Custom CNC Metal Cutting Demystified: From Material Choice To Final Part

Understanding Custom CNC Metal Cutting Fundamentals

Ever wondered how engineers transform a solid block of aluminum into a precisely shaped aerospace bracket? Or how medical device manufacturers create implants with tolerances measured in thousandths of an inch? The answer lies in custom CNC metal cutting—a manufacturing process that combines computer precision with metalworking expertise to produce parts tailored to exact specifications.

CNC stands for Computer Numerical Control, referring to the use of computers to automate the control, precision, and movement of machine tools. Unlike manual fabrication methods where skilled laborers physically guide cutting tools, CNC technology uses programmed instructions to direct every movement with remarkable accuracy. According to Hmaking, this process uses computerized equipment to guide machining tools in transforming metal from a workpiece into a finished product through CNC software—essentially a program made of coded instructions that ensure precise, repeatable, and accurate movement.

What Makes CNC Metal Cutting Custom

So what separates custom CNC metal cutting from standard machining? The distinction comes down to personalization at every stage of production. Standard machining typically produces predetermined parts using fixed parameters and CNC equipment configured for repetitive tasks. Custom work, however, adapts the entire process to your unique project requirements.

Imagine you need a specialized mounting bracket with non-standard dimensions, made from a specific aluminum alloy, with holes positioned precisely 0.375 inches apart. A custom approach means the manufacturer programs toolpaths specifically for your geometry, selects cutting tools optimized for your chosen metal sheet material, and calibrates the machine to achieve your exact tolerance requirements. Every decision—from feed rates to finishing passes—gets tailored to your part.

This bespoke nature becomes especially valuable when working with unique geometries that don't fit standard templates, tight tolerances required for critical applications, specialized materials like titanium or exotic alloys, and small production runs where mass-production tooling isn't cost-effective.

From Digital Design to Physical Part

The journey from concept to completed component follows a defined workflow that bridges digital design and CNC physical manufacturing. It starts with Computer-Aided Design (CAD), where engineers create a detailed 3D model defining critical measurements and properties of the physical part. This digital blueprint captures every dimension, angle, and feature your part requires.

Next comes Computer-Aided Manufacturing (CAM), where software analyzes your 3D model and generates toolpaths—the precise routes cutting tools will follow. As Tormach explains, CAM software helps create the toolpaths your machine will follow, essentially serving as the bridge from digital manufacturing to physical manufacturing. The CAM program determines which tools to use, in what sequence, and how they should move to efficiently remove material while achieving specified tolerances.

The final translation happens through G-code—the language CNC machines understand. This running set of commands and coordinates moves the machine while managing elements like tool changes, coolant, and spindle speeds. Some experienced machinists even write G-code manually, but most custom metal fabrication relies on CAM-generated instructions for complex geometries.

- CAD/CAM Programming: Digital design files translated into machine-readable toolpaths specific to your part geometry

- Material-Specific Tooling: Cutting tools, speeds, and feeds optimized for your chosen metal—whether aluminum, steel, or specialty alloys

- Tolerance Specifications: Precision requirements defined for each feature, from standard machining tolerances to ultra-tight specifications

- Finish Requirements: Surface quality specifications ranging from as-machined to polished, anodized, or powder-coated surfaces

Understanding these fundamentals empowers you to communicate effectively with manufacturers, specify your requirements accurately, and make informed decisions about your custom metal parts projects. Whether you're developing prototypes or planning limited production runs, this knowledge forms the foundation for successful outcomes in precision metal fabrication.

Core CNC Cutting Processes and When to Use Each

Now that you understand how digital designs become physical parts, the next question becomes: which cutting process actually shapes your metal? This decision significantly impacts your part's quality, cost, and production timeline. While many manufacturers list their capabilities, few explain when each process truly shines—and when it falls short.

Four primary CNC cutting methods dominate precision metal fabrication: milling, turning, drilling, and routing. Each employs distinct mechanics that make it ideal for specific geometries and applications. Choosing the wrong process doesn't just waste money—it can compromise dimensional accuracy or surface finish quality that your application demands.

CNC Milling Explained

Picture a rotating metal cutter approaching a fixed workpiece from above, systematically removing material layer by layer. That's CNC milling in action. The workpiece remains stationary while the cutting tool spins at high speed, traversing along multiple axes (typically X, Y, and Z) to carve complex shapes.

What makes milling so versatile? According to RapidDirect, milling performs a variety of operations such as drilling, slotting, contouring, and surface finishing in a single setup. This multi-functional capability makes it the go-to choice for parts requiring flat surfaces, pockets, slots, and intricate 3D contours.

Consider an engine block with its complex network of passages, mounting surfaces, and precision bores. Or an aerospace bracket featuring angled surfaces and weight-reducing pockets. These parts showcase milling's strength: handling prismatic geometries that demand precision from multiple angles.

Common milling operations include:

- Face Milling: Creates flat surfaces by removing material from the workpiece's face

- End Milling: Cuts slots, pockets, and intricate profiles along the cutter's sides

- Profile Milling: Achieves complex shapes by tracing the workpiece's contour

- Text Milling: Engraves detailed designs, logos, or identification marks on surfaces

However, milling has limitations. When your part requires primarily cylindrical features, a machine cutter metal removal through milling becomes inefficient compared to turning. The process also generates higher tooling costs and longer cycle times for certain geometries.

When to Choose Turning Over Milling

Turning flips the script entirely. Instead of the tool rotating, your workpiece spins rapidly while a stationary metal cutter removes material. This fundamental difference makes turning exceptionally efficient for round or cylindrical components.

Imagine manufacturing a precision shaft, a threaded fastener, or a hydraulic piston rod. As Unionfab explains, CNC turning excels in producing axially symmetric parts requiring high precision and excellent surface finishes. The continuous rotation creates naturally smooth surfaces on cylindrical features—something milling struggles to match.

CNC turning operations encompass:

- Facing: Creates flat surfaces on the workpiece ends

- Threading: Adds precise internal or external threads

- Grooving: Produces grooves or recesses for O-rings and snap rings

- Boring: Enlarges existing holes or refines internal dimensions

The trade-off? Turning cannot efficiently produce flat surfaces, angular features, or asymmetric geometries. Parts requiring slots, pockets, or complex contours need milling—or a combination of both processes using multi-axis machines.

CNC Drilling: Precision Hole-Making

While milling machines can create holes, dedicated CNC drilling delivers superior accuracy and efficiency for hole-intensive parts. Consulting a drill chart or drill bit size chart ensures proper tool selection for your application's diameter requirements.

Drilling isn't a single operation—it's actually a family of hole-making processes:

- Standard Drilling: Creates initial holes using rotating drill bits—fast and cost-effective

- Boring: Enlarges and corrects hole position after drilling, improving cylindrical precision

- Reaming: The finishing touch—smoothens holes to exact dimensions with mirror-like internal surfaces

When reviewing a drill size chart for your project, remember that drilling establishes the initial hole, boring corrects alignment, and reaming achieves final tolerance. For critical applications—think bearing seats or precision pin holes—all three operations work in sequence.

CNC Routing for Sheet Goods and Softer Metals

CNC router CNC machines occupy a distinct niche, optimized for rapid cutting of softer materials and sheet goods. While structurally lighter than milling machines, routers spin cutters at exceptionally high speeds—ideal for aluminum sheet, brass, and non-ferrous metals.

Routers shine when cutting profile shapes from flat stock, creating signage or decorative metalwork, and handling high-volume production of simpler geometries. Their lower cost and faster speeds make them accessible for many shops.

The limitations? Routers lack the rigidity for cutting hard metals like steel or achieving the tightest tolerances. Their lighter frames generate more vibration during aggressive cuts, which can compromise precision on demanding applications.

CNC Process Comparison Table

| Process Type | Best Applications | Typical Materials | Achievable Tolerances | Ideal Part Geometries |

|---|---|---|---|---|

| CNC Milling | Engine blocks, brackets, housings, mold cavities | Aluminum, steel, stainless steel, titanium, brass, plastics | ±0.001" to ±0.005" typical | Prismatic shapes, flat surfaces, pockets, slots, 3D contours |

| CNC Turning | Shafts, pins, bushings, pulleys, threaded fasteners | Aluminum, steel, brass, stainless steel, copper | ±0.0005" to ±0.003" typical | Cylindrical, conical, rotationally symmetric parts |

| CNC Drilling | Hole patterns, bolt circles, precision bores | All machinable metals | ±0.001" to ±0.005" (reamed holes tighter) | Parts requiring multiple precise holes |

| CNC Routing | Sheet profiles, signage, decorative panels, gaskets | Aluminum, brass, copper, plastics, composites | ±0.005" to ±0.015" typical | 2D profiles, shallow 3D features from sheet stock |

Practical Examples: Matching Process to Part

Still wondering which process fits your project? Consider these real-world examples:

- Medical implant housing: CNC milling handles the complex external geometry while turning creates the internal bore—often completed on a single multi-axis machine

- Automotive drive shaft: CNC turning produces the shaft body; milling adds keyways or flats for mounting

- Electronic enclosure: CNC routing quickly profiles aluminum sheet panels; drilling adds mounting holes

- Hydraulic manifold: Deep-hole drilling creates internal passages; milling machines connection ports

Understanding these process distinctions empowers you to communicate precisely with manufacturers, anticipate cost implications, and ensure your custom parts arrive meeting every specification. With this foundation, you're ready to explore another critical decision: selecting the right metal for your application.

Metal Selection Guide for CNC Projects

You've identified the right cutting process for your part geometry—but which metal should actually go into the machine? This decision shapes everything from tooling requirements to final part performance. Choose wisely, and your component delivers years of reliable service. Choose poorly, and you'll face premature failures, excessive costs, or parts that simply don't function as intended.

Unlike process selection, material choice involves balancing multiple competing factors: mechanical strength, corrosion resistance, weight, machinability, and budget. According to TrustBridge, material selection should not be based solely on mechanical properties—cost per unit, machinability, weight, corrosion resistance, and thermal conductivity all affect your decision.

Let's break down the most common metals used in custom CNC metal cutting and exactly when each makes sense for your application.

Matching Materials to Application Requirements

Every metal brings distinct advantages to specific applications. Understanding these strengths helps you match material properties to your project's functional demands.

Aluminum Alloys dominate CNC machining for good reason. These metals aluminium offer an exceptional strength-to-weight ratio, natural corrosion protection, and outstanding machinability. When you need lightweight components that cut quickly and cost-effectively, aluminum sheet metal becomes your go-to choice.

As Hubs notes, aluminum alloys have an excellent strength-to-weight ratio, high thermal and electrical conductivity, and natural protection against corrosion—making them often the most economical option for prototypes and production parts alike.

Common aluminum grades include:

- 6061 Aluminum: The workhorse grade—excellent machinability, good strength, and broad availability for general-purpose applications

- 7075 Aluminum: Aerospace-grade strength approaching some steels, but at higher cost

- 5083 Aluminum: Superior seawater resistance for marine and construction uses

Stainless Steel Alloys deliver when strength, hygiene, and corrosion resistance matter most. Stainless steel sheet metal components appear throughout medical devices, food processing equipment, and chemical handling systems. These alloys combine high ductility with excellent wear resistance.

The 316 stainless steel grade deserves special attention. With superior resistance to saline solutions and aggressive chemicals, it's the preferred choice for marine hardware, surgical instruments, and pharmaceutical processing equipment. While more expensive than 304 stainless, the enhanced corrosion protection justifies the premium in harsh environments.

Carbon Steel offers the most cost-effective path to high-strength components. When corrosion isn't a concern—or protective coatings can address it—carbon steel plate material delivers excellent mechanical properties at lower material costs. Grades like 1018 machine easily and weld reliably, making them ideal for structural components, fixtures, and industrial machinery.

Brass brings unique advantages beyond its attractive golden appearance. Excellent electrical conductivity makes it essential for electrical connectors, while low friction characteristics suit fluid handling components. When comparing brass vs bronze for your application, brass generally offers superior machinability and lower cost, while bronze provides better wear resistance for bearing applications.

Cost vs Performance Trade-offs

Here's what most manufacturers won't tell you: material cost represents only part of your total part expense. Machinability dramatically affects cycle time—and harder materials wear through tooling faster, adding hidden costs.

Consider this: brass machines so easily that cycle times often run 30-40% faster than equivalent steel parts. That faster cutting speed offsets brass's higher raw material cost for many applications. Conversely, titanium's exceptional strength comes with slow machining speeds and rapid tool wear—often doubling or tripling the machining cost compared to aluminum.

| Material | Key Properties | Best Industries/Applications | Machinability Rating | Relative Cost |

|---|---|---|---|---|

| Aluminum 6061 | Lightweight, corrosion-resistant, excellent thermal conductivity | Aerospace, automotive, electronics enclosures, prototyping | Excellent | Low |

| Aluminum 7075 | High strength (comparable to steel), good fatigue resistance | Aerospace structural components, high-stress applications | Good | Medium |

| 304 Stainless Steel | Good corrosion resistance, high strength, weldable | Food processing, architectural, general industrial | Moderate | Medium |

| 316 Stainless Steel | Superior chemical/saline resistance, biocompatible | Marine, medical implants, pharmaceutical equipment | Moderate | Medium-High |

| 1018 Carbon Steel | Good strength, excellent weldability, cost-effective | Fixtures, machine parts, structural components | Good | Low |

| 4140 Alloy Steel | High strength, wear-resistant, heat-treatable | Gears, shafts, high-stress industrial components | Moderate | Medium |

| C360 Brass | Excellent conductivity, low friction, decorative appearance | Electrical connectors, fluid fittings, decorative hardware | Excellent | Medium |

| Titanium Grade 5 | Exceptional strength-to-weight, biocompatible, corrosion-proof | Aerospace, medical implants, military applications | Poor | Very High |

Material Certifications for Regulated Industries

Working in aerospace, medical, or defense sectors? Material traceability becomes non-negotiable. Regulated industries require certified mill test reports documenting chemical composition, mechanical properties, and heat treatment records.

For medical applications using 316 stainless steel or titanium, verify that materials meet ASTM specifications and come with full certifications. Aerospace components often require materials from approved supplier lists with complete chain-of-custody documentation. Discuss certification requirements early in your project—sourcing certified aluminum sheet or stainless steel sheet with proper documentation may extend lead times.

Understanding how material selection impacts tooling wear, machine time, and finishing requirements empowers you to make informed decisions. But even the perfect material choice means nothing without proper tolerance specifications—the subject we'll explore next.

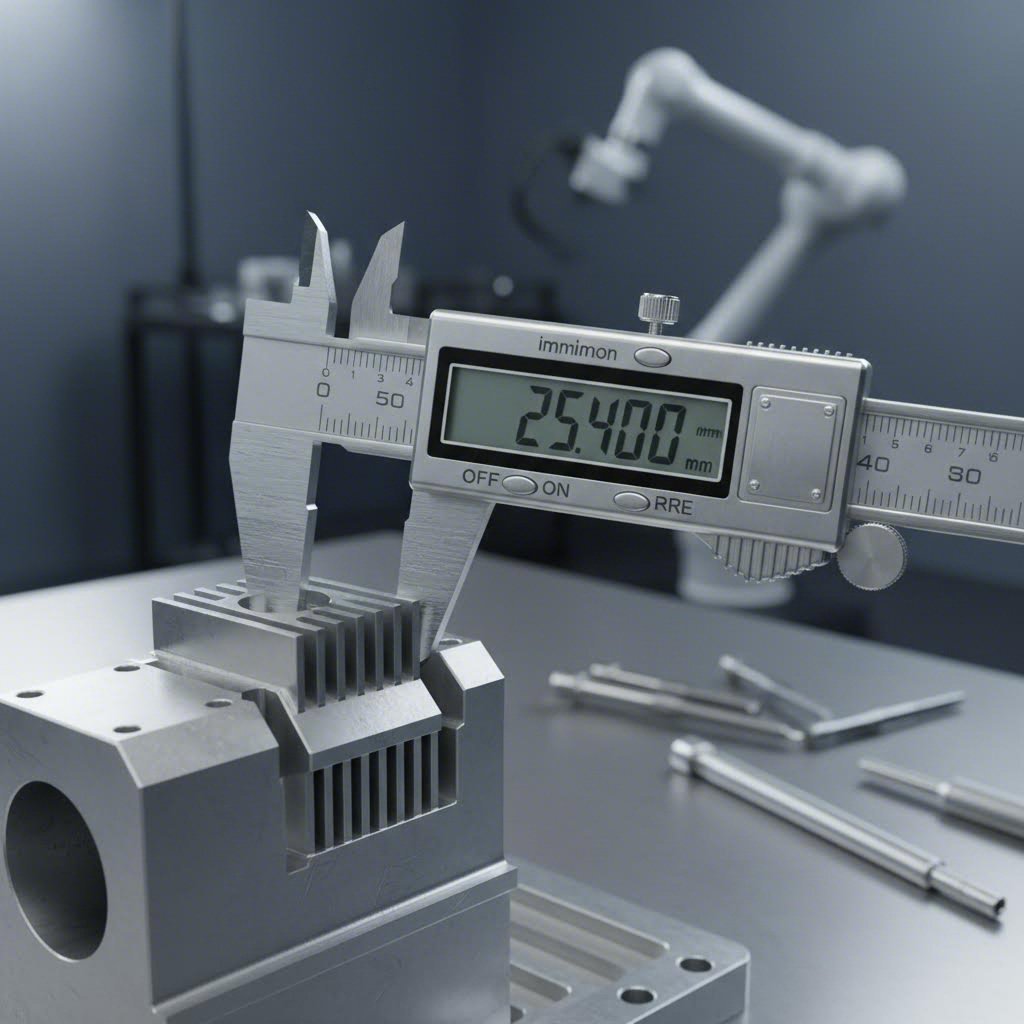

Tolerance Specifications and Precision Requirements

You've selected the perfect material for your custom CNC metal cutting project—but here's where many engineers stumble. Specifying tolerances incorrectly can either drain your budget unnecessarily or cause parts that simply won't fit together. Understanding tolerance specifications transforms you from someone requesting quotes to someone making informed manufacturing decisions.

What exactly does ±0.005 inch mean for your part? It indicates the manufactured dimension can vary by five-thousandths of an inch above or below the nominal size. For a 1.000-inch hole, acceptable diameters range from 0.995 to 1.005 inches. That tolerance band—the complete range of allowable dimensions—directly impacts whether your part functions as intended.

According to American Micro Industries, CNC machining typically achieves tolerances of ±0.005 inch (0.127 mm) as a standard benchmark, while precision machining operations can achieve tighter tolerances of ±0.001 inch or better when applications require exceptional accuracy. This distinction matters because tighter tolerances demand more expensive equipment, slower cutting speeds, and additional inspection processes.

Reading and Specifying Tolerances

Tolerance specifications appear in several standardized formats on engineering drawings. Understanding these formats prevents miscommunication that leads to rejected parts or costly rework.

The most common tolerance expressions include:

- Bilateral Tolerances: ±0.005 inch—the dimension can vary equally above or below nominal

- Unilateral Tolerances: +0.002/-0.000 inch—variation allowed in only one direction

- Limit Dimensions: 1.000/0.995 inch—specifies maximum and minimum acceptable sizes directly

Decimal precision directly correlates with manufacturing difficulty. As American Micro Industries explains, a tolerance of ±0.02 inch permits a range 10 times wider than a tolerance of ±0.002 inch, significantly affecting production complexity and cost. Each additional decimal place of precision typically multiplies your machining expense.

When reviewing a sheet metal gauge chart or gauge size chart for your project, recognize that standard gauge sizes like 14 gauge steel thickness (approximately 0.0747 inch) or 11 gauge steel thickness (approximately 0.1196 inch) come with their own inherent tolerances. Sheet stock varies slightly from nominal, and your machined features must account for this base material variation.

Understanding GD&T Basics

Encounter symbols on drawings that look like hieroglyphics? You're likely seeing Geometric Dimensioning and Tolerancing—GD&T for short. This standardized system describes how parts should fit together and function, going beyond simple dimensional tolerances.

According to CNC Cookbook, GD&T is a set of standardized symbols and conventions that make it easier for customers, manufacturers, and supply chain participants to successfully communicate. The system addresses not just size variations, but shape deviations like flatness, roundness, and position accuracy.

Key GD&T concepts you'll encounter include:

- Datums: Reference points that establish where measurements originate—similar to setting Part Zero on a CNC machine

- Feature Control Frames: Boxes containing symbols that define geometric tolerances for specific features

- Position Tolerance: Defines how far a feature's center can deviate from its true intended location

- Form Tolerances: Controls like flatness, cylindricity, and straightness that govern feature shape

Why does GD&T matter? As the CNC Cookbook explains, the system expresses tolerances in ways that are often beneficial to manufacturing cost. Traditional plus/minus tolerancing creates square tolerance zones, while GD&T's position tolerance uses circular zones—allowing more acceptable parts from the same manufacturing process.

When Tighter Tolerances Matter

Not every feature on your part needs ultra-precision. Understanding when tight tolerances genuinely matter—and when they waste money—separates experienced engineers from novices.

Tight tolerances become essential for:

- Mating surfaces: Parts that must fit together with specific clearances or interference fits

- Bearing seats: Locations where shafts interface with bearings requiring precise diameters

- Sealing surfaces: Areas where O-rings or gaskets must create reliable seals

- Assembly alignment: Features that position components relative to each other

Conversely, non-critical features—external surfaces that don't interface with other parts, cosmetic areas covered by housings, or dimensions with generous assembly clearance—can use standard tolerances without compromising function.

According to GD&T Basics, if your desired end-product does not require high tolerance values such as ±0.002mm, machinists can deliver the part in less time and charge you significantly less. The tensile strength of your material doesn't change with tighter tolerances—but your invoice certainly does.

Tolerance Classes Comparison

| Tolerance Range | Typical Applications | Cost Impact | Required Equipment |

|---|---|---|---|

| ±0.015" to ±0.030" (Commercial) | Non-critical features, rough dimensions, general fabrication | Low—standard machining rates apply | Standard CNC mills and lathes |

| ±0.005" to ±0.010" (Standard Precision) | Most functional features, typical assembly fits, general mechanical components | Moderate—represents baseline CNC capability | Well-maintained CNC equipment with proper tooling |

| ±0.001" to ±0.003" (Precision) | Bearing fits, precision assemblies, critical mating surfaces, aerospace components | High—slower feeds, multiple passes, careful inspection | Precision CNC machines, climate-controlled environments, calibrated tooling |

| ±0.0005" or tighter (Ultra-Precision) | Optical components, precision instruments, high-performance aerospace, medical implants | Very High—specialized processes, extensive inspection | Grinding, lapping, specialized ultra-precision machines, metrology-grade inspection |

The Cost of Over-Specifying

Here's what many designers overlook: specifying ±0.001 inch when ±0.005 inch works perfectly wastes significant money. Tighter tolerances require slower cutting speeds, additional finishing passes, more frequent tool changes, and extended inspection time. Each factor compounds your per-part cost.

The reverse problem—under-specifying tolerances—creates equally serious issues. Parts that technically meet loose specifications may not assemble correctly, creating costly field failures or production line shutdowns. As American Micro Industries notes, parts exceeding tolerance limits become unusable in most applications, resulting in increased waste and production costs.

The solution? Apply tight tolerances only where function demands them. Use gauge sizes appropriate to your material thickness, verify tolerance requirements against actual assembly needs, and communicate with your manufacturer about which features truly require precision. This balanced approach delivers functional parts without budget-busting precision where it provides no benefit.

With tolerance fundamentals established, you're ready to explore another critical decision: choosing between CNC machining and alternative cutting technologies like laser and waterjet for your specific application.

Comparing CNC Milling with Laser and Waterjet Cutting

You understand tolerances, you've selected your material—but now comes a question that catches many engineers off guard: should your part be CNC machined, laser cut, or processed using waterjet? Each technology excels in specific scenarios, and choosing incorrectly means paying more for inferior results.

Here's what most manufacturers won't tell you: no single cutting method works best for every application. According to SendCutSend, material selection, size, tolerance, post-processing needs, and more are all considered when choosing the best fabrication method—where one cutting method falls short, another offers a solution.

Let's break down exactly when each technology makes sense for your custom metal cutting project.

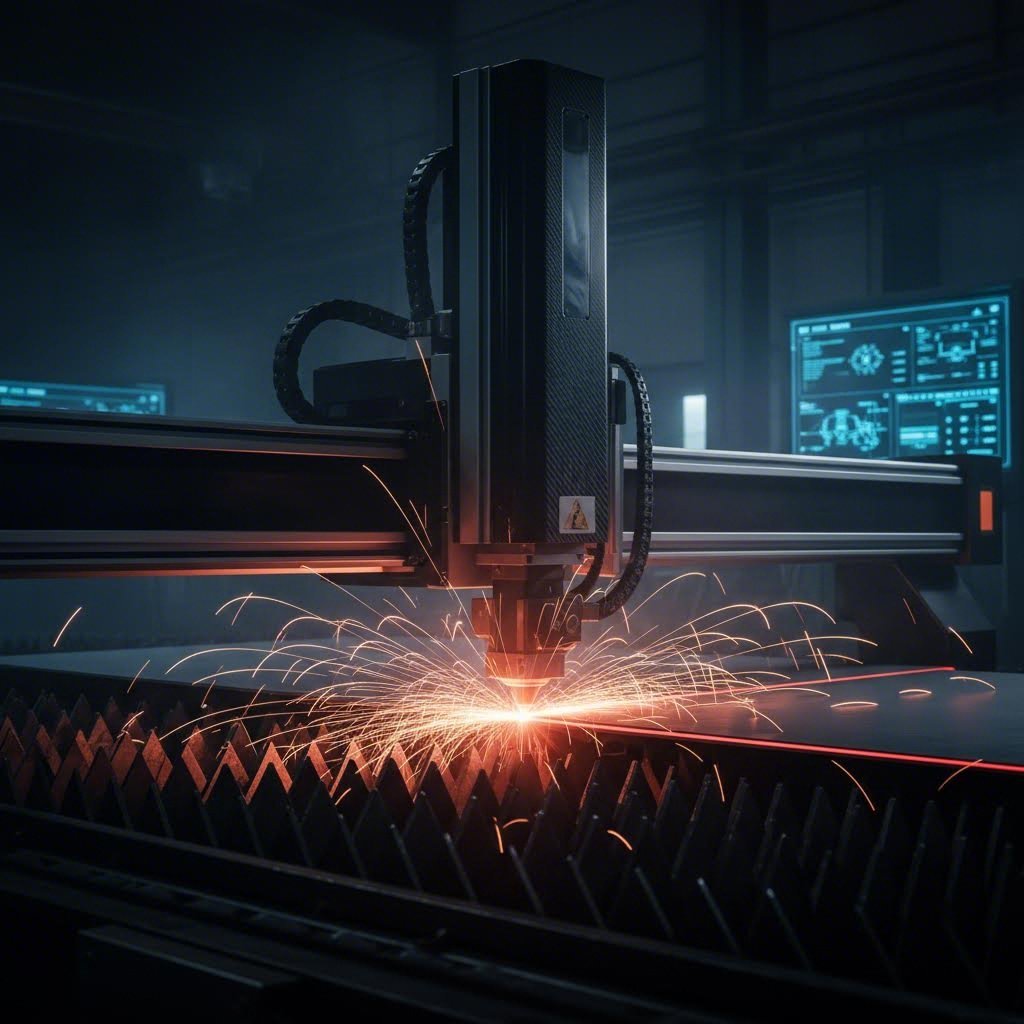

CNC Machining vs Laser Cutting

Think of CNC milling and metal laser cutting as complementary tools rather than competitors. They solve fundamentally different problems.

CNC Milling removes material using rotating cutters that physically contact your workpiece. The cutter plunges into the stock and travels along programmed paths, creating three-dimensional features—pockets, contours, angled surfaces, and complex geometries impossible to achieve with 2D cutting processes.

A laser cutter, by contrast, uses a focused light beam to melt, burn, or vaporize material along a flat cutting path. As SendCutSend explains, laser cutting is the process of using a laser to make two-dimensional cuts into stock material—a very fine amplified light beam that melts, burns, and even vaporizes through work material along a preprogrammed path.

When should you search for "laser cutting near me" versus requesting CNC machining quotes? Consider these distinctions:

- Part Geometry: Need a flat profile cut from sheet stock? Laser excels. Require 3D features, pockets, or machined surfaces? CNC milling is your answer.

- Speed: Laser cut metal production runs significantly faster—upwards of 2,500 inches per minute for thin materials. CNC milling moves slower but creates features lasers simply cannot.

- Edge Quality: Laser cutting produces slightly rough striations on thicker materials (over 0.187 inch). CNC milling delivers consistent surface finishes regardless of depth.

- Kerf Considerations: The kerf—the width of material removed during cutting—affects small features. Lasers burn away additional material, potentially losing intricate details. CNC cutters offer predictable material removal.

Here's the practical reality: if your part starts as flat sheet stock and remains essentially 2D, laser cutting delivers speed and economy. The moment you need threaded holes, varying depths, machined surfaces, or complex 3D geometry, CNC machining becomes essential.

Laser Cutting Pros

- Extremely fast cutting speeds for sheet profiles

- Excellent precision with tight tolerances on 2D shapes

- Minimal material contact reduces fixturing complexity

- Cost-effective for high-volume flat parts

Laser Cutting Cons

- Limited to 2D cutting—no 3D features possible

- Heat-affected zone (HAZ) can alter material properties near cuts

- Thickness limitations vary by material and laser power

- Intricate small details may be lost in the kerf

Understanding Waterjet Cutting Advantages

What happens when your material cannot tolerate heat? Titanium alloys, tempered steel, heat-treated components, and composites all suffer when exposed to thermal cutting processes. This is where waterjet cutting shines.

Waterjet uses extremely high-pressure water mixed with abrasive garnet particles to erode material along programmed paths. No heat transfers to your workpiece—eliminating any heat-affected zone entirely. According to SendCutSend, waterjet cutting produces an incredibly high-quality surface finish along the cut edge, and unlike CNC routing and laser cutting, dross and burrs are eliminated.

Consider waterjet when:

- Heat sensitivity matters: Aerospace regulations often prohibit heat-affected zones entirely

- Thick stock requires cutting: Waterjet handles material thicknesses that challenge lasers

- Composite materials need processing: Carbon fiber, G10, and phenolic materials that delaminate under heat or routing cut cleanly with waterjet

- Surface finish is critical: The abrading action produces smooth edges without secondary finishing

The trade-off? Speed. Waterjet cutting moves significantly slower than laser or CNC routing. For production quantities of simpler parts, this speed difference translates directly into higher per-part costs. But for heat-sensitive applications or difficult materials, waterjet remains the only viable solution.

Plasma Cutting: When It Makes Sense

Searching for "plasma cutting near me" typically indicates projects involving thicker steel plate at production volumes. Plasma cutting uses ionized gas to melt through conductive metals—primarily carbon steel, stainless steel, and aluminum in thicker sections.

Plasma excels at:

- Cutting thick steel plate (up to several inches)

- High-speed processing of structural steel components

- Cost-effective production of parts where precision tolerances aren't critical

However, plasma carries significant limitations. Edge quality suffers compared to laser or waterjet, with rougher surfaces requiring secondary finishing for many applications. Tolerances run looser—typically ±0.030 inch or more—making plasma unsuitable for precision assemblies. The substantial heat-affected zone also limits applications in heat-sensitive industries.

Choosing the Right Cutting Technology

How do you navigate these options? Start with three questions: What geometry does your part require? What material are you cutting? What tolerances must you achieve?

| Technology | Material Thickness Range | Edge Quality | Heat Affected Zone | Best Materials | Typical Tolerances | Relative Speed |

|---|---|---|---|---|---|---|

| CNC Milling | Limited by machine envelope—typically up to 6"+ depth | Excellent—controllable surface finish | Minimal with proper coolant | All machinable metals, plastics, composites | ±0.001" to ±0.005" | Moderate—varies with complexity |

| CNC Routing | Typically under 1" for metals | Good—superior finish on plastics/composites | Low | Aluminum, brass, plastics, wood, composites | ±0.005" | Fast for sheet goods |

| Laser Cutting | Up to 1" steel; varies by material/power | Good to excellent—striations on thicker stock | Present but minimal with modern equipment | Steel, stainless, aluminum, brass, copper | ±0.003" to ±0.005" | Very fast—up to 2,500 IPM |

| Waterjet Cutting | Up to 8"+ depending on material | Excellent—smooth, burr-free edges | None—cold cutting process | Any material including composites, glass, stone | ±0.005" to ±0.009" | Slow—significantly slower than laser |

| Plasma Cutting | 1/8" to 6"+ for steel | Rough—requires secondary finishing | Significant | Conductive metals—steel, stainless, aluminum | ±0.020" to ±0.030" | Fast for thick materials |

Decision Framework for Your Project

Use this practical decision tree to identify your optimal cutting technology:

- Does your part require 3D features, pockets, or machined surfaces? If yes, CNC milling is required—laser and waterjet produce only 2D profiles.

- Is your part essentially a flat profile from sheet stock? If yes, consider laser cutting for speed and economy on most metals.

- Does your application prohibit any heat-affected zone? If yes, waterjet becomes your primary option for 2D profiles.

- Are you cutting thick steel plate where precision isn't critical? Consider plasma for cost-effective processing.

- Working with composites, plastics, or softer metals? CNC routing often delivers superior surface finish at competitive speeds.

Remember: many projects benefit from combining technologies. A manufacturer might laser cut your flat profiles, then CNC machine critical features—achieving both speed and precision where each matters most.

Understanding these technology trade-offs positions you to request appropriate processes and evaluate quotes intelligently. With cutting method selection clarified, the next consideration becomes equally important: understanding what drives custom CNC metal cutting costs and how to optimize your budget without sacrificing quality.

Cost Factors and Budget Optimization Strategies

You've selected your cutting process, chosen the right material, specified tolerances, and identified the optimal cutting technology. Now comes the question everyone asks but few manufacturers answer transparently: what will this actually cost?

Custom CNC metal cutting pricing often feels like a black box. Quotes arrive with total figures but little explanation of what drives those numbers. Understanding the cost structure empowers you to make design decisions that deliver quality parts without unnecessary expense—and helps you evaluate whether quotes reflect fair market pricing.

What Drives Custom CNC Pricing

Every custom machined part carries costs from six primary factors. According to Komacut, the choice of material significantly impacts both the cost and the machining process—materials like stainless steel and titanium require more time and specialized tooling, thereby increasing costs, while softer materials such as aluminum reduce both machining time and tool wear.

Here's how each factor influences your bottom line:

- Raw Material: The actual metal stock your part gets machined from. Material costs vary dramatically—aluminum runs significantly cheaper than titanium, and standard alloys cost less than specialty grades. Volume matters too: larger blanks cost more, and material waste affects utilization.

- Machine Time: CNC machines bill by the hour, with rates varying by equipment type. According to Komacut, 3-axis milling typically runs $35-50 per hour, while 5-axis machines command $75-120 per hour. Complex geometries requiring multiple setups or slower feed rates extend cycle times.

- Programming and Setup: Before any cutting begins, someone must program toolpaths and configure the machine. These fixed costs get amortized across your order quantity—making single prototypes disproportionately expensive compared to production runs.

- Tooling Wear: Cutting tools don't last forever. Harder materials like stainless steel consume tools faster, adding replacement costs. Tight tolerances requiring fresh, sharp tooling also increase this expense.

- Finishing Operations: Surface treatments add costs based on complexity. An as-machined finish costs nothing extra, while anodized aluminum parts require secondary processing. Powder coat finishes, bead blasting, and polishing each add labor and material expenses.

- Quality Inspection: Every part requires verification. Standard inspection adds minimal cost, but precision parts requiring CMM measurement or comprehensive documentation increase inspection time significantly.

One often-overlooked factor? Lead time urgency. Rush orders requiring expedited production typically carry premiums of 25-50% or more. Planning ahead saves real money.

Strategies to Reduce Part Costs

Here's what experienced engineers know: smart design decisions reduce costs without compromising function. According to Geomiq, reducing CNC machining costs involves combining design optimization, careful material selection, and efficient manufacturing techniques—ensuring your project is cost-effective without sacrificing quality.

Consider these proven strategies:

Simplify Your Design

Complex features requiring specialized tooling, multiple setups, or intricate programming drive costs upward. As Factorem explains, part complexity influences costs through increased machining time, specialized tooling, and custom fixtures designed with the end product's geometry in mind. Before finalizing your design, ask: does every complex feature serve a functional purpose?

Optimize Material Utilization

CNC machining is subtractive—material removed becomes waste. Geomiq notes that depending on part complexity, this technique results in material wastage of 30% to 70% of the original blank volume. Designing parts that nest efficiently within standard stock sizes reduces material costs significantly.

Relax Non-Critical Tolerances

Specifying ±0.001 inch everywhere when only mating surfaces require that precision wastes money. Standard tolerances of ±0.005 inch satisfy most applications and machine faster. Reserve tight tolerances for features where function demands them.

Design for Manufacturability

Avoid features that require specialized tools or multiple repositioning operations. Internal corners should include radii matching standard end mill sizes. Wall thicknesses should stay above minimum recommendations for your material. These DFM principles reduce cycle time and tooling costs.

Leverage Batch Quantities

Setup costs remain fixed whether you order one part or one hundred. Geomiq's analysis shows ordering ten units instead of one can reduce per-unit cost by 70%, while hundred-unit batches achieve 90% savings per part. If you'll eventually need multiple parts, ordering together makes financial sense.

Choose Finishes Wisely

Secondary finishing adds cost. An anodized finish on aluminum provides corrosion protection and aesthetic appeal—but only specify it where needed. Parts hidden inside assemblies rarely require premium finishes. Similarly, aluminum welding for assemblies adds cost over single-piece designs when welding isn't functionally necessary.

The most effective cost reduction happens early in design. Communicating with your manufacturer during development—before drawings are finalized—often reveals simple changes that dramatically reduce machining expense while maintaining full functionality.

With cost factors understood, you're positioned to make informed budget decisions. Next, we'll explore design guidelines that ensure your CAD files translate smoothly into manufacturable parts—avoiding costly revisions and delays.

Design Guidelines for Successful CNC Projects

You've calculated costs and understand what drives pricing—but here's where many projects stumble before machining even begins. Poor design preparation creates revision cycles that delay production, inflate expenses, and frustrate everyone involved. The good news? Following proven design guidelines ensures your custom CNC metal cutting project moves from quote to completed parts without costly detours.

Design for Manufacturability—DFM for short—applies engineering principles that make parts easier and more economical to produce. According to Modus Advanced, effective DFM implementation can reduce manufacturing costs by 15-40% and cut lead times by 25-60% compared to non-optimized designs. Those aren't small savings. They represent the difference between budget-friendly prototypes and projects that spiral beyond initial estimates.

Let's walk through the specific DFM principles that apply to sheet metal fabrication and precision CNC work—along with the file preparation steps that get your project quoted and produced faster.

Preparing Your CAD Files for CNC

Before your design can become metal fabrication parts, it needs translation into formats CNC equipment understands. Not all CAD file formats work equally well, and submitting the wrong format can delay your quote or introduce errors during programming.

As JLCCNC explains, accuracy starts at the file level—CNC machines follow instructions down to the fraction of a millimeter, so if your CAD data is incomplete, in the wrong format, or overly complex, you can end up with production delays and costly revisions.

Here's what you need to know about file formats and submission requirements:

- STEP (.stp, .step): The universal standard for CNC machining. STEP files preserve complete 3D geometry with full accuracy across different CAD systems. When in doubt, export STEP.

- IGES (.igs, .iges): An older but widely compatible format suitable for most custom sheet metal fab applications. Works well but may occasionally lose some surface data on complex geometries.

- Parasolid (.x_t, .x_b): Excellent accuracy for SolidWorks and compatible systems. Preserves detailed geometry reliably.

- Native CAD Formats: Files from SolidWorks, Inventor, Fusion 360, or other major platforms. Many manufacturers accept native files directly, which preserves all design intent.

- Avoid STL and OBJ: These mesh-based formats work for 3D printing but break smooth curves into tiny triangles—unsuitable for precision CNC work.

Beyond file format, include these essential details with your submission:

- Material specification with specific alloy grade

- Critical tolerances called out for features requiring precision

- Surface finish requirements for each relevant surface

- Quantity needed and target lead time

- Any certifications required for regulated industries

Complete submissions get quoted faster. Manufacturers don't need to email back with clarifying questions, and programmers can begin toolpath generation immediately.

Critical DFM Principles for CNC Metal Cutting

Certain design choices create manufacturing headaches that translate directly into longer lead times and higher costs. Understanding these constraints before finalizing your design prevents expensive revision cycles.

Internal Corner Radii

Here's a fundamental reality of CNC machining: end mills are round. They physically cannot create sharp 90-degree internal corners. According to Modus Advanced, specifying the largest radius your design can accommodate enables the use of larger, more rigid cutting tools that resist deflection and provide superior surface finishes.

Practical guidelines for internal corners:

- Minimum radius: 0.005" (0.13mm)—requires specialized small tooling

- Recommended radius: 0.030" (0.76mm) or larger—allows standard tooling

- Deep pockets: Increase to 0.060" (1.52mm) to reduce tool deflection

Sharp corners require specialized small-diameter cutters that deflect under cutting forces, slow feed rates, and multiple finishing passes. Adding appropriate radii can reduce programming time by 50-100%.

Minimum Wall Thickness

Thin walls vibrate during machining, causing poor surface finish and dimensional inaccuracy. Material type determines safe minimums:

- Aluminum: 0.040" (1mm) minimum; 0.060" recommended

- Steel/Stainless: 0.050" (1.27mm) minimum; 0.080" recommended

- Brass: 0.030" (0.76mm) minimum; 0.050" recommended

Walls thinner than these minimums may require special fixturing, reduced cutting speeds, or multiple light passes—all adding cost and time.

Hole Depth-to-Diameter Ratios

Deep, narrow holes present significant challenges. Standard drills become unstable when depth exceeds four times the diameter. For precision bending operations or assembly features requiring deeper holes, expect increased costs for peck drilling cycles or specialized deep-hole drilling equipment.

- Standard drilling: depth up to 4× diameter

- Deep drilling: 4-10× diameter requires peck cycles

- Ultra-deep: beyond 10× diameter needs specialized processes

Thread Specifications

How you specify threads affects both manufacturability and cost. According to Modus Advanced, software default specifications for threaded holes often create unnecessary manufacturing constraints—CAD programs typically default to cut tap specifications while manufacturers may prefer roll tapping for improved thread quality.

Best practice: specify thread class (2B for internal threads, 2A for external) rather than dictating specific drill sizes. This allows manufacturers to optimize their processes while ensuring your functional requirements are met.

Also consider tapping depth carefully. Every tap requires thread lead-in—bottoming taps need 1-2 threads, plug taps need 3-5 threads, and taper taps need 7-10 threads. Ensure drilling depth exceeds tapping depth by this margin, or specify through-holes when possible.

Common Design Mistakes to Avoid

Beyond specific dimensional guidelines, certain design approaches consistently create manufacturing problems. Avoiding these pitfalls keeps your project on schedule and budget.

Knife Edges

When two surfaces meet at extremely acute angles, the resulting sharp edge is fragile and problematic. These features chip during machining, create burrs requiring secondary operations, and damage easily during handling. The solution? Add small outside fillets of 0.005-0.015" radius to eliminate knife edges. Manufacturers typically add these during production regardless—specifying them upfront saves everyone time.

Complex Curves Without Functional Purpose

Elaborate curves and varying radii that look impressive in CAD create significant manufacturing bottlenecks. Modus Advanced notes that complex curves can increase programming time by 100-300% and machining time by 200-400%. Before finalizing any curved feature, ask: does this geometry serve a specific functional purpose, or is it purely aesthetic?

Features Requiring Five-Axis Machining

Angled surfaces and compound contours may require five-axis equipment—costing 300-600% more than three-axis operations. Whenever possible, align features with X, Y, and Z planes to enable simpler machining. If complex angles are truly necessary, communicate this early so manufacturers can quote appropriately.

Over-Constrained Tolerances

Specifying tight tolerances on every dimension wastes money. Apply precision requirements only where function demands them, and use standard tolerances elsewhere. This principle extends to surface finish—not every surface needs the same treatment.

Surface Finish Options and Applications

Surface finishing affects both aesthetics and function. According to Fictiv, surface finish characteristics are particularly important if your part contacts other components—roughness plays a key role in contact mechanics since higher roughness values increase friction and cause faster wear.

Understanding your options helps you specify appropriately:

As-Machined

Parts come directly from the CNC with visible tool marks. Surface roughness typically measures 63-125 Ra (microinches). This finish works for internal components, prototypes, and parts receiving secondary finishing. Cost: baseline—no additional processing required.

Bead Blasted

Pressurized media impacts the surface, creating a uniform matte texture that hides machining marks. Excellent for aesthetic parts and as preparation before other finishes. Bead blasting works on most metals and provides even coverage on complex geometries including corners and fillets.

Anodized

An electrochemical process creating a durable oxide layer on aluminum. Anodizing improves corrosion resistance, provides electrical insulation, and enables color options. Type II anodizing adds 0.0002-0.001" thickness—critical to account for when tolerances are tight. Type III (hardcoat) provides even greater wear resistance for demanding applications.

Powder Coated

Electrostatically applied powdered paint cured at high temperature creates thick, durable coatings in virtually any color. Powder coating works on steel, stainless steel, and aluminum. Be aware that this finish adds measurable thickness—typically 0.002-0.006"—requiring masking of precision features and threaded holes.

Custom Laser Etching

For part identification, logos, or serialization, laser etching provides permanent marking without affecting dimensional accuracy. This laser fabrication technique works on virtually any metal surface and can be combined with other finishes.

When specifying finishes, remember that different surfaces on the same part can receive different treatments. Mating surfaces might remain as-machined for dimensional accuracy while exposed surfaces receive anodizing for aesthetics and protection.

How Proper Preparation Accelerates Your Project

Following these design guidelines and file preparation steps delivers tangible benefits beyond cost savings. Manufacturers can generate accurate quotes faster when submissions are complete and designs follow DFM principles. Programming time decreases when geometries work with standard tooling rather than requiring workarounds.

Perhaps most importantly, well-prepared designs minimize revision cycles. Each round of design changes adds days or weeks to your timeline. Getting it right initially—with appropriate radii, reasonable tolerances, and properly formatted files—keeps your custom metal cutting project moving steadily from concept toward delivery.

With design preparation mastered, you're ready to evaluate potential manufacturing partners. The next section covers what certifications matter, which questions to ask suppliers, and how to identify manufacturers capable of meeting your specific requirements.

Selecting the Right Custom CNC Manufacturing Partner

You've optimized your design, selected the perfect material, and specified appropriate tolerances. Now comes a decision that determines whether your project succeeds or fails: choosing the right manufacturing partner. The quality of your final custom CNC metal cutting results depends entirely on the capabilities, expertise, and reliability of the shop producing your parts.

Here's the reality many engineers discover too late: not all CNC fabrications shops are created equal. According to WMTCNC, the CNC supplier you select plays a vital role in your value chain—beyond simply producing parts, they influence your speed to market, product reliability, and overall profitability. A wrong choice can result in delays, quality issues, or budget overruns that damage customer trust and internal efficiency.

So how do you separate qualified steel fabricators from shops that will struggle with your requirements? The answer lies in systematic evaluation of certifications, capabilities, and communication practices.

Certifications That Matter for Your Industry

Certifications reveal whether a manufacturer operates with documented quality systems—or simply claims to. For regulated industries, specific certifications aren't optional: they're requirements your supply chain must meet.

ISO 9001 represents the baseline. This internationally recognized standard indicates a company maintains structured quality management processes with documented procedures, regular audits, and continuous improvement practices. If a potential supplier lacks ISO 9001, proceed with caution—even for non-critical components.

IATF 16949 builds on ISO 9001 with automotive-specific requirements. According to Advisera, IATF 16949 adds many requirements around process design and control, competence for specific individuals, statistical tools, and measurement system analysis. This certification demonstrates automotive-grade quality systems capable of meeting the demanding requirements of chassis, suspension, and structural component production.

For automotive applications, IATF 16949 certification isn't merely impressive—it's often mandatory for tier-one and tier-two suppliers. Manufacturers like Shaoyi (Ningbo) Metal Technology maintain this certification specifically because automotive OEMs require documented quality systems that go beyond general ISO standards.

AS9100D addresses aerospace, space, and defense industry needs. This standard focuses on problems such as product safety, configuration management, and prevention of counterfeit parts. If your components will fly, AS9100D certification indicates the manufacturer understands the zero-defect mentality aerospace applications demand.

Beyond quality management certifications, consider:

- NADCAP: Special process accreditation for heat treatment, chemical processing, and non-destructive testing

- ITAR Registration: Required for defense-related work with export-controlled technical data

- ISO 13485: Medical device quality management systems

When evaluating metal fabricators near me or searching for fabrication shops near me, always verify certifications directly. Request copies of current certificates and confirm the scope covers the processes you need.

Evaluating Manufacturer Capabilities

Certifications confirm quality systems exist—but capabilities determine whether a shop can actually produce your parts. According to WMTCNC, evaluate whether the supplier uses advanced CNC lathes, milling machines, grinders, and coordinate measuring machines (CMMs), and verify their technical team is proficient with CAD/CAM tools and skilled in multi-axis machining.

Equipment matters significantly. A shop running older three-axis machines may struggle with geometries that five-axis equipment handles routinely. Ask about:

- Machine types and axis capabilities: Three-axis, four-axis, or five-axis machining centers

- Envelope sizes: Maximum part dimensions the equipment can accommodate

- Automation level: Robotic loading, pallet changers, and lights-out manufacturing capabilities

- Inspection equipment: CMMs, optical comparators, surface finish measurement tools

Material expertise is equally critical. Not every steel fabrication shop handles titanium or exotic alloys competently. Ask whether they regularly work with your specific material and understand its machining characteristics. Shops experienced with your material type will quote more accurately and produce better results.

One often-overlooked capability? Rapid prototyping and DFM support. The best manufacturing partners don't just make parts—they help you design better parts. Comprehensive DFM support reduces revision cycles by identifying manufacturability issues before production begins. Look for manufacturers offering rapid prototyping capabilities, such as 5-day turnaround, that enable faster product development cycles without compromising quality.

Questions to Ask Potential Suppliers

Before committing to a manufacturing partner, gather the information you need to make an informed decision. According to W.H. Bagshaw, the quality of your final product depends on the quality of your precision-machined parts, so you can't afford to work with just any provider.

Ask these essential questions when evaluating any potential supplier for your custom metal work:

- What are your typical lead times for similar parts? Understand standard timelines and whether expedited options exist.

- What minimum order quantities do you require? Some shops focus on production volumes while others welcome prototype quantities.

- Do you offer prototyping services? Rapid prototyping—ideally in five days or less—enables design validation before committing to production tooling.

- What secondary operations can you perform in-house? Shops handling finishing, assembly, and inspection internally reduce logistics complexity and lead times.

- Do you outsource any part of the machining process? Outsourcing adds lead time and potential quality variability.

- What documentation do you provide? Material certifications, inspection reports, and first-article documentation matter for regulated industries.

- What is your quote turnaround time? Manufacturers offering fast quote response—such as 12-hour turnaround—demonstrate operational efficiency that typically extends to production.

- Do you offer inventory stocking programs? For ongoing production needs, blanket orders and Kanban programs reduce per-order costs.

- What CAD file formats do you accept? Confirm compatibility with your design software.

- Can you provide references from similar projects? Speaking with existing customers reveals real-world performance.

Assessing Communication and Responsiveness

Technical capabilities mean nothing if you can't communicate effectively with your supplier. WMTCNC emphasizes judging a manufacturer's ability to understand technical drawings, provide DFM feedback, and suggest machining alternatives—responsive, clear communication ensures you won't be left in the dark when issues arise.

Pay attention during your initial interactions. Does the supplier ask clarifying questions that demonstrate they understand your requirements? Do they provide thoughtful feedback on your design, or simply quote what you send? The best partners function as extensions of your engineering team.

Response time matters throughout the relationship. If obtaining a quote takes weeks, expect similar delays during production. Manufacturers demonstrating quick response capabilities—like 12-hour quote turnaround—typically maintain that responsiveness when you need production updates or have questions about your order.

Verifying Quality Inspection Processes

Quality inspection determines whether your parts actually meet specifications. WMTCNC recommends asking about inspection tools—pin gauges, micrometers, CMMs—and requesting samples or inspection reports. Proper QC documentation is crucial for regulated industries like aerospace or automotive.

Key quality questions include:

- What inspection equipment do you use, and is it regularly calibrated?

- Do you perform in-process inspection or only final inspection?

- What first-article inspection documentation can you provide?

- How do you handle non-conforming parts?

- What is your process for corrective action when quality issues arise?

For custom stainless steel parts or other precision components, confirm the shop's inspection capabilities match your tolerance requirements. Shops claiming precision machining capabilities should have CMMs and environmental controls that support accurate measurement.

Finding Qualified Manufacturers

When searching for small metal fabrication near me or custom fab near me, consider expanding your geographic search. The best manufacturer for your project may not be the closest one. Modern logistics make shipping economical for most parts, and quality differences between shops often outweigh minor shipping cost variations.

Online directories, industry associations, and referrals from colleagues provide starting points. However, always verify capabilities through direct conversation and, ideally, facility visits for significant production programs.

WMTCNC suggests a practical validation approach: start with a prototype project. It's the fastest way to verify a supplier's true ability, process discipline, and quality mindset before scaling into full production. A small initial order reveals communication patterns, actual lead time performance, and part quality without risking a large production commitment.

Building Long-Term Partnerships

The goal isn't finding a vendor for a single order—it's identifying a manufacturing partner who grows with your needs. WMTCNC notes that a trustworthy supplier becomes a long-term extension of your team, capable of supporting rapid innovation and sustained excellence.

Look for manufacturers who invest in continuous improvement, maintain modern equipment, and demonstrate genuine interest in your project's success. The best relationships develop when both parties benefit from collaboration—you receive quality parts on time, and they earn reliable, ongoing business.

With evaluation criteria understood and questions prepared, you're positioned to select a manufacturing partner confidently. The final step? Preparing your project for production and moving from concept to completed parts—which we'll cover in the next section.

Taking Your Next Steps in Custom Metal Fabrication

You've absorbed a comprehensive education in custom CNC metal cutting—from understanding fundamental processes to evaluating manufacturing partners. Now it's time to transform that knowledge into action. Whether you're developing a prototype for validation or planning production quantities, the path forward follows a logical sequence that ensures success.

Think of your project as a series of interconnected decisions, each building on the previous. Process selection depends on your part geometry. Material choice aligns with application requirements. Tolerance specifications match functional needs. And your manufacturing partner must demonstrate capabilities that support every requirement you've identified.

Let's synthesize everything into actionable steps you can follow immediately.

Your Custom CNC Project Checklist

Before requesting quotes or contacting manufacturers, ensure you've addressed each critical element. This preparation dramatically accelerates the quoting process and prevents costly misunderstandings during production.

- Finalize your design files. Export production-ready 3D models in STEP or native CAD formats. According to MakerVerse, projects with complete files get quoted and produced faster—upload only final geometry without assemblies or reference parts, and use clear versioned filenames like "Bracket_7075_V3.step."

- Prepare supporting documentation. Create 2D technical drawings specifying key dimensions, tolerances following ISO 2768 or ASME Y14.5 standards, thread specifications (e.g., M6 × 1), and surface finish requirements. Include revision numbers and dates for traceability.

- Specify material and alloy grade. Don't just request "aluminum"—specify 6061-T6, 7075-T651, or your exact alloy requirement. For custom stainless steel parts, indicate whether you need 304, 316L, or another grade based on your corrosion and strength requirements.

- Define surface finish requirements. Determine whether each surface needs as-machined, bead-blasted, anodized, or powder-coated treatment. Remember that different surfaces can receive different finishes—specify precisely where each applies.

- Establish tolerance specifications. Apply tight tolerances only where function demands them. Call out critical dimensions explicitly in your technical drawings while allowing standard tolerances elsewhere to optimize costs.

- Determine quantity and production timeline. Prototype quantities, initial production runs, and ongoing volume needs each affect pricing and lead time. Communicate your full requirements including potential future volumes.

- Identify certification requirements. If your industry requires specific documentation—mill test reports, first-article inspection, IATF 16949 compliance for automotive, or AS9100 for aerospace—specify these upfront.

- Request quotes from qualified manufacturers. Contact multiple suppliers who demonstrate relevant certifications, appropriate equipment capabilities, and material expertise matching your project needs.

According to FVMT, submitting RFQs with missing information slows down the quoting process or leads to inaccurate quotes. Use this checklist to ensure you've covered all the bases before reaching out to potential partners.

Moving from Concept to Production

With your documentation prepared, the path from concept to finished parts fabrication becomes straightforward. Each step builds logically on your preparation work.

Submit Complete Quote Requests

Send your 3D files, technical drawings, material specifications, and quantity requirements together. The more complete your submission, the faster you'll receive accurate pricing. Manufacturers offering quick quote turnaround—such as 12-hour response—demonstrate operational efficiency that typically extends throughout production.

Evaluate Quotes Critically

Compare not just price, but lead time, included finishing operations, inspection documentation, and shipping terms. The lowest quote often excludes elements that higher-priced competitors include. Ensure you're comparing equivalent scopes.

Validate with Prototypes

For new designs, start with prototype quantities before committing to production volumes. Rapid prototyping capabilities—ideally 5-day turnaround or faster—enable design validation without extended delays. This small investment often prevents expensive corrections during production.

Leverage DFM Support

The best manufacturing partners review your design and suggest improvements before production begins. Comprehensive DFM support identifies manufacturability issues, recommends cost-saving modifications, and reduces revision cycles. This collaborative approach delivers better parts faster.

Confirm Documentation Requirements

Before production begins, confirm exactly what documentation you'll receive: material certifications, dimensional inspection reports, first-article approvals. For custom metal work in regulated industries, documentation requirements should be explicitly agreed upon.

Plan for Scale

If your prototype succeeds, you'll need production quantities. Discuss volume pricing, blanket order programs, and inventory stocking options early. Manufacturers positioned for both prototyping and mass production simplify this transition.

Putting Your Knowledge Into Action

You now possess the knowledge to navigate custom metal cutting projects confidently. You understand which cutting processes match specific geometries, how material selection affects performance and cost, why proper tolerance specification matters, and what distinguishes qualified manufacturers from those who'll struggle with your requirements.

The metal fab industry rewards prepared customers. Complete documentation, clear specifications, and informed questions position you as a customer manufacturers want to serve well. Your parts arrive faster, meet specifications consistently, and cost less when you've done the preparation work upfront.

For automotive and precision metal component needs, manufacturers offering comprehensive services—from rapid prototyping through automated mass production—streamline the entire journey from design to delivery. Look for partners demonstrating IATF 16949 certification, quick quote turnaround, and genuine DFM expertise to optimize your custom cut metal projects.

Your next step? Take that design file you've been developing, prepare the documentation using this checklist, and request quotes from qualified manufacturers. The path from concept to production-ready parts is clearer than ever—and you're ready to walk it confidently.

Frequently Asked Questions About Custom CNC Metal Cutting

1. How much does CNC cutting usually cost?

Custom CNC metal cutting costs depend on six primary factors: raw material type and volume, machine time (3-axis milling runs $35-50/hour while 5-axis costs $75-120/hour), programming and setup costs amortized across your order quantity, tooling wear rates based on material hardness, finishing operations like anodizing or powder coating, and quality inspection requirements. Simple parts in small runs typically cost $10-50 per part, while precision-engineered components may exceed $160 each. Ordering in batches significantly reduces per-unit costs—ten units instead of one can cut costs by 70%. IATF 16949-certified manufacturers like Shaoyi Metal Technology offer 12-hour quote turnaround to help you understand exact pricing quickly.

2. How much does metal cutting cost?

Metal cutting costs vary based on the cutting method, material type, and thickness. Sheet cutting ranges from $0.50 to $2 per linear inch or $20-30 per hour depending on the technique. Laser cutting excels for thin sheet profiles with speeds up to 2,500 inches per minute, making it economical for 2D parts. Waterjet cutting costs more due to slower speeds but eliminates heat-affected zones for sensitive materials. CNC milling handles 3D geometries at moderate speeds with excellent precision. For cost optimization, consider relaxing non-critical tolerances, consolidating features, and ordering in batch quantities to amortize setup costs across more parts.

3. How much does custom sheet metal fabrication cost?

Custom sheet metal fabrication averages $4-48 per square foot depending on material selection, complexity, and finishing requirements. Aluminum sheet metal costs less and machines faster than stainless steel, which requires specialized tooling and slower feed rates. Factors affecting your total include material grade (6061 aluminum vs. 316 stainless steel), tolerance specifications (standard ±0.005" vs. precision ±0.001"), surface finishes (as-machined, anodized, or powder-coated), and order quantity. Manufacturers offering comprehensive DFM support can identify design optimizations that reduce costs by 15-40% without sacrificing quality or function.

4. What is the difference between CNC milling and laser cutting?

CNC milling uses rotating cutters to remove material from a workpiece, creating three-dimensional features like pockets, contours, and machined surfaces. Laser cutting uses a focused light beam to cut 2D profiles from sheet stock at extremely high speeds. Choose CNC milling when your part requires 3D features, threaded holes, varying depths, or complex geometries. Select laser cutting for flat profiles from sheet material where speed and economy matter most. Many projects combine both technologies—laser cutting profiles quickly, then CNC machining critical features where precision is essential.

5. How do I choose the right CNC manufacturing partner?

Evaluate potential manufacturers based on certifications (ISO 9001 minimum, IATF 16949 for automotive, AS9100 for aerospace), equipment capabilities (3-axis vs. 5-axis machining), material expertise with your specific alloys, and communication responsiveness. Ask about lead times, minimum order quantities, prototyping capabilities, secondary operations offered, and documentation provided. Look for partners offering rapid prototyping (5-day turnaround), comprehensive DFM support to reduce revision cycles, and quick quote response times. Starting with a prototype order validates a supplier's actual performance before committing to production volumes.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —