Metal Cutting Design Secrets: From First File To Flawless Parts

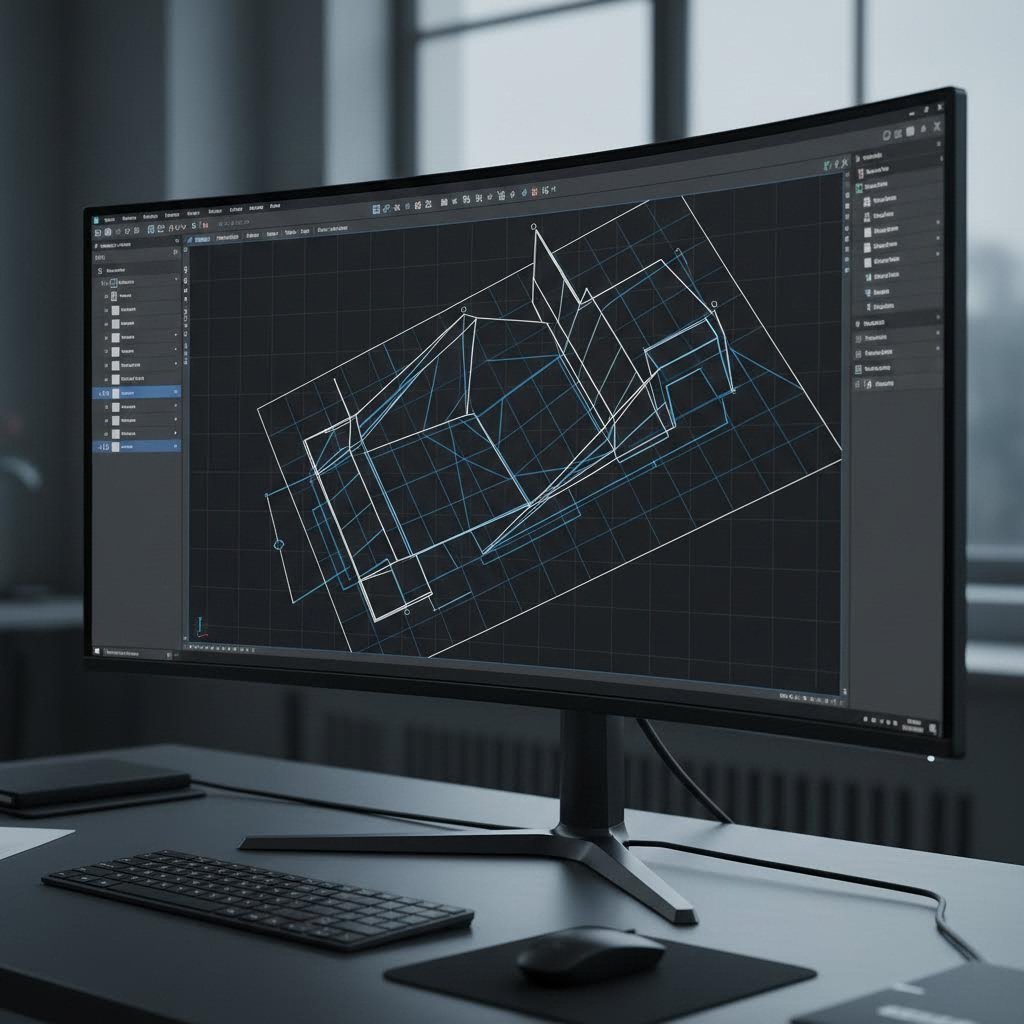

Understanding Metal Cutting Design Fundamentals

Ever wondered why some metal parts come off the cutting table looking flawless while others end up as expensive scrap? The difference usually comes down to what happens long before any metal cutter touches raw material. Metal cutting design is the strategic process of preparing digital files and specifications that guide precision metal fabrication equipment to produce accurate, functional parts.

Whether you're working with a laser cutter, plasma system, or waterjet machine, the principles remain consistent: your design file is the blueprint that determines everything from dimensional accuracy to material waste. This guide serves as a technology-agnostic resource for both decorative artists creating custom signage and industrial engineers developing structural components.

What Metal Cutting Design Actually Means for Fabricators

At its core, this discipline involves translating your concept into a machine-readable format optimized for cutting operations. It encompasses far more than simply creating a vector drawing. You'll need to consider material thickness, cutting method capabilities, thermal effects, and assembly requirements before generating your final file.

The metal fabrication process begins with understanding that each cutting technology has unique strengths and limitations. Laser cutting delivers exceptional precision for intricate patterns, plasma excels at thicker materials with speed, and waterjet handles heat-sensitive metals without thermal distortion. Your design choices must align with whichever method you'll use.

Design decisions made before production begins determine approximately 80% of final part quality, cost, and lead time outcomes.

The Bridge Between Digital Files and Physical Parts

Think of your design file as a communication tool between your intentions and the fabrication equipment. When you prepare a file for laser cutting, you're essentially programming a sophisticated machine to follow exact paths, pierce at specific points, and navigate around features in a particular sequence.

This bridge between digital and physical requires understanding several key concepts:

- Vector-based geometry that defines precise cut paths

- Material-specific tolerances that account for kerf width and thermal expansion

- Feature sizing rules that ensure structural integrity after cutting

- Nesting strategies that maximize material utilization

Beginners often focus exclusively on the aesthetic outcome without considering how the cutting process itself affects results. However, successful fabricators know that proper design preparation prevents costly errors, reduces material waste, and ensures parts fit together as intended during assembly. The following sections will equip you with the specific guidelines and numerical parameters needed to transform your concepts into production-ready files.

Material Selection and Design Implications

Choosing the right metal for your project isn't just about grabbing whatever sheet is closest. Each material behaves differently under concentrated heat or high-pressure water, and those behaviors directly influence how you should approach your design file. Understanding these relationships helps you avoid frustrating revisions and wasted materials.

Matching Materials to Cutting Methods

Different metals aluminium, steel, and specialty alloys each have unique thermal conductivity, reflectivity, and hardness characteristics that determine which cutting technology delivers the best results. Fiber lasers excel with reflective metals like aluminum sheet metal because their wavelength is absorbed efficiently by these materials. Plasma cutting handles thicker steel plate economically, while waterjet remains the go-to choice for heat-sensitive materials or extremely hard alloys.

When designing for stainless steel sheet, you'll need to account for the material's tendency to work-harden during cutting. This characteristic, particularly pronounced in austenitic grades like 316 stainless steel, means your design should minimize the number of piercing points and avoid features that require the cutting head to dwell in one location. For galvanized sheet metal, consider that the zinc coating can produce additional fumes and may affect edge quality differently than bare steel.

How Metal Properties Shape Your Design Choices

Thermal conductivity dramatically affects how heat dissipates from the cutting zone. Aluminum conducts heat approximately five times better than stainless steel, which sounds beneficial but actually creates challenges. The rapid heat dissipation means you need higher power settings to maintain a clean cut, and intricate designs with closely spaced features may experience heat accumulation issues despite the material's conductivity.

Hardness presents another critical consideration. AR500 steel plate, with its Brinell hardness ranging from 450 to 510, demands specialized approaches. According to MD Metals, waterjet cutting is often recommended for AR500 because its cool cutting nature retains the plate's integrity without affecting hardness. Conventional thermal cutting methods can compromise the heat treatment that gives this abrasion-resistant steel its remarkable properties.

Consider these material-specific design principles:

- Aluminum: Allow wider spacing between intricate features to prevent heat buildup; design for faster cutting speeds

- Stainless Steel: Minimize sharp internal corners that create stress points; account for slightly wider kerf widths

- Mild Steel: Most forgiving material; suitable for complex designs with tight tolerances

- AR500: Avoid bending radii tighter than manufacturer specifications; prefer waterjet for precision work

| Material Type | Recommended Cutting Method | Maximum Thickness | Design Considerations | Common Applications |

|---|---|---|---|---|

| Aluminum Sheet | Fiber Laser, Waterjet | 25mm (fiber laser at 6kW+) | High reflectivity requires fiber wavelength; excellent heat dissipation allows faster speeds; prone to burr formation on exit side | Electronic enclosures, aerospace components, decorative panels, heat sinks |

| Stainless Steel Sheet | Fiber Laser, Waterjet | 25mm (fiber laser); virtually unlimited (waterjet) | Work-hardening tendencies; minimize piercing points; nitrogen assist gas produces oxide-free edges for welding | Medical devices, food processing equipment, marine hardware, architectural features |

| Steel Plate (Mild) | Fiber Laser, Plasma, Waterjet | 50mm+ (plasma); 25mm (fiber laser at 6kW+) | Most forgiving material for complex designs; oxygen assist increases cutting speed on thicker sections; consider scale removal needs | Structural components, machine frames, automotive chassis, general fabrication |

| AR500 (Abrasion Resistant) | Waterjet (preferred), Plasma | 50mm (waterjet); 25mm (plasma with care) | Thermal cutting may affect hardness; avoid tight bend radii to prevent cracking; waterjet preserves material properties | Mining equipment wear plates, ballistic armor, conveyor components, impact-resistant shields |

Your material choice ripples through every subsequent design decision. Selecting aluminum sheet for a lightweight bracket means designing for its specific kerf width and accounting for its thermal behavior. Choosing stainless steel sheet for a food-grade component requires understanding how nitrogen assist gas affects your edge finish. These material-specific considerations become second nature as you gain experience, but having them explicitly mapped from the start prevents costly learning experiences on actual production runs.

Minimum Feature Sizes and Tolerance Guidelines

So you've selected your material and cutting method. Now comes the question that separates successful designs from rejected files: how small can your features actually be? Unlike other creative disciplines where you can push boundaries freely, metal cutting design demands adherence to specific numerical thresholds. Violate these minimums, and you'll end up with incomplete cuts, distorted features, or parts that simply don't function as intended.

Critical Dimensions Every Designer Must Know

Before diving into specific numbers, you need to understand why these minimums exist. When a laser beam or plasma arc passes through metal, it doesn't create a mathematically perfect line. Instead, it removes a small channel of material known as the kerf. According to SendCutSend, fiber laser kerf typically ranges from 0.006" to 0.040" (0.152mm to 1mm) depending on material thickness, while CO2 laser kerf falls between 0.010" and 0.020" (0.254mm to 0.508mm).

This kerf width directly determines your minimum feature sizes. Any detail smaller than the kerf width simply cannot exist in the finished part because the cutting process consumes more material than the feature contains. This is why understanding your cutting method's kerf characteristics forms the foundation of proper design.

Consulting a sheet metal gauge chart becomes essential when translating your design intent into manufacturable specifications. Here's an important clarification: gauge sizes aren't consistent across materials. As Makerverse explains, a 16-gauge sheet doesn't mean the same thing for aluminum as it does for steel. The gauge system originated as 19th-century manufacturing shorthand where smaller numbers indicate thicker sheets, but different materials follow different scales entirely.

For practical reference, 14 gauge steel thickness measures approximately 1.9mm (0.075"), while 11 gauge steel thickness comes in around 3.0mm (0.120"). These thickness values directly influence your minimum feature calculations since thicker materials generally require proportionally larger minimum features.

Minimum Feature Size Rules by Material Thickness

The relationship between material thickness and minimum hole diameter follows predictable patterns, though specific ratios vary by material type. Reference data from ADS Laser Cutting provides concrete minimums for common materials:

| Material Thickness | Mild Steel (Min Hole) | Stainless Steel (Min Hole) | Aluminum (Min Hole) |

|---|---|---|---|

| 1.0mm | 0.50mm | 0.50mm | 1.00mm |

| 2.0mm | 1.00mm | 1.00mm | 1.50mm |

| 3.0mm (≈11 gauge) | 1.00mm | 1.00mm | 2.00mm |

| 6.0mm | 3.00mm | 1.00mm | 4.00mm |

| 10.0mm | 5.00mm | 1.00mm | 7.00mm |

| 20.0mm | 10.00mm | 2.50mm | 13.00mm |

Notice how aluminum consistently requires larger minimum holes compared to steel at equivalent thicknesses. This reflects aluminum's thermal behavior and how quickly heat dissipates from the cutting zone. Stainless steel, interestingly, maintains remarkably consistent minimum hole sizes even as thickness increases, making it an excellent choice for designs requiring small features in thicker materials.

Beyond hole diameters, apply these essential minimum feature guidelines when using a gauge size chart to plan your designs:

- Minimum hole diameter ratio: As a general rule, hole diameter should equal or exceed material thickness. For precision work, use the material-specific values above.

- Minimum slot width: Slots should be at least 1.5 times the material thickness. Narrower slots risk incomplete cuts and material deformation.

- Edge-to-edge spacing: Maintain at least 1.0 to 1.5 times material thickness between adjacent features to prevent thermal bridging and structural weakness.

- Edge-to-hole distance: Features should sit at least 1.0 times material thickness from any outer edge to maintain structural integrity.

- Tab connection dimensions: For parts requiring tabs during cutting, size tabs at minimum 2.0 times material thickness wide and 0.5 times thickness in length.

- Minimum internal corner radius: Internal corners should have radii of at least 0.5mm to allow the cutting head to navigate without dwelling excessively.

Understanding Kerf and Compensation Techniques

The tolerance of laser cutting depends heavily on proper kerf management. Kerf isn't just the width of material removed; it changes based on cutting geometry, assist gas pressure, beam power, and material properties. This variability is why modern fabrication services handle kerf compensation automatically rather than requiring designers to adjust their files manually.

However, understanding kerf still matters for design decisions. When two cut paths run parallel and close together, the combined kerf from both cuts can leave web sections thinner than intended. If your design shows a 2mm web between two cutouts, and each cut removes 0.3mm of kerf, the actual web width becomes approximately 1.4mm. For structural applications, this difference matters significantly.

Professional fabrication software applies kerf compensation by offsetting the cutting path to either side of your design line. For external contours, the offset moves outward to preserve your intended dimensions. For internal features like holes, the offset moves inward. This happens automatically, but you should design with these adjustments in mind:

- Intricate patterns: Features smaller than 0.008" to 0.040" (depending on process and material) may be lost entirely due to kerf consumption.

- Nested parts: When cutting parts that fit together, account for kerf on both mating surfaces to achieve proper clearance or interference fits.

- Text and fine details: Minimum stroke width for legible text should exceed twice the kerf width; otherwise, characters will blur or disappear.

The laser cutting tolerance you can achieve depends on following these dimensional guidelines consistently. Parts designed within these parameters arrive from fabrication ready to use, while designs that push beyond these limits often require secondary operations or redesign entirely. With these numerical foundations established, your next challenge becomes preparing files that communicate these specifications accurately to fabrication equipment.

File Formats and Preparation Standards

You've nailed your dimensions and selected the perfect material. But here's where many promising projects stall: the file itself. Submitting the wrong format or a file riddled with hidden errors can delay production for days or result in parts that look nothing like your design. Understanding file format requirements transforms you from someone who creates designs into someone who delivers production-ready files.

Choosing the Right File Format for Your Project

Three file formats dominate the metal cutting landscape, and each serves a distinct purpose in your workflow. Choosing correctly depends on your design complexity, the fabrication equipment being used, and how much control you need over the cutting process.

DXF (Drawing Exchange Format) stands as the industry workhorse. According to DXF4You, nearly all CNC machines and design programs can open, read, and process DXF files, making them an industry standard for metal cutting applications. This format stores vector-based information that machines use to guide cutting tools along precise paths. Whether you're using a laser cutter, plasma system, or waterjet, DXF provides reliable cross-platform compatibility that simplifies collaboration between designers and fabricators.

SVG (Scalable Vector Graphics) excels for web-based design workflows and simpler projects. Many laser cutter ideas start as SVG files because they're easily created in free software and maintain perfect scalability. However, SVG files may require conversion before industrial CNC equipment can process them, and they don't support the layer organization capabilities that complex projects demand.

G-code represents the machine-level language that CNC equipment actually executes. While you typically won't create G-code directly, understanding its role helps you appreciate why proper file preparation matters. Your DXF or SVG file gets converted into G-code instructions that tell the machine exactly where to move, when to fire the laser or plasma, and what speed to maintain throughout each operation.

| Format | Best Use Case | Advantages | Limitations |

|---|---|---|---|

| DXF | Professional fabrication, complex industrial parts | Universal compatibility, layer support, precise dimensional control | Larger file sizes, requires CAD software knowledge |

| SVG | Simple designs, hobbyist projects, web-based workflows | Free software support, web compatibility, easy to edit | Limited layer organization, may require conversion for CNC use |

| G-code | Direct machine control, specialized operations | Maximum control over cutting parameters, machine-specific optimization | Machine-specific format, requires post-processing knowledge |

For most laser cutting ideas and professional applications, DXF remains the safest choice. As noted in fabrication industry guidelines, when using software like CorelDraw or Inkscape, you should export your design as AI or DXF with millimeter units and outlines only before submitting to ensure maximum compatibility.

File Preparation Checklist Before Submission

Even the best design software for laser cutting can't prevent human error during file preparation. Following a systematic workflow catches problems before they become expensive production delays. Here's your complete step-by-step process from concept to submission-ready files:

- Create your design using vector geometry. Whether you're working in Adobe Illustrator, CorelDraw, AutoCAD, or specialized design software for laser cutting like xTool Creative Space, ensure every cutting path consists of true vectors rather than raster images. Raster graphics work for engraving but cannot define cutting paths.

- Convert all text to outlines or paths. Laser cutters cannot process active text boxes directly. Converting text to shapes ensures your typography appears exactly as designed regardless of what fonts the fabricator has installed.

- Organize elements using proper layers. Separate cutting paths from engraving or marking paths using distinct layers. This layering approach helps the machine interpret your design correctly and reduces the risk of errors during production.

- Clean up overlapping and duplicate geometry. Overlapping lines cause the machine to cut the same path multiple times, wasting time and potentially damaging material. Use your software's cleanup tools to eliminate duplicates and merge coincident endpoints.

- Verify line types and widths. Lines convey specific meanings to cutting software. According to xTool, line widths indicate whether the machine should cut, engrave, or score. A line width of 0.2pt might indicate cutting, while thicker lines like 1pt might designate engraving areas.

- Check dimensions and scale accuracy. Confirm your design uses the correct unit of measurement (millimeters vs. inches) and that all dimensions match your intended part sizes. Scaling errors between software systems cause more rejected parts than almost any other issue.

- Apply appropriate nesting and spacing. Position parts at least 2mm apart to prevent burning or merged cuts. Leave a minimum 5mm margin from material edges to account for edge wear and positioning tolerances.

- Run simulation or preview if available. Many CNC software programs offer simulation tools that visualize the cutting path before production. This step identifies potential problems like incorrect toolpaths before committing to actual material.

- Export using correct format settings. When exporting DXF files, select appropriate version compatibility (R14 or 2000 formats offer broadest support) and ensure units match your fabricator's requirements. Verify that all geometry exports as polylines or paths rather than blocks or references.

- Document special requirements clearly. Label material type, thickness, and quantity requirements either within the file using a notes layer or in accompanying documentation. Clear communication prevents assumptions that lead to incorrect production.

Common file errors that cause production delays include unclosed paths (where cutting lines don't form complete shapes), self-intersecting geometry, extremely short line segments that confuse toolpath generation, and embedded raster images mistaken for cutting paths. Most design software for laser cutting includes verification tools that flag these issues before export.

When designing for laser cutting, remember that fills and lines serve different purposes. Lines define precise cutting paths that the machine follows exactly, while filled areas indicate regions for engraving where the laser removes material in passes. Confusing these elements results in parts that engrave where they should cut through or vice versa.

Your file preparation directly impacts both production speed and part quality. A clean, properly formatted file moves through the fabrication queue without delay, while problematic files require back-and-forth communication that extends lead times. With your files properly prepared, the next consideration becomes how those cut parts will actually fit together in their final application.

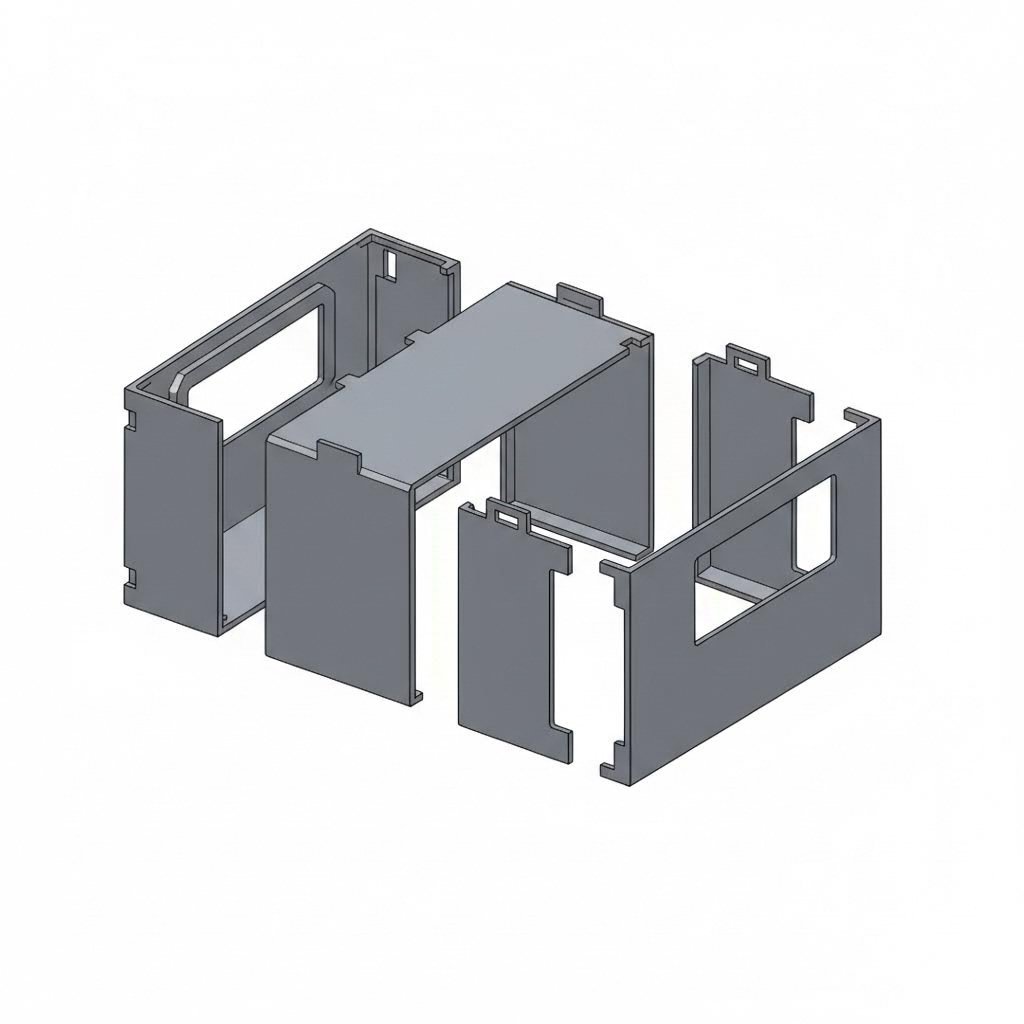

Design for Assembly and Integration

Your laser cut parts look perfect on the cutting table. But here's the reality check: those individual components still need to become a functional assembly. Whether you're building an electronics enclosure or fabricating structural brackets, how you design for assembly determines whether pieces snap together effortlessly or require hours of grinding, shimming, and frustration.

Designing Parts That Fit Together Perfectly

The most elegant metal cutting designs anticipate assembly from the very first sketch. Rather than treating fabrication and assembly as separate concerns, experienced designers integrate connection features directly into their flat patterns. This approach eliminates alignment guesswork, reduces fixture requirements, and creates assemblies that practically build themselves.

According to Fictiv, well-designed self-fixturing components like tabs and slots can reduce fixture setup time by 40-60% in low- to medium-volume production runs. These interlocking features act as built-in locators, maintaining part-to-part gap consistency within ±0.2mm while eliminating reliance on external jigs.

When designing tab-and-slot connections, follow these proven guidelines:

- Tab width: Size tabs at minimum 1.5 to 2 times the material thickness to ensure adequate engagement strength

- Slot clearance: Apply 0.05-0.1mm clearance per side for laser-cut parts requiring friction-fit assembly

- Tab length: Extend tabs at least equal to material thickness to provide sufficient engagement depth

- Corner relief: Add 0.5-1mm radius reliefs at internal slot corners to accommodate cutting tool geometry

- Kerf compensation: Remember that slots cut nominally may need enlargement by half the kerf width per side for critical fits

Hardware mounting provisions require similar forethought. If your design needs threaded connections but the material is too thin for tapping, consider designing holes sized for press-fit hardware or rivets. Speaking of rivets, they offer an excellent cost-effective alternative to bolted connections, particularly for joining thinner materials where their per-piece economy and vibration resistance prove advantageous.

Assembly-Ready Features in Your Cut Files

Different assembly methods impose distinct requirements on your design. Choosing the right approach depends on your tolerance needs, production volume, and whether the assembly requires future disassembly.

| Assembly Method | Tolerance Requirements | Design Complexity | Best Applications |

|---|---|---|---|

| Tab-and-Slot | ±0.1-0.2mm slot clearance per side; maintains part alignment within ±0.2mm during welding | Medium - requires careful geometry planning but uses standard cutting operations | Welded enclosures, self-fixturing assemblies, prototype frames, modular products requiring tool-free disassembly |

| Hardware Fastening | Clearance holes per ASME 18.2.8 standards; typically 0.4-0.8mm larger than fastener diameter | Low - standard hole patterns with readily available fasteners | Serviceable assemblies, adjustable connections, joining dissimilar materials, high-strength structural joints |

| Welded Assembly | 0.1-0.15mm gap allowance per side for weld shrinkage compensation | Medium to High - requires weld preparation features and thermal distortion planning | Permanent structural connections, watertight enclosures, high-temperature applications, load-bearing frames |

| Interlocking Designs | Press-fit requires 0.05-0.1mm interference; loose-fit allows 0.1-0.3mm clearance | High - puzzle-like geometry demands precise calculation of mating features | Tool-free assembly, decorative items, packaging, temporary prototypes, displays requiring repeated disassembly |

For welded assemblies, your design must account for thermal effects beyond just the joint itself. Fictiv recommends alternating tack weld locations (such as Tab 1 and Tab 3, then Tab 2 and Tab 4) to balance thermal stress and minimize warping. Avoid oversized slots that lead to thin weld sections or trapped molten metal during the welding process.

Aluminum welding presents particular challenges due to the material's high thermal conductivity and oxide layer formation. When designing aluminum parts intended for welding, incorporate larger tab features that provide adequate heat sinking and ensure sufficient material remains after thermal distortion.

Bending Considerations for Formed Assemblies

Many assemblies combine flat laser cutting with subsequent bending operations. This combination of laser cutting and bending creates three-dimensional forms from two-dimensional flat patterns, but success depends on understanding how bending affects your overall design.

When you bend sheet metal, the material stretches along the outer surface while compressing along the inner surface. According to Approved Sheet Metal, the bend allowance calculation determines how much extra material length you need in your flat pattern to achieve the correct final dimensions after forming.

The K-Factor, typically ranging between 0.3 and 0.5 for most sheet metal applications, represents where the neutral axis falls within the material thickness during bending. This value directly influences your flat pattern calculations:

- Bend Allowance: The arc length of the neutral axis in a bend, added to leg lengths to determine flat pattern size

- Bend Deduction: The amount subtracted from desired part size to compensate for material stretching during bending

- Inside Setback: The distance from the bend's interior apex to where mating flanges can sit flush

- Minimum Bend Radius: Typically 1-2 times material thickness; tighter radii risk cracking, especially in harder materials

For flat laser cutting operations that precede bending, position holes and features away from bend lines. Features too close to bends will distort as the material forms, potentially elongating holes or shifting their positions relative to other assembly features. A safe rule of thumb places all features at least 2-3 times the material thickness away from any bend line.

Consider how your bend sequence affects assembly access as well. A bracket that folds into a U-shape may trap hardware mounting points inside if you don't plan the forming sequence carefully. Design your flat pattern so that all fastener locations, alignment features, and mating surfaces remain accessible after each progressive bend.

The interplay between cutting precision and bending accuracy determines your final assembly fit. Even perfectly cut parts can produce misaligned assemblies if bend allowances aren't calculated correctly for your specific material and tooling. As your designs become more sophisticated, balancing these considerations becomes second nature, but the fundamental principle remains constant: every design decision should anticipate how individual parts will ultimately work together as a unified assembly.

Decorative Versus Industrial Design Approaches

Imagine designing an ornate garden gate with flowing scrollwork. Now imagine designing a suspension bracket that must withstand thousands of load cycles. Both projects involve metal cutting design, but they couldn't be more different in their priorities. Understanding when aesthetics lead and when engineering requirements dominate helps you approach each project with the right mindset from the start.

Artistic Designs vs Industrial Specifications

Decorative applications prioritize visual impact above all else. When creating laser cut metal designs for wall art, signage, or architectural elements, your primary constraints involve appearance, shadow effects, and how light interacts with cutout patterns. Structural integrity matters only enough to prevent the piece from falling apart during handling and installation.

Custom metal signs exemplify this aesthetic-first approach. Your design decisions center on legibility, brand representation, and visual hierarchy rather than load-bearing capacity. Intricate filigree patterns that would be structurally reckless in a machine component become perfectly appropriate when the part's only job is looking beautiful on a wall.

Industrial specifications flip these priorities entirely. A chassis mount or suspension component must survive repeated stress cycles, thermal expansion, vibration, and environmental exposure. Appearance becomes secondary to function, and every design choice must answer the question: will this feature compromise structural performance?

Design priorities for decorative and artistic applications include:

- Visual complexity: Intricate patterns, fine details, and elaborate negative spaces create visual interest and shadow depth

- Edge quality: Smooth, burr-free edges matter for both appearance and safe handling in display environments

- Pattern density: How much material removal creates the desired transparency and light transmission effects

- Scale relationships: Proportions between positive and negative space that read well at intended viewing distances

- Surface finish compatibility: Design features that accept paint, powder coating, or patina treatments effectively

- Installation provisions: Hidden mounting points that don't compromise the visible design aesthetic

Design priorities for industrial and functional applications include:

- Load path continuity: Material distribution that efficiently transfers forces without stress concentrations

- Fatigue resistance: Generous corner radii and smooth transitions that prevent crack initiation under cyclic loading

- Dimensional stability: Features that maintain critical tolerances despite thermal cycling and mechanical stress

- Weight optimization: Strategic material removal that reduces mass without compromising strength-to-weight ratios

- Assembly interface precision: Mounting holes and mating surfaces held to tight tolerances for reliable fitment

- Serviceability access: Design geometry that permits inspection, maintenance, and component replacement

When Aesthetics Meet Engineering Requirements

Some projects refuse to fit neatly into either category. Architectural metalwork often demands both visual elegance and structural adequacy. A decorative railing must look stunning while also supporting human weight safely. These hybrid applications require you to satisfy engineering minimums first, then optimize appearance within those constraints.

For metal laser cutting design that bridges both worlds, start by establishing non-negotiable structural requirements. Determine minimum material thicknesses, maximum span lengths, and required safety factors based on the application's loading conditions. Only after locking in these parameters should you explore decorative possibilities within the remaining design space.

Consider how designs for laser cutting magnet applications illustrate this balance. Decorative refrigerator magnets prioritize intricate patterns and visual appeal, while industrial magnetic fixtures demand precise dimensions and robust geometry. The cutting technology remains identical, but design philosophy diverges completely based on end-use requirements.

Pattern libraries and template resources can accelerate both decorative and industrial design workflows. Services like ez laser designs offer pre-made patterns that handle aesthetic considerations, freeing you to focus on adapting those elements to your specific material and dimensional requirements. However, never assume that a decorative pattern translates directly to structural applications without engineering validation.

The sweet spot for laser cut designs metal often lies in functional art: pieces that perform a practical purpose while also delivering visual satisfaction. A custom bracket that displays elegant proportions. A machine guard featuring tasteful ventilation patterns. A structural support with chamfered edges and radiused corners that happen to look refined. These designs succeed because they treat aesthetics as a bonus achieved within engineering constraints rather than a goal that compromises function.

Whether your next project prioritizes beauty, durability, or both, clarity about these distinctions prevents costly misalignments between design intent and final performance. Decorative work tolerates structural inefficiency in service of visual goals. Industrial work demands structural adequacy regardless of appearance. Knowing which lens to apply keeps your designs appropriate for their intended purpose and saves you from the frustration of parts that look perfect but fail in service, or perform flawlessly but disappoint aesthetically.

Common Design Mistakes and How to Avoid Them

You've followed the cutting guidelines, selected appropriate materials, and prepared your files carefully. Yet somehow, parts still come off the table with problems. Sound familiar? Even experienced designers encounter production issues that trace back to preventable design decisions. Understanding these common pitfalls before they consume your material budget transforms frustrating surprises into predictable, avoidable outcomes.

Mistakes That Waste Material and Time

The laser cutting process is remarkably precise, but it cannot compensate for fundamental design errors. According to fabrication industry analysis, most production failures stem from a handful of recurring mistakes that designers make repeatedly. Here are the top design errors along with their solutions:

- Insufficient corner radii: Sharp internal corners create stress concentration points and force the cutting head to decelerate abruptly. This dwelling causes excessive heat buildup, leading to poor edge quality and potential material damage. Solution: Add minimum 0.5mm internal radii to all corners, increasing to 1-2mm for thicker materials or high-stress applications.

- Improper nesting and heat stacking: Cutting multiple parts too close together allows heat from adjacent cuts to accumulate. This thermal buildup causes warping, dimensional inaccuracy, and degraded edge quality across entire sheets. Solution: Maintain at least 2mm spacing between parts and use nesting software that alternates cutting locations to distribute heat evenly across the workpiece.

- Ignoring kerf compensation: As production experts note, the laser removes a small portion of material during cutting. Failing to compensate for this kerf causes parts not to fit together correctly, particularly in tab-and-slot assemblies. Solution: Confirm your fabricator applies appropriate kerf offsets, or adjust mating features by half the kerf width per side when designing critical fits.

- Features too close to edges: Holes, slots, or cutouts positioned near material edges lack sufficient supporting material and may deform during cutting or handling. Solution: Position all features at least 1.0 to 1.5 times material thickness from any outer edge.

- Overly complex geometries: Designs with excessive nodes, extremely short line segments, or unnecessary detail slow processing and increase error risk. Solution: Simplify paths by removing redundant points, converting small features to simpler shapes, and eliminating details smaller than the cutting process can reliably reproduce.

- Wrong layer organization: If layers in your design file aren't set correctly, the machine may cut before engraving or process operations out of sequence, causing alignment issues and wasted material. Solution: Organize layers logically with clear naming conventions, placing interior features before exterior contours in the cutting sequence.

- Skipping test cuts: Proceeding directly to production without validating settings on a test piece leads to unexpected issues with expensive materials. Solution: Always run a small test cut with identical material and settings before committing to full production runs.

Troubleshooting Design Issues Before Production

Understanding dross formation helps you design parts that emerge cleaner from the cutting process. So what exactly is dross? Define dross as the resolidified molten metal that adheres to the bottom edge of laser cut materials during cutting. According to quality control research, dross occurs when molten material doesn't eject cleanly from the cut zone and instead solidifies on the underside of the workpiece.

While dross formation depends partly on machine settings and assist gas flow, your design choices influence its severity. Parts with many pierce points, tight internal features, or inadequate spacing accumulate more dross because the cutting head must slow down repeatedly. Designing smoother cutting paths with fewer directional changes reduces dross by maintaining consistent cutting speeds throughout the operation.

Thermal distortion represents another challenge that cutting metal laser processes can introduce. As thermal management studies explain, heat-affected zones cause uneven expansion and contraction that leads to warping. Several factors influence distortion severity:

- Material thickness variance: Inconsistent stock thickness creates unpredictable heat distribution

- Heat distribution patterns: Concentrated cutting in one area builds up thermal stress

- Cooling rate differences: Thin sections cool faster than thick areas, creating internal stresses

- Cut path sequencing: Poor ordering allows heat to accumulate rather than dissipate

Smart nesting software addresses many distortion concerns automatically. Modern systems analyze part geometry and generate cutting sequences that minimize thermal stress by alternating between different sheet areas. The software spaces parts strategically and optimizes torch paths to prevent heat stacking, particularly important when working with laser cut materials prone to distortion like thin sheet metal or aluminum.

Safety considerations also affect your file preparation. Poor ventilation during cutting leads to smoke buildup that reduces laser efficiency and creates hazardous conditions. While ventilation is primarily an operational concern, your design impacts it indirectly. Highly intricate patterns with extensive cutting time generate more fumes than simpler designs. If your project involves materials with special cutting requirements, document these clearly so operators can adjust ventilation and protective measures accordingly.

Before submitting any file for production, run through this quick troubleshooting checklist:

- Have all internal corners been radiused appropriately for material thickness?

- Is spacing between features adequate to prevent thermal bridging?

- Are pierce points positioned away from critical edges where dross might affect fit?

- Does the design allow for logical cutting sequence from interior to exterior?

- Have you verified that all features exceed minimum size thresholds for the material?

- Is the material specified appropriate for the intended cutting method?

Catching these issues during design costs nothing. Discovering them after cutting wastes material, time, and money. With a solid understanding of common mistakes and their prevention strategies, you're prepared to move from troubleshooting individual issues to implementing a complete, systematic workflow that carries your designs smoothly from initial concept through finished production.

Complete Design to Production Workflow

You've mastered the fundamentals, selected materials, established tolerances, and avoided common pitfalls. Now it's time to see how all these elements connect in a complete journey from initial concept to finished metal cut piece. Understanding this end-to-end workflow transforms isolated knowledge into a repeatable system that delivers consistent results every time.

From Sketch to Finished Part

Every successful sheet metal fabrication project follows a predictable sequence of phases. Whether you're producing a one-off prototype or preparing for mass production, these stages remain consistent. The difference between amateur and professional outcomes often comes down to how thoroughly each phase is executed before advancing to the next.

According to Die-Matic's production guide, the design phase involves engineers and product designers working together to ensure parts meet functionality, cost, and quality requirements. This collaborative approach catches potential issues when changes are still inexpensive to implement.

The metal fab industry has evolved significantly in how design intent translates to production reality. Modern workflows leverage digital tools at every stage, creating documentation trails that ensure consistency between what you envision and what arrives from fabrication.

Your Complete Production Roadmap

Here's the sequential workflow that carries your concept through to finished laser cutting parts:

- Concept development and requirements definition. Start by clarifying what your part needs to accomplish. Define functional requirements, dimensional constraints, material preferences, and quantity expectations. As EZG Manufacturing explains, this phase establishes size and weight targets, material requirements, performance criteria, and budget parameters. Document everything—vague requirements lead to misaligned outcomes.

- Initial design and CAD modeling. Translate your concept into precise digital geometry. Create 3D models or 2D profiles using appropriate design software, applying the minimum feature sizes and tolerance guidelines covered earlier. This is where understanding steel fabrication constraints pays dividends, as you'll design within manufacturable parameters from the start rather than discovering problems later.

- Design for manufacturability (DFM) review. Before committing to production, have your design evaluated for manufacturing efficiency. According to Cadrex's fabrication guide, DFM involves reviewing product designs to ensure final assemblies meet desired outcomes and can be manufactured efficiently. This review catches excessive forming operations, inappropriate tolerances, and features that add cost without functional benefit. Professional manufacturing partners like Shaoyi Metal Technology offer comprehensive DFM support that identifies design issues early, preventing costly revisions after tooling begins.

- Material selection and sourcing confirmation. Verify that your specified material is available in required thicknesses and quantities. For stainless steel sheet metal applications, confirm the specific grade meets both functional requirements and cutting method compatibility. Material lead times can extend project schedules significantly, so early confirmation prevents delays.

- Prototype fabrication and validation. Before committing to production tooling or large material orders, produce sample parts to verify fit, function, and appearance. Rapid prototyping services compress this validation phase dramatically. Shaoyi's 5-day rapid prototyping capability allows you to hold physical parts quickly, test assembly interfaces, and confirm that your design performs as intended before scaling up.

- Design revision and optimization. Prototype testing almost always reveals opportunities for improvement. Perhaps a mounting hole needs repositioning, a bend radius requires adjustment, or material thickness should change. Iterate your design based on physical testing feedback, then validate again if changes are significant.

- Production file preparation. Generate final production files following the format and preparation standards covered earlier. Ensure all geometry is clean, layers are organized correctly, and specifications are documented clearly. For cnc cut parts, verify that your files contain only the vector information needed for cutting operations.

- Tooling and fixture development. For production quantities, specialized tooling may be required. Progressive dies, forming fixtures, and assembly jigs all require development time. According to Die-Matic, tooling is pivotal to efficient, precise manufacturing—choosing the right dies and collaborating with design engineers during prototyping proves out the intended process.

- Production run execution. With validated designs and prepared tooling, production proceeds through the cutting, forming, and finishing operations your parts require. Quality control measures throughout this phase ensure consistency across all produced parts.

- Post-processing and finishing. Raw cut parts often require secondary operations: deburring to remove sharp edges, surface treatments for corrosion protection, or assembly operations that combine multiple components. Plan these steps during initial design to ensure parts arrive ready for their intended application.

- Quality inspection and documentation. Final inspection verifies that finished parts meet specifications. Dimensional checks, visual inspection, and functional testing confirm production success. For automotive applications requiring IATF 16949-certified quality, this documentation becomes part of the permanent quality record.

- Delivery and integration. Completed parts ship to your facility or directly to assembly locations. Proper packaging prevents transit damage, and clear labeling ensures parts reach their intended destinations without confusion.

This workflow applies whether you're ordering laser cut parts online for a hobby project or sourcing precision components for automotive chassis and suspension systems. The difference lies in how rigorously each phase is executed and documented.

Professional DFM review at the design stage catches approximately 70-80% of potential production issues before any material is cut, saving both time and cost compared to discovering problems during fabrication.

For complex projects or high-volume production, partnering with experienced manufacturers streamlines this entire process. Shaoyi Metal Technology's 12-hour quote turnaround accelerates early project phases, giving you rapid feedback on feasibility and cost before committing significant design resources. Their automated mass production capabilities then scale validated designs efficiently once prototyping confirms your design intent.

The gap between concept and finished part shrinks dramatically when you approach each phase systematically. Rushing through early stages to reach production faster typically backfires, creating rework cycles that consume more time than methodical preparation would have required. Whether you're a first-time designer or an experienced engineer, following this roadmap consistently produces better outcomes than improvising your way through the fabrication process.

With the complete workflow mapped out, your final consideration becomes matching your current skill level to appropriate next steps and resources for continued growth in metal cutting design capabilities.

Taking Your Designs from Concept to Reality

You've absorbed the fundamentals, explored material considerations, and mapped the complete production workflow. But where do you go from here? The answer depends entirely on where you're starting. Whether you're sketching your first bracket or optimizing complex assemblies for mass production, your next steps should match your current capabilities while stretching you toward the next level.

Your Next Steps Based on Experience Level

Growth in metal cutting design follows a predictable progression. Each stage builds on previous knowledge while introducing new challenges that expand your capabilities. Here's a structured path that moves you from foundational skills through professional-level competency.

Beginner Level: Building Your Foundation

- Master one CAD program thoroughly. Rather than dabbling in multiple software packages, develop deep proficiency in a single tool. Free options like Fusion 360 or Inkscape provide excellent starting points without financial commitment.

- Start with simple, single-part designs. Create basic brackets, mounting plates, or decorative items that involve only cutting operations—no bending or complex assemblies yet.

- Learn to read and apply a sheet metal gauge chart. Understanding material thickness conventions prevents costly specification errors on your first orders.

- Order sample parts from online fabrication services. Search for metal fabrication near me or use online platforms to get hands-on experience with how your digital files translate to physical parts.

- Study your mistakes. When parts don't turn out as expected, analyze what went wrong. Did features fall below minimum sizes? Were tolerances too tight? Each failure teaches something valuable.

- Explore finishing options. Understanding processes like powder coating services and anodizing helps you design parts that accept these treatments effectively from the start.

Intermediate Level: Expanding Your Capabilities

- Introduce bending operations. Design parts that combine flat cutting with formed features. Learn bend allowance calculations and K-factor applications for your commonly used materials.

- Design multi-part assemblies. Create tab-and-slot connections, hardware mounting provisions, and interlocking features that self-locate during assembly.

- Develop material-specific expertise. Rather than treating all metals identically, understand how aluminum, stainless steel, and mild steel each behave differently under cutting and forming operations.

- Build relationships with fabrication shops near me. Local steel fabricators and metal fabricators near me often provide valuable feedback on design manufacturability that online services cannot match.

- Create design templates. Develop reusable starting points for common part types—mounting brackets, enclosure panels, structural gussets—that incorporate proven design rules.

- Experiment with secondary operations. Learn how anodizing affects tolerances, how powder coating services add thickness to features, and how these finishes interact with your design geometry.

Advanced Level: Professional-Grade Design

- Optimize for production efficiency. Design parts that minimize cutting time, reduce material waste through intelligent nesting, and streamline downstream operations.

- Master tolerance stack-up analysis. Predict how individual part variations accumulate in assemblies and design appropriate clearances to ensure reliable fitment.

- Design for automated production. Understand how your design choices affect robotic handling, automated welding, and high-volume manufacturing processes.

- Develop DFM review capabilities. Learn to evaluate designs for manufacturability before submission, catching issues that would otherwise require revision cycles.

- Specialize in demanding applications. Automotive chassis components, aerospace structures, and medical devices each impose unique requirements that separate advanced practitioners from generalists.

- Build manufacturing partnerships. Complex projects benefit from early collaboration with experienced fabricators who can provide DFM guidance during design rather than after.

Building Your Metal Cutting Design Skills

Progression through these levels isn't strictly linear. You might tackle advanced tolerance analysis for one project while returning to beginner-level explorations when working with an unfamiliar material. The key is continuous learning through hands-on practice combined with study of underlying principles.

According to SendCutSend's educational resources, structured learning paths that combine video instruction with practical projects accelerate skill development significantly compared to trial-and-error approaches alone. Their Community College series walks designers through CAD fundamentals, cutting process understanding, bending calculations, and finishing operations in a logical progression.

Knowing when to seek professional support marks the transition from hobbyist to serious practitioner. As James Manufacturing notes, professional metal fabricators stay up to date with the latest industry advancements and use cutting-edge technology to deliver superior results. They can help you meet stringent design specifications while ensuring consistent product quality that in-house capabilities often cannot match.

Consider engaging professional manufacturing support when your projects involve:

- Tight tolerances that exceed typical fabrication capabilities

- Materials requiring specialized cutting equipment or expertise

- Production quantities that justify tooling investment

- Quality certifications like IATF 16949 for automotive applications

- Complex assemblies requiring coordinated multi-operation workflows

- Time-critical projects where rapid prototyping accelerates development

For designers working on automotive chassis, suspension, or structural components, Shaoyi Metal Technology offers a practical resource for moving from design to production. Their 12-hour quote turnaround provides rapid feedback on manufacturability and cost, allowing you to iterate designs quickly based on real production constraints. This responsiveness proves particularly valuable during early project phases when design decisions remain fluid.

Your metal cutting design journey doesn't end with mastering technical skills. The most successful practitioners combine technical proficiency with clear communication, systematic documentation, and collaborative relationships with manufacturing partners. Each project teaches something new, whether it's a material behavior you hadn't encountered or an assembly technique that simplifies production.

Start where you are. Use the guidelines in this resource to inform your next design. Order parts, evaluate results, and refine your approach. The gap between first attempts and professional-quality work closes faster than you might expect when you approach each project as both a production task and a learning opportunity.

Frequently Asked Questions About Metal Cutting Design

1. What is the best way to cut designs in metal?

The best cutting method depends on your material thickness, precision requirements, and budget. Laser cutting delivers exceptional accuracy for intricate patterns in thin to medium-gauge materials like mild steel, stainless steel, and aluminum, producing smooth edges with tight tolerances. Plasma cutting offers cost-effective speed for thicker steel plates, while waterjet cutting handles heat-sensitive metals and extremely hard alloys without thermal distortion. For automotive chassis and structural components requiring IATF 16949-certified quality, manufacturers like Shaoyi Metal Technology provide comprehensive DFM support to match your design with the optimal cutting method.

2. How thick of steel can a 1000W laser cut?

A 1000W fiber laser typically cuts up to 5mm stainless steel and similar thicknesses in mild steel, though cut quality decreases near maximum capacity. For thicker materials, higher-powered systems are necessary: 2000W lasers handle 8-10mm, while 3000W+ systems can process 12-20mm depending on quality settings. When designing for laser cutting, always verify your fabricator's specific capabilities and adjust minimum feature sizes accordingly, as thicker materials require proportionally larger holes and wider spacing between features.

3. What are the different types of metal cutting?

Metal cutting processes fall into four main categories: mechanical cutting (shearing, sawing, punching), abrasive cutting (waterjet with abrasive particles, grinding), thermal cutting (laser, plasma, oxy-fuel), and electrochemical cutting (EDM, electrochemical machining). Each method offers distinct advantages for specific applications. Laser cutting excels at precision and intricate details, plasma handles thick materials economically, and waterjet preserves material properties in heat-sensitive applications. Your design file preparation should account for the specific cutting method's kerf width, minimum feature capabilities, and thermal effects.

4. What file format is best for metal laser cutting?

DXF (Drawing Exchange Format) remains the industry standard for metal cutting applications due to its universal compatibility with CNC machines and design software. DXF files store precise vector geometry, support layer organization for complex projects, and maintain dimensional accuracy across platforms. SVG works well for simpler designs and web-based workflows but may require conversion for industrial equipment. Always export with correct unit settings (millimeters or inches as required), convert text to outlines, and verify all geometry consists of clean vectors without overlapping lines or unclosed paths.

5. How do I avoid common mistakes in metal cutting design?

The most frequent design errors include insufficient corner radii (add minimum 0.5mm internal radii), features placed too close together causing heat accumulation (maintain at least 2mm spacing), ignoring kerf compensation for mating parts, and positioning holes too near edges (keep features at least 1-1.5x material thickness from edges). Always verify minimum feature sizes against your material thickness using a gauge chart, run test cuts before production, and consider DFM review services from experienced manufacturers to catch issues before they waste material and time.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —