धातुओं की लेजर कटिंग को डिकोड किया गया: पहली बीम से लेकर दोषरहित किनारे तक

धातुओं की लेजर कटिंग की समझ और इसका महत्व

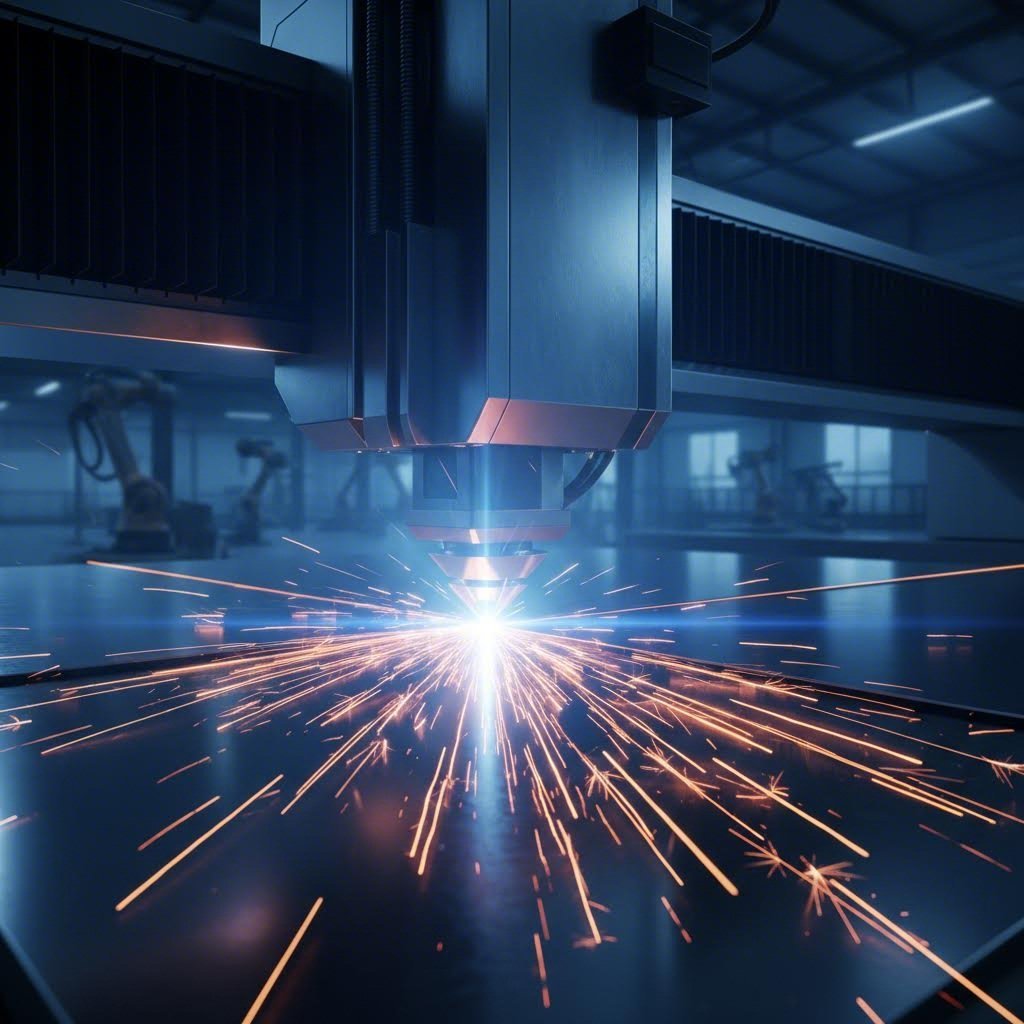

एक प्रकाश की किरण की कल्पना करें जो इतनी केंद्रित हो कि यह स्टील को मक्खन के माध्यम से गर्म चाकू की तरह काट दे। आधुनिक धातु निर्माण में लेजर तकनीक के साथ काटने पर ठीक ऐसा ही होता है। ऑटोमोटिव चेसिस घटकों से लेकर जटिल एयरोस्पेस भागों तक, धातुओं की लेजर कटिंग ने मौलिक रूप से बदल दिया है निर्माता सटीक घटकों को कैसे बनाते हैं लगभग हर उद्योग में।

तो यह तकनीक वास्तव में क्या है? धातुओं की लेजर कटिंग एक ऊष्मीय कटिंग प्रक्रिया है जो एक सटीक रूप से प्रोग्राम किए गए पथ के साथ सामग्री को पिघलाने, जलाने या वाष्पीकृत करने के लिए एक केंद्रित, उच्च-शक्ति वाली लेजर बीम का उपयोग करती है। परिणाम? साफ किनारे, जटिल डिज़ाइन, और शुद्धता जो पारंपरिक कटिंग विधियाँ सरलता से मिलान नहीं कर सकतीं।

लेजर बीम ठोस धातु को कैसे बदलते हैं

जादू खुद प्रकाश के साथ शुरू होता है। एक धातु लेज़र कटिंग प्रणाली उत्प्रेरित उत्सर्जन नामक प्रक्रिया के माध्यम से अत्यंत सघन बीम उत्पन्न करती है। यह बीम फाइबर ऑप्टिक्स या दर्पणों के माध्यम से एक कटिंग हेड तक पहुँचता है, जहाँ विशेष लेंस इसे इतना केंद्रित करते हैं कि इसका व्यास मात्र 0.01 मिमी —यह मानव बाल की तुलना में लगभग 8 गुना छोटा होता है।

जब यह केंद्रित ऊर्जा धातु से संपर्क करती है, तो यह 10¹³W से अधिक शक्ति घनत्व प्राप्त कर लेती है। इतने चरम सांद्रता में, सबसे कठोर धातुएँ भी लगभग तुरंत पिघल जाती हैं। लेज़र कटिंग की क्रिया या तो सामग्री को पिघला देती है (फ्यूजन कटिंग) या पूरी तरह से वाष्पित कर देती है (उच्चतर कटिंग), जबकि सहायक गैसें पिघले हुए मलबे को उड़ाकर साफ-सुथरे किनारे बना देती हैं।

सटीक धातु कटिंग के पीछे का भौतिकी

लेज़र धातु कटिंग को संभव बनाने वाले दो प्रमुख गुण हैं:

- एकवर्णीकरण: लेज़र लगभग समान तरंग दैर्ध्य पर प्रकाश उत्पन्न करता है, जिससे ऊर्जा की निरंतर आपूर्ति संभव होती है

- संगतता: प्रकाश तरंगें पूर्ण संरेखण में यात्रा करती हैं, जिससे बीम दूरी तक फोकस बनाए रख सके और अविश्वसनीय रूप से छोटे फोकल बिंदु तक पहुँच सके

ये विशेषताएँ निर्माताओं को स्टील, एल्युमीनियम या टाइटेनियम के साथ काम करते समय भी मिलीमीटर के अंशों में मापी गई सटीकता के साथ 80 मिमी मोटाई तक की धातु की चादरों को काटने की अनुमति देती हैं।

लेजर कटिंग सामग्री की बर्बादी को काफी कम करती है और उत्पादन की गति बढ़ाती है—निर्माता अधिक परियोजनाओं को अपनाने और गुणवत्ता में समझौता किए बिना त्वरित टर्नअराउंड समय की पेशकश कर सकते हैं।

आधुनिक निर्माण के लिए धातु लेजर कटिंग का महत्व क्यों है? लाभ महत्वपूर्ण हैं: कठोर सहनशीलता के लिए अतुल्य सटीकता, 150 मिमी/सेकंड तक की कटिंग गति, लागत बचत में परिवर्तित होने वाली न्यूनतम सामग्री बर्बादी, और पारंपरिक तरीकों से असंभव जटिल ज्यामिति बनाने की क्षमता। चिकित्सा उपकरण निर्माण से लेकर वास्तुकला धातु कार्य तक के उद्योग इस तकनीक पर रोजाना निर्भर करते हैं।

इस मार्गदर्शिका के माध्यम से, आपको लेज़र द्वारा धातु काटने की प्रक्रिया कैसे काम करती है, इसके चरण बह चरण विवरण मिलेंगे, विशिष्ट अनुप्रयोगों के लिए कौन से लेज़र प्रकार सबसे उत्तम प्रदर्शन करते हैं, और सामान्य गुणवत्ता संबंधी समस्याओं का निवारण कैसे करें। चाहे आप उपकरण विकल्पों का मूल्यांकन कर रहे हों या अपनी वर्तमान प्रक्रियाओं को अनुकूलित करने की तलाश में हों, आपको जागरूक निर्णय लेने के लिए आवश्यक व्यावहारिक अंतर्दृष्टि मिलेगी।

चरण दर चरण संपूर्ण लेज़र कटिंग प्रक्रिया की व्याख्या

अब जब आप समझ गए हैं कि यह तकनीक क्यों महत्वपूर्ण है, तो आइए इसके कार्यप्रणाली में गहराई से उतरें। एक लेज़र कटिंग प्रणाली कच्ची विद्युत ऊर्जा को सटीकता में परिवर्तित करती है एक सावधानीपूर्वक समन्वित क्रम के माध्यम से कटौती करती है। प्रत्येक चरण को समझने से आपको परिणामों को अनुकूलित करने और समस्याओं के उत्पन्न होने पर उनका निवारण करने में सहायता मिलती है।

किरण उत्पादन से लेकर पूर्ण कट तक

लेज़र द्वारा धातु काटने में आपकी अपेक्षा से अधिक चरण शामिल होते हैं। बिजली चालू करने से लेकर तैयार भाग तक की पूर्ण अनुक्रम यहाँ दी गई है:

- लेज़र किरण उत्पादन: प्रक्रिया लेजर स्रोत से शुरू होती है। फाइबर लेजर में, आयटर्बियम जैसे दुर्लभ-पृथ्वी तत्वों से डोप किए गए ऑप्टिकल फाइबर लगभग 1.06 माइक्रॉन की तरंगदैर्ध्य के साथ एक शक्तिशाली बीम उत्पन्न करते हैं। धातु सामग्री में अवशोषण बेहतर होने के कारण CO2 लेजर की तुलना में यह छोटी तरंगदैर्ध्य फाइबर प्रणालियों को लेजर कटिंग प्रक्रिया के लिए विशेष रूप से प्रभावी बनाती है।

- बीम डिलीवरी: उत्पन्न बीम लचीली फाइबर-ऑप्टिक केबलों या सटीक रूप से संरेखित दर्पणों की एक श्रृंखला के माध्यम से यात्रा करता है। फाइबर ऑप्टिक डिलीवरी पारंपरिक CO2 लेजर द्वारा आवश्यक जटिल दर्पण प्रणालियों को समाप्त कर देती है, जिससे रखरखाव कम होता है और विश्वसनीयता में सुधार होता है।

- फ़ोकसिंग: एक समांतरीकरण लेंस पहले बीम को समांतर करता है, फिर एक फोकसिंग लेंस इसे एक छोटे बिंदु पर केंद्रित करता है। यह उच्च शक्ति घनत्व—अक्सर 10¹³ W प्रति वर्ग सेंटीमीटर —को बनाता है, जो मोटी धातुओं को काटने के लिए आवश्यक होता है।

- सामग्री अंतःक्रिया: जब फोकसित किरण कार्यपृष्ठ से संपर्क करती है, तो तीव्र ऊष्मा के कारण सामग्री तेजी से पिघल जाती है या वाष्पित हो जाती है। फोकल बिंदु की सटीकता से उष्मा-प्रभावित क्षेत्र कम से कम रहता है, जिससे आसपास के क्षेत्र में विरूपण रोका जा सकता है।

- मलबे का निष्कासन: कटिंग हेड एक सह-अक्षीय सहायक गैस जेट को इंगित करता है जो कट से पिघली हुई सामग्री को दूर उड़ा देता है, साफ कर्फ बनाता है और कार्यपृष्ठ को ठंडा करता रहता है।

- पथ क्रियान्वयन: सीएनसी प्रोग्रामिंग माइक्रॉन-स्तरीय सटीकता के साथ कटिंग हेड को निर्धारित पथ पर मार्गदर्शन करती है, जिससे उत्पादन चक्रों में उत्कृष्ट पुनरावृत्ति सुनिश्चित होती है।

इस अनुक्रम में प्रत्येक चरण सामंजस्य में काम करना चाहिए। धातु के लिए लेजर कटिंग मशीन इन सभी तत्वों को एक एकीकृत इकाई में जोड़ती है, जहां ऑपरेटर केवल सामग्री लोड करते हैं, डिज़ाइन अपलोड करते हैं, और प्रणाली को उल्लेखनीय सटीकता के साथ कार्य करने देते हैं।

धातु कटिंग की गुणवत्ता में सहायक गैसों की भूमिका

यहाँ कुछ ऐसी बात है जिसे कई शुरुआती लोग नजरअंदाज कर देते हैं: आपके द्वारा चुनी गई गैस लेजर के समान ही आपके परिणामों को प्रभावित करती है। धातु काटने वाली लेजर मशीन कटिंग की गुणवत्ता, गति और किनारों की समाप्ति को अनुकूलित करने के लिए सहायक गैसों पर निर्भर करती है। प्रत्येक गैस एक अलग उद्देश्य के लिए उपयोग होती है:

| सहायक गैस | सर्वश्रेष्ठ उपयोग | मुख्य लाभ | विचार |

|---|---|---|---|

| नाइट्रोजन | स्टेनलेस स्टील, एल्यूमीनियम, सजावटी धातुएँ | साफ, ऑक्साइड-मुक्त किनारे, सामग्री के रंग को बनाए रखता है, दिखाई देने वाले भागों के लिए आदर्श | उच्च खपत, सर्वोत्तम परिणामों के लिए उच्च शुद्धता की आवश्यकता |

| ऑक्सीजन | माइल्ड स्टील, मोटी कार्बन स्टील | ऊष्माक्षेपी अभिक्रिया कटिंग शक्ति में वृद्धि करती है, मोटी सामग्री पर तेज गति | कटिंग किनारे पर ऑक्साइड परत बनाता है, पोस्ट-प्रोसेसिंग की आवश्यकता हो सकती है |

| संपीड़ित वायु | पतली धातुएँ, लागत-संवेदनशील अनुप्रयोग | सबसे किफायती विकल्प, आसानी से उपलब्ध | इसमें 21% ऑक्सीजन शामिल है—किनारों को डीबर करने की आवश्यकता हो सकती है, सटीक कार्य के लिए उपयुक्त नहीं |

नाइट्रोजन सबसे व्यापक रूप से उपयोग की जाने वाली सहायक गैस है जब उच्च गुणवत्ता वाले कटौती की आवश्यकता होती है। इसके निष्क्रिय गुण ऑक्सीकरण को रोकते हैं, जिससे बिना रंग बदले चमकदार, साफ किनारे प्राप्त होते हैं। इससे वे भाग जो दृष्टिगोचर रहेंगे या बाद में लेपित किए जाने हैं, के लिए आवश्यक बनाता है।

इसके विपरीत, ऑक्सीजन धातु के साथ एक ऊष्माक्षेपी प्रतिक्रिया उत्पन्न करती है—अर्थात लेज़र की कटौती शक्ति को गुणा करता है। इससे लेज़र धातु कटौती मशीन मोटी सामग्री को तेज़ी से काट सकती है, हालाँकि परिणामी ऑक्साइड परत के कारण इन भागों को आमतौर पर अतिरिक्त फिनिशिंग की आवश्यकता होती है।

आपके कटौती पथ को नियंत्रित करने वाली सीएनसी प्रणाली सिर्फ सिर को हिलाने से अधिक कार्य करती है। आधुनिक नियंत्रक सामग्री के प्रकार, मोटाई और ज्यामिति के आधार पर वास्तविक समय में शक्ति, गति और गैस दबाव को समायोजित करते हैं। वे कोनों पर त्वरण के लिए क्षतिपूर्ति करते हैं, पियर्स क्रम को अनुकूलित करते हैं, और यह सुनिश्चित करते हैं कि गुणवत्ता स्थिर रहे चाहे आप एक भाग या एक हजार भाग काट रहे हों।

इन मूल बातों को समझने से आप विभिन्न लेजर तकनीकों का आकलन करने के लिए तैयार हो जाते हैं। लेकिन आपकी विशिष्ट धातुओं और अनुप्रयोगों के लिए कौन सा प्रकार का लेजर सबसे अच्छा काम करता है?

लेजर कटर के प्रकार और उनकी धातु कटिंग क्षमता

सही धातु लेजर कटर का चयन केवल शक्ति के बारे में नहीं है—यह आपकी विशिष्ट सामग्री और उत्पादन लक्ष्यों के अनुसार तकनीक को मिलाने के बारे में है। तीन मुख्य प्रकार के लेजर कटर धातु निर्माण क्षेत्र में प्रभुत्व स्थापित करते हैं , जिनमें प्रत्येक की विशिष्ट विशेषताएँ हैं जो उन्हें विभिन्न अनुप्रयोगों के लिए आदर्श बनाती हैं।

इन अंतरों को समझने से आप महंगी गलत मिलान से बच सकते हैं। आइए इसे समझें कि प्रत्येक तकनीक को क्या अलग करता है और उनका उपयोग कब करना चाहिए।

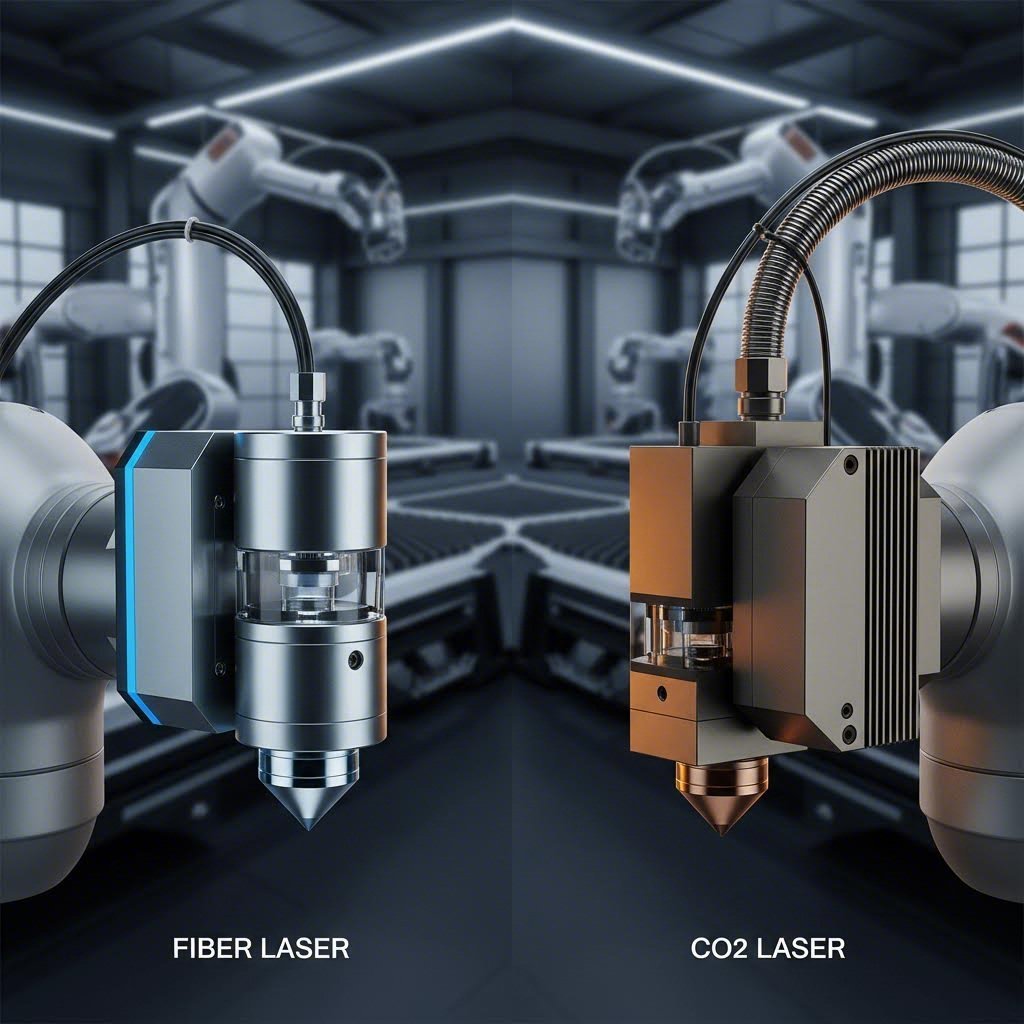

धातु अनुप्रयोगों के लिए फाइबर लेजर बनाम CO2 लेजर

दशकों से इन दो तकनीकों के बीच प्रतिस्पर्धा ने विनिर्माण निर्णयों को आकार दिया है। आपको यह जानना चाहिए:

फाइबर लेज़र अपने तरल-अवस्था फाइबर ऑप्टिक केबल्स को दुर्लभ-पृथ्वी तत्वों जैसे इटर्बियम के साथ डोप करके प्रकाश उत्पन्न करते हैं। वे लगभग 1.06 माइक्रोमीटर की तरंगदैर्ध्य उत्पन्न करते हैं—जो CO2 लेज़र की तुलना में लगभग 10 गुना छोटी होती है। यह छोटी तरंगदैर्ध्य अत्यंत महत्वपूर्ण है क्योंकि धातुएं इसे काफी अधिक दक्षता से अवशोषित करती हैं, जिसके परिणामस्वरूप तेज और साफ कट बनते हैं।

जब आप धातु के लिए फाइबर लेज़र कटिंग कर रहे होते हैं, तो आपको महत्वपूर्ण लाभ दिखाई देंगे:

- कार्यक्षमता: फाइबर लेज़र प्राप्त करते हैं 30-40% विद्युत-प्रकाशिक दक्षता cO2 प्रणालियों की तुलना में केवल 10% के मुकाबले

- गति: उपयुक्त सामग्री पर लगभग 3 से 5 गुना तेज कटिंग गति

- परियोजना: कम ऑप्टिकल घटकों वाली पूरी तरह सीलबंद डिज़ाइन का अर्थ है कम नियमित रखरखाव

- जीवनकाल: 25,000 कार्य घंटे तक — लगभग CO2 उपकरणों की तुलना में 10 गुना अधिक

CO2 लेजर एक सीलबंद ट्यूब में गैस मिश्रण का उपयोग करके 10.6 माइक्रोमीटर पर प्रकाश उत्पन्न करते हैं। जबकि धातुओं के लिए यह लंबी तरंगदैर्ध्य कम दक्ष होती है, फिर भी CO2 लेज़र कटिंग स्टील विशिष्ट अनुप्रयोगों के लिए व्यवहार्य बनी हुई है—विशेष रूप से मोटी प्लेटों के लिए जहां यह तकनीक दशकों से सिद्ध विश्वसनीयता प्रदान करती है।

CO2 प्रणालियां तब उत्कृष्ट प्रदर्शन करती हैं जब आपको चाहिए:

- एक ही सुविधा में धातु और गैर-धातु दोनों का संसाधन

- मोटी धातु प्लेटों (10-25 मिमी) को काटना, जहां स्थापित मापदंड सुसंगत गुणवत्ता सुनिश्चित करते हैं

- प्रारंभिक निवेश कम है (हालाँकि संचालन लागत अधिक रहती है)

Nd:YAG लेजर एक विशिष्ट निचले बाजार में कब्जा जमाए हुए हैं। ये सॉलिड-स्टेट लेज़र अत्यंत सूक्ष्म कार्य के लिए असाधारण सटीकता प्रदान करते हैं लेकिन पतली सामग्री तक ही सीमित हैं। आप इन्हें आभूषण निर्माण, इलेक्ट्रॉनिक्स निर्माण और माइक्रोमशीनिंग अनुप्रयोगों में पाएंगे, जहां उत्पादन गति से अधिक महत्व माइक्रॉन में मापे जाने वाले सहिष्णुता का होता है।

अपने धातु प्रकार के लिए सही लेजर तकनीक का चयन करना

सामग्री का प्रकार यह निर्धारित करता है कि कौन सी तकनीक सर्वोत्तम प्रदर्शन करेगी। तांबा, एल्यूमीनियम और पीतल जैसी धातुएं CO2 तरंगदैर्ध्य की तुलना में फाइबर लेज़र तरंगदैर्ध्य को बहुत अधिक कुशलता से अवशोषित करती हैं। इसीलिए धातु काटने के लिए फाइबर लेज़र CO2 प्रणालियों के लिए एक बार जिनके साथ गंभीर समस्याएं हुआ करती थीं, प्रतिबिंबित मिश्र धातुओं के लिए अब जाना-माना विकल्प बन गया है।

5 मिमी का दहलीज एक महत्वपूर्ण प्रदर्शन सीमा को दर्शाता है। इस मोटाई से कम पर, फाइबर लेज़र अतुल्य गति और दक्षता के साथ प्रभुत्व रखते हैं। इससे ऊपर, फाइबर लेज़र अभी भी अच्छा प्रदर्शन करते हैं, लेकिन गति का लाभ कम हो जाता है। 25 मिमी से अधिक मोटी प्लेटों के लिए, उच्च-शक्ति वाले फाइबर लेज़र (12kW और उससे अधिक) अब CO2 क्षमताओं से आगे निकल चुके हैं, 60kW प्रणालियों के साथ 100 मिमी तक की कटिंग मोटाई तक पहुँच रहे हैं।

| लेजर प्रकार | सर्वोत्तम धातु अनुप्रयोग | सामान्य मोटाई श्रेणी | चालन लागत | काटने की गति | रखरखाव की आवश्यकताएं |

|---|---|---|---|---|---|

| फाइबर लेजर | इस्पात, स्टेनलेस स्टील, एल्यूमीनियम, तांबा, पीतल, टाइटेनियम | 0.5-100 मिमी (शक्ति पर निर्भर) | कम (90%+ दक्षता) | cO2 की तुलना में 3-5 गुना तेज | न्यूनतम—सीलबंद डिज़ाइन, कम घटक |

| Co2 लेजर | मामूली इस्पात, स्टेनलेस स्टील, मिश्र धातु/अधातु दुकानें | आमतौर पर 25 मिमी तक | उच्च (5-10% दक्षता) | मध्यम | नियमित—दर्पण संरेखण, लेंस बदलना |

| Nd:YAG लेज़र | पतले सटीक भाग, आभूषण, इलेक्ट्रॉनिक्स, सूक्ष्म निर्माण | 6mm तक | मध्यम | धीमा—सटीकता पर केंद्रित | मध्यम—लैंप प्रतिस्थापन चक्र |

धातु लेजर कटर का मूल्यांकन करते समय, अपनी उत्पादन मात्रा के साथ-साथ सामग्री की आवश्यकताओं पर विचार करें। उच्च मात्रा वाले संचालन को फाइबर तकनीक की गति और कम संचालन लागत से अधिक लाभ मिलता है। धातुओं और गैर-धातु दोनों को काटने वाली दुकानों के लिए उनकी बहुमुखी प्रतिभा के कारण CO2 प्रणाली अधिक व्यावहारिक लग सकती है। और विशेष सटीक कार्य Nd:YAG को उसकी सीमाओं के बावजूद उचित ठहराता है।

प्रारंभिक निवेश की तस्वीर भी बदल गई है। एक ही शक्ति स्तर पर फाइबर लेजर अब आमतौर पर cO2 प्रणालियों की तुलना में सस्ते होते हैं परिपक्व तकनीक और उच्च मांग के कारण। अपने 10 गुना लंबे जीवनकाल और नाटकीय रूप से कम ऊर्जा खपत के साथ संयोजन में, धातु-केंद्रित संचालन के लिए फाइबर लेजर अक्सर मजबूत दीर्घकालिक रिटर्न प्रदान करते हैं।

बेशक, सही लेजर प्रकार का चयन करना केवल समीकरण का एक हिस्सा है। विभिन्न धातुएँ फाइबर और CO2 के बीच चयन से परे अद्वितीय चुनौतियाँ प्रस्तुत करती हैं—और यहीं विशिष्ट सामग्री पैरामीटर को समझना आवश्यक हो जाता है।

लेजर कटिंग के लिए धातु प्रकार और मोटाई क्षमता

क्या आपने कभी सोचा है कि आपका लेजर माइल्ड स्टील को आसानी से काट लेता है, लेकिन तांबे के साथ संघर्ष क्यों करता है? ऊष्मीय चालकता, परावर्तकता और गलनांक जैसे भौतिक गुणों के आधार पर प्रत्येक धातु लेजर ऊर्जा के प्रति अलग-अलग प्रतिक्रिया करती है—जो कटिंग प्रदर्शन को प्रभावित करते हैं। इन सामग्री-विशिष्ट व्यवहारों को समझने से उचित पैरामीटर चुनने और महंगी ट्रायल-एंड-एरर से बचने में मदद मिलती है।

आइए देखें कि विभिन्न धातुएं लेजर ऊर्जा के साथ कैसे प्रतिक्रिया करती हैं और विभिन्न शक्ति स्तरों से आप वास्तविकता में कितनी मोटाई की कटिंग की अपेक्षा कर सकते हैं।

धातु के आधार पर कटिंग पैरामीटर और विचार

माइल्ड स्टील अभी भी सबसे लेजर-अनुकूल धातु बनी हुई है। ऊर्जा के उत्कृष्ट अवशोषण और भविष्यसूचक तापीय व्यवहार के कारण माइल्ड स्टील लेजर कटिंग मोटाई की एक विस्तृत श्रृंखला में आसान बनाता है। HG लेजर के अनुसार, 3000W फाइबर लेजर 20 मिमी मोटी कार्बन स्टील तक को संभाल सकता है, जबकि 10kW प्रणाली 18-20 मिमी प्रति सेकंड की गति से तेज चमकदार सतह कटिंग प्राप्त करती है।

जब स्टील प्लेट को लेजर काटा जाता है, तो ऑक्सीजन सहायक गैस एक उष्माक्षेपी प्रतिक्रिया पैदा करती है जो कटिंग पावर को प्रभावी ढंग से बढ़ा देती है। इससे कार्बन स्टील पर पतले लेजर अपने वर्ग से ऊपर की क्षमता दिखा सकते हैं। इसका नुकसान क्या है? ऑक्सीजन कट एज पर एक ऑक्साइड परत छोड़ देती है जिसे वेल्डिंग या कोटिंग से पहले हटाने की आवश्यकता हो सकती है।

स्टेनलेस स्टील अलग-अलग चुनौतियाँ प्रस्तुत करता है। इसकी क्रोमियम सामग्री थर्मल चालकता को प्रभावित करती है और अधिक जिद्दी ड्रॉस पैदा करती है। उद्योग डेटा दिखाता है कि 3000W लेजर स्टेनलेस स्टील को 10 मिमी तक काट सकता है, जबकि 4000W तक बढ़ाने से क्षमता 16 मिमी तक बढ़ जाती है—हालांकि 12 मिमी से ऊपर एज की गुणवत्ता की गारंटी देना कठिन हो जाता है।

स्टेनलेस स्टील के साथ काम करते समय शीट मेटल लेजर कटिंग के लिए नाइट्रोजन सहायक गैस आवश्यक है। यह ऑक्सीकरण को रोकती है और उज्ज्वल, चमकदार एज फिनिश बनाए रखती है जो दृश्य घटकों या वेल्डिंग की आवश्यकता वाले भागों के लिए महत्वपूर्ण है।

एल्यूमिनियम उच्च तापीय चालकता और परावर्तकता के कारण संचालन में चुनौतियों का सामना करना पड़ता है। ऊष्मा सामग्री के माध्यम से तेजी से फैल जाती है, जिससे कटिंग क्षेत्र को बनाए रखने के लिए अधिक शक्ति की आवश्यकता होती है। 2000W प्रणाली आमतौर पर 5 मिमी एल्यूमीनियम तक सीमित रहती है, जबकि 3000W की प्रणाली 8 मिमी तक जा सकती है।

उच्च-शक्ति वाली प्रणालियों ने एल्यूमीनियम की क्षमता में भारी सुधार किया है। अब 10kW फाइबर लेज़र 40 मिमी मोटाई तक की स्टील और एल्यूमीनियम प्लेटों को काट सकते हैं—एक मोटाई जो कुछ ही वर्षों पहले अप्राप्य लगती थी।

तांबे और एल्यूमीनियम में परावर्तकता चुनौतियों पर काबू पाना

तांबा, पीतल और कांस्य सबसे कठिन परावर्तकता चुनौतियां प्रस्तुत करते हैं। ये धातुएं लेज़र ऊर्जा को कटिंग हेड की ओर वापस परावर्तित कर सकती हैं, जिससे महंगे ऑप्टिक्स को नुकसान हो सकता है। पारंपरिक CO2 लेज़र इन सामग्रियों के साथ गंभीर रूप से संघर्ष करते थे।

फाइबर लेज़र ने खेल बदल दिया है। उनकी छोटी 1.06μm तरंगदैर्ध्य CO2 की लंबी तरंगदैर्ध्य की तुलना में परावर्तक धातुओं द्वारा अधिक कुशलता से अवशोषित होती है। Vytek पल्स्ड फाइबर लेज़र विशेष लाभ प्रदान करते हैं—वे उच्च शिखर शक्ति के साथ छोटे बर्स्ट में ऊर्जा मुक्त करते हैं, जिससे गर्मी को पल्स के बीच में फैलने का समय मिलता है। इससे उत्तम किनारों वाले साफ़ कट बनते हैं और ऊष्मा-प्रभावित क्षेत्र न्यूनतम रहता है।

तांबे और पीतल के कटिंग के लिए, इन दृष्टिकोणों पर विचार करें:

- ऑक्सीजन सहायक गैस का उपयोग करें: यह तेज़ी से छेद करता है, इससे पहले कि परावर्तक धातु ऊर्जा को लेज़र स्रोत पर वापस न लौटा दे

- कम गति से शुरू करें: परावर्तक सतह के ऊर्जा को विक्षेपित करने से पहले उचित ताप संचय की अनुमति देता है

- पल्स्ड लेज़र पर विचार करें: उच्च शिखर शक्ति वाले बर्स्ट निरंतर तरंग संचालन की तुलना में परावर्तक सतहों में अधिक प्रभावी ढंग से घुसते हैं

टाइटेनियम अपनी श्रेणी में स्थान रखता है। इसकी परावर्तकता तांबे की तुलना में कम होने के बावजूद, टाइटेनियम की प्रतिक्रियाशील प्रकृति गैस प्रबंधन में सावधानी मांगती है। नाइट्रोजन या आर्गन शील्डिंग ऑक्सीकरण को रोकती है जो सामग्री के संक्षारण प्रतिरोध को कमजोर कर सकती है—एयरोस्पेस और चिकित्सा अनुप्रयोगों में जहां टाइटेनियम सबसे अधिक प्रचलित है।

| धातु प्रकार | अधिकतम मोटाई (3kW) | अधिकतम मोटाई (6kW+) | अनुशंसित लेजर | पसंदीदा सहायक गैस | विशेष विचार |

|---|---|---|---|---|---|

| माइल्ड स्टील | 20mm | 40मिमी+ | फाइबर या CO2 | ऑक्सीजन (गति) या नाइट्रोजन (साफ किनारा) | सबसे अधिक उदार सामग्री; ऑक्सीजन ऑक्साइड परत बनाता है |

| स्टेनलेस स्टील | 10 मिमी | 25-50mm | फाइबर | नाइट्रोजन | 12मिमी से ऊपर गुणवत्तापूर्ण किनारा उच्च शक्ति की आवश्यकता होती है; दृश्यमान भागों के लिए ऑक्सीजन से बचें |

| एल्यूमिनियम | 8 मिमी | 40मिमी | फाइबर | नाइट्रोजन | उच्च तापीय चालकता के लिए अधिक शक्ति की आवश्यकता होती है; ऑक्सीजन कट की गुणवत्ता कम कर देता है |

| ताँबा | 8 मिमी | 15मिमी+ | फाइबर (पल्स किया गया पसंदीदा) | ऑक्सीजन | अत्यधिक परावर्तक—जल्दी छेदना; विशेष तकनीकों की आवश्यकता होती है |

| पीतल | 8 मिमी | 15मिमी+ | फाइबर (पल्स किया गया पसंदीदा) | ऑक्सीजन | तांबे के समान; जस्ता सामग्री विषैली धुएं पैदा करती है—वेंटिलेशन सुनिश्चित करें |

| टाइटेनियम | 6 मिमी | 15mm | फाइबर | नाइट्रोजन या आर्गन | अभिक्रियाशील—ऑक्सीकरण रोकने के लिए निष्क्रिय ढाल की आवश्यकता होती है |

ऊर्जा और क्षमता के बीच संबंध एक भविष्यसूचक पैटर्न का अनुसरण करता है। बोडोर के अनुसार, पतली सामग्री (0.1-5 मिमी) 1-3 किलोवाट लेज़र के साथ अच्छी तरह काम करती है, मध्यम मोटाई (5-15 मिमी) को 4-8 किलोवाट की आवश्यकता होती है, और 15 मिमी से अधिक की भारी प्लेट्स को कुशल धातु शीट लेज़र कटिंग के लिए 10 किलोवाट या उससे अधिक की आवश्यकता होती है।

ध्यान रखें कि अधिकतम कटिंग मोटाई गुणवत्ता वाली कटिंग मोटाई से भिन्न होती है। एक धातु लेज़र कटिंग मशीन सैद्धांतिक रूप से 3 किलोवाट पर 20 मिमी स्टील को काट सकती है, लेकिन एक चिकना, बर्र-मुक्त किनारा प्राप्त करने के लिए आमतौर पर उस आंकड़े को लगभग 40% तक कम करने की आवश्यकता होती है। जब सटीकता महत्वपूर्ण हो, तो उपकरण को अपनी सीमा तक धकेलने के बजाय अपनी मोटाई आवश्यकताओं से आराम से अधिक ऊर्जा रेटिंग चुनें।

सामग्री क्षमताओं को मैप करने के बाद, आप सोच सकते हैं कि लेज़र कटिंग वैकल्पिक प्रौद्योगिकियों के मुकाबले कैसे खड़ी है। प्लाज्मा या वॉटरजेट लेज़र की तुलना में कब अधिक उचित होते हैं?

लेजर कटिंग बनाम प्लाज्मा, वॉटरजेट और EDM विधियाँ

आपने देखा है कि लेजर कटिंग क्या कर सकती है—लेकिन क्या यह हमेशा सबसे अच्छा विकल्प होता है? ईमानदार जवाब है: नहीं। विभिन्न कटिंग प्रौद्योगिकियाँ अलग-अलग परिदृश्यों में उत्कृष्ट होती हैं, और इन व्यापार-ऑफ़ को समझने से महंगी गलतियों से बचा जा सकता है। चाहे आप धातु के लिए लेजर कटर का मूल्यांकन कर रहे हों या वैकल्पिक विकल्पों पर विचार कर रहे हों, यह विक्रेता-तटस्थ तुलना आपको आवश्यक तथ्य देती है।

चार प्रमुख प्रौद्योगिकियाँ आपका ध्यान आकर्षित करने के लिए प्रतिस्पर्धा करती हैं: लेजर कटिंग, प्लाज्मा कटिंग, वॉटरजेट कटिंग, और विद्युत डिस्चार्ज मशीनिंग (EDM)। प्रत्येक के पास अपनी अनूठी ताकत होती है—और प्रत्येक में ऐसी सीमाएँ होती हैं जो विशिष्ट अनुप्रयोगों के लिए महत्वपूर्ण होती हैं।

जब लेजर कटिंग प्लाज्मा और वॉटरजेट से बेहतर प्रदर्शन करती है

आइए उसी के साथ शुरू करें जिसमें धातुओं की लेजर कटिंग सबसे अच्छा काम करती है। जब पतली से मध्यम सामग्री पर सटीकता और गति आपकी प्राथमिकता होती है, तो आमतौर पर लेजर प्रौद्योगिकी जीतती है। फैब्रिकास्ट के सहिष्णुता विश्लेषण के अनुसार लेजर कटिंग ±0.001" से ±0.005" तक की टॉलरेंस प्राप्त करती है—जो प्लाज्मा की ±0.020" से ±0.030" की सीमा की तुलना में काफी कम है।

यहाँ एक लेजर कटिंग मशीन धातु प्रणाली उत्कृष्ट प्रदर्शन करती है:

- पतली सामग्री की गति: फाइबर लेजर 1/4" मोटाई से कम की सामग्री में प्रभुत्व स्थापित करते हैं, ऐसी गति प्राप्त करते हुए जिसकी तुलना प्लाज्मा और वॉटरजेट से नहीं की जा सकती

- किनारे की गुणवत्ता: लेजर सबसे स्वच्छ किनारे उत्पन्न करता है—चिकनी सतह के साथ न्यूनतम ऊष्मा-प्रभावित क्षेत्र जिसमें अक्सर द्वितीयक प्रसंस्करण की आवश्यकता नहीं होती

- जटिल ज्यामिति: छोटी कर्फ चौड़ाई और सटीक बीम नियंत्रण जटिल डिजाइन को सक्षम करते हैं जो प्लाज्मा के चौड़े कट पथ के साथ संभव नहीं है

- दोहराव सक्षमता: सीएनसी-नियंत्रित लेजर प्रणाली हजारों पुर्जों में समान परिणाम प्रदान करती है

लेकिन मोटी सामग्री पर प्लाज्मा कटिंग एक अलग कहानी बयां करती है। एक सीएनसी प्लाज्मा टेबल 1/2" माइल्ड स्टील को 100 इंच प्रति मिनट से अधिक की गति से काटती है—और यह लाभ मोटाई बढ़ने के साथ और बढ़ता है। जब आप संरचनात्मक इस्पात, भारी उपकरण घटकों या जहाज निर्माण प्लेटों को संसाधित कर रहे हों, तो गति, मोटाई क्षमता और प्रति इंच कम लागत के संयोजन के कारण प्लाज्मा कटिंग आर्थिक दृष्टिकोण से उचित होती है।

जल जेट कटिंग की एक अद्वितीय स्थिति है। 90,000 PSI तक के दबाव पर संचालित होकर, जल जेट उत्पन्न करता है शून्य ऊष्मा-प्रभावित क्षेत्र । यह तब महत्वपूर्ण होता है जब धातु को काटा जाता है जिसे लेजर प्रणाली ऊष्मा से विकृत कर देगी—उदाहरण के लिए ऊष्मा-संवेदनशील मिश्रधातुओं, परतदार सामग्री, या उन भागों के बारे में जहाँ धातुकीय गुणों को अपरिवर्तित रहना चाहिए। जल जेट 24" तक मोटी सामग्री को भी संभालता है और लगभग किसी भी चीज़ को काटता है: धातुएँ, पत्थर, कांच, कंपोजिट्स।

इसका समझौता क्या है? जल जेट सबसे धीमा विकल्प है, आमतौर पर केवल 5-20 इंच प्रति मिनट की गति से काटता है, जो सामग्री के आधार पर भिन्न होता है। उच्च मात्रा में उत्पादन के लिए, इस गति की कमी महत्वपूर्ण बोतलबंदी पैदा करती है।

अपनी आवेदन आवश्यकताओं के अनुरूप कटिंग प्रौद्योगिकी का चयन करना

EDM (इलेक्ट्रिकल डिस्चार्ज मशीनिंग) एक विशेष निचले खंड की सेवा करता है। यह असाधारण सटीकता के साथ सामग्री को विद्युत डिस्चार्ज का उपयोग करके क्षरण करता है—±0.0001" तक सहिष्णुता प्राप्त करता है, जैसा कि उद्योग डेटा । जब आपको चालक सामग्री पर अत्यधिक सटीक कार्य की आवश्यकता होती है, EDM कोई अन्य विधि के बराबर नहीं है ऐसी सटीकता प्रदान करता है।

हालांकि, EDM आमतौर पर चारों विधियों में सबसे धीमी होती है और विभिन्न कार्यों के लिए अलग-अलग तार सेटअप की आवश्यकता होती है। जब विशेष किनारों के निपटान की आवश्यकता हो या उपकरण और डाई अनुप्रयोगों में उन्नत ज्यामिति को काटना हो, तो बहुत बड़े भागों को कच्चा बनाने के लिए यह आदर्श है।

धातु काटने के लिए मशीन का चयन करते समय अपनी विशिष्ट प्राथमिकताओं पर विचार करें:

लेजर कटिंग के फायदे

- पतली से मध्यम सामग्री के लिए उच्चतम परिशुद्धता (±0.001" से ±0.005")

- न्यूनतम द्वितीयक परिष्करण की आवश्यकता वाली उत्कृष्ट किनारा गुणवत्ता

- 1/4" मोटाई से कम की सामग्री पर सबसे तेज़ गति

- प्लाज्मा की तुलना में छोटा ऊष्मा-प्रभावित क्षेत्र

- जटिल डिज़ाइन और कसे हुए सहिष्णुता के लिए आदर्श

लेजर कटिंग के नुकसान

- 1" से अधिक मोटाई की सामग्री पर प्रदर्शन में महत्वपूर्ण कमी आती है

- प्लाज्मा की तुलना में उपकरण का उच्च प्रारंभिक निवेश

- मुख्य रूप से धातु सामग्री तक सीमित (CO2 गैर-धातु क्षमता जोड़ता है)

- ऊष्मा-संवेदनशील अनुप्रयोगों पर कुछ तापीय विरूपण अभी भी संभव है

प्लाज्मा कटिंग के फायदे

- कटे हुए प्रति इंच में सबसे कम संचालन लागत

- मध्यम से मोटी सामग्री (आर्थिक रूप से 2"+ तक) के लिए उत्कृष्ट

- मोटी प्लेटों पर सबसे तेज़ विकल्प

- लेजर प्रणालियों की तुलना में कम प्रारंभिक निवेश

- विद्युत चालक सामग्री को कुशलतापूर्वक संभाल सकता है

प्लाज्मा कटिंग के नुकसान

- बड़े ऊष्मा-प्रभावित क्षेत्र में तनाव के निशान बनते हैं

- कम परिशुद्धता (±0.020" से ±0.030" तक सामान्य)

- धातु अवशेष/अपरद (slag/dross) अक्सर द्वितीयक प्रसंस्करण की आवश्यकता होती है

- हानिकारक धुएं के लिए उचित वेंटिलेशन की आवश्यकता होती है

वॉटरजेट कटिंग के फायदे

- शून्य ऊष्मा-प्रभावित क्षेत्र—कोई तापीय विकृति नहीं

- लगभग किसी भी सामग्री को 24" तक की मोटाई में काटता है

- अच्छी परिशुद्धता (±0.003" से ±0.005")

- सैटिन सुचिकन किनारे की परिष्करण

- कोई सामग्री कठोरीकरण या धातुकर्म परिवर्तन नहीं

जलधारा कटिंग के नुकसान

- सबसे धीमी कटिंग गति (प्रति मिनट 5-20 इंच)

- अपघर्षक के उपभोग के कारण संचालन लागत सबसे अधिक

- अपघर्षक के निपटान और प्रबंधन की आवश्यकता

- उपकरण और जल प्रबंधन के लिए बड़ा स्थान आवश्यक

| कटिंग मेथड | परिशुद्धता सहिष्णुता | अधिकतम व्यावहारिक मोटाई | ऊष्मा प्रभावित क्षेत्र | चलाने की लागत | आदर्श अनुप्रयोग |

|---|---|---|---|---|---|

| लेजर कटिंग | ±0.001" से ±0.005" | 1" तक (लागत प्रभावी) | छोटा | मध्यम | प्रिसिजन पार्ट्स, जटिल डिज़ाइन, पतली-मध्यम शीट मेटल, उच्च मात्रा में उत्पादन |

| प्लाज्मा कटिंग | ±0.020" से ±0.030" | 2"+ (आदर्श 0.018"-2") | बड़ा | कम | संरचनात्मक स्टील, भारी उपकरण, जहाज निर्माण, एचवीएसी, उच्च गति वाली मोटी प्लेट काटना |

| वॉटरजेट कटिंग | ±0.003" से ±0.005" | अधिकतम 24" (कच्ची कटिंग) | कोई नहीं | उच्च | ऊष्मा-संवेदनशील सामग्री, बहु-सामग्री काटना, मोटी प्लेटें, एयरोस्पेस घटक |

| EDM | ±0.0001" से ±0.001" | अधिकतम 12" | न्यूनतम | मध्यम-उच्च | अत्यंत सटीक कार्य, औजार और डाई, जटिल ज्यामिति, केवल चालक सामग्री |

तो आपकी आवश्यकताओं के अनुरूप कौन सी तकनीक है? अपने आप से ये प्रश्न पूछें:

- आपकी आम सामग्री की मोटाई क्या है? 1/4" से कम—लेज़र प्रभावशाली है। 1" से अधिक—प्लाज्मा या वॉटरजेट लाभ प्राप्त करता है।

- आपकी सहनशीलता आवश्यकताएँ कितनी कठोर हैं? अत्यधिक सटीक कार्यों के लिए EDM की आवश्यकता हो सकती है। सामान्य निर्माण कार्य प्लाज्मा के साथ काम करते हैं।

- क्या ऊष्मा-प्रभावित क्षेत्र का महत्व है? यदि धातुकर्मीय गुणों को अपरिवर्तित रहना चाहिए, तो आपके लिए जलधारा एकमात्र विकल्प है।

- आपका उत्पादन आयतन क्या है? उच्च मात्रा में पतली सामग्री के कार्यों के लिए लेज़र की गति लाभदायक होती है। दुर्लभ मोटी प्लेट काटने के लिए लेज़र में निवेश का औचित्य नहीं हो सकता।

- संचालन लागत के लिए आपका बजट क्या है? प्लाज्मा प्रति इंच सबसे कम लागत प्रदान करता है; अपघर्षक की खपत के कारण जलधारा की लागत सबसे अधिक होती है।

कई निर्माण दुकानें पाती हैं कि लेज़र द्वारा धातु काटने की क्षमता उनकी 80% आवश्यकताओं को पूरा करती है, जबकि जलधारा या प्लाज्मा सेवा प्रदाताओं के साथ संबंध बनाए रखने से शेष कार्य संभाला जाता है। यह संकर दृष्टिकोण निष्क्रिय रहने वाले उपकरणों में अत्यधिक निवेश के बिना मुख्य कार्य के लिए सटीकता को अधिकतम करता है।

इन तकनीकी अंतरों को समझना आवश्यक है—लेकिन यहां तक कि सर्वोत्तम उपकरण भी खराब परिणाम उत्पन्न करते हैं जब कटिंग पैरामीटर्स को अनुकूलित नहीं किया जाता है। जब किनारों पर बर्र बनते हैं, ड्रॉस जमा होता है, या किनारे खुरदरे निकलते हैं, तो क्या होता है?

लेजर कटिंग की सामान्य दोष और गुणवत्ता संबंधी समस्याओं का निवारण

सही ढंग से पैरामीटर सेट न होने पर सबसे उन्नत लेज़र धातु कटिंग उपकरण भी निराशाजनक परिणाम देते हैं। कटे हुए किनारों पर बर्र? नीचे चिपका हुआ ड्रॉस? मुख्य कटाई के बाद घंटों तक द्वितीयक फिनिशिंग की आवश्यकता? ये समस्याएं ऑपरेटरों को रोजमर्रा की आधार पर परेशान करती हैं—लेकिन एक बार जब आप समझ जाते हैं कि इनका कारण क्या है, तो इन्हें लगभग हमेशा ठीक किया जा सकता है।

समस्याओं का प्रभावी निवारण करने की कुंजी आपके कट्स द्वारा दी गई जानकारी को पढ़ने में निहित है। प्रत्येक दोष विशिष्ट पैरामीटर समायोजन की ओर इशारा करता है। आइए सबसे आम गुणवत्ता संबंधी समस्याओं को समझें और तुरंत लागू करने योग्य व्यावहारिक समाधानों पर चर्चा करें।

बर्र निर्माण संबंधी समस्याओं का निदान और समाधान

बर्र—कटिंग लाइनों के साथ-साथ ऊपर उठे हुए किनारे या खुरदुरे उभार—धातु शीट को लेज़र से काटते समय सबसे परेशान करने वाले दोषों में से एक हैं। ये भागों के फिट को खराब करते हैं, सुरक्षा जोखिम पैदा करते हैं, और आपके कार्यप्रवाह में महंगी डीबरिंग प्रक्रियाएं जोड़ते हैं।

बर्र निर्माण के लक्षण:

- कटौती के ऊपरी या निचले किनारों के साथ-साथ ऊपर उठे हुए, तेज किनारे

- अस्थायी प्रक्षेपण जो उंगलियों या संलग्न भागों में फंस जाते हैं

- कटाव पथ के साथ-साथ भिन्न होने वाले असंगत किनारा प्रोफ़ाइल

सामान्य कारण:

- कटिंग गति बहुत तेज़ है: लेज़र सामग्री को पूरी तरह से पिघलाने के लिए पर्याप्त ऊर्जा प्रदान नहीं करता है, जिससे किनारों के साथ आंशिक रूप से संलग्न धातु शेष रह जाती है

- कटिंग गति बहुत धीमी है: अत्यधिक ऊष्मा निर्माण के कारण गर्म धातु स्वच्छ रूप से बाहर निकलने के बजाय जमा हो जाती है

- अपर्याप्त सहायक गैस दबाव: गलित सामग्री को प्रभावी ढंग से उड़ाया नहीं जाता है, जिससे कटाव किनारे पर पुनः ठोसीकरण हो जाता है

- गलत फोकस स्थिति: जब फोकल बिंदु सामग्री की सतह के सापेक्ष बहुत ऊंचा या बहुत नीचे होता है, तो ऊर्जा वितरण असमान हो जाता है

- घिसा या गंदा नोजल: अशांत गैस प्रवाह टर्बुलेंस पैदा करता है जिससे ड्रॉस चिपक जाता है

लागू करने योग्य समाधान:

- कटिंग गति को 5% के इंक्रीमेंट में समायोजित करें—अनुसार मेट प्रिसिजन टेक्नोलॉजीज , अनुशंसित सेटिंग्स से 10% कम पर शुरू करें और गुणवत्ता खराब होने तक बढ़ाएं, फिर वापस कम करें

- पिघली हुई सामग्री को पूरी तरह से बाहर निकालना सुनिश्चित करने के लिए सहायक गैस दबाव बढ़ाएं

- स्क्रैप सामग्री पर परीक्षण कट्स का उपयोग करके फोकस स्थिति की पुष्टि करें—किनारे की गुणवत्ता में सुधार होने तक फोकस को ऊपर या नीचे ले जाएं

- जिन नोजल्स में घिसावट, क्षति या दूषितकरण दिखाई दे, उनका निरीक्षण करें और प्रतिस्थापित करें

- विशेष रूप से इस्पात लेजर कटिंग के लिए, सुनिश्चित करें कि ऑक्सीजन शुद्धता विनिर्देशों को पूरा करती हो (उत्तम परिणामों के लिए 99.5%+)

ड्रॉस को समाप्त करना और किनारे की गुणवत्ता में सुधार करना

कट्स के निचले हिस्से पर चिपका ठोस भट्टी अवशेष (ड्रॉस), आपके कार्यप्रवाह में समस्याएं पैदा करता है। यह भागों के ढेर लगाने में हस्तक्षेप करता है, वेल्डिंग क्रियाओं को जटिल बनाता है, और समय लेने वाली सफाई की मांग करता है। यह समझना कि ड्रॉस क्यों बनता है, आपको इसे पूरी तरह से रोकने में मदद करता है।

ड्रॉस जमाव के लक्षण:

- नीचे के कट एज पर सख्त धातु के मनके या लगातार उभरी हुई रिज

- कटाई के बाद नीचे की ओर खुरदुरी, असमान सतह जिसे ग्राइंडिंग या फाइलिंग की आवश्यकता होती है

- निचली ओर उभरे हुए भागों के कारण सपाट न रखे जा सकने वाले पुर्जे

सामान्य कारण:

- गैस दबाव बहुत कम: पिघली हुई धातु को पूरी तरह से कर्फ के माध्यम से उड़ाने के लिए पर्याप्त बल की कमी

- फीड दर बहुत तेज़: पूरी तरह से पिघलने के लिए पर्याप्त ऊर्जा प्राप्त नहीं कर पाने वाला सामग्री

- कर्फ बहुत संकरा: मेट का कट क्वालिटी गाइड इसे ऊपरी किनारों पर चिकनाहट और ऑक्सीकरण की कमी और निचले हिस्से पर भारी ड्रॉस के रूप में पहचानता है

- नोज़ल का आकार बहुत छोटा: गैस प्रवाह को सीमित करता है, जिससे प्रभावी मलबे को हटाने में रोक लगती है

- स्टैंडऑफ दूरी गलत है: बहुत कम दूरी से कर्फ संकरा होता है; बहुत अधिक दूरी से कर्फ चौड़ा होता है—दोनों स्थितियों में ड्रॉस की समस्या उत्पन्न होती है

लागू करने योग्य समाधान:

- ड्रॉस गायब होने तक गैस दबाव को क्रमिक रूप से बढ़ाएं—लेकिन अत्यधिक दबाव से चौड़ा कर्फ बनने पर ध्यान दें

- अधिक पूर्ण सामग्री निकासी की अनुमति देने के लिए फीड दर को कम करें

- यदि कर्फ बहुत संकरा है तो कर्फ को चौड़ा करने के लिए फोकस स्थिति समायोजित करें, या यदि बहुत चौड़ा है तो उसे संकरा करें

- मोटी सामग्री पर गैस प्रवाह में सुधार के लिए बड़े नोजल आकार का उपयोग करें

- सामग्री की मोटाई की आवश्यकताओं के अनुरूप स्टैंडऑफ ऊंचाई की पुष्टि करें

- लेजर द्वारा शीट धातु काटते समय सुनिश्चित करें कि सामग्री समतल हो और निरंतर स्टैंडऑफ बनाए रखने के लिए उचित समर्थन प्राप्त हो

ऊष्मा-प्रभावित क्षेत्रों और सामग्री विकृति को दूर करना

अत्यधिक ऊष्मा-प्रभावित क्षेत्र (HAZ) और सामग्री में विकृति थर्मल प्रबंधन समस्याओं को दर्शाते हैं। ये समस्याएँ विशेष रूप से तब आम होती हैं जब पतली चादरों या ऊष्मा-संवेदनशील मिश्र धातुओं से धातु के भागों को लेजर काटा जा रहा होता है।

अत्यधिक HAZ के लक्षण:

- कटे हुए किनारों के आसपास रंग में परिवर्तन (नीलापन, पीलापन या भूरापन)

- कट रेखा से दूर फैले दृश्यमान ऊष्मा चिह्न

- किनारे के कठोर या भुरभुरे क्षेत्र जो मोड़ते समय दरारें उत्पन्न करते हैं

- पदार्थ में ऐंठन या विकृति, विशेष रूप से पतली चादरों पर

सामान्य कारण:

- लेजर शक्ति बहुत अधिक: आवश्यकता से अधिक ऊर्जा अत्यधिक ऊष्मा निर्माण करती है

- कटिंग गति बहुत धीमी है: लंबे समय तक ऊष्मा का संचार सामग्री के आसपास के हिस्सों में होता है

- सहायक गैस का गलत चयन: नाइट्रोजन के बजाय ऑक्सीजन का उपयोग करना, जबकि नाइट्रोजन से साफ और ठंडे कट प्राप्त होते हैं

- अपर्याप्त शीतलन: मशीन शीतलन प्रणाली इष्टतम संचालन तापमान बनाए नहीं रख रही है

- भाग की ज्यामिति की समस्याएँ: लंबे, संकीर्ण खंड जिनमें ऊष्मा निकास के लिए कोई मार्ग नहीं है

लागू करने योग्य समाधान:

- कटिंग क्षमता को पर्याप्त बनाए रखते हुए लेजर शक्ति कम करें

- किसी एक क्षेत्र में ऊष्मा के ठहराव के समय को कम करने के लिए कटिंग गति बढ़ाएं

- ऑक्सीकरण और ऊष्मा को कम करने के लिए स्टेनलेस स्टील और एल्यूमीनियम में नाइट्रोजन सहायक गैस में बदलें

- पतली सामग्री के लिए पल्स कटिंग मोड लागू करें—पल्स के बीच ऊष्मा विघटन की अनुमति देता है

- ऊष्मा को केंद्रित करने के बजाय शीट भर में वितरित करने के लिए कटिंग क्रम को अनुकूलित करें

- कटिंग के दौरान पतले भागों की कठोरता बनाए रखने के लिए टैबिंग रणनीतियों पर विचार करें

अधूरी कटौती और खुरदरे किनारों को हल करना

जब आपकी लेज़र कटर धातु प्रणाली सामग्री को पूरी तरह काटने में विफल रहती है—या खुरदरे, नुकीले किनारे पैदा करती है—तो उत्पादकता प्रभावित होती है। भागों को फिर से काम करने की आवश्यकता होती है, सामग्री बर्बाद हो जाती है, और डिलीवरी के समयसीमा चूक जाती है।

अधूरी कटौती के लक्षण:

- शीट से साफ तरीके से अलग न होने वाले भाग

- मैनुअल तोड़ने या द्वितीयक कटौती की आवश्यकता वाले खंड

- कटौती पथ के साथ असंगत प्रवेश गहराई

खुरदरे किनारों के लक्षण:

- दृश्यमान स्ट्रिएशन निशान (कट सतह के ऊर्ध्वाधर नीचे चलने वाले खांचे)

- अनियमित, लहरदार किनारे के प्रोफाइल

- महत्वपूर्ण कोणीयता—कट फलक सामग्री की सतह के लंबवत नहीं है

सामान्य कारण:

- अपर्याप्त लेज़र शक्ति: सामग्री की मोटाई में पूरी तरह कटौती करने के लिए पर्याप्त ऊर्जा नहीं

- गंदे या क्षतिग्रस्त ऑप्टिक्स: लेंस पर मलबे या खरोंच बीम को विकृत करते हैं और कटिंग शक्ति कम करते हैं

- लेजर बीम का गलत संरेखण: बीम ऑप्टिकल पथ के माध्यम से सही ढंग से यात्रा नहीं कर रहा है

- सामग्री से संबंधित समस्याएं: ऊर्जा अवशोषण में हस्तक्षेप करने वाले पैमाने, जंग या कोटिंग

- नोजल सेंटरिंग गलत है: गलत नोजल सेंटरिंग एक तरफ साफ और दूसरी तरफ खुरदुरे के साथ असममित कटौती पैदा करती है

लागू करने योग्य समाधान:

- सामग्री की मोटाई के अनुसार लेजर पावर उचित रूप से बढ़ाएं—निर्माता के कट चार्ट को देखें

- उचित लेंस क्लीनर और बिना रुई वाले कपड़ों का उपयोग करके सभी ऑप्टिकल घटकों को साफ़ करें

- बीम संरेखण जांच करें और आवश्यकतानुसार दर्पणों को समायोजित करें

- कटिंग से पहले सुनिश्चित करें कि सामग्री साफ हो और सतह के दाग से मुक्त हो

- संरेखण उपकरणों का उपयोग करके नोजल के केंद्रित होने की पुष्टि करें—यदि क्षतिग्रस्त हो तो बदल दें

- शीट में समग्र मोटाई की जांच करें

त्वरित संदर्भ: लक्षण के अनुसार पैरामीटर समायोजन

कटिंग गुणवत्ता की समस्याओं का निदान करते समय, अपने पहले समायोजन की पहचान करने के लिए इस त्वरित संदर्भ का उपयोग करें:

| लक्षण | कर्फ समस्या | पहला समायोजन | द्वितीयक समायोजन |

|---|---|---|---|

| भारी धतूरा, सुचारु ऊपरी किनारा | बहुत संकीर्ण | फोकस स्थिति ऊपर ले जाएं | फीड दर कम करें, गैस दबाव बढ़ाएं |

| खुरदुरे किनारे, कोने पर जलन | बहुत चौड़ा | फोकस स्थिति नीचे लाएं | फीड दर बढ़ाएं, गैस दबाव कम करें |

| एकतरफा खुरदुरापन | असममित | नोजल को पुनः केंद्रित करें | नोजल क्षति की जाँच करें, संरेखण सत्यापित करें |

| अपूर्ण प्रवेश | चर | फीड दर कम करें | शक्ति बढ़ाएं, ऑप्टिक्स साफ करें, फोकस की जाँच करें |

| अत्यधिक ऊष्मा चिह्न | चर | फीड दर बढ़ाएं | शक्ति कम करें, नाइट्रोजन गैस पर स्विच करें |

याद रखें कि लेजर कटिंग मूल रूप से ऊष्मा निवेश और सामग्री निकासी के बीच एक संतुलन है। मेट प्रिसिजन टेक्नोलॉजीज , "लेजर के साथ मृदु इस्पात को काटना लेजर बीम के साथ गर्म की जाने वाली सामग्री की मात्रा और कट में प्रवाहित होने वाली सहायक गैस की मात्रा के बीच का संतुलन है।" जब इस संतुलन में किसी भी दिशा में अत्यधिक बदलाव आता है, तो गुणवत्ता संबंधी समस्याएं उत्पन्न होती हैं।

सबसे प्रभावी ऑपरेटर व्यवस्थित समस्या निवारण आदतें विकसित करते हैं: एक बार में एक ही चर को बदलें, विशिष्ट सामग्री और मोटाई के लिए क्या काम करता है, यह दस्तावेजीकरण करें, और समस्याओं के विकसित होने से पहले नियमित रखरखाव करें। यह प्रो-एक्टिव दृष्टिकोण आपके लेजर कटिंग मेटल पार्ट्स ऑपरेशन को सुचारू रूप से चलाए रखता है—और दोषपूर्ण पार्ट्स को आपके ग्राहकों के हाथों में जाने से रोकता है।

बेशक, ट्रबलशूटिंग तकनीकों का केवल तभी महत्व होता है जब ऑपरेटर उन्हें लागू करते समय सुरक्षित रहें। लेजर कटिंग के ऑपरेशन के आसपास कौन से सुरक्षा उपकरण और सुरक्षा प्रोटोकॉल लागू होने चाहिए?

सुरक्षा पर विचार और सुरक्षा उपकरण की आवश्यकताएँ

इस्पात को काटने के लिए पर्याप्त शक्तिशाली धातु कटिंग लेजर किसी भी व्यक्ति के लिए स्पष्ट खतरे पैदा करता है। फिर भी, अक्सर तब तक सुरक्षा को नजरअंदाज किया जाता है जब तक कि कुछ गलत नहीं हो जाता। OSHA के लेजर सुरक्षा दिशानिर्देश , लेजर कटिंग को इतना प्रभावी बनाने वाली एकाग्र ऊर्जा एक क्षण भर में स्थायी अंधापन पैदा कर सकती है—और यह केवल एक ही खतरा है जिसका ऑपरेटर प्रतिदिन सामना करते हैं।

चाहे आप शीट धातु लेजर कटिंग उपकरण चला रहे हों या एक निर्माण फर्श की निगरानी कर रहे हों, इन जोखिमों को समझना आपकी टीम और आपके निवेश दोनों की रक्षा करता है। आइए जानें कि आपको क्या जानना चाहिए।

धातु लेजर ऑपरेशन के लिए आवश्यक सुरक्षा उपकरण

धातु को काटने के लिए उपयोग किए जाने वाले औद्योगिक लेज़र क्लास IV में आते हैं—जो सबसे अधिक खतरे का वर्गीकरण है। OSHA के अनुसार, क्लास IV लेज़र सीधे आंखों के लिए खतरा, विसरित परावर्तन के खतरे और आग के जोखिम को एक साथ प्रस्तुत करते हैं। इसका अर्थ है कि सुरक्षा को कई प्रकार के खतरों का सामना करना चाहिए।

वैयक्तिक सुरक्षा उपकरण (PPE) की आवश्यकताएं:

- लेजर सुरक्षा चश्मा: उस लेज़र की विशिष्ट तरंगदैर्ध्य के लिए रेट किया जाना चाहिए जो धातु को काटता है। फाइबर लेज़र लगभग 1.06 μm पर संचालित होते हैं, जबकि CO2 लेज़र 10.6 μm पर उत्सर्जित करते हैं—प्रत्येक को अलग-अलग सुरक्षात्मक फिल्टर की आवश्यकता होती है। Codinter के सुरक्षा विश्लेषण के अनुसार, यह सुनिश्चित करना अत्यंत महत्वपूर्ण है कि आंखों के लिए उपयोग किया जाने वाला सामान ठीक से फिट बैठे और शामिल ऊर्जा स्तरों के लिए पर्याप्त ऑप्टिकल घनत्व (OD) प्रदान करे

- ज्वाला प्रतिरोधी कपड़े: कटिंग संचालन के दौरान उत्पन्न जलने और चिंगारियों से त्वचा की सुरक्षा करता है

- ऊष्मा-प्रतिरोधी दस्ताने: गर्म सामग्री या घटकों को लेज़र धातु मशीन के पास संभालते समय आवश्यक होता है

- श्वसन सुरक्षा: उन सामग्रियों को काटते समय आवश्यक होता है जो खतरनाक धुएं उत्पन्न करती हैं—इसके बारे में नीचे और अधिक

सीधा-सादा लगता है? यहाँ समस्या शुरू होती है। मानक सुरक्षा चश्मे आपकी रक्षा नहीं करेंगे—केवल पर्याप्त ऑप्टिकल घनत्व वाले, तरंगदैर्ध्य-विशिष्ट लेज़र सुरक्षा चश्मे ही पर्याप्त सुरक्षा प्रदान करते हैं। OSHA दिशानिर्देश बताते हैं कि उपकरण के अधिकतम पहुँच योग्य उत्सर्जन स्तर और विशिष्ट तरंगदैर्ध्य सीमा के आधार पर चश्मे का चयन किया जाना चाहिए।

सुविधा और इंजीनियरिंग नियंत्रण आवश्यकताएँ:

- मशीन आवरण: पूरी तरह से बंद लेज़र प्रणालियाँ बीम के बाहर निकलने को रोकती हैं। इन आवरणों में इंटरलॉक होना चाहिए जो दरवाज़ों या एक्सेस पैनल्स के खुलने पर लेज़र को स्वचालित रूप से बंद कर दे।

- बीम गार्ड: इधर-उधर टकराने वाली प्रतिबिंबों को रोकने के लिए लगाए गए भौतिक अवरोध, जो आमतौर पर अप्रतिबिंबकारी सामग्री से बने होते हैं

- चेतावनी संकेत: लेज़र खतरों की पहचान कराने वाले स्पष्ट, दृश्यमान लेबल लेज़र नियंत्रित क्षेत्र के अंदर और बाहर दोनों जगह लगाए जाने चाहिए

- एक्सेस कंट्रोल: केवल अधिकृत कर्मचारियों के लिए प्रवेश प्रतिबंधित—अप्रशिक्षित व्यक्तियों को दुर्घटनावश उजागर होने से रोकना

- आपातकालीन बंद नियंत्रण: स्वचालित शटडाउन बटन जो लेज़र स्रोत को तुरंत बिजली आपूर्ति काट देते हैं

संचालन प्रोटोकॉल:

- मानक संचालन प्रक्रियाएँ (SOPs): सभी पहलुओं को कवर करने वाली लिखित प्रक्रियाएं, जिसमें सामग्री हैंडलिंग, मशीन सेटअप और आपातकालीन प्रतिक्रियाएं शामिल हैं

- व्यापक प्रशिक्षण: सभी ऑपरेटरों को स्वतंत्र रूप से काम करने से पहले लेज़र खतरों, उचित उपकरण उपयोग और आपातकालीन प्रक्रियाओं की समझ होनी चाहिए

- नियमित रखरखाव अनुसूची: दस्तावेजीकृत निरीक्षण और रखरखाव कार्यक्रम सुनिश्चित करते हैं कि सुरक्षा उपकरण कार्यात्मक बने रहें

- लेज़र सुरक्षा अधिकारी (LSO): ANSI Z 136.1 खतरों का आकलन करने और नियंत्रण लागू करने के लिए एक योग्य व्यक्ति को नामित करने की सिफारिश करता है

अपनी सुविधा में धुएं और आग के जोखिम का प्रबंधन

जब एक उच्च-शक्ति वाली लेज़र धातु को वाष्पित कर देती है, तो वह बस गायब नहीं हो जाती। वह सामग्री हवा में कणों के रूप में फैल जाती है—अक्सर उपमाइक्रोन आकार की—जो फेफड़ों में गहराई तक प्रवेश कर सकती है। के अनुसार निर्माता लेज़र वेल्डिंग और कटिंग बहुत ही बारीक कणों का उत्पादन करते हैं जिन्हें सांस द्वारा अधिक आसानी से अवशोषित किया जा सकता है और जो अन्य प्रक्रियाओं से उत्पन्न बड़े कणों की तुलना में श्वसन स्वास्थ्य के लिए अधिक खतरनाक होते हैं।

आपको संबोधित करने वाले सामग्री-विशिष्ट धुएं के खतरे:

- जस्ता-लेपित (यशदलेपित) धातुएं: जस्ता ऑक्साइड की अधिक मात्रा उत्पन्न करती हैं, जिससे धातु धुएं का बुखार होता है—बुखार, ठंड लगना और मांसपेशियों में दर्द जैसे फ्लू जैसे लक्षण। उद्योग स्रोत यशदलेपित सामग्री को विशेष रूप से खतरनाक मानते हैं

- रसोई बदला: हेक्सावैलेंट क्रोमियम (हेक्स क्रोम), निकल और मैंगनीज युक्त धुएं उत्पन्न करता है। इन पदार्थों को सांस लेने से कर्मचारियों को फेफड़ों के नुकसान, तंत्रिका संबंधी समस्याओं और कैंसर के कई रूपों का खतरा उत्पन्न होता है

- एल्युमिनियम: एल्युमीनियम और मैग्नीशियम ऑक्साइड का उत्पादन करता है, जिससे धातु धुएं का बुखार और दीर्घकालिक श्वसन समस्याएं होती हैं

- लेपित या पेंट की गई सामग्री: वाष्पीकरण के दौरान सतह उपचार विषैले यौगिक छोड़ सकते हैं—कटिंग से पहले हमेशा सामग्री सुरक्षा डेटा शीट्स की जाँच करें

वेंटिलेशन प्रणाली की आवश्यकताएँ:

प्रभावी धुआँ निकासी अनिवार्य है। OSHA घातक या संभावित खतरनाक धुएँ को लागू थ्रेशहोल्ड लिमिट मान (TLVs) या अनुमेय एक्सपोजर सीमाओं (PELs) से नीचे लाने के लिए पर्याप्त वेंटिलेशन की आवश्यकता होती है।

स्रोत कैप्चर प्रणाली—जो कटिंग बिंदु पर सीधे धुएँ को निकालती है—लेजर ऑपरेशन के लिए सबसे प्रभावी है। The Fabricator के अनुसार, उपमाइक्रोन लेजर कटिंग धुएँ के लिए MERV16 या उच्च दक्षता वाले फिल्टर वाले कार्ट्रिज धूल संग्रहक की सिफारिश की जाती है। स्टेनलेस स्टील या हेक्सावेलेंट क्रोमियम उत्पन्न करने वाली अन्य सामग्री को काटते समय HEPA आफ्टरफिल्टर की आवश्यकता हो सकती है।

अग्नि रोकथाम और शमन:

लेजर कटिंग में केंद्रित तीव्र ऊष्मा वास्तविक आग के खतरे पैदा करती है—विशेष रूप से जब ज्वलनशील सामग्री के पास कटिंग की जा रही हो या मलबे के जमा होने दिया जा रहा हो। ओएसएचए (OSHA) ने टिप्पणी की है कि उन कैबिन सामग्री को जिन पर 10 W/cm² से अधिक विकिरण तीव्रता पड़ रही हो, आग लग सकती है, और यहां तक कि प्लास्टिक कैबिन सामग्री का भी ज्वलनशीलता और विषैली धुआं उत्सर्जन क्षमता के लिए मूल्यांकन किया जाना चाहिए।

- कार्य क्षेत्र को साफ रखें: कटिंग क्षेत्र से ज्वलनशील सामग्री को हटा दें

- स्वचालित अग्नि दमन स्थापित करें: अग्निशामक या स्प्रिंकलर प्रणालियों को त्वरित प्रतिक्रिया के लिए स्थित किया जाना चाहिए

- उपयुक्त कैबिन सामग्री का उपयोग करें: ज्वाला-प्रतिरोधी सामग्री या व्यावसायिक रूप से डिज़ाइन की गई लेजर कैबिन आग लगने के जोखिम को कम करती हैं

- संचालन के दौरान निगरानी करें: लेजर कटिंग उपकरण को कभी भी बिना निगरानी के चलते न छोड़ें

परावर्तक सामग्री के जोखिम:

तांबा, पीतल और एल्युमीनियम लेजर ऊर्जा को कटिंग हेड की ओर वापस परावर्तित करते हैं—जिससे ऑप्टिक्स को नुकसान हो सकता है और अप्रत्याशित बीम खतरे उत्पन्न हो सकते हैं। इन सामग्रियों को काटते समय:

- सत्यापित करें कि आपकी लेजर धातु मशीन को परावर्तक सामग्री प्रसंस्करण के लिए रेट किया गया है

- पृष्ठ-प्रतिबिंब को कम करने के लिए विशेष तकनीकों (ऑक्सीजन सहायक गैस, नियंत्रित पियर्स अनुक्रम) का उपयोग करें

- सुनिश्चित करें कि प्रकाश किरण पथ के आवरण परावर्तित ऊर्जा का सामना कर सकें

- सेटअप और निगरानी के दौरान ऑपरेटरों के लिए अतिरिक्त आंख सुरक्षा पर विचार करें

विनियामक मानक और प्रशिक्षण सर्वोत्तम प्रथाएँ

विनियामक परिदृश्य को समझने से आप एक अनुपालन सुरक्षा कार्यक्रम बनाने में सक्षम होते हैं। प्रमुख मानकों में शामिल हैं:

- ANSI Z 136.1: संयुक्त राज्य अमेरिका में लेजर के सुरक्षित उपयोग के लिए मास्टर मानक, जो खतरे का आकलन, वर्गीकरण, नियंत्रण उपाय और प्रशिक्षण आवश्यकताओं को शामिल करता है

- OSHA 29 CFR 1926.54: निर्माण उद्योग में लेजर आवश्यकताएँ

- OSHA 29 CFR 1910.1096: कुछ उच्च-वोल्टेज लेजर पावर सप्लाई के लिए लागू आयनकारी विकिरण मानक

- FDA/CDRH विनियम: लेजर निर्माताओं के लिए संघीय लेजर उत्पाद प्रदर्शन मानक आवश्यकताएँ

प्रभावी ऑपरेटर प्रशिक्षण केवल एक मैनुअल पढ़ने से आगे बढ़ता है। उद्योग की सर्वोत्तम प्रथाओं की अनुशंसा करती हैं:

- ऑपरेटरों द्वारा उपयोग किए जाने वाले विशिष्ट उपकरण के साथ व्यावहारिक प्रशिक्षण

- सुरक्षा आदतों को मजबूत करने के लिए नियमित रूप से पुनरावृत्ति प्रशिक्षण

- आग प्रतिक्रिया, चोट उपचार और उपकरण खराबी प्रोटोकॉल को शामिल करते हुए आपातकालीन प्रक्रिया अभ्यास

- अनुपालन सत्यापन के लिए सभी प्रशिक्षण गतिविधियों की प्रलेखन

- बदला लेने के डर के बिना सुरक्षा चिंताओं की रिपोर्ट करने के लिए स्पष्ट संचार चैनल

याद रखें: सुरक्षा एक बार की घटना नहीं है। कोडइंटर के अनुसार, सुरक्षित संचालन बनाए रखने के लिए नियमित रूप से सुरक्षा प्रक्रियाओं की समीक्षा और अद्यतन करना, निरंतर शिक्षा प्रदान करना और नवीनतम मानकों और सर्वोत्तम प्रथाओं के बारे में जागरूक रहना आवश्यक है।

उचित सुरक्षा प्रोटोकॉल लागू होने पर, आपकी टीम आत्मविश्वास के साथ लेज़र कटिंग द्वारा प्रदान की जाने वाली सटीकता और गति का लाभ उठा सकती है। लेकिन यह प्रौद्योगिकी ठीक कहाँ-कहाँ सबसे बड़ा प्रभाव डाल रही है? ऑटोमोटिव उत्पादन लाइनों से लेकर एयरोस्पेस विनिर्माण सेल तक, धातु के साथ काम करने वाले लगभग हर उद्योग में इसके अनुप्रयोग पाए जाते हैं।

उद्योग अनुप्रयोग: ऑटोमोटिव से लेकर एयरोस्पेस विनिर्माण तक

आप जिस कार से चलाते हैं और जिस हवाई जहाज़ में उड़ते हैं, लेज़र द्वारा धातुओं की कटिंग आधुनिक जीवन को गति देने वाले घटकों को आकार देती है। यह प्रौद्योगिकी लगभग हर विनिर्माण क्षेत्र में अनिवार्य बन गई है—इसलिए नहीं क्योंकि यह फैशन में है, बल्कि इसलिए क्योंकि यह वास्तविक उत्पादन चुनौतियों को हल करती है जिन्हें अन्य तरीकों से समाधान नहीं मिल सकता।

लेज़र कटिंग इतनी सार्वभौमिक मूल्यवान क्यों है? यह तीन गुणों को जोड़ती है जिनकी निर्माता लगातार तलाश करते हैं: हजारवें इंच में मापी गई सटीकता, उच्च मांग वाले अनुसूचियों के साथ कदम मिलाकर चलने वाली उत्पादन गति, और पुनरावृत्ति जो यह सुनिश्चित करती है कि 10,000 नंबर वाला भाग ठीक एक नंबर वाले भाग के बराबर हो। आइए जानें कि विभिन्न उद्योग इन क्षमताओं का उपयोग कैसे करते हैं।

ऑटोमोटिव और एयरोस्पेस प्रिसिजन मेटल कॉम्पोनेंट्स

ऑटोमोटिव निर्माण लेज़र द्वारा धातु काटने की मशीनों को आवश्यक उत्पादन उपकरण के रूप में अपना चुके हैं। के अनुसार Alternative Parts , ऑटोमोबाइल निर्माताओं ने पहले स्टैम्पिंग और डाइ-कास्टिंग विधियों पर भरोसा किया था, लेकिन वे तकनीक तेजी से बढ़ती मांग और तेजी से जटिल डिजाइनों के साथ तालमेल रखने के लिए बहुत अक्षम साबित हुई।

आज की शीट मेटल लेजर कटिंग मशीन सिस्टम महत्वपूर्ण वाहन घटकों का उत्पादन करती है जिनमें शामिल हैंः

- चेसिस और संरचनात्मक घटक: फ्रेम रेल, क्रॉस-एजेंट और सुदृढीकरण ब्रैकेट जिन्हें क्रैश सुरक्षा प्रदर्शन के लिए तंग सहिष्णुता की आवश्यकता होती है

- बॉडी पैनल और ट्रिम भाग: दरवाजे, हुड और फेंडर के लिए लेजर कट धातु पैनल जहां किनारे की गुणवत्ता पेंट आसंजन और संक्षारण प्रतिरोध को प्रभावित करती है

- सस्पेंशन घटक: नियंत्रण बाहों, बढ़ते ब्रैकेट्स, और सुदृढीकरण प्लेटों को लगातार आयामी सटीकता की आवश्यकता होती है

- आंतरिक संयोजनः जटिल ज्यामिति वाले सीट फ्रेम, डैशबोर्ड समर्थन और तंत्र आवास

लाइटवेटिंग एक उभरती हुई ऑटोमोटिव एप्लीकेशन को दर्शाता है जिसे अब गति प्राप्त हो रही है। निर्माता ईंधन दक्षता में सुधार करने, निर्माण लागत कम करने और स्थिरता में सुधार करने के लिए भारी पारंपरिक सामग्री को हल्के विकल्पों से बदल रहे हैं। लेज़र कटिंग उन्नत उच्च-सामर्थ्य इस्पात और एल्युमीनियम मिश्र धातुओं के सटीक संसाधन को सक्षम करता है जो बिना संरचनात्मक निखार के लाइटवेटिंग को संभव बनाते हैं।

ऑटोमोटिव निर्माताओं के लिए व्यापक समाधान की तलाश में, सटीक धातु निर्माण भागीदार घटक निर्माण के लिए लेज़र कटिंग को स्टैम्पिंग के साथ जोड़ते हैं। शाओयी (निंगबो) मेटल टेक्नोलॉजी इस एकीकृत दृष्टिकोण के उदाहरण हैं—शीस, निलंबन और संरचनात्मक घटकों के लिए IATF 16949-प्रमाणित गुणवत्ता के साथ 5-दिवसीय त्वरित प्रोटोटाइपिंग के साथ-साथ स्वचालित बड़े पैमाने पर उत्पादन की पेशकश करते हैं। यह प्रमाणन सुनिश्चित करता है कि गुणवत्ता प्रबंधन प्रणाली ऑटोमोटिव OEM द्वारा मांगी जाने वाली कठोर आवश्यकताओं को पूरा करती है।

एयरोस्पेस विनिर्माण लेजर काटने की क्षमताओं को और आगे बढ़ाता है। ग्रेट लेक्स इंजीनियरिंग के अनुसार, एयरोस्पेस घटकों को सख्त सटीकता और स्थायित्व मानकों को पूरा करना चाहिए - यहां तक कि सबसे मामूली विचलन 30,000 फीट की दूरी पर सुरक्षा और प्रदर्शन को खतरे में डाल सकता है।

औद्योगिक धातु लेजर काटने की मशीन प्रणाली एयरोस्पेस अनुप्रयोगों में उत्कृष्टता प्राप्त करती है जिनमें शामिल हैंः

- संरचनात्मक तत्व: स्टेनलेस स्टील और टाइटेनियम जैसी सामग्री से बने ब्रैकेट, माउंटिंग प्लेट और फ्रेम घटक

- इंजन घटक: गर्मी के ढाल, नलिकाएं और जलने वाले उपकरण के लिंकर, जिन्हें कम से कम गर्मी प्रभावित क्षेत्रों के साथ साफ कटौती की आवश्यकता होती है

- आंतरिक संरचनाएं: सीट फ्रेम, ओवरहेड बिन तंत्र और रसोई उपकरण वजन में कमी और स्थायित्व को संतुलित करते हैं

- उपग्रह और अंतरिक्ष यान के भागोंः अति-सटीक घटकों जहां हर ग्राम मायने रखता है और विफलता एक विकल्प नहीं है

ऊंचाई पर हिमांक से नीचे के तापमान, टेकऑफ़ के दौरान तीव्र वायुमंडलीय बल और जमीन व उड़ान संचालन के बीच तापीय चक्रण जैसी चरम परिस्थितियों में भी भागों की अखंडता बनाए रखने सुनिश्चित करने के लिए प्रौद्योगिकी की न्यूनतम ऊष्मा-प्रभावित क्षेत्र के साथ साफ कटौती उत्पन्न करने की क्षमता।

इलेक्ट्रॉनिक्स, आर्किटेक्चर और मेडिकल एप्लीकेशन

इलेक्ट्रॉनिक्स निर्माण उन घटकों के लिए लेजर कटिंग पर निर्भर करता है जिन्हें किसी अन्य तरीके से उत्पादित करना असंभव होगा। उद्योग विश्लेषण के अनुसार, यह प्रौद्योगिकी तांबे और पीतल जैसी धातुओं से सर्किट बोर्ड, अर्धचालक सामग्री और कनेक्टर्स को बारीक विवरण और उच्च सटीकता के साथ काटती है।

प्रमुख इलेक्ट्रॉनिक्स अनुप्रयोगों में शामिल हैं:

- प्रिंटेड सर्किट बोर्ड (PCBs): सटीक आउटलाइन कटिंग और विशेषता निर्माण

- एन्क्लोज़र और हाउसिंग: RF शील्डिंग, हीट सिंक माउंटिंग प्लेट्स और कनेक्टर पैनल

- हीट सिंक्स: जो न्यूनतम स्थान में तापीय अपव्यय को अधिकतम करने वाली जटिल फिन ज्यामिति

- कनेक्टर्स और टर्मिनल: माइक्रॉन-स्तरीय सटीकता की आवश्यकता वाले लघुकृत घटक

जैसा कि 3ERP बताता है, जेब-साइज़ फोन से लेकर अल्ट्रा-थिन लैपटॉप तक, आज के उपभोक्ता इलेक्ट्रॉनिक्स पहले की तुलना में छोटे और अधिक शक्तिशाली हैं। फाइबर लेज़र कटर की सटीकता और दक्षता तकनीक निर्माताओं को स्वच्छतम और सबसे सटीक कट बनाए रखते हुए छोटे लेकिन जटिल घटकों को तेज़ी से काटने की अनुमति देती है।

वास्तुकला और सजावटी उद्योग सौंदर्यात्मक रूप से आकर्षक तत्व बनाने के लिए लेज़र कटिंग मशीन शीट मेटल सिस्टम का उपयोग करते हैं जो साथ ही साथ संरचनात्मक आवश्यकताओं को भी पूरा करते हैं। अनुप्रयोग कार्यात्मक और कलात्मक दोनों क्षेत्रों में फैले हुए हैं:

- फैसेड पैनल: इमारत के बाहरी हिस्सों के लिए जटिल पैटर्न के साथ लेज़र कट मेटल पैनल जो सौंदर्य और मौसम प्रतिरोध के बीच संतुलन बनाते हैं

- आंतरिक डिज़ाइन तत्व: कस्टम रूम डिवाइडर, सजावटी स्क्रीन और छत के तत्व

- साइनेज: मार्गदर्शन, ब्रांडिंग और विनियमन अनुपालन के लिए स्पष्ट, दृष्टिगत रूप से आकर्षक मेटल साइन

- अनुकूलित फर्नीचर: जटिल लेज़र मेटल प्रोफाइल वाले मेटल आधार, फ्रेम और सजावटी घटक

अल्टरनेटिव पार्ट्स के अनुसार, CO2 और फाइबर लेज़र कटर दोनों स्थापत्य अनुप्रयोगों में उत्कृष्ट हैं क्योंकि कई भवन परियोजनाएं विभिन्न सामग्री का उपयोग करती हैं। कंपनियां एक ही सुविधा में धातु घटकों के लिए फाइबर कटर और गैर-धातु सामग्री के लिए CO2 कटर का उपयोग करती हैं।

चिकित्सा सामग्री निर्माण उच्च गुणवत्ता और स्वच्छता मानकों के अनुरूप घटकों के उत्पादन के लिए लेज़र कटिंग पर निर्भर करता है। यह तकनीक स्टेनलेस स्टील, टाइटेनियम और विशिष्ट मिश्र धातुओं को सर्जिकल उपकरणों, नैदानिक उपकरणों और डिवाइस हाउसिंग में काटती है।

महत्वपूर्ण चिकित्सा अनुप्रयोगों में शामिल हैं:

- शल्य चिकित्सा उपकरण: छुरी, बलपूर्वक और विशेष उपकरण जिनमें बर्र-मुक्त किनारे की आवश्यकता होती है

- इम्प्लांटेबल उपकरण: स्टेंट, अस्थि प्लेट और संयुक्त घटक जिनमें जैव-अनुकूलता और सटीकता की आवश्यकता होती है

- नैदानिक उपकरण हाउसिंग: संवेदनशील इलेक्ट्रॉनिक्स के लिए कड़े सहन के साथ सुरक्षात्मक आवरण

- प्रयोगशाला उपकरण: नमूना धारक, माउंटिंग ब्रैकेट और विशिष्ट फिक्सचर

लेज़र कटिंग द्वारा प्राप्त साफ, बर्र-मुक्त किनारे और उच्च सटीकता सुनिश्चित करती है कि भाग संवेदनशील चिकित्सा प्रक्रियाओं में उपयोग के लिए सुरक्षित हैं। अनुसार ग्रेट लेक्स इंजीनियरिंग , पतली सामग्री के साथ काम करने की क्षमता जटिल, लघु उपकरणों के निर्माण को समर्थन देती है—चिकित्सा प्रौद्योगिकी के कम आक्रामक प्रक्रियाओं की ओर बढ़ने के साथ यह एक महत्वपूर्ण क्षमता है।

धातु निर्माण में प्रोटोटाइप से उत्पादन तक

शायद लेजर कटिंग की सबसे परिवर्तनकारी क्षमता उत्पाद विकास चक्र को तेज करने की उसकी क्षमता में निहित है। वही प्रौद्योगिकी जो उत्पादन भागों के हजारों का उत्पादन करती है, प्रोटोटाइप की मात्रा को सप्ताहों के बजाय दिनों में उत्पन्न कर सकती है।

इसका क्या महत्व है? स्टैम्पिंग जैसी पारंपरिक टूलिंग-आधारित प्रक्रियाओं को निर्माण करने में सप्ताह लगने वाले महंगे डाई की आवश्यकता होती है। डिज़ाइन में परिवर्तन का अर्थ है नया उपकरण और अधिक देरी। लेजर कटिंग इस बोझ को पूरी तरह से खत्म कर देती है—एक नया CAD फ़ाइल अपलोड करें और तुरंत कटिंग शुरू करें।

3ERP के विश्लेषण के अनुसार, शीट धातु लेजर कटिंग जटिल प्रोटोटाइप से लेकर बड़े पैमाने पर उत्पादन भागों तक बनाने के लिए गति, सटीकता और बहुमुखी प्रतिभा को जोड़ती है। यह लचीलापन सक्षम करता है:

- त्वरित डिज़ाइन पुनरावृत्ति: पारंपरिक तरीकों से एक डिज़ाइन बनाने में जितना समय लगता है, उतने ही समय में कई डिज़ाइन विकल्पों का परीक्षण करें

- कार्यात्मक प्रोटोटाइप: उत्पादन सामग्री से कटे पुर्जे जो अंतिम प्रदर्शन का सही प्रतिनिधित्व करते हैं

- ब्रिज उत्पादन: उच्च मात्रा वाली विधियों के लिए टूलिंग की प्रतीक्षा करते समय छोटे बैच उत्पादन

- कम मात्रा वाला उत्पादन: उन मात्रा के लिए लागत प्रभावी निर्माण जिसमें टूलिंग निवेश का औचित्य नहीं बनता

स्वचालित उद्योग जैसे उद्योगों के लिए, जहां बाजार में तेजी से उत्पाद पेश करने से प्रतिस्पर्धात्मक लाभ मिलता है, त्वरित प्रोटोटाइपिंग क्षमताएं अमूल्य साबित होती हैं। विनिर्मेयता के लिए डिज़ाइन (DFM) में व्यापक समर्थन प्रदान करने वाले धातु निर्माण भागीदार—जैसे शाओयी की 12-घंटे की कोट टर्नअराउंड और 5-दिन की त्वरित प्रोटोटाइपिंग —इंजीनियरिंग टीमों को डिज़ाइन को त्वरित रूप से मान्य करने और प्रोटोटाइप से उत्पादन तक आसानी से संक्रमण करने में सहायता करते हैं।

एक ही तकनीकी प्लेटफॉर्म में प्रोटोटाइपिंग गति और उत्पादन क्षमता का संयोजन निर्माताओं द्वारा उत्पाद विकास के दृष्टिकोण में एक मौलिक परिवर्तन लाता है। चाहे आप वास्तुकला स्थापनाओं के लिए लेज़र धातु प्रोफाइल बना रहे हों या ऑटोमोटिव अनुप्रयोगों के लिए सटीक चेसिस घटक, लेज़र कटिंग आधुनिक निर्माण की मांग के अनुसार लचीलापन प्रदान करती है।

लगभग हर उद्योग में अपने अनुप्रयोगों के फैलाव के साथ, सवाल यह उठता है: आप अपनी विशिष्ट आवश्यकताओं के लिए सही दृष्टिकोण कैसे चुनें? क्या आपको उपकरण में निवेश करना चाहिए या सेवा प्रदाताओं के साथ साझेदारी करनी चाहिए?

अपने प्रोजेक्ट के लिए सही लेज़र कटिंग दृष्टिकोण का चयन

आपने तकनीक का पता लगाया है, विधियों की तुलना की है, और अनुप्रयोगों को समझा है—अब वह निर्णय आता है जो वास्तव में आपके लाभ पर प्रभाव डालता है। क्या आपको धातु के लिए एक सीएनसी लेज़र कटर में निवेश करना चाहिए? किसी सेवा प्रदाता के साथ साझेदारी करनी चाहिए? सही उत्तर आपके संचालन के विशिष्ट कारकों पर निर्भर करता है, और गलत निर्णय लेने से आपको अति-उपयोगिता उपकरण या उत्पादन के अवसरों के नुकसान के कारण हजारों रुपये का नुकसान हो सकता है।

चलिए जटिलता को दूर करें और इस निर्णय को आत्मविश्वास के साथ लेने के लिए एक व्यावहारिक ढांचा प्रदान करें।

आपके धातु कटिंग तकनीक निर्णय के लिए मुख्य कारक

उपकरण या सेवा प्रदाताओं का मूल्यांकन करने से पहले, आपको पांच महत्वपूर्ण मापदंडों पर स्पष्टता की आवश्यकता है जो प्रत्येक अनुवर्ती निर्णय को आकार देंगे:

1. उत्पादन मात्रा आवश्यकताएं

आपको कितने भागों की आवश्यकता है, और कितनी बार? AP प्रेसिजन के लागत विश्लेषण के अनुसार, उच्च मात्रा वाले संचालन उपकरण में निवेश को सही ठहराते हैं, जबकि अनियमित या कम मात्रा वाली आवश्यकताएँ आउटसोर्सिंग को पसंद करती हैं। केवल वर्तमान मांग को ही नहीं, बल्कि अगले 3-5 वर्षों में वास्तविक वृद्धि के अनुमान को भी ध्यान में रखें।

2. सामग्री के प्रकार और मोटाई

आपकी सामग्री की मिश्रण यह निर्धारित करती है कि कौन सी लेजर तकनीक—और इसलिए कौन सा उपकरण वर्ग—आपकी आवश्यकताओं के अनुरूप है। पतले स्टेनलेस स्टील के साथ शीट धातु को संभालने वाले लेजर कटर को उस लेजर कटर की तुलना में अलग क्षमताओं की आवश्यकता होती है जो 1" कार्बन स्टील प्लेट को प्रोसेस करता है। जैसा कि स्टीलवे लेज़र कटिंग , अधिकांश सेवा प्रदाता अपनी वेबसाइटों पर अपनी सामग्री की मोटाई विनिर्देश और संगत शीट धातुओं का विवरण देते हैं, जो आपको तुरंत सत्यापित करने में सहायता करता है कि क्या वे आपकी आवश्यकताओं को पूरा कर सकते हैं।

3. सटीकता सहिष्णुता

आपका अनुप्रयोग किस स्तर की आयामी शुद्धता की मांग करता है? अधिकांश अनुप्रयोगों के लिए शीट धातु के लेजर कटिंग मशीन ±0.001" से ±0.005" तक की सहनशीलता प्राप्त करती है। यदि आपके भागों को अधिक कड़े विनिर्देशों की आवश्यकता है, तो आपको उपकरण क्षमता और ऑपरेटर कौशल—चाहे आंतरिक रूप से हो या बाह्य स्रोत से—दोनों की पुष्टि करनी होगी।

4. बजट पर विचार

उपकरण लागत में भारी अंतर होता है। उद्योग की मूल्य निर्धारण डेटा के अनुसार, लेजर कटर्स की कीमत एंट्री-लेवल मॉडल्स के लिए लगभग $1,000 से लेकर औद्योगिक-ग्रेड मशीनों के लिए $20,000 से अधिक तक होती है—उच्च-स्तरीय उत्पादन प्रणालियों की कीमत छह अंकों तक पहुंच सकती है। खरीद मूल्य के अलावा, इन बातों को ध्यान में रखें:

- स्थापना और सुविधा संशोधन

- ऑपरेटर प्रशिक्षण और प्रमाणन

- निरंतर रखरखाव और खपत सामग्री

- ऊर्जा लागत (फाइबर लेजर CO2 प्रणालियों की तुलना में 30-40% कम ऊर्जा का उपभोग करते हैं)

- फर्श की जगह की आवश्यकता

5. आंतरिक उपकरण बनाम बाह्य स्रोत

इस मौलिक विकल्प के लिए सावधानीपूर्वक विश्लेषण की आवश्यकता होती है। प्रत्येक मार्ग में अलग-अलग लाभ और समझौते शामिल हैं।

आंतरिक उपकरण के लाभ

- उत्पादन अनुसूची और प्राथमिकताओं पर पूर्ण नियंत्रण

- बाह्य साझेदारों के साथ कोई शिपिंग देरी या समन्वय नहीं

- गुप्त डिज़ाइन और प्रक्रियाओं की सुरक्षा

- उच्च उत्पादन मात्रा पर लंबे समय तक लागत लाभ

- डिज़ाइन परिवर्तन या आपातकालीन ऑर्डर के तुरंत जवाब देने की क्षमता

आंतरिक उपकरणों के नुकसान

- महत्वपूर्ण प्रारंभिक पूंजी निवेश

- निरंतर रखरखाव लागत और उपकरण बंद होने का जोखिम

- फर्श की जगह की आवश्यकता जो मौजूदा सुविधाओं पर दबाव डाल सकती है

- ऑपरेटर विशेषज्ञता विकसित करने के लिए प्रशिक्षण निवेश

- सीएनसी धातु लेजर कटर प्रणाली के विकसित होने के साथ प्रौद्योगिकी अप्रचलन का जोखिम

आउटसोर्सिंग के लाभ

- पूंजीगत उपकरण में निवेश या रखरखाव का बोझ नहीं

- स्वामित्व जोखिम के बिना उन्नत तकनीक तक पहुँच

- मांग के साथ बढ़ने वाली लचीली क्षमता

- उन ऑपरेटरों से विशेषज्ञता जो रोजाना धातु काटते हैं

- आंतरिक संसाधनों को मुख्य क्षमताओं पर केंद्रित करना

आउटसोर्सिंग के दोष

- अनुसूची और उत्पादन प्राथमिकताओं पर कम नियंत्रण

- सामग्री आवाजाही के लिए शिपिंग लागत और अग्रिम समय

- प्रदाताओं के बीच संभावित गुणवत्ता में भिन्नता

- जटिल या विकसित डिज़ाइन के लिए संचार अधिभार

- बहुत अधिक मात्रा में प्रति-भाग उच्च लागत

के रूप में एपी प्रिसिजन नोट्स , आउटसोर्सिंग मशीनरी के स्वामित्व से संबंधित मुद्दों—उपकरण विफलताओं, स्क्रैप धातु भंडारण और पुनर्चक्रण प्रबंधन सहित—से बचने में मदद करती है, और विशेषज्ञ श्रमिकों को नियुक्त करने की आवश्यकता को खत्म कर देती है।

प्रिसिजन मेटल फैब्रिकेशन विशेषज्ञों के साथ साझेदारी

जब आउटसोर्सिंग उचित होती है, तो सही साझेदार का चयन आपका सबसे महत्वपूर्ण निर्णय बन जाता है। सभी लेजर कटर शीट मेटल प्रदाता समान क्षमताएं प्रदान नहीं करते हैं, और गलत विकल्प पूरे उत्पादन अनुसूची में समस्याएं पैदा कर सकता है।

स्टीलवे के व्यापक मार्गदर्शिका के अनुसार, मूल्यांकन के प्रमुख मापदंडों में प्रदाता का अनुभव, तकनीकी क्षमताएं, टर्नअराउंड समय और पारदर्शी मूल्य निर्धारण शामिल हैं। लेकिन इन बुनियादी बातों के परे, सर्वश्रेष्ठ साझेदार कुछ अधिक मूल्यवान प्रदान करते हैं: डीएफएम (डिज़ाइन फॉर मैन्युफैक्चरेबिलिटी) समर्थन।

DFM का महत्व क्यों है? GMI Solutions के अनुसार, DFM उत्पाद डिज़ाइन और इंजीनियरिंग को सबसे सरल निर्माण विधि तक पहुँचाने में मार्गदर्शन करता है। यह दृष्टिकोण डिज़ाइन चरण के भीतर ही समस्याओं का पता लगाता है—यह सबसे उपयुक्त परिदृश्य है क्योंकि इससे समाधान अनावश्यक रूप से महंगे या समय लेने वाले नहीं बनते, और उत्पादन प्रभावित नहीं होता है।

लाभ तेजी से बढ़ते हैं:

- लागत में कमी: DFM पूरे प्रोजेक्ट में गैर-आवश्यक तत्वों को हटा देता है, जिससे महत्वपूर्ण प्रत्यक्ष और अप्रत्यक्ष बचत होती है

- गुणवत्ता में सुधार: निर्माण की जटिलता को कम करने से अंतिम उत्पाद की एकरूपता में सुधार होता है

- बाजार में तेज उपलब्धता: डिज़ाइन संबंधी समस्याओं को शुरुआत में पकड़ने से विश्वसनीय उत्पाद ग्राहकों तक तेजी से पहुँचते हैं

- प्रतिस्पर्धात्मक लाभ: DFM अनुभव वाले निर्माताओं के साथ साझेदारी करने वाले OEM को मापा जा सकने वाला बाजार स्थिति लाभ मिलता है

विशेष रूप से ऑटोमोटिव निर्माताओं के लिए, व्यापक क्षमता वाले साझेदार—लेजर कटिंग के साथ स्टैम्पिंग, बड़े पैमाने पर उत्पादन के साथ त्वरित प्रोटोटाइपिंग—खोजना, आपूर्ति श्रृंखला में काफी सुगमता लाता है। इस तरह की कंपनियां जैसे शाओयी (निंगबो) मेटल टेक्नोलॉजी इस एकीकृत दृष्टिकोण के उदाहरण यह हैं: 5-दिवसीय त्वरित प्रोटोटाइपिंग, स्वचालित बड़े पैमाने पर उत्पादन, IATF 16949-प्रमाणित गुणवत्ता, व्यापक DFM समर्थन, और 12 घंटे में उद्धरण प्रस्तुति। गति, प्रमाणन और इंजीनियरिंग समर्थन का यह संयोजन दर्शाता है कि एक सच्ची विनिर्माण साझेदारी लेन-देन आधारित विक्रेता संबंध की तुलना में क्या प्रदान करती है।

आपकी लेजर कटिंग मूल्यांकन जाँच सूची

उपकरण खरीद या सेवा प्रदाता साझेदारी में प्रतिबद्ध होने से पहले, इस क्रियान्वयन योग्य जाँच सूची पर काम करें:

- मात्रा मूल्यांकन: अपनी मासिक/वार्षिक भाग आवश्यकताओं और वृद्धि प्रक्षेपण की गणना करें। क्या मात्रा पूंजीगत उपकरण निवेश को उचित ठहराती है?

- सामग्री सूची: उन सभी धातु प्रकारों, मोटाइयों और किसी भी विशेष मिश्र धातुओं की सूची बनाएं जिन्हें आप संसाधित करने की आवश्यकता है। उपकरण या प्रदाता क्षमताओं के साथ संगतता सत्यापित करें।

- सहिष्णुता आवश्यकताएँ: प्रत्येक भाग परिवार के लिए आयामी सटीकता की आवश्यकताओं को दस्तावेजीकृत करें। सुनिश्चित करें कि आपका दृष्टिकोण आवश्यक परिशुद्धता को लगातार प्राप्त करता है।

- कुल लागत विश्लेषण: उपकरण, रखरखाव, श्रम, प्रशिक्षण, फ़्लोर स्पेस और ऊर्जा सहित वास्तविक लागतों की तुलना करें, आपके अनुमानित आयतन के अनुसार आउटसोर्सिंग प्रति-भाग मूल्य निर्धारण के विरुद्ध।

- समयरेखा मूल्यांकन: लीड टाइम आवश्यकताओं का आकलन करें। क्या आउटसोर्सिंग की टर्नएराउंड समय आपके उत्पादन शेड्यूल को पूरा कर सकता है?

- गुणवत्ता प्रमाणन आवश्यकताएँ: आवश्यक प्रमाणपत्रों की पहचान करें (ऑटोमोटिव के लिए IATF 16949, एयरोस्पेस के लिए AS9100)। सत्यापित करें कि प्रदाता के पास उचित प्रमाण पत्र हैं।

- DFM क्षमता: आकलन करें कि क्या साझेदार डिज़ाइन समर्थन प्रदान करते हैं जो उत्पादन सुगमता को अनुकूलित करता है और लागत को कम करता है।

- प्रोटोटाइप आवश्यकताएँ: नए डिज़ाइन पर कितनी जल्दी पुनरावृत्ति करने की आवश्यकता है, इस पर विचार करें। त्वरित प्रोटोटाइपिंग वाले साझेदार विकास चक्र को संक्षिप्त करते हैं।

- द्वितीयक कार्य: फ़िनिशिंग आवश्यकताओं की सूची बनाएँ (पाउडर कोटिंग, मोड़ना, असेंबली)। एकीकृत प्रदाता बहु-विक्रेता समन्वय को समाप्त कर देते हैं।

- संचार और समर्थन: प्रतिक्रियाशीलता का आकलन करें। आपको कोट्स कितनी जल्दी मिल सकते हैं? तकनीकी संसाधन कितने सुलभ हैं?

धातु काटने के लिए लेजर मशीन, जो एक ऑपरेशन के लिए सही हो सकती है, दूसरे के लिए पूरी तरह गलत हो सकती है। छोटे मात्रा में विविध सामग्री को संसाधित करने वाली जॉब शॉप की आवश्यकताएँ उस ऑटोमोटिव आपूर्तिकर्ता से भिन्न होती हैं जो मासिक रूप से हजारों समान ब्रैकेट्स का उत्पादन करता है। इसका कोई सार्वभौमिक "सर्वश्रेष्ठ" उत्तर नहीं है—केवल आपकी विशिष्ट स्थिति के लिए सर्वोत्तम उत्तर है।

चाहे आप अपनी सुविधा में एक लेजर कटर मशीन धातु प्रणाली में निवेश करें या सटीक निर्माण विशेषज्ञों के साथ साझेदारी करें, लक्ष्य वही रहता है: अपने व्यापार उद्देश्यों का समर्थन करने वाली लागत पर गुणवत्तापूर्ण पुर्जे प्राप्त करना। इस गाइड में दिए गए ढांचों और चेकलिस्ट का उपयोग करके अपने विकल्पों का व्यवस्थित रूप से मूल्यांकन करें, और आप ऐसा निर्णय लेंगे जो आपके ऑपरेशन के लिए आने वाले वर्षों तक फायदेमंद रहेगा।

धातुओं के लेजर कटिंग के बारे में अक्सर पूछे जाने वाले प्रश्न

1. धातु लेजर कटिंग की लागत कितनी होती है?

धातु लेजर कटिंग आमतौर पर स्टील प्रसंस्करण के लिए प्रति घंटे 13-20 डॉलर के बीच होती है। कुल लागत सामग्री के प्रकार, मोटाई, कटिंग की जटिलता और उत्पादन मात्रा पर निर्भर करती है। उदाहरण के लिए, 70 इंच प्रति मिनट की दर से 15,000 इंच कटिंग की आवश्यकता वाली परियोजना में लगभग 3.57 घंटे का सक्रिय कटिंग समय लगता है। उच्च मात्रा वाले ऑपरेशन अक्सर अनुकूलित नेस्टिंग और कम सेटअप समय के माध्यम से प्रति भाग कम लागत प्राप्त करते हैं। प्रमाणित निर्माताओं जैसे शाओयी के साथ साझेदारी करने से सटीक परियोजना बजट निर्धारण के लिए 12 घंटे के भीतर उद्धरण प्राप्त करने के साथ-साथ प्रतिस्पर्धी मूल्य भी मिलती है।

2. लेजर कटर से कौन सी धातुओं को काटा जा सकता है?

लेजर कटर माइल्ड स्टील, स्टेनलेस स्टील, एल्युमीनियम, टाइटेनियम, तांबा और पीतल को प्रभावी ढंग से प्रसंस्कृत करते हैं। माइल्ड स्टील उत्कृष्ट ऊर्जा अवशोषण के कारण सर्वोत्तम कटिंग प्रदर्शन प्रदान करता है। स्टेनलेस स्टील को ऑक्साइड-मुक्त, साफ किनारों के लिए नाइट्रोजन सहायक गैस की आवश्यकता होती है। एल्युमीनियम और तांबा परावर्तकता की चुनौतियां प्रस्तुत करते हैं जिन्हें फाइबर लेज़र CO2 प्रणालियों की तुलना में अधिक प्रभावी ढंग से संभालते हैं। ऑक्सीकरण रोकने के लिए टाइटेनियम को निष्क्रिय गैस शील्डिंग की आवश्यकता होती है। उच्च-शक्ति वाली फाइबर लेजर प्रणालियों के साथ सामग्री की मोटाई क्षमता 1 मिमी से कम पतली शीटों से लेकर 40 मिमी से अधिक की प्लेटों तक होती है।

3. धातुओं के लिए फाइबर लेजर और CO2 लेजर कटिंग में क्या अंतर है?

फाइबर लेज़र 1.06 μm तरंगदैर्ध्य पर 30-40% दक्षता के साथ काम करते हैं, जो पतली से मध्यम धातुओं पर 3-5 गुना तेज़ कटिंग गति प्रदान करते हैं और तकरीबन 25,000 कार्य घंटे के आयुष्य के साथ आते हैं। CO2 लेज़र 10.6 μm तरंगदैर्ध्य का उपयोग करते हैं, जिनकी दक्षता केवल 10% होती है, लेकिन धातु और गैर-धातु दोनों को काटने में उत्कृष्ट होते हैं। फाइबर लेज़र तांबे और एल्यूमीनियम जैसी परावर्तक धातुओं पर बेहतर तरंगदैर्ध्य अवशोषण के कारण प्रभावी होते हैं। मोटी स्टील प्लेट्स और विभिन्न प्रकार की सामग्री के साथ काम करने वाली शॉप्स के लिए CO2 सिस्टम अभी भी उपयुक्त बने हुए हैं।

4. लेज़र कटर धातु में कितनी मोटाई तक काट सकते हैं?

कटिंग मोटाई लेजर शक्ति और धातु के प्रकार पर निर्भर करती है। एक 3kW फाइबर लेजर मामूली इस्पात को 20 मिमी तक, स्टेनलेस स्टील को 10 मिमी तक और एल्यूमीनियम को 8 मिमी तक काट सकता है। उच्च-शक्ति वाले 10kW प्रणाली कार्बन स्टील और एल्यूमीनियम पर 40 मिमी से अधिक प्राप्त कर सकते हैं। अत्यधिक उच्च-शक्ति वाले 60kW प्रणाली 100 मिमी मोटाई तक की स्टील को प्रसंस्कृत कर सकते हैं। हालाँकि, गुणवत्तापूर्ण कटिंग मोटाई आमतौर पर अधिकतम क्षमता से 40% कम होती है। सुसंगत किनारे की गुणवत्ता और सटीकता के लिए, उन शक्ति रेटिंग का चयन करें जो आपकी मोटाई आवश्यकताओं से आराम से अधिक हों।

5. क्या लेजर कटिंग प्लाज्मा या वॉटरजेट कटिंग की तुलना में बेहतर है?

प्रत्येक तकनीक विभिन्न परिदृश्यों में उत्कृष्ट है। लेज़र कटिंग 1/4" मोटाई तक की सामग्री पर उच्चतम सटीकता (±0.001" से ±0.005") और सबसे तेज़ गति प्रदान करती है तथा इसमें न्यूनतम द्वितीयक परिष्करण की आवश्यकता होती है। प्लाज्मा कटिंग प्रति इंच सबसे कम संचालन लागत प्रदान करती है और मोटी सामग्री (2"+) को अधिक किफायती ढंग से संभालती है। वॉटरजेट कटिंग शून्य ऊष्मा-प्रभावित क्षेत्र उत्पन्न करती है, जिससे यह ऊष्मा-संवेदनशील मिश्र धातुओं और 24" मोटाई तक की सामग्री के लिए आदर्श बनाती है। अपनी विशिष्ट सहनशीलता आवश्यकताओं, सामग्री की मोटाई, उत्पादन मात्रा और ऊष्मा संवेदनशीलता के मुद्दों के आधार पर चयन करें।

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —

छोटे पर्चे, उच्च मानदंड। हमारी तेजी से प्रोटोटाइपिंग सेवा मान्यता को तेजी से और आसानी से बनाती है —