Stansade stålfjädrar: Den viktigaste uppgraderingen för din lastbil

TL;DR

Stansade stålfjädrar är en vanlig fabrikskomponent i många tunga lastbilar, men de blir ofta en svag länk när du monterar en upphöjd fjädring. Att uppgradera till specialtillverkade aftermarket-fjädrar är avgörande för upphöjda fordon. Detta korrigerar fjäderns geometri, återställer korrekt justering och hantering, förhindrar farliga kulsnittsfel och sparar dig från kostsam förtidig däckslitage.

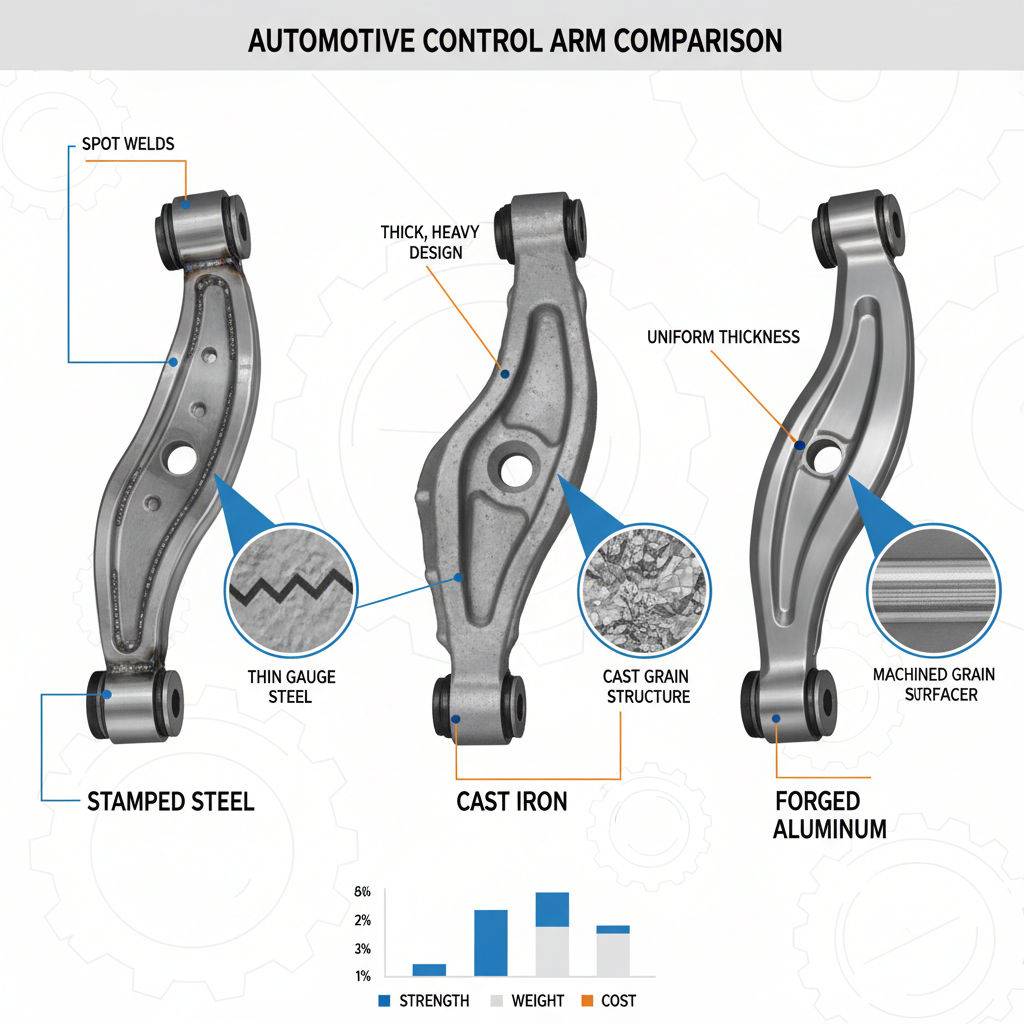

Förstå typer av styrarmar: Stansad stål jämfört med alternativen

Ett fordon's styrarmar är en viktig del av fjädringssystemet. Som namnet antyder styr de hjulens rörelse och fungerar som en stark pivotpunkt som kopplar samman fordonets chassi till hjulnavet. Enligt en guide från GMT Rubber gör denna koppling att dina däck kan röra sig upp och ner jämnt över ojämnheter samtidigt som stabilitet och kontroll bibehålls. För tunga lastbilar är dessa armar styrka och design av yttersta vikt, och det material de är tillverkade av spelar en betydande roll för deras prestanda.

Stansade stålreglage tillverkas genom att plåtar av stål pressas till en önskad form, ofta genom att svetsa ihop två halvor. Denna process är kostnadseffektiv, vilket är anledningen till att de är ett populärt val för originaltillverkare (OEM). De är dock generellt den minst robusta varianten, känsliga för böjning vid tunga belastningar och benägna att rosta. För biltillverkare är det avgörande att uppnå precision i denna process. Företag som specialiserar sig på högvolymproduktion, såsom Shaoyi (Ningbo) Metal Technology Co., Ltd. , utnyttjar avancerade automatiserade anläggningar för att producera komplexa stansade komponenter som uppfyller strikta IATF 16949-kvalitetsstandarder för fordonsindustrin.

Däremot tillverkas armar i gjutjärn eller gjuten aluminium genom att hälla smält metall i en form. Dessa är vanligtvis starkare och mer styva än armar i plåtstansat stål. Armar i smidd stål eller aluminium representerar toppen vad gäller hållfasthet. Smidningsprocessen innebär att metallen formas under extremt högt tryck, vilket riktar dess inre kornstruktur och resulterar i en komponent som är exceptionellt motståndskraftig mot stötar och trötthet. Det gör smidda armar till ett främsta val för extrema terrängkörningar eller tunga dragapplikationer.

För att hjälpa dig förstå de viktigaste skillnaderna finns här en jämförelse av de vanligaste materialen för tvärslenar:

| Attribut | Stansad stål | Gjutjärn/Stål | Smidd/Godsaluminium |

|---|---|---|---|

| Styrka | Bra (Tillräckligt för standardanvändning) | Bättre (Bra för tung användning) | Bäst (Överlägset för extrem användning) |

| Vikt | Ljus | Tungt | Lättast |

| Kosta | Lägsta | Moderat | Högsta |

| Korrosionsbeständighet | Dålig (kräver beläggning) | Bra | Excellent |

| Ideell Användningsscenario | Standard daglig körning | Tungt byggda lastbilar, SUV:er | Högprestanda och terräng |

Osäker på vad din lastbil har? Som experter på Kryptonite Products förklara, kan du utföra en enkel magnettest. Om magneten fastnar har du stål (antingen stansad eller gjuten). Stansade armar kan ofta identifieras genom sina svetsade sömmar och ihåliga känsla. Om magneten inte fastnar har du aluminiumarmar.

Varför din upphöjda lastbil behöver en aftermarket reglerarmuppdatering

Att lyfta en tung lastbil gör mer än att bara höja dess höjd; det förändrar i grunden fabrikens upphängningsgeometri. När du lyfter en lastbil 2 tum eller mer tvingas de ursprungliga stansade stålreglerarmarna ofta att arbeta i vinklar de inte är konstruerade för. Detta skapar en kedjereaktion av problem som komprometterar både prestanda och säkerhet. Det mest betydande problemet är felaktiga justeringsvinklar, särskilt kamrering (hjulets vertikala lutning) och styraxelns vinkel (caster).

När fabriksarmar är översträckta kan kulsniten – de kritiska svängrören som förbinder armen med styrleden – låsa sig eller nå sin maximala rörelsegräns. Detta begränsar inte bara upphängningens rörelse utan lägger också en enorm belastning på kulsniten själv, vilket leder till förtida slitage. En trasig kulsnit kan få katastrofala konsekvenser och potentiellt orsaka att hjulet lossnar från fordonet. Som produktbeskrivningar från leverantörer som Bds suspension betonar är eftermarknadens reglagearmar specifikt utformade med korrigerade kulsnitsvinklar för att fungera tillsammans med lyftruckar, vilket säkerställer smidig och säker funktion genom hela upphängningens rörelseområde.

Att uppgradera till eftermarknadens styrvägar ger flera konkreta fördelar. För det första gör det att en tekniker kan korrekt justera fordonets hjulinställning, rätta till kamrarna och styrningsaxlarnas lutning enligt fabriksspecifikationerna. Detta resulterar direkt i bättre styrrespons, förbättrad stabilitet på motorväg och, allra viktigast, jämn däckslitage. För det andra är de byggda för hållbarhet och använder ofta starkare material som tjockväggigt rörstål eller smidd aluminium för att tåla den ökade belastningen från större däck och terrängkörning. Slutligen förbättrar många konstruktioner fjäderns rörelseutrymme, vilket ger större hjulrörelse – en avgörande fördel vid terrängkörning.

Om du har en lyft lastbil, var uppmärksam på dessa tecken som indikerar att dina fabriksmonterade styrvägar inte längre är tillräckliga:

- Ojämn eller förhastad däckslitage , särskilt på inner- eller ytterkanterna.

- Otydlig eller vag styrning som kräver kontinuerlig justering på vägen.

- En hårdför körning eller skrammel/ljud när du kör över bucklor eller ojämn terräng.

- Svårighet att uppnå korrekt hjulinställning , där teknikern inte kunde få specifikationerna inom det rekommenderade intervallet.

En köpguide till kraftfulla reservdelar för styrväglar

När du har bestämt dig för att uppgradera är nästa steg att välja rätt reservdelar till styrväglar för din lastbil och dess avsedda användning. Marknaden erbjuder ett brett utbud av alternativ, och att förstå de viktigaste egenskaperna hjälper dig att fatta ett välgrundat beslut. Istället för att fokusera på ett enda "bästa" varumärke är det mer effektivt att bedöma komponenterna och konstruktionen som bäst passar dina behov, från daglig körning till extrema terrängkörningar.

När du jämför produkter, fokusera på dessa väsentliga egenskaper:

- Material och konstruktion: Armar är vanligtvis tillverkade av tjockväggat rörstål, boxat (svetsat plåt) stål eller smidd/bearbetat aluminium. Rörstål erbjuder en utmärkt balans mellan hållfasthet och kostnad, medan smidd aluminium ger maximal hållfasthet i lägre vikt, dock till en högre pris.

- Typ av fästelement: Tappar används där tvärbjälken fästs vid ramen. Originalstilens gummibussningar ger en tyst och underhållsfri körning. Polyuretanbussningar, som beskrivs av återförsäljare som Jack-It , ger en fastare och mer responsiv känsla men kan kräva periodisk smörjning för att förhindra gnissling.

- Kvalitet på ballkoppling: Detta är troligen den viktigaste komponenten. Leta efter högvinklade eller uni-ballkopplingar. Högvinklade ballkopplingar är utformade för att fungera utan kileeffekt på upphöjda fordon. Uni-ball är ett racestilens sfäriskt lager som erbjuder största rörelseomfång och styrka, vilket gör dem idealiska för allvarlig terrängkörning.

- Justerbarhet: Vissa kontrollarmar har fast längd och är utformade för en specifik upphöjningshöjd. Justerbara armar gör det möjligt att finjustera styrningsvinklarna (caster/kamber), vilket kan vara avgörande för att uppnå perfekt hjulinställning, särskilt på fordon med högre upphöjning eller specialanpassade konfigurationer.

- Skyddande yta: Ett slitstarkt pulverlackerat ytbehandlingslager är nödvändigt för att skydda stålbalkar mot rost och korrosion, så att de håller under hela fordonets livslängd.

För att förenkla ditt val kan du tänka på alternativen enligt ett "Bra, Bättre, Bäst"-system:

Fördelar: En fastlängds, rörlös stålstyrelängd med OEM-stil gummikopplingar och ett kugellager av hög kvalitet. Detta är en utmärkt och prisvärd uppgradering jämfört med fabriksmonterade plåtbalkar för lastbilar med milda nivåutjämningskit eller mindre lyft som främst används på väg.

Bättre: En justerbar tub- eller boxprofilad stålstyrelängd med polyuretankopplingar och ett kraftigt kugellager för höga vinklar. Detta alternativ är perfekt för entusiaster som vill optimera sin justering och behöver extra hållbarhet för regelbundna terrängkörningar eller släpkärra.

Bäst: En fullt justerbar armen tillverkad av formad stål eller massiv aluminium med uni-ball-leder eller högklassiga, underhållsvänliga sfäriska lager. Denna kategori erbjuder maximal styrka, justerbarhet och upphängningsväg för tunga applikationer och extrema terrängförhållanden.

Vanliga frågor

1. Hur vet jag om min lastbil har stämplade stålkontrollarmar?

Använd först en magnet för att avgöra om reglagearmen är tillverkad av stål eller aluminium. En magnet fastnar vid alla stålarmar (smidda, gjutna eller plåtbetagna) men inte vid en aluminiumarm. Plåtbetagna stålarmar har oftast en synlig söm där två metallbitar svetsats samman och ser ofta mer avrundade och ihåliga ut jämfört med det solidare, kraftigare utseendet hos gjutna stålarmar.

2. Vad är skillnaden mellan stansade och smidda tvärlänkar?

Den främsta skillnaden är hållfasthet och tillverkningsprocess. Armar som är stansade pressas ur plåt, vilket gör dem lättviktiga och billigare men mindre slitstarka. Smidda armar formas ur en solid metallbit under enormt tryck, vilket resulterar i en mycket starkare komponent med bättre motståndskraft mot böjning och påverkan, vilket gör dem idealiska för tunga och prestandakrävande applikationer.

3. Vem tillverkar den bästa övre reglagearmen?

"Bästa" reglagearm beror helt på din fordonstyp, lyfthöjd, budget och hur du använder din lastbil. Istället för att fokusera på ett enskilt varumärke, är det bättre att utvärdera egenskaperna. För daglig körning är en kvalitetsbeständig rörmotor med gummibojor från en anlitad tillverkare utmärkt. För tung terrängkörning skulle en justerbar arm med uni-balls fogar vara ett bättre val. Satsa på högkvalitativa material, slitstarka fogar och en design som korrigerar geometrin för din specifika lyft.

Lilla partier, höga standarder. Vår snabba prototypservice gör validering snabbare och enklare —

Lilla partier, höga standarder. Vår snabba prototypservice gör validering snabbare och enklare —