Metal Plate Cutting Demystified: 3 Methods That Save Time And Money

Understanding Metal Plate Cutting Fundamentals

When you're working with steel or other metals, the first step in any fabrication project often determines its success. Metal plate cutting is the process of separating thick metal stock into precise shapes and sizes using specialized equipment. But what does steel cut mean in practical terms? It's the foundation that makes everything else possible—from structural beams in skyscrapers to precision components in heavy machinery.

Think of it this way: before any welding, bending, or assembly can happen, raw material must be transformed into workable pieces. The accuracy of these initial metal cuts directly impacts every downstream process, affecting fit-up quality, weld integrity, and final product performance.

What Sets Plate Cutting Apart from Sheet Metal Work

Here's where terminology matters. Not all metal cutting is the same, and understanding the distinction between cutting plate and sheet metal work will help you choose the right approach for your project.

According to industry standards outlined by Polished Metals, the key difference comes down to thickness:

- Sheet metal: Typically ranges from 0.5 mm to 6 mm thick, measured in gauges

- Plate metal: Exceeds 6 mm in thickness, often measured in inches

Sheet metal is highly adaptable, malleable, and cost-effective for applications like automotive panels and roofing. Plate cutting, on the other hand, deals with significantly sturdier material used in construction, bridge building, and heavy equipment manufacturing where strength is paramount.

This thickness difference isn't just a technicality—it fundamentally changes which steel cutting methods you'll use and what equipment is required.

Why Precision Cutting Matters in Fabrication

Imagine assembling a puzzle where the pieces don't quite fit. That's what happens when metal cutting lacks precision. According to fabrication experts at Sizemore Welding, poorly cut components create alignment problems, increase rework, and can result in structural deficiencies.

Precise plate cutting delivers tangible benefits throughout the fabrication workflow:

- Tighter tolerances that ensure parts fit together correctly

- Better weld quality thanks to clean, straight edges

- Reduced material waste from accurate cuts and optimized nesting

- Faster assembly times with components that align on the first attempt

When you're cutting metal for critical or load-bearing applications, mistakes at this early stage cause cascading issues throughout production. Quality cuts minimize these risks and ensure every part performs as intended—setting the stage for the specific cutting methods we'll explore next.

Thermal Cutting Methods Explained

When you need to slice through thick steel plate, heat becomes your most powerful ally. Thermal cutting methods use extreme temperatures—sometimes reaching 40,000 degrees Fahrenheit—to melt, vaporize, or oxidize metal along a precise path. These processes dominate industrial steel plate cutting because they handle heavy materials quickly and efficiently.

But here's the challenge: each thermal method brings unique strengths and trade-offs. Understanding these differences helps you select the right approach for your specific project, whether you're fabricating structural components or creating precision parts.

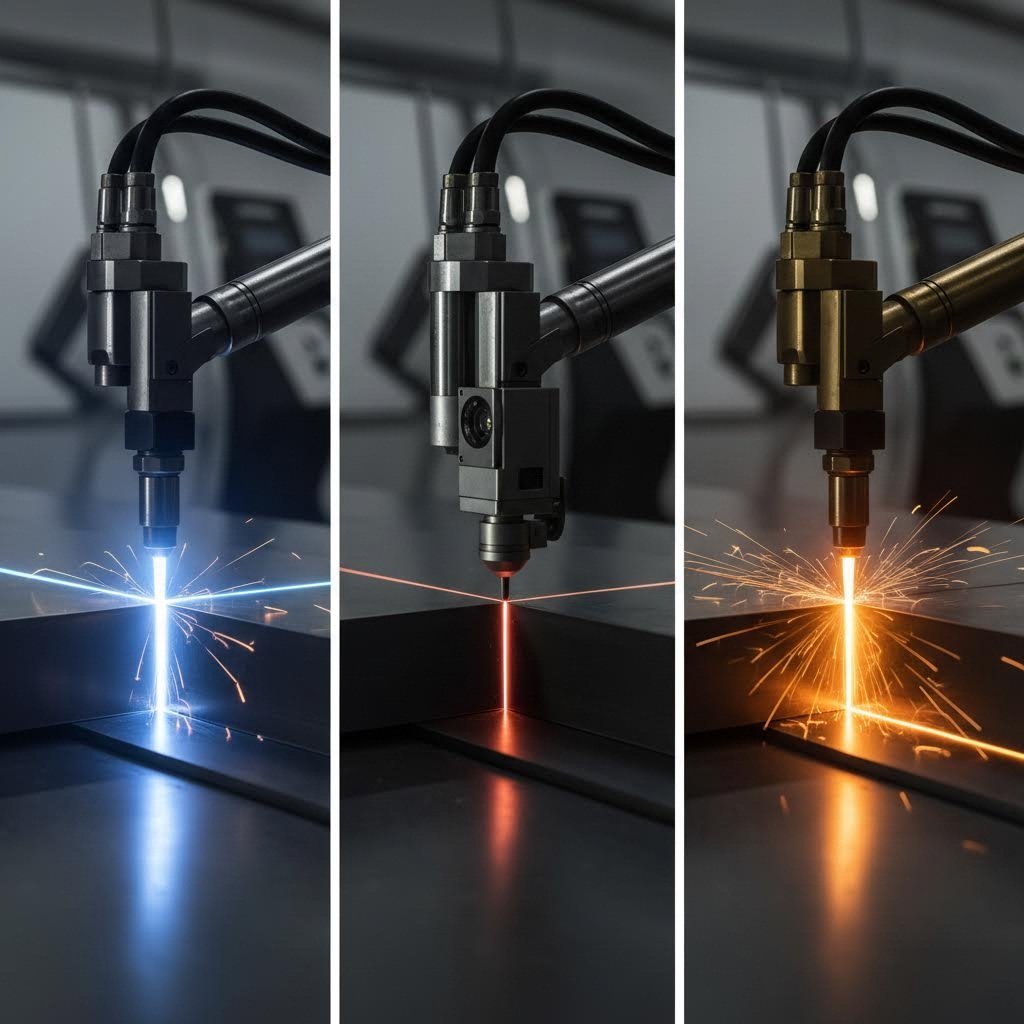

Plasma Cutting for Speed and Versatility

Plasma cutting uses ionized gas forced through a concentrated nozzle to create an electrically conductive arc capable of cutting steel plate at remarkable speeds. According to Koike Aronson, the plasma stream reaches temperatures near 40,000 degrees Fahrenheit—hot enough to melt through metal almost instantly.

What makes plasma stand out for cutting steel plate? It's the combination of speed and material flexibility. Unlike some methods limited to specific metals, plasma handles carbon steel, stainless steel, aluminum, and other conductive materials with ease. This versatility has made it a staple in construction, automotive manufacturing, and metal fabrication shops.

Key advantages of plasma cutting include:

- Fast cutting speeds on medium-thickness materials

- Works on multiple metal types—not just steel

- Lower equipment costs compared to laser systems

- Portable options available for field applications

The trade-off? Plasma produces a wider kerf (cut width) than laser and creates a moderate heat-affected zone. For projects requiring ultra-fine detail or extremely tight tolerances, you may need to consider alternatives.

Laser Cutting Steel Sheet for Precision Work

When precision matters most, laser cutting steel sheet delivers results that other methods simply can't match. High-powered laser beams—either CO2 or fiber lasers—focus intense energy on a tiny point, melting or vaporizing material with surgical accuracy.

Fiber lasers, in particular, represent cutting edge steel technology. They offer exceptional energy efficiency and can produce extremely fine, intricate cuts. The aerospace industry relies heavily on laser cutting for lightweight, durable components that must meet stringent safety standards.

Why choose laser for your project?

- Superior edge quality with minimal post-processing needed

- Tight tolerances for precision applications

- Narrow kerf reduces material waste

- Excellent for complex shapes and detailed patterns

Laser cutting creates the smallest heat-affected zone among thermal methods. As noted by Fractory, this matters because the HAZ occurs where metal experiences structural changes without actually melting—changes that can weaken your final product. Laser's narrow kerf means heat concentrates in a smaller area, minimizing these effects.

The primary limitation? Equipment costs run significantly higher than plasma or oxy-fuel systems, making laser most economical for high-precision work or production environments where quality justifies the investment.

Oxy-Fuel and Flame Cut Steel Plate Applications

For thick steel plate—especially carbon steel measuring several inches deep—oxy-fuel cutting remains the workhorse of heavy industry. This torch cut steel method combines fuel gas (acetylene, propane, or natural gas) with pure oxygen to create an exothermic reaction that literally burns through metal.

Here's how it works: the flame heats steel to its ignition temperature, then a stream of pure oxygen causes rapid oxidation. This reaction generates intense heat that melts the material while the oxygen stream blows molten slag away, creating the cut.

Flame cut steel plate applications dominate in:

- Shipbuilding—cutting massive hull sections

- Heavy construction—preparing structural steel

- Oil and gas—fabricating pipeline components

- Demolition—dismantling large steel structures

Oxy-fuel equipment costs remain the lowest of all thermal methods, and the process excels with very thick material. However, this true steel cutting technique produces the widest heat-affected zone and works only on carbon steel—not stainless steel or aluminum.

Comparing Thermal Cutting Methods

Choosing between plasma, laser, and oxy-fuel depends on your specific requirements. This comparison breaks down the key factors:

| Factor | Plasma Cutting | Laser Cutting | Oxy-Fuel Cutting |

|---|---|---|---|

| Material Thickness | Thin to thick (up to 2+ inches) | Best for thin to medium; fiber lasers handle thicker material | Excellent for very thick plate (6+ inches) |

| Cut Quality/Edge Finish | Good; may require secondary finishing | Excellent; minimal post-processing | Rougher edges; typically needs grinding |

| Cutting Speed | Fast on medium thicknesses | Very fast on thin materials | Slower; best for thick sections |

| Equipment Cost | Moderate | High | Low |

| Heat-Affected Zone | Moderate | Narrow (smallest) | Wide (largest) |

| Best Use Cases | Fabrication shops, construction, automotive repair | Aerospace, precision components, detailed patterns | Shipbuilding, heavy construction, thick carbon steel |

Understanding the Heat-Affected Zone

Every thermal cutting method creates a heat-affected zone—and understanding this phenomenon is critical if you plan to weld your cut pieces afterward.

The HAZ forms between the melted cutting edge and unaffected base metal. In this zone, extreme temperatures change the metal's microstructure without actually melting it. According to Fractory's engineering analysis, these structural changes can reduce strength, alter hardness, and affect fatigue resistance.

Why does this matter for your project? The weakest sections of any welded structure exist in the HAZ. If you're fabricating load-bearing components, overlooking this zone could compromise structural integrity.

Key HAZ considerations:

- Flame cutting and arc welding produce the widest HAZ

- Plasma cutting creates a moderate zone that can be minimized with faster speeds

- Laser cutting generates the narrowest HAZ due to its concentrated heat application

- Thin materials heat up more quickly, creating larger affected zones relative to thickness

Speed matters here. Faster cutting reduces heat exposure time, resulting in a narrower HAZ. For applications requiring maximum strength retention, laser cutting or mechanical methods that generate no HAZ—like waterjet cutting—may be worth considering.

Mechanical and Waterjet Cutting Techniques

What if you need to cut metal without any heat distortion whatsoever? Thermal methods aren't your only option. Mechanical cutting approaches—including saws, shears, and waterjet systems—eliminate the heat-affected zone entirely, preserving your material's original properties from edge to edge.

These methods work differently than plasma or laser. Instead of melting metal, they physically remove or separate material through abrasion, shearing force, or high-pressure erosion. For heat-sensitive alloys, hardened steel, or applications where structural integrity is non-negotiable, mechanical and waterjet techniques often deliver superior results.

Steel Cut Off Saws and Band Saw Applications

When you need clean, straight cuts through solid bar stock or structural sections, saws for cutting steel remain indispensable. Two primary types dominate metal fabrication: cold saws and band saws—each with distinct advantages depending on your application.

A steel cut off saw (cold saw) uses an abrasive disc spinning at high speeds up to 3,000 RPM to slice through material. According to Penn Tool Co., cold saw blades are primarily designed for cutting steel, aluminum, and other metals, delivering precise cuts with minimal burring or material deformation.

Band saws take a different approach. They use a continuous loop of toothed metal blade stretched over two or more wheels, with tension adjusted based on material type and desired cut. This saw for steel cutting excels at following complex patterns and curves that would challenge rigid circular blades.

Key advantages of metal sawing methods:

- No heat-affected zone—material properties remain unchanged

- Excellent for bar stock and structural shapes—tubes, angles, channels

- Precise, repeatable cuts—ideal for production environments

- Lower operating costs—consumable blades are economical

- Versatile material handling—band saws cut wood, plastics, and composites too

The trade-off? When you saw steel, you're limited primarily to straight-line cuts through stock material. Complex shapes require multiple cuts or alternative methods. Speed also lags behind thermal processes for thicker sections, though the quality and consistency often justify the extra time.

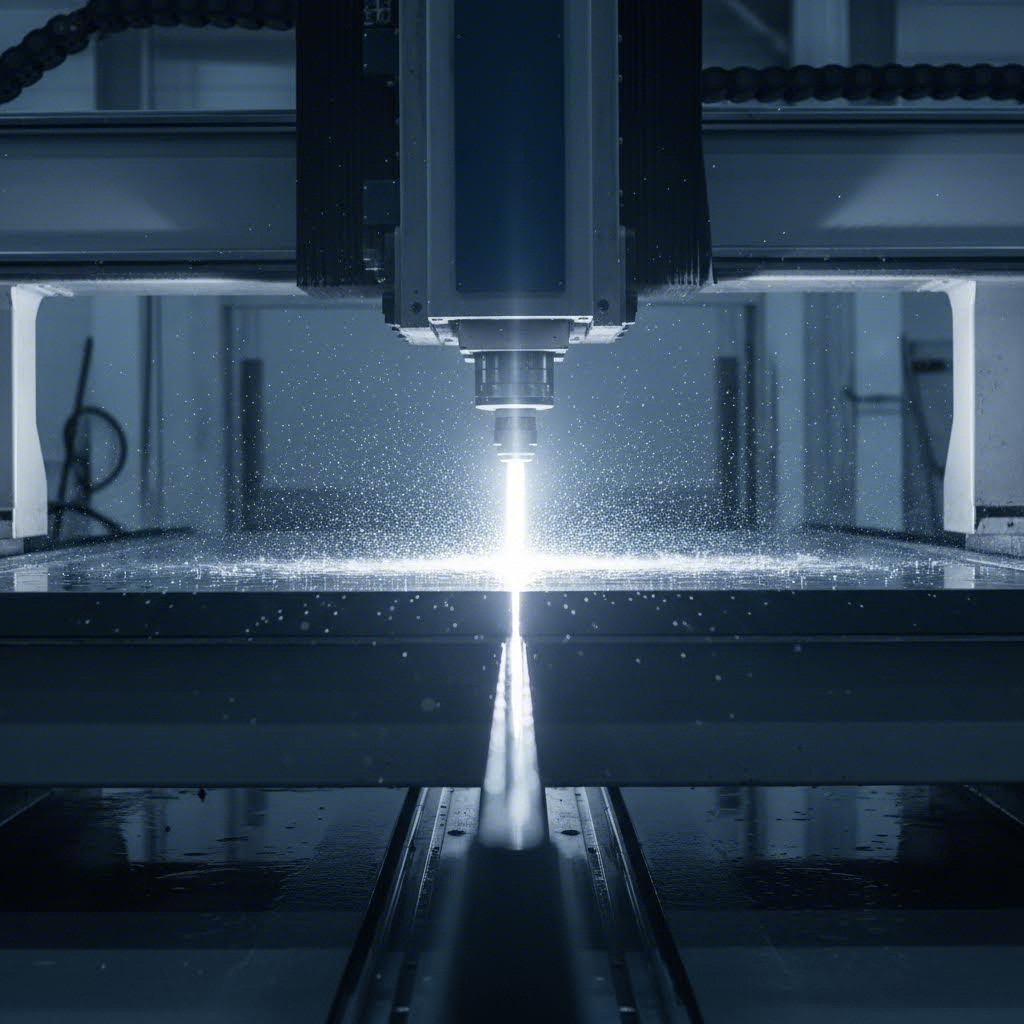

Water Cutting Steel Without Heat Distortion

Imagine cutting through six inches of hardened steel—with water. It sounds impossible, but hydro cutting steel has revolutionized precision fabrication by combining extreme pressure with abrasive particles to slice through virtually any material.

A water pressure cutter generates streams at 3,500 to 6,000 bar (50,000 to 87,000 PSI), according to STM Waterjet. At these pressures, water mixed with garnet abrasive becomes a precision cutting tool capable of handling material thicknesses up to 300 mm—far exceeding most thermal methods.

Why is water cutting steel gaining popularity? The cold cutting process eliminates every thermal disadvantage:

- Zero heat-affected zone—no distortion, deformation, or structural changes

- Cuts hardened materials—titanium, hardened steel, and exotic alloys pose no problem

- Highest precision available—cutting accuracy of +/- 0.1 mm

- Clean, burr-free edges—often requires no secondary finishing

- Environmentally friendly—no toxic fumes, gases, or hazardous waste

- Omnidirectional cutting—the jet cuts from any angle regardless of material orientation

The technology proves particularly valuable for aerospace components, precision prototypes, and any application where heat sensitivity matters. Complex geometries, intricate patterns, and bevel cuts up to 68 degrees are all achievable with modern CNC-controlled waterjet systems.

What about speed? Waterjet cutting typically achieves 65 to 200 mm per minute on metals—slower than plasma on thin materials but competitive with oxy-fuel on thick sections. The precision and material versatility often outweigh speed considerations for critical applications.

Shearing for Straight-Line Production Cuts

Need to process high volumes of straight-edged blanks quickly? Shearing offers unmatched efficiency for straight-line production cuts through sheet and plate material.

Shear machines work like industrial scissors—upper and lower blades pass each other with minimal clearance, fracturing material along a straight line. The process is fast, produces minimal waste, and requires no consumables beyond occasional blade sharpening.

Advantages of shearing include:

- Fastest straight-cut method—ideal for high-volume blanking

- No material waste—unlike thermal or abrasive methods, no kerf removes material

- Cold process—zero HAZ or thermal distortion

- Low operating costs—minimal consumable expense

- Clean edges—ready for immediate downstream processing

Shearing's limitations are equally clear: it handles only straight cuts, maximum thickness depends on machine capacity, and edge quality varies with material hardness. For complex shapes or very thick plate, you'll need to combine shearing with other cutting methods—a workflow consideration that leads directly into selecting the right approach for your specific project requirements.

Power Tools and Workshop Cutting Solutions

Not every metal cutting project requires industrial machinery. Sometimes you're working in a small shop, tackling on-site repairs, or fabricating one-off pieces where hauling material to a service center doesn't make sense. That's where handheld power tools become invaluable—they bring metal plate cutting capability directly to your workbench or job site.

But here's the catch: choosing the wrong tool for your specific project leads to poor cuts, excessive time, or safety hazards. Understanding which workshop tools handle different materials and thicknesses helps you work smarter, not harder.

Choosing the Best Tool to Cut Metal for Your Project

When you're standing in front of a steel plate wondering how to proceed, the best tool to cut metal depends on several factors: material thickness, cut complexity, available workspace, and desired edge quality. Each tool excels in specific scenarios.

Here's how common workshop tools rank by versatility and typical applications:

- Angle grinder—The most versatile metal cutter saw for workshop use. Handles everything from thin sheet to moderately thick plate, performs straight cuts, curve cuts, and grinding operations. Ideal for steel, stainless steel, and aluminum with appropriate disc selection.

- Reciprocating saw—Excellent for demolition work, cutting in tight spaces, and on-site jobs. According to Tampa Steel and Supply, it starts quickly with minimal downtime and cuts through various materials and thicknesses with the right blade.

- Band saw (benchtop)—Superior for straight cuts through bar stock, tubing, and structural shapes. Provides cleaner edges than abrasive methods with no heat distortion.

- Metal cutting jigsaw—Best for intricate curves and detailed patterns in thinner materials. Offers excellent control for decorative metalwork and custom shapes.

- Circular saw with metal blade—Efficient for long, straight cuts through sheet material. Tampa Steel notes you can switch out blades for different applications, though it's limited to straight-line work.

The best cutting tool for metal isn't always the most powerful—it's the one matched to your specific task. A metal saw cutter designed for demolition won't deliver the precision needed for finish work, just as a jigsaw struggles with thick plate that an angle grinder handles easily.

Angle Grinder Techniques for Steel Plate

Want to know how to cut steel with an angle grinder effectively? This versatile tool dominates workshop metal cutting, but success depends on proper technique and disc selection.

According to OneVan Tool, choosing the right cutting wheel is your first critical decision. Different disc types serve different purposes:

- Type 1 (flat wheel)—Most common profile for cutting discs, providing a fine cutting surface for basic metal cutting

- Type 27 (depressed center)—Perfect for cutting tight curves and reaching hard-to-access areas

- Type 41—Features flat center with nut and washer mounting, commonly used for cutting applications

Disc material matters just as much as profile. Benchmark Abrasives explains that aluminum oxide grains work excellently for grinding stainless steel, hard steel, iron, and other metals, offering fast cut rates with extended lifespan. For hardened materials like titanium or nickel alloys, ceramic-based wheels deliver superior performance with their self-sharpening crystalline structure.

Thickness selection also impacts results:

- Thin blades (1.6 mm)—Ideal for intricate cuts and tight spaces; faster cutting but shorter lifespan

- Standard thickness (3 mm)—Perfect balance of stability, blade life, and versatility for general-purpose work

- Thick blades (4.5 mm+)—Heavy-duty cutting through thick metals; generates more heat from increased friction

For clean cuts, follow these technique tips:

- Mark your cutting line precisely using a marker or scribe

- Secure the workpiece firmly with clamps or a vise—never cut unsecured material

- Maintain a firm two-handed grip on the grinder

- Apply gentle, steady pressure—let the disc do the work

- Guide the grinder along your marked line without abrupt movements

- Allow the blade to cool periodically during thick cuts to prevent overheating

Metal Cutting Jigsaws and Reciprocating Saws

When curves and complex shapes matter more than raw power, a metal cutting jigsaw becomes your go-to cutting tool for metal. These precision tools excel where angle grinders struggle—intricate patterns, interior cutouts, and detailed decorative work.

Jigsaws work best on thinner materials where their fine-toothed blades can navigate tight radii. The key to success lies in blade selection:

- Bi-metal blades—Combine flexibility with durability for general steel cutting

- Carbide-tipped blades—Handle abrasive metals and provide longer life

- Fine-tooth designs (18-24 TPI)—Deliver smoother cuts in thin sheet metal

- Coarse-tooth options (8-10 TPI)—Cut faster through thicker material but with rougher edges

Reciprocating saws—sometimes called sawzalls—take a different approach. According to Tampa Steel, they function like motorized hacksaws, making quick work of demolition, pipe cutting, and on-site modifications. The rapid startup reduces downtime, and blade changes take seconds.

These tools share a limitation: both are best suited for straight cuts, though skilled operators can navigate gentle curves. For complex profiles requiring tight tolerances, you may need to consider professional steel plate cutting services.

When to DIY vs. When to Outsource

Workshop tools handle many cutting tasks effectively, but knowing their limits saves time and money. Consider outsourcing to professional services when:

- Material exceeds 1/4 inch thickness—Handheld tools struggle with heavy plate

- Precision tolerances are tight—CNC equipment delivers repeatability manual methods can't match

- Volume is high—Production runs justify automated cutting costs

- Complex nesting optimizes material—Professional software minimizes waste on expensive alloys

- Edge quality is critical—Downstream welding or finishing may require cleaner cuts than workshop tools provide

For smaller operations, the decision often comes down to economics: can you complete the cut efficiently with available equipment, or does the time and material waste exceed what a cutting service would charge? This calculation becomes even more important when selecting the right cutting method for your specific project requirements.

Selecting the Right Cutting Method for Your Project

You've explored thermal methods, mechanical techniques, and workshop tools—but how do you actually decide which approach fits your specific project? Choosing the best way to cut metal isn't about finding a single "best" method. It's about matching capabilities to requirements: your material, thickness, volume, edge quality needs, and downstream processes.

Think of method selection as solving a puzzle. Each variable—thickness, precision, speed, budget—eliminates certain options while favoring others. Get this decision right, and you'll save time, reduce waste, and produce parts ready for the next fabrication step. Get it wrong, and you're looking at rework, delays, or compromised quality.

Matching Cutting Methods to Material Thickness

Material thickness is often your first decision filter. Some methods excel with thin sheet while struggling with thick steel plate—and vice versa. Here's how to cut steel plate based on what you're working with:

Thin sheet (under 6 mm): Laser cutting dominates this range. The concentrated beam handles intricate patterns with minimal heat distortion, and speed advantages maximize productivity. Shearing works excellently for straight-line blanking operations. For workshop projects, jigsaws and angle grinders provide accessible options.

Medium plate (6 mm to 25 mm): Plasma cutting hits its sweet spot here, balancing speed with cost-effectiveness. Waterjet maintains full precision without any HAZ concerns. Band saws handle straight cuts through bar stock and structural sections efficiently.

Thick steel plate (25 mm and beyond): Oxy-fuel remains the workhorse for heavy carbon steel, capable of slicing through material several inches thick. Waterjet systems with sufficient power handle extreme thicknesses while preserving material properties—critical for heat-sensitive alloys or applications requiring zero distortion.

Wondering what's the best way to cut steel sheet for your thin-gauge project? Consider edge requirements alongside thickness. Laser delivers superior finish, but shearing costs less for simple blanks. The best tool to cut metal sheets often depends on shape complexity as much as material gauge.

Production Volume and Speed Considerations

How many parts do you need—and how quickly? Volume dramatically shifts which cutting method makes economic sense.

One-off and prototype work: Speed matters less than flexibility. Waterjet handles nearly any material without tooling changes. Workshop tools work fine for simple shapes. According to SendCutSend's analysis, DIY equipment options provide viable solutions for prototypes and low-volume parts production—but smaller machines take longer to process parts than industrial equipment.

Low to medium volume (10-500 pieces): This range often favors outsourcing. Professional steel plate cutting services spread equipment costs across many customers, delivering per-part economics that DIY setups can't match. Their fiber-optic laser equipment can cut at speeds up to 2,200 inches per minute, producing finished parts in as little as three days.

High volume production: Automation becomes essential. CNC plasma or laser systems with automated material handling maximize throughput. Shearing excels for high-volume blanking of simple shapes. The capital investment justifies itself through consistent quality and reduced labor costs.

Time-to-first-part matters too. As one industry executive noted: "In many cases we can ship finished parts faster than what they can be produced on these newer offerings"—referring to affordable DIY equipment that trades speed for portability and price.

Edge Quality Requirements for Downstream Processes

Here's where many fabricators stumble: they select a cutting method without considering what happens next. Edge quality directly impacts welding, assembly, and finishing operations downstream.

For welding applications: Cut preparation affects joint integrity more than most realize. Rough flame-cut edges require grinding before welding, adding labor and time. Laser-cut edges often weld immediately with proper fit-up. Plasma falls between—acceptable for many structural welds, but precision work may need edge preparation.

For precision assembly: Components that must mate without gaps demand tight tolerances. Waterjet and laser deliver the accuracy needed. Mechanical methods like shearing produce clean edges for straight-line fits. How to cut steel sheet metal for assembly work? Prioritize methods offering +/- 0.1 mm accuracy when tolerances are tight.

For aesthetic applications: Visible edges need different treatment than hidden structural cuts. Waterjet produces smooth, burr-free surfaces requiring minimal finishing. Laser edges show a slight oxidation layer that may need removal. Plasma and oxy-fuel edges typically require grinding for visible applications.

Complete Method Selection Guide

This comprehensive comparison organizes every major cutting method by the factors that matter most for project planning:

| Cutting Method | Material Compatibility | Thickness Range | Edge Quality | Production Speed | Ideal Use Cases |

|---|---|---|---|---|---|

| Laser | Steel, stainless, aluminum, some alloys | Thin to medium (up to 25 mm with fiber) | Excellent—minimal finishing needed | Very fast on thin materials | Precision parts, intricate patterns, aerospace components |

| Plasma | All conductive metals | Thin to thick (up to 50+ mm) | Good—may need light finishing | Fast on medium thicknesses | Fabrication shops, construction, automotive |

| Oxy-Fuel | Carbon steel only | Medium to very thick (150+ mm) | Rough—typically requires grinding | Slow but handles extreme thickness | Shipbuilding, heavy construction, demolition |

| Waterjet | Any material—metals, stone, composites | Up to 300 mm | Excellent—smooth, burr-free | Moderate (65-200 mm/min on metals) | Heat-sensitive materials, precision prototypes, exotic alloys |

| Band Saw | All metals, plus wood and plastics | Limited by blade and machine capacity | Good—clean, straight edges | Moderate | Bar stock, tubing, structural shapes |

| Shearing | Sheet and plate metals | Up to machine capacity (typically 25 mm) | Good—clean for straight cuts only | Very fast for straight lines | High-volume blanking, straight-edge production |

| Angle Grinder | Steel, stainless, aluminum | Thin to moderate plate | Variable—depends on technique | Slow to moderate | Workshop projects, on-site cutting, modifications |

DIY Cutting vs. Professional Services: Making the Call

The decision between handling cuts yourself or outsourcing involves more than equipment capability. According to industry analysis, hidden costs matter significantly: raw materials, storage, recycling, plus the time involved with these activities must factor into your insource vs. outsource calculation.

When DIY makes sense:

- Simple cuts within your equipment's capability

- Immediate need—no time for shipping

- Low quantities where setup costs favor in-house work

- Learning projects where experience matters more than perfection

When professional steel plate cutting services win:

- Precision requirements exceed workshop tool capabilities

- Material thickness or type demands industrial equipment

- Volume justifies per-part pricing advantages

- Complex nesting could significantly reduce expensive material waste

- Tight deadlines—professional shops often deliver faster than DIY processing

Strategic flexibility matters too. Leaving parts production to a trusted partner allows you to focus on design innovation and growth rather than equipment maintenance and material handling. And if there's a problem with a cut part, reputable partners will recut at no additional cost—a guarantee DIY operations can't offer.

Whatever method you choose, one factor remains constant: safety. Each cutting approach brings unique hazards that demand specific protective measures—a critical topic we'll address next.

Safety Considerations and Protective Equipment

Every steel cut you make exposes you to hazards that can cause serious injury—or worse. Burns, radiation exposure, respiratory damage, and hearing loss aren't just theoretical risks. They're real consequences of cutting metal without proper protection. Yet surprisingly, safety guidance remains one of the most overlooked topics in metal fabrication resources.

Here's what you need to know: each cutting method brings unique dangers requiring specific protective measures. What's effective against steel with a plasma cutter differs dramatically from waterjet safety requirements. Understanding these distinctions before you start cutting keeps you working safely for years to come.

Personal Protective Equipment for Each Cutting Method

When deciding what to use to cut metal, your PPE selection must match your chosen method. According to the American Welding Society's Safety Fact Sheet No. 33, protective equipment requirements vary significantly across cutting operations.

Thermal Cutting PPE (Plasma, Laser, Oxy-Fuel):

- Eye and face protection—Helmet with filter lens complying with ANSI Z87.1; safety glasses with side shields worn underneath. Filter shade selection depends on amperage: plasma cutting under 20 amps requires shade 4-5, while higher amperages demand shade 6-8 or welding helmets.

- Head covering—Fire-resistant welder's cap protecting hair and scalp from sparks, spatter, and UV radiation

- Hand protection—Dry, hole-free, insulated leather welding gloves providing heat resistance and burn protection

- Body protection—Oil-free clothing made of wool or heavy cotton; long sleeves with buttoned cuffs; leather aprons, capes, and sleeves as needed

- Foot protection—Leather, steel-toed boots meeting ASTM F2412 and F2413 standards; fire-resistant boot protectors in heavy spark areas

- Hearing protection—Approved earplugs or muffs, especially when working overhead or in enclosed spaces

Mechanical Cutting PPE (Saws, Shears, Grinders):

- Eye protection—Safety glasses with side shields or full-face shield to guard against flying metal fragments, chips, and grinding debris

- Hearing protection—Essential for band saws, angle grinders, and reciprocating saws that generate sustained noise levels exceeding safe thresholds

- Hand protection—Cut-resistant gloves appropriate for material handling; remove loose gloves when operating rotating equipment

- Body protection—Close-fitting clothing without loose ends that could catch in machinery; leather apron for spark protection during grinding

Waterjet Cutting PPE:

- Eye and face protection—Safety glasses or face shield protecting against abrasive particle spray and water mist

- Hearing protection—Required due to high-decibel noise from pressurized water and abrasive flow

- Body protection—Water-resistant clothing; steel-toed boots with slip-resistant soles for wet floor conditions

- Awareness training—Understanding high-pressure stream dangers; never place hands near the cutting head during operation

Ventilation and Fume Management

Cutting steel generates more than sparks and slag—it produces hazardous fumes that pose serious respiratory risks. According to OSHA's welding safety guidelines, workers are often exposed to fumes containing chromium, nickel, manganese, and zinc that cause both acute and chronic respiratory issues.

Metal fume fever represents a particular concern. This flu-like illness results from inhaling zinc oxide fumes common when cutting galvanized steel. Symptoms include chills, fever, nausea, and muscle aches—typically appearing hours after exposure.

Protect yourself with proper ventilation strategies:

- Local exhaust ventilation—Position fume extraction equipment near the cutting point to capture contaminants at their source

- General ventilation—Ensure adequate airflow throughout the workspace; outdoor cutting eliminates many fume accumulation concerns

- Respiratory protection—When ventilation proves inadequate, use NIOSH-approved respirators appropriate for metal fumes

- Material awareness—Know what you're cutting; coated, painted, or plated metals release additional toxic compounds requiring enhanced protection

Plasma cutting demands particular attention. As MCR Safety notes, noise, air quality, and electrocution rank among the most dangerous risks when working with plasma cutters—each capable of causing long-lasting health consequences.

Fire Prevention and Workshop Safety Protocols

Thermal cutting methods transform your workspace into a fire hazard zone. Sparks travel up to 35 feet, and hot slag can smolder for hours before igniting nearby combustibles. According to OSHA requirements, welders must keep workspaces free of combustible materials and follow NFPA 51B hot work safety standards.

Essential fire prevention measures:

- Clear the work area—Remove flammable materials within 35 feet of cutting operations; cover immovable combustibles with fire-resistant blankets

- Fire extinguisher placement—Keep appropriate extinguishers (Class ABC minimum) within immediate reach; know their locations before starting work

- Fire watch duties—OSHA requires a fire watch when combustible materials are closer than 35 feet or when wall or floor openings expose combustibles. Fire watches must remain on-site at least 30 minutes after work ends.

- Hot work permits—For designated areas, obtain proper authorization before cutting operations begin

- Personal preparation—Remove flammables, matches, and lighters from pockets; avoid synthetic fabrics that melt and adhere to skin

Safe material handling for heavy steel plates:

- Use proper lifting techniques or mechanical assistance for plates exceeding comfortable handling weight

- Secure workpieces firmly before cutting—never cut unsupported material

- Position yourself to avoid falling cut pieces

- Allow hot metal cuts to cool before handling; use tongs or heat-resistant gloves when moving warm pieces

- Store scrap and finished pieces to prevent tripping hazards

"Clothing shall provide sufficient coverage, and be made of suitable materials, to minimize skin burns caused by sparks, spatter, or radiation." — ANSI Z49.1 Safety in Welding, Cutting, and Allied Processes

Safety isn't optional—it's the foundation that makes productive metal cutting possible. With proper PPE, ventilation, and fire prevention protocols in place, you're ready to explore how modern CNC integration and automation are transforming cutting operations across the industry.

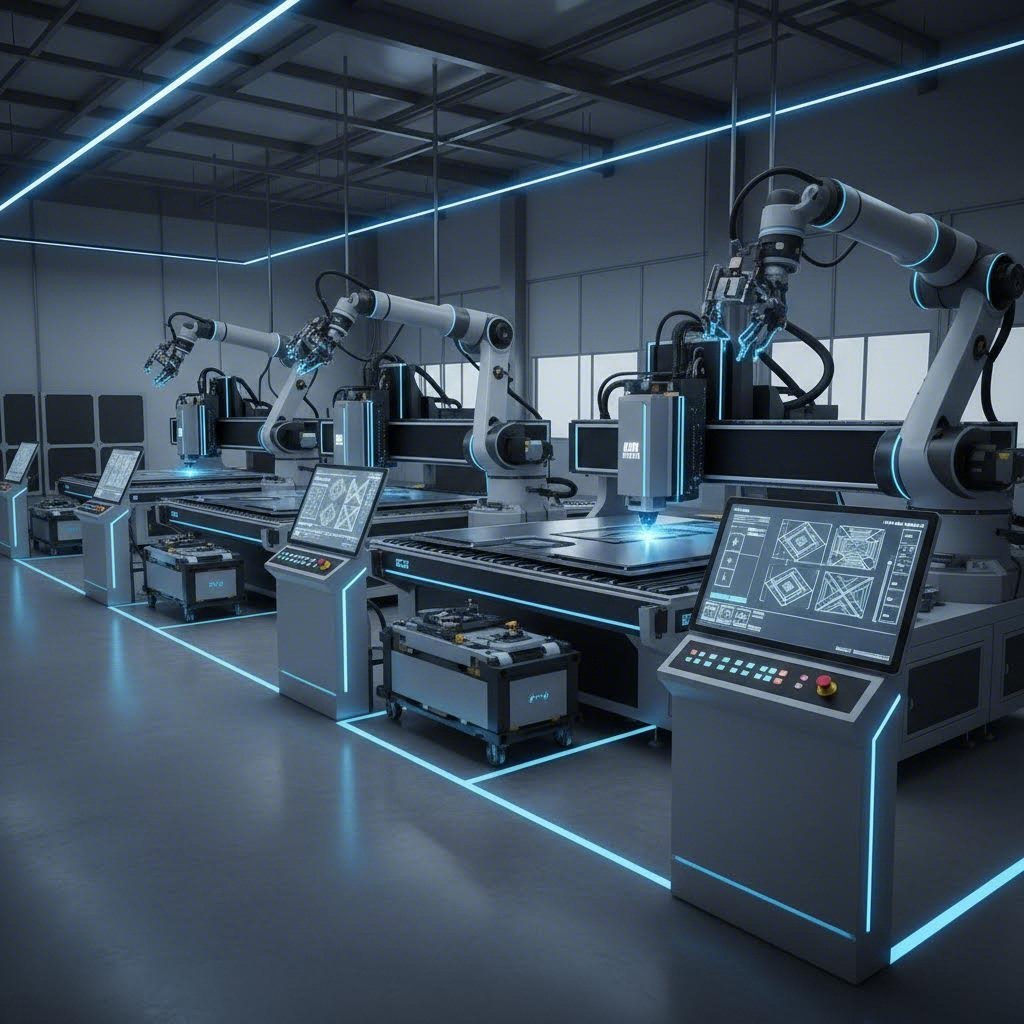

CNC Integration and Automated Cutting Systems

What separates a good fabrication shop from a great one? Increasingly, the answer lies in automation. Modern steel sheet cutting machines don't just follow programmed paths—they integrate with sophisticated software systems that optimize every aspect of the cutting process, from initial programming to final part delivery.

According to ShopSabre, CNC plasma machines are designed to tackle large-scale cutting, manufacturing jobs, and one-off custom fabrication in a fraction of the time it would take with hand tools. You can program and cut diverse shapes on demand, with no pre-heating or cooling required. This capability transforms how shops approach processing steel plate—shifting from reactive job-by-job work to strategic production planning.

CNC Programming for Consistent Cut Quality

Imagine cutting the same complex part 500 times with identical precision on each piece. That's what CNC programming delivers—and it's why steel cutting services increasingly rely on computer-controlled systems rather than manual operation.

The secret lies in how CNC machines execute cuts. Once programmed, the torch or cutting head moves along an exact path set by the computer. According to industry analysis, this approach is reliable and consistent every time, leading to unmatched precision on essentially any cut, no matter how complex or refined.

Key advantages of CNC-controlled cutting include:

- Repeatability—Every part matches the programmed specifications, eliminating variation between pieces

- Complex geometry handling—Intricate patterns that would challenge manual operators become routine

- Reduced operator dependency—Consistent quality regardless of which technician runs the machine

- Digital documentation—Programs can be stored, modified, and reused for future orders

Modern systems take this further by incorporating real-time feedback. Sensors monitor cutting conditions and adjust parameters automatically—compensating for material variations, torch wear, or environmental factors that might otherwise affect cut quality.

Nesting Software for Material Optimization

Here's where automation delivers dramatic cost savings. According to Hypertherm, plate metal and other raw materials are expensive, and it's best to "nest" as many parts together as possible. This maximizes plate utilization, reduces material waste, and lowers material costs.

What exactly is nesting? It's the efficient placement of multiple parts onto a given surface area—think of it as solving a puzzle where every piece must fit with minimal gaps. Modern nesting software uses mathematical algorithms to automatically arrange shapes, rotating and moving parts for the best overall fit and tightest material usage.

The results speak for themselves. A typical industry nest may achieve 70% material utilization with 30% scrap. Advanced software pushes these numbers even higher through features like:

- True shape nesting—Recognizes actual part geometry and interlocks pieces together, rather than placing rectangular borders around each part

- Automatic interference detection—Prevents parts from overlapping or spacing too closely

- Multi-job optimization—Analyzes different plate sizes to determine which combination yields highest utilization

- Cut path sequencing—Orders cuts to minimize torch travel time and heat buildup

For shops using a steel cutter tool on expensive materials like stainless steel or aluminum, these optimization capabilities often pay for the software investment within months through material savings alone.

Automated Production Line Integration

The future of metal plate cutting extends beyond the cutting table itself. According to Makerverse's 2025 industry analysis, automation is increasingly critical in sheet metal fabrication, streamlining tasks such as cutting, bending, forming, and assembly.

Modern automated systems handle high-volume, repetitive tasks with precision and consistency, reducing human error and improving production efficiency. Automated laser cutting machines, robotic bending arms, and CNC punch presses operate seamlessly with minimal human intervention—creating integrated workflows that transform raw material into finished parts with limited manual handling.

What does full automation look like in practice?

- Automated material loading—Plates move from storage to cutting table without manual intervention

- Continuous operation—24/7 production capability multiplies output capacity

- Integrated quality control—AI-driven systems monitor operations in real-time, detecting deviations before they compromise final products

- Downstream coordination—Cut parts flow automatically to bending, welding, or assembly stations

"Adopting 24/7 automated production lines means faster turnaround times and increased capacity, enabling companies to respond quickly to customer demands and market changes."

This integration particularly benefits rapid prototyping capabilities. Steel cutting saws and traditional methods might require days of setup and manual processing. Automated CNC systems can deliver prototype parts in as little as five days—accelerating product development cycles and enabling faster iteration on designs.

The accessibility of these technologies has expanded dramatically. Where CNC plasma and automated cutting once required massive capital investment, systems now serve shops ranging from large industrial operations to sole contractors. This democratization means smaller fabricators can compete on quality and turnaround time with much larger competitors—leveling the playing field through technology rather than scale.

Of course, all this capability comes with costs that must be carefully evaluated. Understanding the economics of equipment investment versus outsourcing helps determine whether automation makes sense for your specific situation.

Cost Analysis and Budget Planning

You've identified the right cutting method for your project—but can you afford it? Cost analysis often separates successful fabrication operations from those struggling with razor-thin margins. The challenge isn't just choosing between plasma, laser, or waterjet. It's understanding the complete financial picture: equipment investment, operating expenses, hidden costs, and the often-overlooked economics of outsourcing versus in-house production.

Here's what most cost comparisons miss: the cheapest cutting method on paper rarely delivers the lowest total project cost. A steel plate cutter with lower upfront expense might generate higher waste, require more secondary finishing, or demand extensive maintenance. Smart budget planning accounts for every factor affecting your bottom line.

Equipment Investment vs Outsourcing Economics

Should you buy cutting equipment or outsource to professional services? This fundamental decision shapes your entire cost structure—and the right answer depends on your specific situation.

According to industry analysis, the reasoning behind equipment investment is "spend today to earn tomorrow." When you own a machine, you control production timing, know exactly how long jobs take, and establish pricing based on your actual costs. For shops with consistent cutting volume, ownership often makes financial sense over time.

But equipment ownership brings substantial commitments:

- Capital outlay—CNC plasma systems range from $15,000 to $300,000+; fiber lasers command $200,000 to $1 million+; waterjet systems fall between $100,000 and $500,000

- Facility requirements—Dedicated floor space, electrical upgrades, ventilation systems, and safety infrastructure

- Maintenance obligations—Regular service, part replacement, and eventual major overhauls

- Operator training—Skilled technicians command premium wages; training new operators takes time

- Technology obsolescence—Equipment designed for 15-20 years of service may become outdated before fully depreciated

Outsourcing shifts these burdens to your cutting partner. You pay per part or per job, avoiding capital investment entirely. According to Metal Cutting Corporation, choosing the wrong precision cutting method can result in production delays, material waste, or quality issues that cost time and money—risks that experienced service providers help you avoid through their expertise and established processes.

When does outsourcing make the most sense?

- Low to moderate volume—Insufficient work to justify equipment investment

- Specialized requirements—Exotic materials or precision tolerances beyond your equipment's capability

- Variable demand—Fluctuating workloads that would leave owned equipment idle

- Capital constraints—Cash better deployed in core business activities

- Speed requirements—Professional services with rapid turnaround capabilities accelerate your supply chain

Per-Cut Cost Factors Across Methods

Every time you cut steel, multiple cost categories accumulate. Understanding these factors helps you estimate true per-part expenses—and identify where savings opportunities exist.

Consumables represent your most visible ongoing expense:

- Plasma cutting—Electrodes, nozzles, and shield cups wear with each arc start; consumable life varies from 1-4 hours of cutting depending on amperage and material

- Laser cutting—Assist gases (nitrogen, oxygen), lenses, and nozzles; fiber lasers reduce consumable costs versus CO2 systems

- Oxy-fuel—Oxygen and fuel gases; tips require periodic replacement

- Waterjet—Garnet abrasive (the largest ongoing expense), mixing tubes, orifices, and high-pressure seals

- Steel saw cutting—Blade replacement costs vary by material hardness and cut frequency

Energy consumption often surprises operators with its impact:

- High-power fiber lasers can draw 30-100+ kW during operation

- Waterjet intensifier pumps consume 30-100 HP continuously

- Plasma systems scale energy use with amperage settings

- Compressed air systems supporting cutting operations add indirect electrical costs

Labor includes more than operator wages. Setup time, programming, material handling, and quality inspection all contribute. Automated systems reduce per-part labor but require skilled technicians for programming and maintenance.

Material waste compounds every other cost. When you cut steel plate inefficiently, you're discarding material you've already purchased. Kerf width matters—laser's narrow cut removes less material than plasma's wider kerf, which removes less than oxy-fuel. Nesting optimization, as discussed earlier, dramatically affects utilization rates.

Relative Cost Comparison by Production Volume

Different cutting methods favor different production scenarios. This comparison illustrates how costs shift based on volume:

| Cost Factor | Low Volume (1-50 parts) | Medium Volume (50-500 parts) | High Volume (500+ parts) |

|---|---|---|---|

| Setup/Programming | High per-part impact | Moderate—costs spread across more pieces | Minimal per-part contribution |

| Best Thermal Method | Outsource laser/plasma | In-house plasma or outsource laser | In-house CNC plasma or laser |

| Best Mechanical Method | Band saw for simple cuts | Automated saw or outsource waterjet | Shearing for blanks; automated sawing |

| Material Optimization Priority | Lower—fewer parts to nest | Important—waste adds up quickly | Critical—small percentage gains yield large savings |

| Outsourcing Advantage | Strong—avoid setup costs entirely | Moderate—compare per-part quotes to in-house costs | Weaker—volume justifies equipment investment |

Hidden Costs in Metal Cutting Operations

The expenses you don't anticipate often hurt most. Beyond obvious equipment and consumable costs, several hidden factors affect your true cutting economics:

Secondary processing requirements: A steel metal cutter producing rough edges creates downstream grinding, deburring, or machining costs. Cheaper cutting methods that require extensive finishing may cost more overall than precision methods delivering weld-ready edges.

Quality failures and rework: Parts that don't meet specifications waste material, labor, and time. According to Sintel Inc., catching manufacturing challenges in the design phase prevents expensive redesigns or delays during production, saving time and money.

Inventory and storage: Raw material sitting in your facility ties up capital. Scrap accumulation requires handling and disposal. These carrying costs rarely appear in per-part calculations but affect profitability.

Downtime and maintenance: Every hour your equipment sits idle for repairs or service represents lost production capacity. Preventive maintenance costs money upfront but prevents costlier emergency repairs.

Opportunity cost: Time spent managing cutting operations—purchasing materials, scheduling jobs, troubleshooting issues—diverts attention from higher-value activities like sales, design, or customer relationships.

How DFM Support Reduces Overall Project Costs

Here's where smart partnerships pay dividends before cutting even begins. Design for Manufacturing (DFM) analysis examines your part designs through a manufacturing lens, identifying opportunities to reduce costs without compromising functionality.

According to documented studies, applying DFM principles delivers a 47% average cost saving in labor and substantial reduction in product development and assembly time. These savings stem from several key practices:

- Part consolidation—Combining multiple components into single pieces reduces cutting operations, assembly time, and material costs

- Material optimization—Selecting appropriate materials and standardizing sizes reduces waste and sourcing expenses

- Tolerance rationalization—Specifying tight tolerances only where functionally necessary avoids expensive precision processing on non-critical features

- Manufacturing process alignment—Designing parts that match available cutting capabilities eliminates costly workarounds

For automotive and precision applications, working with manufacturing partners who offer comprehensive DFM support—like Shaoyi (Ningbo) Metal Technology with their IATF 16949-certified quality systems and 12-hour quote turnaround—helps optimize designs before production begins. Their DFM expertise identifies cost reduction opportunities early, when changes are inexpensive to implement rather than costly to correct.

The math is straightforward: a few hours of DFM analysis costing hundreds of dollars can eliminate thousands in unnecessary manufacturing expense. When combined with rapid prototyping capabilities that deliver parts in as little as five days, you can validate designs quickly and iterate efficiently before committing to production volumes.

Cost optimization doesn't end with choosing the right cutting method or partner. It's an ongoing process that starts with design decisions and extends through every aspect of production—a comprehensive approach that professional cutting services help you implement from first quote through final delivery.

Working with Professional Cutting Services

You've explored cutting methods, analyzed costs, and evaluated your options. Now comes the practical question: how do you actually partner with a professional cutting service to get parts made? Whether you're wondering how do you cut metal for a complex prototype or how do I cut steel for production volumes, working with the right service provider transforms your designs into finished components.

The relationship between your project requirements and a cutting partner's capabilities determines success. Choose wisely, and you'll receive precision parts on schedule. Choose poorly, and you're facing delays, quality issues, and frustrating back-and-forth communication that costs time and money.

Evaluating Metal Cutting Service Providers

Not all cutting services deliver equal results. When you need to know how do you cut steel with professional precision, evaluating potential partners against specific criteria helps you identify shops capable of meeting your requirements.

According to Metal Works of High Point, selecting the right fabrication provider requires examining several key factors that directly impact your project's success:

- Experience and track record—Look for providers with proven history on projects similar to yours. Newer companies may lack experience with your specific material types or complexity levels. A long track record of successful projects indicates reliability and problem-solving capability.

- Equipment and technology—The provider's cutting equipment determines efficiency and quality. Choose partners who invest in state-of-the-art equipment and stay current with technological advancements. Modern CNC systems, fiber lasers, and automated material handling translate to better parts.

- Workforce expertise—Companies with smaller teams may struggle with deadlines. Ensure your fabricator employs highly skilled, qualified craftsmen who can deliver quality work consistently. Ask about welder certifications and operator training programs.

- Customer service and communication—Responsive communication throughout your project prevents misunderstandings. The right partner provides transparent pricing, realistic timelines, and proactive updates when issues arise.

- Finishing capabilities—Providers offering complete services—cutting through finishing—save time and ensure consistency. In-house powder coating, deburring, and secondary processing eliminate coordination headaches between multiple vendors.

- Turnaround capabilities—Rapid quote response and fast production matter. Partners offering 12-hour quote turnaround and expedited processing help you meet tight project deadlines.

How can I cut metal projects that require automotive-grade quality? Start by verifying the provider's certification status—a topic that deserves focused attention.

Quality Certifications That Matter

Certifications aren't just wall decorations—they represent verified commitments to quality systems that protect your projects. For critical applications, working with certified manufacturers ensures consistency that uncertified shops simply cannot guarantee.

ISO 9001:2015 establishes the foundation. According to industry experts, this certification confirms a company values quality and maintains systems to deliver superior products consistently. ISO-certified facilities follow documented procedures, conduct regular audits, and implement continuous improvement processes.

IATF 16949 raises the bar significantly for automotive applications. According to OGS Industries, this certification meets all ISO 9001 requirements—and then some. It ensures compliance with lean manufacturing principles, defect prevention, variance deterrence, and waste reduction.

What does IATF 16949 certification mean for your cutting projects?

- Consistent quality—Processes are monitored and measured to maximize productivity and deliver consistent outcomes across every production run

- Reduced product variation—Reviewed and improved manufacturing processes ensure metal components consistently meet high-performance vehicle specifications

- Reliable supply chain—The internationally recognized certification establishes a benchmark for sourcing, creating a stronger, more dependable supplier network

- Reduced waste—Streamlined processes and improved management systems minimize material waste and support environmental initiatives

- Defect prevention—Tested and proven fabrication processes diminish inefficiencies and minimize defects before they reach your assembly line

For automotive and precision industrial applications, partnering with IATF 16949-certified manufacturers like Shaoyi (Ningbo) Metal Technology ensures quality from cutting through final assembly. Their certification covers custom metal stamping parts and precision assemblies for chassis, suspension, and structural components—with 5-day rapid prototyping capabilities that accelerate product development cycles.

Preparing Your Project for Professional Cutting

Proper file preparation prevents costly delays and ensures your parts arrive matching your design intent. According to PTSMAKE's technical guidance, getting files ready correctly is crucial—improper preparation leads to costly revisions and production delays.

File format requirements:

- DXF files—The universal language for cutting operations. Clean up unnecessary elements, check for overlapping lines, ensure proper scale, and verify all dimensions before submission.

- Convert text to geometry—Text elements cause interpretation issues across different CAD systems. Converting to vector geometry ensures your annotations cut correctly.

- Merge connecting lines—Broken line segments confuse CNC programming. Ensure continuous paths for each cut profile.

- Verify layer organization—Separate cutting paths, dimensions, and annotations on distinct layers with clear naming conventions.

Specification documentation should include:

- Material type and grade—Specify exactly what you need: 304 stainless steel, A36 carbon steel, 6061 aluminum, etc.

- Thickness requirements—State precise material gauge or plate thickness

- Quantity needed—Include prototype quantities and anticipated production volumes

- Tolerance requirements—Identify critical dimensions requiring tight tolerances versus areas where standard precision suffices

- Edge quality specifications—Note if parts require weld-ready edges, specific surface finishes, or deburring

- Secondary processing needs—List any bending, welding, coating, or assembly requirements

The Complete Workflow: Design Through Finished Parts

Understanding the full production sequence helps you plan timelines and communicate effectively with your cutting partner:

- Design submission—Provide CAD files, specifications, and quantity requirements. Quality partners offering rapid quote turnaround—like 12-hour response times—accelerate this phase.

- DFM review—Experienced manufacturers analyze your design for manufacturability, identifying potential issues and cost reduction opportunities before production begins.

- Quotation and approval—Review pricing, lead times, and any design recommendations. Approve to proceed.

- Programming and nesting—CNC programmers optimize your parts for cutting, maximizing material utilization and planning cut sequences.

- Material sourcing—If not customer-supplied, the cutting service procures appropriate material grades and thicknesses.

- Cutting production—Your parts are cut using the appropriate method—laser, plasma, waterjet, or mechanical processes.

- Secondary processing—Deburring, bending, welding, coating, or assembly operations as specified.

- Quality inspection—Certified facilities verify parts meet specifications before shipping.

- Delivery—Finished parts ship to your facility, ready for your assembly operations.

For readers needing precision automotive or industrial cutting, certified manufacturing partners ensure quality throughout this entire workflow. Shaoyi (Ningbo) Metal Technology delivers this complete service—from rapid prototyping through automated mass production—with comprehensive DFM support that optimizes your designs before cutting begins.

The journey from raw steel plate to finished component involves numerous decisions, each affecting quality, cost, and timeline. By selecting the right cutting method, preparing proper documentation, and partnering with certified service providers, you transform metal plate cutting from a challenge into a competitive advantage—delivering precision parts that meet your specifications, on time and within budget.

Frequently Asked Questions About Metal Plate Cutting

1. How to cut metal plates at home?

For home metal plate cutting, your best options depend on material thickness. Tin snips work for thin sheet metal under 1mm. For thicker plates up to 6mm, an angle grinder with the appropriate cutting disc delivers versatility for straight and curved cuts. Band saws handle bar stock and structural shapes efficiently without heat distortion. For plates exceeding 6mm, consider outsourcing to professional services with plasma or waterjet capability, as handheld tools struggle with heavy material and may compromise cut quality and safety.

2. What is the best way to cut thick steel plate?

For thick steel plate exceeding 25mm, oxy-fuel cutting remains the industry workhorse for carbon steel, capable of slicing through material several inches thick at the lowest equipment cost. Waterjet cutting handles extreme thicknesses up to 300mm while preserving material properties with zero heat-affected zone—ideal for heat-sensitive alloys or precision applications. Plasma cutting serves medium-thick plates efficiently, balancing speed with cost-effectiveness. The best method depends on your specific requirements: material type, edge quality needs, and whether heat distortion is acceptable for downstream welding operations.

3. What are the different types of plate cutting methods?

Metal plate cutting divides into three main categories: thermal methods (plasma, laser, oxy-fuel) that use heat to melt or oxidize material; mechanical methods (saws, shears) that physically separate material through cutting force; and abrasive methods (waterjet) that erode material using high-pressure streams with garnet particles. Thermal cutting offers speed for industrial applications but creates heat-affected zones. Mechanical methods produce no HAZ but limit complex shapes. Waterjet delivers precision on any material without heat distortion, making it ideal for aerospace and heat-sensitive components.

4. How much does professional metal plate cutting cost?

Professional cutting costs vary based on method, material, thickness, and volume. Key cost factors include equipment type (laser costs more than plasma), consumables (gases, abrasives, blades), material waste from kerf width, and secondary finishing requirements. For low volumes, outsourcing typically proves more economical than equipment investment. High-volume production may justify in-house systems. Working with IATF 16949-certified manufacturers like Shaoyi Metal Technology provides DFM support that optimizes designs before cutting, potentially reducing overall project costs through improved material utilization and eliminated rework.

5. What safety equipment do I need for cutting steel?

Safety requirements vary by cutting method. Thermal cutting (plasma, laser, oxy-fuel) demands welding helmets with appropriate filter shades, fire-resistant clothing, insulated leather gloves, steel-toed boots, and hearing protection. Ensure proper ventilation to manage hazardous metal fumes that can cause respiratory issues including metal fume fever. Mechanical cutting requires safety glasses with side shields, hearing protection, and cut-resistant gloves. Waterjet operations need eye protection from abrasive spray, hearing protection, and water-resistant clothing. Keep fire extinguishers within reach for thermal operations and clear combustibles from the work area.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —