Ключови процеси за термична обработка за максимален живот на матрицата

Накратко

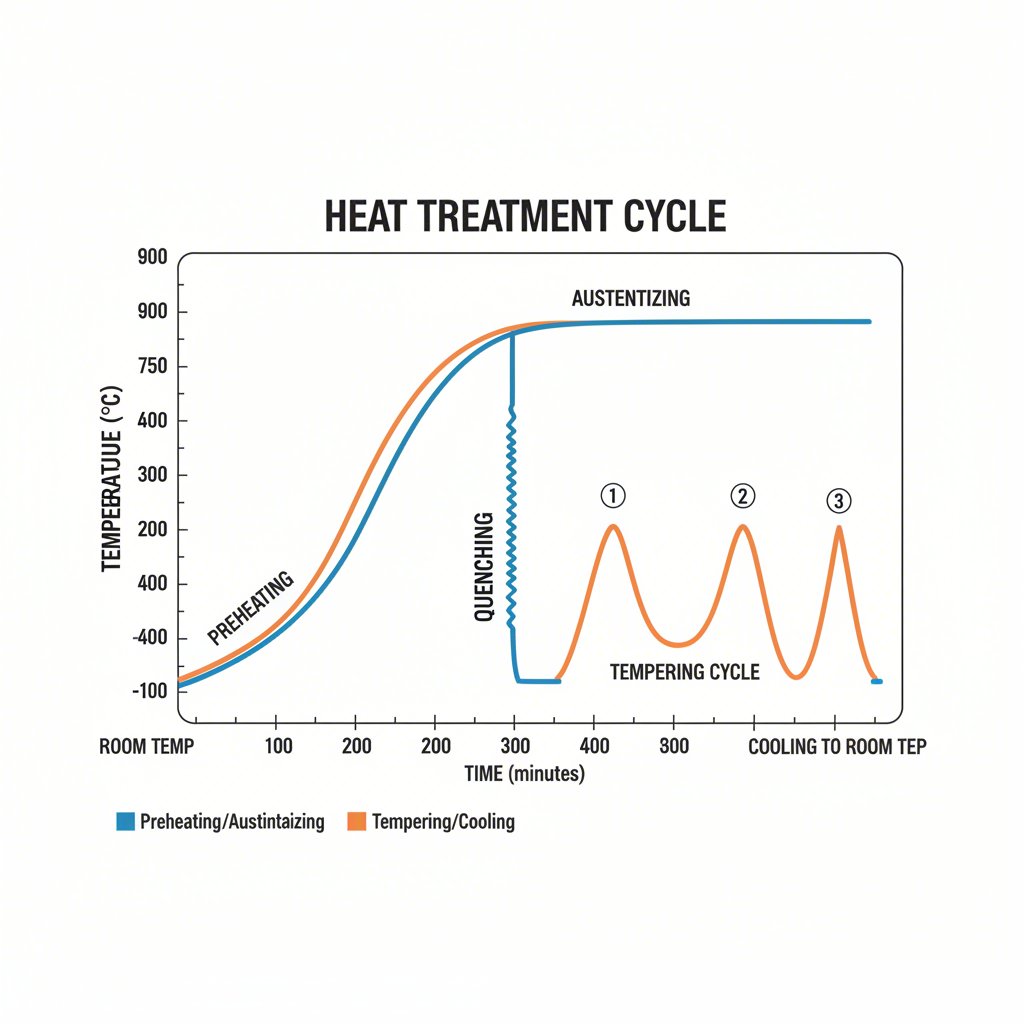

Термичната обработка на матрици е критичен, многоетапен металургичен процес, предназначен да подобри механичните свойства на инструменталните стомани. Той включва прецизна последователност от контролирани цикли на нагряване и охлаждане, включително ключови етапи като отжигане, аустенизация, гасене и отпускане. Основната цел на тези процеси за термична обработка на матрици е постигането на оптимална твърдост, изключителна якост и повишена издръжливост, осигурявайки, че инструментът може да издържи на огромните натоварвания при производствени операции като штамповане и леене.

Основните процеси на термична обработка – обяснени

Разбирането на топлинната обработка на матричните стомани изисква детайлен преглед на специфичните металургични трансформации, които се случват на всеки етап. Всеки процес има ясно определена цел и заедно допринасят за крайния успех и срок на служене на матрицата. Тези процеси не са самостоятелни операции, а част от интегрирана система, при която успехът на един етап зависи от правилното изпълнение на предишния. Основната цел е чрез управление на микроструктурата на стоманата да се получи комбинация от твърдост, втвърдяване и стабилност, точно настроена според конкретното приложение на матрицата.

Пътуването започва с процеси, предназначени да подготвят стоманата за втвърдяване. Изгаряне включва загряване на стоманата до определена температура, последвано от много бавно охлаждане, процедура, която размеква метала, усъвършенства неговата зърнеста структура и премахва вътрешните напрежения от предходни производствени етапи. Това прави стоманата по-лесна за механична обработка и я подготвя за еднороден отклик при последващи твърдеенето. След това, Предварително загряване е решаваща стъпка за намаляване на термичния шок, преди стоманата да бъде изложена на високите температури, необходими за твърдеенето. Като се повиши бавно температурата на инструмента до междинна стойност (обикновено около 1250°F или 675°C), риска от деформация или пукане значително се намалява, особено при сложни геометрии на матрици.

Фазата на твърдеене сама по себе си включва две ключови стъпки: аустенитизиране и гасене. Изключване , или нагряването при висока температура, е процесът, при който стоманата се нагрява до критична температура (в диапазона от 1450°F до 2375°F, или от 790°C до 1300°C, в зависимост от сплавта), за да се трансформира кристалната ѝ структура в аустенит. Продължителността и температурата трябва да се контролират прецизно, за да се разтворят карбидите, без да се допусне прекомерен растеж на зърната. Незабавно след това Отваряване включва бързото охлаждане на стоманата в среда като масло, вода, въздух или инертен газ. Това бързо охлаждане задържа въглеродните атоми и превръща аустенита в мартензит – изключително твърда, но крехка микроструктура. Изборът на охлаждаща среда е от решаващо значение и зависи от способността на стоманата да се закалява.

След закаляването матрицата е твърде крехка за практически употреба. Степене на възстановяване е окончателният задължителен процес, който включва повторно загряване на закаления инструмент до по-ниска температура (обикновено между 350°F и 1200°F или 175°C и 650°C) и задържане за определено време. Този процес намалява крехкостта, отстранява напреженията от закаляването и подобрява якостта, като запазва голяма част от твърдостта. Много високолегирани инструментални стомани изискват няколко цикъла на отпускане, за да се осигури пълна микроструктурна стабилност. Сроден процес, Отпускане на напрежения , може да се извърши преди окончателната механична обработка или след процеси като електроерозия (EDM), за премахване на вътрешните напрежения, които биха могли да доведат до деформации по време на експлоатация.

| Процес | Основна цел | Типичен диапазон на температурата (°F/°C) | Резултат |

|---|---|---|---|

| Изгаряне | Мекне на стоманата, отстраняване на напрежения, подобряване на обработваемостта | 1400-1650°F / 760-900°C | Мека, равномерна микроструктура |

| Изключване | Трансформация на микроструктурата в аустенит за закаляване | 1450-2375°F / 790-1300°C | Стоманата е готова за закаляване |

| Отваряване | Бързо охлаждане за образуване на твърда мартенситна структура | Висока топлина към заобикалящата среда | Максимална твърдост, висока крехкост |

| Степене на възстановяване | Намаляване на крехкостта, увеличаване на якостта, отстраняване на напреженията | 350-1200°F / 175-650°C | Балансирана твърдост и якост |

| Отпускане на напрежения | Минимизиране на деформациите от машинна обработка или интензивна употреба | 1100-1250°F / 600-675°C | Намалени вътрешни напрежения |

Стъпка по стъпка ръководство за цикъла на термична обработка на матрици

Успешната термична обработка на матрица не е извършване на отделни процеси изолирано, а изпълнение на прецизно планирана последователност. Всеки етап се базира на предходния, като всяко отклонение може да компрометира крайната цялостност на инструмента. Типичен цикъл осигурява постепенна и контролирана трансформация на свойствата на стоманата. Съвременната термична обработка често се извършва в силно контролирани среди, като вакуумни пещи, за предотвратяване на замърсяване на повърхността, например окисление и декарбуритизация.

Целият процес изисква прецизност и експертност, тъй като крайното качество на матрицата директно влияе върху производствената ефективност и качеството на детайлите. За индустрии, които разчитат на високоефективни режещи инструменти, като автомобилното производство, овладяването на този цикъл е от съществено значение. Например, водещи производители на персонализирани штамповъчни матрици за автомобилна индустрия, като Shaoyi (Ningbo) Metal Technology Co., Ltd. , използват дълбока експертност в материалознанието и термичната обработка, за да произвеждат компоненти, отговарящи на строгите изисквания на производителите на оригинални части (OEM) и доставчици от първо ниво. Успехът им зависи от точното изпълнение на цикли като този, описан по-долу.

Пълният цикъл на термична обработка обикновено включва следните стъпки, изпълнявани в определен ред:

- Отжиг (ако е необходимо): Като първоначална стъпка суровата инструментална стомана се отжига, за да се осигури меко, свободно от напрежения и обработваемо състояние. Това подготвя материала за равномерно закаляване и е от решаващо значение, ако стоманата е била подложена на предходна обработка или заваряване.

- Отслабване на напреженията (по избор, но препоръчително): За форми със сложна геометрия или такива, които са подложени на обширна механична обработка, се извършва цикъл за отстраняване на напреженията преди закаляването, за да се минимизира риска от деформация по-късно в процеса.

- Прегряване: Формата се загрява бавно и равномерно до междинна температура. Този решаващ етап предотвратява топлинен шок, когато детайлът се премести в пещта за аустенитизиране при висока температура, като по този начин се намалява риска от огъване или пукане.

- Аустенитизиране (висока температура): Инструментът се нагрява до специфичната за него температура на закаляване и се задържа — или „напоява“ — достатъчно дълго, за да достигне равномерна температура по целия си напречен разрез и да се превърне в аустенит. Времето и температурата са критични параметри, определени от класа на стоманата.

- Гасене: Веднага след аустенизирането, матрицата се охлажда бързо. Методът зависи от вида стомана; за стомани, закаляващи се на въздух, може да се използва обдуване с вентилатор или високонапорен инертен газ, докато стоманите, закаляващи се в масло, се потапят в маслено легло с контролируема температура. Целта е да се постигне напълно мартензитна структура.

- Степен на оцветяване: Закалената матрица, сега изключително твърда, но крехка, трябва незабавно да се отпуска, за да се предотврати пукане. Тя се нагрява повторно до много по-ниска температура, за да се отстранят вътрешните напрежения, да се намали крехкостта и да се получи окончателният желан баланс между твърдост и якост. Високолегирани стомани често изискват два или дори три цикъла на отпускане, за да се осигури пълна металургична стабилност.

Разширени съображения за големи и гига матрици

Въпреки че основните принципи на термичната обработка са приложими за всички матрици, предизвикателствата нарастват значително с увеличаването на размера. Големите матрици, а особено „Гига матриците“, използвани в съвременното автомобилно производство за отливане на големи конструктивни елементи, представляват уникални металургични предизвикателства. Масивните им напречни сечения затрудняват равномерното загряване и охлаждане, което увеличава риска от топлинни градиенти, вътрешни напрежения, деформации и непълно зазвъртяване. Стандартните процедури често са недостатъчни за тези приложения и се изисква специализирано оборудване и модифицирани процеси, за да се осигури успех.

Един от основните предизвикателства е постигането на постоянна скорост на охлаждане в цялата матрица по време на закаляване. Повърхността се охлажда много по-бързо от ядрото, което може да доведе до нееднородни микроструктури и свойства. За преодоляване на този проблем най-добрите практики в индустрията, като тези, описани от Асоциацията за леене под налягане в Северна Америка (NADCA), често изискват използването на напреднали вакуумни пещи, оборудвани с системи за газово закаляване при високо налягане (HPGQ). Тези системи използват инертни газове като азот или аргон при високи налягания, за да отвеждат топлината по-ефективно и равномерно в сравнение с неподвижен въздух, осигурявайки контролирано закаляване, което минимизира деформациите, докато се постига необходимата твърдост в дълбочината на инструмента.

Освен това, процесът на отпускане за големи и Giga матрици е по-сложен. Поради огромните вътрешни напрежения, възникващи по време на гасенето на такава голяма маса, еднократно отпускане е недостатъчно. За Giga матрици като стандартна практика се счита минимум два цикъла на отпускане, като между всеки цикъл матрицата се охлажда до стайна температура. Този многостепен подход осигурява по-пълна трансформация на остатъчния аустенит в стабилна, отпусната мартенситна структура, което е от решаващо значение за постигане на необходимата якост и размерна стабилност. Тези напреднали протоколи не са просто препоръки; те са задължителни изисквания за производството на инструменти, които могат да издържат на екстремните налягания и термичните цикли, присъщи на големомащабни операции по леене под налягане.

Често задавани въпроси относно топлинната обработка на матрици

1. Какви са 4-те вида процес на топлинна обработка?

Въпреки че съществуват много конкретни процедури, четирите основни вида топлинна обработка обикновено се считат за отжигане, закаляване, отпускане и премахване на остатъчни напрежения. Отжигането размеква метала, закаляването увеличава неговата якост, отпускането намалява крехкостта и подобрява ударната въздръжливост, а премахването на остатъчни напрежения елиминира вътрешните напрежения, причинени от производствените процеси.

2. Какво е топлинната обработка при прецово леене?

В контекста на прецовото леене, топлинната обработка се отнася до процесите, прилагани върху стоманените прецове или форми, а не върху отлите (които също могат да бъдат подложени на топлинна обработка). Целта е да се подобрят физическите и механични свойства на преца, като твърдост, якост и устойчивост на термична умора. Това гарантира, че прецът ще издържи на високите налягания и термични удари при многократно впръскване на разтопен метал, като по този начин се максимизира експлоатационният му живот.

3. Какъв е процесът на закаляване на прецовата стомана?

Процесът на закаляване на инструменталната стомана включва две основни етапа. Първият е аустенитизирането, при което стоманата се нагрява до висока критична температура (обикновено между 760–1300 °C или 1400–2375 °F), за да се трансформира нейната кристална структура. Това незабавно се следва от гасене – бърз процес на охлаждане, използвайки среда като вода, масло или въздух. Това бързо охлаждане фиксира твърда мартенситна микроструктура, която осигурява висока якост и устойчивост на износване на стоманата.

Малки порции, високи стандарти. Нашата услуга за бързо проектиране на прототипи прави валидацията по-бърза и лесна —

Малки порции, високи стандарти. Нашата услуга за бързо проектиране на прототипи прави валидацията по-бърза и лесна —