Segredos do corte por láser de chapa metálica: desde fibra contra CO2 ata cortes perfectos

Como realmente funciona o corte con láser de chapa de metal

Imaxina un feixe de luz tan poderoso que pode cortar o aceiro endurecido coma unha faca quente a manteiga. Esa é a esencia da tecnoloxía láser de corte de chapa de metal, un proceso que transformou fundamentalmente a forma en que os fabricantes se achegan á fabricación de precisión. Pero que pasa cando ese feixe concentrado se atopa co metal?

No seu núcleo, un máquina de Corte a Laser de Metal xenera un feixe coherente de enerxía luminosa a través dun proceso chamado emisión estimulada. Este feixe é entón focalizado a través de ópticas especializadas nun punto incriblemente pequeno na superficie do material. O resultado? Calor intenso que derrite, queima ou vaporízase rapidamente o metal seguindo un camiño programado con precisión.

A física detrás da interacción do raio láser

Cando un raio láser choca cunha superficie metálica, comeza unha fascinante reacción en cadea. Segundo a investigación sobre física do corte por láser , unha parte da radiación reflíctese, pero unha porción considerable é absorbida e convértese en enerxía térmica. Aquí é onde resulta interesante: a capacidade do material para absorber radiación aumenta á vez que se quenta, creando un bucle de realimentación positivo que fai que o proceso sexa cada vez máis eficiente.

Cando a temperatura aumenta, o metal experimenta sucesivas transformacións de fase:

- O material sólido quenta rapidamente no punto focal

- Iníciase a fusión cando as temperaturas superan o punto de fusión do metal

- Coa enerxía suficiente, prodúcese a vaporización

- En casos de interacción láser intensa, a sublimación directa pode evitar completamente a fase líquida

Durante o corte láser de metais, forma-se un kerf característico (a largura do corte) mentres o material fundido é expulsado polo gas de axuda. Este proceso dinámico implica interaccións complexas entre o metal fundido en movemento e o fluxo de gas — todo isto ocorre en milisegundos.

O estreitamento do feixe de enerxía e a precisión coa que se poden mover as lentes láser garante unha calidade de corte extremadamente alta, permitindo executar deseños complexos a altas velocidades de avance incluso en materiais difíciles ou fráxiles.

Por que os fabricantes están abandonando os métodos tradicionais de corte

Entón, por que os fabricantes elixen cada vez máis un láser para cortar metais fronte aos métodos tradicionais? As vantaxes son convincentes. Ao contrario que os cortadores rotativos, que requiren refrigerantes (que poden contaminar as pezas), ou os procesos de rectificado que deixan residuos de carburo, un láser para máquina de corte implica só enerxía e gases, polo que non supón ningún risco de contaminación do material.

A velocidade conta unha historia aínda máis dramática. Unha máquina para cortar metal usando tecnoloxía láser pode procesar unha chapa de acero de 40 mm aproximadamente 10 veces máis rápido que unha serra de fita e 50-100 veces máis rápido que o corte por fío. Cando se teñen en conta as posibilidades ilimitadas de complexidade 2D posibles con movementos controlados por G-code, enténdese por que o corte láser se converteu na solución preferida para a fabricación de precisión.

Xa sexa que estea avaliando a compra de equipos ou explorando opcións de subcontratación, comprender estes principios fundamentais é esencial. As seccións seguintes guiarano a través de todo, desde a tecnoloxía de fibra fronte á de CO2 ata a compatibilidade co material, axudándoo a tomar decisións informadas sobre o seu investimento nunha máquina de corte de metal por láser.

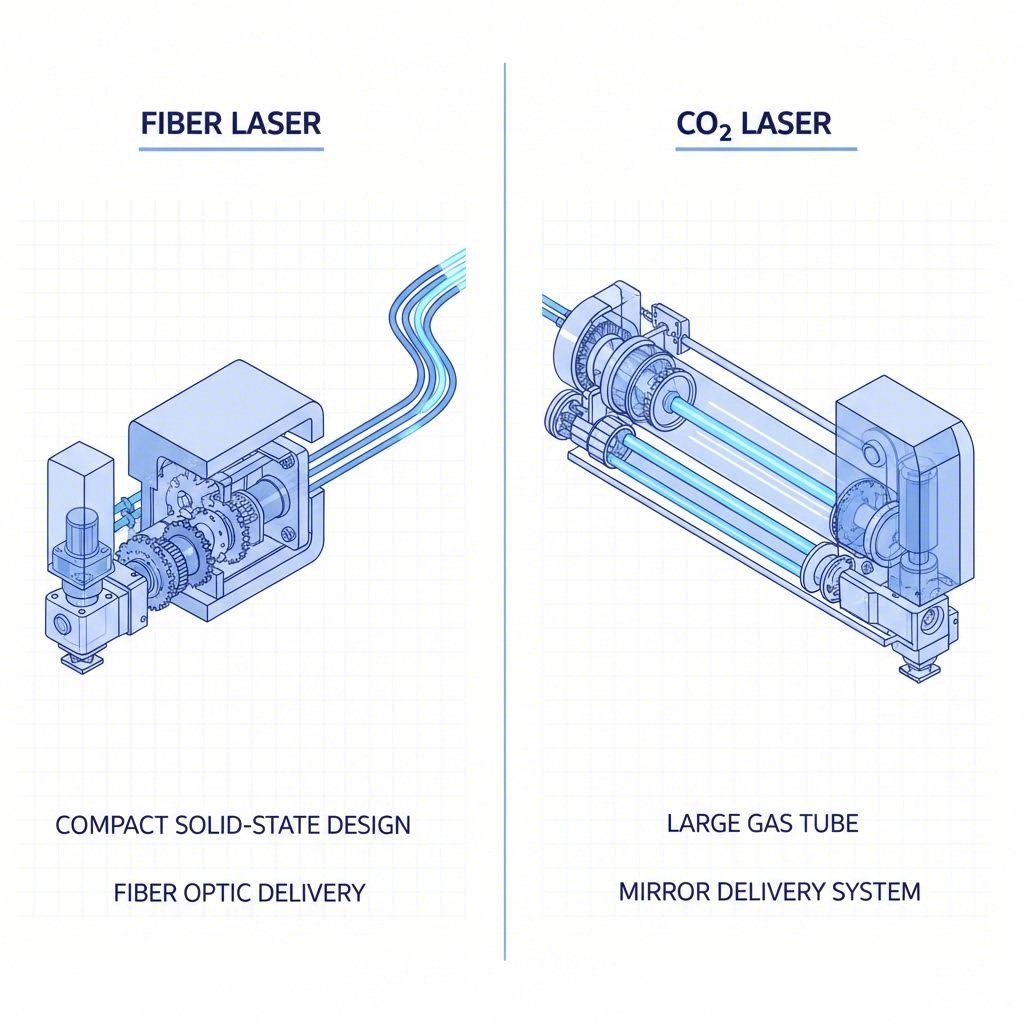

Tecnoloxía Láser de Fibra vs Láser CO2 Explicada

Agora que entende como funciona o corte por láser, probabelmente estea preguntándose: que tipo de láser debería usar en realidade? Aquí é onde o debate entre fibra e CO2 se volve crítico, e é unha decisión que afecta directamente á súa eficiencia produtiva, aos custos operativos e ao retorno do investimento.

Aquí está a realidade: os láseres de fibra e os láseres de CO2 xeran os seus feixes mediante mecanismos fundamentalmente diferentes, o que resulta en características de rendemento distintas. Escoller entre eles non se trata de atopar unha tecnoloxía "mellor", senón de adaptar a ferramenta axeitada á súa aplicación específica.

Tecnoloxía de Láser de Fibra e a Súa Vantaxe de Lonxitude de Onda

Unha máquina de corte por láser de fibra xera luz a través dun deseño de estado sólido que utiliza cables de fibra óptica. O feixe resultante ten unha lonxitude de onda de aproximadamente 1,06 μm, e este aparentemente pequeno detalle técnico crea enormes vantaxes prácticas para o corte de metais.

Por que é tan importante a lonxitude de onda? Os metais absorben lonxitudes de onda máis curtas moito máis eficientemente. De acordo con A análise técnica de Bodor , metais reflectivos como o cobre, aluminio e latón absorben a enerxía do láser de fibra dramaticamente mellor ca a enerxía do láser CO2. Esta absorción superior tradúcese directamente en cortes máis rápidos, limpos e precisos.

Os números de eficiencia contan unha historia convincente:

- Os láseres de fibra acadan unha eficiencia electroóptica de aproximadamente 30-40%

- Os láseres CO2 conseguen só uns 10% de eficiencia

- Esta vantaxe de eficiencia de 3-4 veces significa que os láseres de fibra consomen significativamente menos electricidade mentres ofrecen velocidades de corte máis rápidas

Para metais finos a medios, unha máquina de corte por láser de fibra CNC pode cortar 2-3 veces máis rápido que sistemas CO2 comparables. Esta diferenza de velocidade existe porque os metais absorben máis facilmente a lonxitude de onda máis curta do láser de fibra, convertendo máis enerxía láser en acción de corte en vez de desperdicio reflectido.

Os requisitos de mantemento favorecen aínda máis a tecnoloxía de fibra. O deseño completamente sellado dun cortador láser de fibra elimina os espellos e os axustes de alixñamento que requiren os sistemas CO2. Menos compoñentes ópticos significa menos servizos de mantemento rutineiros e menos tempos de inactividade, unha consideración importante para operacións de alto volume.

Cando os láseres de CO2 aínda son unha boa opción

Isto quere dicir que os láseres CO2 están obsoletos? De ningún xeito. Os sistemas CO2 utilizan unha mestura de gas nun tubo sellado para xerar luz a 10,6 μm, unha lonxitude de onda que os materiais non metálicos absorben excepcionalmente ben.

Se o seu taller procesa madeira, acrílico, plásticos ou tecidos xunto con metal, os láseres CO2 ofrecen unha versatilidade sen igual. Proporcionan bordos máis suaves e acabados pulidos en materiais orgánicos que os láseres de fibra simplemente non poden igualar. Para talleres de materiais mixtos, esta flexibilidade supera a miúdo as vantaxes de eficiencia da tecnoloxía de fibra.

Os láseres de CO2 seguen sendo relevantes para aplicacións específicas en metais. Cando se cortan chapas finas de metal ata 25 mm en entornos que requiren capacidade tanto para metais como para non metais, a comodidade dun único sistema versátil pode xustificar a perda de eficiencia.

Incluso os sistemas láser de fibra de escritorio están entrando no mercado para fabricación metálica a pequena escala, pero o CO2 segue sendo o estándar entre aficionados e pequenas empresas que traballan principalmente con non metais.

| Especificación | Laser de fibra | Láser de CO2 |

|---|---|---|

| Longitude de onda | ~1,06 μm | ~10,6 μm |

| Eficiencia Eléctrica | 30-40% | ~10% |

| Requisitos de manutenção | Baixa (deseño sellado, menos compoñentes ópticos) | Maior (alixamento de espellos, substitución de lentes) |

| Compatibilidade con metais | Excelente (inclúe metais reflectantes) | Adequado para chapas finas; ten dificultades con aliños reflectantes |

| Compatibilidade con non metálicos | Limitado | Excelente (madeira, acrílico, tecidos, plásticos) |

| Velocidade en Metais Finos (0,5-6 mm) | 2-3 veces máis rápido que o CO2 | Línea base |

| Capacidade en Metais Grosos (>25 mm) | Preferido (os sistemas de alta potencia chegan ata 100 mm) | Limitado a uns 25 mm como máximo |

| Investimento Inicial | Xeralmente máis baixo a potencia equivalente | Maior debido a tecnoloxía madura pero complexa |

| Custo operativo a longo prazo | Máis baixo (ahorro enerxético, menos consumibles) | Maior (consumo de enerxía, pezas de substitución) |

O marco de decisión vólvese máis claro cando se centra nos seus materiais principais. Para fabricación metálica dedicada—especialmente con ligas reflectantes e requisitos de alta produtividade—os sistemas CNC con láser de fibra ofrecen maior velocidade, eficiencia e aforro a longo prazo. Para entornos de materiais mixtos ou especialización non metálica, a tecnoloxía CO2 segue sendo unha opción práctica.

Unha vez clarificada a selección do tipo de láser, a seguinte consideración é igualmente importante: que metais concretos pode cortar, e que limitacións de espesor debe esperar? A seguinte sección proporciona unha guía completa de compatibilidade de materiais que responde a estas preguntas clave.

Guía de compatibilidade de materiais e limitacións de espesor

Escolleu o tipo de láser, pero ¿pode realmente cortar os materiais que necesitades? Esta pregunta atrapa a incontables compradores que asumen que todos os metais se comportan de xeito idéntico baixo un raio láser. A realidade é moito máis matizada, e comprender os comportamentos específicos dos materiais permitiríavos evitar erros custosos.

Cada metal aporta propiedades únicas á mesa de corte: puntos de fusión, condutividade térmica, reflectividade e tendencias á oxidación. Estas características determinan non só se un cortador láser para metais pode procesar un material, senón tamén ata que grosor se pode chegar, que calidade de bordo se acadará e que parámetros fornecerán resultados optimizados.

Parámetros de corte por tipo de metal e grosor

Ao traballar cun cortador láser para metais, descubrirás rapidamente que non existen configuracións válidas para todos os casos. Analicemos o que podes esperar dos materiais máis comúns.

Acero de carbono continúa sendo o metal máis adecuado para o láser dispoñible. A súa alta taxa de absorción e comportamento de fusión previsible faino ideal tanto para principiantes como para entornos de produción. Con un láser de fibra de 1kW, podes cortar acero ao carbono ata uns 10 mm de grosor de forma neta, mentres que os sistemas de maior potencia (6kW e superiores) amplían esta capacidade ata 25 mm ou máis. Cal é a clave para cortes limpos? Encontrar o equilibrio entre potencia e velocidade para minimizar formación de Resíduos (Dross) na beira inferior.

Aceiro inoxidable require máis precaución. A súa dureza e natureza reflectiva precisan velocidades de corte máis lentas e configuracións de frecuencia máis altas en comparación co acero ao carbono. Un sistema de 1kW pode traballar con inoxidable ata uns 5 mm, con velocidades recomendadas entre 10-20 mm/s. O uso de nitróxeno como gas auxiliar evita a oxidación e proporciona esa calidade de beira pulida e sen óxido que normalmente requiren as aplicacións con inoxidable.

Aluminio presenta retos únicos que colle a moitos operadores desprevidos. Cando se corta aluminio con láser, estás combatendo dúas propiedades simultaneamente: alta reflectividade que rebota a enerxía do láser, e unha excelente condutividade térmica que disipa rapidamente o calor da zona de corte. Os láseres de fibra manexan o corte de aluminio moito mellor que os sistemas CO2 debido á súa lonxitude de onda máis curta, pero aínda necesitarás configuracións de potencia ao redor do 60-80% e velocidades de 10-20 mm/s para obter resultados óptimos. O grosor máximo para un sistema de 1kW adoita estar limitado a 3 mm.

Cobre e Latón levar o corte por láser ao seu límite. Estas aleacións moi reflectivas e conductoras termicamente requiren enfoques especializados: son imprescindibles os láseres de fibra (o CO2 simplemente non funciona de forma efectiva), e necesitarás un posicionamento de foco preciso xunto con velocidades máis lentas. Empezar os cortes nas bordas do material ou facer furos de inicio previamente axuda a superar a barreira inicial de reflectividade. Espera grosores máximos ao redor de 2 mm para o cobre con niveis de potencia estándar.

Titanio ofrece unha excelente compatibilidade con láser a pesar da súa reputación como material difícil. A súa menor condutividade térmica en realidade traballa a seu favor, concentrando o calor na zona de corte. Con todo, o titanio reacciona de forma agresiva co oíxeno a altas temperaturas, polo que é esencial usar un gas de asistencia inerte (normalmente argón) para conseguir bordos limpos e sen contaminación.

| Material | Grosor Máx. (1kW) | Potencia recomendada | Clasificación da Calidade do Canto | Consideracións especiais |

|---|---|---|---|---|

| Acero de carbono | 10mm | 80-100% | Excelente | Use asistencia con oíxeno para cortes máis rápidos; nitróxeno para bordos máis limpos |

| Aceiro inoxidable | 5mm | 90-100% | Moi Boa | A asistencia con nitróxeno evita a oxidación; require velocidades máis lentas |

| Aluminio | 3mm | 60-80% | Boa | A alta reflectividade require láser de fibra; use asistencia con nitróxeno ou aire |

| Cobre | 2 mm | 90-100% | Moderado | Láser de fibra imprescindible; comece polas beiras ou pre-furade; o foco preciso é crítico |

| Latón | 3mm | 80-100% | Boa | Desafíos semellantes ao cobre; as boquillas especializadas poden axudar no arrefriamento |

| Titanio | 4mm | 70-90% | Excelente | Require asistencia con argón para previr a oxidación; a menor condutividade axuda ao corte |

Expectativas de Calidade de Bordo para Diferentes Materiais

A calidade do bordo non é só cuestión de estética: afecta directamente a procesos posteriores como soldadura, pintura e montaxe. Cando cortas chapa metálica con láser, comprender que acabado esperar axúdache a establecer estándares realistas de calidade e a identificar cando algo falla.

Materiais de groso delgado (menos de 3 mm) xeralmente prodúcense os bordos máis limpos en todos os tipos de metal. O láser atravesa rapidamente, minimizando as zonas afectadas polo calor e reducindo as posibilidades de formación de borras. Verás mínima descoloración e bordos que frecuentemente non requiren acabado secundario.

Grosor medio (3-10 mm) introduce máis variables. A acumulación de calor vólvese significativa, e a relación entre velocidade de corte e calidade do bordo apertase. Se é moi rápido, verás cortes incompletos ou exceso de borras. Se é moi lento, a zona afectada polo calor agrándase, provocando descoloración e posibles deformacións en materiais sensibles.

Corte de chapa grusa (10 mm ou máis) require unha optimización coidadosa dos parámetros. A calidade do bordo xeralmente diminúe ao aumentar o grosor—observarás estrías máis pronunciadas (as liñas verticais visibles nas beiras cortadas), zonas afectadas polo calor máis amplas e maior posibilidade de adhesión de borra na superficie inferior.

Os metais reflectantes como o aluminio e o cobre presentan desafíos particulares de calidade de bordo. Segundo A investigación de Accumet sobre os desafíos do mecanizado láser , estes materiais reflicten a enerxía láser, o que pode provocar fusión inconsistente e perfís de bordo irregulares. A solución implica o uso de lásers de fibra que operan en lonxitudes de onda máis curtas, que penetran as superficies reflectantes de forma máis eficaz que os sistemas CO2.

Os sistemas de enfoque automático melloran drasticamente a consistencia dos bordes en diferentes grosores. Estes mecanismos seguidores de altura axustan continuamente o punto de enfoque mentres a cabezadora de corte se move sobre o material, compensando a deformación das follas, as variacións da superficie e as inconsistencias de grosor. Sen enfoque automático, os operarios deben optimizar manualmente o enfoque para cada grosor de material, un proceso que leva tempo e que introduce erros humanos.

O beneficio práctico? Unha posición de enfoque constante asegura que o raio láser manteña unha densidade de enerxía óptima na superficie de corte, producindo unha calidade uniforme dos bordes incluso ao cortar láminas metálicas con lixeiras variacións de grosor ou irregularidades da superficie.

Comprender o comportamento do material é só unha parte do problema. O gas auxiliar que elixe desempeña un papel igualmente crítico na determinación da calidade do corte, a velocidade e as características dos bordes, un tema sorprendentemente ausente na maioría das guías sobre esta tecnoloxía.

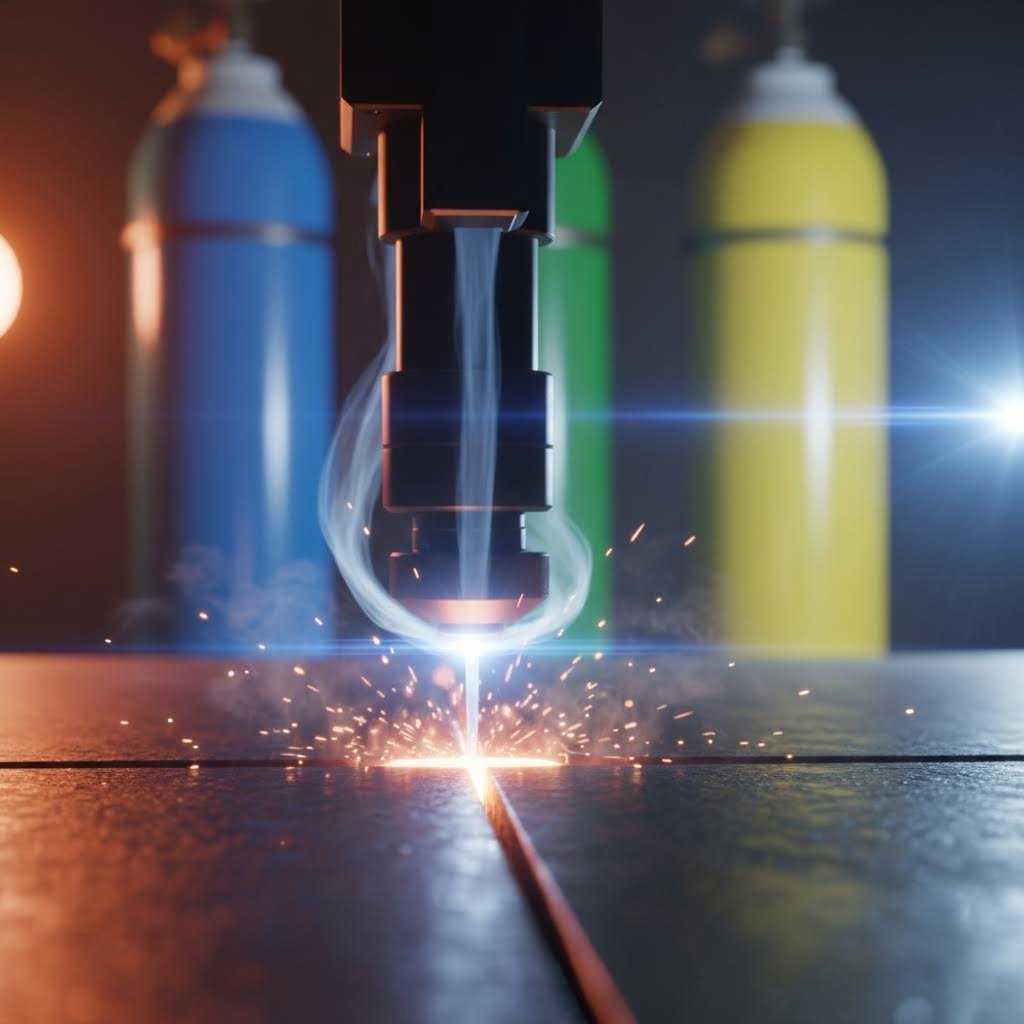

Selección do gas auxiliar para obter unha calidade de corte óptima

Aquí vai un segredo que separa aos operadores amateurs dos profesionais experimentados: o gas que flúe a través da túa cabeza de corte é igual de importante que o láser en si. Moitos principiantes asumen que o gas auxiliar é simplemente "aire", pero escoller entre osíxeno, nitróxeno ou aire comprimido pode transformar completamente a velocidade de corte, a calidade do borde e os custos operativos mensuais.

Imaxina o gas auxiliar como o socio invisible do teu láser. Mentres o feixe funde o metal, o fluxo de gas realiza tres funcións críticas: expulsar o material fundido da zona de corte, controlar a oxidación na superficie de corte e arrefriar o material circundante para minimizar a distorsión térmica. Domina esta variable e desbloquearás niveis de rendemento que outros non poden igualar.

Selección de Osíxeno vs Nitróxeno vs Aire Comprimido

Cada gas auxiliar aporta vantaxes distintas para materiais e aplicacións específicos. Comprender cando usar cada un é esencial para optimizar as túas operacións con láser de corte de metais.

Oxíxeno é a opción tradicional para o corte láser de acero en aceros ao carbono e aceros suaves. Aquí está o motivo: o oxíxeno non só expulsa o metal fundido, senón que participa activamente no proceso de corte mediante unha reacción exotérmica. Cando o oxíxeno entra en contacto co acero quente, queima o material, xerando calor adicional que acelera a velocidade de corte e posibilita a penetración en chapas máis grosas.

- Ventaxas: Velocidades de corte máis rápidas en acero ao carbono; permite o corte de materiais máis grosos (6 mm a 25 mm ou máis); menor consumo de gas en comparación co nitróxeno; rentable para a produción en masa de acero ao carbono

- Desvantaxes: Crea unha capa de óxido negro nas beiras cortadas; as beiras oxidadas requiren rectificado antes de pintar ou soldar; non é adecuado para acero inoxidable ou aluminio; calidade de beira limitada en pezas onde a aparencia é crítica

Nitróxeno adoptase unha aproximación oposta. Como gas inerte, crea unha atmosfera protectora que evita calquera reacción química entre o metal quente e o aire circundante. Segundo Análise técnica de Pneumatech , o nitróxeno produce cortes limpos e sen óxidos cunha calidade de bordo superior, o que o converte na opción preferida para o corte láser de metais cando importan a aparencia e o procesamento posterior.

- Ventaxas: Ofrece bordos prateados de "corte brillante" sen oxidación; as pezas están listas inmediatamente para soldar ou recubrir con pó; esencial para o acero inoxidable e o aluminio; produce a máis alta calidade de bordo dispoñible

- Desvantaxes: Maiores custos operativos debido ao consumo a alta presión; velocidades de corte máis lentas ca co osíxeno no acero ao carbono; require depósitos de maior tamaño ou xeración no sitio para operacións de alto volume

Aire comprimido representa a tendencia de crecemento máis rápida no corte láser de metais, especialmente con sistemas de alta potencia (3 kW a 12 kW). O aire é aproximadamente un 80 % de nitróxeno e un 20 % de osíxeno, proporcionando un compromiso entre os dous gases puros: certo efecto de arrefriamento do nitróxeno e un modesto incremento térmico do osíxeno.

- Ventaxas: Practicamente sen custo despois do investimento no compresor; adecuado para aceiro inoxidable fino (<3 mm), aceiro galvanizado e aceiro ao carbono (<10 mm en sistemas de alta potencia); elimina a logística e almacenamento de cilindros de gas

- Desvantaxes: Prodúce bordos amarelos claros cunha lixeira oxidación; require un compresor de alta calidade con secador e filtraxe libre de aceite; o aire contaminado (auga ou aceite) danará a óptica do láser; a calidade do borde é inferior á do nitróxeno puro

| Tipo de gas | Materiais Principais | Aparencia do borde | Custo relativo | Mellor Aplicación |

|---|---|---|---|---|

| Oxíxeno (O2) | Aceiro ao carbono grosso (6-25 mm+) | Negro (oxidado) | Baixo | Corte de produción a alta velocidade; compoñentes estruturais |

| Nitróxeno (N2) | Aceiro inoxidable, aluminio, latón | Prateado (limpo) | Alta | Equipamento para alimentos; pezas decorativas; compoñentes listos para soldar |

| Aire comprimido | Metais finos, aceiro galvanizado | Amarillo claro | O máis baixo | Fabricación xeral; aplicacións sensibles ao custo |

Como o gas de axuda afecta á calidade e velocidade de corte

Elixir o gas axeitado é só a metade da ecuación: os axustes de presión inflúen directamente nos resultados. Un cortador láser para acero comportarase de forma moi distinta a 5 bar fronte a 15 bar, e comprender esta relación é o que separa os cortes bos dos excelentes.

Para operacións láser de corte con axuda de oxíxeno , a presión e o caudal controlan a intensidade da reacción exotérmica. Unha maior presión incrementa a reacción química co peza, xerando máis calor pero tamén arriscándose a un exceso de fusión nas beiras. Segundo a guía de resolución de problemas de Bodor, se estás a ver ranuras grandes nas superficies de acero carbono grosas, elevar o teu punto focal polo menos +15 mm e aumentar a altura do bico ata uns 1,4 mm pode mellorar significativamente a calidade das beiras.

Para corte con nitróxeno , a alta presión é esencial—normalmente de 10-20 bar segundo o grosor do material. O gas inerte debe expulsar completamente o material fundido da liña de corte antes de que poida volver solidificarse e crear bordos. Unha presión insuficiente orixina rebarbas no bordo inferior; unha presión excesiva pode causar turbulencias que afectan á calidade do corte.

Directrices xerais de presión en función do grosor do material:

- Materiais finos (0,5-3 mm): Presións máis baixas (6-10 bar para nitróxeno) evitan o traspaso; velocidades de corte máis rápidas compensen a forza reducida do gas

- Espesor medio (3-10 mm): Presións moderadas (10-15 bar para nitróxeno) equilibran a expulsión do material coa calidade do bordo; esta franxa require o axuste máis preciso dos parámetros

- Materiais grozos (10 mm ou máis): Presións máis altas (15-20+ bar para nitróxeno) aseguran a eliminación completa do material fundido de liñas de corte profundas; velocidades máis lentas permiten tempo suficiente para unha expulsión exhaustiva

Ao cortar acero inoxidable con nitróxeno e experimentar rebarbas, probe a baixar o punto focal, aumentar o diámetro do bico e reducir o ciclo de traballo. Para superficies ennegrecidas durante o corte con aire, a causa adoita ser unha velocidade de corte lenta: a superficie de corte reacciona co aire durante demasiado tempo. Aumentar a velocidade evita esta exposición prolongada e mantén bordos máis limpos.

Aínda que seleccione perfectamente o gas e os valores de presión, outros defectos poden comprometer os seus resultados. A seguinte sección analiza os problemas comúns de corte e os axustes de parámetros que os eliminan.

Resolución de problemas comúns en defectos de corte láser

Axustou a selección do gas, adaptou a potencia ao grosor do material e programou un traxecto de corte impecable, aínda así as pezas acabadas non teñen o aspecto correcto. Soa familiar? Incluso operarios experimentados atopan defectos que parecen aparecer sen avisar, convertendo traballos prometedores en montóns de refugo.

Aquí vai a boa nova: a maioría dos defectos no corte de metal por láser seguen patróns previsibles con causas identificables. Unha vez que entendas a relación entre os parámetros de corte e a formación de defectos, poderás resolver problemas en minutos en vez de horas. Examinemos os problemas máis comúns e os axustes que os eliminan.

Identificación de escoria, rebarbas e zonas afectadas polo calor

Antes de poder solucionar un problema, necesitas identificalo correctamente. Cada tipo de defecto indica un desequilibrio específico de parámetros — e tratar o síntoma equivocado perde tempo mentres o problema real persiste.

Escoria aparece como metal fundido solidificado adherido á beira inferior do teu corte. Cando cortas chapa metálica con láser e observas formacións rugosas semellantes a contas por baixo, a escoria é a culpable. Segundo a análise de defectos de JLCCNC, a escoria indica xeralmente que o material fundido non está sendo expulsado do corte con suficiente rapidez — volve solidificarse antes de que o gas auxiliar o poida expulsar completamente.

Rebordos son saliencias afiadas ao longo das beiras cortadas que atrapan os dedos e interferen co axuste das pezas. Ao contrario do rebarbo (que pende por debaixo do material), os rebordos esténdense cara fóra desde a propia beira. Unha máquina de corte por láser de metal produce rebordos cando o feixe non secciona limpiamente as fibras do material, deixando metal parcialmente derretido que endurece formando aristas afiadas.

Zonas afectadas polo calor (HAZ) maniféstanse como descoloración—patróns irisados, amarelecemento ou áreas escurecidas ao redor da liña de corte. Tal como A guía técnica de SendCutSend explica, a HAZ prodúcese cando o metal se quenta por riba da súa temperatura de transformación sen chegar a derretirse, alterando permanentemente a microestrutura nesa zona.

As consecuencias van máis alá do aspecto estético:

- A HAZ pode crear zonas fráxiles propensas a rachaduras baixo tensión

- A microestrutura alterada complica as operacións subseguintes de soldadura

- As áreas descoloridas poden rexeitar a adhesión de pintura ou recubrimento en pó

- Para compoñentes aeroespaciais e estruturais, a HAZ pode comprometer os requisitos de resistencia críticos para a seguridade

Enrolamento transforma láminas planas en pezas curvadas ou retorcidas, especialmente problemático con materiais de groso reducido. Cando se corta con láser stock de chapa metálica inferior a 2 mm, a distribución desigual do calor provoca expansión diferencial: unha área medra mentres que zonas adxacentes permanecen frías, creando tensións internas que dobran o material.

Calidade deficiente do bordo manifesta-se como estrías visibles, liñas de corte inconsistentes ou superficies que se senten ásperas ao tacto. Aínda que as dimensións sexan tecnicamente correctas, os bordos ásperos indican desaxustes de parámetros ou problemas mecánicos no sistema de corte con láser metálico.

Axustes de parámetros para eliminar defectos comúns

Cada defecto remóntase a un desequilibrio entre tres variables principais: velocidade de corte, potencia do láser e posición de foco. Comprender como interactúan estas variables proporciona o marco diagnóstico necesario para resolver case calquera problema de calidade.

Pense nisto deste xeito: demasiada potencia combinada cunha velocidade excesivamente lenta xera un exceso de calor—o que provoca unHAZ amplo, deformacións e oxidación. Pouca potencia con velocidade excesiva orixina cortes incompletos, rebarbas e escoria. A posición de enfoque determina se a enerxía se concentra precisamente na superficie do material ou se se dispersa ineficazmente por riba ou por debaixo.

Lista de comprobación para resolución de problemas de escoria e polboreira:

- Aumente a presión do gas auxiliar para mellorar a expulsión do material fundido

- Axuste a distancia entre o bico e a peza—se é excesiva, reduce a efectividade do gas

- Verifique que o bico non estea obstruído nin danado por acumulación de salpicaduras

- Reduza a velocidade de corte en materiais grosos para permitir a penetración completa

- Comprobe a posición de enfoque; un enfoque incorrecto causa fusión incompleta na parte inferior da ranura

- Use soportes elevados para o corte (mesas con listóns ou grades alveolares) para que a escoria caia limpiamente

Lista de comprobación para eliminación de rebarbas:

- Diminúa a velocidade de corte para asegurar o corte completo do material

- Recalibre o alixamento do feixe—os láseres desalineados producen unha calidade de bordo inconsistente

- Inspeccione o estado da lente e do bico; os compoñentes desgastados degradan o enfoque do feixe

- Axuste o punto de enfoque máis preto da superficie do material para un fusión de bordo máis limpa

- Verifique a configuración correcta de potencia segundo o tipo e grosor do material

Lista de comprobación para a redución da zona afectada polo calor:

- Aumente a velocidade de corte para reducir o tempo de exposición ao calor

- Baixe a potencia do láser ao nivel efectivo mínimo para cortes limpos

- Cambie ao gas auxiliar de nitróxeno para previr a decoloración relacionada coa oxidación

- Considere modos de corte pulsado que limiten a entrada continua de calor

- Para aplicacións sensibles ao calor, avalíe o corte por chorro de auga como alternativa

Lista de comprobación para previr deformacións:

- Utilice suxeicións axeitadas — mordazas, xigues ou mesas de baleiro manteñen as follas finas planas

- Empregue modos de láser pulsado para minimizar a acumulación de calor cumulativa

- Optimice a secuencia do traxecto de corte para distribuír o calor uniformemente por toda a folla

- Engada placas protectoras auxiliares para obter un soporte adicional do material

- Aumente a velocidade de corte para reducir a concentración localizada de calor

O soporte do material require atención especial cando se corta chapa metálica con láser. De acordo co Guía de resolución de problemas de LYAH Machining , un soporte inadecuado é unha das principais causas tanto de deformacións como dunha calidade de corte inconsistente. Unha mesa de corte de metal deseñada axeitadamente utiliza superficies de listóns ou estrutura alveolar que minimizan os puntos de contacto mentres fornecen un soporte estable en toda a folla.

Por que importa a xeometría do soporte? As superficies planas tradicionais crean pontes térmicas que conducen o calor de forma desigual e atrapan o rezume baixo a peza. As mesas con listóns permiten que o gas auxiliar e o material fundido saían libremente mentres limitan o contacto a cordoas estreitas. Este deseño evita a acumulación de calor, reduce os danos por reflexión no reverso do material e posibilita cortes consistentes en formatos grandes de chapa.

Para materiais finos especialmente, considere engadir placas protectoras ou empregar sistemas de fixación ao baleiro. Estas aproximacións manteñen as chapas perfectamente planas durante todo o ciclo de corte, evitando a distorsión térmica que causa curvaturas e erros dimensionais.

Cando os problemas de calidade das bordas persisten a pesar dos axustes de parámetros, investigue os factores mecánicos: a óptica suxeira dispersa o feixe e degrada o enfoque; as beiras gastadas interrumpen os patróns de fluxo de gas; a vibración no sistema de pórtico crea estrías visibles. O mantemento regular—limpeza de lentes, substitución de consumibles e verificación da calibración da máquina—impide que estas causas secundarias encubran os seus esforzos de optimización de parámetros.

Unha vez dominado o diagnóstico de defectos, está listo para abordar a seguinte decisión crítica: escoller o nivel adecuado de potencia do láser para os seus requisitos de produción específicos e rango de materiais.

Escolla a Potencia Adequada do Láser para a Súa Aplicación

Así que xa domina a compatibilidade de materiais e o diagnóstico de problemas, pero aquí é onde moitos compradores cometen o seu erro máis caro: escoller o nivel incorrecto de potencia. Pouca potencia déixao loitando con limitacións de espesor e tempos de ciclo lentos. En exceso? Gastou de máis nunha capacidade que nunca usará.

A verdade é que unha máquina de corte por láser para metais non é unha compra válida para todos. Niveis de potencia que van desde 1 kW a máis de 20 kW satisfán necesidades de produción moi diferentes, e comprender o que cada nivel ofrece realmente axuda a investir sabiamente en vez de gastar en exceso.

Relación entre niveis de potencia e requisitos de produción

Que significa realmente a potencia do láser para as súas operacións diárias? Segundo a orientación técnica de Bodor, a potencia—medida en vatios—determina a velocidade e eficacia coa que o seu láser corta diferentes materiais. Pero a relación non é linear, e unha maior potencia non implica automaticamente mellores resultados.

Así é como diferentes niveis de potencia se traducen en capacidade real:

sistemas de 1 kW a 3 kW: Estas opcións de cortadoras láser industriais de nivel de entrada destacan no procesamento de chapa fina. Agardábanse cortes limpos en acero inoxidable ata 5 mm, acero ao carbono ata 10 mm e aluminio ata 3 mm. Para talleres especializados en sinalización, ferraría decorativa, compoñentes de climatización ou fabricación lixeira, este rango de potencia ofrece unha precisión excelente sen requirir un investimento de capital excesivo.

sistemas de 4 kW a 8 kW: O rango máis empregado para a fabricación xeral de metais. Unha cortadora láser CNC nesta categoría manexa aceiros estruturais de grosor medio, aliñas máis espesas e volumes de produción máis altos. Poderá cortar eficientemente acero ao carbono de 15 mm e traballar con placas de acero inoxidable ata 12 mm cunha calidade de bordo aceptable.

sistemas de 10 kW a 20 kW+: Corte pesado para aplicacións exigentes. Segundo O análise de potencia de ACCURL , estes sistemas de corte láser de aceiro cortan aceiro ao carbono por encima de 25 mm e aceiro inoxidable ata 50 mm. Industrias como a construción naval, a fabricación de equipos pesados e a fabricación de estruturas metálicas dependen desta capacidade para procesar chapas grosas rapidamente.

Comprensión da relación potencia-espesor-velocidade

A potencia, o espesor e a velocidade forman un triángulo interconectado. Aumenta unha variable, e afecta ás outras. Unha maior potencia permite cortar materiais máis groscos OU manter o mesmo espesor a velocidades máis rápidas. Esta relación afecta directamente á economía da súa produción.

Considere este exemplo práctico: cortar aceiro ao carbono de 10 mm cun láser de 3 kW pode acadar 1,5 metros por minuto. Pasar a un sistema de 6 kW, e ese mesmo corte acelera a máis de 3 metros por minuto, duplicando a súa produtividade sen cambiar o material nin a calidade. Para produción en gran volume, esta diferenza de velocidade se traduce en ganancias significativas de capacidade.

| Nivel de potencia | Máx. aceiro ao carbono | Máx. aceiro inoxidable | Máx. aluminio | Velocidade relativa (chapa fina) | Mellor Aplicación |

|---|---|---|---|---|---|

| 1-3kW | 10mm | 5mm | 3mm | Línea base | Sinalización, HVAC, fabricación lixeira |

| 4-6kW | 16mm | 10mm | 8mm | 1,5-2x máis rápido | Fabricación xeral, pezas para automoción |

| 8-12kW | 25 mm | 20mm | 16mm | 2-3 veces máis rápido | Fabricación pesada, compoñentes estruturais |

| 15-20kW+ | 40mm+ | 50mm | 30mm | 3-4x máis rápido | Construción naval, equipos pesados, chapa graxa |

Pero máis rápido non sempre é mellor economicamente. Unha máquina de corte de acero que consume 20kW require moita máis electricidade ca unha unidade de 6kW. Se a súa produción rara vez supera os 10mm de grosor, esa capacidade extra está inactiva mentres as facturas de luz aumentan. O punto óptimo? Adecuar o investimento en potencia ao seu típico carga de traballo, non o seu requisito máximo ocasional.

Para a avaliación do volume de produción, pregúntese: cantas pezas por turno necesito? Cal é o rango típico de grosor do material? Con que frecuencia realiza traballos con chapas grosas? Se o 80% do seu traballo implica chapa metálica inferior a 6 mm, un sistema de gama media cunha calidade de feixe superior adoita superar a unha máquina de maior potencia con óptica inferior.

O equilibrio entre capital e capacidade tamén inclúe consideracións sobre mantemento. Os sistemas de maior potencia xeran máis calor, o que require unha infraestrutura de refrigeración máis robusta e posiblemente substitucións máis frecuentes dos consumibles. Os sistemas de menor potencia con fontes láser de fibra eficientes ofrecen a miúdo un custo total de propiedade máis baixo para aplicacións axeitadas.

Unha vez clarificada a selección da potencia, queda un tema crítico conspicuamente ausente na maioría das discusións sobre equipos: os requisitos de seguridade que protexen aos seus operarios e garanticen o cumprimento normativo.

Requisitos de seguridade para operacións láser de corte de metais

Aquí vai un tema que a maioría das guías de equipos omiten convenientemente: a seguridade. Porén, operar un cortador láser industrial sen os protocolos de seguridade adecuados pon en risco grave aos seus empregados e expón o seu negocio a sancións reguladoras, reclamacións por responsabilidade e posibles peches.

O corte láser industrial implica feixes de enerxía concentrada capaces de danar instantaneamente os ollos e a pel, combinados con fumes e partículas que se acumulan no tecido pulmonar ao longo do tempo. Comprender estes riscos non é opcional; é fundamental para a operación responsable de calquera máquina de corte de metais.

Clasificacións de seguridade láser e equipo protexente

Todo sistema láser recibe unha clasificación que indica o seu nivel de risco potencial. De acordo coa Guía completa de seguridade de Keyence , estas clasificacións van desde totalmente seguro ata gravemente perigoso:

- Clase 1: Seguro baixo todas as condicións de uso normal — non se requiren precaucións especiais

- Clase 2: Seguro para visualización accidental; inclúe láseres visibles onde o reflexo do parpadeo proporciona protección

- Clase 2M: Seguro para visualización a ollo nu, pero perigoso cando se mira a través de instrumentos ópticos

- Clase 3R: Baixo risco de lesión, pero require precaución durante a exposición directa ao feixe

- Clase 3B: Perigoso para a exposición ocular directa; require medidas activas de seguridade

- Clase 4: Alto risco de lesións oculares e na pel; pode encender materiais e supor riscos de lume

A maioría dos sistemas industriais de corte por láser están na Clase 4 —a categoría de maior perigo—. Con todo, isto é o que moitos operadores non teñen en conta: unha cabina axeitada pode converter incluso un sistema Clase 4 nun entorno Clase 1, asegurando a seguridade en toda a instalación.

Que fai efectiva unha cabina? A barrera debe conter completamente a luz láser, impedindo que saia calquera radiación do feixe durante o funcionamento normal. Segundo o Norma ANSI Z136.1 —o documento fundacional para os programas de seguridade láser na industria—os encerados deben incorporar dispositivos de interlocución de seguridade que apaguen automaticamente o láser se se abren durante o funcionamento.

Equipamento ocular protexente seguirá sendo esencial sempre que as portas do encerado estean abertas ou durante os procedementos de mantemento. Pero non colla calquera lentes de seguridade— as gafas de seguridade para láser deben coincidir coa lonxitude de onda específica e a potencia de saída da súa máquina de corte de metal. Os láseres de fibra (lonxitude de onda de 1,06 μm) e os láseres de CO2 (lonxitude de onda de 10,6 μm) requiren lentes protexentes completamente diferentes. O uso de equipo ocular inadecuado non proporciona protección ningunha mentres crea unha falsa sensación de seguridade.

Formación do operador forma o compoñente humano de calquera programa de seguridade eficaz. A norma ANSI Z136.1 define os requisitos específicos de formación e establece o papel dun Oficial de Seguridade con Láseres (LSO) que ten a responsabilidade de implementar e supervisar os protocolos de seguridade. A formación debería cubrir os riscos do feixe, riscos non relacionados co feixe, procedementos de emerxencia e o uso axeitado de todo o equipo protector.

Requisitos de ventilación e extracción de fumes

Cando un feixe láser vaporiza o metal, este non desaparece simplemente—transformase en partículas en suspensión, gases e fumes que supoñen riscos respiratorios graves. De acordo coa orientación técnica de AccTek Laser, estas emisións inclúen vapores metálicos, óxidos e posibles gases nocivos que se acumulan rapidamente en espazos pechados de traballo.

As consecuencias dunha ventilación inadecuada van máis aló dos riscos inmediatos para a saúde:

- Problemas respiratorios por inhalación de partículas metálicas

- Risco de lume e explosión por acumulación de gases inflamables

- Dano no equipo cando os fumes recobren compoñentes ópticos e lentes

- Desempeño reducido do láser e vida útil máis curta do equipo

- Incumprimento normativo e posibles pechados de instalacións

Os sistemas adecuados de extracción de fumes deben capturar as emisións na fonte—directamente da zona de corte—antes de que se disipen no aire circundante. Isto require unha velocidade de fluxo de aire axeitada para superar a columna térmica que xorde do corte, combinada cun filtro capaz de reter partículas submicrónicas.

Moitas rexións teñen normas específicas de calidade do aire no lugar de traballo aplicables ás operacións industriais de corte con láser. O cumprimento requirexeralmente especificacións documentadas do sistema de ventilación, calendarios regulares de mantemento dos filtros e monitorización periódica da calidade do aire.

Lista de comprobación completa de seguridade para operacións de corte con láser:

- Verificar a clasificación do láser e asegurarse de que o encerramento teña a cualificación axeitada

- Instalar dispositivos de seguridade en todos os puntos de acceso ao encerramento

- Proporcionar gafas protectoras específicas para a lonxitude de onda a todo o persoal

- Designar e formar a un Oficial de Seguridade Láser cualificado

- Colocar sinais de aviso en todos os puntos de entrada ás zonas de láser

- Instalar un sistema de extracción de fumes cunha velocidade de captación axeitada na zona de corte

- Implementar calendarios regulares de substitución de filtros e mantemento

- Documentar os Procedementos Operativos Estándar (POE) para todas as operacións con láser

- Establecer procedementos de parada de emerxencia e formar a todos os operadores

- Programar o seguimento periódico da calidade do aire para verificar a eficacia da ventilación

- Mantén os estándares de seguridade eléctrica: as fontes de alimentación de alto voltaxe para láser supoñen riscos de electrocución

- Manter o equipo de extinción de incendios accesible e inspeccionado regularmente

O cumprimento das normativas varía segundo a xurisdición, pero a maioría dos países industriais teñen normas de seguridade no posto de traballo que se aplican ao equipo láser. Nos Estados Unidos, as normas da OSHA intersecan coas normas ANSI; as operacións europeas deben cumprir os requisitos da EN 60825. Investigar para comprender as obrigas reguladoras específicas evita multas costosas e, máis importante, protexe ás persoas que operan o seu equipo.

Coas protocoles de seguridade establecidos, estás preparado para tomar a decisión estratéxica final: ¿deberías investir en equipos propios de corte por láser, ou terceirizar os servizos con provedores especializados ten máis sentido para a túa operación?

Estrutura de decisión: Equipamento propio fronte a terceirización

Asimilaches o coñecemento técnico—tipos de láser, compatibilidade de materiais, selección de potencia, protocoles de seguridade. Agora chega a pregunta que determina se esta información levará a un equipo na túa fábrica ou a facturas dun socio externo: ¿deberías mercar un cortador láser para chapa metálica, ou terceirizar as túas necesidades de corte?

Esta decisión atrapa a incontables fabricantes. Alguns invierten centos de miles nun equipo que nunca utilizan completamente. Outros terceirizan durante anos, perdendo cartos que poderían ter financiado dúas veces a súa propia máquina. A diferenza entre estes resultados? Unha análise clara das túas necesidades reais de produción.

Análise de custos: inversión capital fronte a terceirización

Comecemos cos números—porque "a intuición" non é unha estratexia financeira. Segundo O análise detallado de custos de Arcus CNC , as contas a miúdo favorecen o equipo propio moito antes do que a maioría dos fabricantes esperan.

Consideremos un escenario real: un fabricante que utiliza 2.000 chapas de aceiro mensualmente a 6,00 $ por peza dun fornecedor externo gasta 144.000 $ anuais en corte láser subcontratado. O mesmo volume procesado nun láser de fibra de 3 kW en instalacións propias—including materias primas, electricidade, gas e man de obra—custa aproximadamente 54.120 $ ao ano. O aforro anual? Case 90.000 $.

Con un paquete completo de máquina de corte de chapa metálica que custa arredor de 50.000 $, o período de retorno calcula-se en uns 6-7 meses. Despois diso, cada dólar aforrado vai directamente ao seu beneficio neto.

Pero o prezo da factura do seu socio de subcontratación non conta toda a historia. Cando paga un servizo de corte láser, está cubrindo os seus:

- Incremento do material (normalmente 20% ou máis)

- Tempo de máquina (150-300 $ por hora)

- Taxas de programación e configuración

- Marxe de beneficio (a miúdo 30% ou máis)

- Gastos xerais do centro, servizos públicos e man de obra

Esencialmente estás a financiar o equipo doutra persoa—sen chega-lo a posuír.

O investimento interno require cálculos diferentes. Ademais do prezo do corte por láser de metal, orzamenta a instalación (2.000-5.000 $), equipos auxiliares como compresores e ventilación (3.000 $ ou máis) e despesas operativas continuadas. Un sistema típico de corte por láser CNC custa aproximadamente 30-50 $ por hora en funcionamento cando se inclúe a electricidade, o gas auxiliar, os consumibles e a man de obra asignada.

| Factor | Equipamento interno | Subcontratación |

|---|---|---|

| Investimento Inicial | 30.000-100.000 $ ou máis (equipamento, instalación, equipamentos auxiliares) | 0 $ (sen gasto de capital) |

| Custo por peza (baixo volume) | Maior (custos fixos repartidos entre menos pezas) | Meno (pago só polo que necesitas) |

| Custo por peza (alto volume) | Significativamente menor (amortización de custos fixos) | Maior (markup compounds con volume) |

| Tempo de espera | Horas a días (acceso inmediato) | Días a semanas (depende da cola) |

| Flexibilidade de deseño | Iteracións ilimitadas a custo mínimo | Cada revisión supón novos cargos |

| Control de calidade | Supervisión directa; corrección inmediata | Depende do socio; as disputas provocan atrasos |

| Protección IP | Os deseños permanecen no interior | Ficheiros CAD compartidos fóra |

| Limitacións de capacidade | Limitado polas horas da máquina; escalable con turnos | Sujeito á dispoñibilidade do fornecedor |

| Responsabilidade de mantemento | O seu equipo encárgase das reparacións e conservación | Responsabilidade do fornecedor |

| Punto de Equilibrio | Normalmente entre 1.500 e 2.500 $/mes en gastos subcontratados | Por debaixo deste límite, a subcontratación resulta máis vantaxosa |

O punto de equilibrio varía segundo a operación, pero unha regra útil emerxe dos datos do sector: se está a gastar máis de 20.000 $ anuais en corte láser de chapa subcontratado, probabelmente estea pagando por unha máquina que non posúe. Por riba de 1.500-2.500 $ por mes en facturas de corte láser, o cálculo do ROI xeralmente inclínase a favor de traer a capacidade internamente.

Cando os servizos de corte láser teñen máis sentido

Isto significa que todo o mundo debería mercar equipos? De xeito ningún. A subcontratación ofrece vantaxes claras en situacións específicas — e recoñecer estas circunstancias evita investimentos excesivos e custosos.

Volume baixo e inconsistente: Se as súas necesidades de corte láser varían de forma impredecible ou son inferiores a 500-1.000 dólares mensuais, un cortador láser para chapa metálica está inactivo a maioría do tempo. Está pagando depreciación, mantemento e espazo en superficie por unha capacidade que rara vez utiliza. Ao subcontratar convértese un custo fixo nun custo variable que se adapta á demanda real.

Requisitos de capacidade especializada: Require o seu proxecto ocasional corte de chapa de 50 mm de grosor ou procesamento de aleacións exóticas? En vez de investir máis de 300.000 dólares en equipos de ultra-alta potencia para traballos infrecuentes, manteña un sistema estándar no interior para o traballo diario e subcontrate os requisitos especiais con socios que teñan a capacidade adecuada.

Prototipado e desenvolvemento rápidos: O desenvolvemento de produtos segue unha economía diferente da produción. Cando está iterando deseños —cortando dez variacións para atopar a xeometría óptima—, a velocidade e a flexibilidade son máis importantes que o custo por peza. O socio ideal de subcontratación para prototipado ofrece unha entrega rápida sen cantidades mínimas de pedido.

No que debes fixarte nun socio de externalización? O tempo de resposta importa enormemente. Segundo a guía de servizos de corte láser de Steelway, o prazo afecta directamente á túa capacidade para enviar produtos e responder ás demandas dos clientes. Agardar dúas semanas polas pezas cortadas significa dúas semanas de ingresos atrasados.

Para aplicacións automotrices, os requisitos de certificación engaden unha capa adicional. A certificación IATF 16949 demostra que un socio fabricante mantén sistemas de xestión da calidade deseñados especificamente para cadeas de suministro automotriz. Empresas como Shaoyi (Ningbo) Tecnoloxía do metal exemplifican o que se debe buscar nun socio de externalización: prototipado rápido en 5 días, resposta a orzamentos en 12 horas e procesos certificados IATF 16949 para chasis, suspensión e compoñentes estruturais.

A aproximación híbrida adoita ofrecer resultados óptimos. Moitos fabricantes exitosos operan sistemas de corte por láser de metal no interior da empresa de rango medio para o 90% da súa produción diaria—acer doce, inoxidable, espesores estándar—mentres subcontratan traballos especializados que requirirían unha inversión de capital desproporcionada. Esta estratexia aproveita os beneficios de custo da propiedade onde o volume o xustifica, sen adquirir capacidade en exceso para casos excepcionais.

Preguntas clave para avaliar a súa situación:

- Canto está a gastar actualmente mensualmente en corte láser subcontratado?

- Canta demora na produción resulta dos prazos de entrega dos fornecedores?

- Consomen atención directiva as disputas de calidade?

- Está a compartir deseños patentados con fornecedores externos?

- Podería reasignar persoal existente para operar o equipo, ou necesitaría contratar novos empregados?

- Ten a súa instalación espazo, infraestrutura eléctrica e ventilación adecuadas?

Para os fabricantes que gastan por riba do limiar de equilibrio cunha demanda estable e previsible, o equipo propio adoita ofrecer unha mellor economía e control. Para aqueles con necesidades esporádicas, requisitos especializados ou programas activos de prototipado, as parcerías estratéxicas de subcontratación —especialmente aquelas que ofrecen prazos rápidos e certificacións específicas do sector— proporcionan flexibilidade sen compromiso de capital.

A decisión depende finalmente do seu perfil de produción único. Comprender ambos os camiños —e cando cada un ten sentido— permítelle tomar a decisión que realmente beneficia ao seu negocio en vez de seguir suposicións do sector.

Dando o seguinte paso na súa viaxe co corte láser

Adquiriches unha base ampla—dende a física da interacción feixe-material ata a selección entre fibra e CO2, compatibilidade de materiais, optimización do gas auxiliar, resolución de defectos, selección de potencia e protocolos de seguridade. E agora? O coñecemento sen acción permanece teórico. Cal é a diferenza entre os fabricantes que transforman as súas operacións e aqueles que simplemente recollen información? Un plan de acción claro.

Xa sexa que esteas pensando en mercar un cortador láser de metal ou explorando parcerías de subcontratación, o camiño a seguir require unha avaliación estruturada. Resumamos todo en pasos prácticos que podes implementar inmediatamente.

Avaliación dos teus requisitos de produción

Antes de contactar con calquera fornecedor ou provedor de servizos, inviste tempo nunha autoavaliación honesta. Acelerar este paso leva a compras de equipos desaxustados ou parcerías que non satisfán as túas necesidades reais.

Comeza documentando o teu estado actual:

- Que materiais e grosores procesas máis frecuentemente?

- Cal é o seu volume mensual habitual en número de follas ou distancia de corte lineal?

- Canto está a gastar actualmente en cortes subcontratados ou procesos alternativos?

- Que problemas de calidade afectan ao seu fluxo de traballo actual?

- Onde os atrasos nos prazos lla están custando ingresos ou satisfacción do cliente?

Segundo as directrices DFM de Jiga, integrar os principios de Design for Manufacturing (deseño para fabricación) ao principio do proceso de avaliación evita desaxustes costosos entre a intención de deseño e a capacidade de fabricación. Isto aplícase tanto se está mercando unha máquina láser de corte de metal como se escolle un socio de subcontratación: a máquina que corta o metal debe axustarse aos seus requisitos de deseño.

As súas respostas moldean todo o que vén a continuación. A fabricación de alta produción en acero ao carbono apunta cara a solucións diferentes que a prototipaxe de baixo volume en múltiples aliños. Os requisitos de tolerancias estreitas para compoñentes aeroespaciais requiren capacidades distintas que o traballo xeral de fabricación.

Preguntas clave que debe facer aos fornecedores de equipos ou servizos

Armado co teu perfil de produción, estás listo para contactar con posibles socios, xa sexan vendedores de equipos ou provedores de servizos. Segundo a guía de compra de Revelation Machinery, facer as preguntas correctas distingue aos compradores informados daqueles que lamentan as súas decisións.

Para vendedores de equipos:

- Que materiais e grosores pode cortar eficazmente esta máquina láser de chapa metálica?

- Que tolerancias de precisión alcanza o sistema, e podes demostralo con cortes de proba nos meus materiais reais?

- Cal é o custo total de propiedade, incluíndo instalación, formación, consumibles e mantemento?

- Que infraestrutura de refrigeración e ventilación necesitarei?

- Que características de seguridade inclúe, e cumpren cos estándares ANSI Z136.1 ou equivalentes?

- Podo programar unha inspección para ver o equipo en funcionamento antes da compra?

Para provedores de servizos:

- Cal é o tempo habitual de resposta, e ofreces opcións aceleradas para traballos urxentes?

- Que formatos de ficheiro aceptades, e podedes axudar coa optimización de deseño?

- Ofrecédes soporte de deseño para fabricación para axudar a reducir custos e mellorar a calidade?

- Que certificacións tedes, especialmente para industrias reguladas como a automobilística ou aerospacial?

- Como xestionades o control de calidade e que ocorre cando as pezas non cumpren as especificacións?

- Podedes atender tanto a prototipado como a volumes de produción sen cambiar de fornecedor?

De acordo co Guía de avaliación de servizos de Wrightform , os mellores provedores de servizos de corte láser de chapa metálica combinan tecnoloxía avanzada con procesos centrados no cliente. Buscade socios que optimicen o aninhamento de materiais para reducir os vosos custos, ofrezcan servizos de acabado que eliminen operacións secundarias e amosen experiencia específica do sector relevante para as vosas aplicacións.

Lista de verificación de accións priorizada:

- Documentade a vosa liña de base: Calculade o gasto actual mensual en corte láser (custos subcontratados, man de obra para procesos alternativos ou reprocesos relacionados coa calidade)

- Define os teus requisitos de material: Liste todos os tipos de metal e intervalos de grosor que necesitará procesar nos próximos 3 a 5 anos

- Avaliar a preparación da infraestrutura: Verifique o espazo dispoñible no chan, capacidade eléctrica, suministro de aire comprimido e capacidade de ventilación para equipos internos

- Calcule os limiares de punto muerto: Determine se o seu volume xustifica o investimento en capital ou se é mellor subcontratar

- Solicite orzamentos de varias fontes: Compare polo menos tres fornecedores de equipos ou provedores de servizos antes de comprometerse

- Exixa demostracións: Xa sexa que compre equipos ou elixa un socio, insista en cortes de mostra usando os seus materiais e deseños reais

- Verificar certificacións: Para industrias reguladas como a automobilística, aeroespacial ou outras, confirme que os socios posúan as certificacións de calidade adecuadas

- Avalíe o soporte DFM: Prioriza fornecedores e socios que axuden activamente a optimizar os teus deseños para a fabricación

Para fabricantes que exploran a subcontratación—en particular aqueles en aplicacións automotrices que requiren sistemas de calidade certificados— Shaoyi (Ningbo) Tecnoloxía do metal representa o tipo de socio que merece ser avaliado. A súa certificación IATF 16949, a capacidade de prototipado rápido en 5 días e un prazo de resposta de orzamentos en 12 horas amosan a rapidez que distingue aos socios estratéxicos dos fornecedores comúns. O seu apoio integral ao DFM axuda a optimizar deseños tanto para cortes a láser como para estampación, reducindo custos mentres se mellora a calidade nos compoñentes de chasis, suspensión e estruturais.

A tecnoloxía da que aprendiches nesta guía segue evolucionando—os niveis de potencia aumentan, mellora a calidade do feixe, expándese a automatización. Pero os principios fundamentais permanecen constantes: adaptar a capacidade aos requisitos, priorizar a calidade e a seguridade, e elixir socios que comprendan as demandas específicas da túa industria.

O teu seguinte paso? Colla esa lista de verificación de accións e comeza co punto un. A brecha entre saber e facer é onde reside a vantaxe competitiva.

Preguntas frecuentes sobre o corte por láser de chapa metálica

1. Que tipo de láser pode cortar chapa metálica?

Os láseres de fibra son a opción preferida para cortar chapa metálica debido á súa lonxitude de onda de 1,06 μm, que os metais absorben eficientemente. Destacan no corte de acero, acero inoxidable, aluminio, cobre e latón, con velocidade superior e mellor calidade de bordo. Os láseres CO2 tamén poden cortar chapas finas de metal ata 25 mm, pero teñen dificultades cos aliños reflectantes. Para fabricación metálica dedicada, as máquinas de corte por láser de fibra ofrecen velocidades 2-3 veces máis rápidas en metais finos e requiren menos mantemento que os sistemas CO2.

2. Canto custa o corte láser de metal?

Os custos de corte láser de metal varían segundo a propiedade do equipo ou a subcontratación. Os servizos subcontratados cobran normalmente entre 13 e 20 dólares por hora de máquina, máis o incremento do material e taxas de configuración. As operacións internas teñen un custo aproximado de 30 a 50 dólares por hora, incluíndo electricidade, gas auxiliar e consumibles. Para producións de alto volume, o equipo propio amortízase normalmente en 6 a 12 meses. Os fabricantes que gastan máis de 1.500 a 2.500 dólares mensuais en cortes subcontratados xeralmente benefíciense dunha inversión en equipos.

3. Que grosor de aceiro pode cortar un láser de 1000 W?

Un láser de fibra de 1000 W corta eficazmente o acero ao carbono ata un grosor de 10 mm e o acero inoxidable ata 5 mm. A capacidade en aluminio alcanza aproximadamente 3 mm debido ás súas propiedades reflectivas. Para materiais máis espesos, son necesarios sistemas de maior potencia: os láseres de 6 kW poden traballar con acero ao carbono de 16 mm, mentres que os sistemas de 12 kW ou máis cortan 25 mm ou máis. A calidade do bordo diminúe co grosor, polo que os mellores resultados obtéñense cando se axusta o nivel de potencia ás necesidades típicas do material e non á capacidade máxima.

4. Cal é a diferenza entre o láser de fibra e o láser de CO2 para o corte de metais?

Os láseres de fibra xeran luz cunha lonxitude de onda de 1,06 μm a través de cables de fibra óptica, acadando unha eficiencia eléctrica do 30-40 %. Os láseres CO2 producen luz cunha lonxitude de onda de 10,6 μm cunha eficiencia do 10 %. Esta diferenza de lonxitude de onda significa que os metais absorben mellor a enerxía do láser de fibra, o que resulta en velocidades de corte máis rápidas e un mellor rendemento en aliños reflectantes como o aluminio e o cobre. Os láseres CO2 seguen sendo valiosos para talleres de materiais mixtos que procesan madeira, acrílico e plásticos ademais de metal.

5. Debería mercar equipos de corte por láser ou subcontratar a un provedor de servizos?

A decisión depende do volume mensual e da consistencia da produción. Se os custos de corte subcontratados superan os 1.500-2.500 $ mensuais cunha demanda estable, o equipo propio adoita ofrecer un mellor ROI con períodos de amortización de 6-12 meses. Subcontratar resulta axeitado para volumes baixos/inconsistentes, requisitos especializados de placas grosas ou necesidades de prototipado rápido. Moitos fabricantes adoptan enfoques híbridos, procesando traballos estándar internamente mentres subcontratan tarefas especializadas a socios certificados, como provedores certificados IATF 16949 para aplicacións automotrices.

Pequeños lotes, altos estándares. O noso servizo de prototipado rápido fai que a validación sexa máis rápida e fácil —

Pequeños lotes, altos estándares. O noso servizo de prototipado rápido fai que a validación sexa máis rápida e fácil —