Bandslayoutdesign: Principer för progressiva stansverktyg

TL;DR

Utformning av layout för progressivt diesnitt är en viktig ingenjörsprocess för att strategiskt placera arbetsstycken på en kontinuerlig metallband. Dess huvudsakliga mål är att maximera materialutnyttjandet, ofta med en effektivitet över 75 %, samtidigt som spill minimeras. En välplanerad layout säkerställer exakt, höghastighets- och kostnadseffektiv massproduktion av delar genom att skapa en optimerad sekvens av skär-, böj- och formsättningsoperationer inom en enda verktygsenhet.

Grundläggande om layout för progressivt diesnitt

I grunden är en layout för progressivt diesnitt den tekniska ritningen som styr hur en metallkomponent ska tillverkas från en kontinuerlig spole. Det är ett avgörande steg i progressiv stämplingsprocess , en metod där en metallremsa förs genom en serie stationer, var och en som utför en särskild operation. Layoutens design påverkar direkt materialkostnaden, produktionshastigheten, delkvaliteten och den totala driftseffektiviteten. En lyckad design är en noggrann balans av flera faktorer, vilket säkerställer att delen tillverkas enligt specifikationen samtidigt som mängden råmaterial minimeras.

Den strategiska betydelsen av remslayouten kan inte överdrivas. Den avgör hela händelseförloppet inom verket, från initialt genomslagning till det slutliga delavskärningen. En dåligt utformad layout kan leda till onödigt spill, inkonsekvent delkvalitet, förtida verktygsslitage och kostsamma produktionsuppehåll. Tvärtom är en optimerad layout grunden för en stabil och lönsam stansningsoperation. Den skapar en robust process som kan köras i hög hastighet under miljontals cykler med minimal intervention.

De främsta målen för en effektiv remslayoutdesign inkluderar:

- Maximera materialutnyttjandet: Det främsta målet är att ordna delar på bandet så att mängden spillmaterial minimeras. Branschens standard är att uppnå minst 75 % materialutnyttjande.

- Säkerställa delarnas noggrannhet: Uppställningen måste bibehålla exakt positionering av delen medan den förflyttas genom varje station, för att säkerställa att alla detaljer formas inom strama toleranser.

- Bibehålla bandintegritet: Föringsbandet – den del av bandet som håller delarna samman – måste vara tillräckligt starkt för att kunna skjutas och dras genom verktyget utan att knäckas eller deformeras.

- Optimera produktionshastigheten: En välplanerad arbetssekvens gör det möjligt för pressen att köras i maximal säker hastighet, vilket ökar produktionen.

- Minimera verktygskomplexiteten: Samtidigt som man optimerar materialutnyttjandet måste konstruktörer även ta hänsyn till komplexiteten och kostnaden för att tillverka själva verktyget. Ett enklare och mer robust verktyg är ofta att föredra framför ett som sparar en marginellt större mängd material men är svårt att underhålla.

Nyckelberäkningar och konstruktionsprinciper

Att skapa en effektiv bandlayout är en teknisk disciplin som bygger på exakta beräkningar och etablerade tekniska principer. Dessa beräkningar säkerställer att bandet behåller sin strukturella integritet samtidigt som avfallet minskas. En designer måste använda sig av en del av materialet som kallas "bron", det är det lilla material som finns kvar mellan delarna och mellan delen och kanten på bandet. Dess tjocklek är avgörande för stabiliteten.

En vanlig formel som används för att bestämma minsta brosttjocklek (B) baseras på materialets tjocklek (t). En allmänt accepterad tumregel är B = 1,25 till 1,5 ton . Till exempel, för en del som är 1,5 mm tjock, skulle bäraren vara ungefär 1,875 mm till 2,25 mm. Denna lilla bärare förhindrar att avfallet vrider sig och kilar dieseln samtidigt som den är tillräckligt stark för att föra delen framåt. Andra viktiga beräkningar innefattar bestämning av total bredd på bandet (W) och steglängden eller takten (C), vilket är avståndet bandet avanceras med varje pressslag.

Utöver beräkningar måste konstruktörer välja det mest lämpliga layoutalternativet för den specifika delgeometrin. Delens orientering och placering på bandet kan dramatiskt påverka materialutnyttjandet. Olika layoutstrategier innebär en kompromiss mellan materialutnyttjande och verktygets komplexitet.

| Layouttyp | Beskrivning | Fördelar | Nackdelar |

|---|---|---|---|

| Enkelrad, ett genomlopp | Delar är arrangerade i en enda rad längs bandet. Detta är den mest raka layouten. | Enkel verktygskonstruktion; förutsägbar matning. | Resulterar ofta i lägre materialutnyttjande. |

| Vinklat genomlopp (nesting) | Delar är vinklade för att kunna placeras tätare tillsammans, ungefär som en pussel. | Kan avsevärt öka materialbesparingen för oregelbundet formade delar. | Kan skapa obalanserade skärkrafter; mer komplicerad verktygskonstruktion. |

| Enkelrad, två pass | Bandet förs genom verktyget en gång, vänds eller roteras sedan och förs igenom en andra gång för att stansa delar i återstående material. | Utmärkt materialutnyttjande för vissa delformer. | Kräver dubbel hantering av materialet; ökad arbetskraft och process tid. |

Bärremsdesign och layoutoptimering

Bärarstreifen, eller bärarwebben, är den skelettartade strukturen i metallbandet som transporterar delen från en station till nästa inom en progressiv verktygsrad. Dess design är grundläggande för lyckad stansoperation. En dåligt designad bärare kan misslyckas med att korrekt positionera delen, vilket leder till verktygsfel, medan en välutformad säkerställer smidig och pålitlig matning. Bäraren måste vara tillräckligt stark för att tåla matkrafterna men samtidigt tillräckligt flexibel för att anpassa sig till omformningsoperationer som kan kräva att delen rör sig vertikalt eller drar in material.

Det finns två huvudtyper av bärare, var och en lämpad för olika tillämpningar. En solid bärare används när bandet måste förbli plant under hela processen, vanligtvis för grundläggande skär- och enkla böjningsoperationer. Den erbjuder maximal stabilitet men ingen flexibilitet för vertikal delrörelse. I motsats till detta har en stretch webb-bärare är konstruerad med strategiska snitt eller slingor som gör att den kan böja sig och deformeras. Denna design är viktig för delar som genomgår djupdragning eller komplex formning, eftersom den tillåter material att strömma från bäraren in i delen utan att förvränga avståndet mellan delarna i bandet.

Att optimera bäraren och den totala layouten innebär flera viktiga överväganden:

- Bärarstyrka: Bäraren måste vara tillräckligt robust för att motstå böjning eller knäckning när den skjuts igenom flera verktygsstationer. Konstruktörer använder ofta erfarenhet och simulering för att säkerställa tillräcklig styrka.

- Flexibilitet: För formningsoperationer måste bäraren ha tillräckligt med 'längd i linjen' i sina fästpunkter för att kunna sträckas utan att brista när delen formas.

- Pilotpositionering: Pilot hål slås i bäraren i de tidiga stationerna. Dessa hål griper tag i pilotnålar i efterföljande stationer för att säkerställa exakt justering och korrigerar eventuella små matningsfel. Bärarkonstruktionen måste erbjuda stabila platser för dessa kritiska funktioner.

- Dellosgöring: Den sista stationen måste skära bort det färdiga delat från bäraren renodlat. Fästpunkterna måste utformas så att de lossnar utan att lämna överdrivna spån eller deformera delen.

Programvarans roll i modern bandlayoutdesign

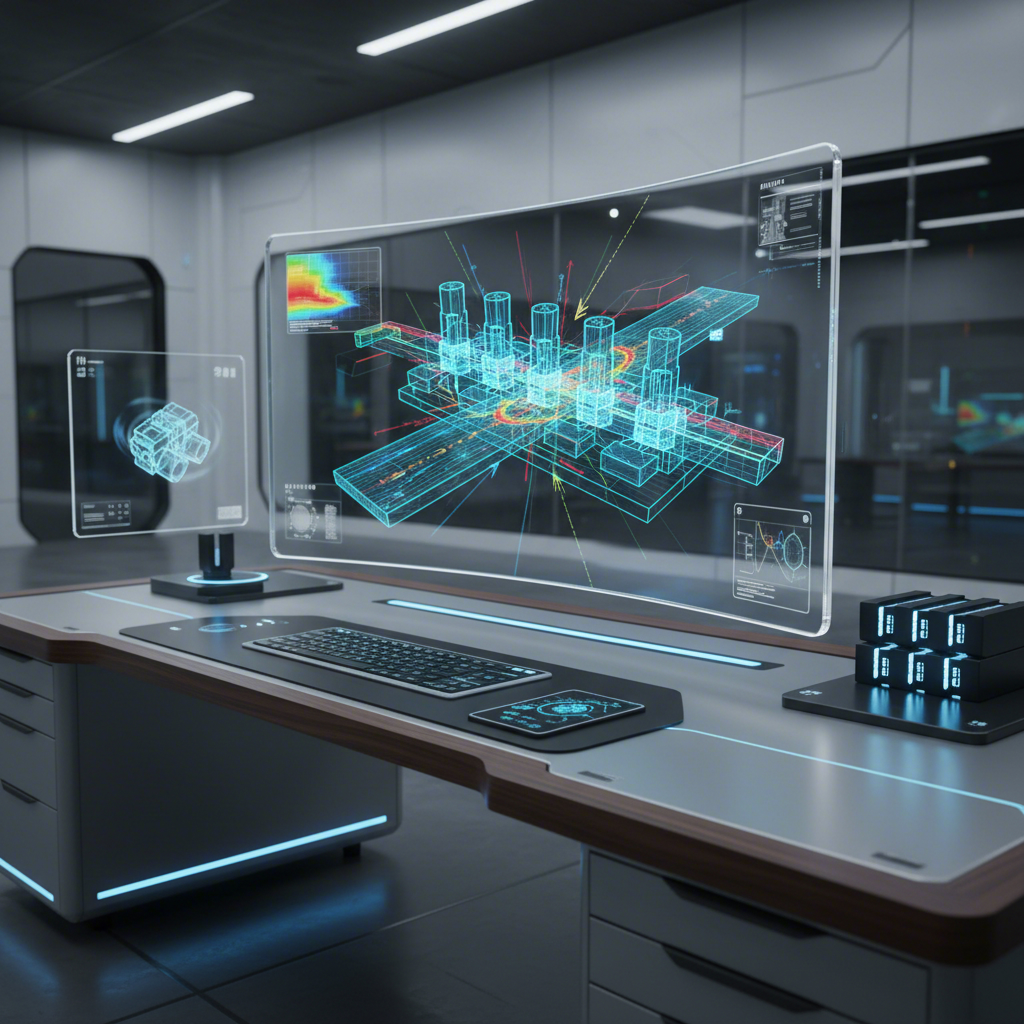

Inom modern tillverkning utförs sällan den komplexa uppgiften att designa bandlayouter för progressiva verktyg manuellt. Specialiserad programvara för datorstödd konstruktion (CAD) och datorstödd ingenjörsutveckling (CAE) har blivit oumbärliga verktyg för ingenjörer. Dessa plattformar gör det möjligt för konstruktörer att skapa, simulera och optimera hela bandlayouten i en virtuell miljö innan något stål skärs, vilket drastiskt förbättrar noggrannheten och minskar utvecklingstiden. Programvaror som Logopress möjliggör snabb modellering av verkliga fasta 3D-band, hantering av flera delar och skapande av parametriskt länkade punchar.

Simulering är en av de mest kraftfulla funktionerna i modern designprogramvara. Ingenjörer kan simulera hela stansprocessen, slag för slag, för att förutsäga hur metallen kommer att flöda, sträckas och tunnas. Denna finita elementanalys (FEA) hjälper till att identifiera potentiella fel som sprickor, veck eller överdriven fjädervåning redan i designfasen. Genom att visualisera dessa problem virtuellt kan designers ändra delgeometrin, justera processparametrar eller ändra bandlayouten för att säkerställa ett lyckat resultat. Den här 'förutsäg-och-optimera'-metoden ersätter de kostsamma och tidskrävande prövning-och-felmetoder som användes tidigare.

Ledande tillverkare av specialverktyg, såsom Shaoyi (Ningbo) Metal Technology Co., Ltd. , utnyttja dessa avancerade CAE-simuleringar för att leverera högprecisions stansverktyg och komponenter för bilindustrin. Genom att använda programvara för att verifiera konstruktioner kan de säkerställa optimal materialutnyttjande och processstabilitet, vilket i slutändan minskar genomloppstider och förbättrar komponentkvaliteten för sina kunder. Denna teknik är en nyckelfaktor för att möta de stränga kraven inom bilindustrin.

| Aspekt | Manuell designprocess | Programstödd design |

|---|---|---|

| Hastighet | Långsam och iterativ, bygger på 2D-ritningar och manuella beräkningar. | Snabb 3D-modellering och automatiserade beräkningar; kan testa dussintals layouter snabbt. |

| Noggrannhet | Benägen för mänskliga fel vid beräkningar och ritning. | Hög precision med parametriska modeller som uppdateras automatiskt vid ändringar. |

| Optimering | Begränsad till ett fåtal beprövade layouter på grund av tidsbegränsningar. | Avancerade nästlingsalgoritmer hittar den optimala layouten för maximala materialbesparingar. |

| Validering | Förlitar sig på fysiska prototyper och kostsamma pressförsök för att hitta problem. | Virtuell simulering (FEA) förutsäger och löser brister innan tillverkningen påbörjas. |

Vanliga frågor

1. Vad är formeln för bandlayout?

Det finns inte en enda formel för hela bandlayouten, utan en uppsättning nyckelberäkningar. En grundläggande är för brotjocklek (B), som ofta beräknas som en multipel av materialtjocklek ('t'), vanligtvis mellan 1,25 × t och 1,5 × t beroende på delens storlek och progression. Andra formler bestämmer bandbredd (W = Delbredd + 2B) och progression (C = Dellängd + B), vilka justeras beroende på specifika delar och layouttyp.

2. Vad är progressivverktygsdesign?

Progressivverktygsdesign är den ingenjörsprocess som innebär att skapa ett komplext stansverktyg (ett progressivt verktyg) som utför flera skär- och formsättningsoperationer samtidigt. När en metallremsa förs igenom verktyget utför varje station en annan åtgärd i sekvens, vilket gör att en färdig del kan produceras vid varje nedslag av pressen. Denna metod är mycket effektiv för massproduktion av komplexa delar.

3. Vilka typer av remslayout finns det?

Vanliga typer av remslayout inkluderar 'enkel rad, en passning', där delarna är ordnade i en rak linje; 'vinklad passning' eller 'nesting', där delarna är vridna för att passa tillsammans mer ekonomiskt; samt 'enkel rad, två passningar', där remsan förs igenom verktyget en andra gång för att utnyttja mer material. Valet beror på delarnas geometri och balansen mellan materialbesparing och verktygskomplexitet.

Lilla partier, höga standarder. Vår snabba prototypservice gör validering snabbare och enklare —

Lilla partier, höga standarder. Vår snabba prototypservice gör validering snabbare och enklare —