Selección de Materiais para Sistemas de Xestión de Colisións Automotrices

RESUMO

A selección de materiais para os sistemas de xestión de colisións en automóbiles é unha disciplina de enxeñaría crítica enfocada en maximizar a seguridade dos ocupantes. O proceso prioriza materiais avanzados, predominantemente aliamentos de aluminio de alta resistencia e compostos emergentes, escollidos pola súa excepcional relación resistencia-peso e capacidade de absorción de enerxía durante unha colisión. Estes materiais permiten aos enxeñeiros deseñar compoñentes que se deforman de xeito previsible, absorbendo a enerxía cinética mentres manteñen a integridade estrutural da cabina de pasaxeiros.

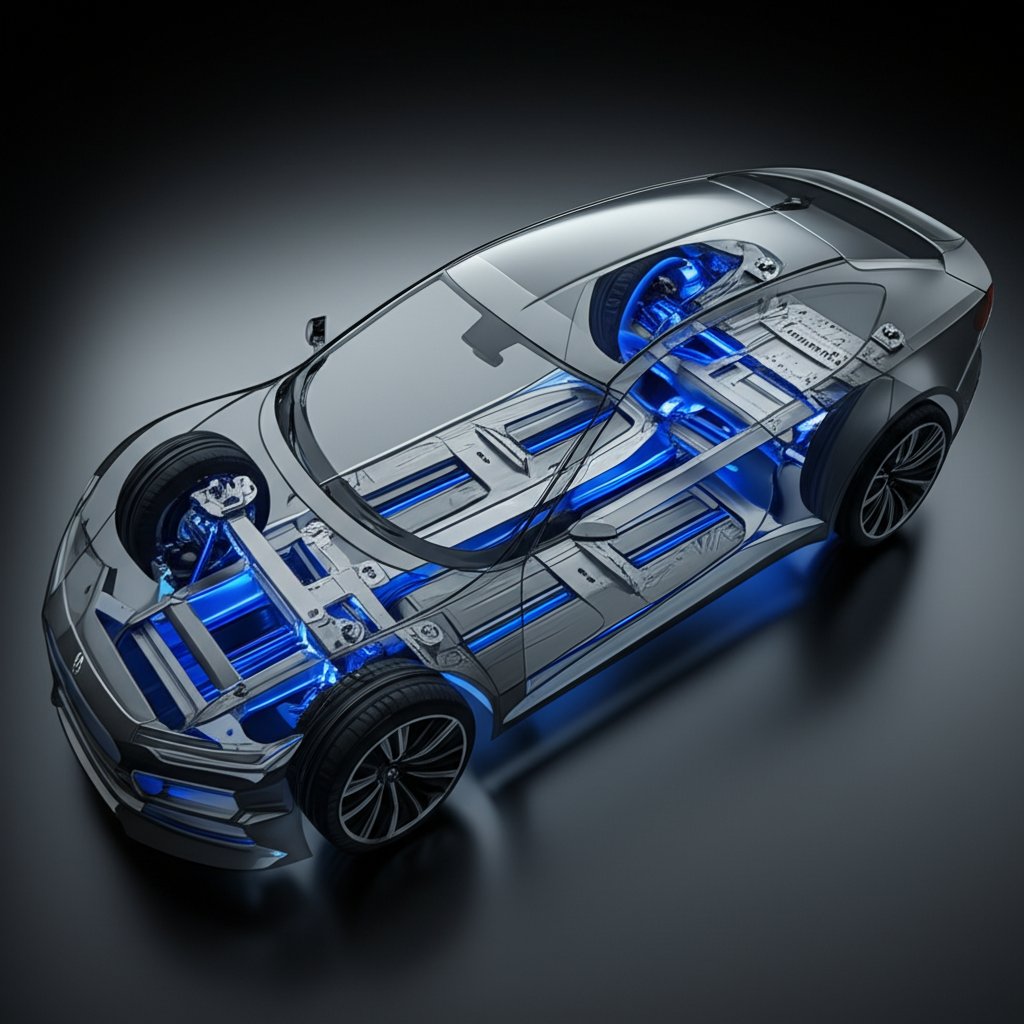

Comprender o papel dos sistemas de xestión de colisións (CMS)

Un sistema de xestión de colisións automobilísticas (CMS) é un conxunto integrado de compoñentes estruturais deseñados para absorber e disipar a enerxía cinética durante unha colisión, protexendo así aos ocupantes do vehículo. A función principal non é previr danos no vehículo senón controlar a deformación da súa estrutura dun xeito previsible, reducindo as forzas transmitidas ao compartimento dos pasaxeiros. Este colapso controlado é un principio fundamental da enxeñaría moderna de seguridade vial.

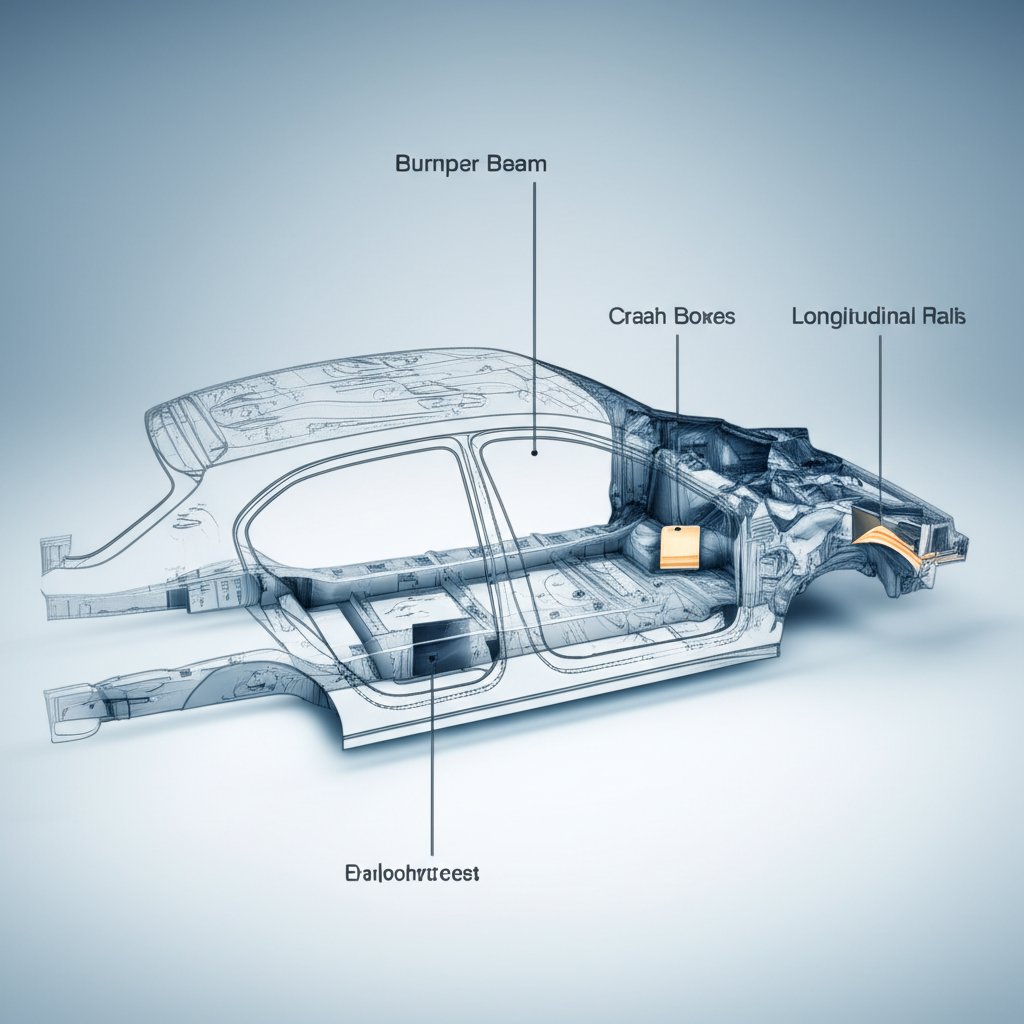

Un CMS típico consta de varios compoñentes principais que funcionan en conxunto. O elemento máis externo é xeralmente o travesaño do paragolpes , un perfil sólido, frecuentemente extrudido e oco, que realiza o contacto inicial e distribúe as forzas do impacto ao longo da parte dianteira ou traseira do vehículo. Detrás do travesaño do paragolpes atópanse os caxas de choque (tamén coñecidos como latas de colapso), que están deseñados para colapsarse como un acordeón baixo cargas axiais. Estes compoñentes son os absorbentes primarios de enerxía. Finalmente, as forzas transfírense aos longarinas do vehículo , que desvía a enerxía restante da célula ríxida de seguridade do pasaxeiro e arredor desta. Segundo detallado polo Consello de Extrusión de Aluminio , esta traxectoria de carga está deseñada minuciosamente para xestionar de forma efectiva as forzas de impacto.

A eficacia dun CMS é crucial tanto nos impactos a alta velocidade como a baixa velocidade. En colisións graves, a súa capacidade de absorber enerxía pode ser a diferenza entre feridas leves e lesións que ponen en perigo a vida. En incidentes a baixa velocidade, un CMS ben deseñado pode minimizar os danos estruturais, o que permite reparacións máis sinxelas e menos custosas. Polo tanto, o deseño e a selección de materiais para estes sistemas están suxeitos a normas rigorosas de seguridade global e protocolos de proba ao consumidor, como os da Administración Nacional de Seguridade do Tráfico nas Estradas (NHTSA) e o Instituto de Seguridade nas Estradas (IIHS).

Propiedades Críticas dos Materiais para Resistencia ao Impacto

A selección de materiais para un sistema de xestión de colisións é un proceso moi analítico guiado pola necesidade de equilibrar varias propiedades de enxeñaría que compiten entre si. O obxectivo final é atopar materiais que poidan absorber a cantidade máxima de enerxía co menor peso posíbel. Estas propiedades son a base do deseño moderno de seguridade automotriz.

As propiedades máis críticas inclúen:

- Alta relación resistencia-peso: Isto é probablemente a característica máis importante. Os materiais cunha alta relación resistencia-peso proporcionan a resistencia necesaria fronte ás forzas de impacto sen engadir masa excesiva ao vehículo. Os vehículos máis lixeiros son máis eficientes en termos de combustible e poden presentar mellores dinámicas de manexo. As aleacións de aluminio son exemplos destacados neste aspecto, xa que ofrecen importantes aforros de peso en comparación co acero tradicional.

- Capacidade de Absorción de Enerxía: A capacidade dun material para absorber enerxía determinase pola súa capacidade de deformarse plasticamente sen fracturarse. Durante un choque, os materiais que poden esmagarse, dobrarse e plicarse absorben a enerxía cinética, reducindo a desaceleración do vehículo e diminuíndo as forzas G sobre os ocupantes. O deseño de compoñentes como as caixas de colisión está especificamente optimizado para maximizar este comportamento.

- Ductilidade e formabilidade: A ductilidade é a medida da capacidade dun material para soportar deformacións plásticas significativas antes de romper. Nun sistema de xestión de colisións (CMS), os materiais dúciles son esenciais porque se dobren e amachucan en vez de facerse anacos. Esta propiedade está estreitamente ligada á formabilidade: a facilidade coa que se pode dar forma a un material en compoñentes complexos como barras de parachoques con múltiples ocos ou perfís de raíles intricados mediante procesos como a extrusión.

- Resistencia á corrosión: Os sistemas de xestión de colisións adoitan estar situados en zonas do vehículo expostas aos elementos. A corrosión pode degradar a integridade estrutural dun material co tempo, comprometendo o seu rendemento nunha colisión. Materiais como o aluminio forman naturalmente unha capa protectora de óxido, que ofrece unha excelente resistencia á corrosión e garante a durabilidade e seguridade a longo prazo.

Material Dominante: Alixas Avanzadas de Aluminio

Durante décadas, as alixas avanzadas de aluminio foron o material escollido para sistemas de xestión de colisións de alto rendemento, unha preferencia claramente apoiada pola súa combinación única de propiedades. Segundo un Documento técnico da SAE International , as características específicas das alixas de aluminio permiten deseñar estruturas lixeiras e rentables con excelente capacidade de absorción de enerxía en caso de colisión. Isto fainas ideais para compoñentes que deben ser resistentes e lixeiros ao mesmo tempo.

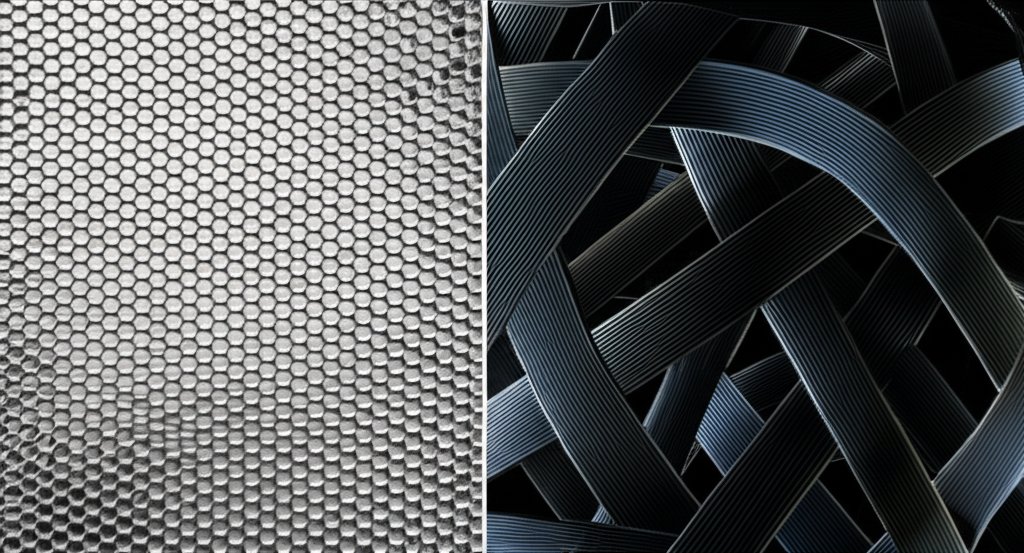

O proceso de extrusión é particularmente vital para a fabricación de compoñentes CMS. A extrusión permite crear perfís complexos, multi-carcasas que poden ser optimizados para a rigidez e a deformación controlada. Esta flexibilidade de deseño é difícil de acadar co estampado tradicional de acero. Como líder do sector Hydro destaca , esta liberdade de deseño sen precedentes, combinada con aliages avanzados, proporciona unha vía directa a sistemas de colisión de alto rendemento. Para proxectos automotrices que requiren tal precisión, os fabricantes especializados son fundamentais. Por exemplo, para proxectos automotrices que requiren compoñentes deseñados con precisión, considere extrusións personalizadas de aluminio dun socio de confianza. Shaoyi Metal Technology ofrece un servizo integral dun só paso, desde a prototipaxe rápida que acelera o seu proceso de validación ata a produción a grande escala, todo xestionado baixo un rigoroso sistema de calidade certificado IATF 16949. Especialízanse en entregar pezas fortes, lixeiras e moi personalizadas adaptadas a especificacións exactas.

Os enxeñeiros utilizan principalmente as ligazóns da serie 6000 (AlMgSi) para estas aplicacións. Estas ligazóns están optimizadas para a resistencia, ductilidade e durabilidade, aínda que son axeitadas tanto para a extrusión como para procesos subseguintes de fabricación, como dobrado e soldadura. As calidades optimizadas para choques están deseñadas para absorber enerxía baixo cargas de aplastamento axial, o que as fai perfectas para caixas de choque, mentres que as calidades optimizadas para resistencia úsanse en barras de parachoques que deben transferir forzas de forma efectiva. Esta capacidade de adaptar as ligazóns a funcións específicas dentro do CMS é unha vantaxe considerable do uso de aluminio.

Alternativas Emerxentes: Compostos e Aceros Avanzados

Aínda que o aluminio segue sendo o material dominante, a busca constante de alixeramento do vehículo e un mellor desempeño en seguridade impulsou a investigación en materiais alternativos. Os compostos avanzados e os aceros de nova xeración están na vangarda desta innovación, cada un ofrecendo un conxunto único de vantaxes e desafíos.

Os composites de matriz metálica de aluminio (MMCs) e os composites de fibra de carbono representan un paso adiante importante en cuestión de rendemento. Estes materiais poden ofrecer relacións resistencia-peso incluso superiores ás das aleacións de aluminio, permitindo unha maior redución de masa. Os principais inconvenientes, con todo, foron tradicionalmente os custos máis altos dos materiais e os procesos de fabricación máis complexos e lentos. Aínda así, o seu rendemento superior fainos viables para vehículos de alta gama e aplicacións específicas nas que a máxima redución de peso é fundamental.

Os aceros avanzados de alta resistencia (AHSS) seguen sendo tamén un forte competidor. Os fabricantes de acero desenvolveron numerosas calidades de AHSS que proporcionan inmensa resistencia, permitindo o uso de materiais máis finos para reducir o peso en comparación cos aceros dulces. Aínda que a miúdo sexan máis pesados ca un compoñente de aluminio comparable, os AHSS poden ser unha solución rentable que aproveita a infraestrutura de fabricación existente. A elección entre aluminio, compósitos e AHSS adoita depender dun complexo análise de compensacións de enxeñaría.

A continuación inclúese unha táboa que resume as características principais destas categorías principais de materiais.

| Propiedade | Ligas de Aluminio Avanzadas | Compostos de Fibra de Carbón | Aceros Avanzados de Alta Resistencia (AHSS) |

|---|---|---|---|

| Relación Forza-Peso | Excelente | Excepcional | Boa a moi boa |

| Absorción de enerxía | Excelente | Excelente (por deseño) | Moi Boa |

| Formabilidade/Fabricabilidade | Excelente (especialmente por extrusión) | Complexo e lento | Boa (estampado) |

| Resistencia á corrosión | Excelente | Excelente | Require recubrimento |

| Custo | Moderado | Alta | Baixa a moderada |

O Marco de Selección: Equilibrar Prestacións, Custos e Posibilidade de Fabricación

A selección final do material para un sistema de xestión de colisións automotriz non se basea nunha única propiedade, senón que é o resultado dun proceso de toma de decisións con múltiples criterios. Os enxeñeiros deben levar a cabo un equilibrio delicado, valorando as compensacións entre o rendemento máximo en caso de colisión, os obxectivos de alixeramento do vehículo, a complexidade de fabricación e o custo total do sistema. Este enfoque global garante que a solución escollida sexa non só segura, senón tamén comercialmente viable.

O marco de toma de decisións implica varias consideracións clave. En primeiro lugar, establécense obxectivos de rendemento baseados nos requisitos rexistradores e nos obxectivos internos de seguridade. Os enxeñeiros utilizan entón sofisticadas ferramentas de enxeñaría asistida por ordenador (CAE) para executar innumerábeis simulacións de choque. Estas simulacións modelan como se comportarán diferentes materiais e deseños en varios escenarios de impacto, permitindo unha rápida iteración e optimización moito antes de que se produzan pezas físicas. Tal como indica o Consello dos Extrusores de Aluminio, é imprescindible que os enxeñeiros de CAE dispoñan de bons datos sobre os materiais para os seus modelos a fin de obter resultados fiábeis.

Unha vez identificados deseños prometedores mediante simulación, realízase unha validación física. Isto inclúe probas a nivel de compoñentes, como a compresión axial de caixas anticolisión, e probas de colisión con vehículos completos para verificar que o sistema funcione como se predixo. Finalmente, téñense en conta o custo e a posibilidade de fabricación. Un material pode ofrecer un rendemento superior, pero se é prohibitivamente caro ou require instalacións de fabricación totalmente novas, pode non ser viable para a produción en masa. A elección óptima é aquela que cumpre ou supera todos os obxectivos de seguridade dentro das limitacións económicas e de produción dun programa específico de vehículo.

Tendencias futuras nos materiais para xestión de colisións

A evolución da selección de materiais para os sistemas de xestión de colisións en automóbiles é un proceso dinámico impulsado pola innovación na ciencia dos materiais e na fabricación. O reto fundamental mantense o mesmo: deseñar sistemas que sexan máis lixeiros, máis resistentes e máis rentables ao tempo que ofrecen unha protección superior. De cara ao futuro, a integración de deseños multimateriais, onde o aluminio, os aceros avanzados e os compósitos se usan conxuntamente para aproveitar as mellores propiedades de cada un, será cada vez máis común. Este enfoque personalizado permite aos enxeñeiros optimizar cada parte da estrutura de seguridade. En última instancia, o obxectivo é un ciclo continuo de mellora que aumente a seguridade do vehículo tanto para ocupantes como para peóns.

Preguntas frecuentes

1. Que materiais se utilizan na redución de peso en vehículos automóbiles?

O alixeramento de vehículos emprega unha variedade de materiais para reducir a masa total do vehículo, mellorando así a eficiencia de combustible e o rendemento. Os materiais comúns inclúen ligazas de aluminio para estruturas do corpo, paneis e sistemas de xestión de colisións; aceros de prensado endurecido e outros aceros avanzados de alta resistencia; compósitos de fibra de carbono para compoñentes estruturais e paneis corporais en vehículos de alto rendemento; e incluso plásticos para pezas non estruturais como paneis interiores e parachoques.

2. Que características de deseño e enxeñaría determinan a resistencia a colisións dun vehículo?

A resistencia dun vehículo aos choques, ou a súa capacidade de protexer os ocupantes nun sinistro, determinase por dous factores principais: a estrutura do vehículo e os seus sistemas de restrición para ocupantes. A estrutura, que inclúe o sistema de xestión de choques e a célula ríxida de seguridade para pasaxeiros, está deseñada para absorber e dirixir a enerxía do impacto. Os sistemas de restrición para ocupantes, que inclúen os cintos de seguridade e as airbags, traballan para controlar a desaceleración dos ocupantes e minimizar o contacto con superficies interiores durante unha colisión.

Pequeños lotes, altos estándares. O noso servizo de prototipado rápido fai que a validación sexa máis rápida e fácil —

Pequeños lotes, altos estándares. O noso servizo de prototipado rápido fai que a validación sexa máis rápida e fácil —