Лазерна рязка на метални листове: отстраняване на дефекти, намаляване на разходите, правилен избор

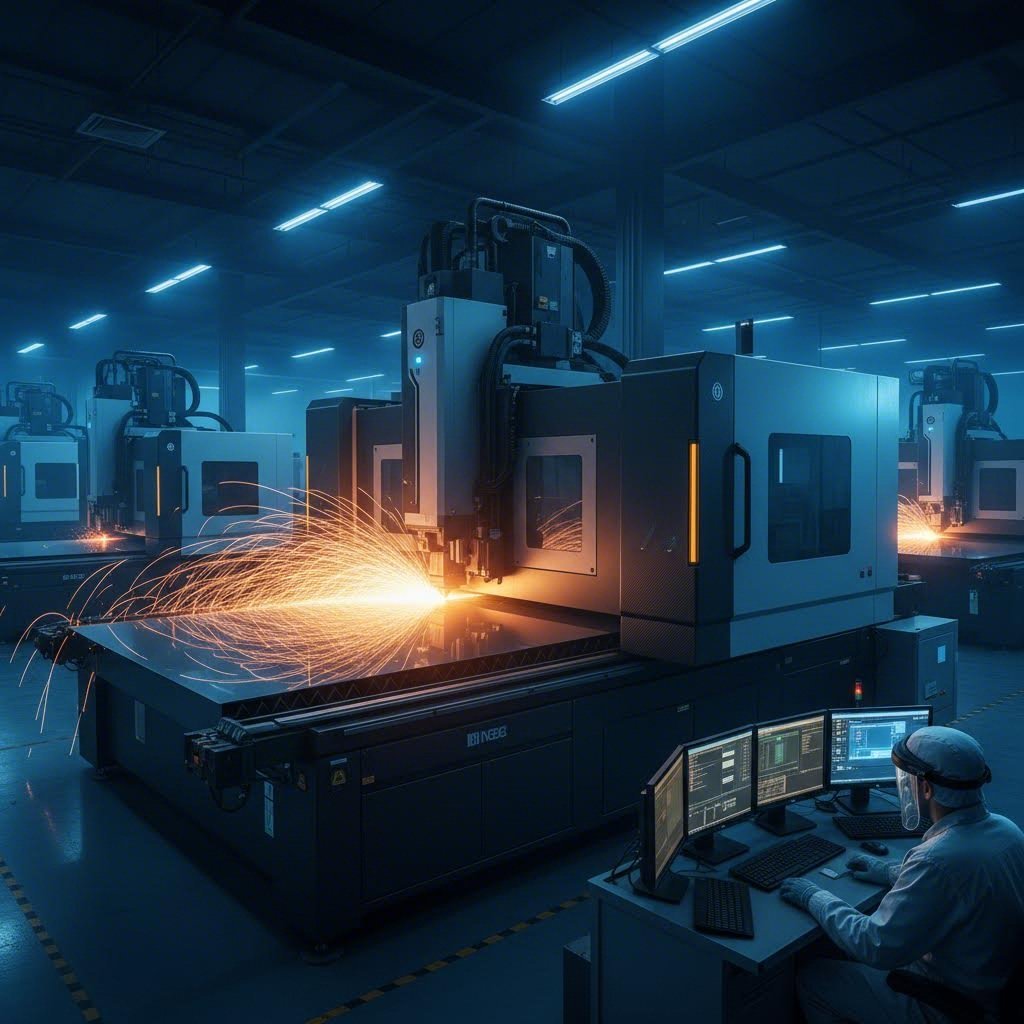

Разбиране на лазерната технология за рязане на метал при производството

Помните ли как като деца насочвахте слънчевата светлина през лупа? Този концентриран лъч можеше да генерира изненадващо висока температура в една точка. Сега си представете този принцип в индустриален мащаб — където точно фокусиран лъч може да достигне температури над 20 000 градуса по Целзий и да прерязва стомана като горещ нож през масло. Това е невероятната наука зад лазерно рязане на метални листове , и тя променя начина, по който производителите подхождат към прецизното производство.

Тази технология се е развила от изключително промишлен инструмент през 60-те години на 20 век до достъпно решение, което задвижва всичко – от автомобилни компоненти до декоративни архитектурни панели. Независимо дали проучвате лазерна рязка на метал за прототип, или разглеждате производство в големи обеми, разбирането на този процес ще ви помогне да определите дали той отговаря на нуждите на вашия проект.

От светлинен лъч до прецизно рязане

В основата си рязката на листови метали с лазер се основава на прекрасно прост принцип: концентрирайте достатъчно светлинна енергия в една точка и можете да стопите или изпарите практически всеки метал. Ето как един лазерен стан за рязане на метал преобразува сурова енергия в прецизни резове:

- Генериране на лазер Процесът започва от лазерния източник – обикновено CO2 лазер, използващ електрически възбудени газови смеси, или влакнест лазер, използващ оптични влакна, наситени с редкоземни елементи.

- Фокусиране на лъча Огледала и специализирани лещи насочват и концентрират лъча в изключително мощна точка от енергия.

- Взаимодействие с материала: Когато този интензивен лъч докосне металната повърхност, той разтапя или изпарява материала в точката на удар, създавайки чисто разделяне.

- CNC прецизност: Системите с числено програмно управление (CNC) насочват лазерната глава с изключителна точност, следвайки програмирани траектории за изпълнение на сложни дизайни с малки допуски.

Резултатът? Можете да извършвате лазерно рязане на метал с изключителна прецизност, постигайки детайли и допуски, които традиционните механични методи просто не могат да достигнат.

Защо производителите на метални конструкции избират лазерна технология

Какво прави лазерното рязане на метал толкова привлекателно за съвременните производители? Отговорът се крие в комбинация от скорост, прецизност и универсалност, които традиционните методи едва ли могат да повторят.

Малко производствени метода могат да се сравняват по скорост на обработка с лазерното рязане. Възможността за рязане на стоманов лист с дебелина 40 мм с помощта на 12 kW лазер с кислородно подпомагане осигурява скорости, които са около 10 пъти по-високи от тези на лентова машина и 50–100 пъти по-високи от жичното рязане.

Освен високата скорост, тази технология предлага няколко убедителни предимства:

- Изключителна прецизност: Лазерни глави с CNC управление извършват точни резове, което позволява сложни модели и тесни допуски, идеални за прототипиране и бързи услуги по обработка на листови метали.

- Високо качество на ръба: Тъй като металите провеждат топлина ефективно, материалът около реза остава сравнително непроменен, което осигурява гладки и прецизни ръбове.

- Гъвкавост на дизайна: От сложни скоби за аерокосмическа индустрия до декоративни табели, една и съща машина може да обработва разнообразни двуизмерни дизайни без смяна на инструменти.

- Намалена загуба на материали: Точни режещи пътища и тесни ширини на реза максимизират използването на материала, което директно влияе на крайната ви печалба.

В това ръководство ще откриете разликите между лазерните системи с влакна, CO2 и диоди, ще научите кои материали и дебелини работят най-добре и ще получите практически познания за отстраняване на често срещани дефекти. Ще намерите също рамки за анализ на разходите и насоки за избор между инвестиции в оборудване и партньорства за услуги - всичко необходимо, за да вземете информирани решения относно интегрирането на тази технология в производствения си работен процес.

Ласъри с въглероден диоид срещу влакна за резка на метали

Така че разбирате основи на лазерното рязане но коя лазерна технология трябва да захранва вашите проекти за производство на метали? Този въпрос оформя решенията за покупка на стойност хиляди долари и пряко влияе на производителността за следващите години. Отговорът зависи от материалите, обема на производството и дългосрочните цели на бизнеса.

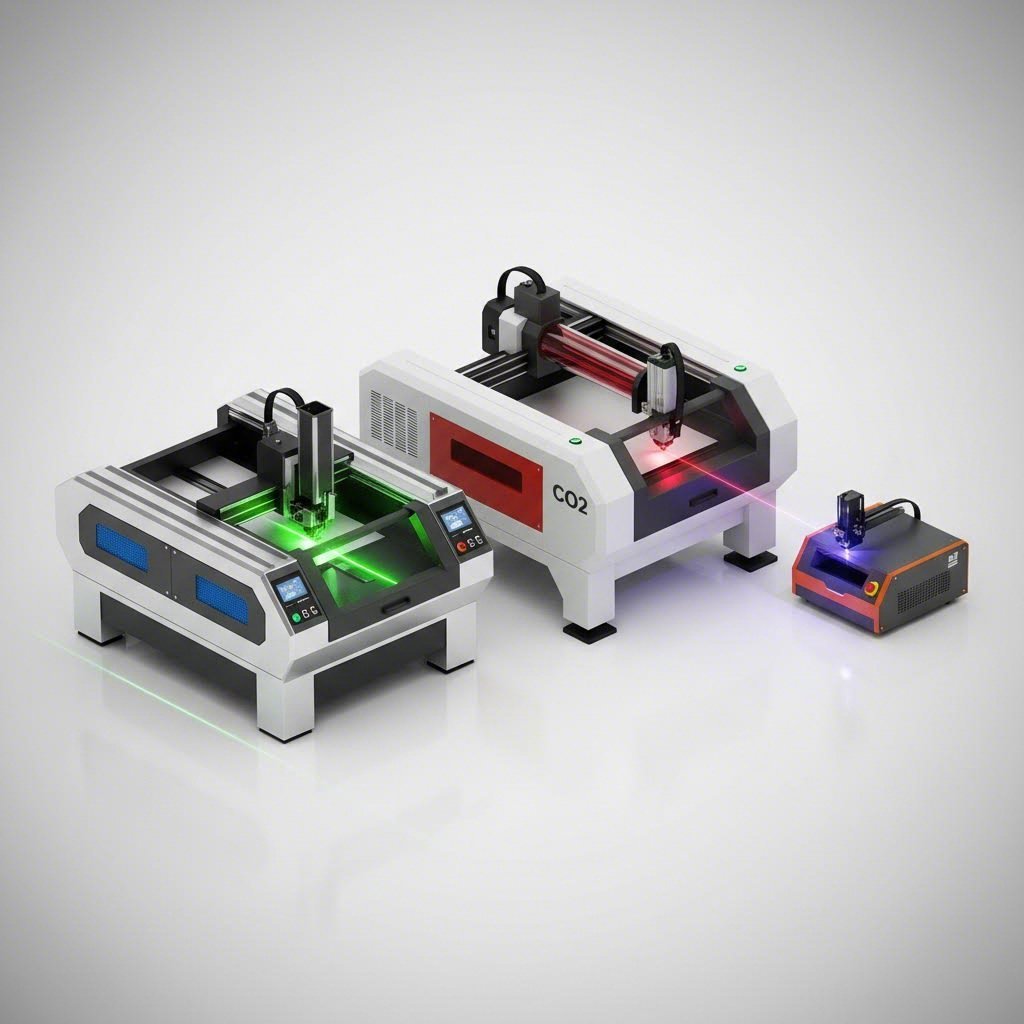

Три основни технологии доминират в сферата на рязане на метал днес: фибрени лазери, CO2 лазери и диодни лазери. Всяка от тях предлага свои специфични предимства, а разбирането на разликите между тях ще ви помогне да вземете по-обмислени решения относно оборудването и извъншни доставки.

Фибрени лазери и тяхното доминиране в рязането на метали

Ако режете метал през 2024 г., фибрените лазери вероятно вече сте ги срещали — и с добро основание. Фибрен лазерен апарат генерира светлина чрез твърдотелна конструкция, използваща оптични кабели, като произвежда вълново дължина около 1,06 μm. Защо това е важно? Тъй като металите абсорбират тази по-къса вълнова дължина значително по-ефективно в сравнение с по-дългите вълни, което води до по-бързо, по-чисто и по-прецизно рязане.

Числата разказват убедителна история. Според Техническия анализ на Bodor , влакнестите лазери постигат около 30–40% електрооптична ефективност в сравнение със само около 10% при CO2 системите. Това предимство в ефективността се превръща директно в по-ниско електричество и значително по-високи скорости на рязане – особено за тънки и средни метални листове.

Рязането на метал с влакнест лазер е особено подходящо за отразяващи метали, които традиционно са били предизвикателство за по-старите технологии. Медта, месингът и алуминият абсорбират ефективно дължините на вълната на влакнестите лазери, което прави тези машини предпочитания избор за разнообразни металообработки. Пълно затворената им конструкция също минимизира нуждата от настройки и намалява текущото поддръжване – важен аспект за натоварени производствени среди.

За производителите, които търсят възможности за стартиране, настолен влакнест лазер предлага достъпна прецизност за по-малки операции, прототипиране и детайлирана работа, без голямото пространство, необходимо за индустриални системи.

Когато все още има смисъл да се използват CO2 лазери

Ето един въпрос, който много производители задават: могат ли CO2 лазерите ефективно да режат метал? Отговорът е да — но с важни оговорки.

CO2 лазерите използват газова смес в запечатана тръба, за да генерират светлина с дължина на вълната 10,6 μm — значително по-дълга от тази при влакнестите системи. Въпреки че металите абсорбират тази дължина на вълната по-малко ефективно, машината за рязане на метал с CO2 лазер все пак може ефективно да обработва стомана и неръждаема стомана, особено когато се използва кислород като помощен газ.

Както пояснява инженерното ръководство на Komaspec, оксидативното рязане с кислород причинява материята да изгаря с ускорено действие при повишени температури. Течният желязен оксид след това се отстранява от разреза под напора на струята кислород. Този процес прави рязането на метал с CO2 лазер практически приложимо за въглеродисти и високовъглеродни стомани, макар да изисква по-висока мощност и по-прецизна настройка на параметрите в сравнение с влакнестите алтернативи.

Там, където CO2 наистина се отличава, е универсалността. Ако вашият процес изисква рязане както на метали, така и на неметали — дърво, акрил, текстил или пластмаси, — CO2 системата осигурява по-гладки ръбове и полирани повърхности върху органични материали, които влакнестите лазери просто не могат да обработят. В среди с комбинирани материали тази гъвкавост често оправдава избора на технология.

Сравнение на технологиите в едно галено

Следната таблица разделя ключовите разлики в производителността между тези три лазерни технологии, за да ви помогне да оцените коя отговаря на вашите конкретни изисквания:

| Параметър | Оптичен лазер | Лазер CO2 | Диоден лазер |

|---|---|---|---|

| Дължина на вълната | ~1,06 μm | ~10,6 μm | ~0,8–1,0 μm |

| Оптимални материали | Всички метали, особено отразяващи сплави | Метали + неметали (дърво, акрил, текстил) | Тънки метали, приложения за гравиране |

| Възможности по дебелина | До 100 mm (с 60 kW системи) | До 25 mm типично | Обикновено под 3 mm |

| Скорост на рязане | Най-бързо за метали | Умерена | По-бавно, подходящо за детайна работа |

| Енергийна ефективност | 30–40% | ~10% | 20–30% |

| Изисквания за поддръжка | Нисък (затворен дизайн на влакното) | По-висок (огледала, лещи, подравняване) | Ниско до умерено |

| Начална инвестиция | Конкурентно на същите нива на мощност | Подобно на влакното, варира според мощността | По-ниска първоначална цена |

| Най-добър за | Производство на метали в големи обеми | Смесени операции метал/неметал | Любителски дейности, гравиране, тънки материали |

Диодните лазери заемат специализирана ниша в тази област. Въпреки че предлагат по-ниски начални разходи и компактни конструкции, ограничена им изходна мощност ги ограничава предимно до тънки метали, гравиране и любителски приложения, а не до промишлено рязане на ламарини.

Вашето технологично решение

Когато оценявате машината за рязане с влакнест лазер с числови команди спрямо алтернативите с CO2, имайте предвид тези насочващи въпроси:

- Фокус върху материала: Режете само метали? Влакнестият лазер осигурява по-висока скорост и ефективност. Имате ли нужда от възможност за рязане на смесени метали и неметали? CO2 осигурява задължителна гъвкавост.

- Изисквания за дебелина: За тънки до средни листове (0,5–20 мм) и двете технологии се представят добре. За дебели плоскости над 25 мм доминират системите с висока мощност влакнест лазер.

- Обем на производството: Средите с висока производителност най-много се възползват от предимството на влакнестия лазер по отношение на скоростта. При производствата с по-нисък обем или различни поръчки гъвкавостта на CO2 може да е по-ценна.

- Дългосрочен възвръщаемост на инвестициите: Влакнестите лазери обикновено осигуряват по-добри икономически резултати при непрекъснато производство с висок обем поради по-ниското енергопотребление и намалените разходи за консумативи.

Няма универсално "най-добър" лазер — има само правилният избор за вашия конкретен материал, обем на работата и икономически цели. След като е заложена тази технологична основа, нека разгледаме как различните метали реагират на лазерното рязане и какви ограничения по дебелина трябва да имате предвид.

Ръководство за дебелина на материала и параметри за рязане

Избрахте лазерната си технология — сега идва практическият въпрос, с който се сблъсква всеки производител: какво може всъщност да реже тази машина? Разбирането на ограниченията по отношение на дебелината на конкретен материал и оптималните параметри разделя успешните проекти от скъпоструващи провали. Всеки метал реагира по различен начин под лазерния лъч и съгласуването на възможностите на оборудването с изискванията за материала осигурява чисто рязане, ефективно производство и прогнозируеми резултати.

Нека разгледаме параметрите за рязане за най-често срещаните метали, които ще срещате при обработка на листови метали.

Параметри за рязане на стомана и неръждаема стомана

Рязането с лазер на мека стомана представлява основната дейност в повечето работилници за металообработка. Този материал абсорбира лазерната енергия ефективно и реагира предвидимо в широк диапазон от дебелини. Според Ръководството на KF Laser за дебелини , тънки стоманени листове (0,5–3 мм) изискват лазери с мощност само от 1000 до 2000 W, докато за средни плочи (4–12 мм) са необходими системи от 2000 до 4000 W. За дебели стоманени плочи с дебелина 13–20 мм ще са ви нужни нива на мощност от 4000 до 6000 W, за да се запази прецизността и скоростта на рязане.

Рязането на стомана с лазер става по-сложно с увеличаване на дебелината. По-дебелите материали изискват по-бавни скорости на рязане, за да се осигури пълно проникване, но това по-дълго време на задържане води до по-големи зони, засегнати от топлина. Компромисът? Запазва се качеството на рязане, но при много дебели сечения може да се наблюдава леко оцветяване на ръба.

Изискванията за мощност при лазерно рязане на неръждаема стомана са подобни – 1000 W до 2000 W се справят с тънки листове до 3 мм, докато 4000 W до 6000 W се използват за плочи до 20 мм. Въпреки това, съдържанието на хром в неръждаемата стомана влияе на избора на помощен газ. Азотът дава безоксидни, ярки ръбове, които са идеални за видими приложения, докато рязането с кислород увеличава скоростта, но оставя по-тъмен оксиден слой, изискващ последваща обработка.

Предизвикателства при алуминия и отразяващите метали

Можете ли да режете алуминий с лазер? Разбира се — но този материал изисква внимание и правилна подготовка. Високата отразяваща способност и топлопроводимост на алуминия създават уникални предизвикателства, които изненадват неопитните оператори.

Когато лазерът достигне повърхността на алуминия, значителна част от енергията на лъча се отразява обратно, вместо да бъде погълната. Както обяснява техническият анализ на 1CutFab, това отразяване причинява три основни проблема: пренасочване на лъча, което води до непълни резове, непостоянно абсорбиране на енергия, резултиращо в грапави ръбове и образуване на зарава, както и потенциално вредно обратно отразяване, което може да повреди лазерната оптика.

Прилагането на лазерно рязане за алуминий изисква по-висока мощност в сравнение с еквивалентни дебелини от стомана. За тънки алуминиеви листове (0,5–3 мм) ефективно работят лазери с мощност 1000W до 2000W. Средни плоскости (4–8 мм) изискват системи от 2000W до 4000W, докато при лазерно рязане на алуминий над 9 мм се изисква мощност от 4000W или повече, за да се преодолее отразяващата способност на материала.

Азотът се използва като предпочитан помощен газ за повечето приложения за лазерно рязане на алуминий, като предотвратява оксидирането и осигурява гладки, чисти ръбове. Някои производители прилагат временни повърхностни покрития, за да увеличат абсорбцията на енергия – тези по-тъмни покрития намаляват отражението, подобряват последователността на рязането и често изпаряват по време на процеса, без да оставят остатъци.

Справочник за параметри на рязане на материали

Следната таблица обобщава възможностите по дебелина и основните аспекти за често използваните метали в производството:

| Материал | Обхват на дебелината | Препоръчителна мощност | Ключови фактори |

|---|---|---|---|

| Мека стомана | 0.5–20 mm | 1000W–6000W | Най-толерантният материал; кислородният асистент увеличава скоростта; по-голяма зона на топлинно въздействие при дебели сечения |

| Неръждаема стомана | 0.5–20 mm | 1000W–6000W | Азот за бляскави ръбове; кислород за по-висока скорост с оксиден слой; рязане с устойчивост на корозия |

| Алуминий | 0,5–15 мм | 1000W–4000W+ | Високата отразяваща способност изисква повече мощност; азотът предотвратява оксидирането; повърхностните покрития намаляват отражението |

| Мед | 0,5–6 mm | 3000W–5000W | Най-висока отразяваща способност; по-ниска плътност на мощността и по-бавни скорости; кислородът подобрява ефективността при дебели листове |

| Латун | 0.5–8 mm | 2000W–4000W | Поведението варира в зависимост от състава на сплавта; умерени настройки с азот или кислород в зависимост от дебелината |

Оптимизиране на резултатите чрез подготовка

Дебелината на материала директно влияе върху три критични резултата: качеството на ръба, скоростта на рязане и размера на зоната, засегната от топлина . По-тънките материали позволяват по-високи скорости с минимална топлинна деформация, докато по-дебелите листове изискват коригиране на параметрите, за да се осигури баланс между дълбочината на проникване и натрупването на топлина.

Преди рязане, имайте предвид следните указания за подготовка на повърхността:

- Очистване на повърхности: Премахнете маслото, мръсотията и оксидацията, които могат да попречат на последователното абсорбиране на лазера

- Равен материал: Деформираните или огънати листове създават непостоянни фокусни разстояния, което води до променливо качество на рязане

- Защитни филми: За отразяващи метали временни покрития подобряват абсорбцията на енергията и намаляват риска от обратно отразяване

- Потвърждение за материал: Проверете състава на материала да съвпада с вашите програмирани параметри – вариациите в сплавите влияят на поведението при рязане

Разбирането на тези специфични изисквания за материал Ви поставя в позиция да постигате последователни, висококачествени резултати. Но дори и при перфектни параметри, могат да възникнат дефекти при рязане – а знанието как да диагностицирате и отстранявате чести проблеми отличава добрите оператори от великите. Преди да преминем към отстраняване на неизправности, нека разгледаме как лазерното рязане се сравнява с алтернативни методи като плазма и водна струя.

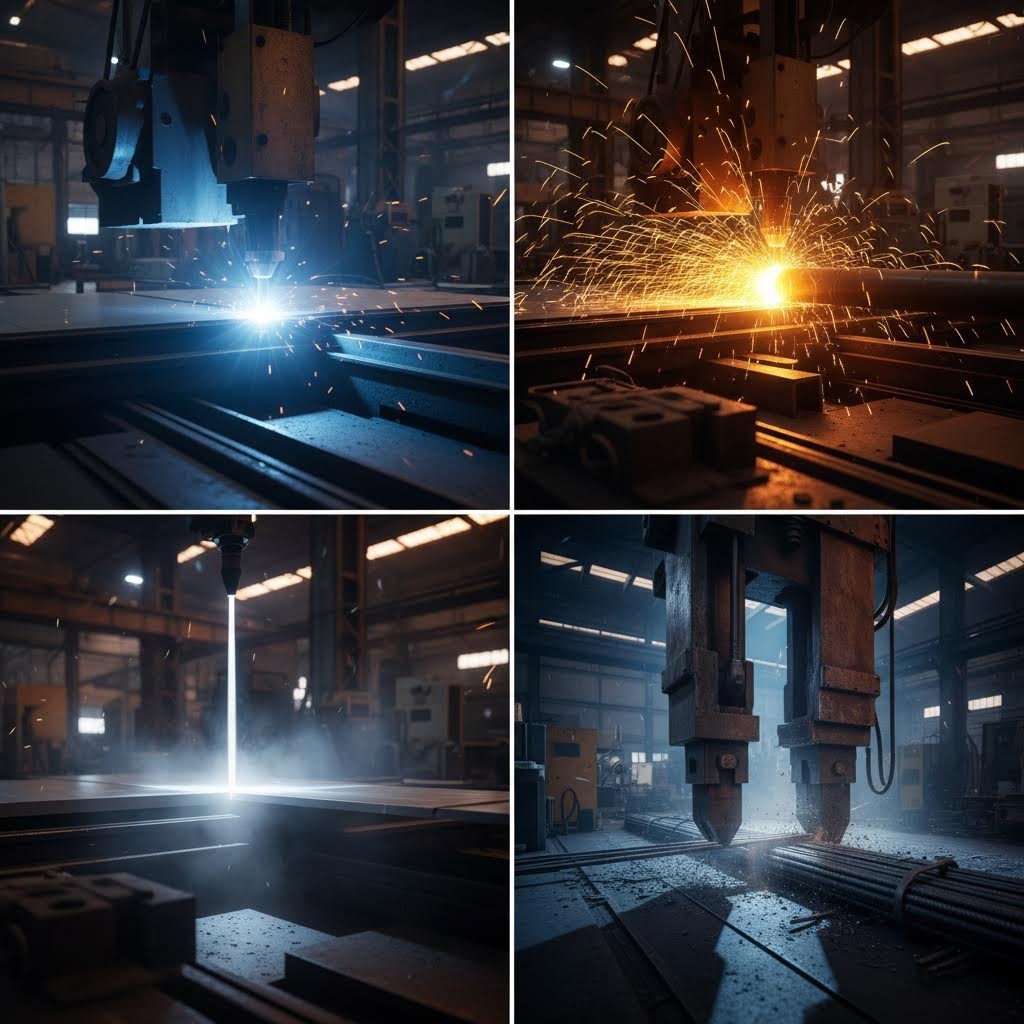

Лазерно рязане срещу плазма, водна струя и механични методи

Сега, след като разбирате лазерната технология и параметрите на материала, остава един ключов въпрос: винаги ли лазерното рязане е правилният избор? Честният отговор е не – и осъзнаването кога алтернативните методи надминават лазерното рязане може да ви спести значително време и пари.

Всяка машина за рязане на метал предлага различни предимства за конкретни приложения. Изборът на неподходяща технология означава или прекомерно плащане за ненужна прецизност, или трудности с недостатъчни резултати. Нека сравним опциите ви, за да изберете подходящата машина за рязане на метал според изискванията на всеки проект.

Сравнение между лазерно и плазмено рязане

Плазменото рязане и лазерното рязане на ламарини често конкурират за едни и същи проекти, но всяко от тях се представя отлично в принципно различни ситуации. Разбирането на тези разлики помага за ефективно разпределяне на работата.

Според Тестови данни на Wurth Machinery , плазменото рязане доминира при работа с дебели проводими метали, като запазва разходите на разумно ниво. Анализът им показва, че плазмените машини постигат отлични резултати при стоманени плочи с дебелина над 1 инч, където лазерните машини се затрудняват да проникнат ефективно.

Ето кога всяка технология се представя най-добре:

- Предимства на плазменото рязане: По-бързо рязане на дебела стомана (1 инч и повече), по-ниски разходи за оборудване (около 90 000 долара за пълни системи), отлично за производство на стоманобетонни конструкции и тежко машинно оборудване

- Предимства на лазера: Надвиснала прецизност при тънки до средни материали, изключително чисти ръбове, които изискват минимална довършителна обработка, възможност за рязане на сложни модели и малки отвори с тесни допуски

Разликата в цената има голямо значение. Системите за плазменно рязане струват приблизително половината от цената на еквивалентното водно-абразивно оборудване и предлагат 3-4 пъти по-бързи скорости на рязане при 1-инчова стомана. В същото време лазерното рязане при металообработването осигурява допуски от ±0,05–0,1 мм в сравнение с ±0,5–1,5 мм при плазменото рязане — съществена разлика при прецизни компоненти.

Когато водно-абразивното рязане надминава лазерното

Водоструйната рязка влиза в употреба, когато топлината е проблем. Тази машина за рязане на метал използва вода под високо налягане, смесена с абразив, за да раздели материали без топлинни ефекти — без деформации, без втвърдяване и без зони, засегнати от топлина.

Анализът на Okdor относно обработката потвърждава, че водоструйната рязка запазва допуски от ±0,03–0,08 mm при всички видове и дебелини на материали — често надминавайки прецизността на лазера. Този процес на студено рязане запазва микроструктурата на материала, което го прави задължителен за термично обработени инструментални стомани и аерокосмически компоненти, при които свойствата на материала трябва да останат непроменени.

Водоструйната рязка може да реже почти всичко, с изключение на закалено стъкло и диаманти, включително камък, стъкло, композити и слоести материали, които биха повредили или затруднили работата на лазерни системи. Какво се губи? По-бавни скорости на обработка и по-високи експлоатационни разходи — водоструйните системи струват около 195 000 щатски долара в сравнение с 90 000 щатски долара за плазмено оборудване.

Сравнение на машини за рязане на метал

Следната таблица предоставя всеобхватно сравнение, което да ви насочи при избора на технология:

| Параметър | Лазерно рязане | Плазмено рязане | Резане с воден струй | Механично ножица |

|---|---|---|---|---|

| Прецизност на допуските | ±0,05-0,1 мм | ±0,5-1,5 мм | ±0,03-0,08 мм | ±0,1-0,5 мм |

| Качество на ръба | Отлично; нужда от допълнителна обработка е минимална | Добро; може да изисква шлайфане | Отлично; гладко, без заострен ръб | Променлива; зависи от състоянието на ножа |

| Диапазон на дебелина на материала | До 25-30 мм (диапазон на прецизност) | над 100 мм ефективно | До 200 мм с постоянна прецизност | Ограничена до 12 мм обикновено |

| Зона, засегната от топлина | Малки, но присъстващи | По-голяма; забележима при тънки материали | Липсва; студен процес на рязане | Липсва; механично разделяне |

| Експлоатационни разходи | Умерена; електроенергия и подпомагащ газ | По-ниски; разходни материали и газ | По-високи; абразивни и поддръжка | Най-ниски; само смяна на дисковете |

| Идеални приложения | Прецизни детайли, сложни дизайни, тънки-средни листове | Дебели стоманени профили, тежко оборудване, корабостроене | Топлоустойчиви материали, аерокосмическа промишленост, смесени материали | Прави резове, изрязване на сурови форми, висок обем от прости форми |

Съпоставяне на технологията с вашите проекти

Как да решите коя машина за рязане на метал отговаря най-добре на вашите конкретни нужди? Имайте предвид следните практически насоки:

- Изберете лазерно рязане, когато: Необходими са ви строги допуски (±0,1 мм или по-добри), сложни шаблони, малки отвори или чисти ръбове при тънки до средни материали

- Изберете плазменно рязане, когато: Работите с дебели проводими метали (над 2,5 см), поставяте скоростта над точността или управлявате ограничен бюджет при производство на структурни елементи

- Изберете водно-абразивно рязане, когато: Свойствата на материала трябва да останат непроменени, рязане на чувствителни към топлина сплави, обработка на неметали или постигане на максимална размерна точност при дебели сечения

- Изберете механично отрязване, когато: Правите само прави резове, обработвате големи обеми от прости заготовки или минимизирате разходите на детайл за основни форми

Много успешни производствени цехове в крайна сметка използват няколко технологии. Както отбелязва Wurth Machinery, плазмената и лазерната рязка често добре допълват една друга — лазерът се справя с прецизната работа, докато плазмата се използва за дебели структурни компоненти. Добавянето на водна струя осигурява ненадмината гъвкавост при специални материали.

Интеграция с последващи операции

Изборът на метод за рязане оказва влияние върху целия процес на фабрикуване. Детайлите, получени чрез лазерно рязане, обикновено изискват минимална подготовка на ръба преди огъване, заваряване или довършителна обработка — чистите ръбове се интегрират безпроблемно с последващите операции. Детайлите, изрязани с плазма, може да се нуждаят от шлайфане или отстраняване на заострените ръбове преди монтаж, което увеличава времето за труд, но често се оправдава от по-високата начална скорост на рязане при дебели материали.

Помислете за цялата си производствена последователност при избора на технология. Ако детайлите преминават директно към прецизно огъване или видима окончателна обработка, по-високото качество на ръба от лазерно или водноструйно рязане елиминира вторични операции. За структурни компоненти, предназначени за заваряване и боядисване, скоростното предимство на плазменото рязане често надвишава съображенията за качеството на ръба.

След като е установена тази сравнителна рамка, вие сте подготвени да изберете подходящия метод на рязане за всеки проект. Но дори и най-добрата технология произвежда дефекти, когато параметрите се променят или оборудването се износя – а знанието как да отстраните тези проблеми прави разликата между ефективни операции и досадни производствени закъснения.

Отстраняване на чести дефекти при рязане и проблеми с качеството

Дори и най-добрият лазерен режещ машини за метал дават разочароващи резултати, когато параметрите се променят или оборудването се износя. Разликата между раздразнен оператор и продуктивен? Точно знание какво причинява всеки дефект – и как да го поправи бързо.

Проблемите с качеството рядко възникват случайно. Всеки дефект разкрива история за това, което се случва в зоната на рязане, а умението да разчитате тези сигнали превръща отстраняването на неизправностите от предположение в систематично решаване на проблеми. Нека декодираме най-често срещаните проблеми, с които ще се сблъскате при лазерното рязане на метални листове.

Диагностициране на дефекти в краищата

Когато детайлите излизат от лазерната машина за рязане на метал с непълни ръбове, идентифицирането на специфичния модел на дефекта сочи директно към основната причина. Ето най-често срещаните проблеми и техните решения:

- Образуване на шлака (налепнала шлака по долния ръб): Този лепкав остатък показва, че разтопеният материал не се отстранява правилно. Според техническия анализ на Durmapress, честите причини включват прекалено висока скорост на рязане, недостатъчно налягане на помощния газ или фокусно положение под повърхността. Решение: намалете скоростта на рязане, увеличете налягането на газа и повдигнете фокусното положение, за да се осигури по-добро изхвърляне на шлаката.

- Изразен наклон (твърди израстъци по ръба на рязане): Наклоните се образуват, когато недостатъчно енергия достига долната част на реза или газовият поток не успява да отстрани разтопения материал. Когато има твърди наклони от всички четири страни, типичните причини обикновено са бавна скорост, ниско налягане на въздуха и фокусиране върху горната повърхност. Увеличете скоростта, повишете налягането на газа и преместете фокуса под повърхността, за да възстановите баланса.

- Неравни ръбове (неравна, структурирана повърхност): Неравна повърхност при рязане често се получава поради повреден сопло или замърсен фокусиращ леща. Преди да настройвате параметрите, проверете тези компоненти — сменете повредените сопла и почистете или сменете мръсните лещи. Ако проблемът продължава, възможно е прекомерното локално натрупване на топлина да причинява деформация на материала.

- Непълни резове (прекъснато проникване): Когато лазерът не може напълно да пререже, имате недостатъчна плътност на енергията. Това означава, че лазерната мощност е твърде ниска, скоростта на рязане е твърде висока или налягането на газа е недостатъчно за дебелината на материала. Увеличете мощността, намалете скоростта или повишете налягането на помощния газ, за да постигнете пълно проникване.

- Топлинна промяна на цвета (сини, лилави или жълти ръбове): Промяната на цвета сочи проблеми с чистотата на газа или прекомерен топлинен вход. Жълтите ръбове при неръждаема стомана показват замърсяване с кислород в азотния Ви доставчик — преминете към азот с по-висока чистота (99,6% или повече). Синя или лилава окраска сочи същия проблем, който с времето може да замърси и фокусиращата Ви леща.

Оптимизиране на параметрите на рязане за чисти резултати

Постоянното качество при производствените серии зависи от разбирането как взаимодействат четири ключови променливи. Когато един параметър се промени, често се налага коригиране на другите, за да се компенсират последствията.

Позиция на фокусната точка определя къде се концентрира максималната енергия спрямо повърхността на материала. За повечето приложения за лазерна рязка на листови метали, фокусът трябва да бъде около центъра на дебелината на материала, за да се осигури равномерно рязане от горе до долу. Ако е твърде високо, ще се наблюдават по-широки резове с възможност за образуване на задръжки. Ако е твърде ниско, шлаката се натрупва върху долната повърхност.

Скорост на рязане контролира колко дълго лазерният лъч взаимодейства с всяка точка по пътя на рязане. Според Ръководството за параметри на Accurl , по-високите скорости на сканиране намаляват времето на взаимодействие, което минимизира топлинната деформация, но потенциално може да намали качеството на рязане при по-дебели материали. По-бавните скорости увеличават абсорбцията на енергия — предимство за дебели или отразяващи материали, но с риск от изгаряния, ако са твърде бавни.

Налягане и вид на помощния газ влияят директно върху ефективността, с която разтопеният материал се отстранява от процепа. Кислородът ускорява рязането чрез екзотермична реакция, но оставя оксидни слоеве. Азотът осигурява чисти, без оксиди ръбове, но изисква по-високо налягане. Чистотата на газа има голямо значение — примесите отклоняват лъча и замърсяват повърхностите на рязане, което води до непостоянни резултати.

Състояние на соплото влияе както върху динамиката на газовия поток, така и върху подаването на лъча. Накърнена или некоректно подравнена дюза създава неравномерно разпределение на газа, което причинява едностранни бразди или непредсказуемо поведение при рязане. Durmapress препоръчва дюзата да бъде точно центрирана и незабавно сменяна, ако отворът стане неокръглен или повреден.

Поддържане на качеството при серийното производство

По-добре е да се предотвратяват дефектите, отколкото да се отстраняват. Приложете тези практики, за да поддържате лазерния си стан работещ с максимална производителност:

- Редовна проверка на лещите: Замърсените или повредени фокусиращи лещи влошават качеството на лъча, преди да се появят видими дефекти. Почиствайте лещите според графика на производителя и ги сменяйте, когато почистването вече не възстановява производителността.

- Проверка на дюзите преди всеки цикъл: Проверете центрирането на дюзата и инспектирайте за повреди — особено след рязане на отразяващи материали, които могат да причинят щети от обратно отразяване.

- Проверка на чистотата на газа: Използвайте газ с чистота 99,5% или по-висока за последователни резултати. Влагата или прашните примеси отклоняват лъча и замърсяват повърхностите.

- Тестово рязане на скрап: Преди производствените цикли извършвайте тестово рязане на материал, съответстващ на спецификациите на вашата задача, за да проверите параметрите, преди да започнете окончателните части.

- Документиране на работните параметри: Записвайте успешните настройки за всеки тип и дебелина на материал, за да изградите справочна библиотека, която ускорява бъдещите настройки и отстраняване на неизправности.

Разбирането на тези причинно-следствени връзки превръща реагирането след инцидент в проактивно управление на качеството. Но дори и перфектните параметри за рязане не означават нищо, ако работното място създава опасности за безопасността — и точно тук много производствени цехове значително изостават.

Протоколи за безопасност и регулаторни изисквания

Ето една реалност, която повечето ръководства за оборудване напълно пропускат: този мощен лазерен рязач по метал, който осигурява прецизни резове, може също да причини постоянна слепота, сериозни изгаряния или пожари на работното място, ако протоколите за безопасност бъдат нарушени. Въпреки това съдържанието на конкурентите последователно пренебрегва тази жизненоважна тема — оставяйки производителите да се ориентират измежду сложните регулаторни изисквания без насока.

Независимо дали използвате лазерен рязач по метал във вашия цех или оценявате доставчици на услуги, разбирането на класификацията за лазерна безопасност и изискванията за съответствие защитава вашия екип и вашия бизнес. Нека разгледаме това, което другите пренебрегват.

Класификации и изисквания за лазерна безопасност

Не всички лазери представляват еднакъв риск. Те OSHA Технически наръчник установява класификационни нива въз основа на потенциалните нива на опасност — и повечето промишлени лазерни машини за рязане на метал попадат в категориите с най-висок риск.

Ето как е структурирана системата за класификация:

- Лазери клас I: Не могат да излъчват радиация на известни нива на опасност. Потребителите обикновено са освободени от контроли за радиационна опасност при нормална работа.

- Лазери клас II и IIIA: Представляват пряка окулярна опасност само след продължително въздействие (0,25 секунди или повече). Изискват етикетиране с „ВНИМАНИЕ“ и основни защитни мерки.

- Лазери клас IIIB: Представляват незабавна пряка окулярна опасност и потенциална опасност от разсеяно отразяване близо до границата от 0,5 вата. Изискват етикетиране с „ОПАСНОСТ“ и всеобхватни контролни мерки.

- Лазери клас IV: Категорията обхваща повечето промишлени метални системи за рязане с лазер. Те представляват пряка опасност за очите, опасност от разсеяно отразяване и пожарна опасност. Задължителни са пълни предпазни ограждения, блокировки и изчерпателни протоколи за безопасност.

Повечето промишлени системи за рязане на листови метали работят като лазери от клас IV – което означава, че важат всички изисквания за безопасност. Въпреки това, много производители проектират оборудването като затворени системи от клас I, при които мощните лазери работят в защитен корпус, който намалява нивата на външна опасност по време на нормална експлоатация.

Предпазно оборудване и организация на работното място

Ефективната лазерна безопасност изисква структурирани мерки за защита, насочени едновременно към различните видове опасности. Стандартите на OSHA и ANSI Z 136.1 определят следните задължителни мерки:

- Правилна вентилация за метални изпарения: Лазерното рязане генерира опасни изпарения и прахови частици, особено при обработка на покрити или обработени метали. Съгласно насоките на OSHA адекватното вентилация трябва да намали вредните или потенциално опасни пари под приложимите прагови гранични стойности. Промишлените системи изискват вграден отработен газ, който улавя изпаренията в зоната на рязане, преди да се разпръснат в работното пространство.

- Изисквания за защита на очите: Лазерните предпазни очила трябва да съответстват на използваната специфична дължина на вълната и да осигуряват адекватна оптична плътност за използваната енергия. За лазери с влакна, работещи на 1,06 μm, е необходима различна защита от системите за CO2 на 10,6 μm. Както е посочено в техническия наръчник на OSHA, изискванията за оптична плътност се увеличават с лазерната мощност. 5-ватов аргонен лазер изисква защита OD 5.9 за експозиции от 600 секунди.

- Протоколи за предотвратяване на пожари: Лазерни лъчи от клас IV могат да възпламенят материали, когато затворените пътища на лъчите са изложени на облъчване над 10 W/cm². Устойчиви на огън материали за затваряне и правилно прекратяване на лъча предотвратяват възпламеняване. Дръжте запалими материали на разстояние от зоните за рязане и имайте противопожарно оборудване в непосредствена близост.

- Съображения за електрическа безопасност: Електроизточници с високо напрежение за промишлени лазери създават риск от електрически удар. Всичко оборудване трябва да бъде инсталирано според Националния електротехнически кодекс, с правилно заземяване, монтаж на кабелни тръби и процедури за заключване/маркиране по време на поддръжка.

Рамка за спазване на регулаторните изисквания

Няколко организации регулират лазерната безопасност в Съединените щати, като създават припокриващи се изисквания, с които операторите трябва да се справят:

- FDA/CDRH: Стандартът за производителност на федерални лазерни продукти изисква производителите да поставят етикети, класификация и вградени функции за безопасност за всички лазерни продукти, продавани в САЩ.

- OSHA: Въпреки че не съществува всеобхватен лазерен стандарт, прилага се Клаузата за общо задължение и строителният стандарт 29 CFR 1926.102(b)(2) постановява изрично използването на подходящи лазерни защитни очила за заетите работници.

- ANSI Z 136.1: Този отраслеви консенсусен стандарт предлага подробни насоки относно оценка на рисковете, максимално допустими граници на облъчване, мерки за контрол и изисквания за обучение. Много работодатели са длъжни да следват тези препоръки, когато OSHA прилага Клаузата за общо задължение.

- Държавни разпоредби: Няколко щата са въвели изисквания за регистрация на лазери и лицензиране на оператори. Аризона, Флорида и други са приели части от Предложените държавни разпоредби за лазери.

Обучение на оператори и процедури при аварийни ситуации

Оборудването е толкова безопасно, колкото и хората, които го управляват. Подробното обучение трябва да включва разпознаване на опасности, правилна работа с оборудването, аварийни процедури и специфични протоколи за безопасност за вашата инсталация. Много обекти назначават Офицер по лазерна безопасност (LSO), отговорен за наблюдението на безопасната употреба, провеждане на оценки на риска и осигуряване на спазването на регулаторните изисквания.

Стандартните операционни процедури трябва да документират последователността при стартиране и изключване на машината, протоколите за работа с материали, стъпките за аварийно реагиране и изискванията за безопасност при поддръжката. Редовните проверки на оборудването потвърждават правилното функциониране на блокировките, неповредеността на кутиите и работата на предупредителните системи според проекта.

След като са установени протоколите за безопасност, сте в позиция да работите отговорно — но разбирането на финансовата страна на лазерната рязка ви помага да вземате по-умни бизнес решения относно инвестиции в оборудване спрямо външно изпълнение.

Анализ на разходите и ценообразуващи фактори за лазерна рязка

Значи сте овладели технологията, материалите и изискванията за безопасност — но ето въпроса, който всъщност определя повечето бизнес решения: колко всъщност струва лазерната рязка на метални листове? Изненадващо, тази ключова тема получава минимално внимание в повечето отраслови ръководства, като оставя производителите да се ориентират в ценообразуването без ясни рамки.

Дали оценявате покупка на лазерна режеща машина за листови метали или сравнявате оферти на доставчици на услуги, разбирането на пълната ценова картина предотвратява изненади по бюджета и позволява по-умни решения при набавянето.

Основни фактори, влияещи върху разходите за лазерна рязка

Ценообразуването при лазерната рязка не е просто пресмятане на цена за инч. Няколко променливи взаимодействат, за да определят крайната ви цена, а разбирането на всеки компонент ви помага да оптимизирате разходите, без да жертвате качеството.

- Разходи за материали: Основният метал представлява значителна част от общите разходи. Видът на материала, дебелината и текущите пазарни цени всички допринасят за това. Специализираните сплави или сертифицираните авиационни материали имат по-високи цени, докато стандартният мек стоманен лист остава най-икономичният вариант.

- Време за машинна обработка: Доставчиците на услуги обикновено таксуват на час или на минута действително време за рязане. Според Анализа на пазара на Laser Insights China , тази такса варира в зависимост от възможностите на оборудването – машините за рязане на стоманени листове с по-висока мощност имат по-високи такси, но приключват работата по-бързо, което потенциално може да намали общата цена.

- Такси за настройка: Всяка нова поръчка изисква програмиране, зареждане на материала и проверка на параметрите. Комплексните дизайни или първите прототипи имат по-високи разходи за настройка в сравнение с повтарящи се производствени поръчки. Някои доставчици отменят таксите за настройка при големи поръчки или постоянни договори.

- Фактори за сложност: Сложни дизайни с тесни ъгли, малки отвори или плътно подреждане изискват по-бавни скорости на рязане и по-точен контрол. Декоративна панел с 500 изрязвания струва значително повече на квадратен фут в сравнение с прост правоъгълен заготовка.

- Изисквания за завършване: Операции след рязането, като отстраняване на застоя, шлифоване на ръбове или нанасяне на защитни покрития, добавят труд и време за обработка. Детайлите, предназначени за видими приложения, често изискват допълнителна довършителна обработка, която конструкционните елементи могат да пропуснат.

Видът и дебелината на материала силно взаимодействат с машинното време. Отразяващи метали като алуминий изискват по-висока мощност и по-бавни скорости в сравнение с еквивалентни дебелини от стомана — удвоявайки времето и разходите за обработка. По същия начин, както потвърждава анализът на индустрията, удвояването на дебелината на материала не просто удвоява разходите; то може да ги увеличи значително повече поради експоненциално по-дълги времена за рязане и по-високо енергийно потребление.

Изчисляване икономиката на вашия проект

Колко струва лазерна режеща машина за вашия бизнес? Отговорът зависи от обема на производството, сложността на детайлите и времевия хоризонт. Нека анализираме икономиката на закупуването срещу външното изпълнение.

Инвестиция в собствено оборудване

Закупуването на лазерна режеща машина за листов метал изисква значителен първоначален капитал. Според Анализа на Redsail за рентабилността , индустриални CO2 лазерни режещи машини вариращи от 2 600 до 70 000 долара, докато модели от индустриално класа, способни да обработват по-дебели метали, стоят между 20 000 и 70 000 долара. Високомощни фибрени системи за изискващи производствени среди могат да надхвърлят 100 000 долара.

Освен цената на лазерната режеща машина, вземете предвид и тези постоянни оперативни разходи:

- Консумация на енергия: Високомощните лазери използват значително количество електроенергия — фибрените лазери с КПД 30-40% все още консумират голямо количество енергия по време на продължителни производствени цикли

- Разходи за помощен газ: Употребата на азот и кислород варира в зависимост от материала и режещите параметри и представлява повтарящ се разход

- Поддръжка и разходни материали: Лещи, дюзи, филтри и планирано поддържане добавят предвидими постоянни разходи

- Труд на оператор: Квалифицираните техници получават конкурентни заплати, а обучението на нови оператори изисква инвестиция на време

За да се изчисли възвръщаемостта на инвестициите (ROI), Redsail препоръчва този подход: ако оборудването струва 50 000 щатски долара и осигурява годишна икономия от 20 000 щатски долара при експлоатационни разходи от 5 000 щатски долара, нетната годишна печалба е 15 000 щатски долара – което отговаря на период на възвръщане от около 3,3 години. След като се възстанови първоначалната сума, машината генерира постоянна печалба.

Външно изпълнение чрез доставчици на услуги

Външното изпълнение премахва капитала за инвестиции и прехвърля отговорността за поддръжката към вашия доставчик. Този подход е уместен, когато:

- Обемът на производството не оправдава инвестициите в оборудване

- Търсенето флуктуира непредсказуемо от месец на месец

- Имате нужда от достъп до специализирани възможности, които надхвърлят основната ви дейност

- Ограниченията в паричния поток ограничават големи покупки на оборудване

Въпреки това, разходите за отделни части от доставчици на услуги обикновено надвишават разходите за вътрешно производство при операции с голям обем. Точката на окупуване варира в зависимост от сложността и обема на частите — анализирайте конкретните си изисквания, за да определите тази точка.

Оценяване на Общата Стоимост на Притежание

Разумните решения за оборудване изискват поглед зад ценника. Пазарът на лазерни режещи машини по света, който през 2023 г. е оценен на приблизително 7,12 милиарда щатски долара, се очаква да нараства със средногодишен темп от 5,7% до 2030 г. — което показва значителни постоянни инвестиции в различни индустрии.

При сравняване на вариантите, имайте предвид този модел:

| Фактори на цена | Собствено оборудване | Доставчик на услуги |

|---|---|---|

| Начална инвестиция | $20,000–$150,000+ | Никой |

| Цена на компонент (големи серии) | По-ниски след окупяване | По-високи, но постоянни |

| Цена на компонент (малки серии) | По-високи поради използването | Често по-икономични |

| Контрол върху водещото време | Пълен контрол | Зависи от капацитета на доставчика |

| Контрол на качеството | Директен контрол | Изисква процеси за верификация |

| Гъвкавост | Ограничено от възможностите на оборудването | Достъп до разнообразно оборудване |

За предприятия с постоянна, високотомажна продукция притежанието на оборудване обикновено осигурява по-добри икономически резултати на дълга срока. При променливи нужди или специализирани проекти извънвземането осигурява гъвкавост без капиталови рискове. Много успешни операции комбинират двата подхода — запазвайки ключовите си възможности вътрешно, докато извънвземат допълнителни или специализирани работи.

Разбирането на тези динамики във връзка с разходите Ви позволява ефективно преговаряне с доставчици на услуги и вземане на обосновани инвестиционни решения. Но разходите са само част от уравнението — истинската стойност на лазерната рязка се проявява в конкретни отраслови приложения, където точността директно води до конкурентно предимство.

Отраслови приложения от автомобилна до архитектурна индустрия

Къде прецизното лазерно рязане осигурява най-голяма стойност? Трансформативният ефект на тази технология обхваща индустрии с напълно различни изисквания — от автомобилни компоненти, изискващи допуски на ниво микрони, до декоративни архитектурни панели, където художественото изразяване се среща със структурното инженерство. Разбирането на тези приложения разкрива защо лазерното рязане е станало незаменимо в съвременното производство.

Всяка област има свои уникални стандарти за качество, изисквания за допуски и производствени предизвикателства. Нека разгледаме как лазерното рязане отговаря на тези изисквания в пет ключови приложни области.

Изисквания за прецизност в автомобилната и авиокосмическата промишленост

Малко индустрии поставят по-високи изисквания към технологията за рязане на метал от автомобилната и авиокосмическата промишленост. Рисковете са големи — компоненти, които се повреждат по време на експлоатация, могат да застрашат човешки живот, поради което сертифицирането на качеството е задължително.

В автомобилното производство лазерното рязане се интегрира безпроблемно с операциите по штамповане на метали за производство на пълни автомобилни сглобки. Като Отбелязва Alternative Parts , съвременните производители на автомобили в голяма степен са преминали от штамповане и рязане с матрици към лазерно рязане за производството на различни вътрешни и външни компоненти на автомобили. Този преход преодолява неефективността на традиционните методи, които не могат да поддържат темпото на растящата търсене.

Основни приложения в автомобилната промишленост включват:

- Шаси и конструктивни компоненти: Релси за рама, напречни греди и усилвателни скоби изискват малки допуски, за да се осигури правилен фитинг по време на сглобяването и предвидимо поведение при сблъсък

- Компоненти на окачването: Лостове за управление, монтажни скоби и опори за пружини изискват постоянна прецизност при хиляди бройки

- Панели за купе и облицовки: Врати, части от фартуки и декоративни облицовки се възползват от чистите ръбове при лазерното рязане, които минимизират нуждата от довършителни операции

- Компоненти за намаляване на теглото: Алуминиеви части, изрязани с лазер, и високоякостни стоманени части заместват по-тежките конвенционални материали, като повишават икономичността на горивото и намаляват производствените разходи

Сертификатът IATF 16949 представлява качествения стандарт за автомобилните доставки. Този стандарт осигурява последователни процеси, проследимост и предотвратяване на дефекти — от решаващо значение, когато един неизправен компонент може да доведе до скъпоструващи отзовавания. Производители като Shaoyi (Ningbo) Metal Technology комбинират лазерна рязка с штамповка на метали според сертификата IATF 16949 и предлагат шасита, окачвания и конструктивни компоненти с възможност за бързо прототипиране за 5 дни и предоставяне на оферти за 12 часа, ускорявайки автомобилните доставки.

Приложението в аерокосмическата индустрия изисква още по-висока прецизност. Според анализ на Alternative Parts, качеството и точността са от решаващо значение за производителите в аерокосмическата сфера, тъй като техните продукти работят дълги часове при екстремни условия, като температури под нулата и силни атмосферни натоварвания. Лазерна машина за рязане на стомана, произвеждаща аерокосмически компоненти, трябва да поддържа допуски, често по-строги от ±0,05 мм, като едновременно осигурява пълна проследимост на материала.

Чести приложения в аерокосмическата индустрия включват:

- Конструкционни скоби и монтажни елементи: Носещи компоненти, изискващи сертифицирани свойства на материала и размерна точност

- Секции от фюзелажа и крилете: Рязане в голям формат с последователно качество на ръба по протежение на продължителни режещи пътища

- Заготовки за компоненти на двигатели: Топлоустойчиви сплави, нарязани до прецизни спецификации преди вторични машинни операции

- Вътрешни компоненти: Леки алуминиеви и титанови части за интериорни фикстури и монтаж на оборудване

Архитектурни и декоративни приложения от метал

Освен функционални компоненти, лазерното рязане позволява художествено изразяване в архитектурен мащаб. Всеки лазерно изрязан метален панел, който виждате на фасадите на съвременни сгради, започва като дизайнерски файл, превърнат в материална реалност чрез прецизна технология за рязане.

Като Обяснява VIVA Railings , декоративните метални панели, изрязани с лазер, се изработват с безпрецедентна прецизност и внимание към детайла, което ги превръща в поразително допълнение към всеки интериор или екстериор. Техният асортимент MetalSpaces демонстрира как лазерното рязане позволява геометрични модели, мотиви, вдъхновени от природата, и абстрактни дизайни, които биха били невъзможни с традиционни методи за производство.

Архитектурните приложения обхващат множество строителни системи:

- Декоративни стенни панели: Лазерно изрязани стоманени панели създават впечатляващи интериорни елементи с изящни модели, които играят със светлината и сенките през деня

- Таванны системи: Перфорирани панели осигуряват както визуален интерес, така и акустичен контрол, регулирайки отразяването на звука в търговски пространства

- Системи за слънцезащита: Точно изчислени шаблони за перфорация филтрират слънчевата светлина, намалявайки ослепяването и топлинния прилив, като същевременно запазват възможността за визуален контакт с външната среда

- Фасадно облицоване: Панели с висока устойчивост към атмосферни влияния, изработени от неръждаема стомана или алуминий, предпазват външните части на сградите и създават отличителни архитектурни идентичности

Индустрията на табелите представлява друг важен сектор на приложение. Метални табели, изрязани с лазер, осигуряват дълготрайност и визуално въздействие, които не могат да бъдат постигнати с печатни алтернативи. От идентификация в корпоративни фоайета до системи за навигация и табели за спазване на правила, лазерното рязане осигурява ясни, четими резултати, издържащи години на употреба.

Промишлено и производствено оборудване

Освен видимите приложения, лазерното рязане подпомага машините, които задвижват съвременното производство. Капаци на промишлено оборудване, корпуси на контролни панели и предпазни ограждения всички се възползват от комбинацията от прецизност и ефективност на лазерното рязане.

- Капаци на оборудването: Корпуси от ламарина, предпазващи електронни и механични системи от замърсяване от околната среда

- Защитни ограждения за машини: Сигурносни бариери с вентилационни шаблони, които отговарят на изискванията на OSHA и осигуряват отвеждане на топлината

- Конзоли и монтажни елементи: Стандартизирани компоненти за свързване между различни оборудвани системи

- Компоненти на транспортьори: Странични релси, водачи и монтажни плочи за системи за обработка на материали

В производствените среди често се изискват бързо доставяни резервни части, за да се минимизира прекъсването на производството. Възможността на фибровия лазер да реже персонализирани компоненти от цифрови файлове — без закъснения заради инструменти — го прави незаменим за поддръжката.

Морски и отбранителни приложения

Специализираните сектори налагат собствени изисквания. Судостроителите и производителите на морско оборудване се нуждаят от компоненти, които издържат на корозивната среда на морската вода и отговарят на строги регулаторни стандарти. Както потвърждава Alternative Parts, лазерните рязачки осигуряват висококачествени резове и заваръчни съединения за безопасни и функционални компоненти на морски съдове, включително корпусни секции, палубни фитинги и персонализирани резервни части за по-стари съдове.

Отбранителните и военните приложения изискват спазване на MIL-STD-130 за идентификационно маркиране и изискват компоненти, които работят надеждно в екстремни условия. Лазерното рязане произвежда издръжливо оборудване, подходящо за сурови условия на експлоатация, където отказът не е опция.

Стандарти за качество в различните индустрии

Изискванията за допуски варират значително в зависимост от приложението:

| Отраслов сектор | Обикновена толеранса | Ключови стандарти за качество |

|---|---|---|

| Автомобилни | ±0,1–0,25 мм | IATF 16949, документация PPAP |

| Аерокосмическа | ±0,050,1 mm | AS9100, проследимост на материала |

| Архитектурата | ±0,5–1,0 мм | Строителни норми, класове на огнеустойчивост |

| Индустриално оборудване | ±0,25–0,5 мм | Стандарти за конкретни приложения |

| Морски/военни | ±0,1–0,25 мм | Спецификации MIL-STD, правила на класификационните дружества |

Разбирането на тези изисквания, специфични за индустрията, ви помага да оцените дали оборудването или доставчикът на услуги отговарят на стандартите, които изискват вашите проекти. Но разпознаването на приложенията е само част от уравнението – изборът на правилния път напред изисква оценка дали да инвестираме в оборудване или да сътрудничим със специализирани доставчици на услуги.

Избор между инвестиране в оборудване и партньорство за услуги

Вече проучихте лазерните технологии, материалите, отстраняването на неизправности и структурата на разходите – сега идва решението, което оформя производствената ви стратегия: трябва ли да инвестираме в лазерен рязач за ламарини или да сътрудничим със специализирани доставчици на услуги? Това не е универсално решение, а грешката означава или ненужно задържане на капитал, или загуба на контрол върху критично важни производствени възможности.

Правилният избор зависи от вашите конкретни обстоятелства — обем на производството, изисквания за прецизност, очаквания за бързина на изпълнение и финансови ограничения. Нека създадем рамка, която ви насочва към най-разумния път напред.

Оценка на собствено производство срещу външно подизпълнение при рязане

И двата подхода предлагат ясни предимства, а разбирането на тези компромиси ви помага да съгласувате решението си с бизнес реалностите.

Предимства на собствен лазерен резач за ламарини

- Пълен контрол върху производството: Вие определяте графиките, стандартите за качество и възможностите за персонализация, без външни зависимости

- Икономическа ефективност при големи количества: Според Анализ на индустрията от GF Laser , операциите с висок обем често намират инвестициите в оборудване за по-икономични на дълга срока спрямо повтарящите се такси за услуги

- Способност за бърз отговор: Оборудването на място позволява незабавно прототипиране и корекции, което значително намалява времето за изпълнение

- Защита на интелектуалната собственост: Задържането на чувствителни проекти във вътрешността на компанията елиминира рисковете от излагане на трети страни

Недостатъци на инвестицията в оборудване

- Значителен първоначален капитал: Индустриални лазерни машини за рязане на метал от водещи производители като Trumpf могат да надвишават 600 000 паунда, плюс разходи за инсталиране и подготовката на помещенията

- Разходи за текуща експлоатация: Поддръжката, ремонтите, електроенергията, спомагателните газове и разходните материали създават предвидими, но значителни повтарящи се разходи

- Разходи за обучение и безопасност: Управлението на лазерен резач на метал изисква квалифициран персонал и спазване на регулаторни изисквания, което увеличава оперативната сложност

- Инфраструктура за спомагателни газове: Рязането на алуминий или неръждаема стомана изисква азот в количества, които може да изискват фиксирани резервоари вместо преносими бутилки

Предимства на аутсорсинга към доставчици на услуги

- Нулеви капитали: Отстранете значителните първоначални инвестиции, запазвайки паричния поток за други бизнес приоритети

- Достъп до усъвършенствани технологии: Производствени услуги за лазерна рязка на ламарини обикновено разполагат с висококачествено оборудване и опитни техници

- Мащабируемост без ограничения: Лесно нагласяйте обемите на поръчките според колебанията в търсенето, без ограничения по мощност

- Намалена оперативна сложност: Избягвайте проблеми с поддръжката, нуждата от обучение и отговорностите по спазване на изискванията за безопасност

Недостатъци на аутсорсинга

- Ограничена контрол върху график: Външните зависимости могат да доведат до несигурности в планирането и възможни закъснения в доставките

- Натрупани разходи: Въпреки че се избягва първоначалната инвестиция, текущите такси за услуги се натрупват — което потенциално може да надхвърли разходите за оборудване при операции с висок обем

- Променливо качество: Зависимостта от доставчици въвежда възможни несъответствия, освен ако не установите надеждни процеси за проверка

Вашата рамка за вземане на решения

Оценете своята ситуация спрямо тези пет ключови фактора, за да определите кой подход отговаря на вашата оперативна реалност:

- Темпове на производство: Изчислете годишните си часове за рязане. Ако използвате машина за рязане на ламарини повече от 20–30 часа седмично постоянно, икономическите показатели обикновено благоприятстват вътрешна инвестиция. При епизодични или малкообемни нужди, външното изпълнение позволява избягване на недостатъчно използвани капиталови активи.

- Прецизни допуски: Изискват ли вашите приложения допуски по-строги от ±0,1 мм? Ако е така, уверете се, че потенциалните доставчици могат последователно да спазват тези спецификации — или разгледайте вариант с оборудване, което ви дава директен контрол върху качеството.

- Изисквания за времето за изпълнение: Бързото прототипиране и спешните производствени серии изискват вътрешен капацитет. Ако времевите рамки ви позволяват водещ период от 1-2 седмици, износването остава жизнеспособно. Партньори, предлагат бързо предоставяне на оферти — 12 часа или по-малко — значително намаляват несигурността при планирането.

- Разнообразие от материали: Операциите по рязане на разнообразни материали и дебелини имат полза от достъпа до специализирано оборудване чрез износване. Производството на единичен материал с постоянна дебелина е подходящо за посветено вътрешно оборудване.

- Бюджетни ограничения: Честна оценка на наличния капитал и допустимите периоди за възвръщаемост определя възможността. Хибридният подход — собственост върху оборудване за основни задачи, като се изнасят прекомерните или специализирани поръчки — често оптимизира както инвестициите, така и гъвкавостта.

Какво да търсите у партньор за лазерно рязане

Ако аутсорсингът е подходящ за вашата ситуация, изборът на правилния партньор става от решаващо значение. Според ръководството за избор на доставчици на LS Precision Manufacturing, много покупатели се фокусират изключително върху ценовите оферти, само за да сблъскнат с криени разходи поради проблеми с точността на оборудването, несъвместимост на материали или пропуснати срокове.

Оценете потенциалните партньори по следните критерии:

- Проверка на възможностите на оборудването: Поискайте посещение на обекта или видеообиколка, за да наблюдавате реалното състояние на машините, организацията на работилницата и операционните стандарти. Съвременно влакнесто лазерно оборудване с документирани записи за поддръжка сочи надеждни производствени възможности.

- Експертност в материалите: Потвърдете опита с конкретните материали, които използвате. Различните метали изискват различни параметри за рязане – отразяващата способност на алуминия, управлението на оксидите при неръждаемата стомана и топлинните свойства на медта изискват специализирани познания. Поискайте пробни резове, съответстващи на спецификациите на вашите материали.

- Сертификати за качество: За автомобилни приложения сертификатът IATF 16949 осигурява системно управление на качеството. Работата в авиационната и космическата промишленост изисква съответствие с AS9100. Тези сертификати демонстрират контрол на процесите, който защитава крайните резултати от вашите проекти.

- Отзивчивост при комуникацията: Професионалната инженерна поддръжка предотвратява скъпоструващи недоразумения. Партньорите, които предлагат анализ за възможност за производство (DFM), идентифицират потенциални проблеми преди началото на производството и откриват конструктивни дефекти, които иначе биха се проявили като дефектни части.

- Интегрирани възможности: Търсете партньори, които предлагат пълен спектър от услуги по обработка — рязане, огъване, заваряване и отделка под един покрив. Тази интеграция премахва проблемите с координирането при използването на множество доставчици и намалява общото време за изпълнение.

За прецизно металорязане, което се интегрира с по-широките нужди от автомобилна обработка, производители като Shaoyi (Ningbo) Metal Technology комбинират лазерно рязане с операции по метално теглене под сертификата IATF 16949. Тяхната всеобхватна DFM подкрепа и възможност за предоставяне на оферта в рамките на 12 часа илюстрират подхода им на отзивчиво партньорство, който ускорява доставките – от бързо прототипиране за 5 дни до автоматизирано масово производство.

Прототипиране срещу производство: различни пътища напред

Вашата рамка за вземане на решения се променя в зависимост от фазата на проекта. Бързото прототипиране изисква гъвкавост и скорост, а не икономика на единица продукт – тук обикновено печели външното изпълнение, което осигурява достъп до разнообразни възможности без задължения. Когато дизайновете се стабилизират и обемите нарастват, съотношението се променя. Производствени серии от хиляди идентични части в крайна сметка оправдават инвестицията в оборудване, при условие че постоянното търсене осигурява достатъчно натоварване.

Приложете поетапен подход: външно делегиране по време на разработването и валидирането при малки обеми, след което преоценете закупуването на оборудване, когато обемите на производството се стабилизират и прогнозируемостта на търсенето се подобри. Тази стратегия минимизира риска, като запазва бъдещите възможности.

Независимо от избрания път — инвестиция в оборудване, партньорство за услуги или хибриден подход — знанията, представени в това ръководство, ще ви помогнат да използвате максимално предимството на лазерната рязка в точността, като в същото време избягвате често срещани капани, които провалят проектите по металообработка.

Често задавани въпроси относно лазерната рязка на метални листове

1. Може ли да се режат метални листове с лазер?

Да, съвременните лазерни рязачни машини ефективно режат широк спектър от метални листове, включително стомана, неръждаема стомана, алуминий, титан, месинг и мед. Фибровите лазери са станали индустриален стандарт за рязане на метали поради превъзходното им поглъщане на дължината на вълната от металите, като постигат скорост на обработка до 10 пъти по-висока в сравнение с лентовите триони. Технологията осигурява изключителна прецизност с допуски от ±0,05–0,1 мм, което я прави идеална за всичко – от автомобилни компоненти до декоративни архитектурни панели.

2. Колко струва машина за лазерно рязане на метални листове?

Индустриалните лазерни режещи машини варират значително според мощността и възможностите. Системите с ниво за влизане CO2 започват от около 2600–20 000 долара, докато индустриалните машини, обработващи по-дебели метали, струват 20 000–70 000 долара. Системите с висока мощност влаконен лазер за изискващи производствени среди могат да надхвърлят 100 000 долара. Освен първоначалната цена, трябва да се имат предвид постоянните разходи, включващи електроенергия, подпомагащи газове (азот и кислород), разходни материали като лещи и дюзи и поддръжка. При операции с голям обем, оборудването обикновено се възвръща за 3–4 години чрез намалени разходи на детайл в сравнение с извънвземането.

3. Колко струва лазерната рязка на метал за един проект?

Лазерното рязане на стомана обикновено струва между 13 и 20 долара за час машинно време. Общата цена за проекта зависи от няколко фактора: видът и дебелината на материала, сложността на реза, таксите за настройка и изискванията за довършителна обработка. Например, проект, който изисква рязане на 15 000 инча при скорост 70 инча в минута, съответства на около 3,5 часа активно рязане. Отразяващи метали като алуминий изискват по-висока мощност и по-бавни скорости, което може да удвои времето за обработване. Сложни дизайни с детайлни шарки или тесни допуски също увеличават разходите в сравнение с прости правоъгълни резове.

4. Кои материали никога не бива да режете с лазерен рязач?

Някои материали са опасни или неподходящи за лазерно рязане. Избягвайте PVC (поливинилхлорид), тъй като при нагряване освобождава токсичен хлорен газ. Кожата, съдържаща хром (VI), произвежда опасни изпарения. Въглеродното влакно създава опасни частици и може да повреди лазерната оптика. За металите, изключително дебелите плочи над номиналната мощност на машината ще дадат лоши резултати. Отразяващите метали като мед и алуминий изискват специално оборудване с антиотразяващи функции, за да се предотврати увреждане на лъча на лазерния източник. Винаги проверявайте съвместимостта на материала преди рязане.

5. Не, не. Как да избера между лазери с влакна и CO2 за резка на метали?

Изберете влакнести лазери за целенасочено рязане на метали – те предлагат 30-40% енергийна ефективност спрямо 10% при CO2 системите, по-високи скорости на рязане и превъзходно представяне при отразяващи метали като алуминий и мед. Запечатаният им дизайн също намалява нуждата от поддръжка. Изберете CO2 лазери, ако имате нужда от универсалност за рязане както на метали, така и на неметали (дърво, акрил, текстил). CO2 осигурява по-гладки ръбове при органични материали, които влакнестите лазери не могат да обработват. При среди със смесени материали или по-малки обеми гъвкавостта на CO2 често оправдава компромиса с ефективността.

Малки порции, високи стандарти. Нашата услуга за бързо проектиране на прототипи прави валидацията по-бърза и лесна —

Малки порции, високи стандарти. Нашата услуга за бързо проектиране на прототипи прави валидацията по-бърза и лесна —