Metal Pressing Process Decoded: From Raw Sheet To Precision Part

What Metal Pressing Actually Means in Manufacturing

Ever wondered how a flat sheet of steel transforms into a perfectly shaped car door panel or a precision electronic enclosure? The answer lies in the metal pressing process—a manufacturing technique that shapes our modern world in ways most people never consider.

Metal pressing, also called metal stamping, is a cold-forming manufacturing process that uses specialized dies and high-pressure presses to transform flat sheet metal into precise three-dimensional shapes through permanent plastic deformation—without removing any material.

So what is metal stamping in practical terms? Think of it as controlled deformation. Unlike machining processes that cut away material, pressing metal reshapes it entirely. A flat blank enters the press, tremendous force is applied, and a finished component emerges—all in a matter of seconds.

Understanding the stamping meaning requires distinguishing it from broader forming categories. While "forming" encompasses any process that shapes metal (including hot processes like forging), metal pressing specifically refers to cold-forming operations performed at or near room temperature. This distinction matters because cold working produces parts with superior surface finish, tighter tolerances, and enhanced strength properties through strain hardening.

The Cold-Forming Principle Behind Metal Pressing

What makes cold-forming so effective? When you apply force to sheet metal beyond its yield strength but below its tensile strength, something remarkable happens—the material deforms plastically. This means the shape change becomes permanent once pressure is released.

The physics behind this involves three interacting elements:

- Force distribution: Pressure must be applied uniformly to prevent localized failures or uneven deformation

- Material flow: Metal moves and redistributes during pressing, with compression occurring in some areas while tension develops in others

- Die geometry: The tooling shape precisely controls where and how the material deforms

Cold working offers distinct advantages over hot forming methods. According to manufacturing research from IIT Guwahati, cold-formed parts achieve closer tolerances, better surface finish, and higher strength through strain hardening. Additionally, eliminating heating requirements reduces energy costs significantly.

How Pressure Transforms Flat Stock Into Complex Shapes

When you're asking "what is stamped metal?" you're really asking about transformation through controlled pressure. Here's what actually happens during pressing metal operations:

Pieces of flat sheet metal—typically called blanks—are positioned between die sections. The press then applies force, and the material flows to conform to the die cavity's contours. This stamping means the metal experiences stresses above its yield point, causing plastic deformation that permanently reshapes it.

The beauty of metal pressings lies in repeatability. Once properly set up, a stamping operation can produce thousands—even millions—of identical components. Each cycle delivers the same precise geometry, making this process ideal for high-volume manufacturing applications across automotive, aerospace, electronics, and consumer goods industries.

What separates successful pressing operations from failures? It comes down to understanding how material behavior, tooling design, and process parameters interact. When these elements align correctly, flat stock becomes a complex, precision-engineered component in one swift stroke.

Complete Workflow From Raw Material to Finished Part

You've seen what metal pressing accomplishes—but how does the magic actually happen? Understanding the complete workflow transforms abstract concepts into actionable knowledge. Let's walk through every stage, from the moment raw material arrives until a finished component is ready for assembly.

From Raw Coil to Finished Component

Picture a massive coil of sheet metal weighing thousands of pounds. How does it become precision components measured in thousandths of an inch? The answer involves a carefully orchestrated sequence that metal stamping machines execute with remarkable consistency.

- Material Preparation and Selection: The process begins long before metal touches a stamping press. Engineers select metal sheets or coils based on mechanical properties—strength, ductility, corrosion resistance—and cost factors. According to National Material Company, the selected material must be compatible with both the stamping process and the finished part's functionality.

- Coil Processing and Feeding: Raw coils undergo preparation processes including cutting, slitting, and leveling to achieve proper dimensions and flatness. An automated feeding mechanism then advances the prepared strip through the stamping machine for metal with precise positioning—often within a few thousandths of an inch accuracy.

- Die Setup and Alignment: Before production begins, technicians install the die set and calibrate the press. This critical step ensures proper material flow, adequate clearance for the metal sheet, and appropriate support throughout the stamping cycle.

- The Pressing Operation: As the press initiates action, dies close together and subject the metal to high force and pressure. This deforms the material according to the die contours—performing operations like blanking, bending, coining, or punching either sequentially or simultaneously.

- Part Ejection and Handling: After each stroke, strippers remove the finished component from the carrying web cleanly and without damage. The scrap material—both the carrying web and punched-away metal—is ejected and often transferred via underground conveyor belts to scrap bins.

- Secondary Operations and Finishing: Post-stamping processes may include deburring to remove sharp edges, cleaning, surface treatment, and coating. These steps enhance appearance, durability, and functionality of stamped parts.

- Quality Inspection: Throughout production, operators implement real-time monitoring and inspections to verify that parts meet specified tolerances and quality standards.

The Critical Role of Die Alignment and Setup

Why does die alignment deserve special attention? Because even minor misalignment creates major problems. When strip material advances through progressive stamping operations, it must align within a few thousandths of an inch at each station.

Here's how precision alignment happens: bullet-shaped or conical "pilots" enter previously pierced holes in the strip to ensure exact positioning. This compensates for feeding mechanism limitations that cannot provide the necessary precision in feed length alone. According to Wikipedia's technical documentation, this pilot-hole system is essential because feeding mechanisms typically lack the accuracy required for multi-station progressive operations.

Progressive die and stamping systems represent the pinnacle of continuous production efficiency. The feeding system pushes a strip of metal through all stations of a progressive die, with each station performing specific operations until a finished part emerges. With every stroke of the press, a completed component is produced—production rates can exceed 800 parts per minute for certain applications.

Stamping machines configured for progressive operations require specialized components working in harmony:

- Feeder systems (pneumatic or mechanical) that maintain precise strip advancement

- Die sets with multiple stations for cutting, bending, and forming operations

- Stripper plates that cleanly release finished components

- Sensors and lubrication systems that monitor and optimize the stamping and pressing cycle

The systematic approach described here—from material selection through final inspection—transforms raw metal sheets into precisely shaped components serving diverse industries. But what specific stamping techniques make these transformations possible? The next section breaks down nine essential methods and when to apply each one.

Nine Essential Stamping Techniques and When to Use Each

Now that you understand the complete workflow, a crucial question remains: which stamping process should you actually use? The answer depends on your part geometry, production volume, and quality requirements. Let's explore each technique so you can make informed decisions for your specific applications.

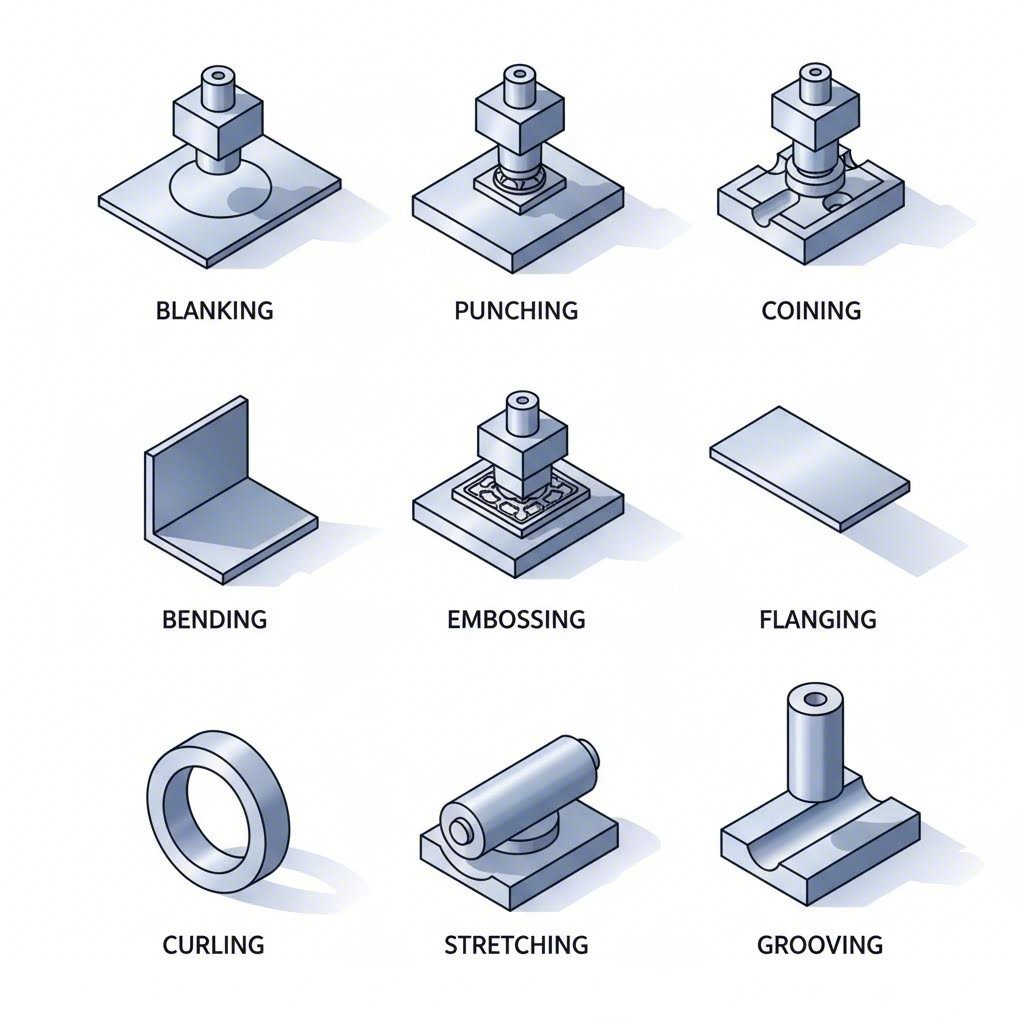

The metal pressing process encompasses nine core sheet metal process techniques—each optimized for different outcomes. Understanding when to apply each method separates successful manufacturing projects from costly mistakes.

Blanking and Punching for Initial Shape Creation

These two techniques form the foundation of most stamping operations, yet they serve opposite purposes. Confusing them leads to material waste and production inefficiencies.

Blanking cuts flat shapes from sheet metal where the punched-out piece becomes your finished product. Think of it as cookie-cutter manufacturing—the "cookie" is what you keep, while the remaining sheet becomes scrap. According to Master Products, this technique is extremely similar to punching, except the roles of product and scrap are reversed.

When should you choose blank stamping? Consider blanking when you need:

- High volumes of identical flat components like washers, gaskets, or base plates

- Precise outer contours with clean edge finishes

- Starting blanks for subsequent forming operations

Punching (also called piercing) creates holes or cutouts within a workpiece. Here, the punched-out material is scrap, and the perforated sheet remains your product. This stamping technology excels at producing precisely located holes for fasteners, ventilation, or assembly purposes.

An excellent example of stamping using punching appears in electrical enclosure manufacturing, where ventilation patterns require dozens of precisely positioned holes. Blank stamping metal and punching often work together—first blanking the overall shape, then punching necessary holes in subsequent operations.

Precision Techniques Including Coining and Embossing

Need intricate surface details or extremely tight tolerances? Coining and embossing deliver results that other stamping methods simply cannot achieve.

Coining applies tremendous pressure to stamp both sides of a workpiece simultaneously, creating raised or indented features with exceptional precision. As HLC Metal Parts explains, this process creates intricate patterns and textures on metal surfaces—exactly how currency coins are manufactured. Coining steel and other metals produces parts with tolerances measured in thousandths of an inch.

Choose coining when your application demands:

- Commemorative items, jewelry, or branded hardware with logos

- Precision stamping parts requiring exceptional flatness

- Surface features that must withstand wear without degrading

Embossing stamps only one side of the workpiece, creating raised or indented patterns while the opposite side shows a mirror image. This technique enhances decoration and adds visual interest to panels, nameplates, and consumer products.

Bending uses a press brake to apply extreme force, deforming metal at specific angles to create V-shaped or U-shaped components. This stamping process is essential for manufacturing casings, enclosures, brackets, and frames. When you need angular features rather than complex curves, bending delivers consistent results at high production speeds.

Flanging bends edges around punched holes at 90-degree angles, creating smooth rims instead of sharp edges. According to manufacturing references, flanging enhances structural strength while improving safety and appearance. You'll find flanged edges on tanks, pipes, automobile body panels, and any application requiring reinforced openings.

Stretching forms protrusions or expanded areas on metal surfaces by pulling material beyond its original dimensions. This technique creates complex automotive components like door panels and roof sections where smooth, flowing contours are essential.

Curling rolls metal edges to form cylindrical shapes or smooth, rounded profiles. This process manufactures pipes, shafts, and hinges while eliminating dangerous sharp edges on consumer products.

Grooving cuts channels into sheet metal surfaces, creating pathways for wiring, drainage, or mechanical connections. Components requiring precise grooves for positioning or assembly rely on this specialized technique.

| Process Name | Primary Application | Typical Industries | Material Thickness Range |

|---|---|---|---|

| Blanking | Cutting flat shapes from sheet stock | Automotive, Electronics, Appliances | 0.5mm - 6mm |

| Punching | Creating holes and cutouts | HVAC, Electrical, Construction | 0.3mm - 12mm |

| Coining | High-precision surface details | Jewelry, Currency, Precision Hardware | 0.2mm - 3mm |

| Bending | Angular deformation for frames/brackets | Furniture, Automotive, Aerospace | 0.5mm - 10mm |

| Flanging | Edge formation and reinforcement | Automotive, Tanks, Pipes | 0.8mm - 6mm |

| Stretching | Surface expansion for complex contours | Automotive Body Panels, Aerospace | 0.6mm - 4mm |

| Embossing | Raised decorative patterns | Consumer Goods, Signage, Crafts | 0.3mm - 2mm |

| Curling | Rolled edges and cylindrical forms | Hinges, Pipes, Safety Components | 0.4mm - 3mm |

| Grooving | Channel creation for connections | Electrical, Mechanical Assembly | 0.5mm - 4mm |

Selecting the right stamping process requires matching your part requirements to technique capabilities. Consider your geometry complexity, tolerance needs, production volume, and material characteristics. Often, manufacturers combine multiple techniques in progressive die operations—blanking the initial shape, punching mounting holes, bending flanges, and embossing identification marks all in one continuous sequence.

With nine core techniques at your disposal, you might wonder which equipment delivers these capabilities most effectively. The next section explores press types—mechanical, hydraulic, and servo systems—helping you match machinery to your specific production requirements.

Choosing Between Mechanical Hydraulic and Servo Presses

You've mastered the nine stamping techniques—but here's the reality check: even the best technique fails without the right press behind it. Selecting your metal stamping press isn't just a purchasing decision; it directly impacts part quality, production speed, and your bottom line. Let's break down the three main press types so you can match equipment to your specific manufacturing needs.

Mechanical Presses for High-Speed Production

Need maximum speed for high-volume production? Traditional mechanical stamping presses remain the workhorses of the industry—and for good reason. According to Stamtec's technical comparison, mechanical presses achieve the greatest production speeds, especially when running relatively flat parts with simpler, shallower forming requirements.

What makes a steel press with mechanical drive so effective? The answer lies in flywheel physics. A heavy flywheel stores rotational energy, then releases it through a clutch-and-brake mechanism during each stroke. This design delivers:

- Highest stroking speeds among all press types—ideal for progressive die operations

- High accuracy and repeatability for consistent part quality

- Simplicity of setup and operation with proven, reliable technology

- Relatively low initial cost compared to servo alternatives

However, mechanical systems come with limitations. Stroke length is typically fixed, slide velocity profiles cannot change within a cycle, and full tonnage capacity only occurs near bottom dead center. For automotive, appliance, and hardware parts processed from coil stock through progressive or transfer dies, these constraints rarely matter—but deep-drawn or complex-formed parts may require different solutions.

Hydraulic and Servo Systems for Precision Control

What if your parts demand deep draws, complex forms, or dwell time at the bottom of the stroke? Hydraulic presses excel in these scenarios—though they sacrifice speed for versatility.

A steel stamping machine with hydraulic drive offers variable stroke length, slide motion control throughout the entire range, and full working energy at any speed. Imagine forming tanks, cylinders, or bowl-shaped components—these parts require material to flow extensively during the pressing operation. Hydraulic systems deliver full press capacity at any point in the stroke, making them ideal for such demanding applications.

The trade-off? Hydraulic presses generally run slower than mechanical alternatives and offer lower accuracy and repeatability. But when production speed takes a back seat to forming capability, hydraulic technology remains the go-to choice for challenging geometries.

Now consider the servo press—a sheet metal stamping machine that combines mechanical efficiency with hydraulic-like flexibility. Servo technology replaces the traditional flywheel, clutch, and brake with high-capacity motors that provide programmable stroke profiles, precise slide motion control, and variable velocity even within a single cycle.

According to industry data, mechanical servo presses offer:

- Variable stroke profiles that can be customized for each job

- Full working energy at any speed—even during slow forming operations

- Cycle speeds approaching traditional mechanical presses in many applications

- High accuracy and repeatability with programmable precision

The catch? Servo systems carry significantly higher initial costs. Two drive technologies exist: link-assisted systems using standard AC servo motors (more cost-effective) and direct drive systems employing proprietary high-torque motors (maximum capability).

For transfer stamping press operations handling complex multi-station work, servo technology increasingly dominates. The ability to program unique profiles—including deep drawing, warm forming, compound pressing, and simulation of link motions—opens manufacturing possibilities that traditional systems simply cannot match.

| Parameter | Mechanical Press | Hydraulic Press | Servo Press |

|---|---|---|---|

| Speed Range | Highest (best for progressive dies) | Slowest (speed-limited) | High (approaches mechanical) |

| Tonnage Capacity | Full near bottom dead center | Full throughout stroke | Full near bottom dead center |

| Precision Level | High accuracy and repeatability | Lower accuracy | Highest programmable precision |

| Energy Consumption | Moderate (flywheel-dependent) | Continuous pump operation | Energy-efficient (on-demand) |

| Best Applications | High-speed flat parts, progressive dies | Deep draws, complex forms, dwell operations | Versatile—drawing, forming, blanking |

| Initial Cost | Relatively low | Relatively low | Relatively high |

| Stroke Flexibility | Fixed (limited adjustment) | Fully variable | Fully programmable |

So which metal stamping press machine fits your operation? The decision framework is straightforward: mechanical presses deliver unmatched speed but lack flexibility; hydraulic machines provide versatility for complex parts but sacrifice throughput; servo presses offer the best of both worlds at premium cost.

Consider your production mix carefully. If you're running high volumes of relatively simple parts, mechanical presses maximize efficiency. For low-volume complex components requiring extensive material flow, hydraulic systems make economic sense. And when you need flexibility across diverse part families with demanding quality requirements, servo technology justifies its higher investment.

With press selection understood, another critical decision awaits: which materials perform best in your chosen stamping process? The next section guides you through material selection—matching metal properties to process requirements for optimal results.

Material Selection Guide for Optimal Stamping Results

You've selected your press type and identified the right stamping techniques—but here's where many projects stumble: choosing the wrong metal for stamping. Material selection isn't about picking the most expensive option; it's about finding the perfect balance between formability, performance, and cost. Get this decision wrong, and you'll face cracking, excessive springback, or parts that fail in service.

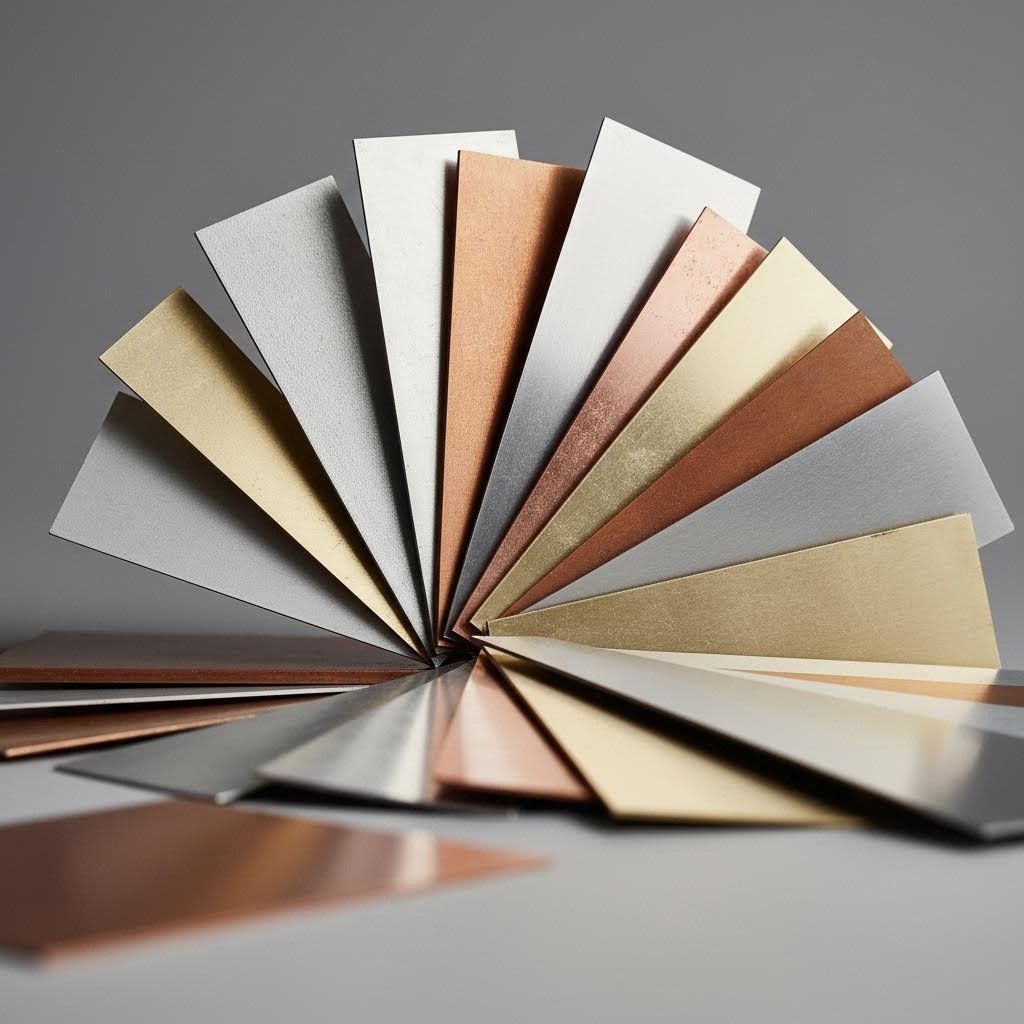

What makes one metal for stamping superior to another? Four key properties determine stampability:

- Ductility: How much the metal can stretch before fracturing—critical for deep draws and complex forms

- Yield strength: The stress level at which permanent deformation begins—affects required tonnage and springback

- Work hardening: How quickly the material strengthens during deformation—impacts multi-stage operations

- Springback behavior: The elastic recovery after forming—determines achievable tolerances and die compensation needs

According to CEP Technologies, selecting the right metal stamping materials requires weighing part end-use, formability, corrosion resistance, and cost. Let's examine how each major material category performs.

Steel Grades and Their Stamping Characteristics

Steel dominates metal pressing applications for good reason—it offers exceptional strength, proven formability, and cost-effectiveness across diverse applications. But "steel" encompasses dozens of grades with vastly different stamping behaviors.

Carbon Steel remains the workhorse material for high-volume production. Available in low, medium, and high carbon variants, these steels offer excellent formability at competitive prices. Low carbon grades (under 0.30% carbon) stamp easily and work well for automotive brackets, appliance housings, and general structural components. Higher carbon content increases hardness but reduces ductility—important considerations when selecting metal stamping materials for your application.

Stainless steel stamping addresses applications demanding corrosion resistance and high strength. Grade 304 stainless delivers tensile strength exceeding 515 MPa with salt spray resistance over 48 hours, according to Tenral's material guide. This makes it ideal for medical equipment shells, food processing components, and outdoor applications. Grade 430 offers lower cost for structural parts without stringent rust prevention requirements.

However, stainless steel presents stamping challenges. Higher yield strength requires greater press tonnage, while increased work hardening rates demand careful process planning for multi-stage operations. Springback behavior is more pronounced compared to mild steel—expect tighter die tolerances and potentially multiple forming iterations.

High-strength low-alloy (HSLA) steels provide enhanced mechanical properties for automotive and aerospace applications. These materials enable weight reduction through thinner gauges while maintaining structural integrity. The trade-off? Reduced ductility and increased springback require more sophisticated die design and process control.

Pre-plated steels streamline production by eliminating post-stamping finishing operations:

- Galvanized steel: Zinc coating thickness of 8μm or greater provides basic rust prevention at low cost—perfect for chassis brackets and appliance panels

- Nickel-plated steel: Higher corrosion resistance than zinc reduces finishing requirements for demanding applications

Aluminum and Copper Alloy Considerations

When weight reduction drives your design requirements, the aluminum stamping process becomes essential. With density at just 2.7 g/cm³—roughly one-third of steel—stamped aluminum delivers dramatic weight savings without sacrificing functionality.

Aluminium stamping parts excel in applications requiring:

- Lightweight components for 5G base station heat sinks and electronic enclosures

- Excellent thermal and electrical conductivity

- Good corrosion resistance without additional coatings

- High recyclability for environmentally conscious manufacturing

The 6061-T6 alloy represents a popular choice for precision aluminum stamping, offering tensile strength between 110-500 MPa with superior formability. One real-world example: a communications company achieved 25% improved heat dissipation efficiency while reducing weight below 100g by switching from copper to precision-stamped 6061-T6 aluminum heat sinks.

Aluminum's softness makes it forgiving during forming but creates challenges with springback control and surface finish protection. Lubricant selection becomes critical—improper lubrication leads to galling and surface defects that compromise both appearance and performance.

Copper stamping addresses applications where electrical conductivity is paramount. With conductivity reaching 98%, copper forms micro-contacts, SIM card springs, and wiring terminals for electronics and telecommunications. The material punches cleanly into intricate shapes, though its relative softness requires careful handling to prevent surface damage.

Brass (copper-zinc alloy) offers an attractive middle ground. H62 brass achieves hardness of HB≥80 with excellent machinability, requiring no secondary processing after stamping. This alloy serves smart door lock mechanisms, automotive HVAC joints, and applications demanding both conductivity and wear resistance.

Phosphor bronze combines copper, tin, and phosphorus for exceptional elasticity, corrosion resistance, and wear properties. Beryllium copper provides even higher strength for demanding applications and can be heat-treated for additional hardness—though material costs are significantly higher.

Material thickness directly impacts both process selection and tonnage requirements. CEP Technologies reports stamping capabilities for coil materials between 0.002 in. and 0.080 in. thick, with press capacities ranging from 15 to 60 tons for small-to-medium parts. Thicker materials demand proportionally higher forces and may limit achievable geometries—particularly minimum bend radii, which typically scale with material thickness.

| Material Type | Tensile Strength (MPa) | Density (g/cm³) | Salt Spray Resistance | Optimal Applications |

|---|---|---|---|---|

| Aluminum Alloys | 110-500 | 2.7 | 24-48h | Heat sinks, electronic enclosures, lightweight structures |

| Stainless Steel (304) | ≥515 | 7.9 | ≥48h | Medical devices, food equipment, outdoor components |

| Copper | 200-450 | 8.9 | 12-24h | Electrical contacts, terminals, connectors |

| Brass (H62) | 300-600 | 8.5 | 24-36h | Lock mechanisms, HVAC fittings, decorative hardware |

| Galvanized Steel | ≥375 | 7.8 | ≥24h | Chassis brackets, appliance panels, cost-sensitive parts |

The relationship between material choice and achievable tolerances deserves careful attention. Harder materials like stainless steel exhibit greater springback, requiring tighter die tolerances and potentially multiple forming operations to hit final dimensions. Softer metals like aluminum form easily but may require additional support during handling to maintain dimensional stability. When tolerance requirements are critical, material testing during prototyping becomes essential—theoretical calculations only go so far in predicting real-world behavior.

With material selection understood, another critical factor demands attention: the tooling that transforms flat stock into finished components. The next section explores die design fundamentals—the precision engineering that makes accurate, repeatable metal pressing possible.

Tooling and Die Design Fundamentals

You've selected the perfect material and matched it to the right press—but here's the truth that separates successful stamping operations from costly failures: your tooling makes or breaks everything. Even the best materials and machinery produce scrap when paired with poorly designed or maintained dies. Understanding metal stamping tooling fundamentals transforms you from a parts buyer into an informed partner who can evaluate suppliers and prevent quality issues before they occur.

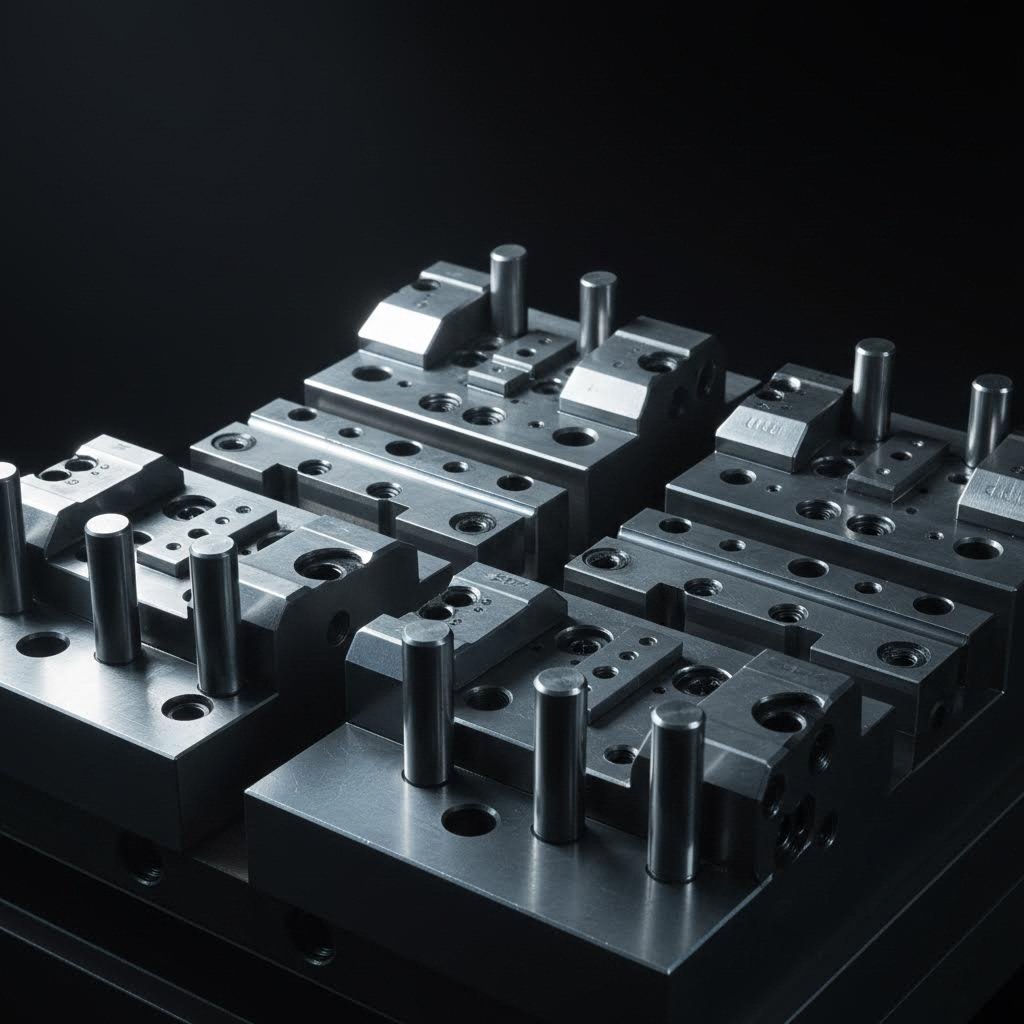

Critical Die Components and Their Functions

What exactly happens inside a stamping die? Think of it as a precision machine within a machine—dozens of components working in perfect synchronization to transform flat metal into complex shapes. According to Evans Metal Stamping's technical guide, the following components are essential to any progressive die:

- Die Set: The foundation that holds all other components in precise alignment—typically consisting of upper and lower plates with guide pins

- Punches: The male tools that penetrate or form the material by pressing into corresponding die cavities

- Die Buttons (Bushings): Hardened inserts that receive punches and define hole geometries—replaceable when worn

- Punch Holder: Secures punches in exact positions while transmitting force from the press ram

- Stripper Plate: Removes material from punches after each stroke and holds stock flat during operations

- Pilot Pins: Bullet-shaped or conical guides that enter previously pierced holes to ensure precise strip positioning

- Slug Clearance: Designed openings that allow punched-out material to fall clear without jamming

Why does punch and die clearance matter so much? Imagine cutting paper with dull scissors versus sharp ones—the principle applies at industrial scale. Proper clearance (typically 5-10% of material thickness per side) ensures clean shearing without excessive burrs or premature tool wear. Too tight, and punches bind or fracture. Too loose, and you get ragged edges requiring secondary deburring operations.

The stripper plate deserves special attention in any sheet metal stamping design. Beyond simply removing material from punches, it serves as a pressure pad that holds stock flat during forming operations. Spring-loaded strippers provide controlled force that prevents wrinkling while allowing material to flow properly during deep draws or complex bends.

Pilot pins solve a problem that feeding mechanisms alone cannot address. When strip material advances through progressive dies, positioning accuracy within a few thousandths of an inch is essential—but feeders typically cannot deliver this precision. Pilots enter previously pierced holes to pull the strip into exact alignment before each operation occurs. Without this compensation, accumulated positioning errors would render multi-station progressive operations impossible.

Progressive Die Design for Complex Parts

When you need complex geometries produced at high volumes, progressive die stamping becomes the method of choice. But what separates excellent stamping design from merely adequate approaches?

According to Kenmode's progressive die overview, designing dies to produce precision parts is one of the most critical steps to ensuring long-term production success. Progressive dies combine multiple operations—blanking, punching, forming, bending—into a single tool that performs all steps as strip material advances through sequential stations.

The relationship between die complexity and part geometry follows a clear pattern. Simple flat parts with holes require only cutting stations. Adding bends introduces forming stations with precision clearances. Complex three-dimensional shapes demand carefully sequenced operations with intermediate carriers that maintain strip integrity until final cutoff.

Bypass notches play a crucial role in progressive die operations. These strategically placed cutouts in carrier strips allow formed features to pass through subsequent stations without interference. Without proper bypass design, raised embossments or bent flanges would collide with die components—halting production and damaging tooling.

Here's where modern technology transforms traditional stamping design capabilities. Advanced CAE (Computer-Aided Engineering) simulation during die design prevents defects and reduces iteration cycles—identifying potential problems like material thinning, wrinkling, or springback before any steel is cut. Companies like Shaoyi leverage CAE simulation backed by IATF 16949 certification to achieve 93% first-pass approval rates on precision stamping dies, delivering cost-effective tooling that meets OEM standards from rapid prototyping through high-volume manufacturing.

Metal stamping equipment configured for progressive operations must accommodate complex die sets while maintaining the precision alignment these tools demand. Features like sub-liners provide adjustment capability, stop blocks control strip advancement, and sensors monitor feed accuracy and detect misfeed conditions before damage occurs.

Die Maintenance Practices for Consistent Quality

Even the most sophisticated steel stamping dies degrade over time. Punch edges dull, clearances increase from wear, and alignment shifts from repeated impacts. Establishing proper maintenance protocols extends die life while preventing the quality drift that leads to rejected parts.

- Regular Inspection Schedules: Examine cutting edges, forming surfaces, and alignment features at defined intervals based on stroke counts—not just when problems appear

- Preventive Sharpening: Regrind punches and die sections before edges deteriorate to the point where burrs become unacceptable—typically every 20,000-50,000 strokes depending on material

- Clearance Monitoring: Measure and document punch-to-die clearances regularly, replacing bushings and components before wear exceeds tolerance limits

- Lubrication Management: Maintain proper lubrication systems that reduce friction, extend component life, and ensure consistent material flow

- Alignment Verification: Check guide pin fits and pilot relationships periodically—even minor misalignment compounds into major quality issues over production runs

- Documentation and Tracking: Record maintenance activities, stroke counts, and any adjustments to establish predictive maintenance baselines

According to JV Manufacturing's guide, selecting a partner with robust quality assurance processes—including inspection protocols and certifications like ISO standards—ensures that each tool and die meets precise tolerances and performance standards. Look for metal stamping presses operators who maintain detailed maintenance records and offer post-delivery support for precision stamping parts production.

The investment in proper die maintenance pays dividends beyond part quality. Well-maintained stamping machinery experiences fewer unplanned shutdowns, produces more consistent output, and delivers lower per-part costs over the tooling lifecycle. When evaluating potential manufacturing partners, their maintenance practices reveal as much about expected quality outcomes as their equipment lists.

With tooling fundamentals understood, a critical question remains: how do you identify and prevent the defects that compromise stamped part quality? The next section maps common stamping problems to their root causes—giving you the knowledge to specify quality requirements and evaluate supplier capabilities effectively.

Quality Control and Defect Prevention Strategies

You've invested in precision tooling and selected the right materials—but here's the uncomfortable truth: defects still happen. The difference between world-class stamping operations and struggling manufacturers isn't avoiding problems entirely; it's understanding why defects occur and preventing them before they compromise your production. Let's decode the engineering behind common stamping failures so you can specify quality requirements with confidence.

Every metal stamped part tells a story about the process that created it. Wrinkles reveal insufficient holding force. Cracks expose excessive material stretching. Burrs signal worn tooling that should have been sharpened thousands of strokes ago. When you understand these cause-and-effect relationships, you transform from someone who rejects bad parts into someone who prevents them from being made in the first place.

Identifying and Preventing Common Stamping Defects

Why do stamped metal parts fail inspection? According to Neway Precision's technical documentation, common defects include burrs, wrinkles, cracks, springback, surface abrasions, and dimensional deviation—each compromising functionality and compliance, particularly in safety-critical applications across automotive, energy, and electronics sectors.

Wrinkles appear as local buckling patterns, typically at flange edges or in deep-drawn areas. What causes them? Unbalanced blank holder force or excessive material flow during forming operations. When material isn't constrained properly, it buckles instead of stretching uniformly. The fix involves adjusting blank holder pressure, optimizing draw bead configurations, or redesigning the material flow path through the die.

Cracks and Fractures represent the opposite problem—material stretched beyond its limits. These defects often occur in high-strength steels like DP780 or TRIP980 with limited elongation, especially at tight radii or in zones experiencing non-uniform strain. Prevention strategies include selecting materials with adequate ductility, increasing die radii (R≥4t where t is material thickness), and potentially implementing hot forming for challenging applications.

Springback frustrates engineers because the part looks correct in the die—then changes shape after ejection. This elastic recovery occurs because not all deformation during forming is plastic; some portion remains elastic and recovers when force is removed. In advanced high-strength steel parts, springback angles can reach 6-10°, significantly affecting final geometry. Compensation requires CAE simulation during die design, overbending strategies, and sometimes additional coining operations to lock in final dimensions.

Burrs—those sharp residual edges from punching or blanking operations—typically indicate worn dies or incorrect punch-to-die clearance. Industry standards often reject burr heights exceeding 0.1mm on safety and sealing surfaces. Prevention requires maintaining proper clearance (typically 10-15% of material thickness) and implementing tool inspection cycles every 10,000-50,000 hits depending on material hardness.

Dimensional Variations occur when tool misalignment or press ram deflection causes stamped metal components to exceed tolerance specifications. Part tolerances exceeding ±0.2mm often fall outside GD&T specifications, rendering components unusable for precision assemblies.

| Defect Type | Root Cause | Prevention Method | Detection Approach |

|---|---|---|---|

| Wrinkles | Insufficient blank holder force; excessive material flow | Increase holder pressure; optimize draw beads; redesign material flow | Visual inspection; surface profilometry |

| Cracks/Fractures | Excessive stretching; tight radii; insufficient material ductility | Select higher-ductility materials; increase die radii; consider hot forming | Visual inspection; dye penetrant testing |

| Springback | Elastic recovery in high-tensile alloys | CAE simulation; overbending compensation; coining operations | CMM measurement; optical comparator |

| Burrs | Worn tooling; incorrect punch-to-die clearance | Maintain 10-15% clearance; implement inspection cycles every 10K-50K strokes | Visual inspection; burr height measurement |

| Surface Scratches | Inadequate lubrication; particulate contamination; rough die surfaces | Apply micro-lubrication; pre-clean materials; polish dies to Ra0.2μm | Visual inspection under controlled lighting |

| Dimensional Inaccuracies | Tool misalignment; press ram deflection; material thickness variation | Add guide posts; verify press parallelism; certify incoming material | CMM inspection; go/no-go gauges |

Quality Control Measures for Consistent Output

Identifying defects after they occur is reactive—and expensive. Modern stamping operations emphasize in-process monitoring and statistical process control (SPC) to catch deviations before they produce scrap.

What does effective quality control look like for metal stamping components? According to NIMS credentialing standards, qualified technicians must demonstrate expert knowledge of SPC recording techniques, material conformance standards, and the ability to distinguish between go/no-go status for both attribute and variable tolerances.

Effective quality systems for stamped parts incorporate multiple layers:

- First-piece inspection: Full dimensional verification before production runs begin—using 3D scanners to compare physical parts against digital models

- In-die sensors: Real-time monitoring of press load, material feed, and forming forces to detect anomalies before defective parts accumulate

- Statistical sampling: Periodic measurement of critical dimensions with results plotted on control charts to identify process drift

- Material traceability: Batch certification ensuring consistent mechanical properties, especially critical for HSLA and advanced high-strength steel grades

The process-engineering perspective emphasizes understanding the "why" behind defects rather than simply identifying them. When a crack appears in stamped steel parts, the question isn't just "what failed?" but "what process parameter shifted to cause this failure?" This root-cause thinking transforms quality control from inspection into prevention.

Proper die design and maintenance remain the foundation of defect prevention. As discussed in the previous section, regular inspection cycles, preventive sharpening, and clearance monitoring address problems at their source. A comprehensive industry guide recommends using CAE software like AutoForm to simulate material flow, springback, and stress distribution during the design phase—catching potential defects before tooling is even manufactured.

The shift toward smart manufacturing is accelerating these capabilities. According to industry surveys, 74% of automotive tier-one suppliers now use real-time data analytics to minimize defect rates and reduce tool changeover times by 20-30%. Digital twin technologies enable continuous comparison between actual production data and simulated performance—flagging deviations that predict quality issues before they manifest in finished parts.

With defect prevention strategies understood, a practical question remains: where do these precision stamped metal parts actually go? The next section explores industry applications—from automotive body panels to medical device enclosures—showing how metal pressing delivers value across diverse sectors.

Industry Applications From Automotive to Medical Devices

Now that you understand how to prevent defects and maintain quality, here's the exciting part: where do all these precision-stamped components actually end up? The metal stamping process touches virtually every industry you can imagine—from the car in your driveway to the smartphone in your pocket. Let's explore specific stamping applications across major sectors and discover why manufacturers consistently choose metal pressing over alternative fabrication methods.

Automotive and Aerospace Precision Components

When you look at a modern vehicle, you're seeing automotive metal stamping in action—everywhere. According to Alsette's manufacturing overview, stamping produces a huge range of automotive components, from highly visible exterior panels to hidden structural reinforcements that keep passengers safe during collisions.

Why does automotive stamping dominate vehicle manufacturing? Three factors make it irreplaceable:

- Speed and efficiency: Modern presses produce hundreds or thousands of parts per hour—essential for keeping pace with assembly line demands

- Cost-effectiveness at scale: Once dies are built, per-part costs drop dramatically across high-volume production runs

- Strength-to-weight optimization: Complex stamped geometries maximize strength while using relatively thin sheet metal, improving fuel efficiency and EV range

Auto metal stamping produces components across three major categories:

Body Panels (Closures and Skin):

- Doors (outer and inner panels)

- Hoods and trunk lids

- Fenders and quarter panels

- Roof panels

These parts require "Class A" surface finish—perfectly smooth and free of defects since they're highly visible to customers.

Structural Components (Body-in-White):

- A, B, and C pillars supporting the roof

- Floor pan sections and frame rails

- Cross members and firewall assemblies

- Inner wheel wells

These stamped parts prioritize crash performance, often utilizing high-strength steels for occupant protection.

Functional Components:

- Mounting brackets for engines, suspension, and radiators

- Heat shields and reinforcement plates

- Seat structures and adjustment mechanisms

- Fuel tank shells

Aerospace applications demand even higher precision—and stamping delivers. According to Manor Tool's aerospace documentation, the accuracy, fine detail, and durability of metal stamped parts makes them ideal for this industry, which requires equipment to meet strict quality standards within exceptionally tight tolerances.

Stainless steel metal stamping produces critical aerospace components including:

- Pressurization systems: Compressors and valves composed of stamped components keep aircraft cabins safely pressurized at altitude

- Electrical systems: Stamped relays and switches control power generation and distribution throughout aircraft

- Flight instrumentation: Altimeters, compasses, fuel gauges, and pressure sensors incorporate precision stamped housings

- Engine controls: Sensors and valves measuring temperature, pressure, and position rely on stamped enclosures

- Actuator components: Landing gear, wing flaps, and bay door mechanisms use stamped parts for hydraulic-to-motion conversion

- Communication antennas: Navigation and communication systems feature numerous precision stamped elements

Aerospace components must withstand extreme temperature fluctuations, corrosion, pressure variations, and high vibration levels—requirements that sheet metal stamping meets through careful material selection and precision forming.

Medical and Electronics Industry Applications

Imagine the precision required when stamped components end up inside medical devices or electronic systems where failure isn't an option. These industries leverage the metal stamping process for fundamentally different reasons than automotive—yet the underlying advantages remain consistent.

Medical Device Manufacturing:

Healthcare applications demand absolute consistency and biocompatibility. Stamped components appear in:

- Surgical instrument housings and handles

- Diagnostic equipment enclosures

- Implantable device components (using specialized biocompatible alloys)

- Hospital bed frames and adjustment mechanisms

- Medical cart structures and mounting brackets

Why choose stamping for medical applications? The process delivers the repeatability required for FDA compliance—every part from the same die is virtually identical to the last. This consistency is critical when components must meet stringent regulatory standards and perform reliably in life-critical situations.

Electronics and Electro-Mechanical Part Stamping:

Your smartphone, laptop, and home appliances contain dozens of stamped metal components you never see. Electronics manufacturers rely on high-precision stamping for:

- Connectors and terminals: Copper stamping creates the micro-contacts enabling electrical connections in everything from USB ports to circuit boards

- EMI/RFI shields: Stamped enclosures protect sensitive electronics from electromagnetic interference

- Heat sinks: Aluminum stamping produces thermal management components for processors and power electronics

- Battery contacts: Precision-stamped springs and clips ensure reliable power delivery in portable devices

- Chassis and frames: Structural components providing rigidity and mounting points for internal assemblies

According to Fictiv's manufacturing guide, stamping is widely used in electronics because once tooling is built, a press can produce dozens to hundreds of identical parts per minute while maintaining tight dimensional consistency over millions of cycles.

Consumer Goods Applications:

Beyond industrial sectors, stamping shapes everyday products:

- Kitchen appliance housings and internal components

- HVAC system brackets and ductwork connections

- Furniture hardware and decorative trim

- Power tool housings and guards

- Sporting goods components and bicycle parts

The common thread across all these stamping applications? High-volume production requirements combined with demanding precision specifications. When manufacturers need thousands or millions of identical components—whether automotive brackets, aerospace housings, medical enclosures, or electronic shields—metal pressing delivers the speed, consistency, and cost-effectiveness that alternative processes simply cannot match.

Understanding where stamped parts go helps clarify when this process makes sense. But how do you determine whether metal pressing is the right choice for your specific project? The next section breaks down economic factors and selection criteria—giving you the framework to make informed manufacturing decisions.

Economic Factors and Process Selection Criteria

You understand where stamped parts go and which industries rely on them—but here's the question that lands on every executive's desk: does metal stamping actually make financial sense for your project? The answer isn't always yes. Understanding the economic decision framework separates smart manufacturing investments from costly mistakes that drain budgets and delay production timelines.

What is a stamping press really costing you? The upfront tooling investment might seem intimidating, but that number means nothing without context. The true calculation involves spreading die costs across production volumes, comparing per-part economics against alternatives, and understanding where break-even points actually fall.

Cost Analysis and Volume Thresholds

Metal stamping economics follow a predictable pattern: high initial investment, dramatically lower per-part costs at scale. According to Manor Tool's cost analysis, stamping isn't ideal for prototypes or low-volume runs because the upfront tooling investment often exceeds traditional machining costs for small batches. However, once production reaches around 10,000+ parts per month, the tooling cost becomes far more economical.

What drives these costs? Five primary factors determine your total investment:

- Tooling and Die Investment: Custom dies designed specifically for your part represent the largest upfront cost—ranging from thousands to hundreds of thousands of dollars depending on complexity

- Material Requirements: Material composition, thickness, and width directly determine long-term component costs

- Part Complexity: Simple parts requiring single strikes cost less than complex geometries needing progressive die stamping with multiple stations

- Estimated Annual Usage (EAU): Higher volumes spread tooling costs across more parts, dramatically reducing per-unit economics

- Lead Times and Logistics: Domestic versus international sourcing significantly impacts total cost when factoring shipping, delays, and quality risks

The relationship between die investment and per-part costs follows an inverse curve. Imagine a $50,000 progressive die producing parts at $0.15 each in material and labor. At 10,000 parts, your tooling adds $5.00 per unit—expensive. At 100,000 parts, tooling contributes just $0.50 each. At 1,000,000 parts, the die cost becomes almost negligible at $0.05 per piece. This math explains why production metal stamping dominates high-volume manufacturing.

Break-even analysis becomes critical for tooling investment decisions. Calculate your total die cost, estimate per-part production expenses, then compare against alternative processes at your projected volumes. The crossover point—where stamping becomes cheaper than alternatives—typically falls between 5,000 and 25,000 parts depending on complexity.

Here's where lead time impacts economics significantly. Traditional die development can take 8-12 weeks, delaying production and extending time-to-market. However, suppliers with rapid prototyping capabilities—delivering functional tooling in as little as 5 days—compress development cycles and reduce opportunity costs. Companies like Shaoyi combine this speed with 93% first-pass approval rates, minimizing the costly iteration cycles that inflate project budgets. For automotive OEMs requiring IATF 16949 certification, their engineering team delivers precision stamping dies tailored to demanding quality standards.

When Metal Pressing Beats Alternative Processes

Metal stamping isn't always the answer—but when conditions align, it's unbeatable. Understanding where high speed stamping excels versus where alternatives make more sense prevents expensive process mismatches.

What is a stamping operation competing against? The primary alternatives include:

- Hydroforming: Uses high-pressure fluid to shape complex hollow parts with single dies

- Roll Forming: Progressively bends sheet metal into continuous profiles of unlimited length

- Casting: Pours molten metal into molds for complex three-dimensional shapes

- CNC Machining: Removes material to create precision parts without dedicated tooling

According to LS Precision's process comparison, the decision fundamentally involves sacrificing flexibility for efficiency. Metal stamping and forming operations require complete die sets that are expensive and time-consuming to produce—but once amortized, unit costs become extremely low for high-volume production.

Hydroforming offers 40-60% lower tooling costs than stamping and excels at complex hollow parts, making it ideal for small-to-medium volumes of structural components. However, cycle times are significantly longer, limiting throughput for mass production scenarios.

Roll forming handles unlimited lengths and complex cross-sections efficiently but requires expensive specialized tooling that makes small-batch production prohibitively costly. It's the method of choice for architectural trim, solar panel frames, and transportation components produced continuously.

CNC machining requires no dedicated tooling—perfect for prototypes and low volumes—but per-part costs remain high regardless of quantity. When volumes exceed a few hundred pieces, the economics typically shift toward stamping.

| Process | Setup Cost | Per-Part Cost at Volume | Achievable Tolerances | Best Volume Range |

|---|---|---|---|---|

| Metal Stamping | High ($10K-$500K+ for dies) | Very Low at scale | ±0.001" - ±0.005" | 10,000+ parts annually |

| Hydroforming | Medium (40-60% less than stamping) | Moderate | ±0.005" - ±0.015" | 100-10,000 parts |

| Roll Forming | High (specialized tooling) | Very Low for continuous runs | ±0.010" - ±0.030" | High-volume continuous profiles |

| Casting | Medium-High (mold investment) | Low-Moderate | ±0.010" - ±0.030" | 500-100,000+ parts |

| CNC Machining | Low (no dedicated tooling) | High (labor-intensive) | ±0.0005" - ±0.001" | 1-500 parts |

When should you choose high speed metal stamping over alternatives? The decision criteria become clear:

- Choose stamping when: Production volumes exceed 10,000 parts annually, parts are relatively flat or shallow-formed, tight tolerances are required, and cycle time matters

- Choose hydroforming when: Complex hollow geometries are needed, volumes are moderate, and tooling budget is constrained

- Choose roll forming when: Continuous profiles of unlimited length are required at high volumes

- Choose machining when: Volumes are very low, designs change frequently, or tolerances exceed stamping capabilities

The sheet metal press economics ultimately favor stamping for most high-volume applications—but only when you partner with suppliers who minimize the risks that inflate costs. Quality issues requiring rework, extended die development timelines, and poor first-pass yields can quickly erode the theoretical cost advantages.

That's why supplier selection matters as much as process selection. Working with manufacturers who offer rapid prototyping, high first-pass approval rates, and certifications meeting OEM requirements—like IATF 16949 for automotive applications—reduces the hidden costs that undermine metal stamping economics. When tooling arrives faster and works correctly the first time, your break-even point arrives sooner, and the per-part cost advantages compound across your entire production run.

Frequently Asked Questions About Metal Pressing

1. What is metal stamping and how does it differ from metal forming?

Metal stamping (also called metal pressing) is a cold-forming manufacturing process that uses specialized dies and high-pressure presses to transform flat sheet metal into precise three-dimensional shapes through permanent plastic deformation without removing material. While 'forming' encompasses any process that shapes metal including hot processes like forging, metal pressing specifically refers to cold-forming operations performed at or near room temperature. This distinction matters because cold working produces parts with superior surface finish, tighter tolerances, and enhanced strength properties through strain hardening.

2. What are the main types of metal stamping processes?

The nine core metal stamping processes include: blanking (cutting flat shapes from sheet stock), punching (creating holes and cutouts), coining (high-precision surface details), bending (angular deformation for frames and brackets), flanging (edge formation and reinforcement), stretching (surface expansion for complex contours), embossing (raised decorative patterns), curling (rolled edges and cylindrical forms), and grooving (channel creation for connections). Each technique serves different applications depending on part geometry, tolerance requirements, and production volume needs.

3. How do I choose between mechanical, hydraulic, and servo presses?

Mechanical presses achieve the highest production speeds and are ideal for progressive die operations with relatively flat parts and simpler forming requirements. Hydraulic presses offer variable stroke length and full working energy at any speed, making them best for deep draws and complex forms requiring dwell time. Servo presses combine mechanical efficiency with hydraulic-like flexibility through programmable stroke profiles and precise slide motion control, though at higher initial costs. Choose based on your production mix: mechanical for high-volume simple parts, hydraulic for low-volume complex components, and servo for diverse part families with demanding quality requirements.

4. What materials work best for metal stamping applications?

Material selection depends on four key properties: ductility, yield strength, work hardening characteristics, and springback behavior. Low carbon steel offers excellent formability for automotive brackets and appliance housings. Stainless steel (Grade 304) provides corrosion resistance for medical and food equipment. Aluminum alloys deliver weight savings for electronic enclosures and heat sinks. Copper excels in electrical applications requiring high conductivity. Material thickness typically ranges from 0.002 to 0.080 inches for coil stock, with thicker materials requiring proportionally higher press tonnage.

5. When does metal stamping become more cost-effective than alternative processes?

Metal stamping economics favor high-volume production, typically becoming cost-effective when volumes exceed 10,000 parts annually. The process involves high initial tooling investment ($10K-$500K+ for dies) but dramatically lower per-part costs at scale. For example, a $50,000 die adds $5.00 per unit at 10,000 parts but only $0.05 at 1,000,000 parts. Working with suppliers offering rapid prototyping (as little as 5 days) and high first-pass approval rates reduces iteration cycles and accelerates break-even points. For lower volumes, CNC machining or hydroforming may prove more economical.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —