Персонализирани централни капаци за ковани джанти: От проблеми с размера до перфектно прилягане

Разбиране на персонализираните ковани централни капаци за гуми

Инвестирахте хиляди в премиум ковани гуми, но все още нещо изглежда не наред. Този обикновен централен капак в средата? Равно е на това да комбинирате дизайнерски костюм с маншетни копчета от доларов магазин. Персонализираните ковани централни капаци за гуми решават този проблем, като предлагат точна посадка, висококачествени материали и прецизна естетика, съответстваща на инвестициите ви в гумите.

За разлика от стандартните пластмасови централни капаци, предназначени за масовия пазар на гуми, тези специализирани компоненти са проектирани специално за уникалните размери и високите изисквания на кованите колелни системи. Разликата не е само във визуалния вид. Тя е структурна, функционална и незабавно забележима за всеки, който цени автомобилното майсторство.

Какво отличава кованите централни капаци за гуми

Стандартните централни капаци за гуми обикновено се произвеждат чрез леене под налягане от пластмаса с универсални размери, предназначени да паснат на широк диапазон от приложения. Те са проектирани за икономическа ефективност, а не за прецизност. Капаците за кованите джанти използват напълно различен подход.

Тези специализирани капаци се изработват чрез процеси на деформация под високо налягане, които подреждат структурата на металното зърно, значително подобрявайки якостта и устойчивостта на умора. Според индустриални спецификации този производствен метод създава компоненти, способни да издържат на динамични натоварвания, термично циклиране и вибрационни модели, характерни за високопроизводително каране.

Централният капак за колесните сглобки на кованите джанти трябва да отговаря на по-строги допуски. Кованите джанти често имат персонализирани размери на централния отвор, които не съвпадат с универсалните спецификации. Универсален капак може да започне да вибрира при високи скорости или изобщо да не се монтира правилно. Централни капаци за джанти, проектирани специално за ковани джанти, премахват тези проблеми благодарение на прецизното си инженерство.

Друга важна разлика е свързана с управлението на топлината. Съвременните условия на движение генерират значително количество топлина в стъпалките на колелата, особено при динамично каране или състезателни събития. Висококачествени персонализирани централни капаци за джанти често включват конструкции, които отвеждат тази топлина по-ефективно в сравнение с фиксираните алтернативи, намалявайки риска от деформация или разрушаване на уплътненията с времето.

Анатомия на качествен централен капак

Преди да изберете подходящ централен капак за джанти за вашия автомобил, е добре да разберете какво всъщност виждате. Всеки качествен централен капак се състои от четири основни компонента, които работят заедно:

- Дизайн на лицевата част: Видимата външна повърхност, която показва логотипи, емблеми или персонализирани графики. Този елемент определя естетическия характер и може да има полирани, матирани, матови или съчетани по цвят повърхности.

- Клипове за фиксиране: Механизмът за монтиране, който задържа капака на колелото ви. Възможностите включват клипове с натискане, резбови връзки или конструкции с бутане. Правилното фиксиране предотвратява изхвърлянето по време на работа с висока скорост.

- Интерфейс на централния отвор: Вътрешният диаметър, който трябва точно да съответства на централния отвор на вашето колело. Неправилен размер води до проблеми с поставянето, вибрации и възможна загуба на капака.

- Материална конструкция: Премиум опциите включват ковани алуминий и титан, които предлагат по-високо съотношение на якост към тегло в сравнение с пластмасовите алтернативи. Изборът на материал директно влияе върху издръжливостта, термостойкостта и дългосрочния външен вид.

Разбирането на тези компоненти ви поставя в позиция да оценявате разумно централните капаци за гуми, вместо да гадаете за съвместимостта. Когато знаете какво прави всеки елемент, подборът на подходящия капак за вашите конкретни кованите джанти става лесен, а не притесняващ.

Инвестицията в подходящи централни капаци носи ползи, които надхвърлят естетиката. Те предпазват монтажния център от пътен отпадък, запазват чист външен вид и показват вниманието към детайла, което отличава продължително обмисления проект от недовършена работа.

Типове централни капаци за ковани джанти

Забелязали ли сте колко някои луксозни автомобили имат централни капаци с лога, които остават напълно изправени, докато гумите се въртят? Това не е магия. Това е умен инженерен подход. При избора на персонализирани централни капаци за ковани джанти, разбирането на различните налични типове ви помага да изберете стила, който отговаря както на естетическите ви цели, така и на навиците ви при шофиране.

Не всички централни капаци функционират по един и същи начин. Някои се въртят заедно с колелата ви, други остават неподвижни, а методите за монтаж варира от прости модели с натискане до сигурни конфигурации с болтове. Всеки тип предлага различни предимства, в зависимост от дизайна на кованите ви джанти и начина на употреба.

Плаващи срещу фиксирани централни капаци – обяснение

Най-важната разлика в дизайна на централните капаци се свежда до един въпрос: дали капакът се върти заедно с колелото или остава неподвижен?

Плаващи централни капаци използват теглена система в комбинация с нисковъртящ лагерен механизъм, който поддържа логото изправено независимо от въртенето на колелото. Според American Wheels Company , теглената основа естествено връща емблемата в изправено положение, докато колелото се върти, създавайки ефекта на премиум клас, който привлича вниманието и се наблюдава при висококласни автомобили от Mercedes-Benz и Rolls-Royce.

Представете си плаващите колани като махало. Гравитацията задържа оловната част отдолу, докато лагерът позволява свободно въртене независимо от колелото. Това означава, че независимо дали стоите паркирани или се движите с магистрални скорости, вашият лого остава перфектно подравнен и видим.

Фиксирани централни капаци прилагат традиционния подход. Те се монтират здраво към колелото и се въртят заедно с него. Въпреки по-простата конструкция, фиксираните капаци имат свои предимства: по-малко движещи се части означава по-малко потенциал за механични повреди и обикновено струват по-малко в сравнение с плаващите. За собствениците на ковано колело, които ценят надеждността повече от визуални трикове, фиксираните капаци предлагат директна функционалност.

Капакът с пинчер представлява интересна вариация. За разлика от плаващи капаци, които остават неподвижни, въртящите се капаци са проектирани да продължават да се въртят след спиране на превозното средство, създавайки привличащо внимание движение. Тези централни капаци с пинчер стават популярни в културата на персонализирани коли и продължават да бъдат смела стилова изява за ентусиасти, търсещи максимален визуален ефект.

Избор на подходящия стил на капак за вашите гуми

Освен решението плаващ срещу фиксиран, ще срещнете различни конфигурации за монтиране, които повлияват както на трудността при инсталиране, така и на дългосрочната сигурност:

Натискови капаци вмъкват се отпред на джантата и се заключват на място чрез клипове за фиксиране. Те са най-често срещаният стил за вторичен пазар и позволяват лесно премахване за почистване или поддръжка на гумите. Въпреки това изискват прецизно съвпадане на диаметъра, за да се предотврати тресене или изхвърляне.

Капаци с болтове фиксиране с нарязани фасони за максимална сигурност при задържане. Те работят особено добре при кованите джанти, използвани в производствени приложения, където вибрациите и температурните цикли биха могли да разхлабят типовете с натискане. Компромисът е малко по-сложна инсталация и демонтаж.

Капаци с резба се винтоват директно в стъпалото на джантата, осигурявайки сигурно монтиране без видими елементи. Този стил често се среща при оригинални луксозни превозни средства и осигурява чист, интегриран вид, който много собственици на ковани джанти предпочитат.

| Тип | Механизъм | Най-добър за | Визуален ефект |

|---|---|---|---|

| Плаващи | Система с теглирани лагери, която поддържа логото неподвижно | Луксозни превозни средства, автомобили за изложби, видимост на марката | Логото остава изправено, докато джантата се върти |

| Фиксирано с натискане напряко | Защелкващи се клипове фиксират капака отпред | Ежедневни превозни средства, лесен достъп за поддръжка | Традиционен въртящ се вид |

| Спинер | Лагерът позволява продължаване на въртенето след спиране | Персонализирани конструкции, привличащи вниманието конфигурации | Продължително въртеливо движение, когато е паркирано |

| Приспиване с болтове | Резбови фиксатори осигуряват сигурно монтиране | Употреба по писти, среди с висока вибрация | Чист изглед с максимална сигурност |

| Засича се | Винтова резба директно в стъпалния хуб | Монтажи по образец на производителя, интегриран изглед | Безшевен фабричен вид |

Кой стил ще подхожда най-добре за вашите кованите джанти зависи от няколко фактора. Джантите с голям диаметър (20 инча и повече) често извличат полза от плаващи модели, тъй като традиционните фиксирани капаци могат да се повредят поради увеличена вибрация и термично напрежение по външния ръб. За високопроизводителни конфигурации обикновено се предпочитат болтови решения поради по-надеждното им закрепване при агресивно каране.

Имайте предвид и модела на спиците на джантата си. Отворените конструкции с максимална видимост към централната хуба показват прекрасно ефекта на плаващ капак. Джантите с по-плътно разположени спици може да не подчертаят толкова ясно плаващия ефект, което прави фиксираните варианти еднакво ефективни при по-ниска цена.

След като стиловете на капаците са уточнени, следващата важна стъпка е да се осигури, че избраният тип всъщност ще пасне точно на вашите джанти. Грешките в размерите продължават да бъдат най-голямото разочарование за собствениците на ковани джанти, които търсят перфектното решение за централен капак.

Основни изисквания за размер и съвместимост

Ето къде повечето индивидуални поръчки за ковани централни капаци за гуми отиват на зле: намирате перфектния дизайн, правите поръчка и след това установявате, че капакът е или твърде широк, за да остане закрепен, или изобщо не седи. Грешките в размерите са причина за мнозинството проблеми с централните капаци, но те напълно могат да бъдат избегнати, ако знаете как правилно да измервате.

За да получите точна посадка, трябва да знаете две ключови мерки: диаметъра на централното отворение на гумата и конфигурацията на болтовия модел. Ако пропуснете едното или другото, ще останете с капаци, които дрънчат, изхвърчат при скорост или просто не могат да бъдат монтирани.

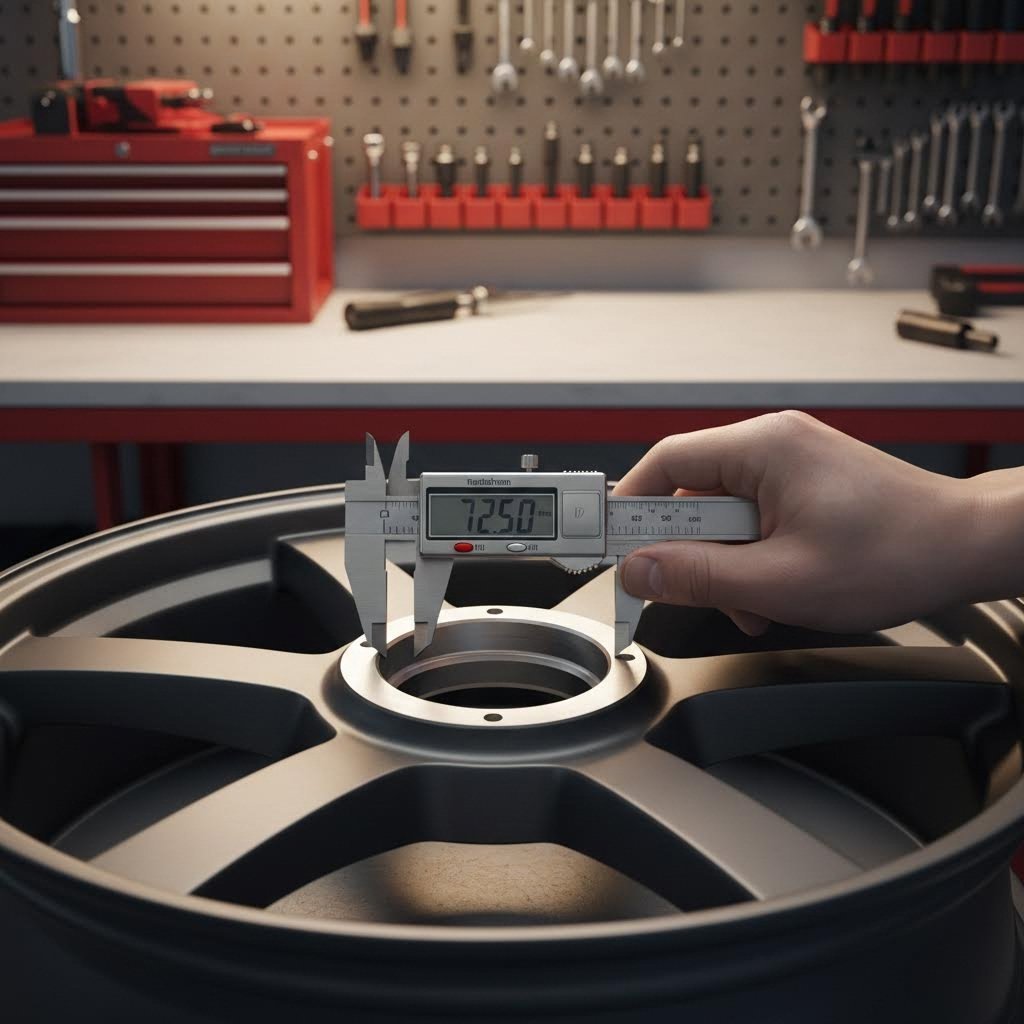

Как да измерите диаметъра на централното отворение

Централното отворение е обработеното отворение от задната страна на гумата, което седи върху хабринга на превозното Ви средство. Според Apex Wheels , това измерване е от решаващо значение, тъй като различни производители често имат идентични модели на болтове, но използват различни централни отворения. Централните Ви капаци за гуми трябва точно да отговарят на тази размерност.

За точно измерване следвайте тези стъпки:

- Премахнете гумата от превозното си средство и я поставете с лицето надолу върху чиста, равна повърхност. Това ще ви осигури лесен достъп до централния отвор.

- Вземете цифрови шублерове. Макар че линийката може да даде приблизителни измервания, шублерите осигуряват необходимата точност. Размерите на капаците за центъра на гумата обикновено се посочват в милиметри , затова използвайте метрични единици.

- Измерете истинския диаметър на отвора. Поставете шублерите в най-широката точка на централния отвор, но внимавайте да не измервате фаската. Повечето гуми имат 3-5 мм фаска на отвора, която е малко по-голяма от действителния отвор.

- Направете няколко измервания. Направете измервания в различни точки на отвора, за да потвърдите съгласуваността. Всякакви отклонения могат да означават износване или повреда, които влияят на поставянето на капачката.

- Запишете измерената стойност в милиметри. Често срещани размери са 54,1 мм, 56,1 мм, 60 мм, 66,6 мм, 72,6 мм и 76 мм, макар че кованите джанти често използват персонализирани размери.

Когато измервате централните капаци на обръча за подмяна, обърнете капака с лице надолу и измерете външния диаметър на частта, която се поставя в колелото. Този размер трябва да е малко по-малък от централния отвор на вашето колело, за да осигури сигурно пасване, като все пак запази стегнатост.

Разбиране на съвместимостта на модела на болтовете

Вашият модел на болтовете влияе на избора на централен капак по начини, които не са незабавно очевидни. Докато централният отвор осигурява физическото прилягане на капака, моделът на болтовете определя кои системи за закрепване работят с конкретната ви конфигурация на джанта.

Моделите на болтовете се изразяват с две числа: броят на отворите за болтове и диаметъра на окръжността, която образуват. Модел 5x120 мм означава пет болта, разположени по окръжност с диаметър 120 мм. Според индустриални спецификации , измерването на шарковете с четен брой отвори (4-дюймов, 6-дюймов) е направо напред, тъй като се измерва директно през срещуположните отвори. Шарковете с пет отвори изискват измерване от центъра на един отвор до средата между двата срещуположни отвора.

Различни производители на ковано колелото проектират интерфейсите за централните капаци около специфични конфигурации на болтовете. Колело с 5-дюймов шарко може да има позиции за фиксиращи клипове, които съвпадат с пространствата между болтовете, докато 4-дюймовите конструкции могат да използват напълно различни подредби на клиповете. Това означава, че универсалните централни капаци за обръчи не винаги оправдават името си, когато става въпрос за висококачествени ковани колела.

Марки на ковани колела като Forgiato, American Force и HRE всяка прилага собствени размери на централния отвор и механизми за фиксиране. Това, което идеално пасва на 22-инчови централни капаци на един производител, не задължително ще работи на друг, дори ако и двете колела имат един и същ шарко и подобни размери на централния отвор.

| Размер на централния капак | Често срещан диаметър (mm) | Типични приложения | Бележки |

|---|---|---|---|

| Малък | 54-60mm | Японски внос, компактни превозни средства, някои европейски модели | центровите капаци с размер 60 мм са сред най-често срещаните размери на вторичния пазар |

| Среден | 63-70 мм | Европейски луксозни марки, автомобили от средния клас, кросоувъри | Често се срещат при превозни средства на BMW, Audi и Mercedes |

| Голяма | 72-83 мм | Пълноразмерни камиони, SUV, американски мускулни коли | GM често използва диаметър на отвора 76 мм |

| Екстра голям | 87-110 мм | Тежкотоварни камиони, ковани колела с голям диаметър (центрови капаци на колела 20 инча и по-големи) | Персонализираните ковани колела често изискват специални размери |

Ако заменяте съществуващи капаци, най-безопасният подход е да измерите това, което вече имате. Свалете текущия си капак и измерете външния диаметър на вмъкване и общия диаметър на предната част. Това ще ви даде точни спецификации за съвпадение, вместо да разчитате на твърденията на производителя, които може да не отчитат производствените допуски.

Имайте предвид, че Coker Tire бележки, че оразмеряването на колелата може да варира дори в рамките на продуктите на един и същ производител. Стоманените колела за хот ръд обикновено приемат капаци с размер 8,25 инча, докато колелата Smoothie използват капаци с 7,5 инча за размери 14–16 инча, но изискват капаци с 7 инча за версиите 17–18 инча. Производителите на ковани колела следват подобни модели със спецификации за капаци, зависими от размера.

С потвърдените мерки, следващото нещо, което трябва да се има предвид, е изборът на материал. Съставът на вашите централни капаци влияе не само върху външния вид, но и върху издръжливостта, теглото и това колко добре допълват инвестицията ви в кованите гуми.

Опции за материал и техните предимства

Определихте размера. Сега идва друго решение, което прави разликата между обикновена инсталация и напълно хармонична конфигурация на гумите: от какъв материал трябва да са направени централните ви капаци? Този избор засяга всичко – от дългосрочната издръжливост до устойчивостта на топлина и визуалната хармония с кованите ви гуми.

Не всички материали се представят еднакво при изискванията на ежедневно шофиране, използване по писта или дори просто при контакт с атмосферните условия. Разбирането на силните и слабите страни на всеки вариант ви помага да изберете капаци, които няма да ви разочароват след няколко месеца реална употреба.

Алуминиеви срещу пластмасови централни капаци

Два най-често срещани материала, с които ще се сблъскате, са алуминий и пластмаса и те се намират на противоположни краища на качествената скала за приложения с ковани гуми.

Алуминиеви централни капаци представляват премиум избора по добра причина. Според Wheelcovers.com , металните капаци се отличават с висока издръжливост и здравина, които ги правят значително по-устойчиви на небрежно отношение в сравнение с пластмасовите аналогы. По-специално алуминият предлага отлична устойчивост към корозия, което го прави идеален за централни капаци на алуминиеви джанти, изложени през цялата година на пътна сол, прах от спирачките и влага.

Има значение и теглото. Докато стоманените централни капаци добавят усещаемо тегло към конструкцията, алуминият осигурява съпоставима якост при много по-малко тегло. При автомобили с перформанс ориентирана настройка, където неподръжданото тегло влияе на управлението, тази разлика има значение.

Пластмасови централни капаци доминират на бюджетния вторичен пазар. Произвеждат се от удароустойчива ABS пластмаса, предлагат устойчивост към ръжда и се предлагат в безброй дизайни и повърхностни обработки. Леки са и евтини, поради което са популярни за ежедневни автомобили, където крайната издръжливост не е приоритет.

Ето обаче уловката: пластмасата може да не издържи на екстремни условия. Цикличните температурни промени предизвикват разширяване и свиване, което с течение на времето отслабва фиксиращите клипове. Високата температура от агресивно спиране може напълно да деформира пластмасовите капаци. Ако сте инвестирали в премиум кованите джанти, използването на пластмасови капаци създава естетическа несъответствие, което намалява визуалния ефект на вашия автомобил.

Централните капаци за стоманени джанти често използват пластмаса, тъй като самата джанта представлява по-икономичен избор. Притежателите на ковани джанти обикновено очакват компонентите им да отговарят на качеството на инвестициите си в джантите, поради което алуминият остава предпочитаният материал за това приложение.

Премиум материали за ентусиасти

Освен дебата алуминий срещу пластмаса, специализираните материали предлагат допълнителни възможности за ентусиасти, търсещи отличаваща се естетика или определени експлоатационни характеристики.

Централни капаци от въглеродно влакно предлагат окончателното лековесно решение с изразено модерно външно оформление. Плетеният модел създава визуален интерес, който подчертава конструкции с ориентация към производителността, особено тези, които вече използват карбонови компоненти за кузов. Въпреки това, капачките от качествен карбон са с висока цена и изискват внимателно обращение по време на монтаж.

Капачки с хромово покритие се изработват върху основа от пластмаса или метал, след което се нанася бляскаво хромово покритие. Те веднага оказват силно визуално въздействие и ефективно се съпротивляват на ръжда, но изискват редовно поддържане, за да се предотврати замърсяването от отпечатъци и падеж по повърхността, което губи блясъка им. Хромираните централни капачки за джанти изглеждат великолепно на автомобили за изложби, но изискват по-грижливо отношение в сравнение с матовите или сатеновите алтернативи.

Съставни материали смесват различни компоненти, за да постигнат определени цели за производителност. Тези опции често комбинират устойчивостта на пукнатини и лекотата на напреднали пластмаси със структурно усилване, като създават капаци, които имат по-добра производителност от чистия пластмасов материал, но струват по-малко от тези от масивен алуминий. При плаващи централни капаци, при които вътрешните механизми на лагерите добавят сложност, композитната конструкция може да намали общото тегло, запазвайки издръжливостта.

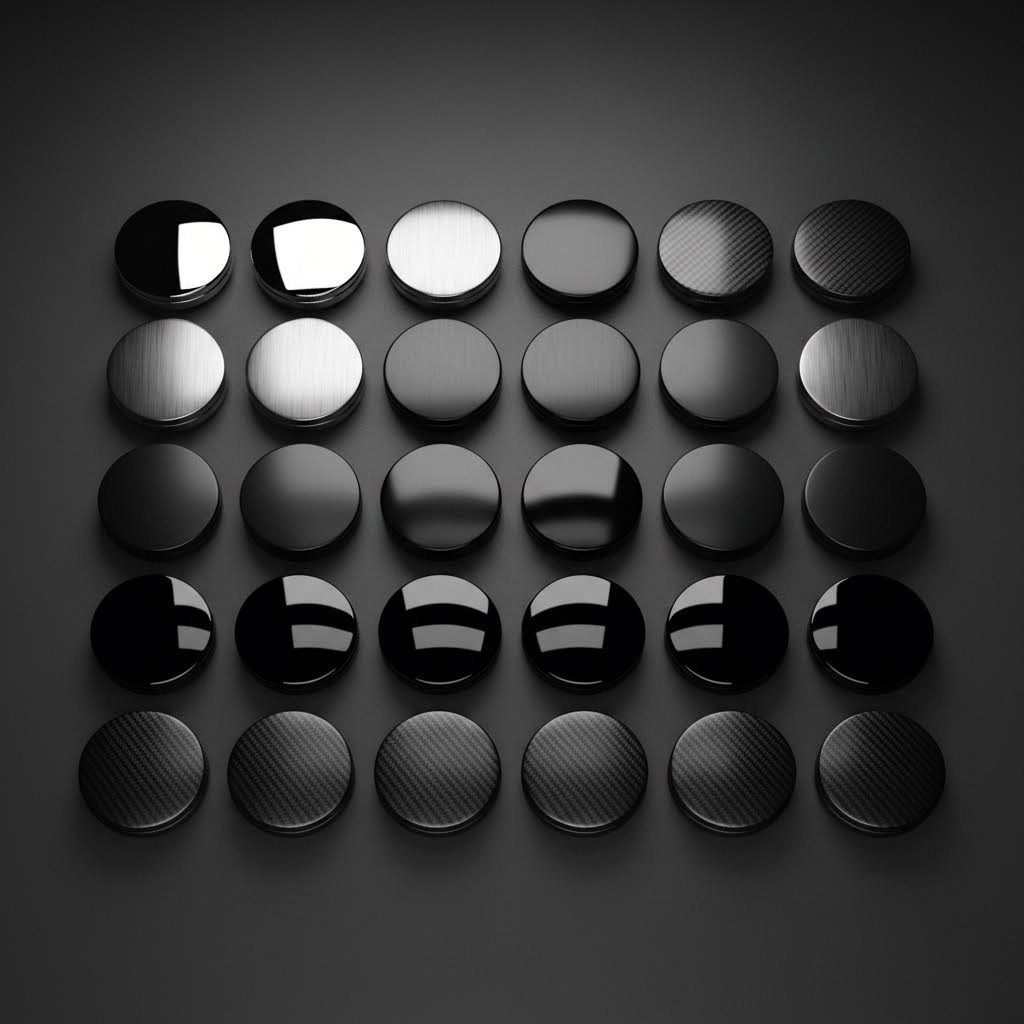

Черните централни капаци заслужават споменаване поради своята универсалност. Достъпни в пластмасови, алуминиеви и композитни изпълнения, черните повърхности подхождат на почти всеки цвят на гуми и скриват натрупването на прах от спирачките по-добре от полирани алтернативи. Дали ще изберете матови, гланцови или сатеново черни варианти зависи от повърхността на вашите гуми и личните ви предпочитания.

| Материал | Тегло | Издръжливост | Диапазон на разходи | Най-добри приложения |

|---|---|---|---|---|

| ABS пластмаса | Много лек | Умерена (склонна към пукане под натоварване) | $15–50 за комплект | Бюджетни конфигурации, временни инсталации, умерени климатични условия |

| Алуминий | Светлина | Отлична (устойчива на удар, топлина, корозия) | $80–200+ за комплект | Високопроизводителни превозни средства, кованите джанти, сурови условия |

| Хромиран | Лек до среден | Добро (зависи от основния материал) | $60-150 на комплект | Показни коли, класически построявания, полирани дискове |

| Въглеродни влакна | Ултра лек | Много добро (крехко при удар в точка) | $150-400+ на комплект | Построявания за писта, приложения с чувствителна маса, модерен външен вид |

| Композитен | Светлина | Добро до отлично | $50-120 на комплект | Балансирана производителност, плаващи капаци |

Защо ентусиастите по кованите джанти предпочитат масово метални капаци? Причината е защита на инвестицията и визуална хармония. Когато сте похарчили хиляди за прецизно изработени ковани джанти, пластмасов централен капак изглежда неуместно. Сякаш сте инсталирали винилови седалки във Ferrari. Технически функционално, но подкопава всичко, което конструкцията представлява.

Металната конструкция също така издържа на топлинните изисквания при агресивно каране, без деформация или разрушаване. Областта около хуба изпитва значителен топлообмен от спирачките, а алуминият разсейва това топлина, запазвайки размерната стабилност. Пластмасовите алтернативи може да издържат при нормално каране, но могат неочаквано да се провалят при по-динамично използване.

След като сте избрали материала, ще искате да проучите как различните повърхностни обработки и възможности за персонализиран дизайн могат допълнително да персонализират централните ви капаци, за да създадете напълно отличителен вид на джантите.

Персонализация и възможности за дизайн

Избрахте подходящия материал. Сега идва вълнуващата част: да направите тези централни капаци недвусмислено свои. Персонализираните кованите централни капаци за колелата предлагат много повече опции за персонализация, отколкото повечето ентусиасти осъзнават, превръщайки функционален компонент в елемент с уникален дизайн, който издига цялостния вид на колелата ви.

Дали строите автомобил за впечатляващо представяне или просто искате всекидневният ви автомобил да се отличава, избраните от вас финиш и дизайн определят крайното впечатление. Нека разгледаме какво е възможно, когато преминете над стандартните готови решения.

Финишни варианти, които издигат колелата ви

Повърхностният финиш на вашите персонализирани централни капаци оказва незабавно визуално въздействие. Според Персонализираните предложения на CCW дори основните централни капаци са налични в няколко финишни варианта, включително полирани, черен гланц и матово черни, с лога, които могат да бъдат боядисани в един цвят или с контрастна рязка обработка за допълнителна дълбочина.

Всеки финишен вариант предлага различен естетически ефект:

- Полирани: Огледален блясък, който драматично отразява светлината. Идеален за съвпадане с хром или полирани ръбове на колелата, макар да изисква редовно поддържане, за да се предотвратят петна от вода и окисляване.

- Почистено: Субтилна линейна текстура, която прикрива малки драскотини, като в същото време осигурява изискан и скромен външен вид. Съчетава се прекрасно с обработени или матови повърхности на колелата.

- Матов: Нерефлектираща повърхност, която осигурява модерен и агресивен вид. Отличен за колела с матово прахово покритие или цялостни "murdered-out" комплектации.

- Лъскаво черно: Дълбоко лъстящо покритие с ефект на мокър блясък, което се комбинира с почти всеки цвят на колело и позволява по-лесно почистване в сравнение с хромовите алтернативи.

- Цветово съчетано: Персонализирано боядисване, подбрано точно да съвпада с цвета на тялото на автомобила или акцентните декоративни елементи, осигурявайки безшевна визуална интеграция.

- Двуцветно: Комбинирани повърхности, при които лицето на капачката контрастира с външния пръстен или логото, добавяйки визуална сложност и дълбочина.

Ключът към успеха се крие в избора на повърхности, които или подчертават, или съзнателно контрастират с външния вид на вашите джанти. Персонализирани капаци за джанти с полирани фасове изглеждат впечатляващо върху матово черни спици, докато капаци от матов алуминий създават хармония с повърхности на джанти с подобна текстура.

Създаване на хармоничен персонализиран вид

Освен повърхностите, персонализираните централни капаци за джанти отварят възможности за индивидуално брандиране и графики, които превръщат гумите в истински елементи на изразяване.

Според RhinoTuning съществуват няколко метода за персонализация чрез добавяне на лога и дизайнерски елементи. Стикери с фирмено име, изработени от висококачествен алуминий, предлагат дълготрайност без избледняване, докато лазерната гравюра осигурява по-премиум опция, при която дизайни се изрязват с прецизност върху повърхността на капака, за да се получи текстурен и постоянен резултат.

Когато работите с производители по създаването на персонализирани централни капаци за джанти, имайте предвид следните подходи за дизайн:

Интеграция на лого остава най-популярната персонализация. Вашите инициали, фамилен герб, лого на компания или любим марка могат да бъдат включени чрез гравиране, тисане или приложени емблеми. Техниките с контрастно изрязване премахват материал около издадените лога, създавайки дълбочина, която отразява светлината по-различно в сравнение с равните печатни дизайни.

Графични елементи надхвърлят простите лога. Геометрични шарки, пистови ивици или абстрактни дизайни могат да обхващат цялата предна част на капачката. Някои ентусиасти включват значими числа, координати или символични изображения, които разказват лична история.

Комбиниране на материали създава визуален интерес, като комбинира различни повърхности в една и съща капачка. Представете си матиран алуминиев лицев плоскост с полирани издадени лога или център от въглеродно влакно, заобиколен от пръстен от фрезован алуминий. Тези комбинации подчертават занаятчийското майсторство и осигуряват уникален визуален ефект.

Процесът по създаване на персонализирани капаци за джанти обикновено започва с предоставянето на вашите дизайнерски файлове или концепции на производителя. Те ще изготвят цифрови макети, показващи как графиката ви ще изглежда на готовия капак. При персонализирани плаващи централни капаци имайте предвид, че дизайна трябва да остава визуално ефектен при гледане от всеки ъгъл, тъй като лицето на капака стои неподвижно, докато заобикалящите го елементи се въртят.

Качеството има огромно значение тук. Като California Chrome Wheel отбелязва, централните капаци често изискват различни методи на обработка в сравнение с джантите, особено когато се постига съвпадение на повърхностите между различни материали. Работата с опитни производители гарантира, че вашите персонализирани централни капаци за джанти ще получат подходяща подготовка на повърхността и техники за финиширане за дълготрайни резултати.

След като сте избрали идеалния финиш и дизайн, следващото предизвикателство е правилната инсталация на тези капаци и осигуряването, че ще остават здраво закрепени при всички условия на движение, с които се сблъсквате.

Ръководство за инсталиране и отстраняване на неизправности

Измерили сте два пъти, избрали сте идеалния материал и най-накрая са пристигнали персонализираните капачета за центровете. Настъпва моментът на истината: правилното им монтиране. Звучи достатъчно просто, нали? Въпреки това неправилното инсталиране причинява повече повреди на капачетата за центрове, отколкото производствените дефекти взети заедно. Няколко минути внимателна грижа по време на монтирането спестяват часове на раздразнение по-късно.

Дали за първи път работите с вторични капачета за центрове или заменяте износени оригинални, правилната техника гарантира, че капачетата ще останат здраво закрепени при високи скорости, температурни колебания и неравни пътни условия.

Ръководство за стъпка по стъпка за инсталация

Преди да докоснете новите си капачета, подготовката прави всичко по-лесно. Според Ръководството за инсталиране на WheelsHome почистването на повърхността на хуба на колелото осигурява правилно поставяне и дългосрочно задържане. Мръсотията, прахът от спирачките и корозията създават зазори, които позволяват движение и в крайна сметка водят до повреда на капачетата.

Следвайте следните стъпки за надеждна инсталация, независимо от типа на капачката:

- Изчистете добре монтажната повърхност. Използвайте обезмасляващ продукт с концентрация приблизително 70%, пръскане на разстояние от около 6 cm. Оставете да се наложи 2 минути, за да се разтвори мръсотията, след което избършете с мека тел четка с кръгови движения около всяка област на подложката.

- Изплакнете и изсушете напълно. Воден поток от 40 psi изхвърля разхлабени отломки. Следвайте с компресиран въздух при 60 psi, за да се премахне цялата влага от зоните на задържане на клип. Заловената вода причинява корозия, която отслабва задържането с течение на времето.

- Проверете новите си капачки преди монтажа. Проверете всички закрепващи клипове за повреда или деформация. Проверете дали диаметърът на централната дупка съответства на спецификациите на колелото. Потърсете всички производствени дефекти, които биха могли да повлияят на монтажа.

- Изравнявайте разделенията с съответните слотове. Повечето допълнителни капаци за центъра на колелата имат фиксиращи езици, проектирани да съвпадат с определени позиции на колелото ви. Областта около клапана често служи като ориентир. Завъртете капака, докато всички езици се подредят със съответните им слотове.

- Приложете равномерно налягане по целия периметър. Използвайте двете си ръце, за да натиснете едновременно от противоположни точки. Постоянна сила от приблизително 120 нютона, разпределена по целия 360-градусов периметър, предпазва скобите от повреда и осигурява равномерно поставяне.

- Слушайте за чутия щракащ звук. Всеки фиксиращ език произвежда характерен щракане, когато бъде правилно закачен. Според спецификациите за монтаж, всяка скоба трябва да се закачи. Ако чуете по-малко щракания, отколкото езиците на капака ви, премахнете го и опитайте отново.

- Проверете безопасната посадка без люфт. Меко опитайте да завъртите капака с ръка. Правилно монтиран капак не позволява никакво движение. Проверете дали процепът между ръба на капака и колелото остава постоянен. Идеално е той да е минимален, около 0,5 мм.

При системите за закрепване с винт и болт процесът е малко различен. Първо затегнете ръчно всички фиксации, за да осигурите правилното навлизане на нишките и да предотвратите повреди по тях. След това приложете окончателния момент на затягане в кръстов модел, като преминавате диагонално през капака, а не последователно около него. Този метод разпределя налягането равномерно и предотвратява деформация.

Централните капаци на алтернативни джанти изискват допълнително внимание по време на първоначалната инсталация. За разлика от оригиналните капаци, проектирани специално за фабричните спецификации на джантите, заместващите централни капаци за джанти може да изискват незначителни корекции, за да се постигне оптимална посадка. Някои алтернативни модели включват регулируеми клипове за закрепване, които компенсират малки отклонения в размерите.

Решаване на често срещаните проблеми с посадката

Дори и при внимателна инсталация, с течение на времето могат да възникнат проблеми. Промените в температурата, вибрациите и условията на движение оказват натиск върху системите за задържане на централните капаци. Ето как да диагностицирате и отстраните най-често срещаните проблеми:

- Лошо затегнати или тропащи капаци: Това обикновено сочи на износени фиксиращи клипове или неправилен размер. Първо премахнете капачката и проверете всички клипове за умора или счупване. Пластмасовите клипове стават крехки с възрастта и при температурни цикли. Ако клиповете изглеждат неповредени, диаметърът на централното отверстие може да е малко по-голям. Приложете тънък слой лента за уплътнение около ръба за вкарване на капачката, за да се създаде допълнително триене.

- Капачки, които изскочват при скорост: При високи скорости се създава значителна центробежна сила, която изпитва системите за фиксиране. Ако капачките излитат по време на шосейно движение, механизмът за задържане е с твърде малък размер за вашия случай. Помислете за преход към винтови капачки за по-сигурно монтиране или проверете дали имате правилния размер капачка за конкретния модел на колелото.

- Капачки, които не сядат напълно: Когато капачките не иска да се закрепят на мястото си, често виновникът е замърсяване в канала за фиксиране. Използвайте компресиран въздух, за да премахнете всички препятствия. Ако каналът е чист, външният диаметър на капачката може да е малко по-голям. Леко шкурене на ръба за вкарване понякога решава проблема, но действайте внимателно, за да не премахнете твърде много материал.

- Прекъснато трополене по време на температурни промени: Металът и пластмасата се разширяват с различна скорост. Капачки, които пасват перфектно при умерено време, могат да се разхлабят по време на студени периоди или горещи летни дни. Това е често срещано при заместващи централни капачки, които не са проектирани специално за термичните характеристики на вашите джанти. Помислете за капачки, изработени от същото семейство материали като джантите ви, за да се минимизира несъответствието при разширение.

- Пукащи фиксиращи клипове по време на монтаж: Прекомерната сила или неправилното подравняване причиняват повреда на фиксаторите. Ако фиксаторите се чупят многократно, вероятно използвате капаци, предназначени за друг тип джанта. Измерете отново централния отвор и проверете съвместимостта, преди да закупите нови.

- Капаците стърчат над повърхността на гумата: Когато капаците не седят плътно, нещо попречава на пълното им вкарване. Проверете за издадени литейни следи или натрупване на боя в централния отвор на джантата. Леко отстраняване на застоя с финокафява хартия често решава проблема.

Околни фактори значително влияят на продължителността на задържане на капаците. Солта за пътищата ускорява корозията в областите на фиксиране, което с времето ослабва хватката. Агресивното каране генерира топлина, която засяга пластмасовите компоненти. Използването на трасе подлага капаците на нива на вибрации, далеч над нормалното шофьорство по пътищата. За изискващи приложения металната конструкция и фиксирането с болтове осигуряват дълготрайност, която моделите с натискане не могат да постигнат.

Редовната проверка предотвратява неочакваната загуба на капачки. На всеки няколко месеца проверявайте здравината на всяка капачка, като приложите леко навъншно налягане. Засичането на изхабена система за закрепване навреме ви позволява да я поправите в гаража си, вместо да гледате как капачката ви подскача по магистралата зад вас.

Разбирането на факторите, които определят цената на централните капачки, ви помага да планирате бюджета си адекватно за качествени компоненти, които няма да се налага често да бъдат заменяни или поправяни.

Разбиране на ценообразуването и факторите за стойност

Защо една централна капачка за колело струва 15 долара, докато друга достига 150? Разликата в цената изглежда абсурдна, докато не разберете какво всъщност влиза в производството на качествени компоненти. Централните капачки за колела по индивидуална поръчка обхващат огромен ценови диапазон и познаването на причините за тези различия ви помага да планирате бюджета си рационално, без да плащате повече за функции, от които нямате нужда, или по-малко за компоненти, които няма да издържат.

Всъщност централните капаци за гуми отразяват реални разлики в материали, производствена сложност и степен на персонализация. Разбирането на тези фактори ви позволява да вземате покупко-решения, базирани на стойност, а не просто да търсите най-ниската цена.

Какво определя цената на централните капаци

Няколко взаимосвързани фактора определят каква цена ще платите за качествени капаци за гуми. Според анализ на ценовата политика в индустрията , плаващите централни капаци обикновено варират между 40 и 150 щатски долара на брой, като основните модели от кован алуминий започват от около 40–60 долара, докато премиум версиите на известни марки достигат 100–150 долара.

Ето какво всъщност влияе върху тези цени:

- Избор на материал: Себестойността на суровините формира основата на ценовата политика. Капаците от ABS пластмаса струват няколко цента за производство , докато кованите алуминиеви изискват скъпи пръти и специализирано оборудване. Още по-високи са цените при титан и въглеродно влакно поради както високата себестойност на материала, така и сложността при обработката.

- Метод на производство: Масово производството на капаци чрез лене с инжектиране струва много по-малко в сравнение с CNC-обработени или кованите алтернативи. Процесът на високонапрежна деформация, при който се получават кованите компоненти, изисква значителни инвестиции във форми и по-бавни темпове на производство, което директно влияе на цената за единица продукт.

- Сложност при персонализацията: Прост капак за гуми без лого струва по-малко от такъв с лазерно гравиране, контрастно изрязани емблеми или многотонови повърхности. Всеки допълнителен процес добавя труд, време за работа на оборудването и стъпки за контрол на качеството, които се натрупват в крайната цена.

- Премиум marca: Установени производители на джанти като HRE, SSR и Rotiform взимат по-високи цени отчасти поради репутацията си, а отчасти поради реални инвестиции в инженерни разработки. Капаците им са проектирани специално за техните системи джанти, осигурявайки прецизно прилягане, което обобщените алтернативи не могат да гарантират.

- Количество: Покупката на единични капаци води до по-високи разходи на единица спрямо комплекти от четири. Въпреки това, за разлика от много автомобилни компоненти, закупуването в по-големи количества рядко предлага значителни отстъпки за кованите централни капаци поради методите за производство в малки серии.

- Изисквания за повърхностна обработка: Хромирането, анодирането и специализираните покрития всеки поотделно добавят етапи в процеса. Според California Chrome Wheel централните капаци често изискват различни подходи при обработката спрямо самите джанти, особено когато трябва да се съгласуват повърхностните финиши между различни материали.

Транспортните разходи също заслужават внимание и могат да увеличат крайната сума с 15–25% в зависимост от теглото и дестинацията. Кованите алуминиеви капаци струват повече за транспортиране в сравнение с леките пластмасови алтернативи.

Балансиране между качество и бюджет

Разликата между масово произвежданите вторични капаци и персонализираните опции надхвърля простото ценностно сравнение. Масовото производство поставя приоритет на икономическа ефективност чрез стандартизирани дизайни, универсални размери и автоматизирана производствена дейност. Тези капаци се справят достатъчно добре в много приложения, но в замяна се жертва точността на поставяне и качеството на материала.

Персонализираните централни капаци за колелата използват противоположния подход. Те са проектирани за специфични модели колела, произвеждат се в по-малки серии с по-строги допуски и често включват висококачествени материали, които оправдават по-високата им цена. За собствениците на кованите колела, които вече са инвестировали хиляди в своите гуми, този подход е логичен. Комплект от алуминиеви капаци за 200 щата представлява малък процент от инвестицията от 5000 щата в колелата, като при това осигурява пропорционално високо качество.

Предвидете тези нива на стойност при планиране на бюджет:

Ниво за начинаещи (40–80 щата на комплект): Основно изработени от кован алуминий или висококачествени композитни материали. Стандартни повърхности без персонализирани лога. Подходящи за ежедневна употреба и конфигурации, при които централните капаци не са визуалният фокус.

Среден клас ($80-$200 на комплект): Премиум материали с множество опции за отделка. Възможност за интегриране на фирмено лого. По-точно прилягане за конкретни джанти. Подходящи за ентусиасти, търсящи баланс между качество и бюджет.

Премиум ($200-$400+ на комплект): Материали от висш клас, включително възможности от въглеродно влакно. Пълна персонализация, включително лазерно гравиране и контрастни емблеми. Проектирани специално за висококласни марки джанти. Създадени за автомобили за изложби и максимален визуален ефект.

Най-евтиният вариант рядко предлага най-добрата стойност. Пластмасови капаци, които се напукват след шест месеца, изискват повече усилия за подмяна в сравнение с алуминиеви алтернативи, които издържат години. По същия начин универсални размери, които причиняват трополене или изхвърляне, напълно обезценяват първоначалната инвестиция.

Когато оценявате цените, попитайте какво включва офертата освен самите капаци. Добри производители предоставят подробни спецификации за съвместимостта, насоки за монтаж и отговорно клиентско обслужване. Тези нематериални елементи не се появяват на ценниковите етикети, но значително повлияват вашето потребителско изживяване.

След като сте установили реалистични очаквания за бюджета, изборът на подходящ производствен партньор става последното важно решение, което ще гарантира дълготрайно удовлетворение от вашите персонализирани централни капаци.

Избор на проверен производствен партньор

Вече сте проучили размерите, материалите и дизайна. Сега идва може би най-важното решение: кой всъщност ще произвежда вашите персонализирани кованите централни капаци за гуми? Този избор определя дали ще получите прецизно проектирани компоненти или разочароващи приблизителни решения, които никога не седят правилно. Доставчикът, когото изберете, влияе върху всичко – от първоначалното качество до дългосрочната издръжливост и дори възможността да поръчате същите капаци години по-късно.

Дали сте индивидуален ентусиаст, поръчващ единичен комплект, или бизнес, набавящ обемни количества за преразпродажба, критериите за оценка остават принципно сходни. Качественото производство оставя следи в крайния продукт, които никаква маркетингова кампания не може да имитира.

Какво да търсите у доставчик на качествени продукти

Не всички производители на централни капаци работят на едно и също ниво. Според анализ на доставчици в индустрията , задължителните критерии за избор включват сертификати за производство, проследимост на материала, капацитет на технологичната оснастка и прозрачност на веригата за доставки. Тези фактори разграничават надеждните партньори от доставчици, които ще ви оставят с проблеми при монтирането.

Ето какво отличава качествените доставчици от останалите:

- Сертификат IATF 16949: Този международен стандарт за управление на качеството в автомобилната индустрия показва, че производителят отговаря на строги изисквания за последователност и проследимост. Според насоките за сертифициране на DEKRA, IATF 16949 обхваща клиентски специфични изисквания, включително части и процеси, свързани с безопасността. Доставчиците с това сертифициране са демонстрирали системен контрол на качеството, който засяга всеки компонент, който произвеждат, включително централните капаци на автомобилни колела.

- Проследимост на материала: Производители с високо качество документират произхода на всеки материал, влизащ в техния обект. За алуминиевите централни капаци това означава точно да се знае коя сплав е използвана и откъде произхожда. Това документиране има значение, когато възникнат проблеми, и става критично за джанти с централни капаци, предназначени за употреба в производителни приложения.

- Вътрешни инженерни възможности: Доставчици със собствени инженерни екипи могат да модифицират дизайни, да отстраняват проблеми с поставянето и да оптимизират производствените процеси. Онези, които разчитат изцяло на външно инженерство, често се затрудняват при изпълнение на персонализирани спецификации и решаване на проблеми.

- Прецизна техника: ЦНЧ машинни центрове, инструменти за качествени измервания и правилното поддържане на режещите инструменти директно влияят върху размерната точност. Установени коване операции използват съвременни технологии с инструменти, обработвани вътрешно, чрез софтуер, който се интегрира директно с системи за обемно моделиране, намалявайки производствените грешки и подобрявайки производителността.

- Процеси за контрол на качеството: Освен сертификати, попитайте за действителните протоколи за проверка. Как се измерват компонентите? Какви проценти на отхвърляне поддържат? Доставчиците, които целят нулеви дефекти чрез стриктна проверка, предлагат последователно по-добри продукти в сравнение с тези, които разчитат на оплаквания от клиенти, за да идентифицират проблеми.

- Производствен капацитет: Може ли доставчикът да осигури мащабиране от прототипни количества до серийно производство? Индивидуалните ентусиасти имат нужда от единични комплекти, но бизнесите изискват постоянен доставки. Производители с гъвкав капацитет обслужват ефективно и двете нужди.

При оценката на доставчици за централни капаци forgiato, американски сила централни капаци или други маркови аксесоари за колела, проверете дали те са официално упълномощени производители или пазарни доставчици. Официалните източници гарантират съвместимост с определени дизайни на колела, докато пазарните доставчици могат да предложат по-ниски цени, но с възможни компромиси по отношение на прилагането.

По същия начин, ако търсите tis централни капаци или компоненти за други популярни марки колела, потвърдете, че доставчикът разбира специфичните системи за фиксиране и размерни изисквания, които изискват тези колела. Общите твърдения за „универсална пригодност“ рядко са валидни за приложения с премиум ковано колела.

От проектиране до производство

Пътят от концепцията до готовите централни капаци разкрива много за възможностите на производителя. За персонализирани дизайни бързото прототипиране ви позволява да проверите поставянето и външния вид, преди да започне производството в серийни количества. Някои установени производители на метални технологии предлагат изработка на прототипи за срок от само 10 дни, което осигурява бързо потвърждаване на персонализираните спецификации.

Предвидете тези етапи при оценката на производствените възможности:

Валидиране на дизайна: Доставчиците с високо качество преглеждат вашите спецификации и предоставят обратна връзка, преди да започне производството. Те ще отчетат възможни проблеми със системите за фиксиране, съвместимостта на материали или изискванията за повърхностна обработка, които биха могли да повлияят на крайния продукт. Такъв съвместен подход предотвратява скъпоструващи грешки.

Производство на проба: Преди да направите пълни поръчки, поискайте пробни образци за физически преглед. Поставете ги на истинските си джанти. Тествайте фиксацията при реални условия на движение. Образците разкриват проблеми с поставянето, които цифровите проекти не могат да предвидят.

Мащабиране на обема: Преходът от пробни партиди към производствени количества трябва да протича безпроблемно с установени доставчици. Производителите с опит в автомобилни компоненти поддържат постоянство в качеството, независимо дали произвеждат четири капаци или четири хиляди. Техните процеси са проектирани за възпроизводимост.

Географски аспекти: Местоположението на доставчика влияе върху транспортните разходи, водещите времена и удобството на комуникацията. Производители, разположени близо до големи пристанища, опростяват логистиката за международни поръчки. За бизнеси, които изискват редовни повторни поръчки, сигурната транспортна инфраструктура е толкова важна, колкото и качеството на продукта.

За тези, които търсят специално forgiato плаващи централни капаци или american force плаващи централни капаци, изборът на доставчик става още по-критичен. Плаващите механизми включват прецизни лагери и теглени сглобки, които изискват много малки допуски. Доставчици без опит в тези сложни конструкции често произвеждат капаци, при които плаващата функция излиза преждевременно от строя или работи нестабилно.

Инвестирането в правилния подбор на доставчици дава дивиденти по време на целия Ви период на собственост. Производителите на качествени продукти гарантират своите изделия с бърза поддръжка при възникване на въпроси. Те запазват записите на Вашите спецификации за бъдещи повторни поръчки. Те разбират, че репутацията им зависи от това всеки компонент да отговаря на очакванията.

Работата с производители, сертифицирани по IATF 16949, осигурява, че вашите персонализирани централни капаци за колелата чрез прецизно коване се подчиняват на същите стандарти за контрол на качеството, приложими за автомобилни компоненти с критично значение за безопасността.

За прецизни решения за горещо коване, подкрепени от строг контрол на качеството, производители като Shaoyi (Ningbo) Metal Technology показват какво предлагат установените партньори в областта на металните технологии. Тяхната сертификация по IATF 16949, възможности за бързо прототипиране и инженерни екипи в рамките на компанията гарантират здрави компоненти, отговарящи точно на спецификациите. Разположени до пристанище Нингбо, те осигуряват производство, съответстващо на глобалните изисквания, с оптимизирани логистически вериги както за отделни ентусиасти, така и за бизнеси, нуждаещи се от серийно производство.

Дали завършвате индивидуална поръчка или набавяте асортимент за автомобилна търговия, доставчикът, когото избирате, определя качеството, което получавате. Вземете си време да проверите сертификатите, поискайте пробни образци и потвърдете производствените възможности, преди да дадете окончателното съгласие. Вашите персонализирани централни капаци за кованите джанти заслужават производствено превъзходство, което отговаря на инвестициите ви в гумите.

Често задавани въпроси относно персонализираните централни капаци за ковани джанти

1. Как да измеря джантата си за персонализирани централни капаци?

За да измерите точния диаметър на централното отвор на джантата, свалете я и я поставете с лицето надолу върху равна повърхност. Използвайте цифрови шублер, разположени в най-широката точка на централното отвор, като избягвате фаската. Направете няколко измервания в милиметри, за да потвърдите последователността. Често срещани размери са 60 мм, 66,6 мм, 72,6 мм и 76 мм, въпреки че за кованите джанти често са необходими персонализирани размери. Също така измерете модела на болтовете, като преброите отворите за болтове и измерите диаметъра на окръжността, която те образуват.

2. В какво се състои разликата между плаващи и фиксирани централни капаци?

Плаващите централни капаци използват механизъм с теглена лагерна система, който поддържа логото в изправено положение независимо от въртенето на колелото, като създава премиум визуален ефект, характерен за луксозни превозни средства. Фиксираните централни капаци са монтирани директно и неподвижно към колелото и се въртят заедно с него. Плаващите капаци предлагат впечатляваща естетика, но имат повече движещи се части, докато фиксираните осигуряват по-проста конструкция с по-малко потенциални механични проблеми и обикновено струват по-малко.

3. Кой произвежда персонализирани централни капаци с лога?

Няколко производителя създават персонализирани централни капаци с индивидуални лога и брандиране. Компании като Venum Wheel, Forzaaa и KapKing се специализират в персонализируеми плаващи и фиксирани централни капаци. Премиум марки за кованите джанти, включително Vossen, Forgiato, American Force и Amani Forged, предлагат брандирани опции за своите конкретни модели джанти. За персонализирано производство със сертифициране по IATF 16949 и възможности за бързо прототипиране, специалисти по метални технологии като Shaoyi могат да произвеждат прецизно проектирани капаци според точни спецификации.

4. По-добри ли са алуминиевите или пластмасовите централни капаци за кованите джанти?

Алуминиевите централни капаци са предпочитаният избор за кованите джанти поради превъзходната им издръжливост, устойчивост на корозия и свойства за топлоотвеждане. Те понасят грубото отношение, промените в температурата и агресивното каране значително по-добре в сравнение с пластмасовите алтернативи. Въпреки че пластмасовите капаци струват по-малко и са подходящи за бюджетни конфигурации, използването на премиум ковани джанти заедно с пластмасови капаци създава естетическо несъответствие. Алуминиевите капаци също отговарят на качеството на инвестицията ви в джантите и запазват размерната стабилност при термичен стрес.

5. Защо централните ми капаци постоянно падат или трептят?

Централните капаци, които вибрират или изхвърлят, обикновено сочат на износени фиксиращи клипове, неправилен размер или неправилна инсталация. Проверете всички клипове за умора или счупване, причинени от промени в температурата. Ако клиповете изглеждат неповредени, диаметърът на централния отвор може да е малко по-голям — приложете тънка лента за уплътнение около ръба за вмъкване на капака, за да се увеличи триенето. За капаци, които излитат при скорости на магистрала, помислете за подмяна на системата с фиксация с болтове или проверете дали имате правилния размер капак за конкретния модел колело.

Малки порции, високи стандарти. Нашата услуга за бързо проектиране на прототипи прави валидацията по-бърза и лесна —

Малки порции, високи стандарти. Нашата услуга за бързо проектиране на прототипи прави валидацията по-бърза и лесна —