Guía do Fabricante para Selar a Porosidade na Fundición

RESUMO

A porosidade na fundición a presión refírese a baleiros microscópicos no interior das pezas metálicas que poden provocar fugas e fallos estruturais. A solución estándar da industria é a impregnación ao baleiro, un proceso no que se introduce un sellante duradeiro nos poros mediante baleiro e despois se cura. Este método segella permanentemente calquera traxectoria de fuga potencial sen alterar as dimensións ou as propiedades físicas do compoñente, o que o converte nun paso esencial para fabricar pezas fiábeis e estancas á presión.

Comprender a Porosidade na Fundición a Presión: A Raíz do Problema

A porosidade é un desafío inherente ao proceso de fundición por inxección, referíndose aos pequenos baleiros ou buratos que se forman cando o metal fundido enfría e solidifica. Aínda que a miúdo sexan microscópicos, estes defectos poden afectar considerablemente o rendemento dun compoñente, especialmente en aplicacións nas que manter a presión é crítico. Comprender os tipos de porosidade é o primeiro paso cara a unha estratexia efectiva de sellado. As dúas formas máis comúns son a porosidade por gas e a porosidade por contracción. A porosidade por gas débese aos gases atrapados que forman burbullas redondas e flotantes preto da superficie da peza fundida. En contraste, a porosidade por contracción ocorre cando o volume do metal diminúe durante o enfriamento, creando baleiros dentados e lineais máis profundos dentro da peza.

Estes baleiros clasifícanse ademais segundo a súa localización e estrutura, presentando cada un retos únicos. Porosidade cega é un vazio conectado á superficie que non atravesa completamente a peza. Aínda que pode non causar fugas inmediatas, pode atrapar fluídos de limpeza dos procesos de pretratamento, que posteriormente poden saír e danar acabados superficiais como revestimentos en pó ou anodizado. Porosidade total crea un camiño directo de fuga dunha superficie a outra, facendo que a peza sexa inservible para calquera aplicación que requirexa estanquidade á presión. Finalmente, porosidade completamente encerrada consiste en vaziños atrapados totalmente dentro das paredes da fundición. Estes son xeralmente inofensivos a menos que queden expostos durante operacións posteriores de mecanizado, momento no que poden converterse en porosidade total.

As consecuencias da porosidade sen sellar son importantes e poden levar a fallas costosas nas compoñentes. Os problemas principais inclúen:

- Camiños de fuga: O problema máis crítico, no que os fluídos ou gases poden escapar a través das paredes da compoñente, é común en pezas como bloques de motor e carcacas de transmisión.

- Defectos no acabado superficial: O aire atrapado pode expandirse e escapar durante o proceso de curado de acabados como o recubrimento en pó, creando pequenos orificios e outras imperfeccións estéticas.

- Puntos de corrosión: Os baleiros poden atrapar humidade e outros axentes corrosivos, provocando a degradación prematura do compoñente desde o interior cara ao exterior.

- Integridade estrutural reducida: Aínda que a micro-porosidade poida non debilitar significativamente unha peza, os baleiros máis grandes poden crear puntos de tensión que levan á fisuración baixo carga.

A solución definitiva: Un análixe a fondo do proceso de impregnación ao baleiro

A impregnación ao baleiro é o método máis eficaz e amplamente adoptado para sellar a porosidade en compoñentes de fundición por inxección. É un proceso controlado que garante un sellado permanente e fiábel ao encher os baleiros internos cun polímero resistente. O proceso é sorprendentemente consistente e pode dividirse en catro etapas principais, tal como detallan líderes do sector como Ultraseal International . Este proceso é vital para compoñentes en sectores exigentes como o automoción, e garantir a integridade das pezas adoita comezar cunha fabricación de alta calidade. Para aplicacións críticas, obter suministros de especialistas en procesos como a forxadura de precisión é un paso inicial clave. Por exemplo, Shaoyi (Ningbo) Metal Technology ofrece pezas forxadas robustas para o sector automoción , onde procesos posteriores como a impregnación poden garantir o rendemento final.

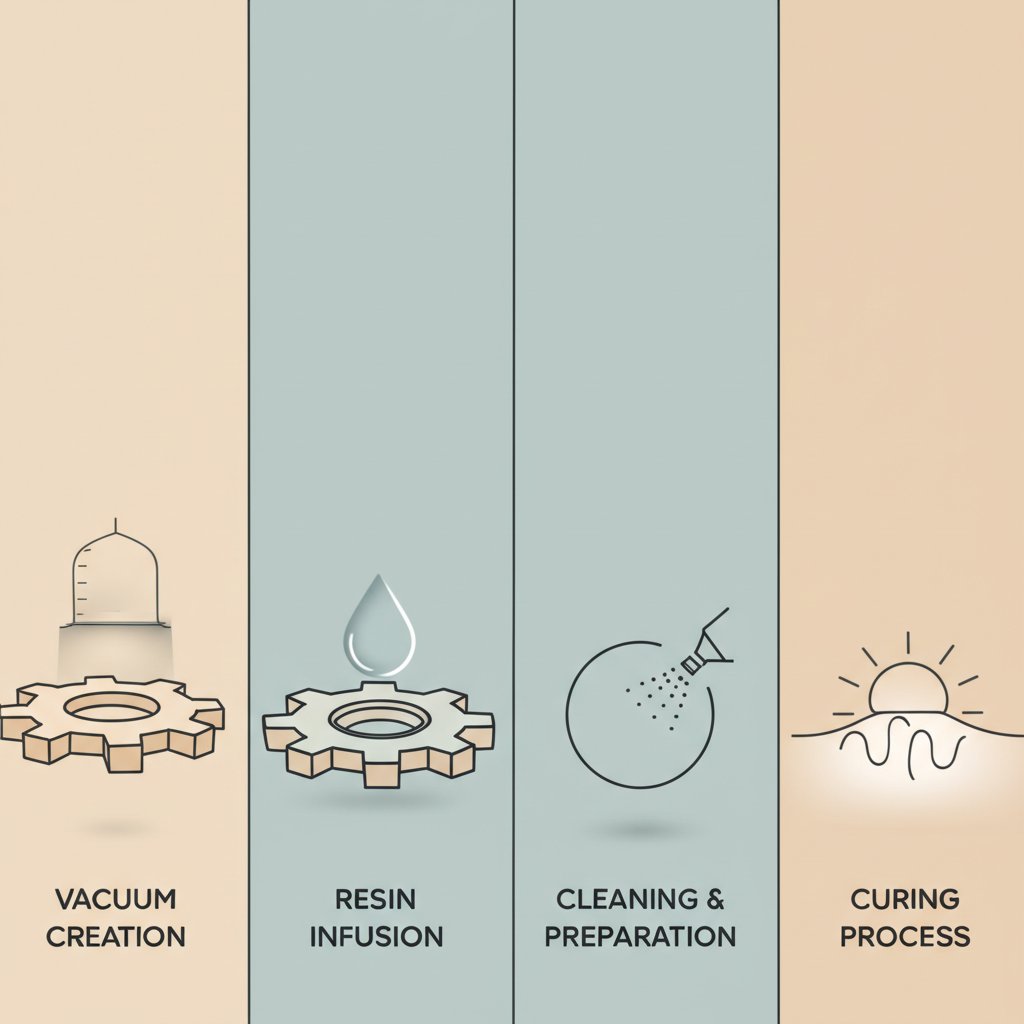

O ciclo de impregnación paso a paso é o seguinte:

- Impregnación: As pezas colócanse nun autoclave ou recipiente a presión, onde se aplica un baleiro para eliminar todo o aire da porosidade. A continuación, as pezas inmérxense nun sellante líquido, e retírase o baleiro. A presión atmosférica forcexa o sellante a entrar profundamente nos poros microscópicos.

- Drenaxe: O exceso de sellante drénxase das superficies internas e externas do compoñente para ser recuperado e reutilizado.

- Lavado frío: As pezas móvense a unha estación de lavado onde se retira suavemente calquera sellante residual das superficies, asegurando que as dimensións e características do compoñente permanezcan inalteradas.

- Cura Quente: Finalmente, os compoñentes colócanse nun baño de auga quente, o que polimeriza o sellante dentro da porosidade. Isto transforma o sellante líquido nun polímero sólido duradeiro, creando un precintado permanente resistente ao calor, aos produtos químicos e á presión.

Aínda que o proceso central sexa constante, existen varios métodos de impregnación ao baleiro, cada un axeitado para diferentes aplicacións e tipos de porosidade. A selección depende da complexidade da peza e da natureza dos camiños de fuga.

| Método de Impregnación | Descrición | Mellor adecuado para |

|---|---|---|

| Baleiro Seco e Presión | Este é o método máis exhaustivo. Despois de extraer un baleiro seco, introdúcese o sellante e despois aplícase presión positiva para asegurar a máxima penetración na porosidade máis fina. | Pezas complexas con porosidade moi fina; aplicacións críticas nas industrias aerospacial, de defensa e automotriz. |

| Vacío seco | Extraeuse un baleiro para eliminar o aire dos poros antes de introducir o sellante, pero non se aplica ningunha etapa final de presión. | Sellado da maioría dos tipos comúns de porosidade e camiños de fuga onde non se necesita presión extrema para a penetración. |

| Vacío húmido | Primeiro inmérxense as pezas no sellante, e despois aplícase un baleiro ás pezas recubertas de sellante. Este método é eficaz para arrastrar o sellante cara a ocos máis grandes. | Pezas de metal en pó, compoñentes eléctricos e fundicións con porosidade máis grande e accesible. |

Punto crítico de decisión: ¿Sellar antes ou despois do acabado e mecanizado?

O momento no que se realiza a impregnación dentro do fluxo de produción xeral non é só cuestión de preferencia—é fundamental para o éxito tanto do sellado como do acabado final. A regra inequívoca, tal como explican os expertos en acabados, é realizar a impregnación ao baleiro despois do mecanizado pero antes de calquera acabado superficial como pintar, recubrimento en pobo ou anodizado. Aderirse a esta secuencia evita un conxunto de defectos costosos e irreversibles.

As operacións de mecanizado, como furar, roscar ou fresar, poden expoñer porosidade previamente pechada, creando novos camiños de fuga. Polo tanto, a impregnación debe producirse despois de rematar todo o mecanizado para asegurar que estes baleiros recén abertos sexan sellados. Se a impregnación se fai antes do mecanizado, o proceso será ineficaz, xa que as ferramentas de corte simplemente abrirán novos poros sen sellar.

Por outro lado, aplicar un acabado superficial antes da impregnación pode levar a fallos catastróficos. Por exemplo, se primeiro se pinta unha peza, o proceso de impregnación—que consiste na inmersión en sellante e auga quente (aproximadamente 195°F / 90°C)—pode degradar a adhesión da pintura ou provocar decoloración e manchas de auga. De xeito semellante, os acabados químicos como os revestimentos cromatados poden danarse polo calor do ciclo de curado do sellante. Quizais o problema máis común sexa a desgasificación no recubrimento en pó. Se a porosidade non está sellada, o aire atrapado dentro dos baleiros expándese durante o curado a alta temperatura do recubrimento en pó. Este aire en fuga atravesa o pó fundido, creando pequenos poros na superficie final, o que compromete tanto a estética como a resistencia á corrosión. Ao impregnar primeiro, estes baleiros enchense con polímero sólido, eliminando o aire atrapado e asegurando un acabado liso e sen defectos.

Para evitar estes problemas, segue estas sinxelas directrices:

- Non impregnar unha peza antes de que se mecanice por completo.

- Non impregnar unha peza despois de ser pintada, recuberta con pó ou anodizada.

- Fai realizar a impregnación como paso final antes de levar un compoñente á liña de acabado.

Elixir os Materias Adecuados: Unha Guía para Selantes de Impregnación

A eficacia da impregnación ao baleiro depende en gran medida da calidade e propiedades do selante empregado. Estes son normalmente resinas de baixa viscosidade deseñadas para penetrar nos poros microscópicos máis pequenos antes de ser curadas nun sólido permanente e inerte. O selante axeitado debe ofrecer unha excelente resistencia térmica e química para soportar o ambiente operativo do compoñente. Os selantes modernos están deseñados para ser compatibles cunha ampla variedade de metais, incluídas fundicións de aluminio, cinc e bronce, sen alterar a súa precisión dimensional.

Os sellantes poden clasificarse de forma xeral, con diferentes formulacións adaptadas a necesidades específicas. Unha distinción clave é entre os tipos reciclables e non reciclables. Os sellantes reciclables están deseñados para que o exceso lavado das pezas poida separarse da auga e reutilizarse, ofrecendo importantes aforros de custo e beneficios medioambientais. Os sellantes non reciclables úsanse en sistemas onde a recuperación non é factible. O método de curado é outro factor diferenciador, coa maioría dos sistemas modernos que utilizan curado térmico nun baño de auga quente. Tamén hai dispoñibles sellantes anaeróbicos, que se curan na ausencia de aire, pero son menos comúns nas aplicacións de fundición en masa.

Ao escoller un sellante, deben considerarse varias propiedades clave para adaptalas ás demandas da aplicación.

| Propiedade | Descrición | Importancia |

|---|---|---|

| Resistencia térmica | A capacidade do sellante para manter a súa integridade a altas temperaturas de funcionamento sen degradarse. | Fundamental para compoñentes de motores, transmisións e pezas que operan en ambientes de moito calor. |

| Resistencia química | A capacidade de resistir á degradación cando está exposto a combustibles, aceites, líquidos arrefredadores e outros fluídos industriais. | Esencial para compoñentes automotrices, aeroespaciais e hidráulicos que están en contacto constante con produtos químicos agresivos. |

| Viscosidade | Unha medida da espesura do sellador ou resistencia ao fluxo. Requírese baixa viscosidade para penetrar poros microscópicos. | Determina a capacidade do sellador para encher eficazmente os camiños de fuga máis pequenos. |

| Método de curado | O proceso que transforma o sellador líquido nun sólido. O máis común é o curado térmico. | Afecta o tempo de procesamento e os requisitos de equipo. Debe ser compatible co material da peza e con calquera proceso posterior. |

Fabricantes líderes como Hernon Manufacturing e Ultraseal ofrecen unha variedade de resinas especializadas para cubrir estas necesidades. Consultar cun fornecedor de selladores é a mellor forma de garantir que o material escollido cumpra os criterios específicos de rendemento para un compoñente determinado, asegurando un sellado fiable e permanente contra a porosidade.

Reflexións Finais sobre Como Alcanzar un Sellado Perfecto

O sellado da porosidade en fundición non é só unha acción correctiva, senón un paso crítico na fabricación moderna para garantir a calidade, confiabilidade e rendemento dos compoñentes. A impregnación ao baleiro destaca como o método definitivo e de confianza na industria para transformar pezas fundidas porosas e potencialmente fuxentes en compoñentes estancos á presión e de alto rendemento. Ao comprender a natureza da porosidade, seguir escrupulosamente o proceso de impregnación e programalo correctamente dentro da secuencia de produción —despois do mecanizado e antes do acabado— os fabricantes poden eliminar efectivamente as rutas de fuga e previr defectos estéticos.

Ademais, a selección coidadosa dun sellante coa resistencia térmica e química axeitada garante que o sellado dure durante toda a vida útil do compoñente. En última instancia, dominar o proceso de impregnación permite aos fabricantes reducir as taxas de refugo, mellorar a calidade do produto e entregar compoñentes que satisfán as demandas cada vez máis estritas das industrias, desde a automoción ata a aerospacial.

Preguntas frecuentes

1. Cal é a finalidade principal da impregnación para a fundición en moldes?

A finalidade principal da impregnación é sellar a porosidade inherente — baleiros ou orificios microscópicos — que se forma nas pezas metálicas durante o proceso de fundición en moldes. Este sellado evita que fluídos ou gases fuxan a través das paredes do compoñente, facendo que a peza sexa estanca á presión e adecuada para a súa aplicación prevista.

2. Modifica a impregnación as dimensións da peza?

Non, un proceso de impregnación ao baleiro correctamente executado non altera as dimensións nin a aparencia física do compoñente. O sellante só reside no interior da porosidade da peza fundida. As etapas de lavado e curado están deseñadas para eliminar todo o sellante en exceso das superficies da peza, deixando a súa xeometría inalterada.

3. Poden selarse todos os tipos de porosidade mediante impregnación?

A impregnación ao baleiro é moi eficaz para selar a micro-porosidade, incluída a porosidade cega e a que pasa de parte a parte, que crean camiños de fuga. Aínda que non está pensada para corrixir defectos estruturais graves, a impregnación ao baleiro úsase para selar tanto a micro como a macro-porosidade. O proceso está deseñado para facer que unha peza fundida, doutro modo correcta, sexa estanca á presión, e non para reparar pezas fundamentalmente defectuosas.

Pequeños lotes, altos estándares. O noso servizo de prototipado rápido fai que a validación sexa máis rápida e fácil —

Pequeños lotes, altos estándares. O noso servizo de prototipado rápido fai que a validación sexa máis rápida e fácil —