Är stansade stålfjädrar tillräckligt starka för din lastbil?

TL;DR

Eftermarknadens stansade stålreglagem är ett tillförlitligt och kostnadseffektivt val för vanlig daglig körning och fabriksmässiga utbyggnader. Årtionden av användning har visat att de är tillräckliga för normala vägförhållanden. Deras främsta svagheter är dock en benägenhet att böjas vid hårda stötar, till exempel vid kollision med en kantsten eller en djup holka, samt potentiella geometriska problem som belastar kulleder när de används tillsammans med lyftkit över två tum.

Förståelse av stansade stålda reglagre

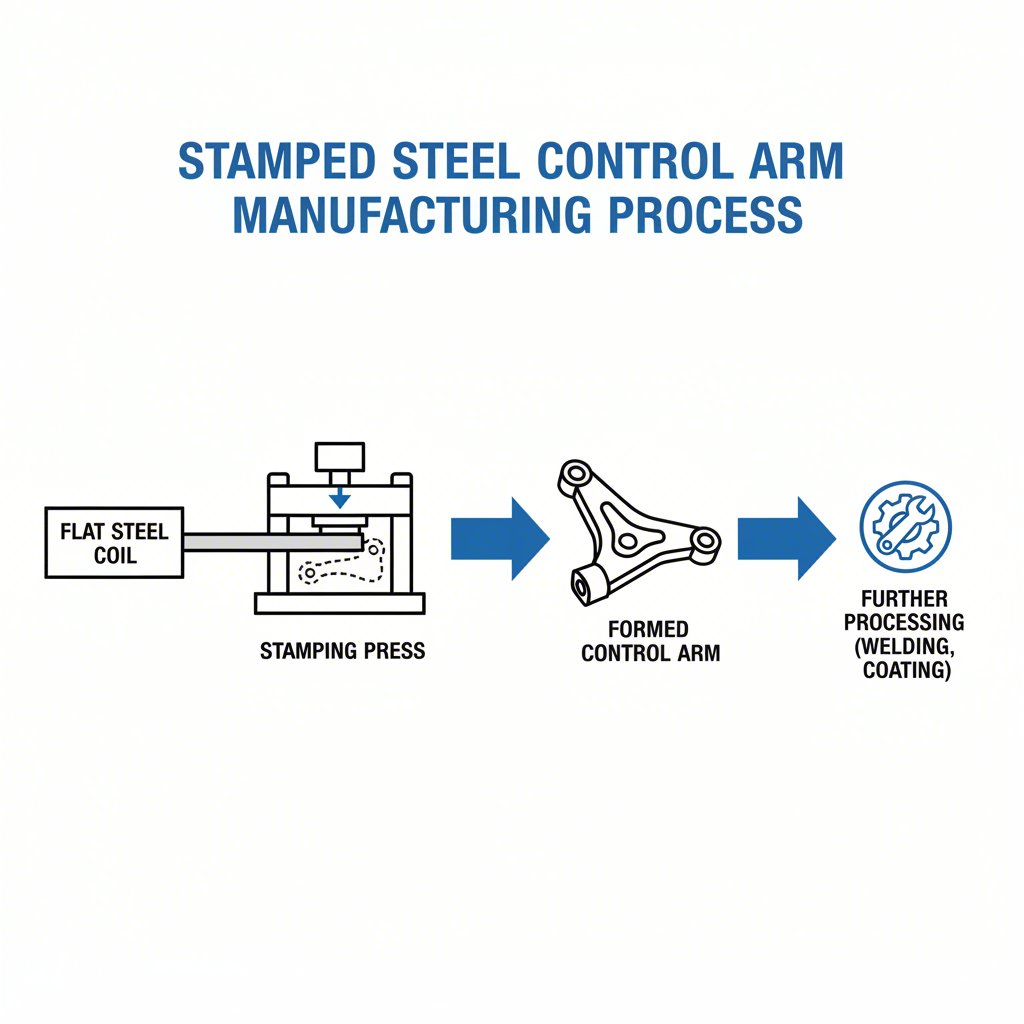

Innan du kan bedöma recensioner är det viktigt att veta vad du har att göra med. Ett stansat stålreglagem är en nyckelkomponent i ditt fordons upphängningssystem och kopplar samman hjulnavet med chassiet. Som namnet antyder tillverkas de genom att plåtar av höghållfast stål stansas till specifika former, vilka sedan svetsas ihop för att bilda det färdiga reglaget. Denna process är mycket effektiv och möjliggör massproduktion, vilket gör den till ett vanligt val bland originaltillverkare (OEM).

Tillverkningsprocessen är det som skiljer dem från andra typer. Till skillnad från smidda armar, som formas genom att hamma en enda bit upphettad stål, eller gjutna armar, som tillverkas genom att hälla smält metall i en form, är stansning en mer ekonomisk metod. Detta resulterar i en komponent som vanligtvis är lättare och billigare att producera. För bilkomponenter där precision och hållbarhet är oeftergivliga hanteras arbetet av specialiserade tillverkare. Till exempel använder företag som Shaoyi (Ningbo) Metal Technology Co., Ltd. avancerade automatiserade processer och följer stränga kvalitetsstandarder för fordonsindustrin, såsom IATF 16949, för att tillverka pålitliga delar för globala märken.

Här är de viktigaste egenskaperna hos stansade stålreglage:

- Tillverkningsmetod: Stansas ur plåtar av stål och svetsas sedan samman.

- Kostnad: Vanligtvis det mest prisvärda alternativet, både för OEM:er och eftermarknaden.

- Vikt: Lättare än jämförbara gjutna eller smidda stålarmar.

- Styrka: Tillräcklig för de flesta vägrelaterade tillämpningar och daglig körning.

Om du är osäker på vilken typ av styrningsarmar din bil har finns det ett enkelt knep. Enligt experter på fjädringstillverkaren MOOG , är stål magnetiskt. Du kan föra en magnet över armen; om den fastnar har du en stålarm (antingen plåtböjd eller gjuten). Om den inte gör det är den troligen tillverkad av aluminium.

Hållbarhet och vanliga svagheter

Den centrala frågan i de flesta recensioner av aftermarket plåtböjda stålarmer handlar om hållbarhet. Samhällets konsensus är tydlig: för en vanlig daglig körning under normala förhållanden är de fullt tillräckliga. I forumdiskussioner nämns ofta att plåtböjda ståldelar har "fungerat bra i årtionden" och är "hållbara nog" för sitt syfte. Såvida du inte utsätter din bil för extrema påfrestningar bör en kvalitetsfull plåtböjd arm från aftermarket fungera lika bra som originaldelen.

Deras design leder dock till specifika felmoder som du behöver känna till. Den vanligaste orsaken till fel är en kraftig stöt. Att köra på ett djupt hål i vägen, glida in i en kantsten eller en mindre kollision kan böja armen. Även om detta är ett brott, betraktar vissa det som förutsägbart; armen absorberar energi genom att deformera sig, vilket ibland kan skydda andra upphängningskomponenter. Detta skiljer sig från en gjuten eller smidd arm, som snarare spricker eller går av under liknande belastning.

En mer kritisk punkt av haveri som diskuteras av fordonsegare är sambandet mellan designen och kulleden. På vissa modeller erbjuder den stansade stålövre tvärarmen minimal stöd för kulleden om den går sönder. Som en användare på en GM-lastbilsforum påpekade, om kulleden lossnar finns det knappt något som hindrar hjulet från att vika sig utåt, vilket kan vara extremt farligt. Detta är en avgörande övervägande, särskilt när man bedömer äldre eller fordon med hög miltalet.

Var uppmärksam på tecken på ett felande styrarm. Proaktiv kontroll är nyckeln till din säkerhet. Leta efter dessa vanliga symtom:

- Klunk- eller poppljud: Särskilt märkbart vid körning över bucklor, acceleration eller inbromsning.

- Styrproblem: Fordonet kan dra åt ena sidan, eller styrningen kan kännas lös och tröghetig.

- Ojämnt däckslitage: Slitna styrarmsfjädrar eller ledbultar kan påverka inställningen negativt, vilket leder till att däcken slits för fort vid en kant.

- Synlig skada: Utför alltid en visuell kontroll efter böjningar, sprickor eller korrosion, särskilt efter något slag.

Stansat stål vs. alternativen: En jämförelse

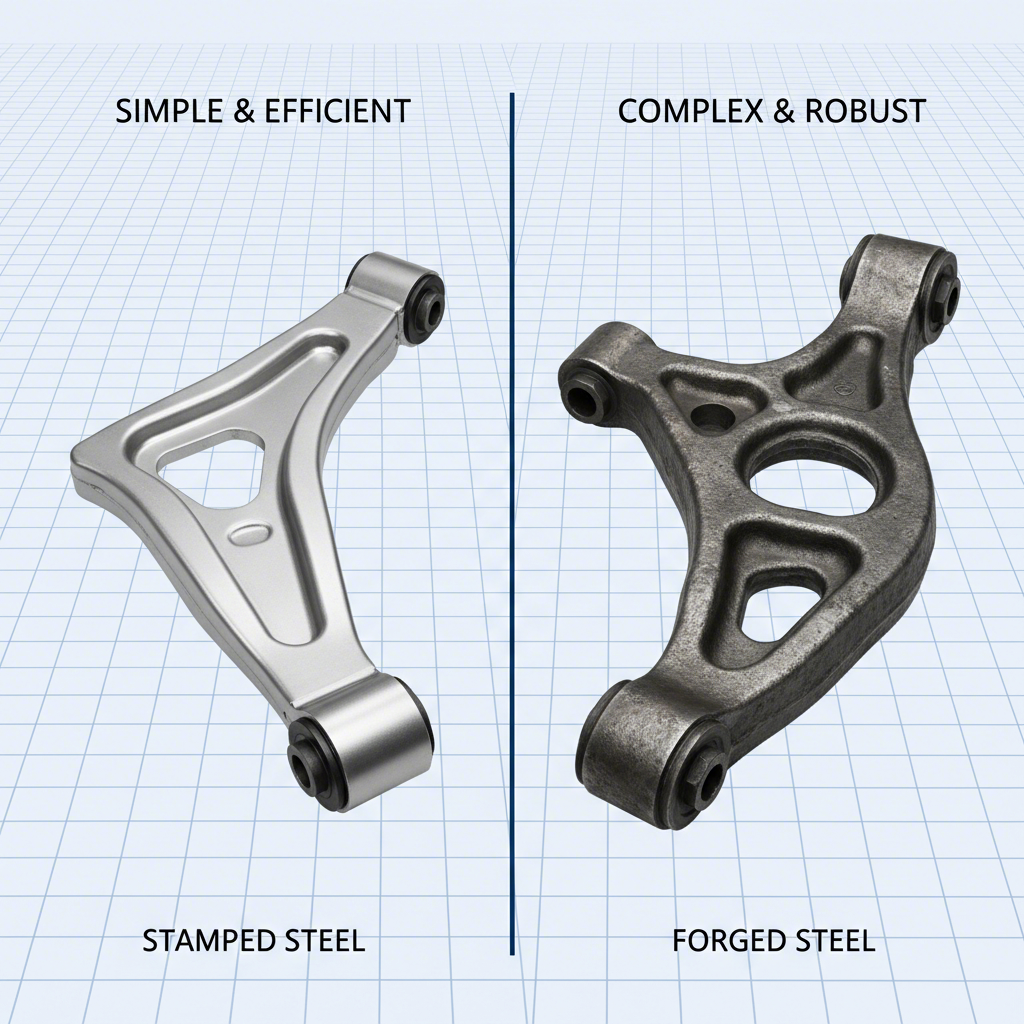

Att välja rätt styrarm innebär att förstå kompromisserna mellan olika typer. Stansad stål är standard, men smidda, gjutna och rörformade armar erbjuder distinkta fördelar för specifika användningsområden. Att förstå dessa skillnader är nyckeln till ett välgrundat beslut för ditt fordon och din körstil.

Varje typ är en produkt av sin tillverkningsprocess, vilket avgör dess kostnad, vikt och hållfasthetsprofil. Smidda armar är kända för sitt exceptionella hållfasthets-till-viktförhållande, medan gjutna armar är ett slitstarkt, om än tungt, OEM-standard på många lastbilar. Rörförmade armar, ofta använda inom prestandaeftermarknaden, erbjuder anpassningsbarhet och hög styvhet. Denna tabell bryter ner de viktigaste skillnaderna för att hjälpa dig att bestämma.

| Armtyp | Tillverkningsprocess | Relativ kostnad | Primär nytta | Ideell Användningsscenario |

|---|---|---|---|---|

| Stansad stål | Stansade och svetsade stålplåtar | Låg | Kostnadseffektivitet och låg vikt | Dagliga fordon, OEM-ersättning |

| Gjutjärn/Stål | Smält metall som hälls i en form | Moderat | Hög styvhet och hållbarhet | Tungt byggda lastbilar, OEM-tillämpningar |

| Smedat Stål/Aluminium | Metall som hammras till form under press | Hög | Maximal hållfasthet och utmattningstålighet | Prestandafordon, tung dragning, terrängkörning |

| Tubstål | Böjda och svetsade stålrör | Hög | Hög hållfasthet, lätt vikt och anpassad geometri | Racing, upphöjda lastbilar, anpassade fjädringar |

Ditt val beror i slutändan på dina behov. För en pendlingbil som bara behöver en tillförlitlig ersättningsdel är en kvalitetsvärd eftermarknadssvept stålfäste ett smart och ekonomiskt val. Om du äger en tung lastbil och sätter värde på absolut hållbarhet för bogsering eller lastning kan ett gjutet eller smidat fäste ge bättre trygghet. För dig som modifierar din bil för prestanda eller terrängkörning är den överlägsna geometrin och styrkan hos ett rörformat fäste ofta värt den extra investeringen.

Den avgörande rollen av upphöjningspaket och uppgraderingar

Ett av de vanligaste ämnena i diskussioner om svepta stålfästen är upphöjnings- och planeringspaket. Här blir begränsningarna i fabrikskonstruktionen tydliga. När du höjer en lastbil förändras hela fjädringsgeometrin. Det serieutrustade övre tvärfästet (UCA) tvingas arbeta i en mycket brantare vinkel än den var utformad för.

Detta skapar ett betydande problem: kulsleden utsätts för konstant belastning och pressas ofta till sin maximala rörelsevinkel redan när bilen står i jämnt läge. Detta kan leda till en rad problem, inklusive påskyndat slitage på kulsleden, dålig justering som inte går att korrigera och en hårdförande körkänsla. I värsta fall kan den översträckta kulsleden helt brista, vilket leder till en katastrofal upphängningsfel.

Därför är eftermarknadens övre tvärarmar (UCA) inte bara en uppgradering utan ofta en nödvändighet för lyfta fordon. Som eftermarknadsexperter förklarar är dessa delar konstruerade för att lösa geometriproblemet. Eftermarknadens tvärarmar ger bättre geometri genom att omplacera kulsleden, vilket möjliggör korrekt hjuljustering och förbättrad upphängningsrörelse på en lyft lastbil. Detta korrigerar vinkeln, minskar spänningen i komponenterna och återställer kvaliteten i körkomforten.

När bör du alltså uppgradera från de standardmässiga stansade stålarmarna?

- Om din lyfthöjd är mer än 2 tum. Detta är tumregeln där kulsnittsvinklar börjar bli problematiska.

- Om du inte kan uppnå korrekt justering. Om din justeringstekniker säger att de inte kan få ditt spårutslag eller styrkastning inom specifikationen efter en lyft, behöver du UCAs som korrigerar geometrin.

- För allvarlig terränkkörning. Eftermarknadens armar är starkare och ger större hjulrörelse och leder, vilket är avgörande för att ta sig fram på ojämn terräng.

- När du byter ut slitna komponenter. Om dina originalkulsnitt eller fästen är utslitna på en lyftad bil, är det ekonomiskt fördelaktigt att uppgradera hela armuppsättningen istället för att bara byta de delar som gått sönder.

Vanliga frågor

1. Vem tillverkar bäst eftermarknadens överarmar?

Det finns inte ett enda "bästa" varumärke, eftersom det idealiska valet beror på din bil och ditt budget. Det finns dock flera företag som är välrenommerade inom branschen för att tillverka kvalitetsstyrfack. Populära märken som ofta rekommenderas inkluderar Moog, Mevotech, Dorman och TrueDrive för OEM-stil ersättningsdelar, medan specialmärken som SPC Performance, ReadyLIFT och Rough Country är kända för sina lösningar för upphöjda lastbilar.

2. Är stansade ståltvärspekar magnetiska?

Ja, det är de. Eftersom de är tillverkade av stål kommer en magnet lätt fästa vid dem. Detta är ett enkelt och effektivt sätt att skilja dem från aluminiumstyrfack, vid vilka en magnet inte kommer att fästa. Det kan hjälpa dig att snabbt identifiera komponenterna på din bil innan du beställer delar.

3. Är reservdelar för reglagearmar något bra?

Absolut, särskilt i samband med fordonmodifieringar. Medan en standardmässig aftermarket stansad arm fungerar som ett tillförlitligt OEM-utbyte, erbjuder specialanpassade styrlänkar betydande fördelar för upphöjda eller prestandaorienterade fordon. De är specifikt utformade för att rätta till upphängningsgeometrin, möjliggöra korrekt hjulinställning, öka hållbarheten och förbättra hjulrörelsen för bättre prestanda i terräng.

Lilla partier, höga standarder. Vår snabba prototypservice gör validering snabbare och enklare —

Lilla partier, höga standarder. Vår snabba prototypservice gör validering snabbare och enklare —