning sign about their overall capabilities.

Partnering with the Right Tooling Experts

Here's what separates successful stamping programs from troubled ones: timing of supplier engagement. As highlighted by Micro-Tronics, modifying a design in the initial stages is relatively easy and cost-effective; modifying a design in the fabrication or production stages is increasingly difficult and costly. The implication is clear—bring your custom metal stamper into the conversation early.

Why does early collaboration matter so much? Consider what happens when engineers design parts without manufacturing input:

- Features that seem reasonable on CAD become expensive or impossible to stamp

- Material selections optimize one property while creating forming challenges

- Tolerances get specified tighter than necessary, inflating tooling costs

- Assemblies require multiple stamped parts when one consolidated design would work

Design for manufacturability (DFM) guidance from experienced custom metal stamping services providers catches these issues before they become embedded in your specifications. A competent engineering team reviews your design intent, identifies potential forming problems, and suggests modifications that maintain function while improving stampability. This collaboration typically saves 15-30% on tooling costs while shortening development timelines.

What should you expect from a qualified partner? Look for suppliers who demonstrate:

- Engineering depth: In-house capability to analyze your designs, simulate forming processes, and recommend improvements—not just quote whatever you send them.

- Prototyping integration: The ability to produce prototype metal stamped parts quickly, enabling design validation before production tooling commitment.

- Quality track record: Documented metrics like first-pass approval rates that demonstrate consistent execution. A 93% first-pass approval rate, for example, indicates a supplier whose engineering processes prevent most issues before production begins.

- Scalability: Capability to support your project from initial prototypes through high-volume production without changing suppliers mid-program.

- Communication responsiveness: Quick, clear answers to technical questions signal an organization that prioritizes customer success over simply processing orders.

For readers ready to move from learning to implementation, Shaoyi Metal Technology exemplifies these partnership qualities. Their engineering team supports projects from rapid prototyping—delivering samples in as little as 5 days—through high-volume manufacturing, backed by IATF 16949 certification and advanced CAE simulation capabilities. Their 93% first-pass approval rate reflects the design-for-manufacturing expertise that transforms good designs into production-ready metal stamped parts.

The stamping manufacturing process, executed properly, delivers unmatched economics for medium to high-volume metal component production. The knowledge you've gained—from operation types and press selection through material properties and quality systems—positions you to evaluate opportunities accurately and engage suppliers effectively. Your next step? Apply this checklist to your specific project, identify qualified partners early, and leverage their expertise to optimize your design before tooling begins. That's how successful stamping programs start.

Frequently Asked Questions About Stamping Manufacturing

1. What are the 7 steps in the stamping method?

The stamping method typically follows these key steps: blanking (cutting initial shapes), piercing (creating holes), drawing (forming depth), bending (angular deformation), air bending (flexible angle forming), bottoming and coining (high-pressure finishing), and pinch trimming (final edge cleanup). Each step uses specialized dies within progressive or transfer stamping systems. The sequence varies based on part complexity, with simpler components requiring fewer operations while automotive parts may incorporate all seven steps plus additional forming stages.

2. What is stamping in auto manufacturing?

In automotive manufacturing, stamping transforms flat metal sheets into vehicle components using custom-designed dies and high-tonnage presses. This process produces body panels, doors, structural reinforcements, brackets, and chassis elements. Automotive stamping demands IATF 16949 certification, tight tolerances of ±0.05mm, and rejection rates below 0.01%. Modern automotive stampers use CAE simulation to optimize die designs and rapid prototyping to validate parts before production tooling investment.

3. Is stamping a machining process?

No, stamping is fundamentally different from machining. Stamping is a forming process that reshapes sheet metal using dies and pressure without removing material. Machining is a subtractive process that cuts away material from solid blocks. Stamping excels at high-volume production with low per-part costs once tooling is established, while machining offers flexibility for low-volume, high-precision components. For volumes exceeding 50,000 parts annually, stamping typically becomes more cost-effective than machining.

4. What is the difference between progressive die and transfer die stamping?

Progressive die stamping feeds a continuous metal strip through multiple stations in a single die, with parts remaining attached until final cutoff. This method achieves speeds exceeding 1,000 strokes per minute, ideal for high-volume simple parts like connectors and brackets. Transfer die stamping moves individual blanks between separate die stations using mechanical fingers, accommodating larger parts and deeper draws. Transfer systems suit automotive body panels and complex geometries that exceed progressive die limitations.

5. How do you select the right metal for stamping applications?

Metal selection depends on four key properties: ductility (deformation without fracturing), yield strength (forming ease versus final strength), work hardening rate (behavior in multi-stage operations), and grain structure (surface finish quality). Low-carbon steel offers excellent formability for brackets and panels. Stainless steel provides corrosion resistance but work-hardens quickly. Aluminum delivers lightweight advantages but requires springback compensation. Copper and brass suit electrical applications due to superior conductivity and formability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —