-

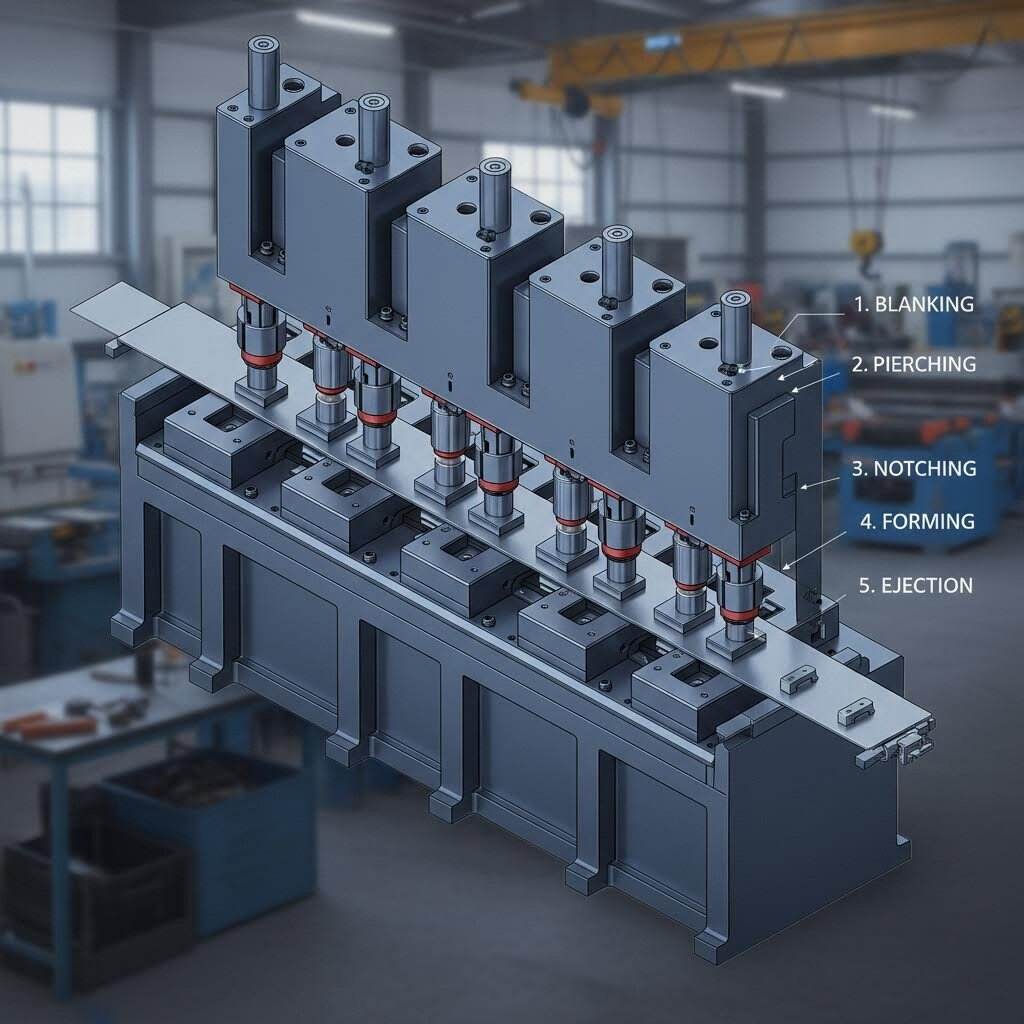

शीट मेटल स्टैम्पिंग डाई के रहस्य: डिज़ाइन की कमियों से लेकर निर्दोष भागों तक

2026/01/27शीट मेटल स्टैम्पिंग डाई डिज़ाइन, प्रकारों, घटकों और ट्रबलशूटिंग पर महारत हासिल करें। लागत कारकों, रखरखाव के सर्वोत्तम अभ्यासों और ऑटोमोटिव गुणवत्ता मानकों के बारे में जानें।

-

यांत्रिक डाई का शरीर-विज्ञान: प्रत्येक खरीदार के लिए आवश्यक 9 मुख्य बिंदु

2026/01/27यांत्रिक डाई के शरीर-विज्ञान, प्रकारों, सामग्रियों और रखरखाव के बारे में जानें। विशेषज्ञ मार्गदर्शिका में प्रोग्रेसिव, कंपाउंड और ट्रांसफर डाइज़ के साथ-साथ आपूर्तिकर्ता चयन के सुझाव शामिल हैं।

-

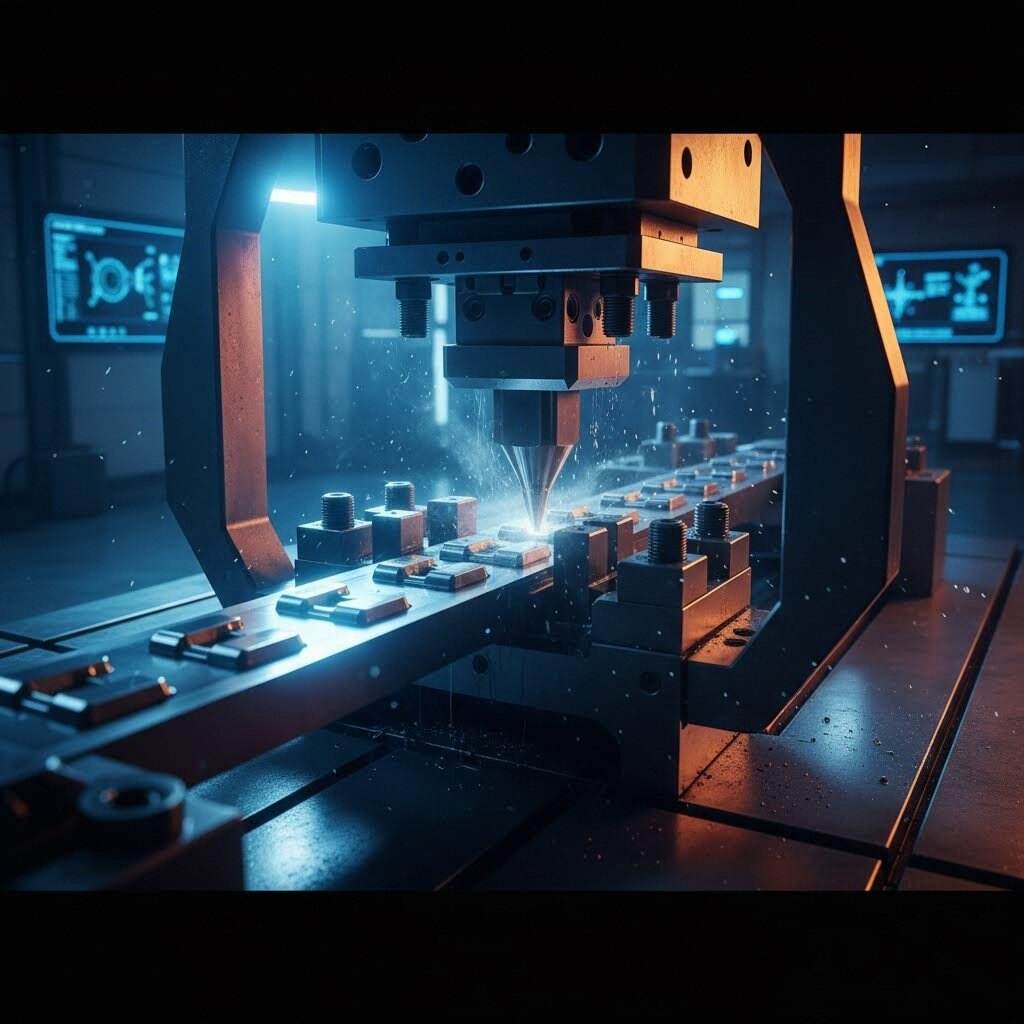

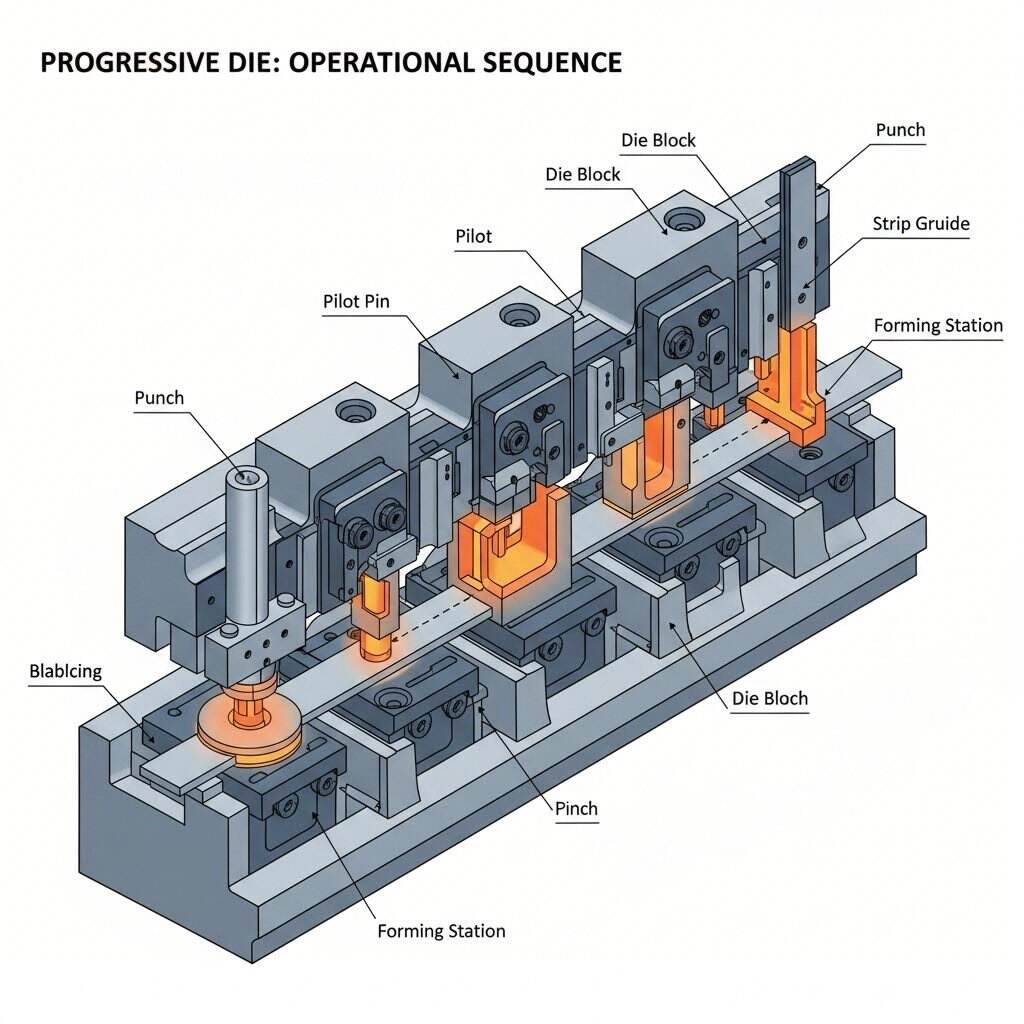

प्रोग्रेसिव डाई स्टैम्पिंग प्रक्रिया: स्टेशन-दर-स्टेशन विस्तृत विश्लेषण

2026/01/27इस स्टेशन-दर-स्टेशन विवरण के साथ प्रगतिशील डाई स्टैम्पिंग प्रक्रिया पर महारत हासिल करें, जिसमें टूलिंग, सामग्री, दोष रोकथाम और DFM दिशानिर्देश शामिल हैं।

-

डाई फॉर्मिंग धातु उजागर: 9 आवश्यक बिंदु जिन्हें इंजीनियर अक्सर याद कर जाते हैं

2026/01/27डाई फॉर्मिंग धातु से संबंधित 9 महत्वपूर्ण बिंदुओं के बारे में जानें जिन्हें इंजीनियर अक्सर याद कर जाते हैं—डाई के प्रकार और फॉर्मिंग ऑपरेशन से लेकर लागत विश्लेषण, सहिष्णुता (टॉलरेंस) और उद्योग अनुप्रयोगों तक।

-

शीट मेटल फॉर्मिंग डाइज़: डिज़ाइन की कमियों से लेकर निर्दोष भागों तक

2026/01/27शीट मेटल फॉर्मिंग डाइज़ पर महारत हासिल करें इस संपूर्ण गाइड के साथ, जिसमें डाई के प्रकार, फॉर्मिंग ऑपरेशन, सामग्री आवश्यकताएँ, डिज़ाइन इंजीनियरिंग और रखरखाव के मूल तत्व शामिल हैं।

-

प्रगतिशील धातु स्टैम्पिंग को सरल बनाया गया: कच्ची कॉइल से लेकर तैयार भाग तक

2026/01/27जानें कि कैसे प्रगतिशील धातु स्टैम्पिंग कच्ची कॉइल को सटीक भागों में बदलती है। संपूर्ण गाइड जिसमें डाई घटक, प्रक्रिया के चरण, सामग्री और सहयोगी चयन शामिल हैं।

-

ट्रांसफर डाई स्टैम्पिंग के रहस्य: जब यह प्रोग्रेसिव डाइज़ को हर बार पीछे छोड़ देता है

2026/01/26इस संपूर्ण मार्गदर्शिका के साथ ट्रांसफर डाई स्टैम्पिंग पर दखल जमाएँ, जो प्रक्रिया के यांत्रिकी, डिज़ाइन विचारों, सामग्री चयन और उन परिस्थितियों को शामिल करती है जहाँ यह प्रोग्रेसिव डाइज़ की तुलना में श्रेष्ठ होता है।

-

कंपाउंड डाइज़ को समझना: जब वे प्रोग्रेसिव स्टैम्पिंग को पीछे छोड़ देते हैं

2026/01/26जानें कि कब कंपाउंड डाइज़ प्रोग्रेसिव स्टैम्पिंग की तुलना में श्रेष्ठ प्रदर्शन करते हैं। इस संपूर्ण मार्गदर्शिका में घटकों, सामग्रियों, रखरखाव और सटीक भागों के लिए चयन मानदंडों को शामिल किया गया है।

-

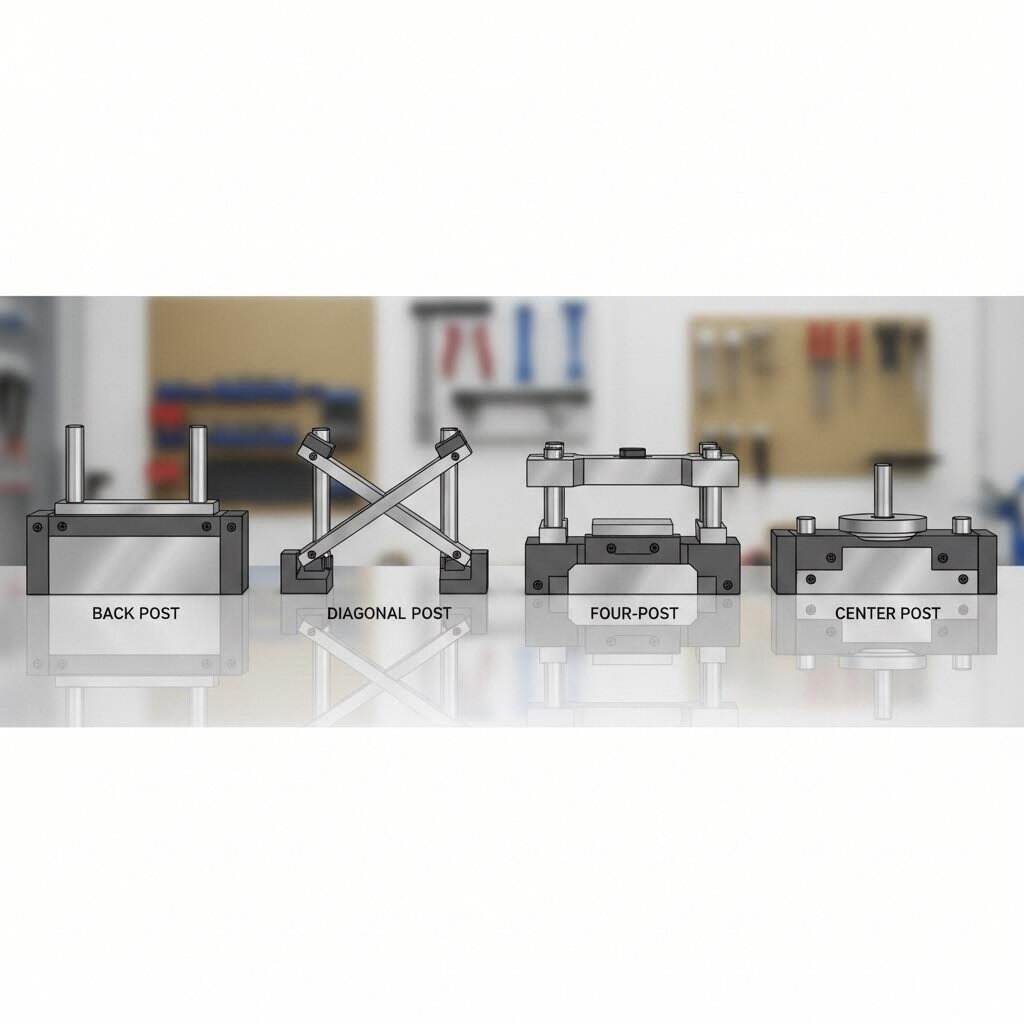

स्टैम्पिंग डाई सेट का चयन: अपने प्रेस, सामग्री और उत्पादन लक्ष्यों के अनुरूप बनाएँ

2026/01/26अपने प्रेस के लिए सही स्टैम्पिंग डाई सेट का चयन कैसे करें, इसके बारे में सीखें। विभिन्न विन्यासों, सामग्रियों, आकारों की तुलना करें और अपनी उत्पादन आवश्यकताओं के लिए गुणवत्तापूर्ण आपूर्तिकर्ताओं को खोजें।

-

स्टैम्पिंग डाई निर्माताओं का खुलासा: मूल्य निर्धारण के बारे में वे जो आपको नहीं बताना चाहते

2026/01/26जानें कि स्टैम्पिंग डाई निर्माता मूल्य निर्धारण, डाई के प्रकार, सामग्री और सहनशीलता के बारे में आपको क्या नहीं बताएँगे। उद्धरणों का मूल्यांकन करने और आपूर्तिकर्ताओं के साथ काम करने के लिए विशेषज्ञ मार्गदर्शिका।

-

धातु प्रेस डाइज़ को समझें: कच्चे इस्पात से लेकर सटीक भागों तक

2026/01/26जानें कि कैसे धातु प्रेस डाइज़ शीट धातु को सटीक भागों में परिवर्तित करती हैं। इसमें डाइज़ के प्रकार, सामग्री, डिज़ाइन सिद्धांत, रखरखाव और आपूर्तिकर्ता चयन के टिप्स शामिल हैं।

-

शीट धातु प्रेस डाइज़ का खुलासा: चयन से लेकर स्रोत निर्धारण के रहस्य तक

2026/01/26विनिर्माण सफलता के लिए शीट धातु प्रेस डाइज़ पर माहिर होने के लिए यह संपूर्ण मार्गदर्शिका: डाइज़ के प्रकार, तकनीकी विशिष्टताएँ, सामग्री संगतता, लागत विश्लेषण और स्रोत निर्धारण के रहस्य।

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —